Experimental Study on the Reinforcement of Calcareous Sand Using Combined Microbial-Induced Carbonate Precipitation (MICP) and Festuca arundinacea Techniques

Abstract

1. Introduction

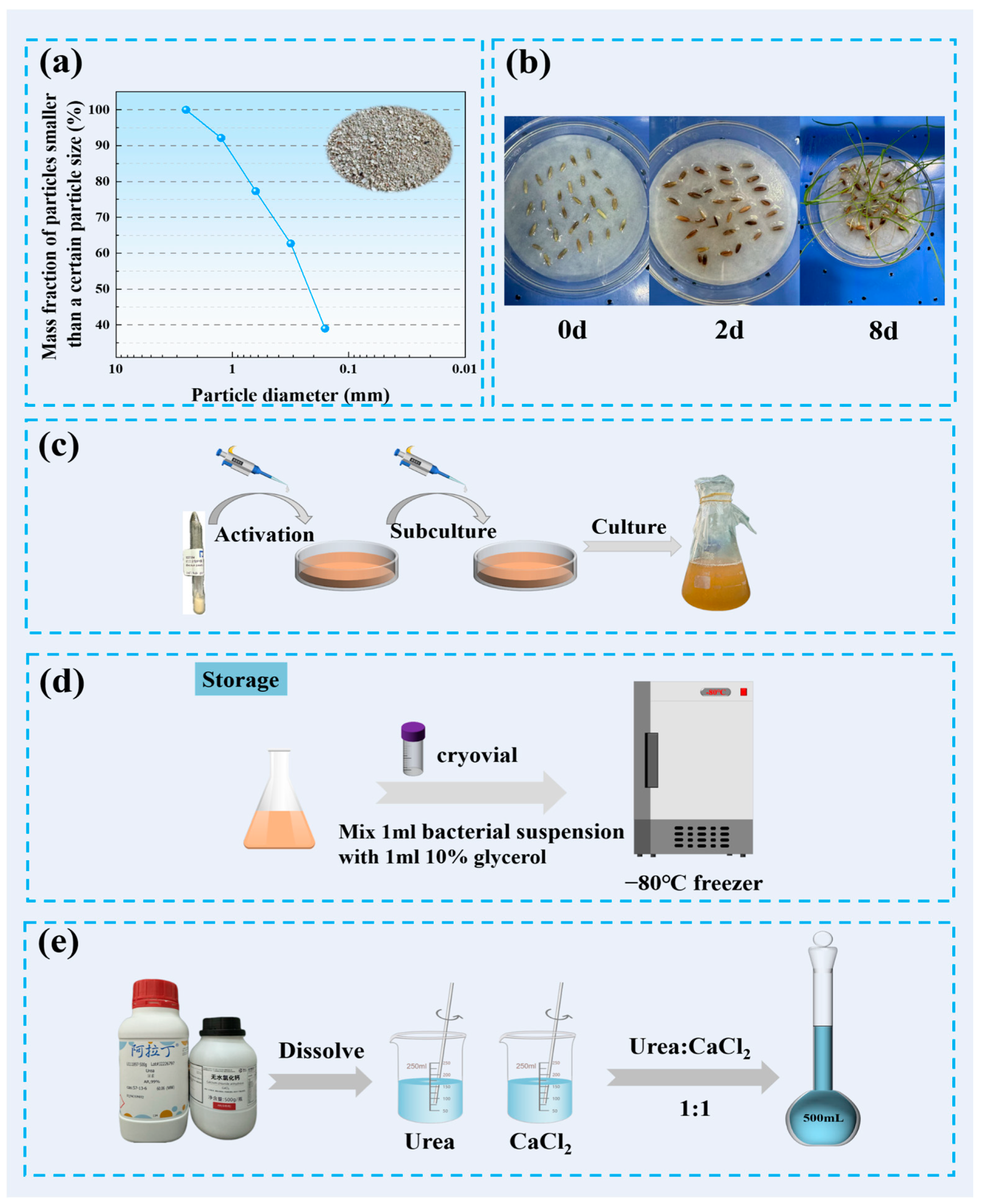

2. Materials and Methods

2.1. Test Materials

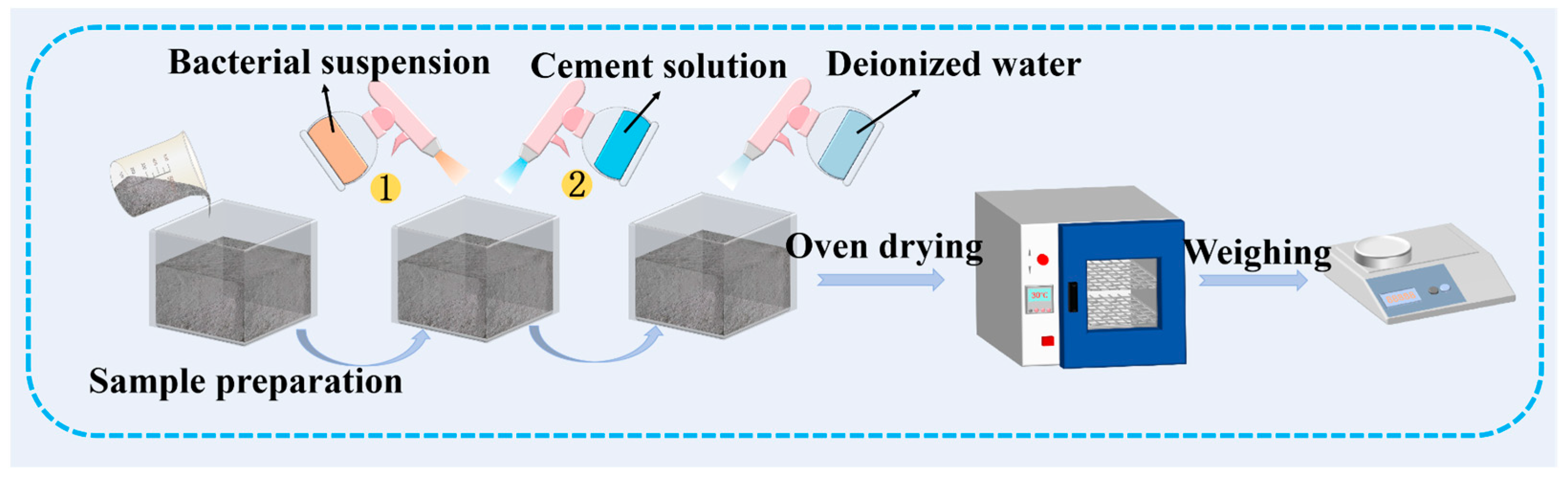

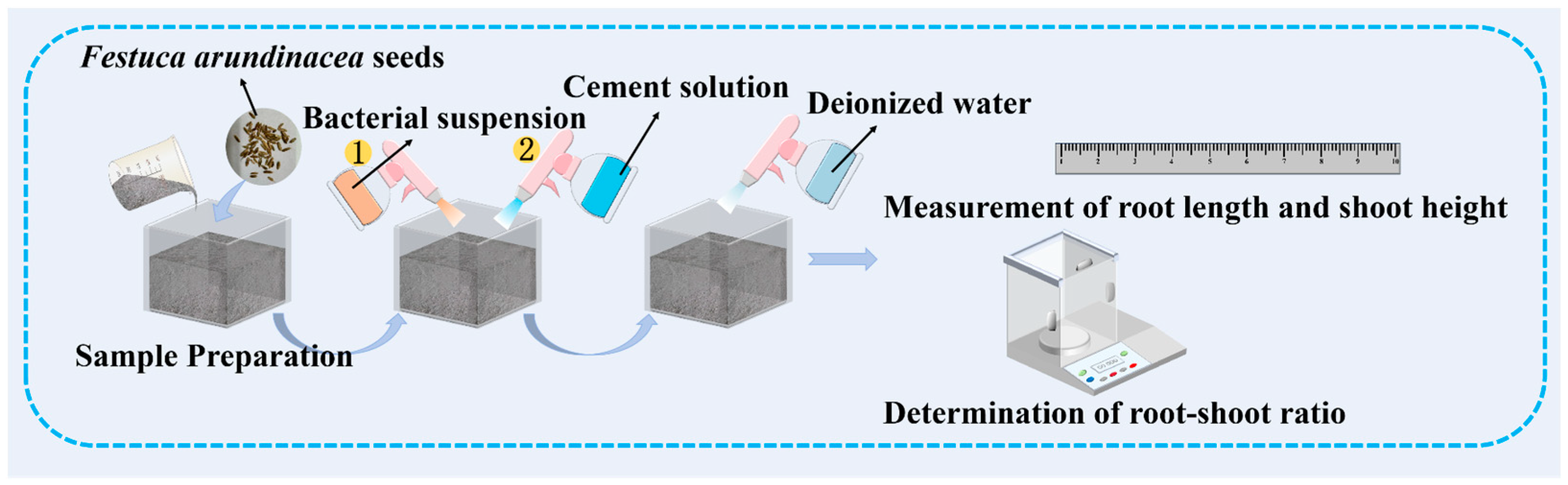

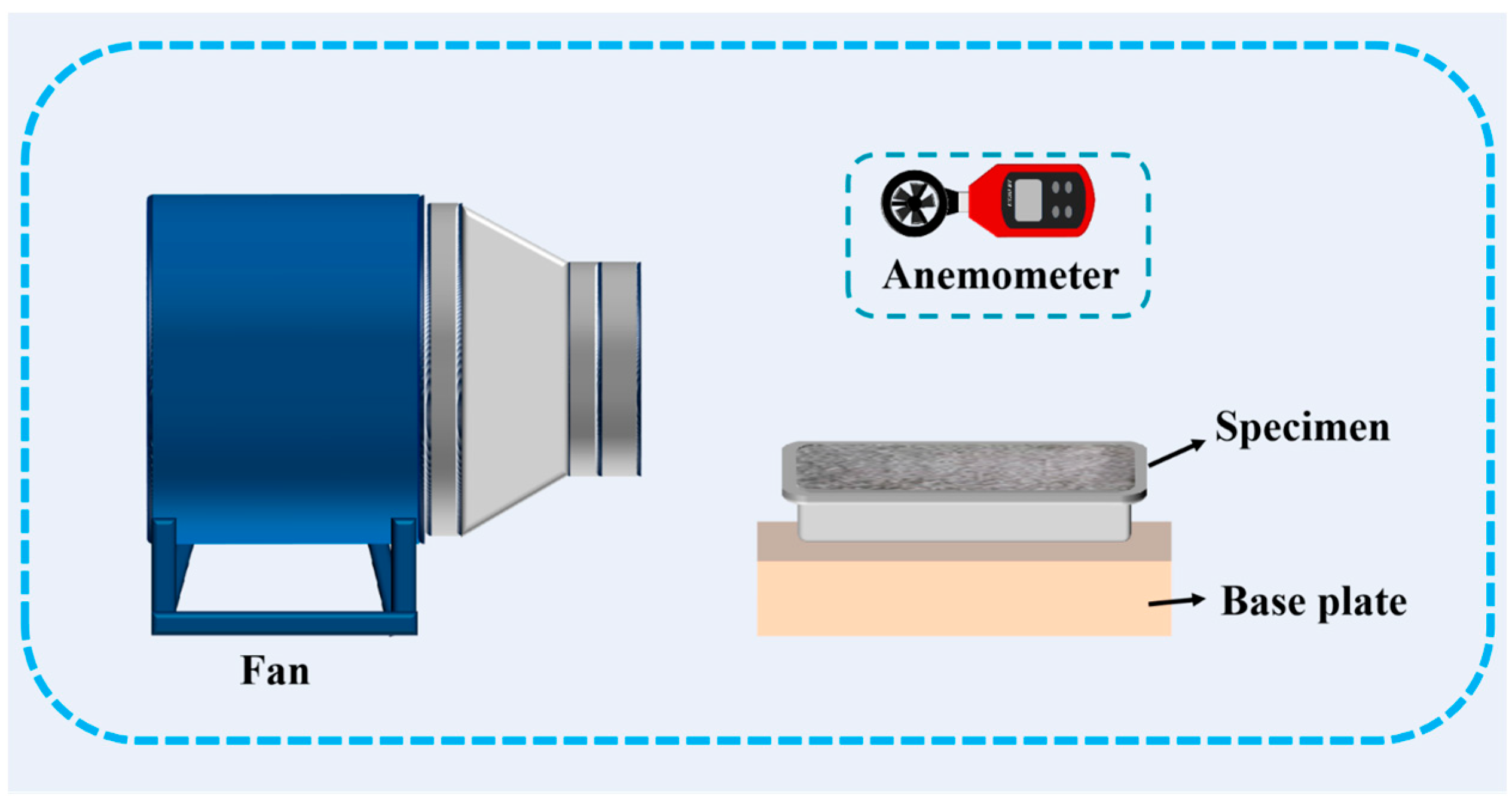

2.2. Test Methods

2.2.1. Water Retention Test

2.2.2. SEM Analysis

2.2.3. Growth Adaptability Test of Festuca arundinacea

2.2.4. Wind Erosion Test

3. Results and Discussion

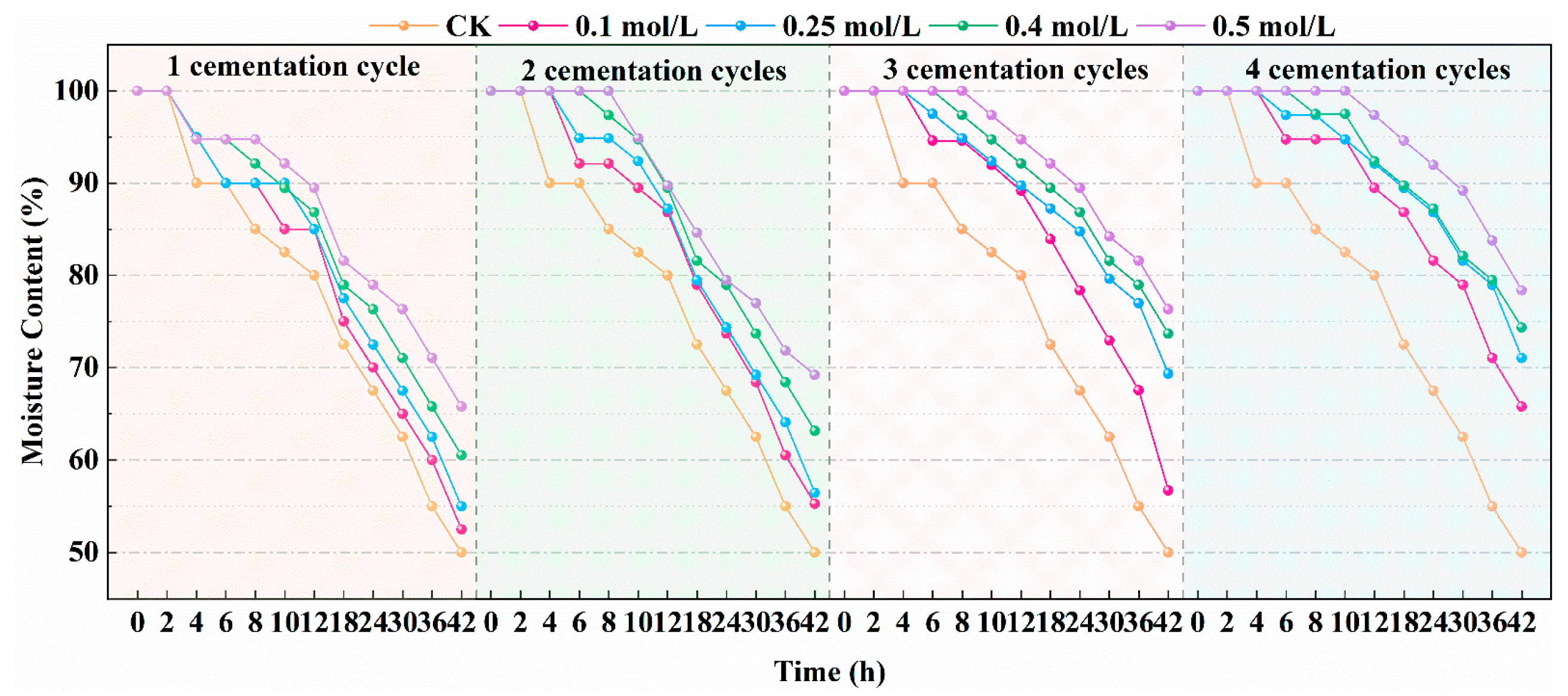

3.1. Effects of Cementation Solution Concentration and Cycles on Water Content

3.2. Microstructural Analysis

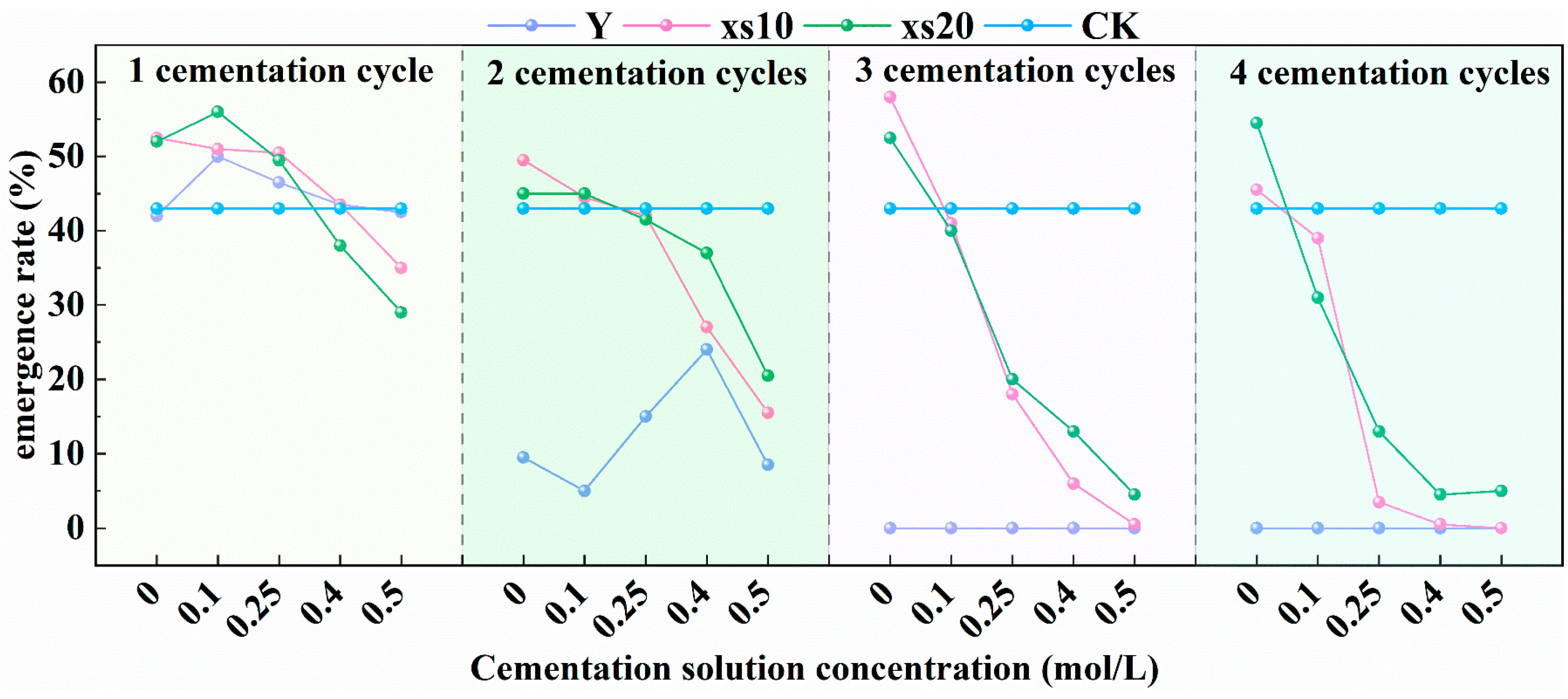

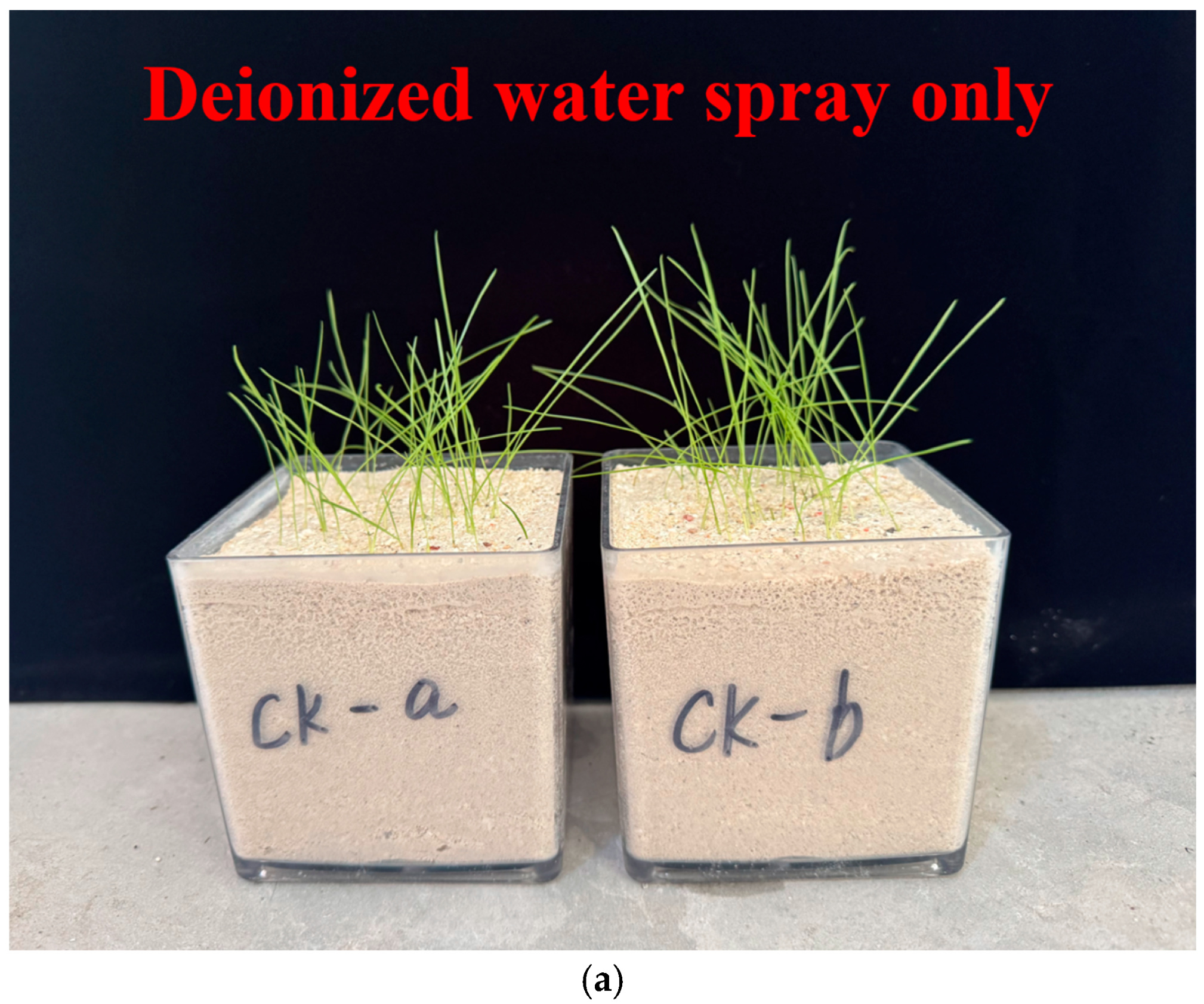

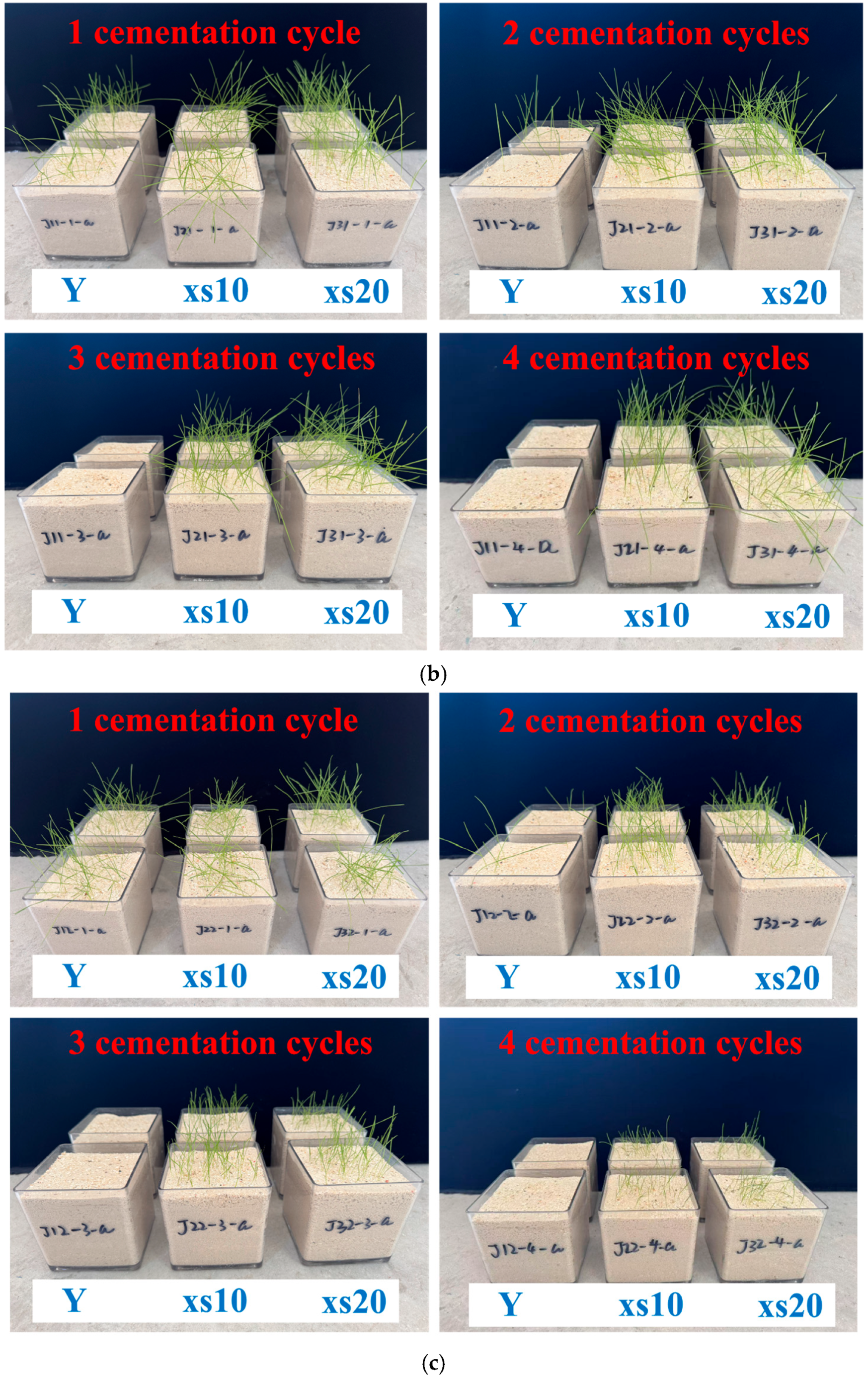

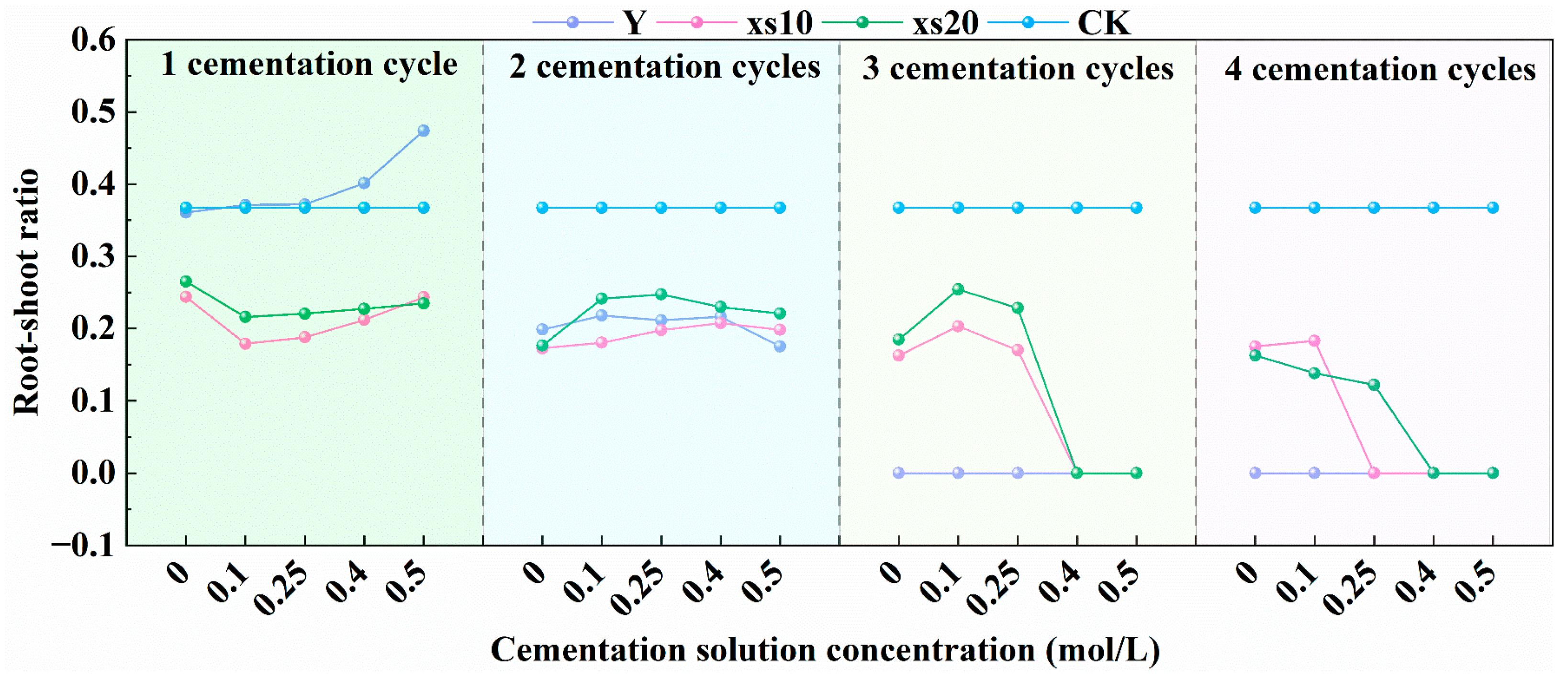

3.3. Impact on Festuca Arundinacea Growth

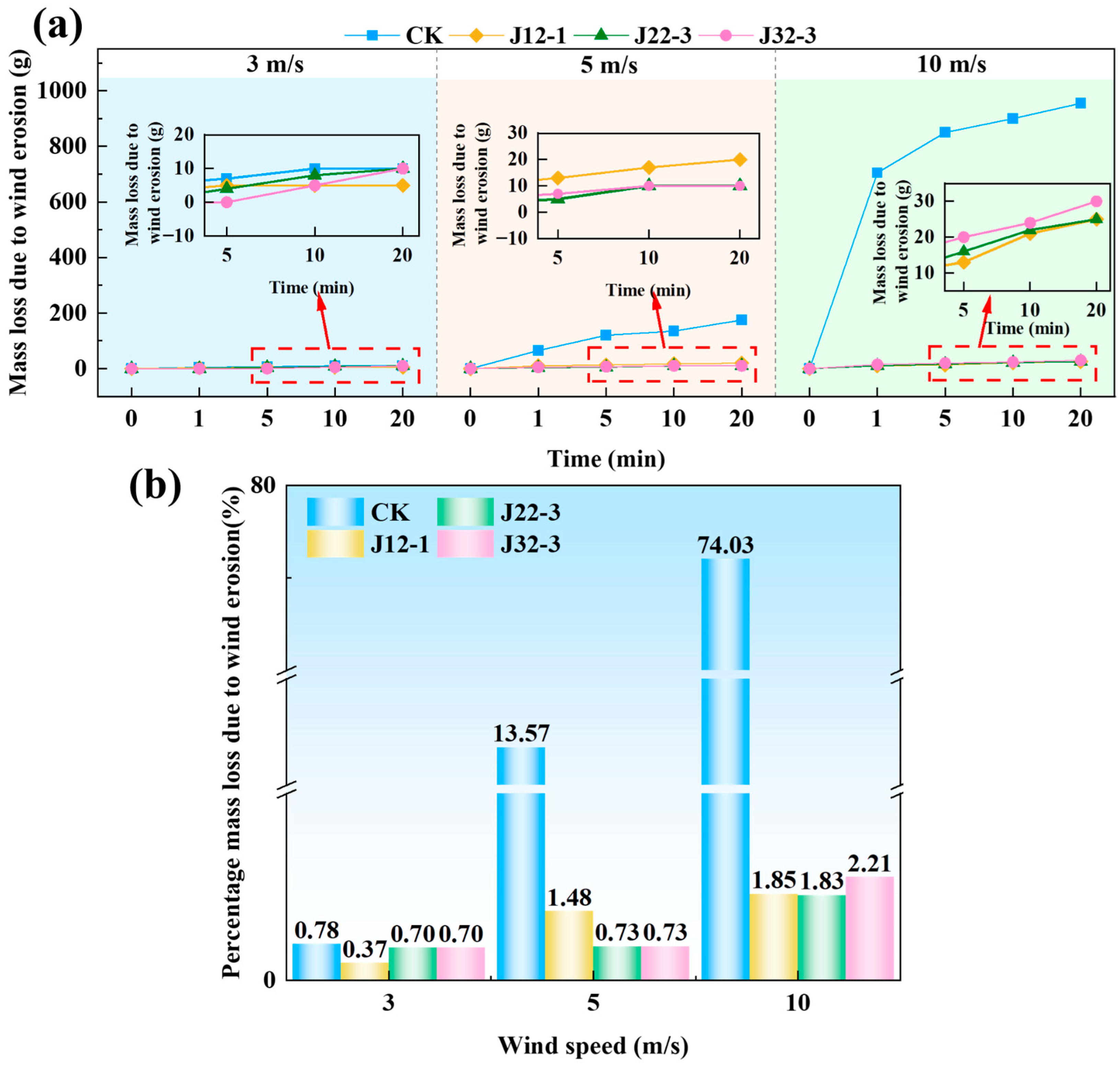

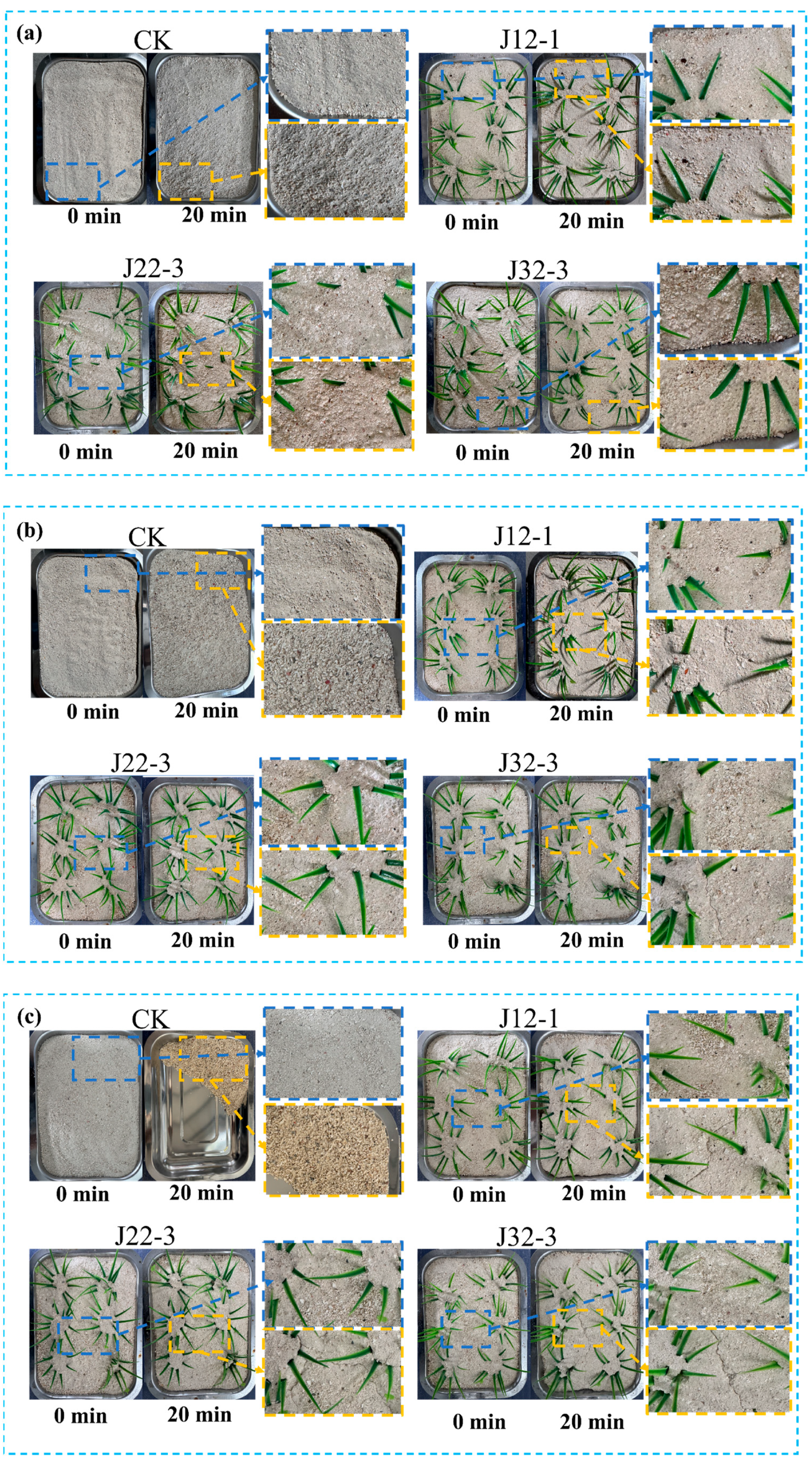

3.4. Wind Erosion Test Results

3.5. Synergistic Reinforcement Mechanism Analysis

4. Conclusions

- (1)

- Based on the water retention test and scanning electron microscope images, it can be seen that with the increase in cementation solution concentration and the number of cementation cycles, more calcium carbonate adheres to and fills in the surface and interstitial space of calcareous sand particles, which effectively improves the water retention performance of the calcareous sand soil body. The best water retention performance is achieved with a 0.5 mol/L cementation solution concentration and four cementation cycles, which is 56.72% higher than that of control group.

- (2)

- Based on the results of Festuca arundinacea growth adaptation test, lower bacterial solution concentration, cementation solution concentration, and cementation cycles promote the growth of Festuca arundinacea, and increasing these parameters gradually inhibits the development of plants.

- (3)

- According to the results of the wind erosion test, MICP-FA reinforcement can enhance the wind erosion resistance of calcareous sand soil body. Under an OD600 = 2.2 bacterial concentration, 0.1 mol/L cementation solution concentration, and one cementation cycle (J12-1), the best wind erosion resistance of the reinforced soil was obtained, and favorable plant growth was maintained. At this time, under a 10 m/s wind speed, the specimen wind erosion mass loss rate was only 1.85%, which was 97.5% lower than that of the control group. (4) MICP-FA reinforcement significantly improves the wind erosion resistance of calcareous sand. The synergistic mechanism includes the surface bonding of MICP and the deep soil anchoring/reinforcement of the Festuca arundinacea root system.

5. Discussion

- (1)

- Only Festuca arundinacea was selected as a test plant in this study, and there are significant differences in its root morphology, secretion and growth habit among different plants, and the synergistic mechanism with MICP technology may be different. The combination of different plants and MICP technology can be considered in the subsequent experiments.

- (2)

- The wind speed set in the wind erosion test did not adequately simulate the extreme wind speed conditions during typhoons on the South China Sea islands. Further evaluation of the wind erosion resistance of MICP-FA0-reinforced calcareous sand can be considered in the subsequent study by referring to the wind speed of the typhoon in the South China Sea islands and reefs.

- (3)

- The issue of how the enhancement of soil strength following MICP treatment influences plant root extension and distribution can be measured in greater detail in subsequent experiments.

- (4)

- This study was carried out under controlled conditions in the laboratory, and the uniformity of the microbial solution and the initial state of the calcareous sand were strictly controlled. However, in actual island projects with a wide range of calcareous sand sites and complex environmental conditions (e.g., temperature), the implementation effect of the MICP-FA technique may change due to scale-up. While plant growth space and conditions are controllable in a laboratory setting, plant root competition, microbial community diversity, and interactions with other environmental factors (e.g., wave wash, tidal action) are more complex in real island ecosystems. It is necessary to conduct simulated field experiments to further investigate the influence of scale changes on the effectiveness of reinforcement, in order to realize an effective transition from the laboratory to the actual project.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Liu, J.-Q.; Cui, J.; Wang, X.-Z.; Shen, J.-H.; Zhu, C.-Q. Particle Breakage Characteristics of a Foundation Filling Material on Island-Reefs in the South China Sea. Constr. Build. Mater. 2021, 306, 124690. [Google Scholar] [CrossRef]

- Cao, L.; Cao, P.; Wang, Z.; Tan, Z.; Shi, F.; Wang, J.; Liu, S. Application of SCMs and Seawater to Cement-Bonded Calcareous Sand: Macro Performance, Micro Mechanism, and Strength Prediction. Constr. Build. Mater. 2024, 419, 135560. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, M.; Yang, Y.; Liu, H.; Gao, X.; Cheng, L. In Situ Microbially Induced Ca-Alginate Polymeric Sealant in Calcareous Sand and Potential Engineering Applications. Acta Geotech. 2024, 19, 4217–4226. [Google Scholar] [CrossRef]

- Sun, T.; Wang, F.; Liu, J.; Chen, Z.; Tuo, M.; Yang, Y. Research on the Bearing Performance of HSCA High-Strength Preloaded Expansion Piles in Calcareous Sand Foundation. Sci. Rep. 2025, 15, 3155. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wen, D.; Ding, H.; Liu, K. Improving Erosion Resistance of Calcareous Sand Slope with Zinc Sulfate Solution. Constr. Build. Mater. 2024, 447, 138113. [Google Scholar] [CrossRef]

- Li, X.; Liu, J. One-Dimensional Compression Feature and Particle Crushability Behavior of Dry Calcareous Sand Considering Fine-Grained Soil Content and Relative Compaction. Bull. Eng. Geol. Environ. 2021, 80, 4049–4065. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, X.; Shen, J.-H.; Cui, J.; Zhu, C.-Q.; Wang, X.-Z. Experimental Study on the Impact of Water Content on the Strength Parameters of Coral Gravelly Sand. J. Mar. Sci. Eng. 2020, 8, 634. [Google Scholar] [CrossRef]

- Xu, D.; Shen, G.; Liu, Q.; Du, W. Dynamic Mechanical Response and Particle Breakage Characteristics of Calcareous Sand. Soil Dyn. Earthq. Eng. 2024, 181, 108653. [Google Scholar] [CrossRef]

- He, S.-H.; Goudarzy, M.; Ding, Z.; Sun, Y. Strength, Deformation, and Particle Breakage Behavior of Calcareous Sand: Role of Anisotropic Consolidation. J. Geotech. Geoenviron. Eng. 2023, 149, 04023002. [Google Scholar] [CrossRef]

- Wei, H.; Liu, H.; Li, X.; Tao, Z.; Wu, Y.; Shen, J.; Yin, M. Effect of Stress Path on the Mechanical Properties of Calcareous Sand. Undergr. Space 2023, 9, 20–30. [Google Scholar] [CrossRef]

- Ma, G.; Xiao, Y.; He, X.; Li, J.; Chu, J.; Liu, H. Kaolin-Nucleation-Based Biotreated Calcareous Sand through Unsaturated Percolation Method. Acta Geotech. 2022, 17, 3181–3193. [Google Scholar] [CrossRef]

- Cao, D.; Fan, L.; Huang, R.; Guo, C. Investigation of the Mechanical Properties of Reinforced Calcareous Sand Using a Permeable Polyurethane Polymer Adhesive. Materials 2024, 17, 5277. [Google Scholar] [CrossRef] [PubMed]

- Tao, G.; Yuan, J.; Chen, Q.; Peng, W.; Yu, R.; Basack, S. Chemical Stabilization of Calcareous Sand by Polyurethane Foam Adhesive. Constr. Build. Mater. 2021, 295, 123609. [Google Scholar] [CrossRef]

- Gu, J.; Lyu, H.; Li, B.; Chen, H.; Xu, X.; Du, X. Assessment of Mechanical Behavior and Failure Criteria under Varied Confining Pressures in Treated Calcareous Sand. Geomech. Energy Environ. 2024, 38, 100548. [Google Scholar] [CrossRef]

- Gu, J.; Lyu, H.; Yang, J.; Zeng, C. Effects of Cement Content and Curing Period on Geotechnical Properties of Cement-Treated Calcareous Sands. Transp. Geotech. 2022, 33, 100732. [Google Scholar] [CrossRef]

- Fang, X.; Shen, C.; Wang, C.; Guo, Y.; Wang, L. Study on Bearing Characteristic of Multi-Pile Composite Foundation with Biocemented Coral Sand Pile. J. Build. Eng. 2024, 98, 111297. [Google Scholar] [CrossRef]

- Shen, C.; Fang, X.; Guo, Y.; Hu, F.; Xiong, P.; Wang, C. Effects of Area Replacement Ratio and Pile Length on Composite Foundation with Biocemented Coral Sand Pile. Geomicrobiol. J. 2025, 42, 286–296. [Google Scholar] [CrossRef]

- Arnepalli, S.K.K.; Gondu, V.R.; Chinthala, S. Sustainable Improvement of Granite Sludge Dust Properties Using Microbially Induced Carbonate Precipitation (MICP): Strength Enhancement, Erosion Prevention, and Dust Mitigation. Environ. Sci. Pollut. Res. 2025, 1–24. [Google Scholar] [CrossRef]

- Fang, X.; Yang, Y.; Chen, Z.; Liu, H.; Xiao, Y.; Shen, C. Influence of Fiber Content and Length on Engineering Properties of MICP-Treated Coral Sand. Geomicrobiol. J. 2020, 37, 582–594. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hora, R.N.; Ahenkorah, I.; Beecham, S.; Karim, M.R.; Iqbal, A. State-of-the-Art Review of Microbial-Induced Calcite Precipitation and Its Sustainability in Engineering Applications. Sustainability 2020, 12, 6281. [Google Scholar] [CrossRef]

- Wang, Z.; Qin, H.; Dong, X.; Zhang, W. Classification of Additives and Their Influence Mechanisms in Improving the Performance of Biologically Induced Carbonate Precipitation. Environ. Res. 2025, 275, 121376. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Li, G.; Li, X.A. Geotechnical Engineering Properties of Soils Solidified by Microbially Induced CaCO3 Precipitation (MICP). Adv. Civ. Eng. 2021, 2021, 6683930. [Google Scholar] [CrossRef]

- Wen, K.; Li, Y.; Amini, F.; Li, L. Impact of Bacteria and Urease Concentration on Precipitation Kinetics and Crystal Morphology of Calcium Carbonate. Acta Geotech. 2020, 15, 17–27. [Google Scholar] [CrossRef]

- Zhang, K.; Tang, C.-S.; Jiang, N.-J.; Pan, X.-H.; Liu, B.; Wang, Y.-J.; Shi, B. Microbial-induced Carbonate Precipitation (MICP) Technology: A Review on the Fundamentals and Engineering Applications. Environ. Earth Sci. 2023, 82, 229. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Wang, Y.; Wang, J.; Cao, J.; Zhang, G. Improved Methods, Properties, Applications and Prospects of Microbial Induced Carbonate Precipitation (MICP) Treated Soil: A Review. Biogeotechnics 2025, 3, 100123. [Google Scholar] [CrossRef]

- Wang, Y.; Konstantinou, C.; Tang, S.; Chen, H. Applications of Microbial-Induced Carbonate Precipitation: A State-of-the-Art Review. Biogeotechnics 2023, 1, 100008. [Google Scholar] [CrossRef]

- Wu, H.; Wu, W.; Liang, W.; Dai, F.; Liu, H.; Xiao, Y. 3D DEM Modeling of Biocemented Sand with Fines as Cementing Agents. Int. J. Numer. Anal. Methods Geomech. 2023, 47, 212–240. [Google Scholar] [CrossRef]

- Li, G.; Zhang, Y.; Hua, X.; Liu, J.; Liu, X. Mechanical Properties of Aeolian Sand Cemented via Microbially Induced Calcite Precipitation (MICP). Sci. Rep. 2024, 14, 22745. [Google Scholar] [CrossRef]

- Chen, R.; Li, G.; Mi, Z.; Wei, K. Experimental Study of Erosion Prevention Model by Bio-Cement Sand. Appl. Sci. 2024, 14, 9571. [Google Scholar] [CrossRef]

- He, S.; Zheng, J.; He, R.; Hosseini, S.M.J.; Zhu, T.; Cheng, L.; Guo, Z. Influence of Edge Scour on Lateral Responses of Monopiles with Precast Microbial Reinforcement. Ocean Eng. 2024, 313, 119493. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, S.; Ahmed, Z.; Alshawmar, F. Application of Microbially Induced CaCO3 on the Reinforcement of Rock Discontinuity. Appl. Sci. 2024, 14, 8952. [Google Scholar] [CrossRef]

- Liu, X.; Fan, J.; Yu, J.; Gao, X. Solidification of Loess Using Microbial Induced Carbonate Precipitation. J. Mt. Sci. 2021, 18, 265–274. [Google Scholar] [CrossRef]

- Liu, S.; Du, K.; Wen, K.; Armwood-Gordon, C.; Li, L. Influence of Rainfall-induced Erosion on the Stability of Sandy Slopes Treated by MICP. Adv. Civ. Eng. 2022, 2022, 5105206. [Google Scholar] [CrossRef]

- Huang, M.; Zhang, Y.; Hu, J.; Hei, Y.; Xu, Z.; Su, J. Experimental Study on Pore Pressure Variation and Erosion Stability of Sandy Slope Model under Microbially Induced Carbonate Precipitation. Sustainability 2023, 15, 12650. [Google Scholar] [CrossRef]

- Dagliya, M.; Satyam, N.; Garg, A. Experimental Study on Optimization of Cementation Solution for Wind-Erosion Resistance Using the MICP Method. Sustainability 2022, 14, 1770. [Google Scholar] [CrossRef]

- Qu, J.; Li, G.; Ma, B.; Liu, J.; Zhang, J.; Liu, X.; Zhang, Y. Experimental Study on the Wind Erosion Resistance of Aeolian Sand Solidified by Microbially Induced Calcite Precipitation (MICP). Materials 2024, 17, 1270. [Google Scholar] [CrossRef]

- Hang, L.; Yang, E.; Zhou, Y.; Song, W.; He, J. Microbially Induced Calcite Precipitation (MICP) for Stabilization of Desert Sand against the Wind-Induced Erosion: A Parametric Study. Sustainability 2022, 14, 11409. [Google Scholar] [CrossRef]

- Wang, Y.; Soga, K.; DeJong, J.T.; Kabla, A.J. Effects of Bacterial Density on Growth Rate and Characteristics of Microbial-Induced CaCO3 Precipitates: Particle-Scale Experimental Study. J. Geotech. Geoenviron. Eng. 2021, 147, 04021036. [Google Scholar] [CrossRef]

- Jiang, N.-J.; Tang, C.-S.; Yin, L.-Y.; Xie, Y.-H.; Shi, B. Applicability of Microbial Calcification Method for Sandy-Slope Surface Erosion Control. J. Mater. Civ. Eng. 2019, 31, 04019250. [Google Scholar] [CrossRef]

- Li, M.; Peng, Y.; Zhang, J.; Zhao, Y.; Wang, Z.; Guo, Q.; Guo, S. Properties of a Backfill Material Prepared by Cementing Coal Gangue and Fly Ash through Microbial-Induced Calcite Precipitation. Constr. Build. Mater. 2023, 384, 131329. [Google Scholar] [CrossRef]

- Karimian, A.; Hassanlourad, M. Mechanical Behaviour of MICP-Treated Silty Sand. Bull. Eng. Geol. Environ. 2022, 81, 285. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, L.; Dong, Y.; Liu, X.; Wang, X. Analysis of Unconfined Compressive Strength and Environmental Impact of MICP-Treated Lead-Zinc Tailings Sand Instead of Sand as Embankment Material. Sci. Total Environ. 2024, 931, 172809. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Shi, F.; Duan, X.; Kang, W.; Feng, C.; Su, F. Effect of Microbially Induced Carbonate Precipitation (MICP) on the Early Strength Enhancement and Micromechanical Properties in Fly Ash Blended Cement. Constr. Build. Mater. 2024, 423, 135675. [Google Scholar] [CrossRef]

- Abbasi, M.; Hosseinpour, I.; Barari, A.; Mirmoradi, S.H. Mechanical Properties of Silty Sand Treated with MICP Technique Subjected to Freeze-Thaw Cycles. Transp. Infrastruct. Geotechnol. 2025, 12, 34. [Google Scholar] [CrossRef]

- Naskar, J.; Sharma, A.K. Assessment of Enhanced Strength and Stiffness Properties of Bio-Engineered Coal Fly Ash. Constr. Build. Mater. 2024, 413, 134793. [Google Scholar] [CrossRef]

- Kumar, P.; Debele, S.E.; Sahani, J.; Rawat, N.; Marti-Cardona, B.; Alfieri, S.M.; Basu, B.; Basu, A.S.; Bowyer, P.; Charizopoulos, N.; et al. Nature-Based Solutions Efficiency Evaluation against Natural Hazards: Modelling Methods, Advantages and Limitations. Sci. Total Environ. 2021, 784, 147058. [Google Scholar] [CrossRef]

- Gong, C.; Ni, D.; Liu, Y.; Li, Y.; Huang, Q.; Tian, Y.; Zhang, H. Herbaceous Vegetation in Slope Stabilization: A Comparative Review of Mechanisms, Advantages, and Practical Applications. Sustainability 2024, 16, 7620. [Google Scholar] [CrossRef]

- Su, X.; Zhou, Z.; Cao, L.; Liu, J.; Wang, P. Estimating Slope Stability by the Root Reinforcement Mechanism of Artemisia Sacrorum on the Loess Plateau of China. Ecol. Model. 2021, 444, 109473. [Google Scholar] [CrossRef]

- Li, S.; Wang, Z.; Stutz, H.H. State-of-the-Art Review on Plant-Based Solutions for Soil Improvement. Biogeotechnics 2023, 1, 100035. [Google Scholar] [CrossRef]

- DiBiagio, A.; Capobianco, V.; Oen, A.; Tallaksen, L.M. State-of-the-Art: Parametrization of Hydrological and Mechanical Reinforcement Effects of Vegetation in Slope Stability Models for Shallow Landslides. Landslides 2024, 21, 2417–2446. [Google Scholar] [CrossRef]

- Gan, F.; Wei, J.; Li, S. Root–Soil Friction Mechanism of Typical Grasses on Purple Soil Bunds in the Three Gorges Reservoir Area, China. J. Soil Sci. Plant Nutr. 2023, 23, 3381–3392. [Google Scholar] [CrossRef]

- Saadati, N.; Mosaddeghi, M.R.; Sabzalian, M.R.; Jafari, M. Soil Mechanical Reinforcement by the Fibrous Roots of Selected Rangeland Plants Using a Large Soil-Root Shear Apparatus. Soil Tillage Res. 2023, 234, 105852. [Google Scholar] [CrossRef]

- Rahman, E.K.A.; Jeludin, M.; Ratnayake, U.; Musthapa, S.M. Impact of Roots on the Shear Strength of Root-Reinforced Soil on Slopes; IOP Publishing: Bristol, UK, 2024; Volume 1369, p. 012022. [Google Scholar]

- Cardoza, R.; Oka, L. Measuring the Effect of Grass Roots on Shear Strength Parameters of Sandy Soils; American Society of Civil Engineers: Reston, VA, USA, 2020; pp. 214–223. [Google Scholar]

- Chakrabarti, M.; Nagabhyru, P.; Schardl, C.L.; Dinkins, R.D. Differential Gene Expression in Tall Fescue Tissues in Response to Water Deficit. Plant Genome 2022, 15, e20199. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wu, F.; Xiang, Y.; Fan, J. Transcriptomic Analysis of Antimony Response in Tall Fescue (Festuca arundinacea). Agriculture 2024, 14, 1504. [Google Scholar] [CrossRef]

- Cornelis, W.M. Hydroclimatology of Wind Erosion in Arid and Semiarid Envirmonments. In Dryland Ecohydrology; Springer: Dordrecht, The Netherlands, 2006; pp. 141–159. [Google Scholar]

- Xu, Y.; Li, Q.; Meng, Q.A.Z.L. Meteorological Parameters and Building Energy Consumption Analysis of South China Sea Islands. J. Civ. Environ. Eng. 2018, 40, 42–47. [Google Scholar]

- Wang, Y.; Wang, G.; Wan, Y.; Yu, X.; Zhao, J.; Shao, J. Recycling of Dredged River Silt Reinforced by an Eco-Friendly Technology as Microbial Induced Calcium Carbonate Precipitation (MICP). Soils Found. 2022, 62, 101216. [Google Scholar] [CrossRef]

- Zhu, W.; Yuan, M.; He, F.; Zhao, Y.; Xiao, Z.; Wang, Q.; Meng, F.; Tang, Q. Effects of Hydroxypropyl Methylcellulose (HPMC) on the Reinforcement of Sand by Microbial-Induced Calcium Carbonate Precipitation (MICP). Appl. Sci. 2022, 12, 5360. [Google Scholar] [CrossRef]

- Liu, B.; Tang, C.S.; Pan, X.H.; Zhu, C.; Cheng, Y.J.; Xu, J.J.; Shi, B. Potential Drought Mitigation through Microbial Induced Calcite precipitation-MICP. Water Resour. Res. 2021, 57, e2020WR029434. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, Y.; Xu, G. How Does Nitrogen Shape Plant Architecture? J. Exp. Bot. 2020, 71, 4415–4427. [Google Scholar] [CrossRef]

- Xie, L.; Zhou, J.; Shen, L.; Ji, Y.; Li, W.; Cheng, Y. Discrete Element Study on Mechanical Properties of MICP-Treated Sand under Triaxial Compression. J. Mar. Sci. Eng. 2024, 12, 1503. [Google Scholar] [CrossRef]

- Hu, Q.; Chen, Q. Experimental Study of Synergistic Reinforcement of Silty Clay with Glutinous Rice Paste and MICP. PLoS ONE 2023, 18, e0284633. [Google Scholar] [CrossRef] [PubMed]

- Lai, Y.; Liu, S.; Cai, Y.; Yu, J. Reinforcement of Different Sands by Low-pH Bio-Mineralization. Materials 2023, 16, 6211. [Google Scholar] [CrossRef] [PubMed]

- Jiang, N.; Cheng, H.; Liu, C.; Fang, Z.; Zou, X. A Wind Tunnel Study of the Effects of Vegetation Structural Characteristics on the Airflow Field. CATENA 2024, 242, 108064. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, B.; Bian, Y.; Gao, Y.; Liu, Y.; Cheng, M.; Wang, L.; Hang, L. Effects of Soybean Urease Induced Carbonate Precipitation on the Seed Emergence and Seedling Growth of Caragana Korshinskii Kom and Its Application in Wind Erosion Control. Plant Soil 2025, 507, 629–653. [Google Scholar] [CrossRef]

- Ji, X. GDS Triaxial Test on the Reinforcement Effects of Bermudagrass Root-Soil Complex. IOP Conf. Ser. Earth Environ. Sci. 2019, 304, 032106. [Google Scholar] [CrossRef]

- Wang, B.; Wang, S. Shear Strength Analysis and Slope Stability Study of Straight Root Herbaceous Root Soil Composite. Appl. Sci. 2023, 13, 12632. [Google Scholar] [CrossRef]

- Ghasemi, P.; Montoya, B.M. Effect of Treatment Solution Chemistry and Soil Engineering Properties Due to Microbially Induced Carbonate Precipitation Treatments on Vegetation Health and Growth. ACS EST Eng. 2022, 2, 2196–2205. [Google Scholar] [CrossRef]

| CC | 1 Cycle | 2 Cycles | 3 Cycles | 4 Cycles | |

|---|---|---|---|---|---|

| CSC (mol/L) | |||||

| 0 mol/L | J11 | J12 | J13 | J14 | |

| 0.1 mol/L | J21 | J22 | J23 | J24 | |

| 0.25 mol/L | J31 | J32 | J33 | J34 | |

| 0.4 mol/L | J41 | J42 | J43 | J44 | |

| 0.5 mol/L | J51 | J52 | J53 | J54 | |

| BSC | Y | xs10 | xs20 | |

|---|---|---|---|---|

| CSC (mol/L) | ||||

| 0 mol/L | J11-n | J21-n | J31-n | |

| 0.1 mol/L | J12-n | J22-n | J32-n | |

| 0.25 mol/L | J13-n | J23-n | J33-n | |

| 0.4 mol/L | J14-n | J24-n | J34-n | |

| 0.5 mol/L | J15-n | J25-n | J35-n | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, X.; Wang, Z.; Qin, Y.; Cao, L.; Cao, P.; Xie, Y.; Xie, Y. Experimental Study on the Reinforcement of Calcareous Sand Using Combined Microbial-Induced Carbonate Precipitation (MICP) and Festuca arundinacea Techniques. J. Mar. Sci. Eng. 2025, 13, 883. https://doi.org/10.3390/jmse13050883

Deng X, Wang Z, Qin Y, Cao L, Cao P, Xie Y, Xie Y. Experimental Study on the Reinforcement of Calcareous Sand Using Combined Microbial-Induced Carbonate Precipitation (MICP) and Festuca arundinacea Techniques. Journal of Marine Science and Engineering. 2025; 13(5):883. https://doi.org/10.3390/jmse13050883

Chicago/Turabian StyleDeng, Xiuqiong, Ziyu Wang, Yuchun Qin, Liang Cao, Peng Cao, Yu Xie, and Yingqi Xie. 2025. "Experimental Study on the Reinforcement of Calcareous Sand Using Combined Microbial-Induced Carbonate Precipitation (MICP) and Festuca arundinacea Techniques" Journal of Marine Science and Engineering 13, no. 5: 883. https://doi.org/10.3390/jmse13050883

APA StyleDeng, X., Wang, Z., Qin, Y., Cao, L., Cao, P., Xie, Y., & Xie, Y. (2025). Experimental Study on the Reinforcement of Calcareous Sand Using Combined Microbial-Induced Carbonate Precipitation (MICP) and Festuca arundinacea Techniques. Journal of Marine Science and Engineering, 13(5), 883. https://doi.org/10.3390/jmse13050883