Development of a Reflective 193-nm DUV Microscope System for Defect Inspection of Large Optical Surfaces

Abstract

1. Introduction

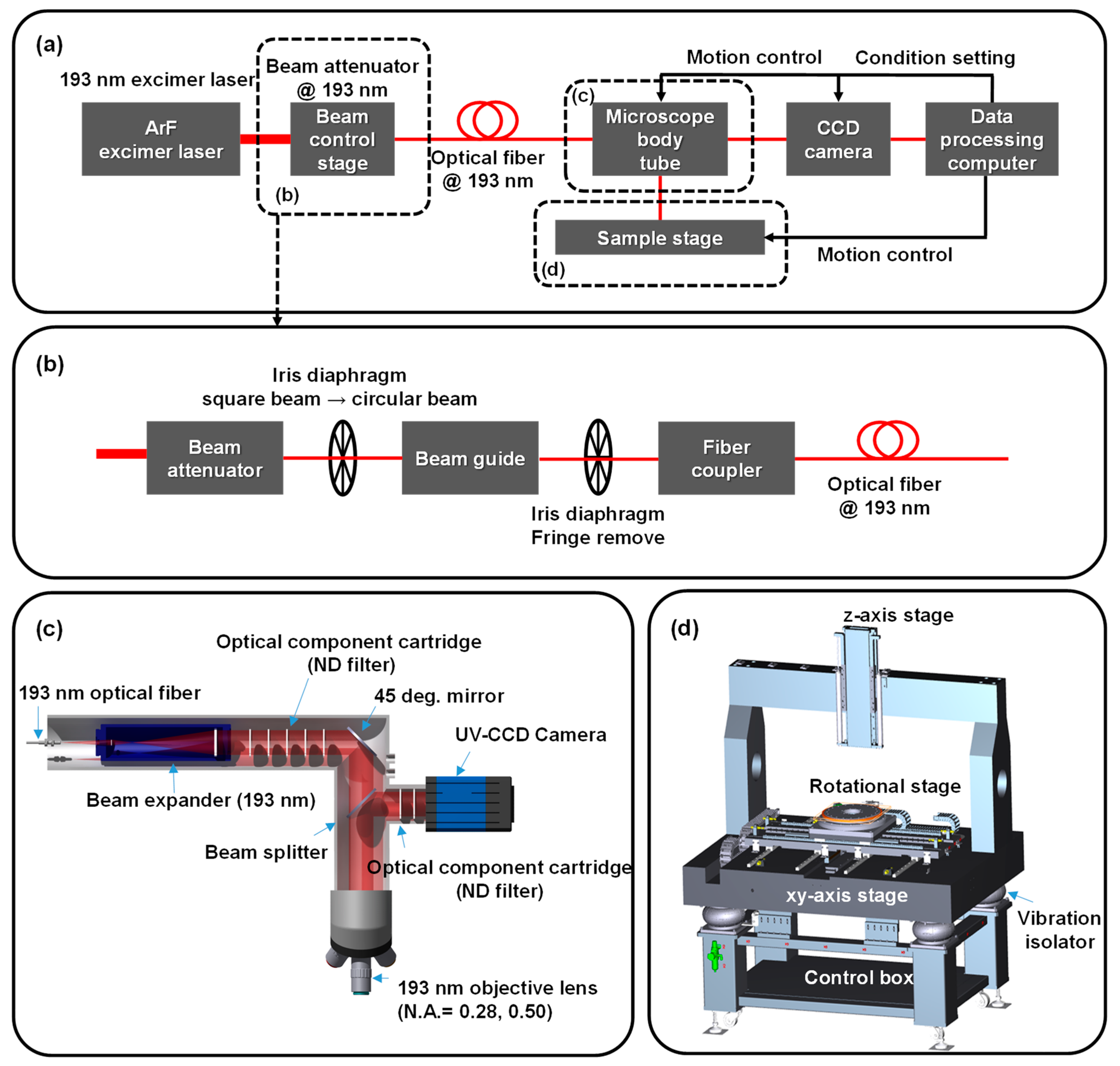

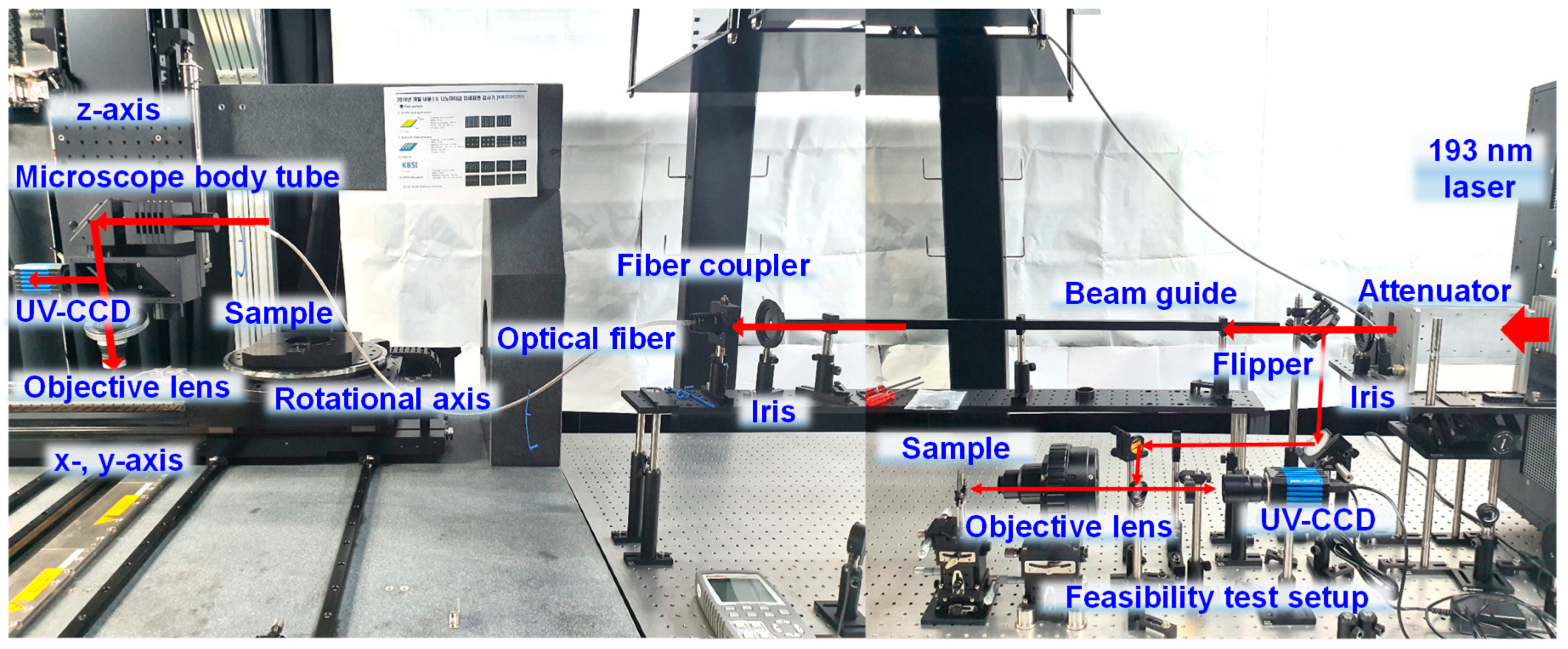

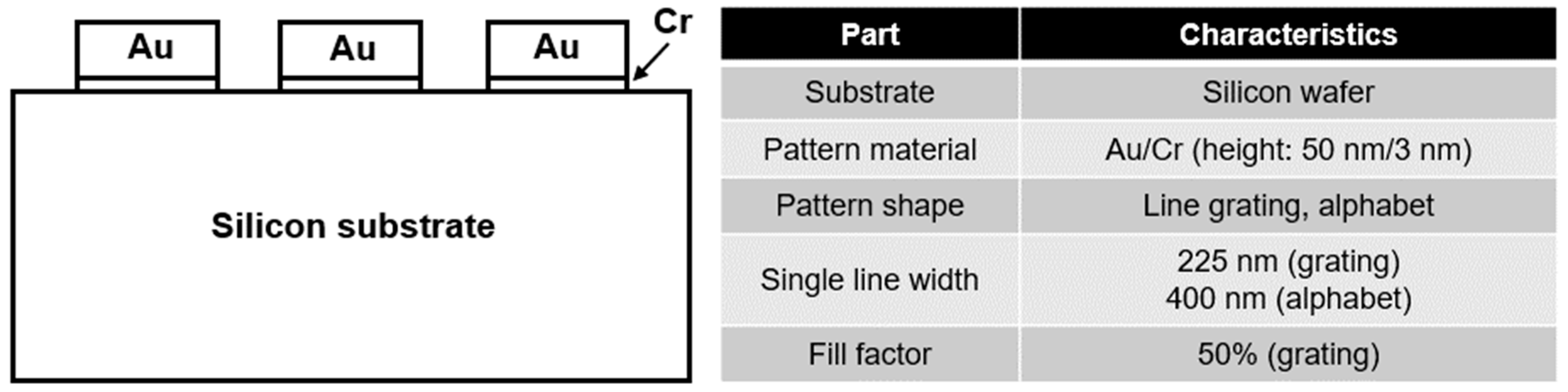

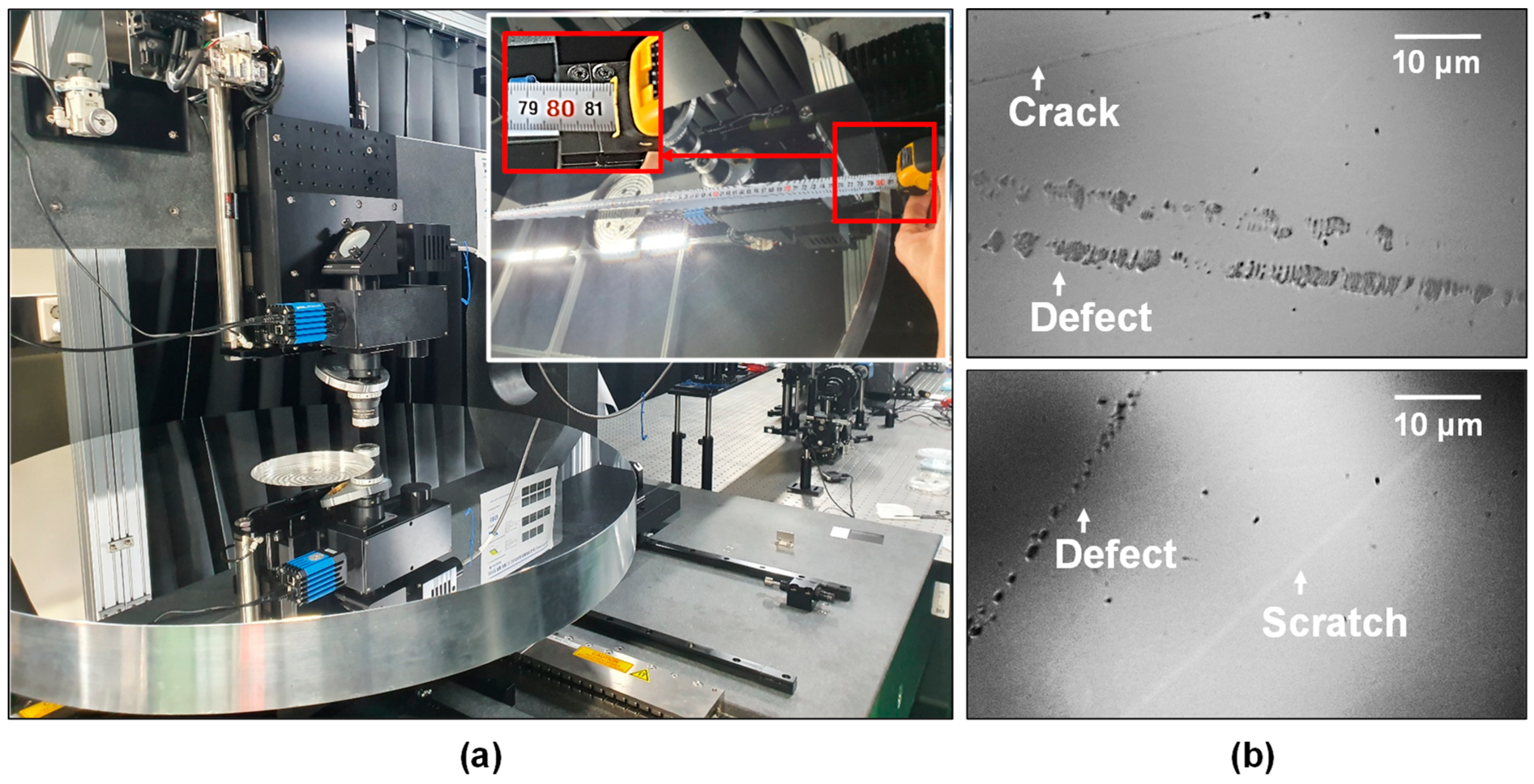

2. Materials and Methods

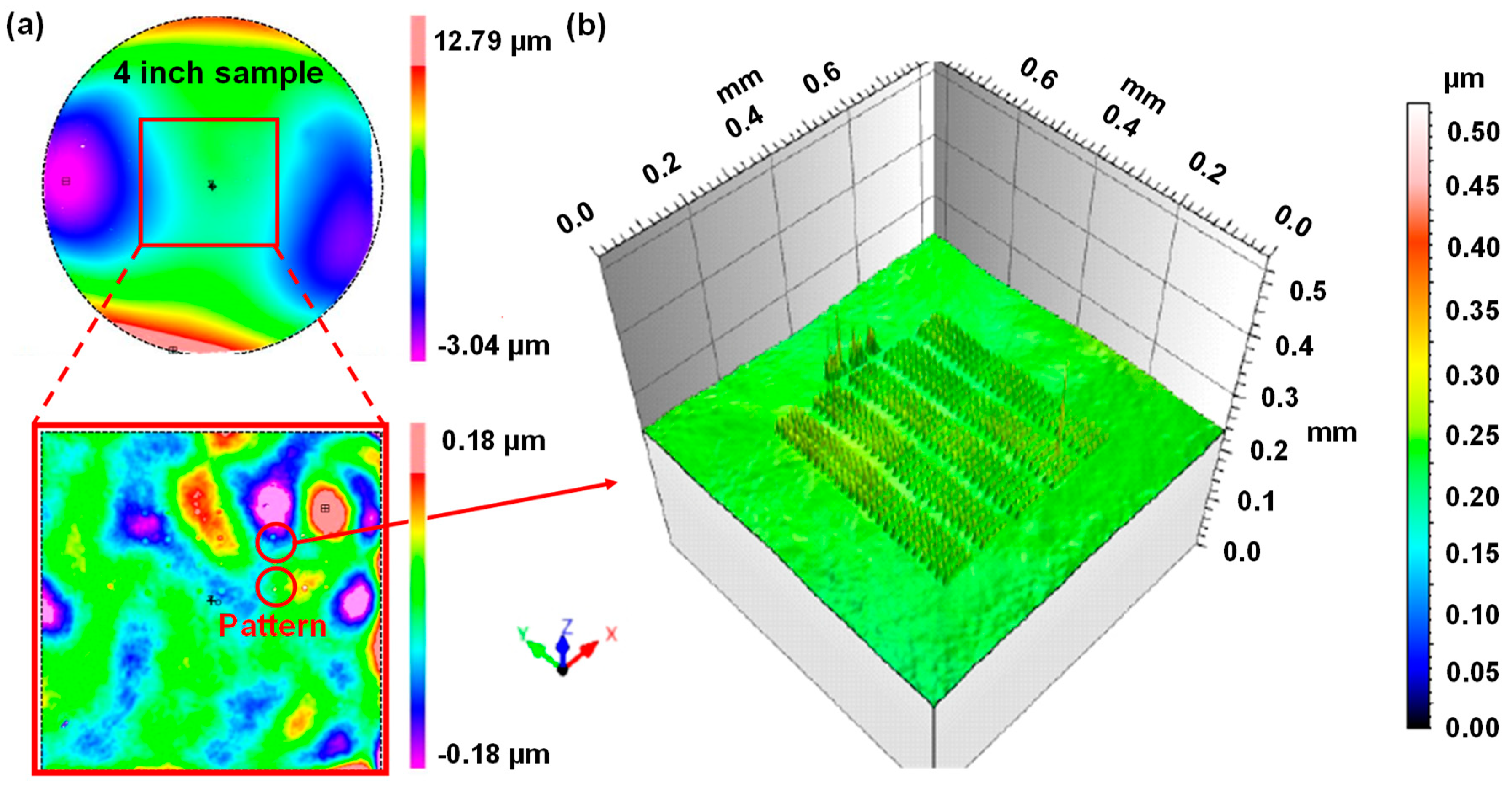

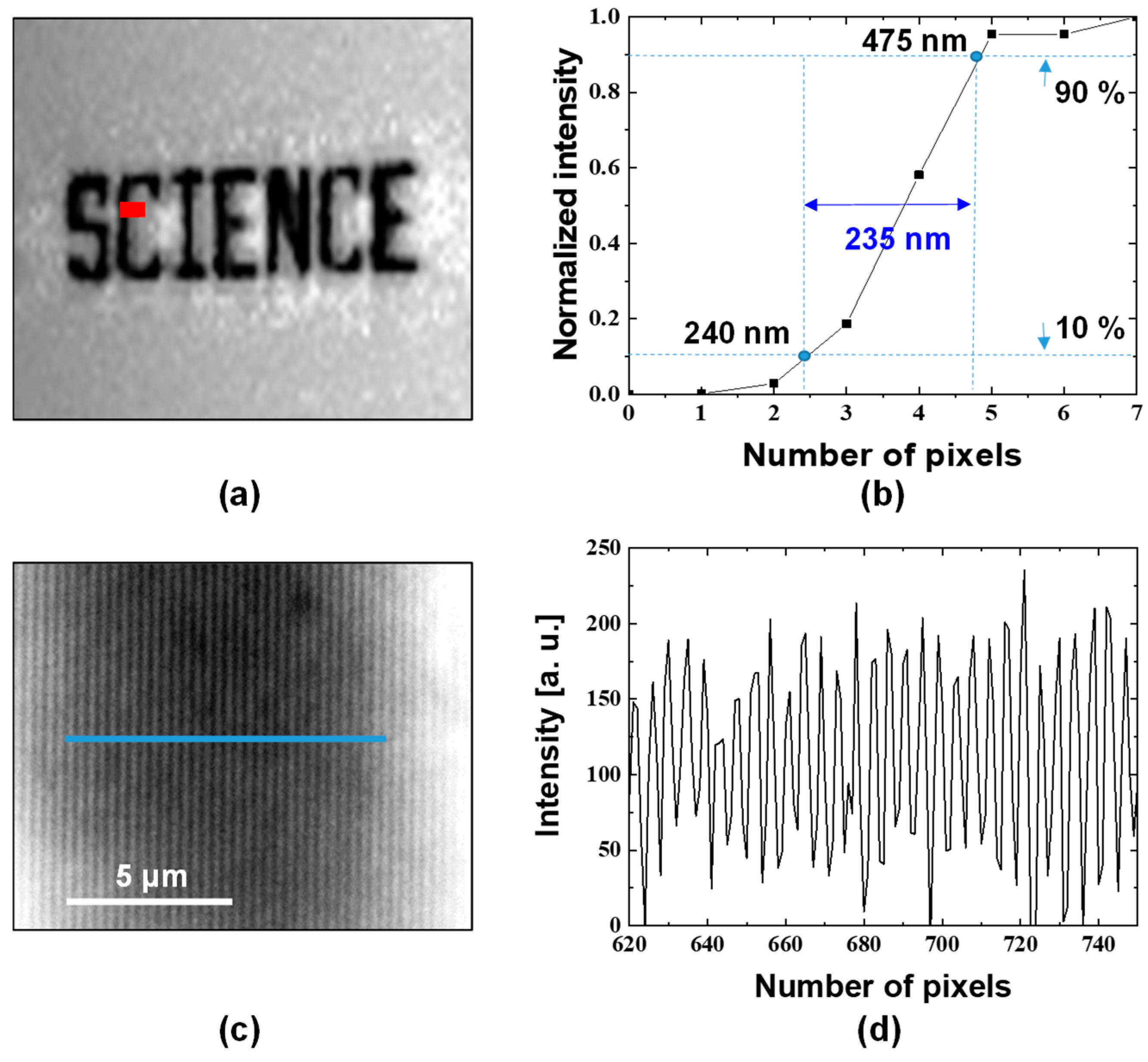

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Briers, J.D. Interferometric testing of optical systems and components: A review. Opt. Laser Technol. 1972, 4, 28–41. [Google Scholar] [CrossRef]

- Kajava, T.T.; Lauranto, H.M.; Friberg, A.T. Interference pattern of the Fizeau interferometer. JOSA A 1994, 11, 2045–2054. [Google Scholar] [CrossRef]

- Goodwin, E.P.; Wyant, J.C. Field Guide to Interferometric Optical Testing; SPIE Press: Bellingham, WA, USA, 2006. [Google Scholar]

- Xu, Z.; Shilpiekandula, V.; Youcef-Toumi, K.; Yoon, S.F. White-light scanning interferometer for absolute nano-scale gap thickness measurement. Opt. Express 1994, 17, 15104–15117. [Google Scholar] [CrossRef]

- Flores, S.M.; Toca-Herrera, J.L. The new future of scanning probe microscopy: Combining atomic force microscopy with other surface-sensitive techniques, optical microscopy and fluorescence techniques. Nanoscale 2009, 1, 40–49. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Lv, J.; Zhao, G.; Wang, G. Free-space laser communication system with rapid acquisition based on astronomical telescopes. Opt. Express 2015, 23, 20655–20667. [Google Scholar] [CrossRef]

- Siewert, F.; Buchheim, J.; Gwalt, G.; Bean, R.; Mancuso, A.P. On the characterization of a 1 m long ultra-precise KB-focusing mirror pair for European XFEL by means of slope measuring deflectometry. Rev. Sci. Instrum. 2019, 90, 021713. [Google Scholar] [CrossRef] [PubMed]

- Yu, T.J.; Lee, S.K.; Sung, J.H.; Yoon, J.W.; Jeong, T.M.; Lee, J. Generation of high-contrast, 30 fs, 1.5 PW laser pulses from chirped-pulse amplification Ti:sapphire laser. Opt. Express 2012, 20, 10807–10815. [Google Scholar] [CrossRef] [PubMed]

- Ye, R.; Chang, M.; Pan, C.S.; Chiang, C.A.; Gabayno, J.L. High-resolution optical inspection system for fast detection and classification of surface defects. Int. J. Optomechatronics 2018, 12, 1–10. [Google Scholar] [CrossRef]

- Chang, M.; Chou, Y.C.; Lin, P.T.; Gabayno, J.L. Fast and high-resolution optical inspection system for in-line detection and labeling of surface defects. CMC Comput. Mat. Contin. 2014, 42, 125–140. [Google Scholar]

- Cao, B.; Hoang, P.; Ahn, S.; Kang, H.; Kim, J.; Noh, J. High-speed focus inspection system using a position-sensitive detector. Sensors 2017, 17, 2842. [Google Scholar] [CrossRef] [PubMed]

- Abuazza, A.; Brabazon, D.; El-Baradie, M.A. Analysis of surface defects using a novel developed fiber-optics laser scanning system. J. Mater. Proc. Technol. 2003, 143, 875–879. [Google Scholar] [CrossRef]

- Hess, S.T.; Girirajan, T.P.; Mason, M.D. Ultra-high resolution imaging by fluorescence photoactivation localization microscopy. Biophys. J. 2006, 91, 4258–4272. [Google Scholar] [CrossRef]

- Hell, S.W.; Wichmann, J. Breaking the diffraction resolution limit by stimulated emission: Stimulated-emission-depletion fluorescence microscopy. Opt. Lett. 1994, 19, 780–782. [Google Scholar] [CrossRef]

- Bewersdorf, J.; Schmidt, R.; Hell, S.W. Comparison of I5M and 4Pi-microscopy. J. Microsc. 2006, 222, 105–117. [Google Scholar] [CrossRef] [PubMed]

- Schrader, M.; Hell, S.W. Three-dimensional super-resolution with a 4Pi-confocal microscope using image restoration. J. Appl. Phys. 1998, 84, 4033–4042. [Google Scholar] [CrossRef][Green Version]

- Deitche, J.; Kempe, M.; Rudolph, W. Resolution in nonlinear laser scanning microscopy. J. Microsc. 1994, 174, 69–73. [Google Scholar] [CrossRef]

- Brunner, R.; Steiner, R.; Rudolf, K.; Dobschal, H.J. Diffractive-refractive hybrid microscope objective for 193 nm inspection systems. In Proceedings of the SPIE’s 48th Annual Meeting, San Diego, CA, USA, 10 November 2003; Volume 5177, pp. 9–15. [Google Scholar]

- Ehret, G.; Pilarski, F.; Bergmann, D.; Bodermann, B.; Buhr, E. A new high-aperture 193 nm microscope for the traceable dimensional characterization of micro-and nanostructures. Meas. Sci. Technol. 2009, 20, 084010. [Google Scholar] [CrossRef]

- Li, Z.; Pilarski, F.; Bergmann, D.; Bodermann, B. A Quantitative 193 nm DUV Microscope. In Proceedings of the Euspen International Conference, Delft, The Netherlands, 31 May–4 June 2010. [Google Scholar]

- Long, T.; Clement, S.W.; Bao, Z.; Wang, P.; Tian, D.; Liu, D. High spatial resolution and high brightness ion beam probe for in-situ elemental and isotopic analysis. Nucl. Instrum. Methods. Phys. Res. 2018, 419, 19–25. [Google Scholar] [CrossRef]

- Kim, H.T.; Kim, I.J.; Kim, C.M.; Jeong, T.M.; Yu, T.J.; Lee, S.K.; Sung, J.H.; Yoon, J.W.; Yun, H.; Jeon, S.C.; et al. Single-shot nanometer-scale holographic imaging with laser-driven x-ray laser. Appl. Phys. Lett. 2011, 98, 121105. [Google Scholar] [CrossRef]

| Axis | X | Y | Z | R | ||||

|---|---|---|---|---|---|---|---|---|

| Type | Spec. | Meas. | Spec. | Meas. | Spec. | Meas. | Spec. | Meas. |

| Actuator | Linear motor | Linear motor | Linear motor + counterbalance | Direct drive motor | ||||

| Max. travel length (mm) | 600 | 600 | 600 | 600 | 300 | 290 | 360° | 360° |

| Max. velocity (mm/s) | 100 | 100 | 100 | 100 | 100 | 100 | 30°/s | 30°/s |

| Resolution (nm) | ≤ 5 | 4.88 | ≤ 5 | 4.88 | ≤ 5 | 4.88 | ≤ 0.01° | ≤ 0.01° |

| Position accuracy (μm) | ± 1.0 | ± 0.3 | ± 1.0 | ± 0.3 | ± 0.5 | ± 0.3 | - | - |

| Bi-dir. repeatability (μm) | ± 0.5 | ± 0.2 | ± 0.5 | ± 0.25 | ± 0.3 | ± 0.3 | ≤ 0.05° | ≤ 0.05° |

| In-position stability (nm) | ± 100 | ± 29 | ± 100 | ± 41 | ± 100 | ±83 | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-S.; Lee, D.-H.; Hyun, S.; Je, S.K.; Park, J.G.; Bae, J.Y.; Kim, G.H.; Kim, I.J. Development of a Reflective 193-nm DUV Microscope System for Defect Inspection of Large Optical Surfaces. Appl. Sci. 2019, 9, 5205. https://doi.org/10.3390/app9235205

Kim H-S, Lee D-H, Hyun S, Je SK, Park JG, Bae JY, Kim GH, Kim IJ. Development of a Reflective 193-nm DUV Microscope System for Defect Inspection of Large Optical Surfaces. Applied Sciences. 2019; 9(23):5205. https://doi.org/10.3390/app9235205

Chicago/Turabian StyleKim, Hong-Seung, Dong-Ho Lee, Sangwon Hyun, Soon Kyu Je, June Gyu Park, Ji Yong Bae, Geon Hee Kim, and I Jong Kim. 2019. "Development of a Reflective 193-nm DUV Microscope System for Defect Inspection of Large Optical Surfaces" Applied Sciences 9, no. 23: 5205. https://doi.org/10.3390/app9235205

APA StyleKim, H.-S., Lee, D.-H., Hyun, S., Je, S. K., Park, J. G., Bae, J. Y., Kim, G. H., & Kim, I. J. (2019). Development of a Reflective 193-nm DUV Microscope System for Defect Inspection of Large Optical Surfaces. Applied Sciences, 9(23), 5205. https://doi.org/10.3390/app9235205