Eco-Friendly Supercapacitors Based on Biodegradable Poly(3-Hydroxy-Butyrate) and Ionic Liquids

Abstract

1. Introduction

2. Materials and Methods

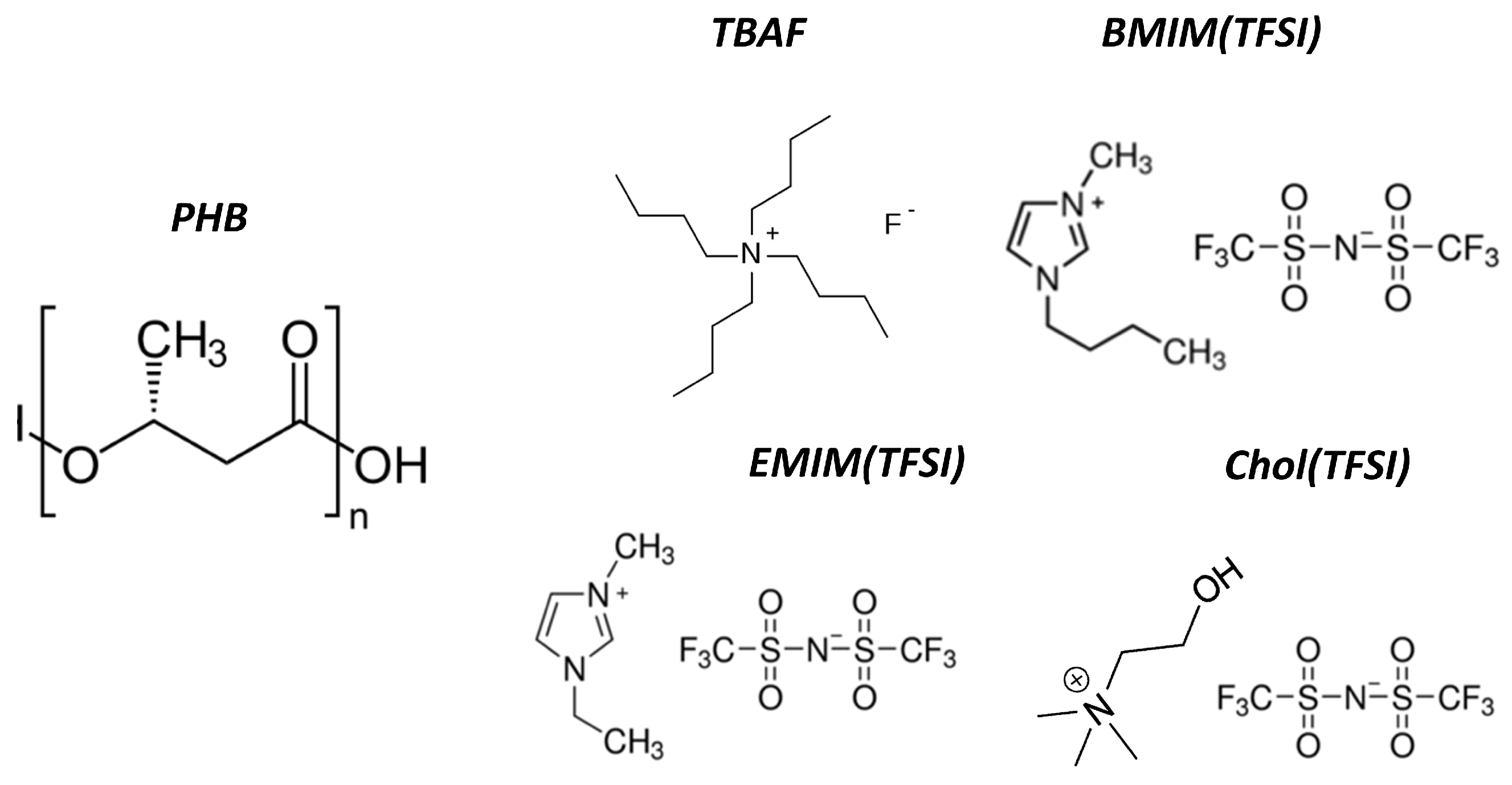

2.1. Materials and Reagents

2.2. Ionogel Synthesis

2.3. Electrode Deposition by Supersonic Cluster Beam Deposition (SCBD)

2.4. Morphological Characterization

2.5. Electrochemical Characterization

3. Results and Discussion

3.1. Supercapacitors Fabrication

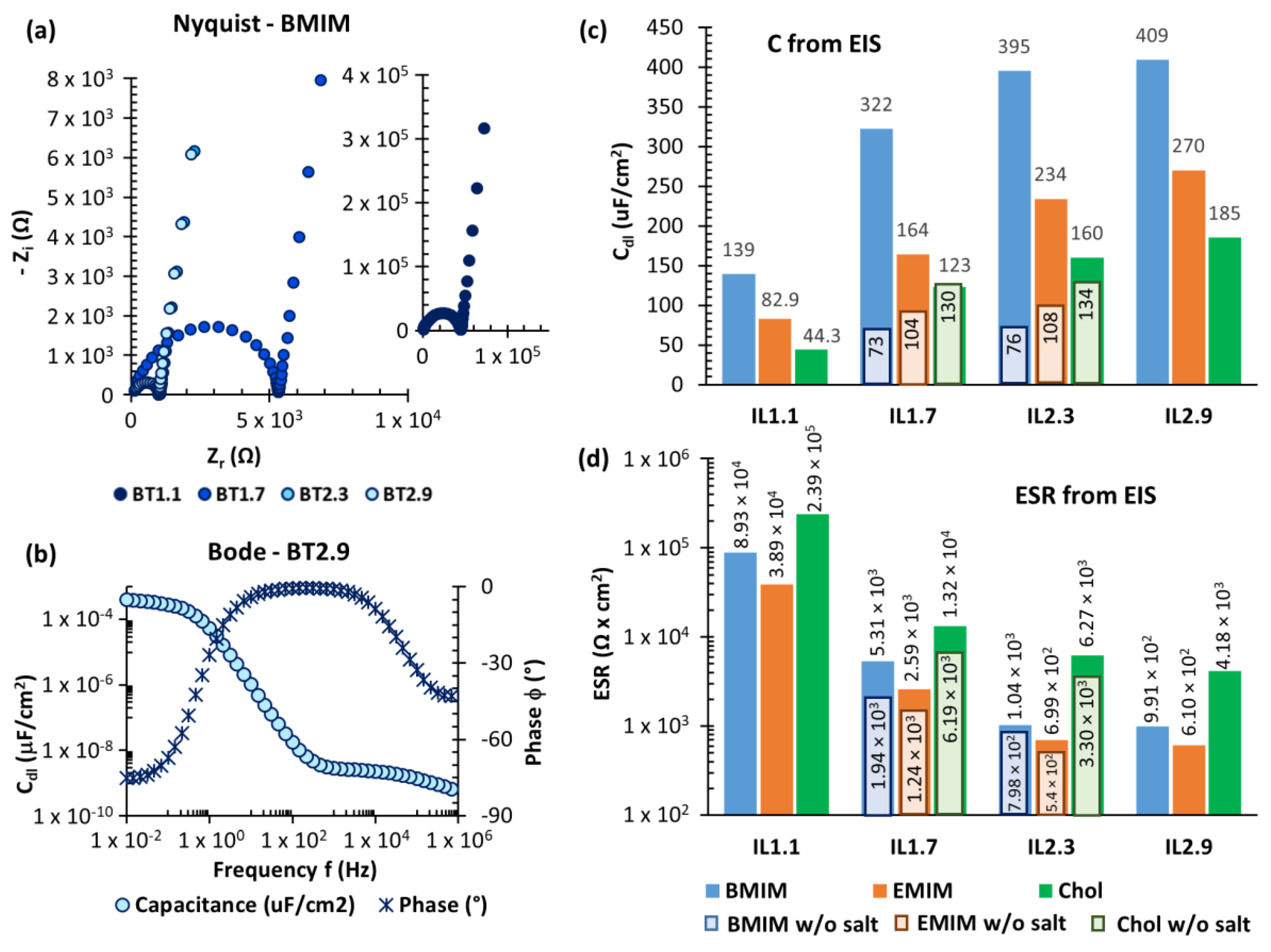

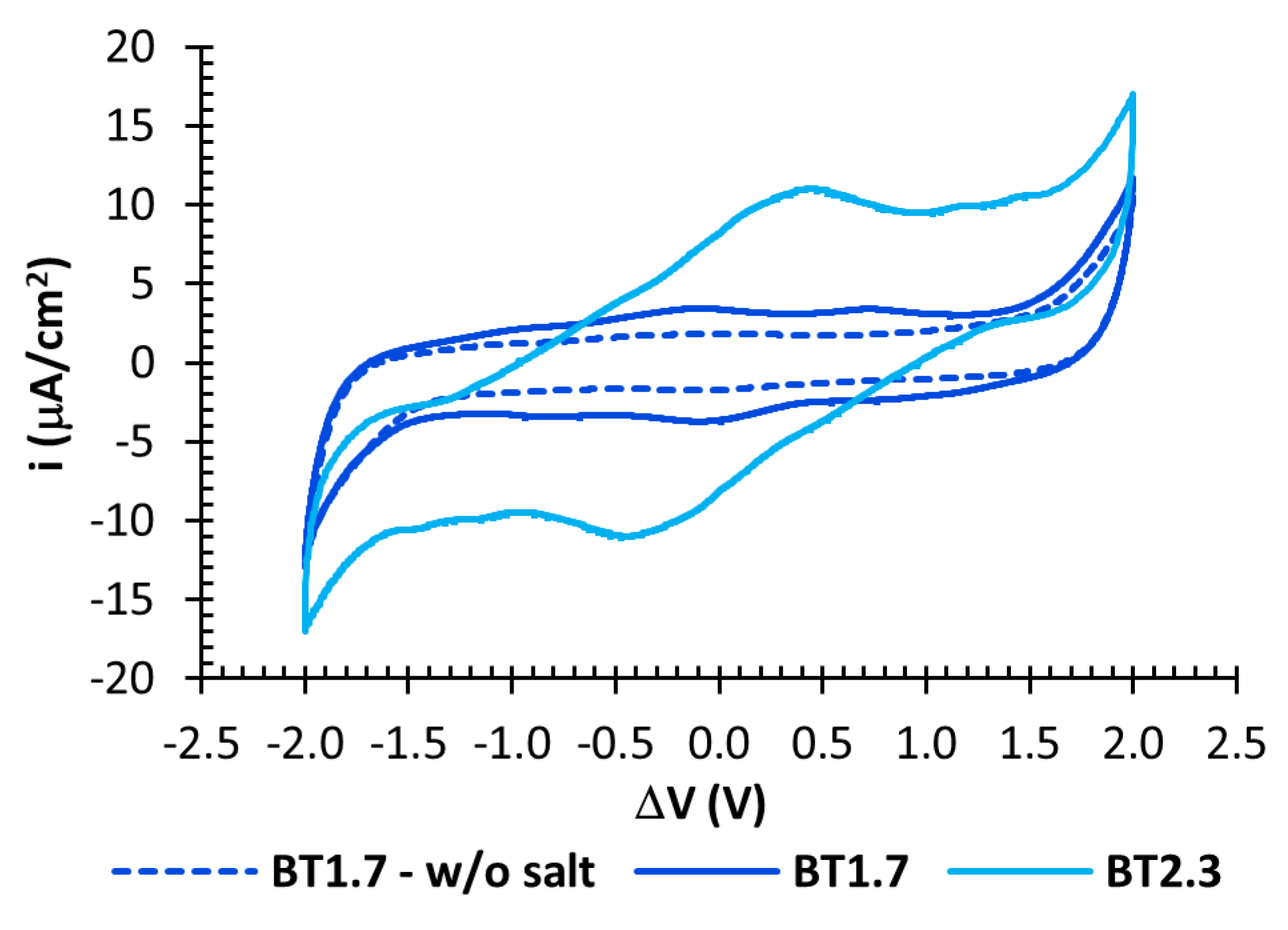

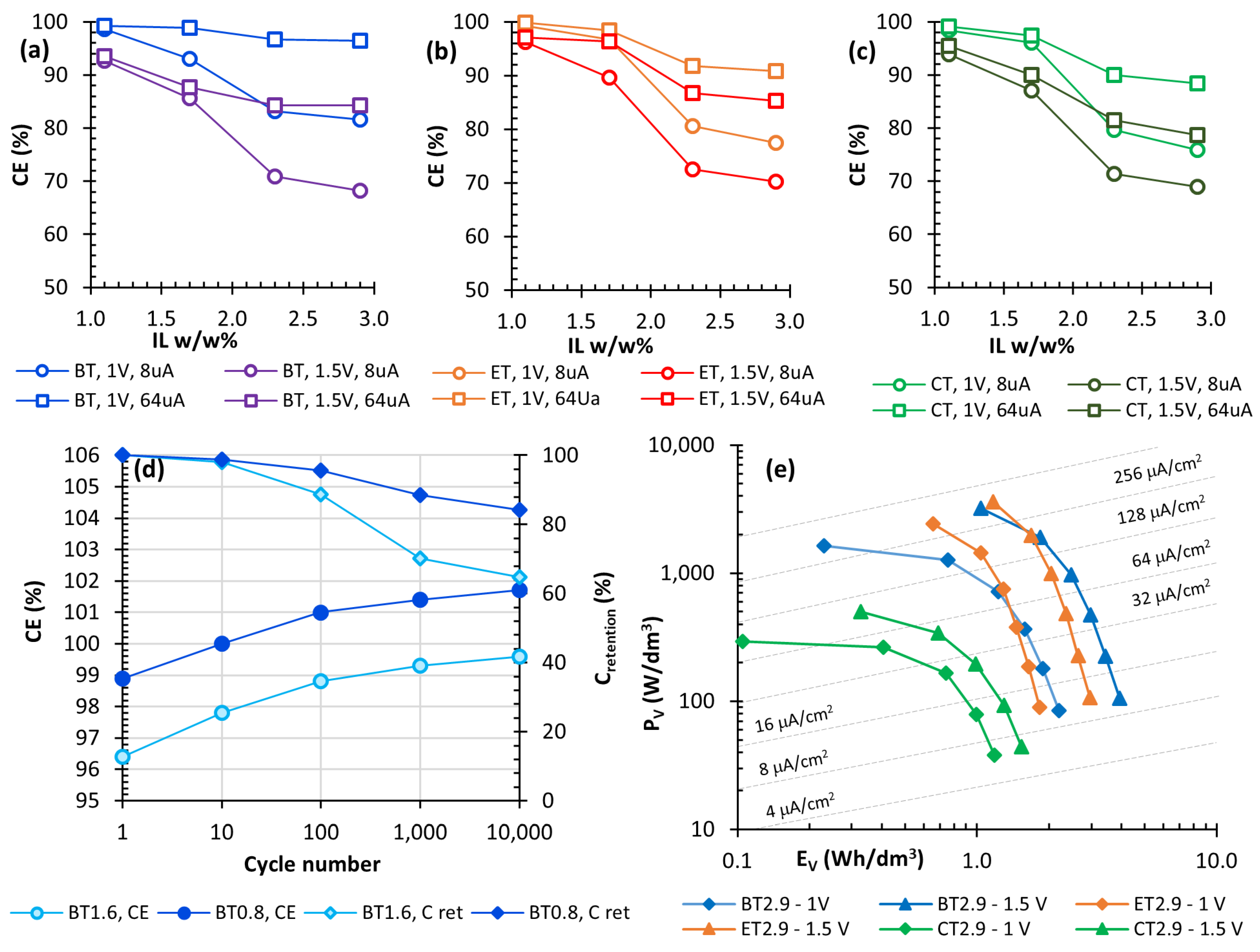

3.2. Electrochemical Characterization

4. Conclusions

5. Patents

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Experimental Details on AFM Measurements

References

- Agate, S.; Joyce, M.; Lucia, L.; Pal, L. Cellulose and nanocellulose-based flexible-hybrid printed electronics and conductive composites–A review. Carbohydr. Polym. 2018, 198, 249–260. [Google Scholar] [CrossRef]

- Xu, W.; Xu, Q.; Huang, Q.; Tan, R.; Shen, W.; Song, W. Electrically conductive silver nanowires-filled methylcellulose composite transparent films with high mechanical properties. Mater. Lett. 2015, 152, 173–176. [Google Scholar] [CrossRef]

- Rossiter, J.; Winfield, J.; Ieropoulos, I. Here today, gone tomorrow: Biodegradable soft robots. Electroact. Polym. Actuators Devices (EAPAD) 2016 2016, 9798, 97981S. [Google Scholar] [CrossRef]

- Walker, S.; Rueben, J.; Van Volkenburg, T.; Hemleben, S.; Grimm, C.; Simonsen, J.; Mengüç, Y. Using an environmentally benign and degradable elastomer in soft robotics. Int. J. Intell. Robot. Appl. 2017, 1, 124–142. [Google Scholar] [CrossRef]

- Pedersen, S.M.; Fountas, S.; Have, H.; Blackmore, B.S. Agricultural robots—System analysis and economic feasibility. Precis. Agric. 2006, 7, 295–308. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Liu, H.; Qing, H.; Li, Z.; Han, Y.L.; Lin, M.; Yang, H.; Li, A.; Lu, T.J.; Li, F.; Xu, F. Paper: A promising material for human-friendly functional wearable electronics. Mater. Sci. Eng. R Rep. 2017, 112, 1–22. [Google Scholar] [CrossRef]

- Boutry, C.M.; Kaizawa, Y.; Schroeder, B.C.; Chortos, A.; Legrand, A.; Wang, Z.; Chang, J.; Fox, P.; Bao, Z. A stretchable and biodegradable strain and pressure sensor for orthopaedic application. Nat. Electron. 2018, 1, 314–321. [Google Scholar] [CrossRef]

- Švorc, Ľ.; Rievaj, M.; Bustin, D. Green electrochemical sensor for environmental monitoring of pesticides: Determination of atrazine in river waters using a boron-doped diamond electrode. Sens. Actuators B Chem. 2013, 181, 294–300. [Google Scholar] [CrossRef]

- Sharma, P.; Bhatti, T. A review on electrochemical double-layer capacitors. Energy Convers. Manag. 2010, 51, 2901–2912. [Google Scholar] [CrossRef]

- Vangari, M.; Pryor, T.; Jiang, L. Supercapacitors: Review of Materials and Fabrication Methods. J. Energy Eng. 2013, 139, 72–79. [Google Scholar] [CrossRef]

- González, A.; Goikolea, E.; Barrena, J.A.; Mysyk, R. Review on supercapacitors: Technologies and materials. Renew. Sustain. Energy Rev. 2016, 58, 1189–1206. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, X.; Wang, Z.; Sun, F.; Dorrell, D.G. A review of supercapacitor modeling, estimation, and applications: A control/management perspective. Renew. Sustain. Energy Rev. 2018, 81, 1868–1878. [Google Scholar] [CrossRef]

- Salanne, M. Ionic Liquids for Supercapacitor Applications. Top. Curr. Chem. 2017, 375, 63. [Google Scholar] [CrossRef] [PubMed]

- Huang, P.-L.; Luo, X.-F.; Peng, Y.-Y.; Pu, N.-W.; Ger, M.-D.; Yang, C.-H.; Wu, T.-Y.; Chang, J.-K. Ionic Liquid Electrolytes with Various Constituent Ions for Graphene-based Supercapacitors. Electrochim. Acta 2015, 161, 371–377. [Google Scholar] [CrossRef]

- Kovalska, E.; Kocabas, C. Organic electrolytes for graphene-based supercapacitor: Liquid, gel or solid. Mater. Today Commun. 2016, 7, 155–160. [Google Scholar] [CrossRef]

- Iro, Z.S. A Brief Review on Electrode Materials for Supercapacitor. Int. J. Electrochem. Sci. 2016, 10628–10643. [Google Scholar] [CrossRef]

- Wang, R.; Wang, Q.-R.; Yao, M.-J.; Chen, K.-N.; Wang, X.-Y.; Liu, L.-L.; Niu, Z.; Chen, J. Flexible ultrathin all-solid-state supercapacitors. Rare Met. 2018, 37, 536–542. [Google Scholar] [CrossRef]

- Niu, Z.; Zhang, L.; Liu, L.; Zhu, B.; Dong, H.; Chen, X. All-Solid-State Flexible Ultrathin Micro-Supercapacitors Based on Graphene. Adv. Mater. 2013, 25, 4035–4042. [Google Scholar] [CrossRef] [PubMed]

- Pu, X.; Liu, M.; Li, L.; Han, S.; Li, X.; Jiang, C.; Du, C.; Luo, J.; Hu, W.; Wang, Z.L. Wearable Textile-Based In-Plane Microsupercapacitors. Adv. Energy Mater. 2016, 6, 1601254. [Google Scholar] [CrossRef]

- Wu, G.; Tan, P.; Wang, D.; Li, Z.; Peng, L.; Hu, Y.; Wang, C.; Zhu, W.; Chen, S.; Chen, W. High-performance Supercapacitors Based on Electrochemical-induced Vertical-aligned Carbon Nanotubes and Polyaniline Nanocomposite Electrodes. Sci. Rep. 2017, 7, 43676. [Google Scholar] [CrossRef]

- Aschberger, K.; Johnston, H.J.; Stone, V.; Aitken, R.J.; Hankin, S.; Peters, S.A.K.; Tran, C.L.; Christensen, F.M. Review of carbon nanotubes toxicity and exposure—Appraisal of human health risk assessment based on open literature. Crit. Rev. Toxicol. 2010, 40, 759–790. [Google Scholar] [CrossRef]

- Li, H.; Qi, C.; Tao, Y.; Liu, H.; Wang, D.-W.; Li, F.; Yang, Q.-H.; Cheng, H.-M. Quantifying the Volumetric Performance Metrics of Supercapacitors. Adv. Energy Mater. 2019, 9, 1900079. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, T.; Qian, F.; Han, T.Y.-J.; Duoss, E.B.; Kuntz, J.D.; Spadaccini, C.M.; Worsley, M.A.; Li, Y. Supercapacitors Based on Three-Dimensional Hierarchical Graphene Aerogels with Periodic Macropores. Nano Lett. 2016, 16, 3448–3456. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Sun, N.; He, X.; Lu, X.; Zhang, S. Physical Properties of Ionic Liquids: Database and Evaluation. J. Phys. Chem. Ref. Data 2006, 35, 1475–1517. [Google Scholar] [CrossRef]

- Quijano, G.; Couvert, A.; Amrane, A.; Darracq, G.; Couriol, C.; Le Cloirec, P.; Paquin, L.; Carrié, D. Toxicity and biodegradability of ionic liquids: New perspectives towards whole-cell biotechnological applications. Chem. Eng. J. 2011, 174, 27–32. [Google Scholar] [CrossRef]

- Matsumoto, M.; Mochiduki, K.; Kondo, K. Toxicity of ionic liquids and organic solvents to lactic acid-producing bacteria. J. Biosci. Bioeng. 2004, 98, 344–347. [Google Scholar] [CrossRef]

- Dubal, D.P.; Chodankar, N.R.; Kim, D.-H.; Gomez-Romero, P. Towards flexible solid-state supercapacitors for smart and wearable electronics. Chem. Soc. Rev. 2018, 47, 2065–2129. [Google Scholar] [CrossRef]

- Calvert, P. Hydrogels for Soft Machines. Adv. Mater. 2009, 21, 743–756. [Google Scholar] [CrossRef]

- Le Bideau, J.; Viau, L.; Vioux, A. Ionogels, ionic liquid based hybrid materials. Chem. Soc. Rev. 2011, 40, 907–925. [Google Scholar] [CrossRef]

- Osada, Y.; Khokhlov, A. Polymer Gels and Networks; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar] [CrossRef]

- Lai, W.-Y.; Wang, Y.; Cheng, T.; Lai, W.-Y.; Pang, H.; Huang, W. Flexible supercapacitors based on paper substrates: A new paradigm for low-cost energy storage. Chem. Soc. Rev. 2015, 44, 5181–5199. [Google Scholar] [CrossRef]

- Li, H.; Yuan, D.; Tang, C.; Wang, S.; Sun, J.; Li, Z.; Tang, T.; Wang, F.; Gong, H.; He, C. Lignin-derived interconnected hierarchical porous carbon monolith with large areal/volumetric capacitances for supercapacitor. Carbon 2016, 100, 151–157. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, Y.; Li, Y.; Dai, J.; Song, J.; Yao, Y.; Gong, Y.; Kierzewski, I.; Xie, J.; Hu, L. All-wood, low tortuosity, aqueous, biodegradable supercapacitors with ultra-high capacitance. Energy Environ. Sci. 2017, 10, 538–545. [Google Scholar] [CrossRef]

- Niu, Q.; Guo, Y.; Gao, K.; Shao, Z. Polypyrrole/cellulose nanofiber aerogel as a supercapacitor electrode material. RSC Adv. 2016, 6, 109143–109149. [Google Scholar] [CrossRef]

- Mantravadi, R.; Chinnam, P.R.; Dikin, D.A.; Wunder, S.L. High Conductivity, High Strength Solid Electrolytes Formed by in Situ Encapsulation of Ionic Liquids in Nanofibrillar Methyl Cellulose Networks. ACS Appl. Mater. Interfaces 2016, 8, 13426–13436. [Google Scholar] [CrossRef]

- Moon, W.G.; Kim, G.-P.; Lee, M.; Song, H.D.; Yi, J. A Biodegradable Gel Electrolyte for Use in High-Performance Flexible Supercapacitors. ACS Appl. Mater. Interfaces 2015, 7, 3503–3511. [Google Scholar] [CrossRef]

- Oraon, R.; De Adhikari, A.; Tiwari, S.K.; Nayak, G.C. Enhanced Specific Capacitance of Self-Assembled Three-Dimensional Carbon Nanotube/Layered Silicate/Polyaniline Hybrid Sandwiched Nanocomposite for Supercapacitor Applications. ACS Sustain. Chem. Eng. 2016, 4, 1392–1403. [Google Scholar] [CrossRef]

- Boyandin, A.N.; Prudnikova, S.V.; Karpov, V.A.; Ivonin, V.N.; Đỗ, N.L.; Nguyễn, T.H.; Lê, T.M.H.; Filichev, N.L.; Levin, A.L.; Filipenko, M.L.; et al. Microbial degradation of polyhydroxyalkanoates in tropical soils. Int. Biodeterior. Biodegrad. 2013, 83, 77–84. [Google Scholar] [CrossRef]

- Polyhydroxyalkanoate (PHA) based Blends, Composites and Nanocomposites. Green Chem. Ser. 2014, 1–17. [CrossRef]

- Ansari, S.; Fatma, T. Cyanobacterial Polyhydroxybutyrate (PHB): Screening, Optimization and Characterization. PLoS ONE 2016, 11, e0158168. [Google Scholar] [CrossRef]

- Emadian, S.M.; Onay, T.T.; Demirel, B. Biodegradation of bioplastics in natural environments. Waste Manag. 2017, 59, 526–536. [Google Scholar] [CrossRef] [PubMed]

- Wegner, K.; Piseri, P.; Tafreshi, H.V.; Milani, P. Cluster beam deposition: A tool for nanoscale science and technology. J. Phys. D Appl. Phys. 2006, 39, R439–R459. [Google Scholar] [CrossRef]

- Soavi, F.; Bettini, L.G.; Piseri, P.; Milani, P.; Santoro, C.; Atanassov, P.; Arbizzani, C. Miniaturized supercapacitors: Key materials and structures towards autonomous and sustainable devices and systems. J. Power Sources 2016, 326, 717–725. [Google Scholar] [CrossRef] [PubMed]

- Bettini, L.G.; Bellacicca, A.; Piseri, P.; Milani, P. Supersonic cluster beam printing of carbon microsupercapacitors on paper. Flex. Print. Electron. 2017, 2, 025002. [Google Scholar] [CrossRef]

- Santaniello, T.; Migliorini, L.; Yan, Y.; Lenardi, C.; Milani, P. Supersonic cluster beam fabrication of metal–ionogel nanocomposites for soft robotics. J. Nanopart. Res. 2018, 20, 250. [Google Scholar] [CrossRef]

- Yan, Y.; Santaniello, T.; Bettini, L.G.; Minnai, C.; Bellacicca, A.; Porotti, R.; Denti, I.; Faraone, G.; Merlini, M.; Lenardi, C.; et al. Electroactive Ionic Soft Actuators with Monolithically Integrated Gold Nanocomposite Electrodes. Adv. Mater. 2017, 29, 1606109. [Google Scholar] [CrossRef] [PubMed]

- Santaniello, T.; Migliorini, L.; Borghi, F.; Yan, Y.; Rondinini, S.; Lenardi, C.; Milani, P. Spring-like electroactive actuators based on paper/ionogel/metal nanocomposites. Smart Mater. Struct. 2018, 27, 065004. [Google Scholar] [CrossRef]

- Villa, S.M.; Mazzola, V.M.; Santaniello, T.; Locatelli, E.; Maturi, M.; Migliorini, L.; Monaco, I.; Lenardi, C.; Franchini, M.C.; Milani, P. Soft Piezoionic/Piezoelectric Nanocomposites Based on Ionogel/BaTiO3 Nanoparticles for Low Frequency and Directional Discriminative Pressure Sensing. ACS Macro Lett. 2019, 8, 414–420. [Google Scholar] [CrossRef]

- Migliorini, L.; Santaniello, T.; Rondinini, S.; Saettone, P.; Franchini, M.C.; Lenardi, C.; Milani, P. Bioplastic electromechanical actuators based on biodegradable poly(3-hydroxybutyrate) and cluster-assembled gold electrodes. Sens. Actuators B Chem. 2019, 286, 230–236. [Google Scholar] [CrossRef]

- Barborini, E.; Piseri, P.; Milani, P. A pulsed microplasma source of high intensity supersonic carbon cluster beams. J. Phys. D Appl. Phys. 1999, 32, L105–L109. [Google Scholar] [CrossRef]

- Borghi, F.; Melis, C.; Ghisleri, C.; Podestà, A.; Ravagnan, L.; Colombo, L.; Milani, P. Stretchable nanocomposite electrodes with tunable mechanical properties by supersonic cluster beam implantation in elastomers. Appl. Phys. Lett. 2015, 106, 121902. [Google Scholar] [CrossRef]

- Vicentini, R.; Da Silva, L.M.; Junior, E.P.C.; Alves, T.A.; Nunes, W.G.; Zanin, H. How to Measure and Calculate Equivalent Series Resistance of Electric Double-Layer Capacitors. Molecules 2019, 24, 1452. [Google Scholar] [CrossRef] [PubMed]

- Tiruye, G.A.; Muñoz-Torrero, D.; Palma, J.; Anderson, M.; Marcilla, R. Performance of solid state supercapacitors based on polymer electrolytes containing different ionic liquids. J. Power Sources 2016, 326, 560–568. [Google Scholar] [CrossRef]

- Westover, A.S.; Tian, J.W.; Bernath, S.; Oakes, L.; Edwards, R.; Shabab, F.N.; Chatterjee, S.; Anilkumar, A.V.; Pint, C.L. A Multifunctional Load-Bearing Solid-State Supercapacitor. Nano Lett. 2014, 14, 3197–3202. [Google Scholar] [CrossRef]

- Mirigliano, M.; Borghi, F.; Podesta’, A.; Antidormi, A.; Colombo, L.; Milani, P. Non-ohmic behavior and resistive switching of Au cluster-assembled films beyond the percolation threshold. Nanoscale Adv. 2019, 1, 3119–3130. [Google Scholar] [CrossRef]

- Ghisleri, C.; Borghi, F.; Ravagnan, L.; Podestà, A.; Melis, C.; Colombo, L.; Milani, P. Patterning of gold–polydimethylsiloxane (Au–PDMS) nanocomposites by supersonic cluster beam implantation. J. Phys. D Appl. Phys. 2013, 47, 015301. [Google Scholar] [CrossRef]

- Gunday, S.T.; Cevik, E.; Yusuf, A.; Bozkurt, A. Nanocomposites composed of sulfonated polysulfone/hexagonal boron nitride/ionic liquid for supercapacitor applications. J. Energy Storage 2019, 21, 672–679. [Google Scholar] [CrossRef]

- Pandey, G.; Hashmi, S. Performance of solid-state supercapacitors with ionic liquid 1-ethyl-3-methylimidazolium tris(pentafluoroethyl) trifluorophosphate based gel polymer electrolyte and modified MWCNT electrodes. Electrochim. Acta 2013, 105, 333–341. [Google Scholar] [CrossRef]

- Ortega, P.F.; Trigueiro, J.P.C.; Silva, G.G.; Lavall, R.L. Improving supercapacitor capacitance by using a novel gel nanocomposite polymer electrolyte based on nanostructured SiO2, PVDF and imidazolium ionic liquid. Electrochim. Acta 2016, 188, 809–817. [Google Scholar] [CrossRef]

- Borghi, F.; Milani, M.; Bettini, L.G.; Podestà, A.; Milani, P. Quantitative characterization of the interfacial morphology and bulk porosity of nanoporous cluster-assembled carbon thin films. Appl. Surf. Sci. 2019, 479, 395–402. [Google Scholar] [CrossRef]

- Singh, M.K.; Kumar, Y.; Hashmi, S. ‘Bucky gel’ of multiwalled carbon nanotubes as electrodes for high performance, flexible electric double layer capacitors. Nanotechnology 2013, 24, 465704. [Google Scholar] [CrossRef] [PubMed]

- Saettone, P.; Cifelli, M.; Migliorini, L.; Generali, G.; Santaniello, T.; Monaco, I.; Milani, P.; Franchini, M.C. Flexible, Biodegradable and Biocompatible Supercondenser. Patent WO2020109841 (A1), 4 June 2020. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Migliorini, L.; Santaniello, T.; Borghi, F.; Saettone, P.; Comes Franchini, M.; Generali, G.; Milani, P. Eco-Friendly Supercapacitors Based on Biodegradable Poly(3-Hydroxy-Butyrate) and Ionic Liquids. Nanomaterials 2020, 10, 2062. https://doi.org/10.3390/nano10102062

Migliorini L, Santaniello T, Borghi F, Saettone P, Comes Franchini M, Generali G, Milani P. Eco-Friendly Supercapacitors Based on Biodegradable Poly(3-Hydroxy-Butyrate) and Ionic Liquids. Nanomaterials. 2020; 10(10):2062. https://doi.org/10.3390/nano10102062

Chicago/Turabian StyleMigliorini, Lorenzo, Tommaso Santaniello, Francesca Borghi, Paolo Saettone, Mauro Comes Franchini, Gianluca Generali, and Paolo Milani. 2020. "Eco-Friendly Supercapacitors Based on Biodegradable Poly(3-Hydroxy-Butyrate) and Ionic Liquids" Nanomaterials 10, no. 10: 2062. https://doi.org/10.3390/nano10102062

APA StyleMigliorini, L., Santaniello, T., Borghi, F., Saettone, P., Comes Franchini, M., Generali, G., & Milani, P. (2020). Eco-Friendly Supercapacitors Based on Biodegradable Poly(3-Hydroxy-Butyrate) and Ionic Liquids. Nanomaterials, 10(10), 2062. https://doi.org/10.3390/nano10102062