Assembly Tolerance Design Based on Skin Model Shapes Considering Processing Feature Degradation

Abstract

:1. Introduction

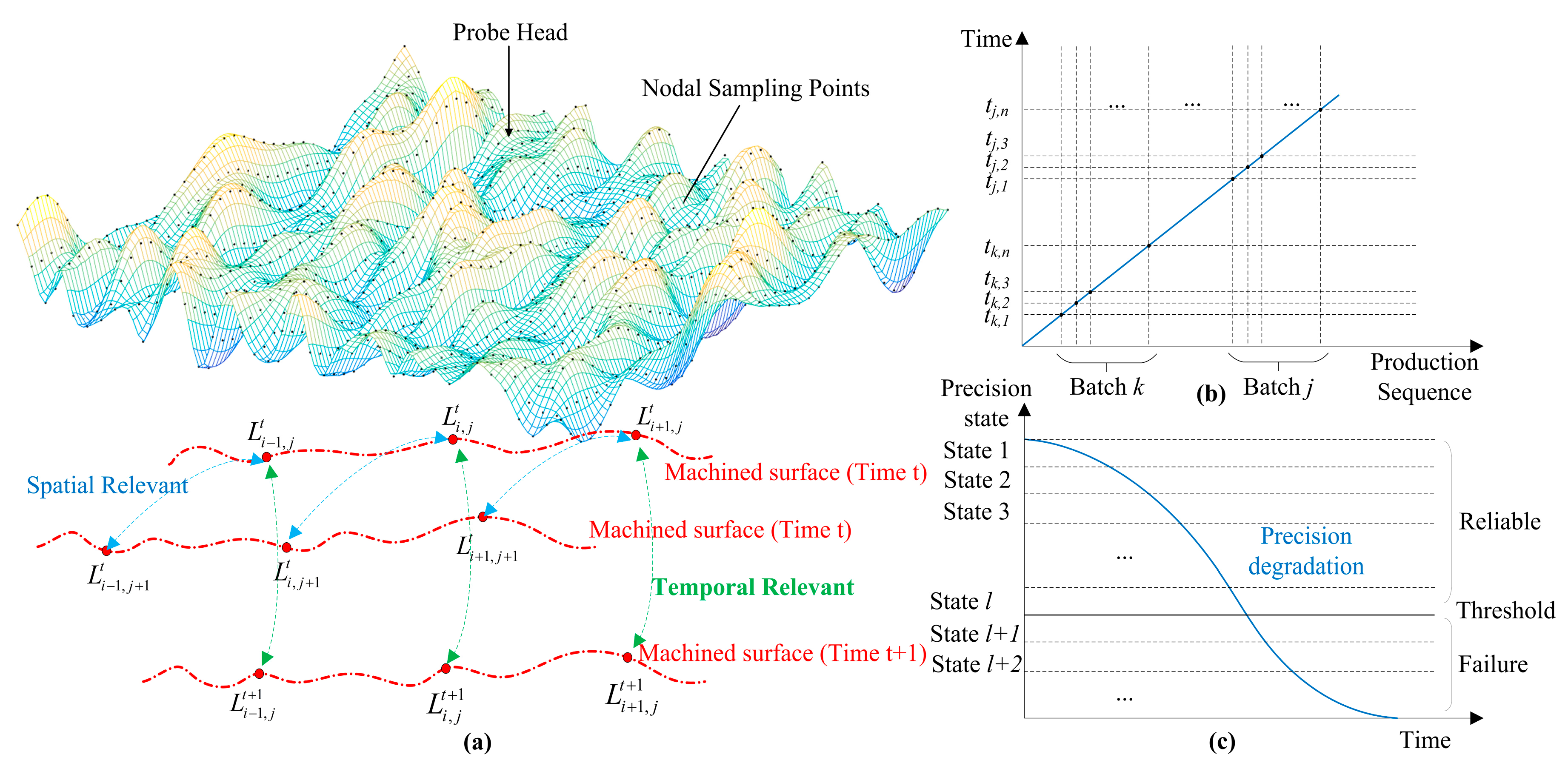

2. Predictive Machined Surface Modeling

2.1. Modeling of the Multi-Dimensional Markov Process

2.2. Calculation of Model Weight Parameters

- (1)

- Set the initial counter k = 0, initial positive definite matrix M(0), and initial parameter weight w(0) . Calculate the initial object function value g0.

- (2)

- If , set the current search direction .

- (3)

- Update the positive definite matrix M(k) based on the Armijo rule with calibration coefficients:

- (4)

- Use a line search function . Update w(k) when reaches the global minimum.

- (5)

- Output w(k) if . Otherwise, k = k + 1 and go back to step (2).

2.3. Prediction of Degraded Surface

3. Constrained 3D Assembly Simulation and Tolerance Synthesis

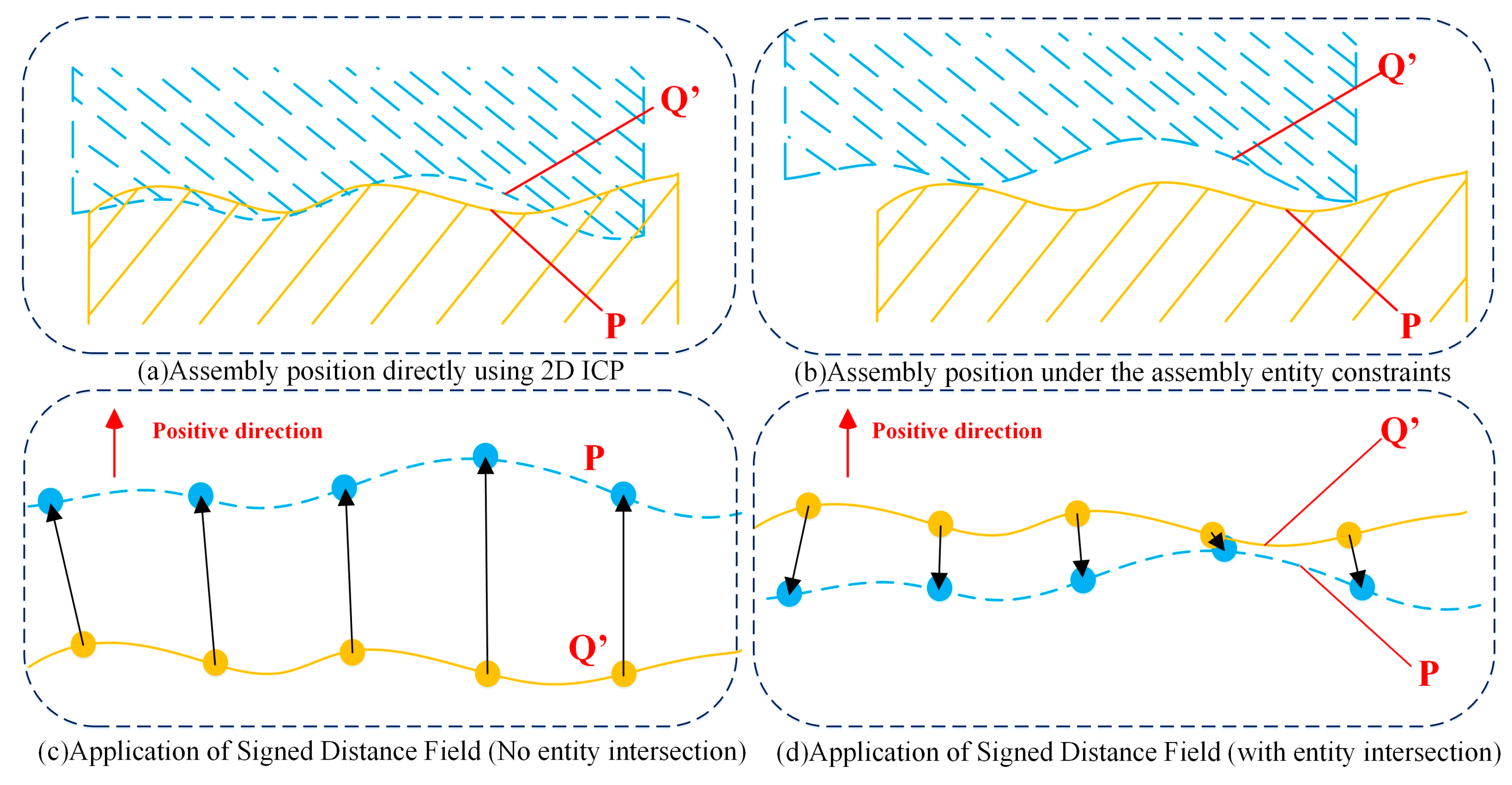

3.1. Constrained Assembly Simulation

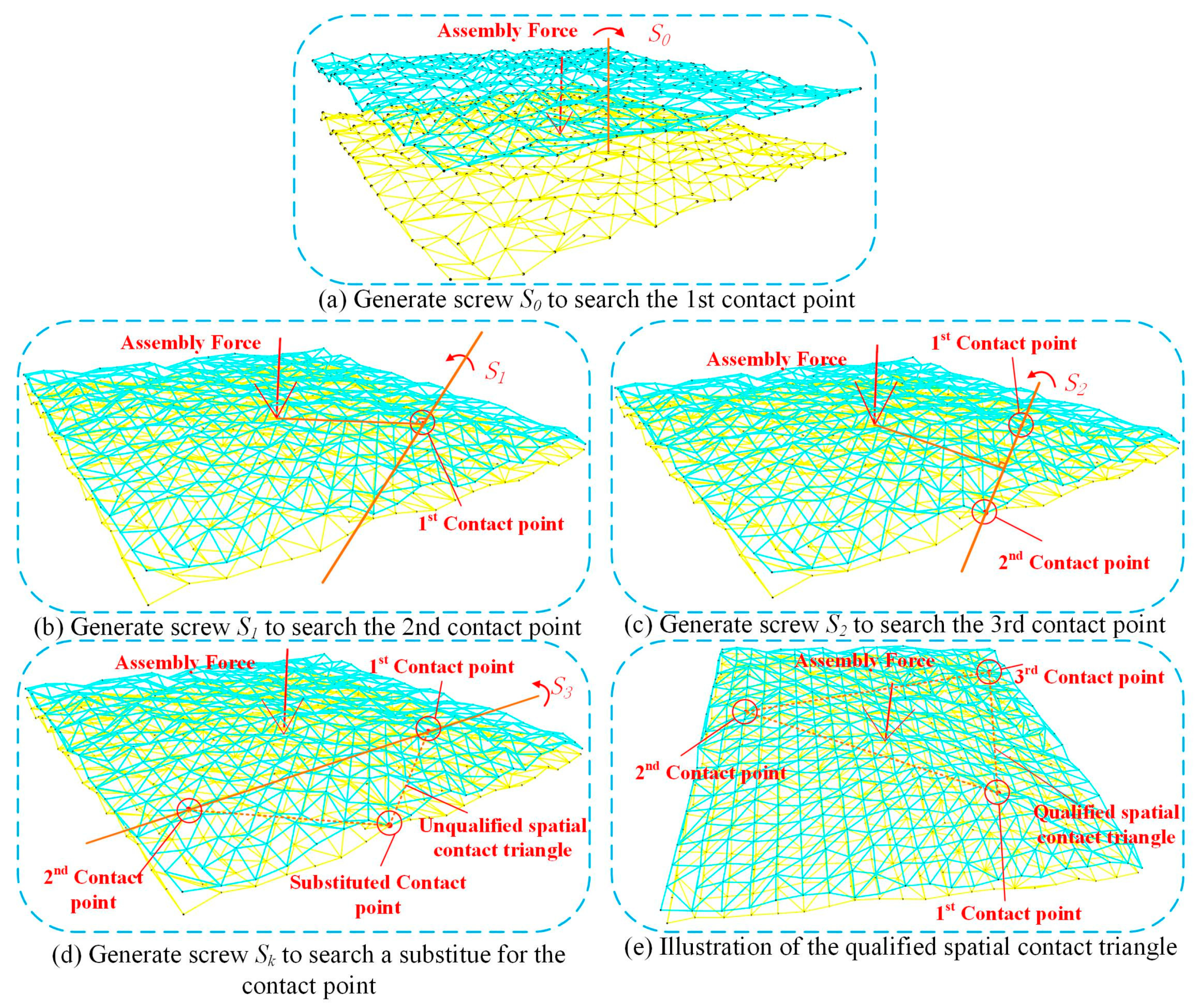

- (1)

- Compute any state of Q′ with one contact point using ICP and ensure (Figure 3a). The contact point is defined as .

- (2)

- Ensure and search the second contact point using twists whose direction of is (Figure 3b), where is the point of intersection of assembly force vector and P.

- (3)

- Ensure and search the third contact point using twists whose direction of is , as shown in Figure 3c.

- (4)

- Check if the current spatial contact triangle is qualified using the assembly force constraints rule: and . If the conditions are not met, choose the two contact points that constitute a line closer to (in Figure 3d) and go back to step (3). Once the conditions are met, the current condition of Q′ is the qualified assembling condition, as shown in Figure 3e.

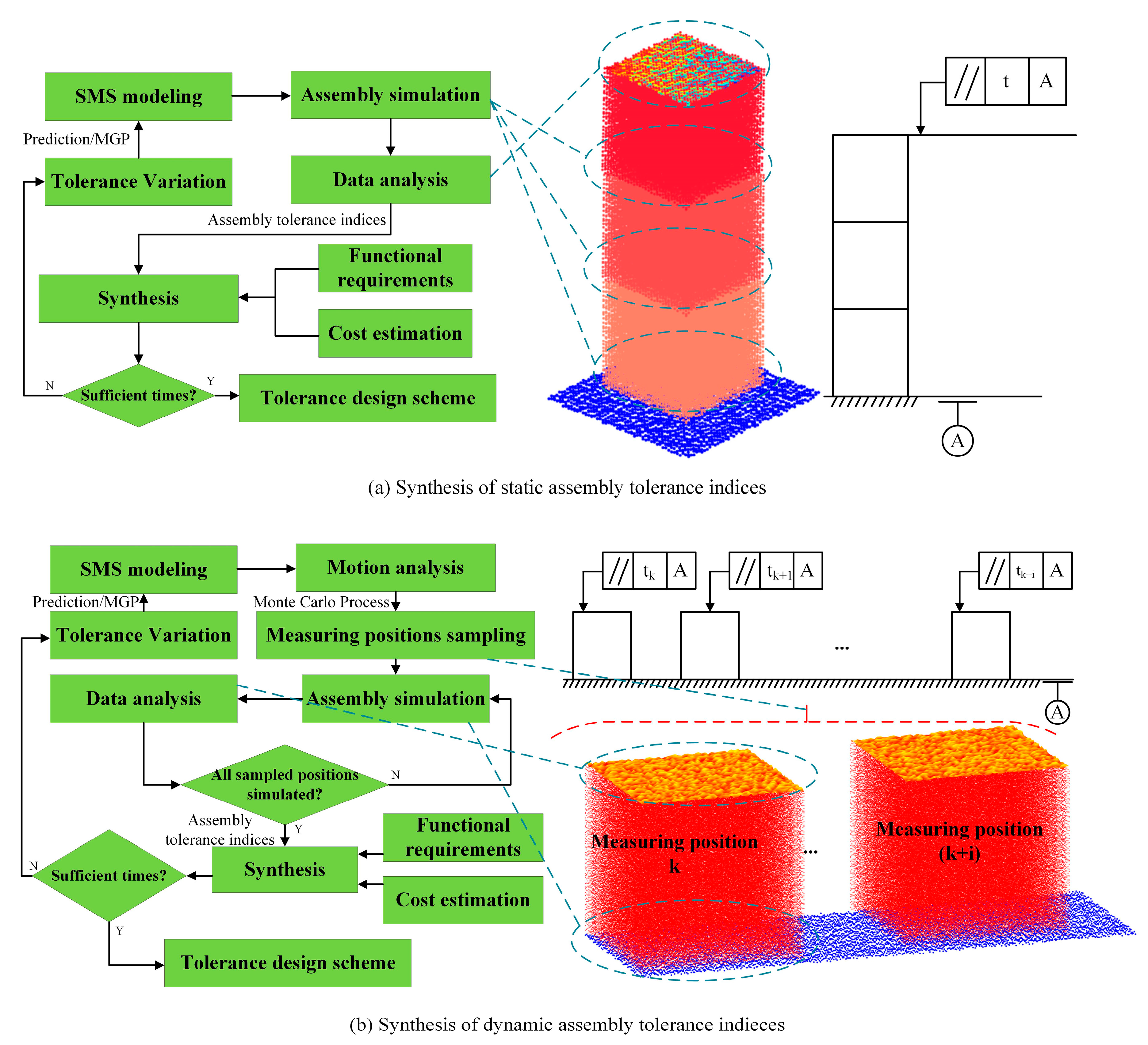

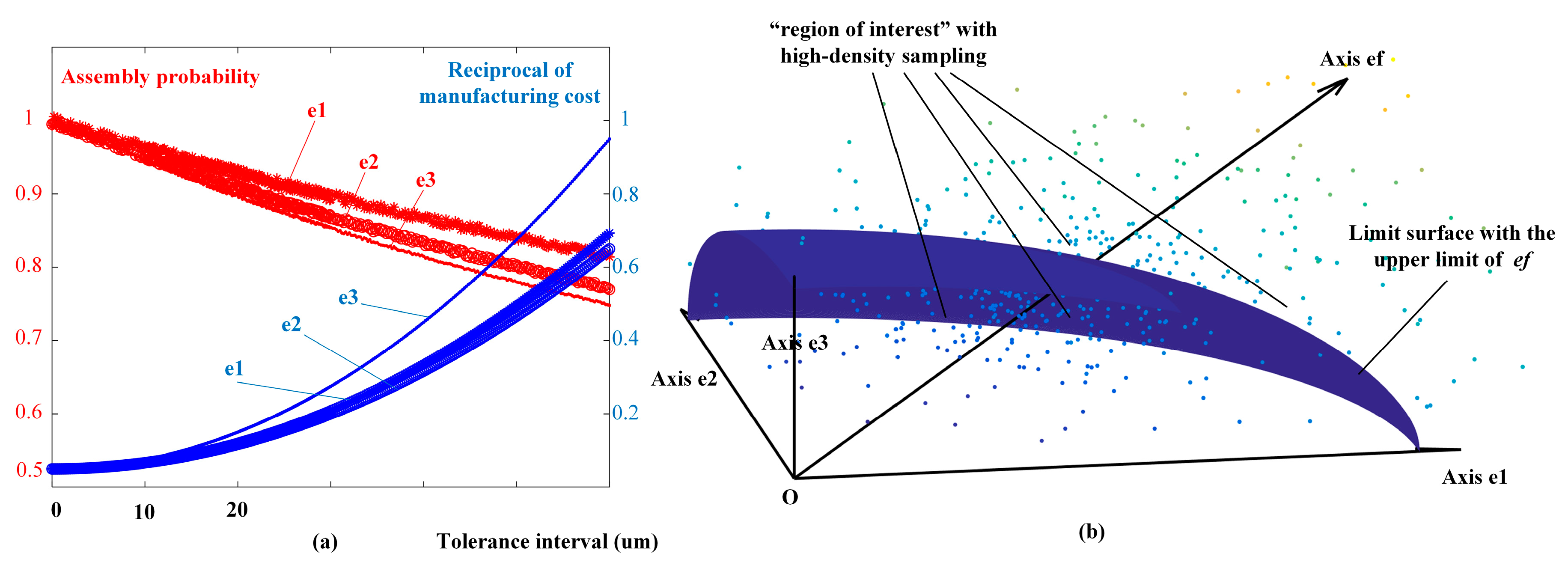

3.2. Static and Dynamic Tolerance Synthesis

4. Case Study

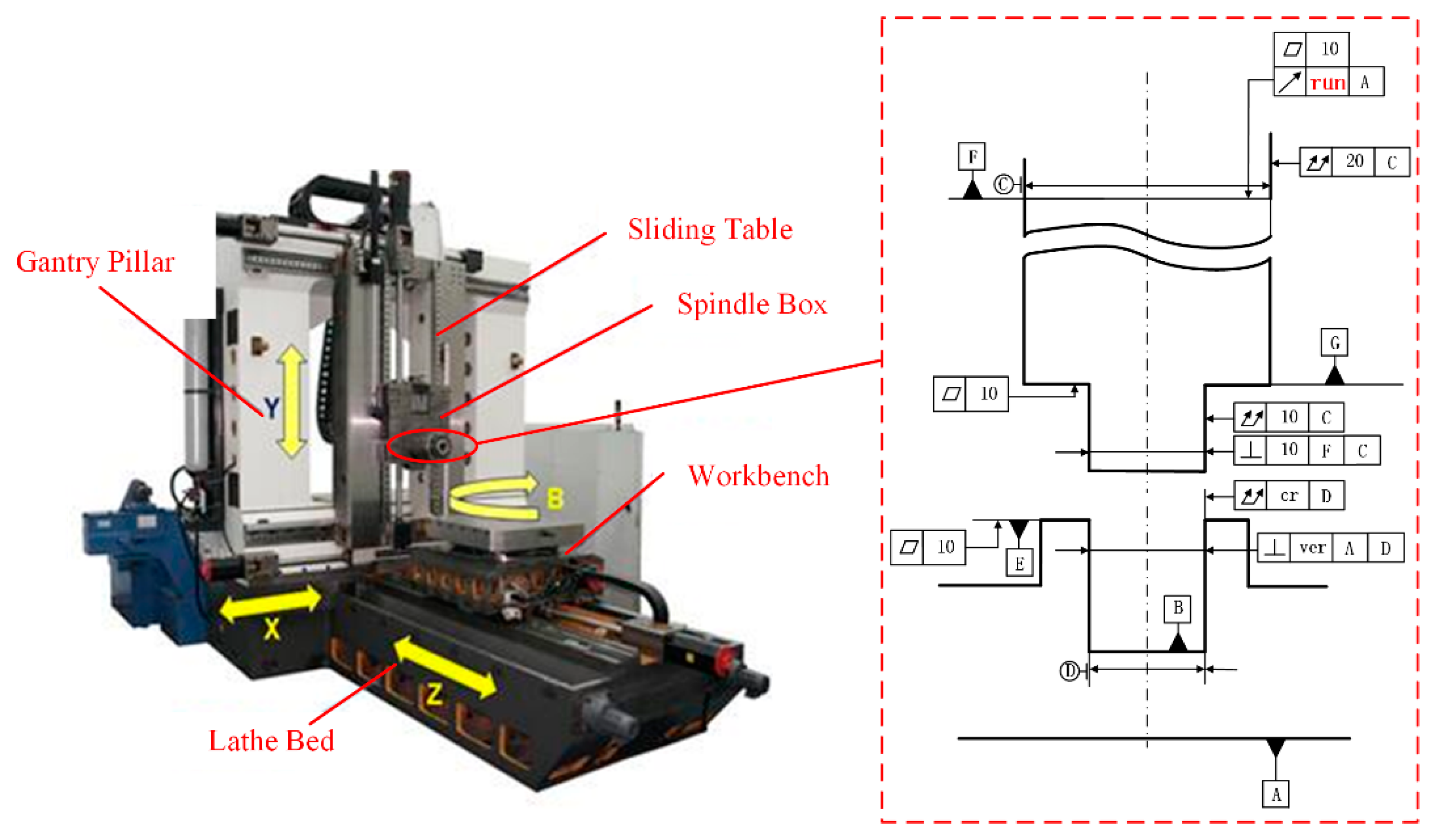

4.1. Description of the Tolerance Allocation Problem

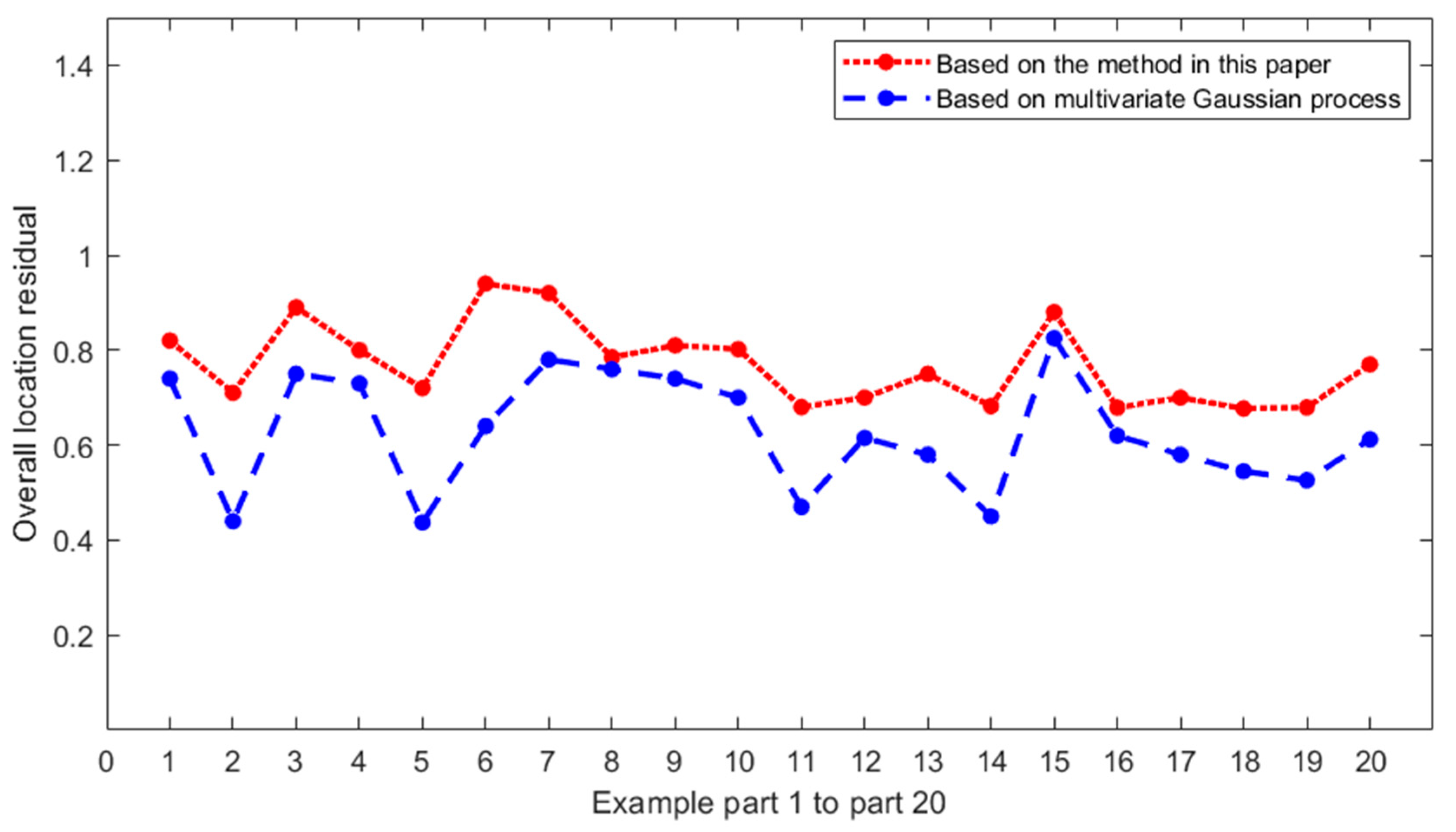

4.2. Stochastic Process Training and Parameter Calculation

4.3. Tolerance Synthesis of Example Rotary Feed Component

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Erboz, G. How to define industry 4.0: The main pillars of industry 4.0. In Proceedings of the 7th International Conference on Management (ICoM 2017), Nitra, Slovakia, 1–2 June 2017. [Google Scholar]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Geetha, K. Tolerance allocation and scheduling for complex assembly. Int. J. Appl. Eng. Res. 2015, 10, 4000–4003. [Google Scholar]

- Shoukr, D.S.L.; Gadallah, M.H.; Metwalli, S.M. The reduced tolerance allocation problem. In Proceedings of the ASME’s International Mechanical Engineering Congress and Exposition (IMECE2016), Phoenix, AZ, USA, 11–17 November 2016. [Google Scholar]

- Khodaygan, S. Meta-model based multi-objective optimisation method for computer-aided tolerance design of compliant assemblies. Int. J. Comput. Integr. Manuf. 2019, 32, 27–42. [Google Scholar] [CrossRef]

- Delos, V.; Arroyave-Tobón, S.; Teissandier, D. Introducing a projection-based method to compare three approaches computing the accumulation of geometric variations. In Proceedings of the ASME 2018 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Quebec City, QC, Canada, 26–29 August 2018. [Google Scholar]

- Lin, E.E.; Zhang, H.C. Theoretical tolerance stackup analysis based on tolerance zone analysis. Int. J. Adv. Manuf. Technol. 2001, 17, 257–262. [Google Scholar] [CrossRef]

- Wang, Y. Closed-loop analysis in semantic tolerance modeling. J. Mech. Des. 2008, 130, 061701. [Google Scholar] [CrossRef]

- Geis, A.; Husung, S.; Oberänder, A.; Weber, C.; Adam, J. Use of vectorial tolerances for direct representation and analysis in CAD-systems. Proc. CIRP 2015, 27, 230–240. [Google Scholar] [CrossRef]

- Heling, B.; Aschenbrenner, A.; Walter, M.S.J.; Wartzack, S. On connected tolerances in statistical tolerance-cost-optimization of assemblies with interrelated dimension chains. Proc. CIRP 2016, 43, 262–267. [Google Scholar] [CrossRef]

- Ameta, G.; Davidson, J.K.; Shah, J.J. Tolerance-maps applied to a point-line cluster of features. J. Mech. Des. 2007, 129, 782–792. [Google Scholar] [CrossRef]

- Bhide, S.; Ameta, G.; Davidson, J.K.; Shah, J.J. Tolerance-maps applied to the straightness and orientation of an axis. In Models for Computer Aided Tolerancing in Design and Manufacturing; Springer: Dordrecht, The Netherlands, 2007. [Google Scholar]

- Chitale, A.N.; Davidson, J.K.; Shah, J.J. Statistical tolerance analysis with sensitivities established from tolerance-maps and deviation spaces. J. Comput. Inf. Sci. Eng. 2019, 19, 041002. [Google Scholar] [CrossRef]

- Cheng, H.; Li, Y.; Zhang, K.F.; Su, J. Bin Efficient method of positioning error analysis for aeronautical thin-walled structures multi-state riveting. Int. J. Adv. Manuf. Technol. 2011, 55, 217–233. [Google Scholar] [CrossRef]

- 1Wang, H.; Liu, J. Tolerance simulation of thin-walled c-section composite beam assembling with small displacement torsor model. Proc. CIRP 2016, 43, 274–279. [Google Scholar]

- Li, H.; Zhu, H.; Zhou, X.; Li, P.; Yu, Z. A new computer-aided tolerance analysis and optimization framework for assembling processes using DP-SDT theory. Int. J. Adv. Manuf. Technol. 2016, 86, 1299–1310. [Google Scholar] [CrossRef]

- Du, Q.; Zhai, X.; Wen, Q. Study of the ultimate error of the axis tolerance feature and its pose decoupling based on an area coordinate system. Appl. Sci. 2018, 8, 435. [Google Scholar] [CrossRef]

- Yan, H.; Cao, Y.; Yang, J. Statistical tolerance analysis based on good point set and homogeneous transform matrix. Proc. CIRP 2016, 43, 178–183. [Google Scholar] [CrossRef]

- Laperrière, L.; Elmaraghy, H.A. Tolerance analysis and synthesis using Jacobian transforms. CIRP Ann. 2000, 49, 359–362. [Google Scholar] [CrossRef]

- Desrochers, A.; Ghie, W.; Laperrière, L. Application of a unified jacobian—Torsor model for tolerance analysis. J. Comput. Inf. Sci. Eng. 2003, 3, 2–14. [Google Scholar] [CrossRef]

- Zeng, W.; Rao, Y.; Wang, P.; Yi, W. A solution of worst-case tolerance analysis for partial parallel chains based on the Unified Jacobian-Torsor model. Precis. Eng. 2017, 47, 276–291. [Google Scholar] [CrossRef]

- Kopardekar, P.; Anand, S. Tolerance allocation using neural networks. Int. J. Adv. Manuf. Technol. 1995, 10, 269–276. [Google Scholar] [CrossRef]

- Luo, C.; Franciosa, P.; Ceglarek, D.; Ni, Z.; Jia, F. A novel geometric tolerance modeling inspired by parametric space envelope. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1386–1398. [Google Scholar] [CrossRef]

- Samper, S.; Formosa, F. Form Defects tolerancing by natural modes analysis. J. Comput. Inf. Sci. Eng. 2007, 7, 44–51. [Google Scholar] [CrossRef]

- Homri, L.; Goka, E.; Levasseur, G.; Dantan, J.Y. Tolerance analysis—Form defects modeling and simulation by modal decomposition and optimization. CAD Comput. Aided Des. 2017, 91, 46–59. [Google Scholar] [CrossRef]

- Lin, E.E. Graph-Matrix-Based Automated Tolerance Analysis and Setup Planning in Computer-Aided Process Planning. Ph.D. Thesis, Texas Tech University, Lubbock, TX, USA, 2000. [Google Scholar]

- Zhang, K.; Li, Y.; Tang, S. An integrated modeling method of unified tolerance representation for mechanical product. Int. J. Adv. Manuf. Technol. 2010, 46, 217–226. [Google Scholar] [CrossRef]

- Schleich, B.; Wartzack, S.; Anwer, N.; Mathieu, L. Skin model shapes: Offering new potentials for modelling product shape variability. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015. [Google Scholar]

- ISO 17450-1. Geometrical Product Specifications (GPS): General Concepts: Part 1: Model for Geometrical Specification and Verification; ISO: Geneva, Switzerland, 2011. [Google Scholar]

- ISO 17450-2. Geometrical Product Specifications (GPS)—General Concepts: Part 2: Basic Tenets, Specifications, Operators, Uncertainties and Ambiguities; ISO: Geneva, Switzerland, 2012. [Google Scholar]

- Ballu, A.; Mathieu, L. Univocal expression of functional and geometrical tolerances for design, manufacturing and inspection. In Computer-Aided Tolerancing; Springer: Dordrecht, The Netherlands, 2011. [Google Scholar]

- Anwer, N.; Ballu, A.; Mathieu, L. The skin model, a comprehensive geometric model for engineering design. CIRP Ann. Manuf. Technol. 2013, 62, 143–146. [Google Scholar] [CrossRef]

- Zhang, M.; Anwer, N.; Mathieu, L.; Zhao, H. A discrete geometry framework for geometrical product specifications. In Proceedings of the 21st CIRP Design Conference, Kaist, Korea, 1 January 2011. [Google Scholar]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Skin Model Shapes: A new paradigm shift for geometric variations modelling in mechanical engineering. CAD Comput. Aided Des. 2014, 50, 1–15. [Google Scholar] [CrossRef]

- Yacob, F.; Semere, D.; Nordgren, E. Octree-based generation and variation analysis of skin model shapes. J. Manuf. Mater. Process. 2018, 2, 52. [Google Scholar] [CrossRef]

- Yan, X.; Ballu, A. Generation of consistent skin model shape based on FEA method. Int. J. Adv. Manuf. Technol. 2017, 92, 789–802. [Google Scholar] [CrossRef]

- Schleich, B.; Anwer, N.; Mathieu, L.; Wartzack, S. Contact and mobility simulation for mechanical assemblies based on skin model shapes. J. Comput. Inf. Sci. Eng. 2015, 15, 021009. [Google Scholar] [CrossRef]

- Dantan, J.-Y. Comparison of skin model representations and tooth contact analysis techniques for gear tolerance analysis. J. Comput. Inf. Sci. Eng. 2015, 15, 021010. [Google Scholar] [CrossRef]

- Yan, X. Assembly Simulation and Evaluation Based on Generation of Virtual Workpiece with Form Defect. Ph.D. Thesis, Université de Bordeaux, Bordeaux, France, 2018. [Google Scholar]

- Wang, J.; Sanchez, J.; Iturrioz, J.; Ayesta, I. Geometrical defect detection in the wire electrical discharge machining of fir-tree slots using deep learning techniques. Appl. Sci. 2018, 9, 90. [Google Scholar] [CrossRef]

- Sun, J.; Rahman, M.; Wong, Y.S.; Hong, G.S. Multiclassification of tool wear with support vector machine by manufacturing loss consideration. Int. J. Mach. Tools Manuf. 2004, 44, 1179–1187. [Google Scholar] [CrossRef]

- Dai, W.; Chi, Y.; Lu, Z.; Wang, M.; Zhao, Y. Research on reliability assessment of mechanical equipment based on the performance–feature model. Appl. Sci. 2018, 8, 1619. [Google Scholar] [CrossRef]

- Ozcelik, B.; Bayramoglu, M. The statistical modeling of surface roughness in high-speed flat end milling. Int. J. Mach. Tools Manuf. 2006, 46, 1395–1402. [Google Scholar] [CrossRef]

- Shu, M.H.; Hsu, B.M.; Kapur, K.C. Dynamic performance measures for tools with multi-state wear processes and their applications for tool design and selection. Int. J. Prod. Res. 2010, 48, 4725–4744. [Google Scholar] [CrossRef]

- Hsu, B.M.; Shu, M.H.; Wu, L. Dynamic performance modelling and measuring for machine tools with continuous-state wear processes. Int. J. Prod. Res. 2013, 51, 4718–4731. [Google Scholar] [CrossRef]

- Moghaddass, R.; Zuo, M.J. A parameter estimation method for a condition-monitored device under multi-state deterioration. Reliab. Eng. Syst. Saf. 2012, 106, 94–103. [Google Scholar] [CrossRef]

- Cannarile, F.; Compare, M.; Baraldi, P.; Di Maio, F.; Zio, E. Homogeneous continuous-time, finite-state hidden semi-markov modeling for enhancing empirical classification system diagnostics of industrial components. Machines 2018, 6, 34. [Google Scholar] [CrossRef]

| Target Accuracy Term | Explanation | Symbol | Design Requirement |

|---|---|---|---|

| Runout of surface F | 0.020 mm | ||

| Accuracy Terms of the Shaft Part | Explanation | Symbol | Nominal Value |

| Flatness of surface F | 0.010 mm | ||

| Total runout of the distal end surface | 0.020 mm | ||

| Total runout of the proximal end surface | 0.010 mm | ||

| Flatness of shoulder surface G | 0.010 mm | ||

| Verticality between the distal end surface and axis C | 0.010 mm | ||

| Accuracy Terms of the Hole Part | Explanation | Symbol | Nominal Value |

| Flatness of the shoulder surface E | 0.010 mm | ||

| Total runout of axis D | 0.012 mm | ||

| Verticality between axis D and surface A | 0.005 mm |

| Feature Terms | Feature Weight Value | Feature Terms | Feature Weight Value |

|---|---|---|---|

| 0.036 | 0.124 | ||

| 0.498 | 0.965 | ||

| 0.015 | 2.326 | ||

| 0.968 | 0.216 | ||

| 1.526 | 2.979 | ||

| 0.732 | 1.521 | ||

| 1.998 | 1.104 |

| Objective Tolerance Term | Assembly Functional Requirement | ||||

|---|---|---|---|---|---|

| To-be-designed tolerance terms | Assembling probability | Relative manufacturing cost | |||

| Nominal value (mm) | 0.010 | 0.012 | 0.005 | 1 | 1 |

| Designed scheme 1 (mm) | 0.013 | 0.016 | 0.009 | 0.957 | 0.644 |

| Designed scheme 2 (mm) | 0.012 | 0.014 | 0.016 | 0.959 | 0.679 |

| Designed scheme 3 (mm) | 0.014 | 0.015 | 0.006 | 0.969 | 0.754 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, C.; Zhang, S.; Qiu, L.; Liu, X.; Wang, Z. Assembly Tolerance Design Based on Skin Model Shapes Considering Processing Feature Degradation. Appl. Sci. 2019, 9, 3216. https://doi.org/10.3390/app9163216

He C, Zhang S, Qiu L, Liu X, Wang Z. Assembly Tolerance Design Based on Skin Model Shapes Considering Processing Feature Degradation. Applied Sciences. 2019; 9(16):3216. https://doi.org/10.3390/app9163216

Chicago/Turabian StyleHe, Ci, Shuyou Zhang, Lemiao Qiu, Xiaojian Liu, and Zili Wang. 2019. "Assembly Tolerance Design Based on Skin Model Shapes Considering Processing Feature Degradation" Applied Sciences 9, no. 16: 3216. https://doi.org/10.3390/app9163216

APA StyleHe, C., Zhang, S., Qiu, L., Liu, X., & Wang, Z. (2019). Assembly Tolerance Design Based on Skin Model Shapes Considering Processing Feature Degradation. Applied Sciences, 9(16), 3216. https://doi.org/10.3390/app9163216