Impact of Bio-Based (Tannins) and Nano-Scale (CNC) Additives on Bonding Properties of Synthetic Adhesives (PVAc and MUF) Using Chestnut Wood from Young Coppice Stands

Abstract

1. Introduction

2. Materials and Methods

2.1. Wood Material

2.2. Adhesives, Additives and Gluing Conditions

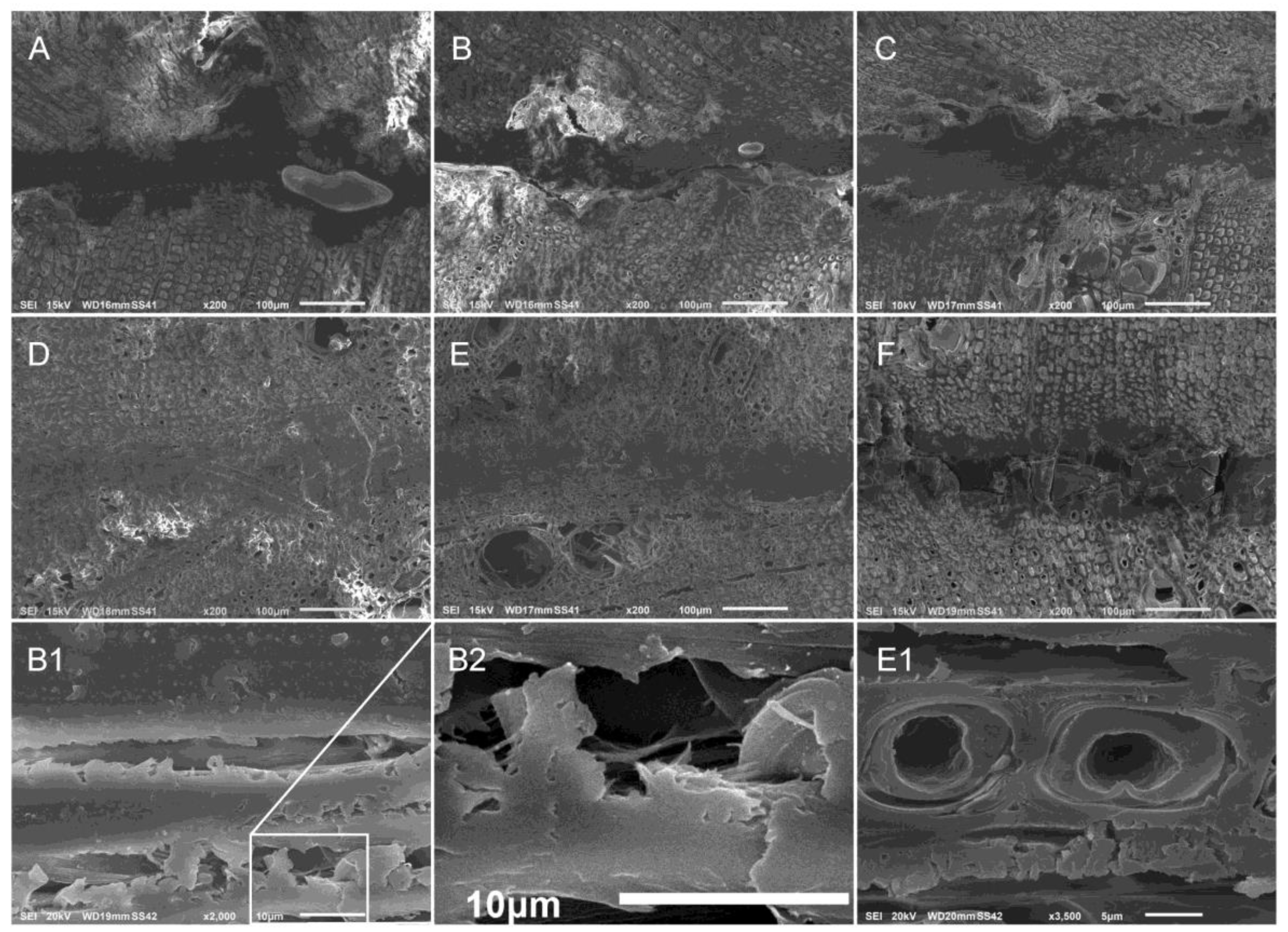

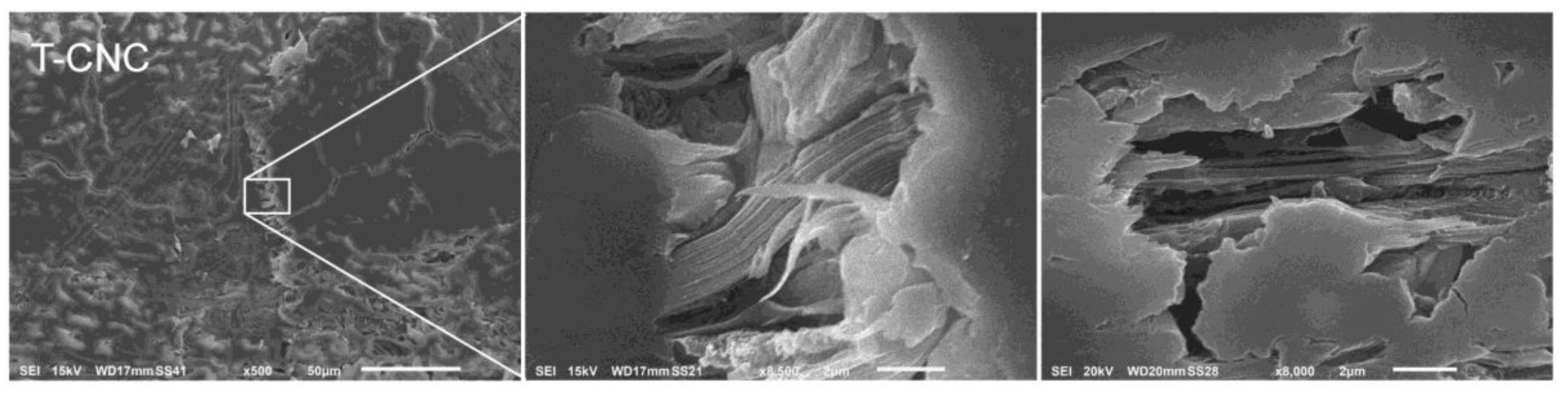

2.3. Scanning Electron Microscopy (SEM) Analysis

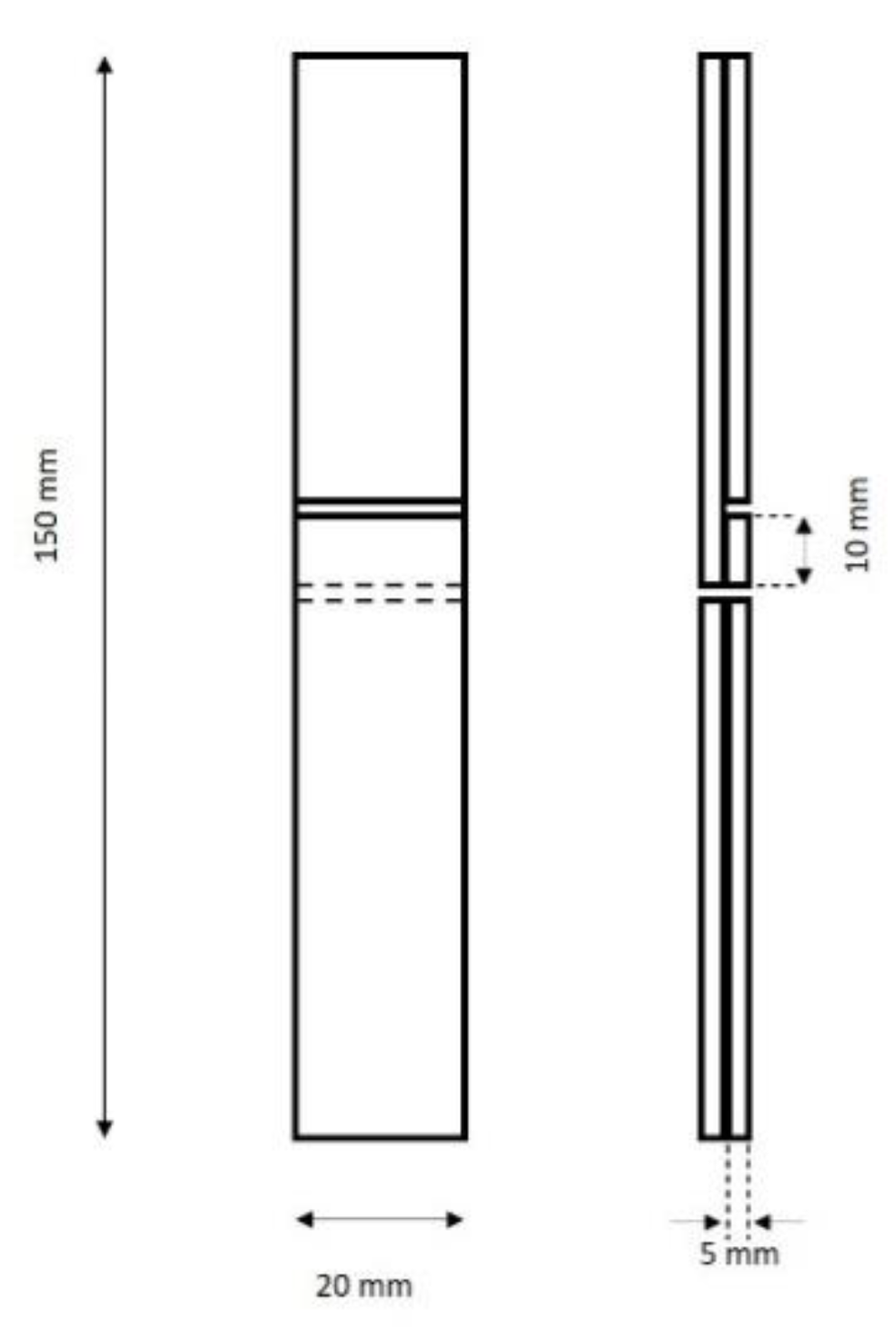

2.4. Mechanical Tests

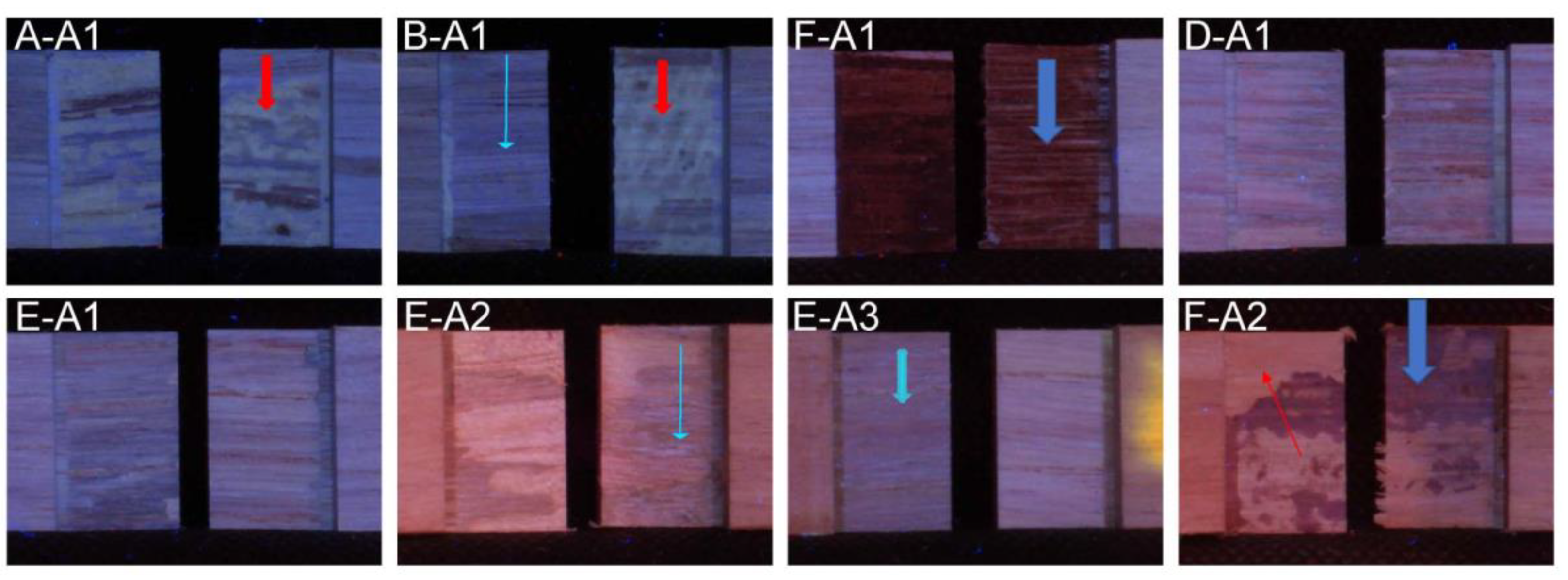

2.5. Ultraviolet Fluorescence Photography

3. Results and Discussions

3.1. Morphological Characterization Using Scanning Electron Microscopy

3.2. Mechanical Properties of Laminated Veneer Lumber Samples

3.3. Dry Conditions

3.4. Wetting (A2) and Wetting-Reconditioning (A3)

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Romagnoli, M.; Fragiacomo, M.; Brunori, A.; Follesa, M.; Mugnozza, G.S. Solid wood and wood based composites: The challenge of sustainability looking for a short and smart supply chain. In Digital Wood Design; Springer: Cham, Switzerland, 2019; pp. 783–807. [Google Scholar]

- De Angelis, M.; Romagnoli, M.; Vek, V.; Poljanšek, I.; Oven, P.; Thaler, N.; Lesar, B.; Kržišnik, D.; Humar, M. Chemical composition and resistance of Italian stone pine (Pinus pinea L.) wood against fungal decay and wetting. Ind. Crops Prod. 2018, 117, 187–196. [Google Scholar] [CrossRef]

- Giovando, S.; Koch, G.; Romagnoli, M.; Paul, D.; Vinciguerra, V.; Tamantini, S.; Marini, F.; Zikeli, F.; Scarascia Mugnozza, G. Spectro-topochemical investigation of the location of polyphenolic extractives (tannins) in chestnut wood structure and ultrastructure. Ind. Crops Prod. 2019, 141, 111767. [Google Scholar] [CrossRef]

- Marini, F.; Portoghesi, L.; Manetti, M.C.; Salvati, L.; Romagnoli, M. Gaps and perspectives for the improvements of sweet chestnut forest-wood chain in italy: A commentary. Ann. Silvic. Res. 2020, in press. [Google Scholar]

- Romagnoli, M.; Cavalli, D.; Pernarella, R.; Zanuttini, R.; Togni, M. Physical and mechanical characteristics of poor-quality wood after heat treatment. iForest 2015, 8, 884–891. [Google Scholar] [CrossRef]

- Corona, P. Communicating facts, findings and thinking to support evidence-based strategies and decisions. Ann. Silvic. Res. 2018, 42, 1–2. [Google Scholar]

- Marini, F.; Battipaglia, G.; Manetti, M.C.; Corona, P.; Romagnoli, M. Impact of climate, stand growth parameters, and management on isotopic composition of tree rings in chestnut coppices. Forests 2019, 10, 1148. [Google Scholar] [CrossRef]

- Moscatelli, M.C.; Romagnoli, M.; Cenfi, S.; Lagomarsino, A.; Di Tizio, A.; Spina, S.; Grego, S. Wood-soil interactions in soil bioengineering slope stabilization works. iForest 2009, 2, 187–191. [Google Scholar] [CrossRef]

- Militz, H.; Busetto, D.; Hapla, F. Investigation on natural durability and sorption properties of Italian Chestnut (Castanea sativa Mill.) from coppice stands. Holz Als Roh—Und Werkst. 2003, 61, 133–141. [Google Scholar] [CrossRef]

- Romagnoli, M.; Cavalli, D.; Spina, S. Wood quality of chestnut: Relationship between ring width, specific gravity, and physical and mechanical properties. BioResources 2014, 9, 1132–1147. [Google Scholar] [CrossRef]

- Romagnoli, M.; Spina, S. Physical and mechanical wood properties of ring-shaken chestnut (Castanea sativa) trees. Can. J. For. Res. 2013, 43, 200–207. [Google Scholar] [CrossRef]

- Spina, S.; Romagnoli, M. Characterization of ring shake defect in chestnut (Castanea sativa Mill.) wood in the Lazio Region (Italy). Forestry 2010, 83, 315–327. [Google Scholar] [CrossRef]

- Mattioli, W.; Mancini, L.D.; Portoghesi, L.; Corona, P. Biodiversity conservation and forest management: The case of the sweet chestnut coppice stands in Central Italy. Plant Biosyst. 2016, 150, 592–600. [Google Scholar] [CrossRef]

- Veigel, S.; Rathke, J.; Weigl, M.; Gindl-Altmutter, W. Particle board and oriented strand board prepared with nanocellulose- reinforced adhesive. J. Nanomater. 2012, 8, 158503. [Google Scholar] [CrossRef]

- Pizzi, A. Wood products and green chemistry. Ann. For. Sci. 2016, 73, 185–203. [Google Scholar] [CrossRef]

- Pizzi, A.; Mittal, K.L. Wood Adhesives; CRC Press: Boca Raton, FL, USA, 2011; ISBN 9789004190924. [Google Scholar]

- Bomba, J.; Šedivka, P.; Hýsek, Š.; Fáber, J.; Oberhofnerová, E. Influence of glue line thickness on the strength of joints bonded with PVAc adhesives. For. Prod. J. 2018, 68, 120–126. [Google Scholar] [CrossRef]

- Lan, P.; François, G.; Pizzi, A.; Zhou, D.G.; Brosse, N. Wood adhesives from agricultural by-products: Lignins and tannins for the elaboration of particleboards. Cellul. Chem. Technol. 2012, 46, 457–462. [Google Scholar]

- Lei, H.; Pizzi, A.; Guanben, D. Environmentally friendly mixed tannin/lignin wood resins. J. Appl. Polym. Sci. 2008, 107, 203–209. [Google Scholar] [CrossRef]

- Stark, N.M.; Cai, Z.; Carll, C. Wood-based composite materials panel products, glued-laminated timber, structural composite lumber, and wood–nonwood composite materials. In Polybutilene Therephthalate (PBT), Synthesis and Properties; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Mansouri, H.R.; Navarrete, P.; Pizzi, A.; Tapin-Lingua, S.; Benjelloun-Mlayah, B.; Pasch, H.; Rigolet, S. Synthetic-resin-free wood panel adhesives from mixed low molecular mass lignin and tannin. Eur. J. Wood Wood Prod. 2011, 69, 221–229. [Google Scholar] [CrossRef]

- Wang, Z.; Gu, Z.; Yan, H.; Cheng, L.; Li, Z. Bonding strength and water resistance of starch-based wood adhesive improved by silica nanoparticles. Carbohydr. Polym. 2011, 86, 72–76. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Wang, S.; Meng, Y.; Hosseinaei, O. Micromechanical properties of the interphase in cellulose nanofiber-reinforced phenol formaldehyde bondlines. BioResources 2014, 9, 5529–5541. [Google Scholar] [CrossRef]

- Heon Kwon, J.; Lee, S.-H.; Ayrilmis, N.; Hyung Han, T. Tensile shear strength of wood bonded with urea–formaldehyde with different amounts of microfibrillated cellulose. Int. J. Adhes. Adhes. 2015, 60, 88–91. [Google Scholar] [CrossRef]

- Cui, J.; Xiaoning, L.; Zhou, X.; Chrusciel, L.; Deng, Y.; Zhou, H.; Zhu, S.; Brosse, N. Enhancement of mechanical strength of particleboard using environmentally friendly pine (Pinus pinaster L.) tannin adhesives with cellulose nanofibers. Ann. For. Sci. 2015, 72, 27–32. [Google Scholar] [CrossRef]

- Leng, W.; Hunt, J.; Tajvidi, M. Effects of density, cellulose nanofibrils addition ratio, pressing method, and particle size on the bending properties of wet-formed particleboard. BioResources 2017, 12, 4986–5000. [Google Scholar] [CrossRef]

- Yang, F.; Wu, Y.; Zhang, S.; Zhang, H.; Zhao, S.; Zhang, J.; Fei, B. Mechanical and thermal properties of waterborne polyurethane coating modified through one-step. Coatings 2019, 10, 40. [Google Scholar] [CrossRef]

- Goswami, J.; Haque, E.; Fox, D.M.; Gilman, J.W.; Holmes, G.A.; Moon, R.J.; Kalaitzidou, K. The effect of cellulose nanocrystal coatings on the glass fiber-epoxy interphase. Materials 2019, 12, 1951. [Google Scholar] [CrossRef] [PubMed]

- Jayaramudu, T.; Ko, H.U.; Kim, H.C.; Kim, J.W.; Muthoka, R.M.; Kim, J. Electroactive hydrogels made with polyvinyl alcohol/cellulose nanocrystals. Materials 2018, 11, 1615. [Google Scholar] [CrossRef] [PubMed]

- Spina, S.; Zhou, X.; Segovia, C.; Pizzi, A.; Romagnoli, M.; Giovando, S.; Pasch, H.; Rode, K.; Delmotte, L. Phenolic resin adhesives based on chestnut (Castanea sativa) hydrolysable tannins. J. Adhes. Sci. Technol. 2013, 27, 2103–2111. [Google Scholar] [CrossRef]

- Vineeth, S.K.; Gadhave, R.V.; Gadekar, P.T. Nanocellulose applications in wood adhesives—Review. Open J. Polym. Chem. 2019, 9, 63–75. [Google Scholar] [CrossRef]

- Cardinali, M.; De Ruggieri, M.B.; Falcucci, C. Diagnostica Artistica: Tracce Materiali Per La Storia Dell’Arte E Per La Conservazione; Palombi: Rome, Italy, 2002; ISBN 8876212639. [Google Scholar]

- EN 302-1. Adhesives for Load Bearing Timber Structures—Test Methods—Part 1: Determination of Longitudinal Tensile Shear Strength; European Commitee for Standardization (CEN): Belgium, Brussels, 2013. [Google Scholar]

- EN 204: 2016. Classification of Thermoplastic Wood Adhesives for Non-Structural Applications; European Commitee for Standardization (CEN): Belgium Brussels, 2016. [Google Scholar]

- Jiang, W.; Tomppo, L.; Pakarinen, T.; Sirviö, J.A.; Liimatainen, H.; Haapala, A. Effect of cellulose nanofibrils on the bond strength of polyvinyl acetate and starch adhesives for wood. BioResources 2018, 13, 2283–2292. [Google Scholar] [CrossRef]

- Böhm, R.; Hauptmann, M.; Pizzi, A.; Friedrich, C.; Laborie, M.P. The chemical, kinetic and mechanical characterization of tannin-based adhesives with different crosslinking systems. Int. J. Adhes. Adhes. 2016, 68, 1–8. [Google Scholar] [CrossRef]

- Pinkl, S.; Veigel, S.; Colson, J.; Gindl-Altmutter, W. Nanopaper properties and adhesive performance of microfibrillated cellulose from different (Ligno-)cellulosic raw materials. Polymers 2017, 9, 326. [Google Scholar] [CrossRef] [PubMed]

- Peng, J.; Ellingham, T.; Sabo, R.; Turng, L.S.; Clemons, C.M. Short cellulose nanofibrils as reinforcement in polyvinyl alcohol fiber. Cellulose 2014, 21, 4287–4298. [Google Scholar] [CrossRef]

- Gindl, W.; Dessipri, E.; Wimmer, R. Using UV-microscopy to study diffusion of melamine-urea-formaldehyde resin in cell walls of spruce wood. Holzforschung 2002, 56, 103–107. [Google Scholar] [CrossRef]

- Kim, S. Environment-friendly adhesives for surface bonding of wood-based flooring using natural tannin to reduce formaldehyde and TVOC emission. Bioresour. Technol. 2009, 100, 744–748. [Google Scholar] [CrossRef]

- Paiva, N.T.; Pereira, J.; Ferra, J.M.; Cruz, P.; Carvalho, L.; Magalhães, F.D. Study of influence of synthesis conditions on properties of melamine–urea formaldehyde resins. Int. Wood Prod. J. 2012, 3, 51–57. [Google Scholar] [CrossRef]

- López-Suevos, F.; Eyholzer, C.; Bordeanu, N.; Richter, K. DMA analysis and wood bonding of PVAc latex reinforced with cellulose nanofibrils. Cellulose 2010, 17, 387–398. [Google Scholar] [CrossRef]

- Zanetti, M.; Causin, V.; Saini, R.; Cardin, A.; Cavalli, R. Effect of tannin on increasing UF adhesive performance at high temperature investigated by TMA and TGA analysis. Eur. J. Wood Wood Prod. 2014, 72, 385–392. [Google Scholar] [CrossRef]

- Veigel, S.; Müller, U.; Keckes, J.; Obersriebnig, M.; Gindl-Altmutter, W. Cellulose nanofibrils as filler for adhesives: Effect on specific fracture energy of solid wood-adhesive bonds. Cellulose 2011, 18, 1227–1237. [Google Scholar] [CrossRef]

| Adhesive Formulations | Adhesive ID | Sample Label | CNC (%) | Tannin (%) | Solid Content (%) | Viscosity (mPas) |

|---|---|---|---|---|---|---|

| Polyvinyl acetate adhesive (PVAc) | PVAc | A | 0 | 0 | 52–54 | 13,000 |

| PVAc + Cellulose Nanocrystals (CNC) | PVAc-CNC | B | 5 | 0 | 54–56 | n.d. |

| PVAc + CNC + Tannin (T) | PVAc-CNC-T | C | 5 | 5 | 60–65 | n.d. |

| Melamine-urea-formaldehyde adhesive (MUF) (ready to use) | MUF | D | 0 | 0 | 60–62 | 10,000–25,000 |

| MUF + CNC | MUF-CNC | E | 5 | 0 | 63–65 | n.d. |

| T + CNC + water | T-CNC | F | 5 | 70 | 68 | n.d. |

| Designation | Treatment |

|---|---|

| A1 | No treatment other than conditioning in standard climate (20/65) |

| A2 | 4 days soaking in cold water at (20 ± 5) °C Samples tested in the wet state |

| A3 | 4 days soaking in cold water at (20 ± 5) °C Reconditioning in standard climate (20/65) to original mass Samples tested in the dry state |

| Sample Label | Adhesive ID | Glue-Line Thickness (µm) |

|---|---|---|

| A | PVA | 92.4 |

| B | PVA-CNC | 64.1 |

| C | PVA-CNC-T | 101.8 |

| D | MUF | 140.0 |

| E | MUF-CNC | 82.8 |

| F | T-CNC | 92.4 |

| Treatment Type | Adhesive ID | # Samples | Mean Shear Strength ± SD (N/mm2) | CV (%) | Shear Strength Min | Shear Strength Max | # Samples under Threshold 2 N/mm2 | Invalid Test Samples | Mean WF ± SD (%) | WF Min (%) | WF Max (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | PVAc | 8 | 5.32 ± 2.06 | 38.72 | 2 | 7.82 | 0 | 0 | 50 ± 25.0 | 10 | 60 |

| PVAc-CNC | 5 | 7.54 ± 3.02 | 40.05 | 2.82 | 11.24 | 0 | 0 | 40 ± 19.2 | 20 | 80 | |

| PVAc-CNC-T | 5 | 6.22 ± 4.52 | 72.66 | 9.25 | 9.99 | 2 | 0 | 40 ± 30.3 | 0 | 80 | |

| MUF-CNC | 8 | 11.95 ± 1.67 | 13.97 | 9.83 | 13.73 | 0 | 0 | 90 ± 9.1 | 70 | 100 | |

| MUF | 8 | 12.19 ± 1.71 | 14.02 | 9.96 | 14.34 | 0 | 0 | 90 ± 7.5 | 80 | 100 | |

| T-CNC | 6 | 5.04 ± 2.22 | 44.04 | 4.84 | 5.24 | 1 | 3 | 8.3 ± 7.5 | 0 | 20 | |

| A2 | PVAc | 4 | 0.85 ± 0.54 | 63.52 | 0.38 | 1.61 | 0 | 0 | 20 ± 5.7 | 20 | 30 |

| PVAc-CNC | 5 | 0.92 ± 0.8 | 86.95 | 0.23 | 1.79 | 0 | 2 | 10 ± 5.4 | 10 | 20 | |

| PVAc-CNC-T | 5 | 0.56 ± 0.34 | 60.71 | 0.17 | 0.95 | 0 | 1 | 30 ± 8.9 | 20 | 40 | |

| MUF-CNC | 5 | 4.31 ± 3.46 | 80.27 | 0.83 | 9.01 | 2 | 0 | 80 ± 5.4 | 80 | 90 | |

| MUF | 5 | 4.62 ± 1.17 | 25.32 | 3 | 6.01 | 1 | 0 | 70 ± 8.9 | 60 | 80 | |

| T-CNC | 3 | INVALID | - | - | - | - | 3 | - | - | - | |

| A3 | PVAc | 2 | 5.33 ± 3.53 | 66.22 | 2.82 | 7.82 | 0 | 0 | 70 ± 21.2 | 60 | 90 |

| PVAc-CNC | 6 | 2.58 ± 3.33 | 129.0 | 0.15 | 8.98 | 2 | 0 | 30 ± 16.4 | 20 | 60 | |

| PVAc-CNC-T | 5 | 4.39 ± 2.35 | 53.53 | 1.23 | 6.74 | 1 | 0 | 60 ± 28.2 | 20 | 80 | |

| MUF-CNC | 5 | 10.51 ± 2.45 | 23.31 | 8.25 | 12.95 | 0 | 0 | 90 ± 17.8 | 60 | 100 | |

| MUF | 4 | 10.8 ± 2.77 | 25.64 | 7.56 | 13.94 | 1 | 0 | 80 ± 12.2 | 60 | 90 | |

| T-CNC | 6 | INVALID | - | - | - | - | 6 | - | - | - |

| PVAc-CNC | PVAc | PVAc-CNC-T | MUF | MUF-CNC | T-CNC |

|---|---|---|---|---|---|

| PVAc-CNC | A2 * | A3 * | A1 * | ||

| PVAc | A2 * A1 *** | A1 *** | A1 * | ||

| PVAc-CNC-T | A2 * A1 ** | A3 * A2 * A1 ** | A1 * A2 * | ||

| MUF | A1 ** A2 * | ||||

| MUF-CNC | A1 ** | ||||

| T-CNC |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marini, F.; Zikeli, F.; Corona, P.; Vinciguerra, V.; Manetti, M.C.; Portoghesi, L.; Scarascia Mugnozza, G.; Romagnoli, M. Impact of Bio-Based (Tannins) and Nano-Scale (CNC) Additives on Bonding Properties of Synthetic Adhesives (PVAc and MUF) Using Chestnut Wood from Young Coppice Stands. Nanomaterials 2020, 10, 956. https://doi.org/10.3390/nano10050956

Marini F, Zikeli F, Corona P, Vinciguerra V, Manetti MC, Portoghesi L, Scarascia Mugnozza G, Romagnoli M. Impact of Bio-Based (Tannins) and Nano-Scale (CNC) Additives on Bonding Properties of Synthetic Adhesives (PVAc and MUF) Using Chestnut Wood from Young Coppice Stands. Nanomaterials. 2020; 10(5):956. https://doi.org/10.3390/nano10050956

Chicago/Turabian StyleMarini, Francesco, Florian Zikeli, Piermaria Corona, Vittorio Vinciguerra, Maria Chiara Manetti, Luigi Portoghesi, Giuseppe Scarascia Mugnozza, and Manuela Romagnoli. 2020. "Impact of Bio-Based (Tannins) and Nano-Scale (CNC) Additives on Bonding Properties of Synthetic Adhesives (PVAc and MUF) Using Chestnut Wood from Young Coppice Stands" Nanomaterials 10, no. 5: 956. https://doi.org/10.3390/nano10050956

APA StyleMarini, F., Zikeli, F., Corona, P., Vinciguerra, V., Manetti, M. C., Portoghesi, L., Scarascia Mugnozza, G., & Romagnoli, M. (2020). Impact of Bio-Based (Tannins) and Nano-Scale (CNC) Additives on Bonding Properties of Synthetic Adhesives (PVAc and MUF) Using Chestnut Wood from Young Coppice Stands. Nanomaterials, 10(5), 956. https://doi.org/10.3390/nano10050956