Enhanced Anti-Mold Property and Mechanism Description of Ag/TiO2 Wood-Based Nanocomposites Formation by Ultrasound- and Vacuum-Impregnation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis

2.2.1. Surface Modification of the Ag/TiO2 Nanoparticles

2.2.2. Ultrasound Impregnation

2.2.3. Vacuum Impregnation

2.3. Anti-Mold Test

2.4. Characterization

3. Results and Discussion

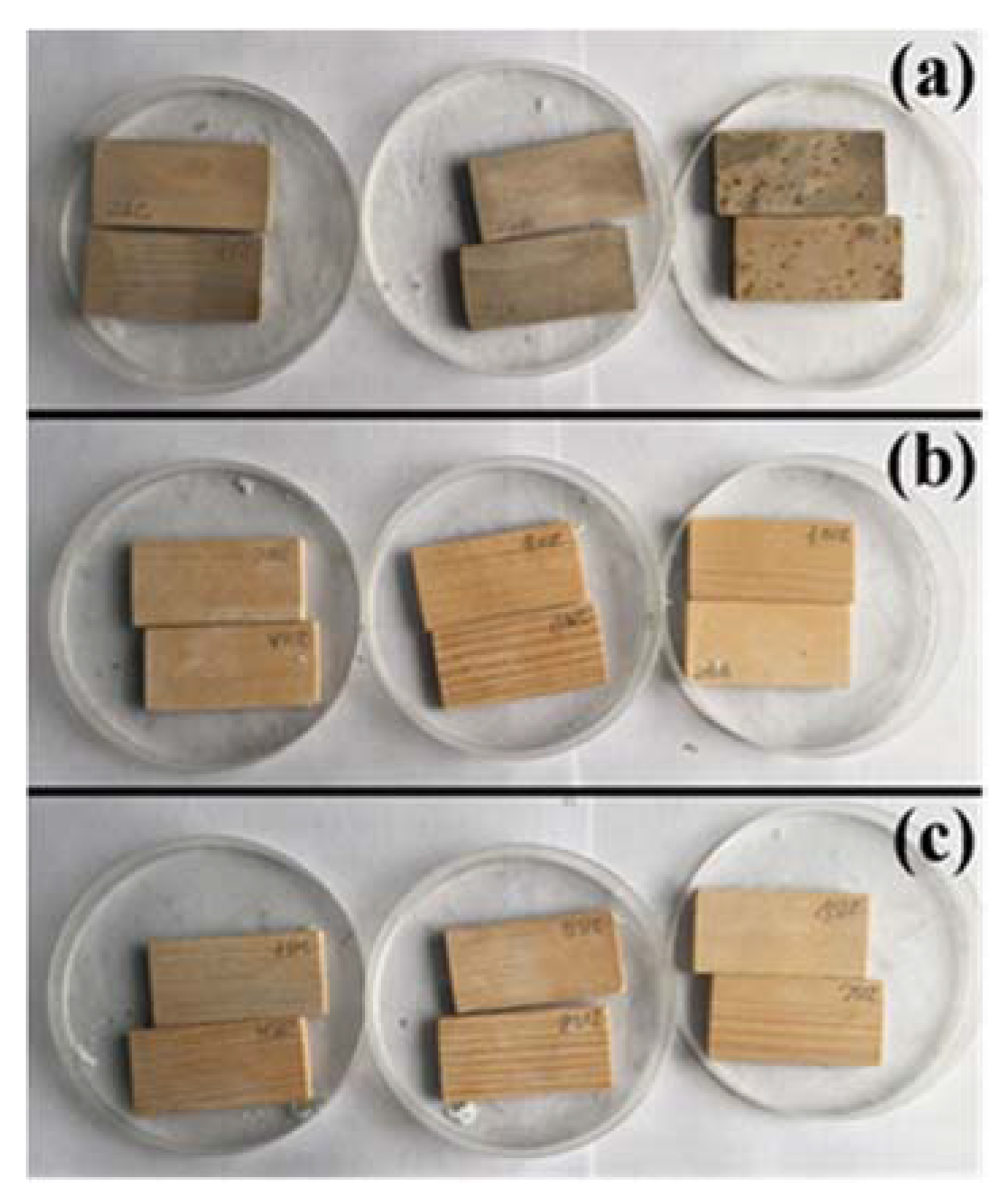

3.1. Anti-Mold Properties

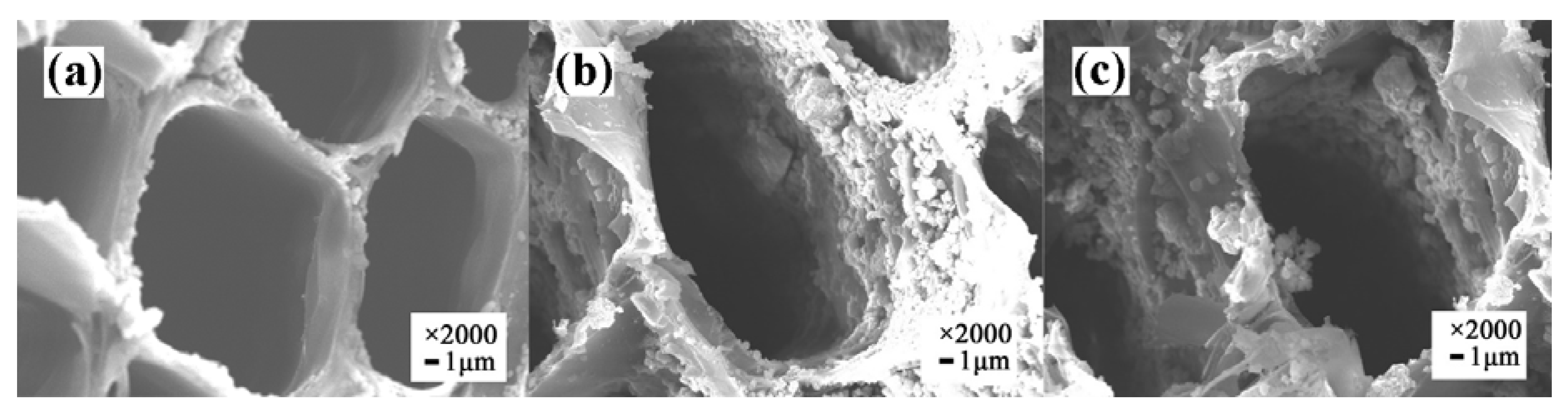

3.2. Field Emission Scanning Electron Microscopy (FESEM) Analysis

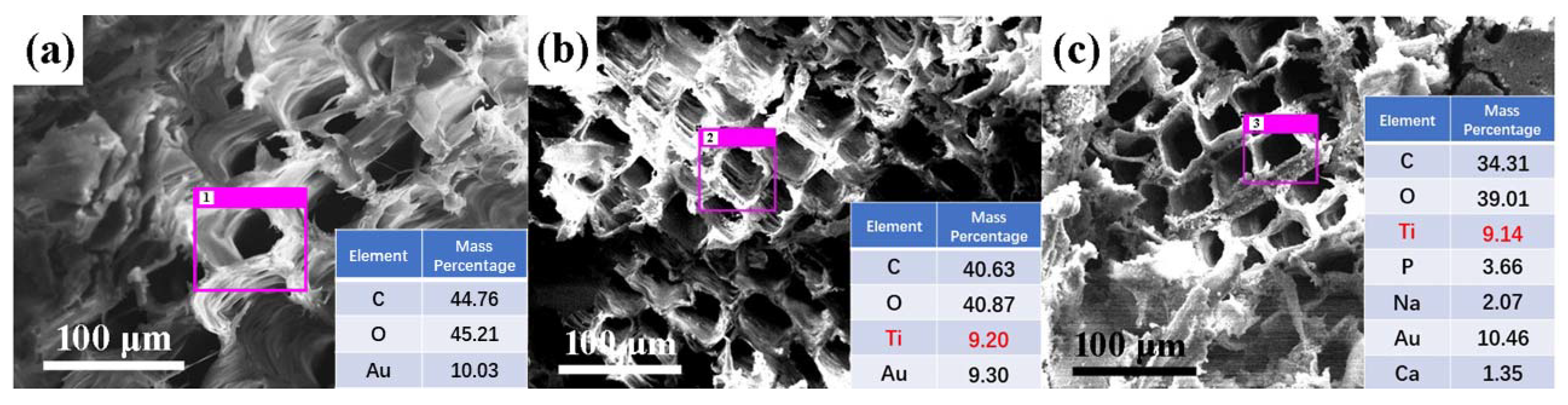

3.3. Energy-Dispersive Spectroscopy (EDS) Analysis

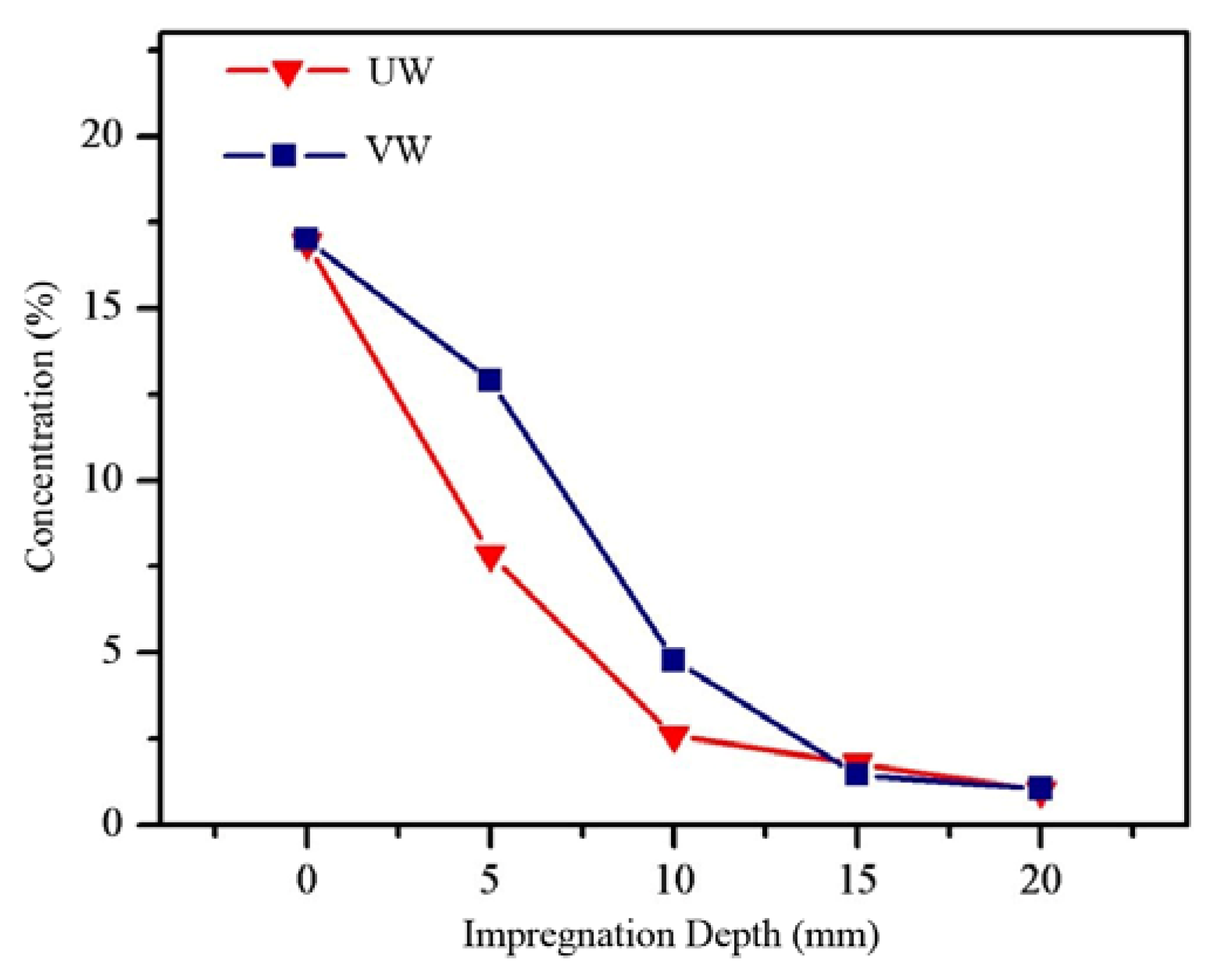

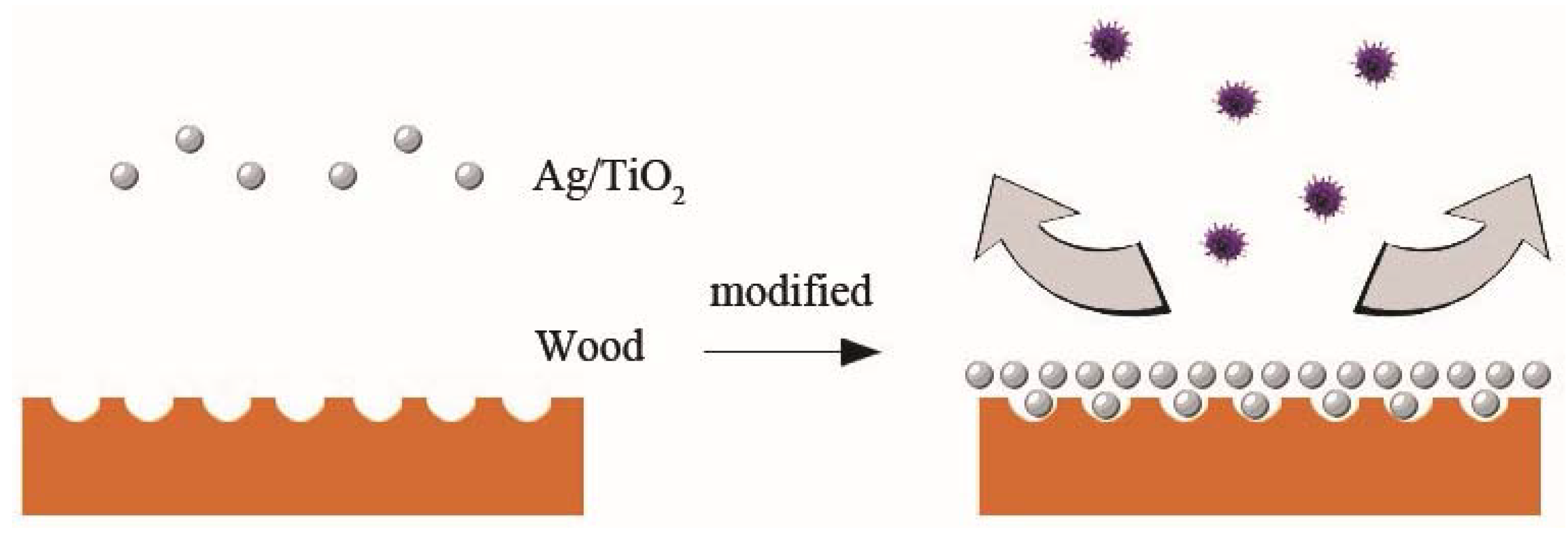

3.4. Distribution of Ag/TiO2

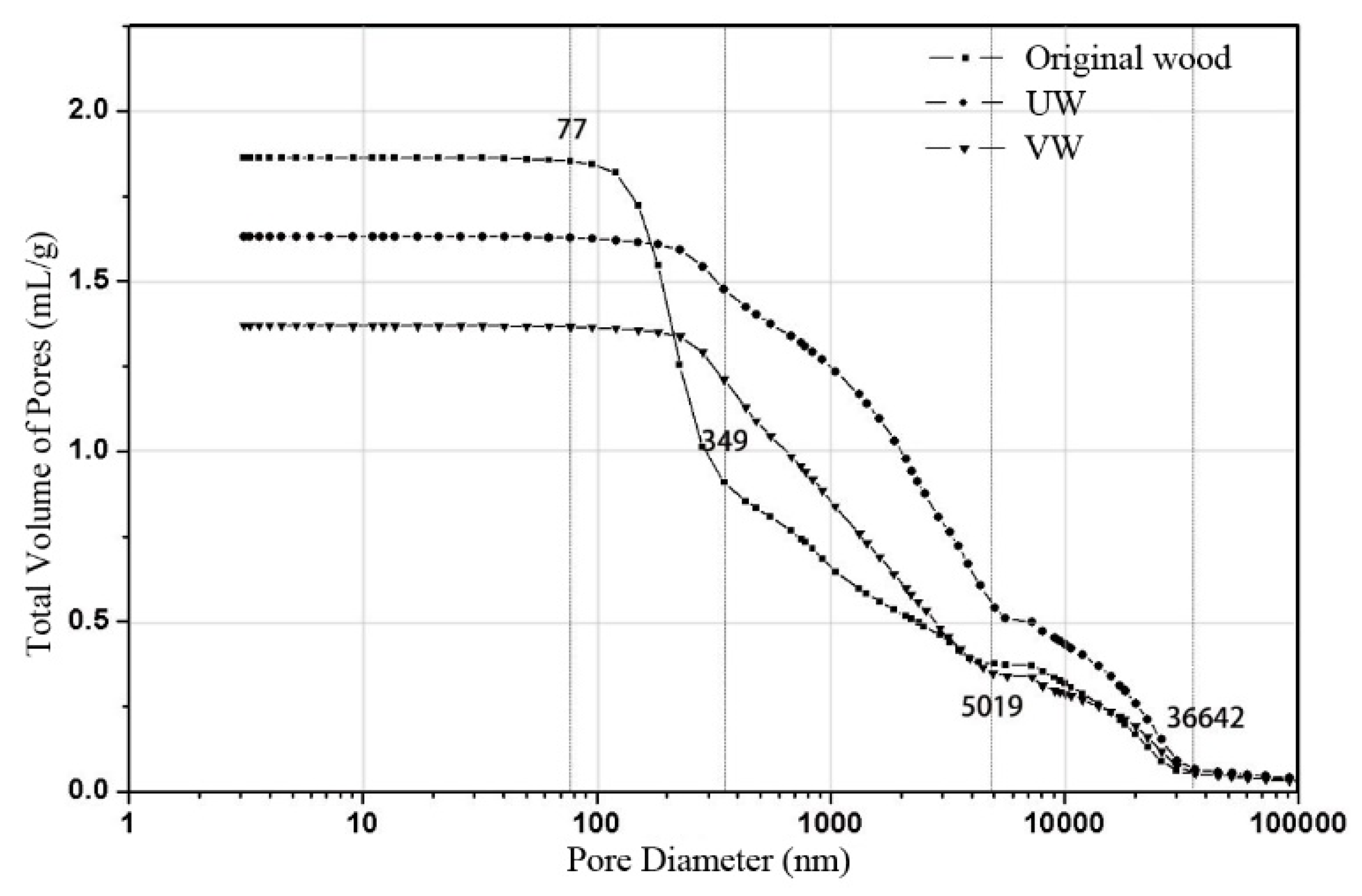

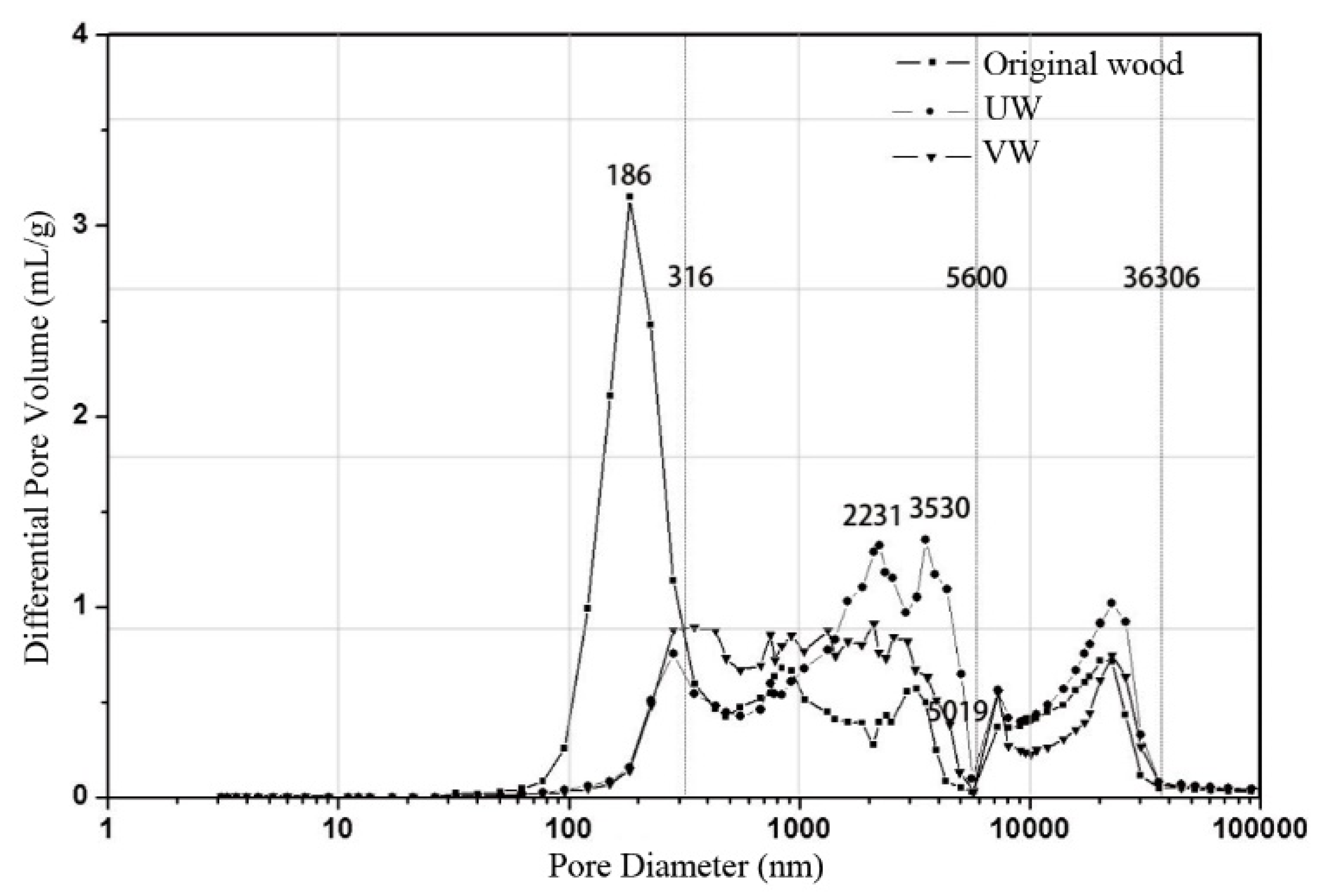

3.5. Mercury Intrusion Porosimetry (MIP) Analysis

3.6. Water Contact Angle (WCA) Analysis

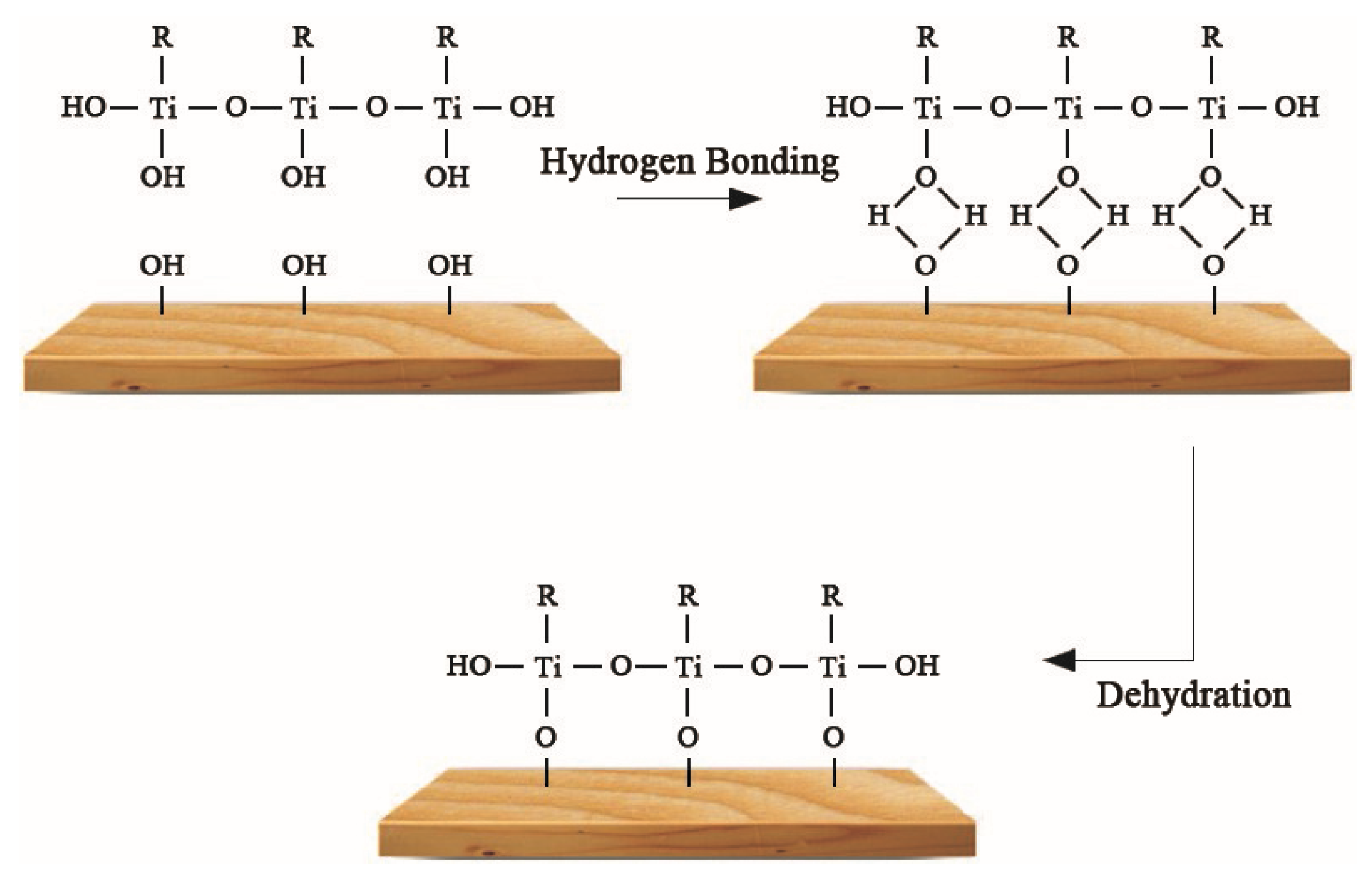

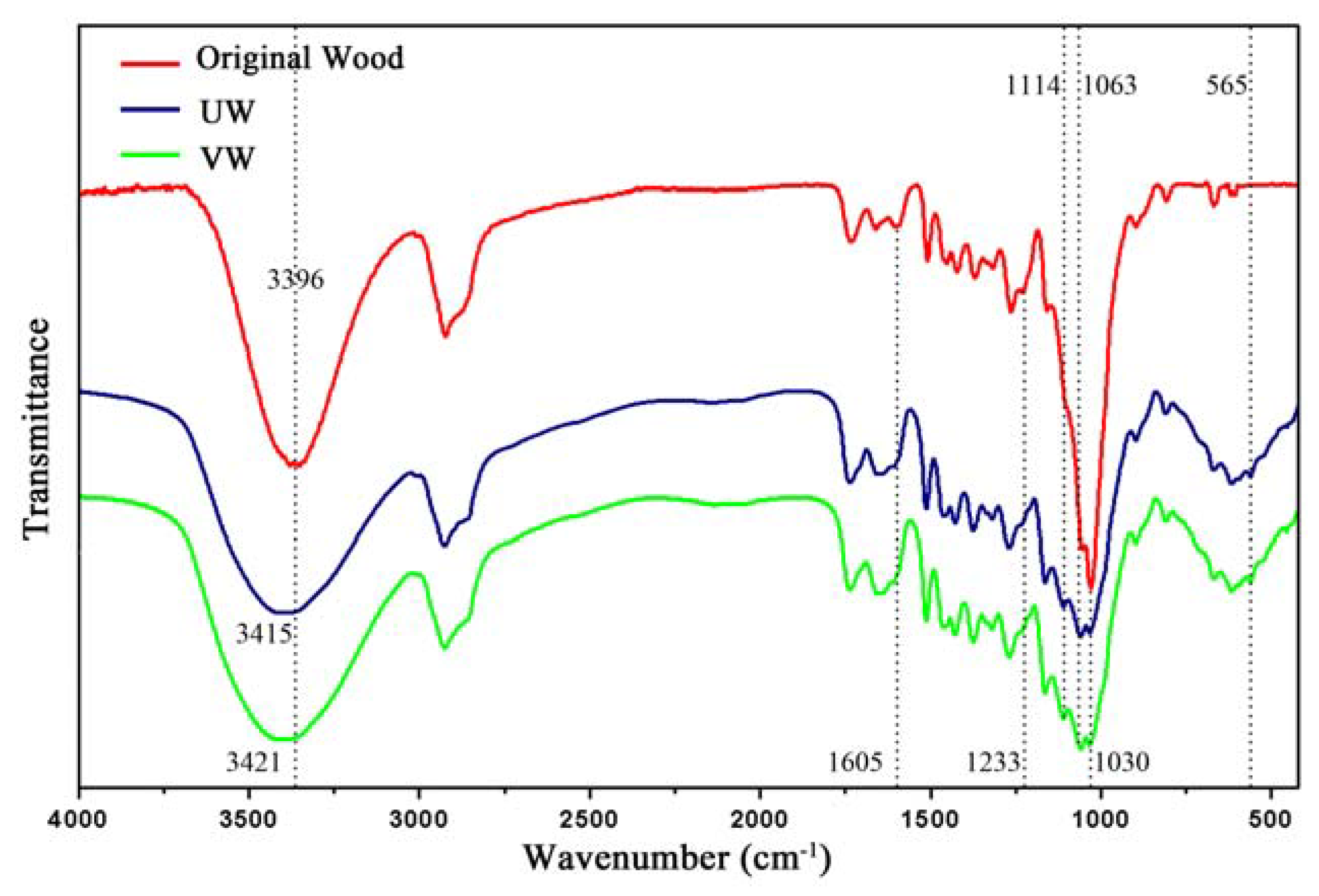

3.7. Fourier Transform Infrared Spectroscopy (FTIR) Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, W.; Chen, M.; Li, Y.; Sun, J.; Liu, Y.; Guo, H. Improving mildew resistance of soy meal by nano-Ag/TiO2, zinc pyrithione and 4-cumylphenol. Polymers 2020, 12, 169. [Google Scholar] [CrossRef] [PubMed]

- Lu, P.; Yun, H.; Zhang, W.; Tu, D.; Hu, C.; Cherdchim, B. A facile method of superhydrophobic coating on rubberwood to improve its anti-mildew performance. BioResources 2019, 14, 7111–7121. [Google Scholar]

- Arima, Y.; Iwata, H. Effect of wettability and surface functional groups on protein adsorption and cell adhesion using well-defined mixed self-assembled monolayers. Biomaterials 2007, 28, 3074–3082. [Google Scholar] [CrossRef] [PubMed]

- Chen, F.; Yang, X.; Wu, Q. Antifungal capability of TiO2 coated film on moist wood. Build. Environ. 2009, 44, 1088–1093. [Google Scholar] [CrossRef]

- Baker, S.E. Aspergillus niger genomics: Past, present and into the future. Med. Mycol. 2006, 44, 17–21. [Google Scholar] [CrossRef]

- Xie, G.; Zhou, Y.; Cao, Y.; Li, L. Anti-mildew properties of copper cured heat-treated wood. BioResources 2018, 13, 5643–5655. [Google Scholar]

- Zhang, X.; Su, H.; Zhao, Y.; Tan, T. Antimicrobial activities of hydrophilic polyurethane/titanium dioxide complex film under visible light irradiation. J. Photochem. Photobiol. A 2008, 199, 123–129. [Google Scholar] [CrossRef]

- Wang, X.; Yu, R.; Wang, K.; Yang, G.; Yu, H. Facile template-induced synthesis of Ag-modified TiO2 hollow octahedra with high photocatalytic activity. Chin. J. Catal. 2015, 36, 1211–2218. [Google Scholar] [CrossRef]

- Rosu, L.; Varganici, C.D.; Mustata, F.; Rusu, T.; Rosu, D.; Rosca, I.; Tudorachi, N.; Teaca, C.A. Enhancing the Thermal and Fungal Resistance of Wood Treated with Natural and Synthetic Derived Epoxy Resins. ACS Sustain. Chem. Eng. 2018, 6, 5470–5478. [Google Scholar] [CrossRef]

- Rosu, L.; Mustata, F.; Varganici, C.D.; Rosu, D.; Rusu, T.; Rosca, I. Thermal behaviour and fungi resistance of composites based on wood and natural and synthetic epoxy resins cured with maleopimaric acid. Polym. Degrad. Stabil. 2019, 160, 148–161. [Google Scholar] [CrossRef]

- Nejad, M.; Cooper, P. Exterior wood coatings. Part-1: Performance of semitransparent stains on preservative-treated wood. J. Coat. Technol. Res. 2011, 8, 449–458. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, D.; Wei, W.; Wang, W.; Wang, X.; Wei, Q.; Niu, M.; Lin, M.; Rao, J.; Xie, Y. Mesoporous aluminosilicate improves mildew resistance of bamboo scrimber with CuBP anti-mildew agents. J. Clean. Prod. 2019, 209, 273–282. [Google Scholar] [CrossRef]

- Okyay, T.O.; Bala, R.K.; Nguyen, H.N.; Atalay, R.; Bayam, Y.; Rodrigues, D.F. Antibacterial properties and mechanisms of toxicity of sonochemically grown ZnO nanorods. RSC Adv. 2015, 5, 2568–2575. [Google Scholar] [CrossRef]

- Petya, P.; Antonio, F.; Margarida, M.F.; Ernest, M.; Ilana, P.; Aharon, G.; Tzanko, T. Sonochemical coating of textiles with hybrid ZnO/chitosan antimicrobial nanoparticles. ACS Appl. Mater. Interfaces 2014, 6, 1164–1172. [Google Scholar]

- Xin, B.; Jing, L.; Ren, Z.; Wang, B.; Fu, H. Effects of simultaneously doped and deposited Ag on the photocatalytic activity and surface states of TiO2. J. Mater. Chem. B 2005, 109, 2805–2809. [Google Scholar] [CrossRef] [PubMed]

- Rengaraj, S.; Li, X. Enhanced photocatalytic activity of TiO2 by doping with Ag for degradation of 2, 4, 6-trichlorophenol in aqueous suspension. J. Mol. Catal. A Chem. 2006, 243, 60–67. [Google Scholar] [CrossRef]

- Lin, L.; Yang, Y.; Via, B.K.; Liu, Y.; Guo, H.; Zhang, F. Modification and characterization of nano-Ag/TiO2 antimold agent for wood materials. Forest Prod. J. 2008, 68, 70–77. [Google Scholar]

- Liu, X.; Chen, X.; Ren, J.; Zhang, C. TiO2-KH550 nanoparticle-reinforced PVA/xylan composite films with multifunctional properties. Materials 2018, 11, 1589. [Google Scholar] [CrossRef]

- Li, S.; Wang, K.; Cheng, J.; Wen, X.; Pi, P.; Yang, Z.; Li, Z. Synthesis of TiO2/poly(styrene-co-divinybenzene) nanocomposite microspheres by grafting copolymerization. Chin. J. Struct. Chem. 2008, 26, 781–786. [Google Scholar] [CrossRef]

- Yeh, M.; Chen, P.; Yang, Y.; Chen, G.; Chen, H. Investigation of Ag-TiO2 interfacial reaction of highly stable Ag nanowire transparent conductive film with conformal TiO2 coating by atomic layer deposition. ACS Appl. Mater. Interfaces 2017, 9, 10788–10797. [Google Scholar] [CrossRef]

- Hu, J.; Shen, Y.; Pang, S.; Gao, Y.; Xiao, G.; Li, S.; Xu, Y. Application of hinokitiol potassium salt for wood preservative. J. Environ. Sci. 2013, 25, S32–S35. [Google Scholar] [CrossRef]

- Sun, F.; Zhou, Y.; Bao, B.; Chen, A.; Du, C. Influence of solvent treatment on mould resistance of bamboo. BioResources 2011, 6, 2091–2100. [Google Scholar]

- Zhang, X.; Xiao, F.; Feng, Q.; Zheng, J.; Chen, C.; Chen, H.; Yang, W. Preparation of SiO2 nanoparticles with adjustable size for fabrication of SiO2/PMHS ORMOSIL superhydrophobic surface on cellulose-based substrates. Prog. Org. Coat. 2020, 138, 105384. [Google Scholar] [CrossRef]

- Rincon, A.G.; Pulgarin, C. Bactericidal action of illuminated TiO2 on pure Escherichia coli and natural bacterial consortia: Post-irradiation events in the dark and assessment of the effective disinfection time. Appl. Catal. B Environ. 2004, 49, 99–112. [Google Scholar] [CrossRef]

- Yu, H.; Du, C.; Huang, Q.; Yao, X.; Hua, Y.; Zhang, W.; Zhou, Z.; Liu, H. Effects of extraction methods on anti-mould property of bamboo strips. BioResources 2018, 13, 2658–2669. [Google Scholar] [CrossRef]

- Plötze, M.; Niemz, P. Porosity and pore size distribution of different wood types as determined by mercury intrusion porosimetry. Eur. J. Wood Wood Prod. 2011, 69, 649–657. [Google Scholar] [CrossRef]

- Sun, Q.; Yu, H.; Liu, Y.; Li, J.; Cui, Y.; Lu, Y. Prolonging the combustion duration of wood by TiO2 coating synthesized using cosolvent-controlled hydrothermal method. J. Mater. Sci. 2010, 45, 6661–6667. [Google Scholar] [CrossRef]

- Chang, H.; Tu, K.; Wang, X.; Liu, J. Fabrication of mechanically durable superhydrophobic wood surfaces using polydimethylsiloxane and silica nanoparticles. RSC Adv. 2015, 5, 30647–30653. [Google Scholar] [CrossRef]

- Li, Z.; Hou, B.; Xu, Y.; Wu, D.; Sun, Y.; Hu, W.; Deng, F. Comparative study of sol–gel-hydrothermal and sol–gel synthesis of titania–silica composite nanoparticles. J. Solid State Chem. 2005, 178, 1395–1405. [Google Scholar] [CrossRef]

- Miyafuji, H.; Saka, S. Fire-resisting properties in several TiO2 wood-inorganic composites and their topochemistry. Wood Sci. Technol. 1997, 31, 449–455. [Google Scholar] [CrossRef]

- Gao, L.; Lu, Y.; Zhan, X.; Li, J.; Sun, Q. A robust, anti-acid, and high-temperature–humidity-resistant superhydrophobic surface of wood based on a modified TiO2 film by fluoroalkyl silane. Surf. Coat. Technol. 2015, 262, 33–39. [Google Scholar] [CrossRef]

- Xue, C.; Jia, S.; Chen, H.; Wang, M. Superhydrophobic cotton fabrics prepared by sol–gel coating of TiO2 and surface hydrophobization. Sci. Technol. Adv. Mater. 2008, 9. [Google Scholar] [CrossRef] [PubMed]

| Sample | Original Wood | UW a | VW b |

|---|---|---|---|

| Mold control effectiveness | 7% | 93% | 97% |

| Structure | Diameter Size | Pore Size Class |

|---|---|---|

| Tracheid | 15–40 μm | Macropore |

| Resin duct | 50–300 μm | Macropore |

| Pit chamber | 4–30 μm | Macropore |

| Pit aperture | 400 nm–6 μm | Macropore |

| Pit membrane | 10 nm–8 μm | Micropore/Mesopore/Macropore |

| Cytoderm | 2–100 nm | Micropore/Mesopore |

| Microfilament clearance | 2–4.5 nm | Micropore |

| Sample | Total Volume of Pore (mL/g) | Average Pore Diameter (nm) | Porosity (%) |

|---|---|---|---|

| Original wood | 1.86 | 332.8 | 70.86 |

| UW | 1.62 | 1139.9 | 61.48 |

| VW | 1.37 | 708.6 | 56.90 |

| Relative Humidity | Sample | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% |

|---|---|---|---|---|---|---|---|---|---|

| Equilibrium moisture content (%) | Original wood | 5.4 | 5.6 | 7.1 | 8.9 | 10.7 | 12.5 | 15.6 | 19.8 |

| UW | 5.0 | 5.2 | 5.3 | 5.3 | 6.1 | 7.6 | 10.1 | 12.1 | |

| VW | 4.8 | 4.9 | 5.0 | 5.2 | 5.8 | 7.1 | 9.7 | 11.6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, L.; Cao, J.; Zhang, J.; Cui, Q.; Liu, Y. Enhanced Anti-Mold Property and Mechanism Description of Ag/TiO2 Wood-Based Nanocomposites Formation by Ultrasound- and Vacuum-Impregnation. Nanomaterials 2020, 10, 682. https://doi.org/10.3390/nano10040682

Lin L, Cao J, Zhang J, Cui Q, Liu Y. Enhanced Anti-Mold Property and Mechanism Description of Ag/TiO2 Wood-Based Nanocomposites Formation by Ultrasound- and Vacuum-Impregnation. Nanomaterials. 2020; 10(4):682. https://doi.org/10.3390/nano10040682

Chicago/Turabian StyleLin, Lin, Jiaming Cao, Jian Zhang, Qiliang Cui, and Yi Liu. 2020. "Enhanced Anti-Mold Property and Mechanism Description of Ag/TiO2 Wood-Based Nanocomposites Formation by Ultrasound- and Vacuum-Impregnation" Nanomaterials 10, no. 4: 682. https://doi.org/10.3390/nano10040682

APA StyleLin, L., Cao, J., Zhang, J., Cui, Q., & Liu, Y. (2020). Enhanced Anti-Mold Property and Mechanism Description of Ag/TiO2 Wood-Based Nanocomposites Formation by Ultrasound- and Vacuum-Impregnation. Nanomaterials, 10(4), 682. https://doi.org/10.3390/nano10040682