Behavior of Fiber-Reinforced Polymer-Confined High-Strength Concrete under Split-Hopkinson Pressure Bar (SHPB) Impact Compression

Abstract

1. Introduction

2. Test Matrix and Material Properties

2.1. Test Matrix

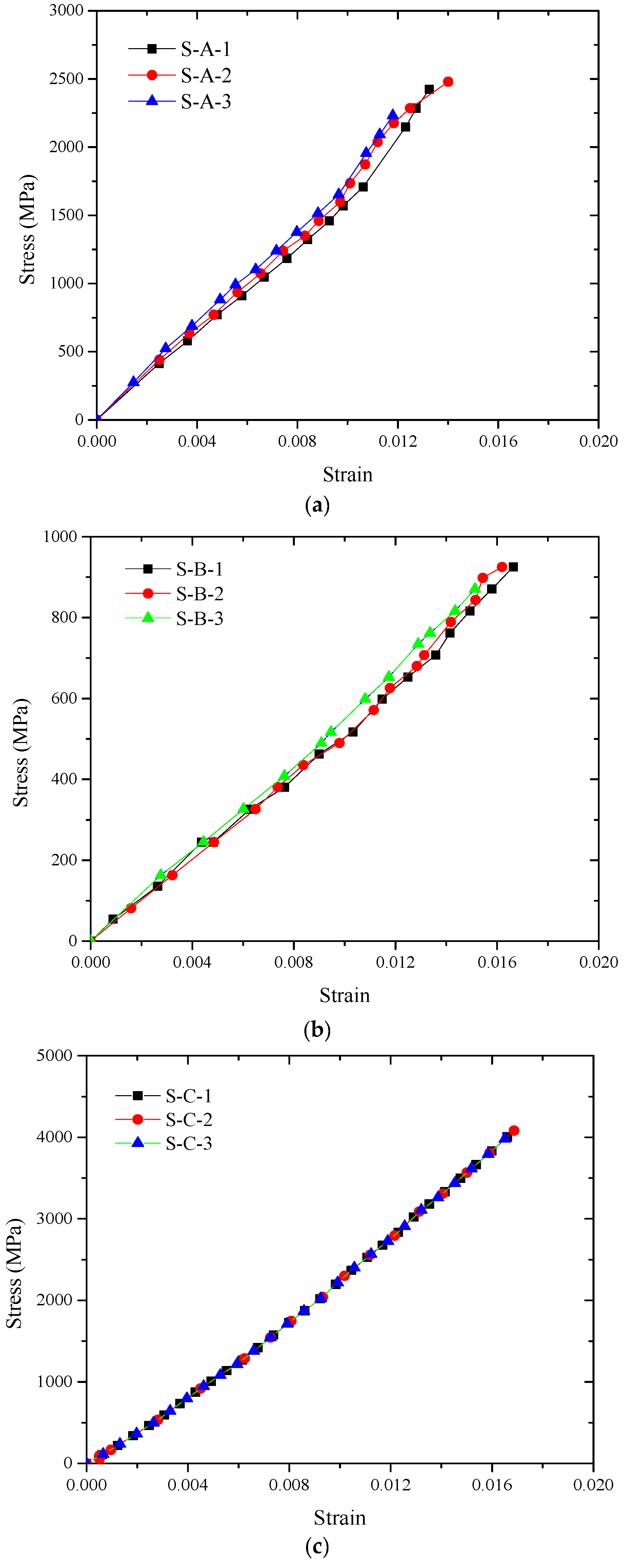

2.2. Material Properties

3. Test Methodologies

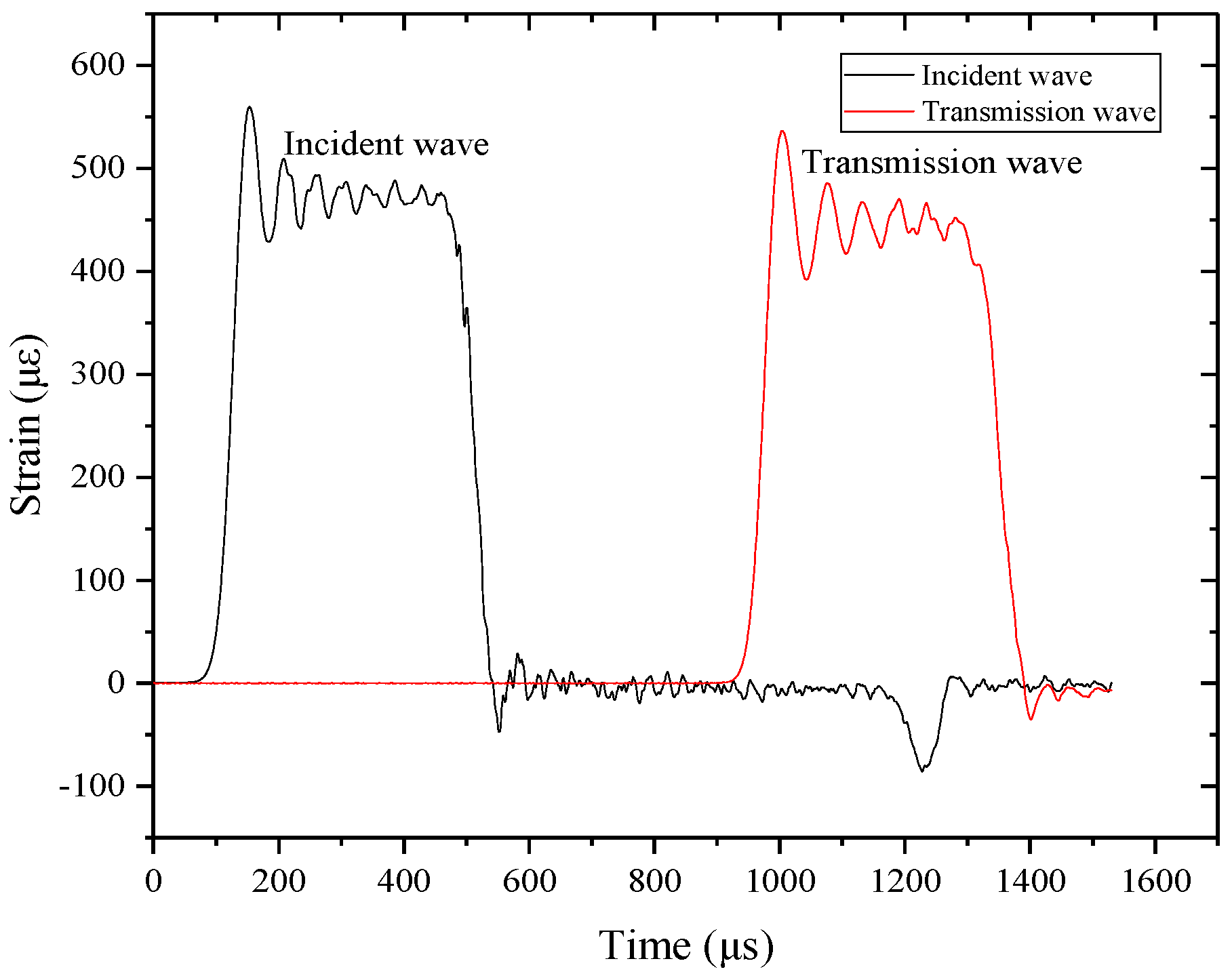

3.1. Instrumentations

3.2. Test Procedure

4. Test Results and Discussions

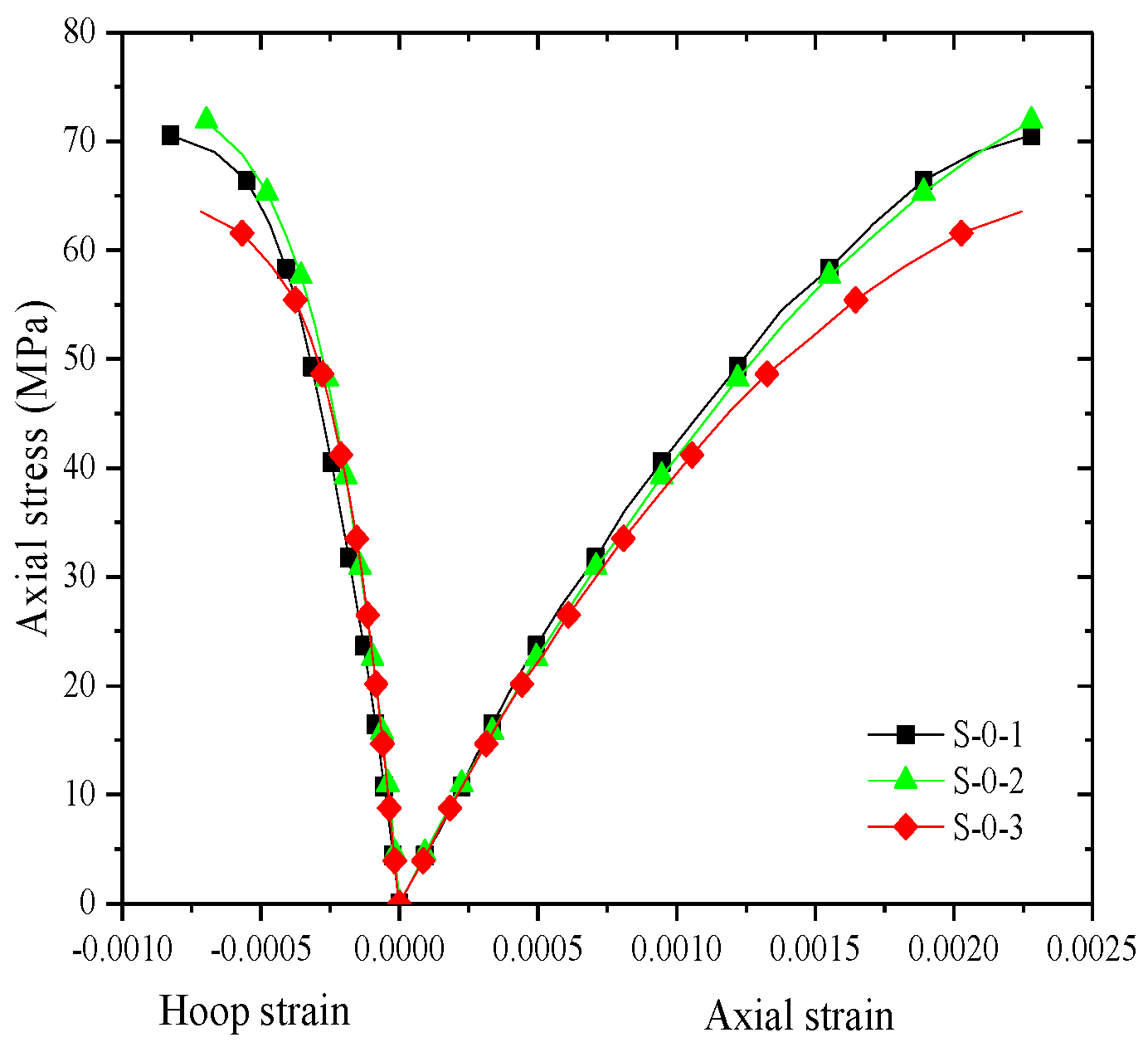

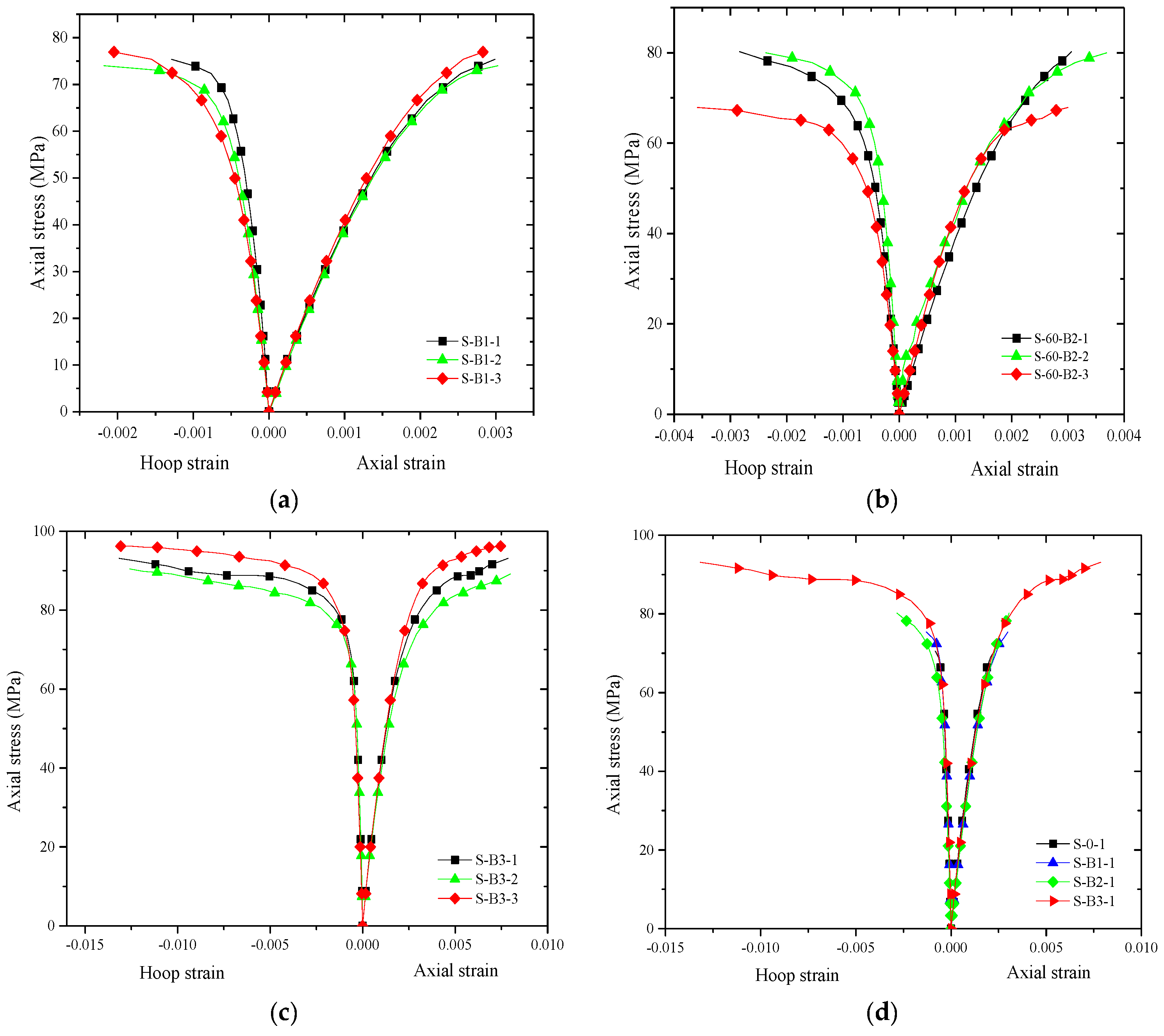

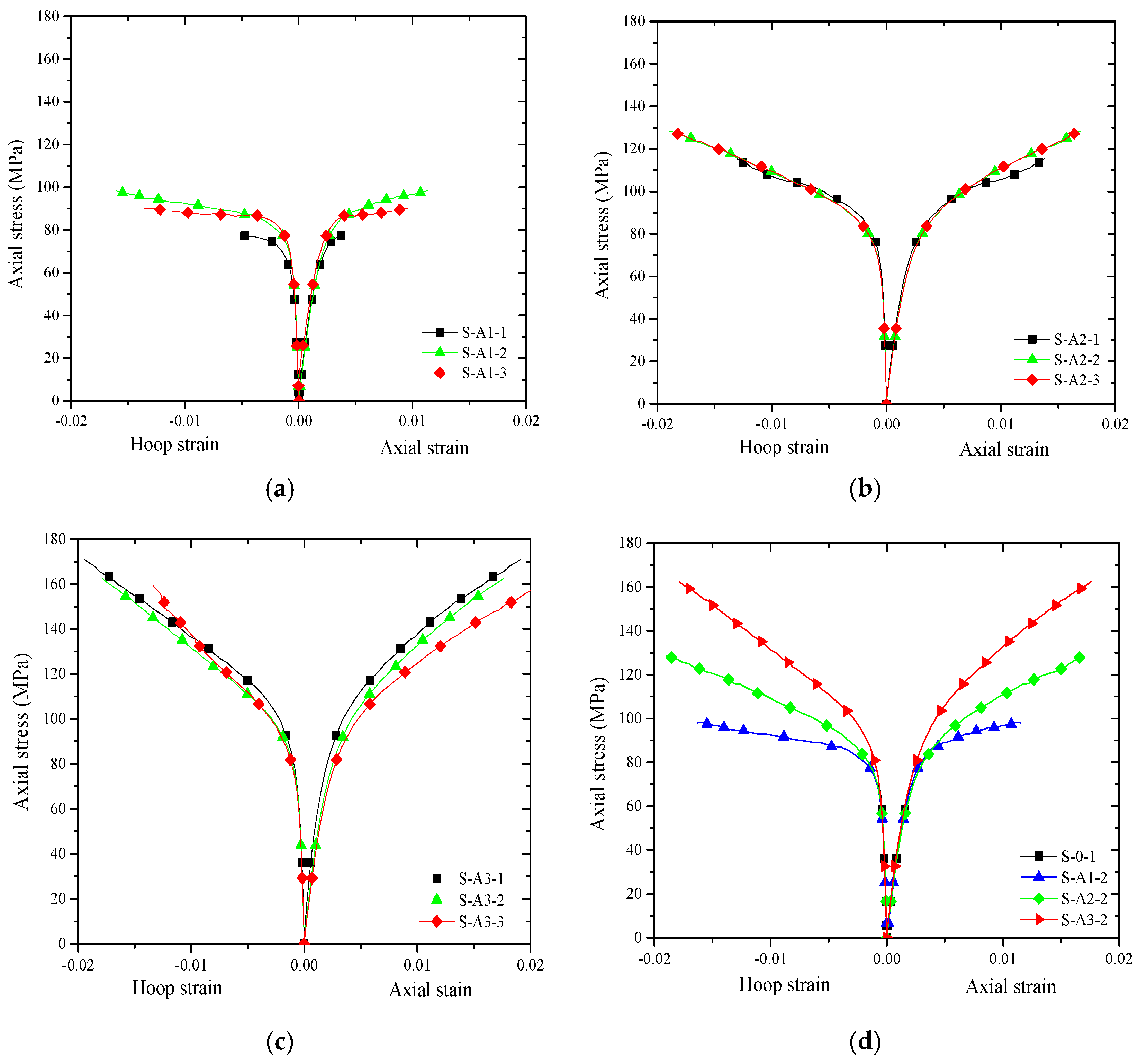

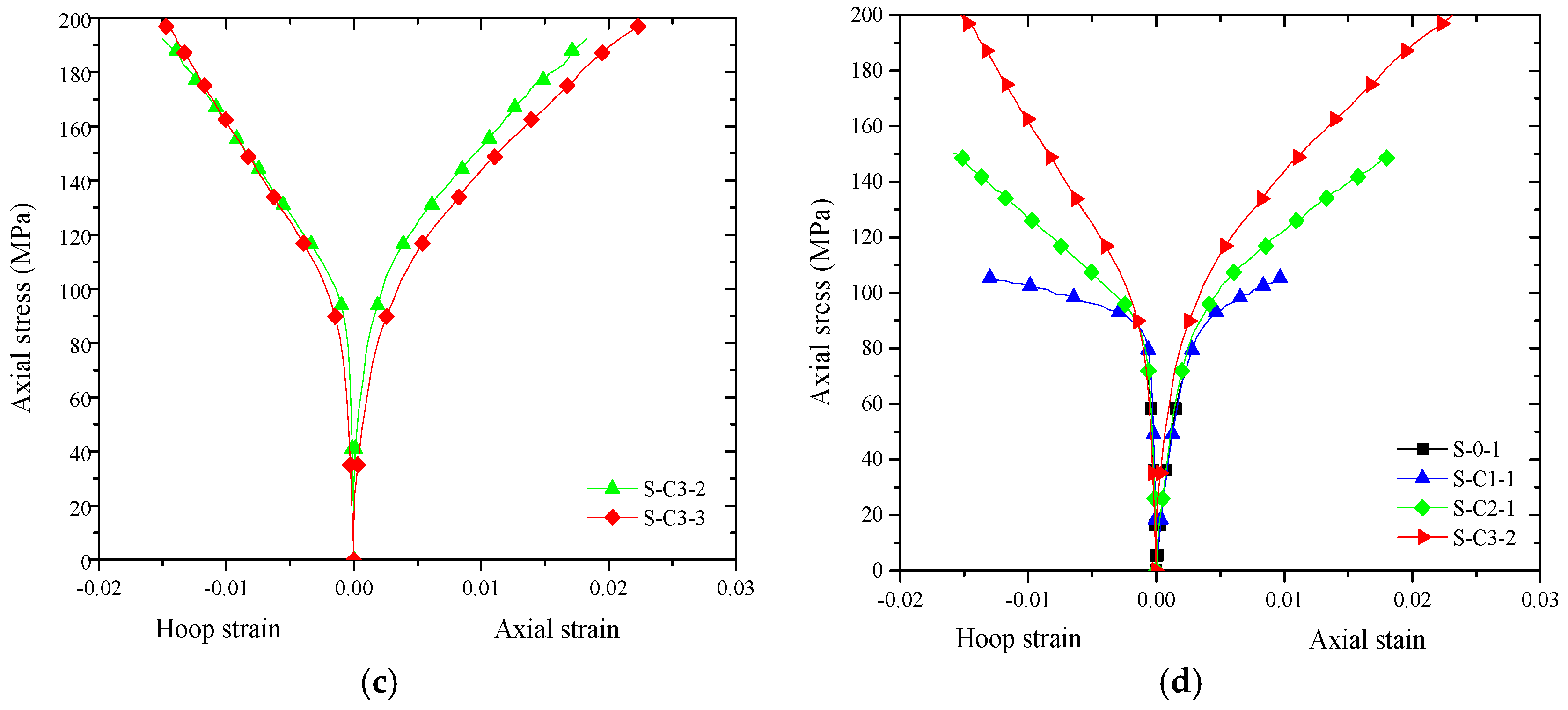

4.1. Quasi-Static Compression Tests

4.2. Dynamic Compression Tests

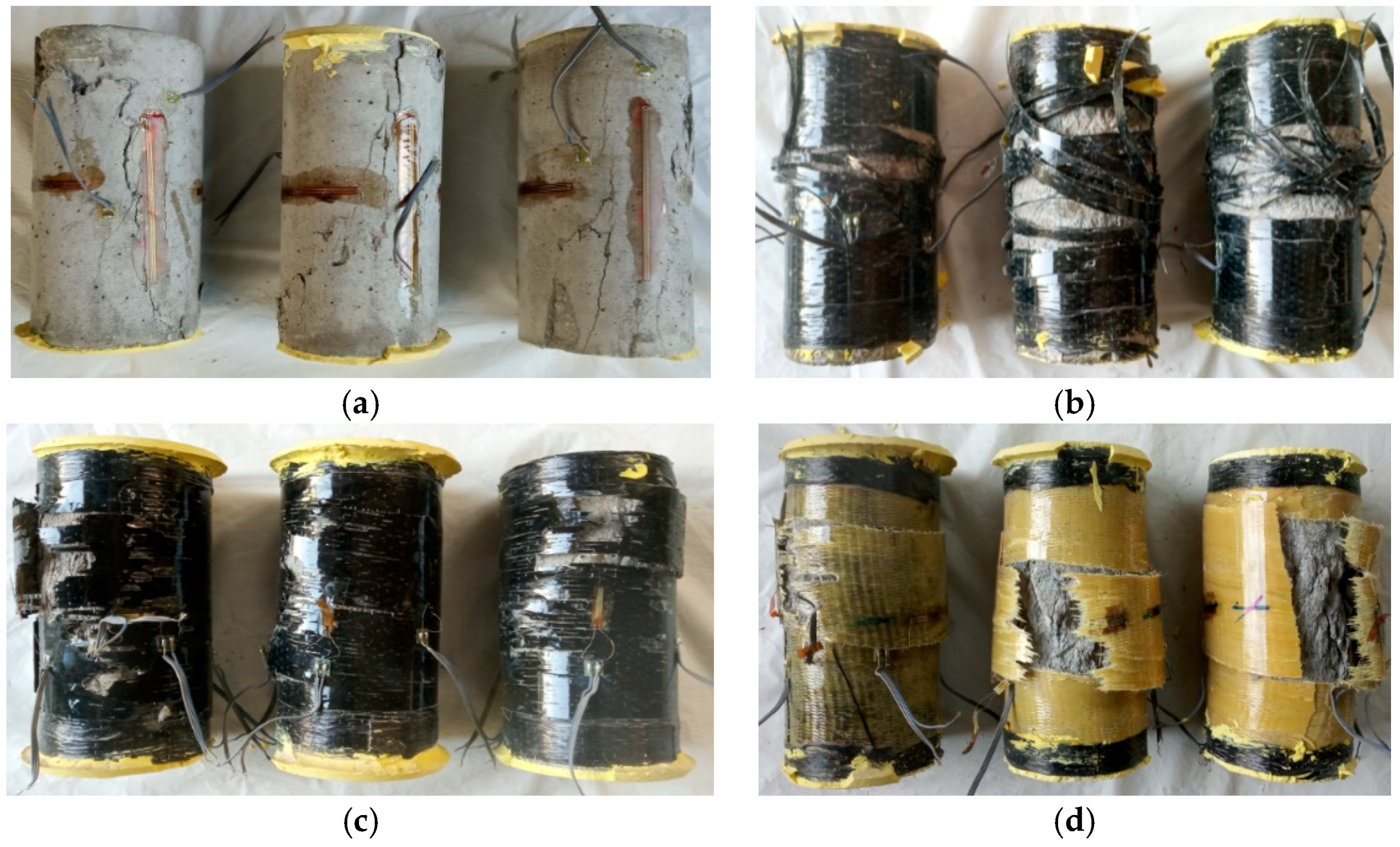

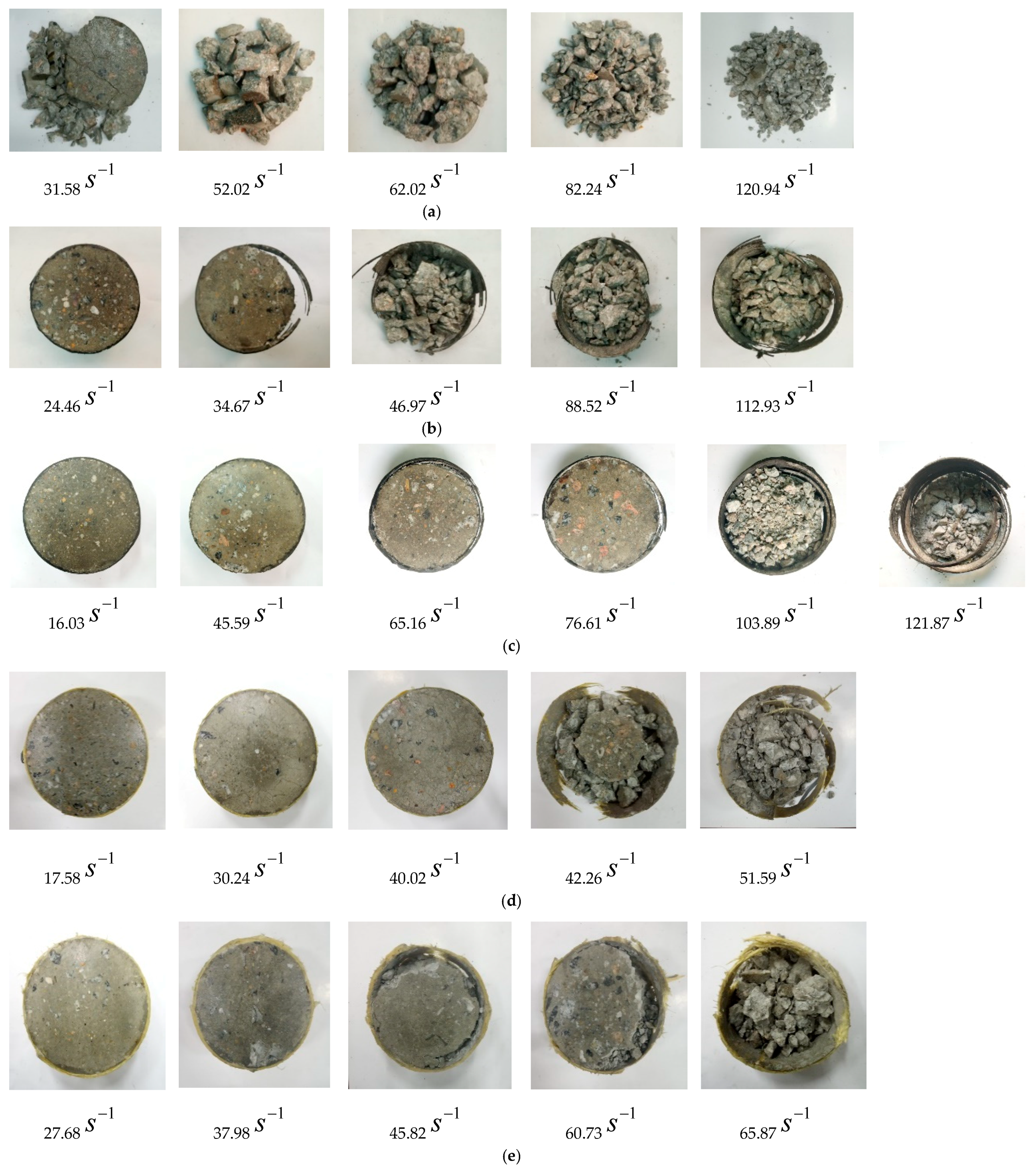

4.2.1. Failure Patterns

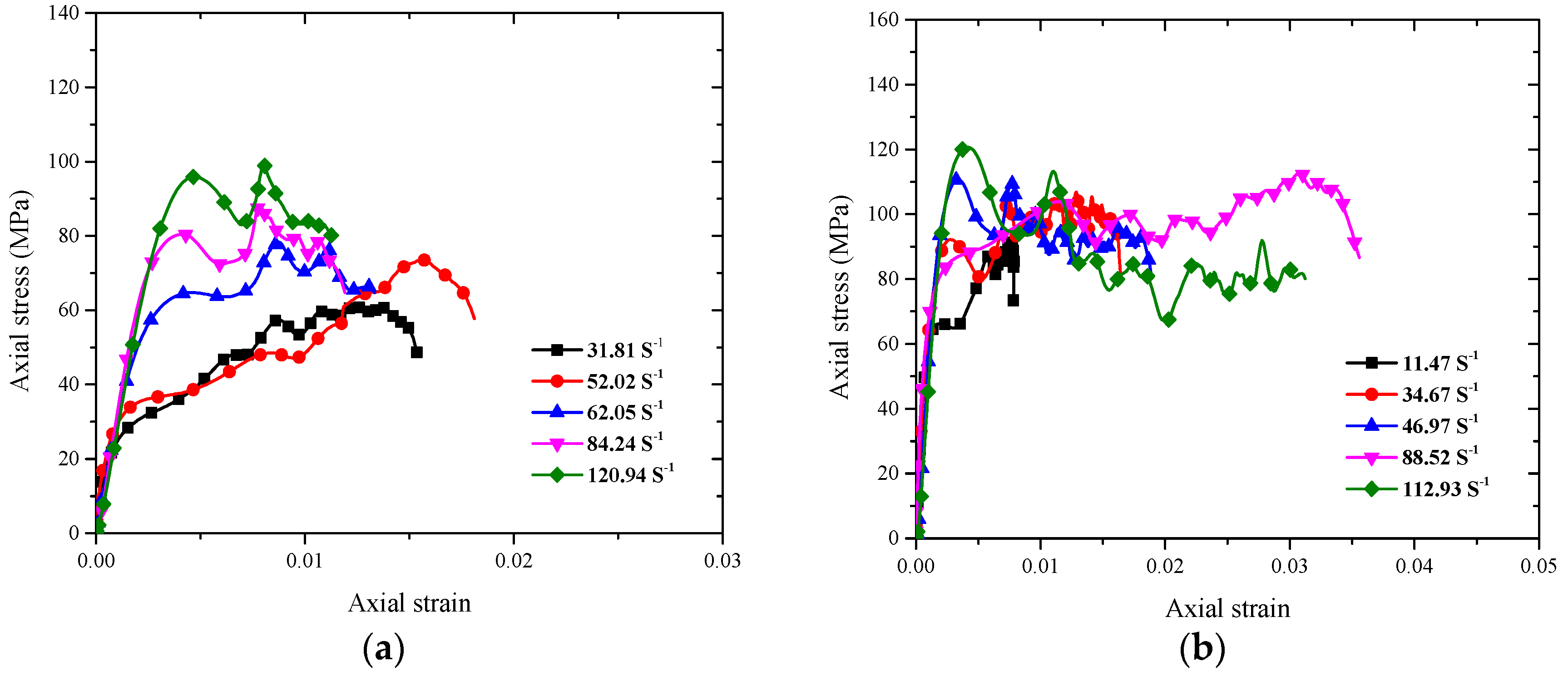

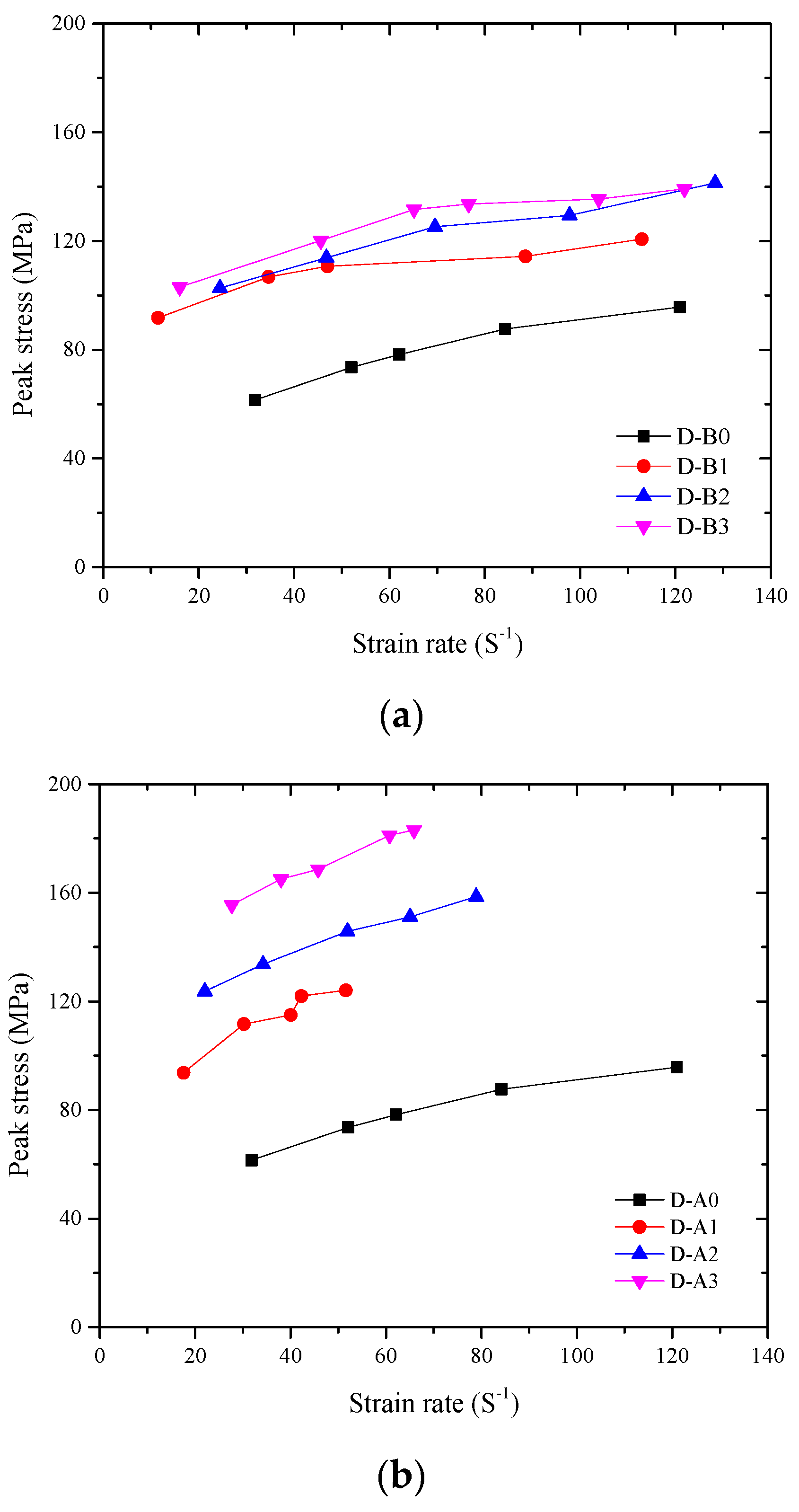

4.2.2. Dynamic Stress–Strain Responses

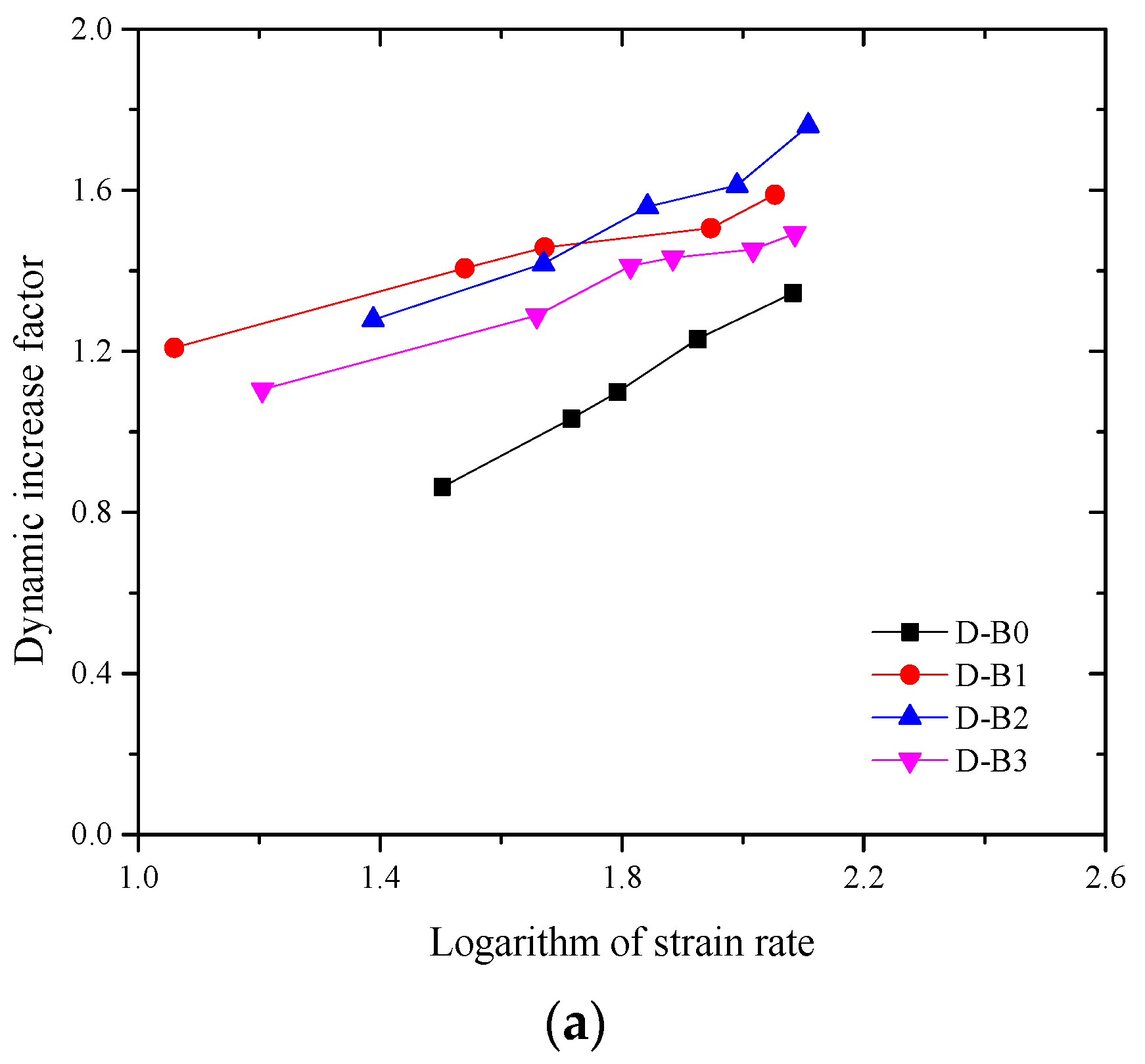

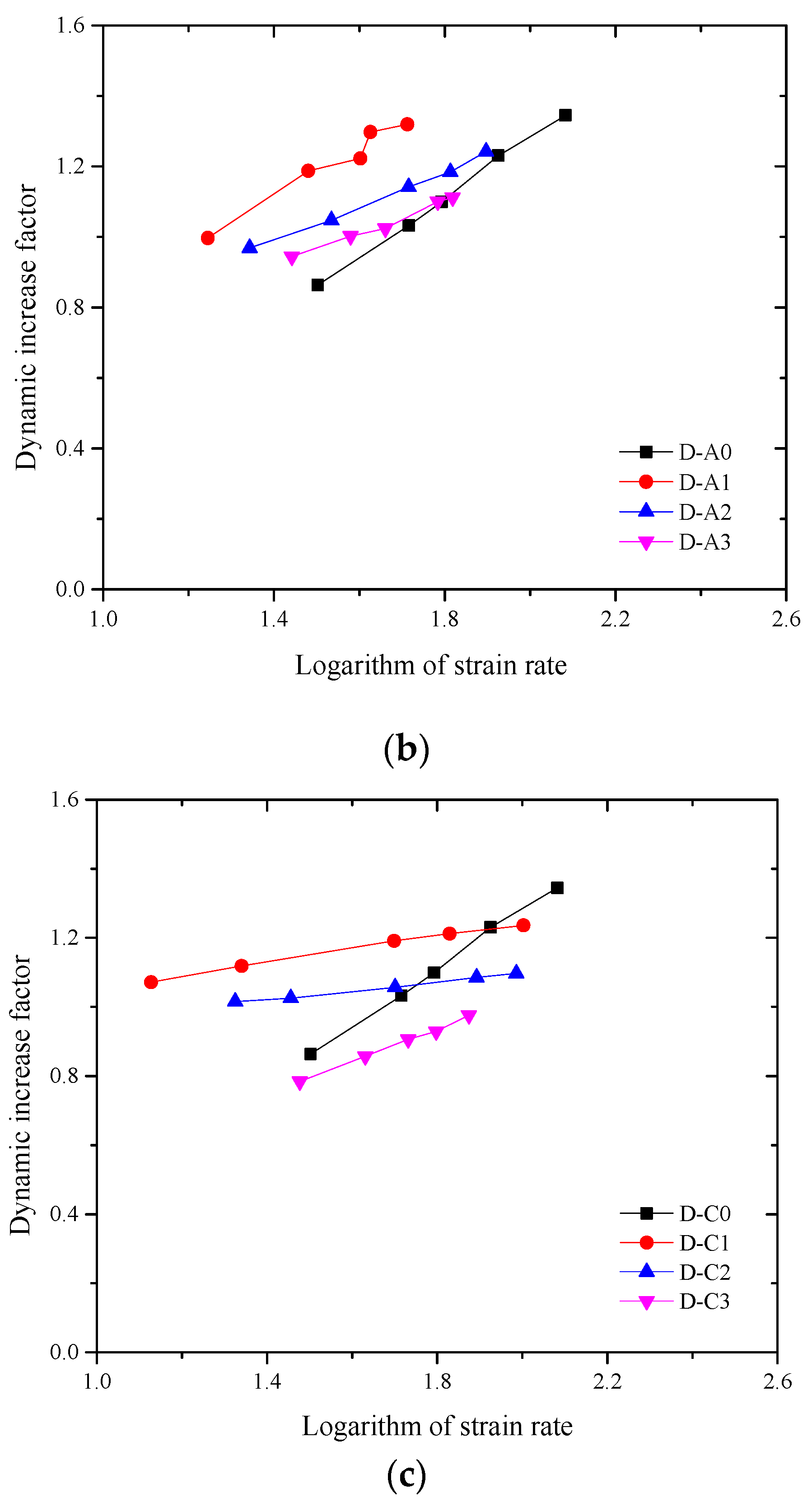

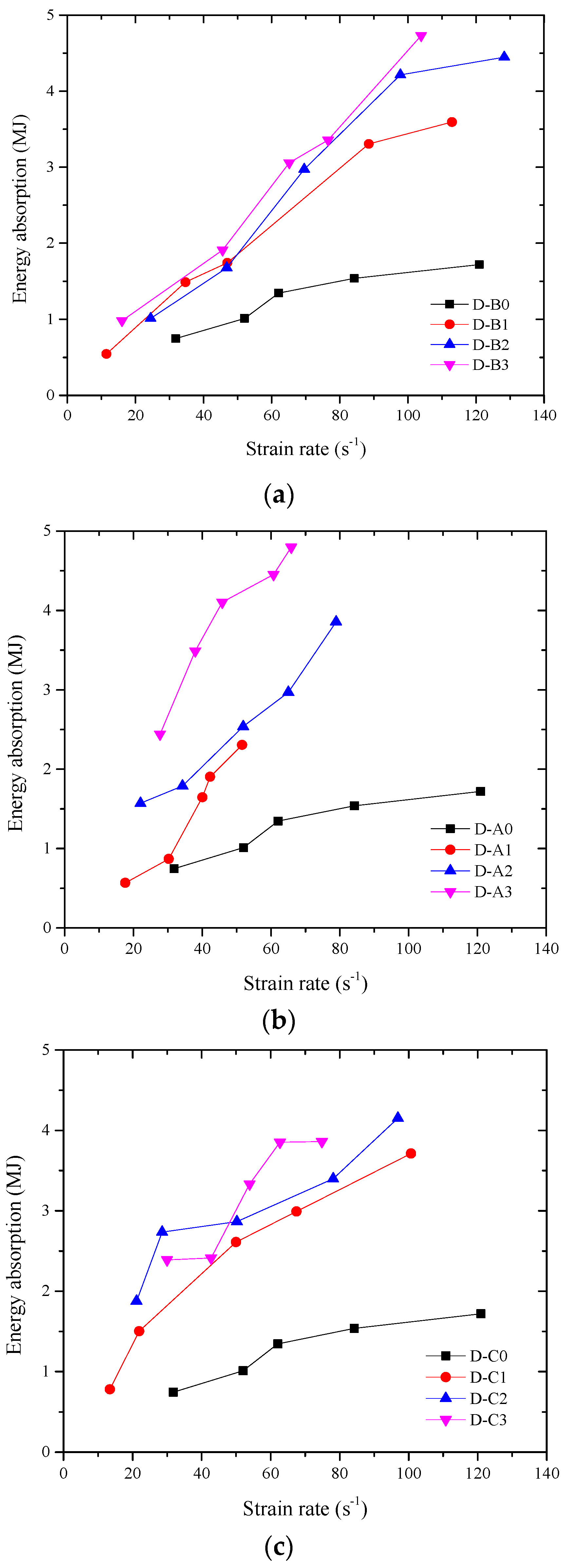

4.2.3. Dynamic Increase Factor and Energy Absorption

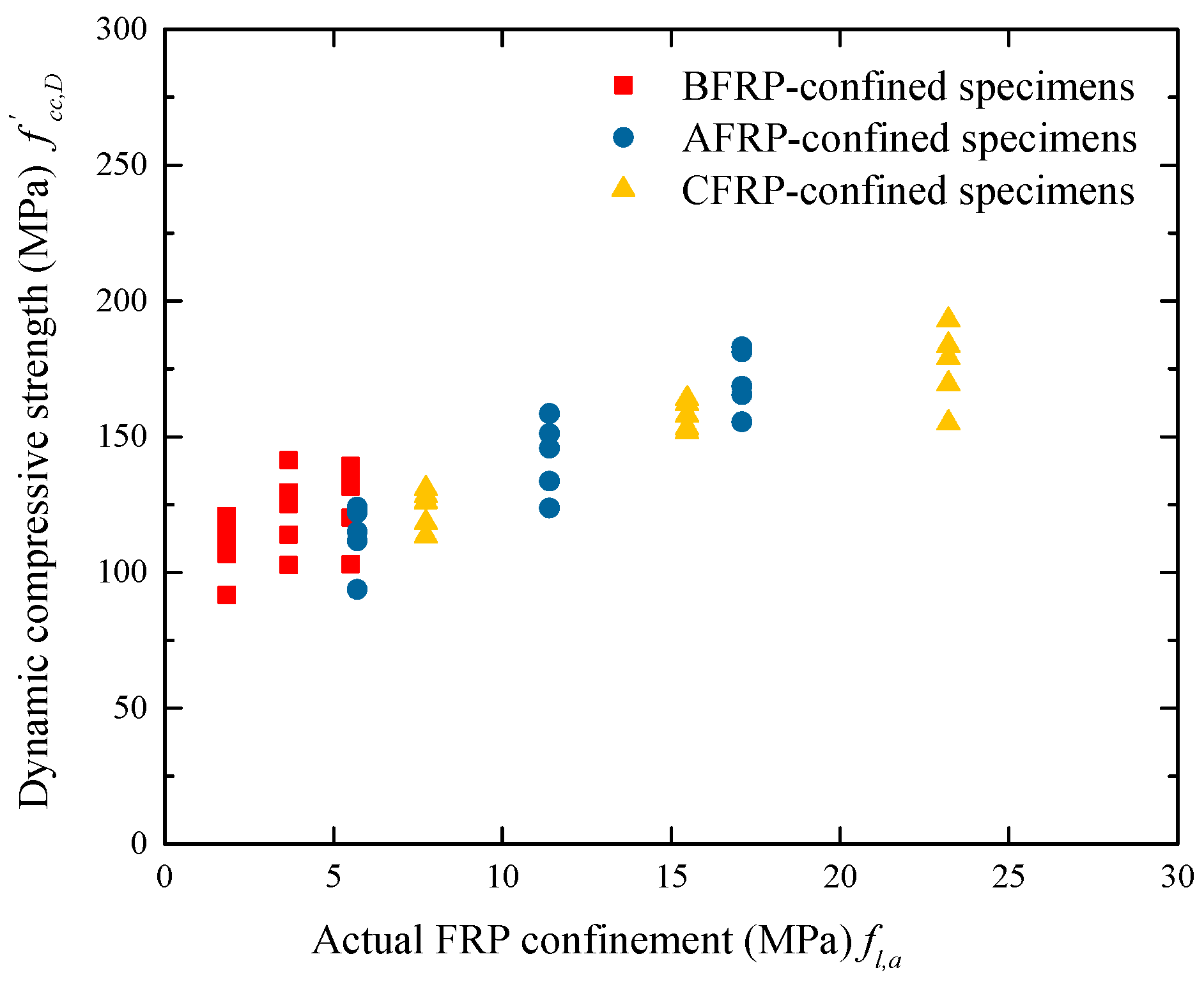

5. Dynamic Compressive Strength Model of FCC

5.1. General

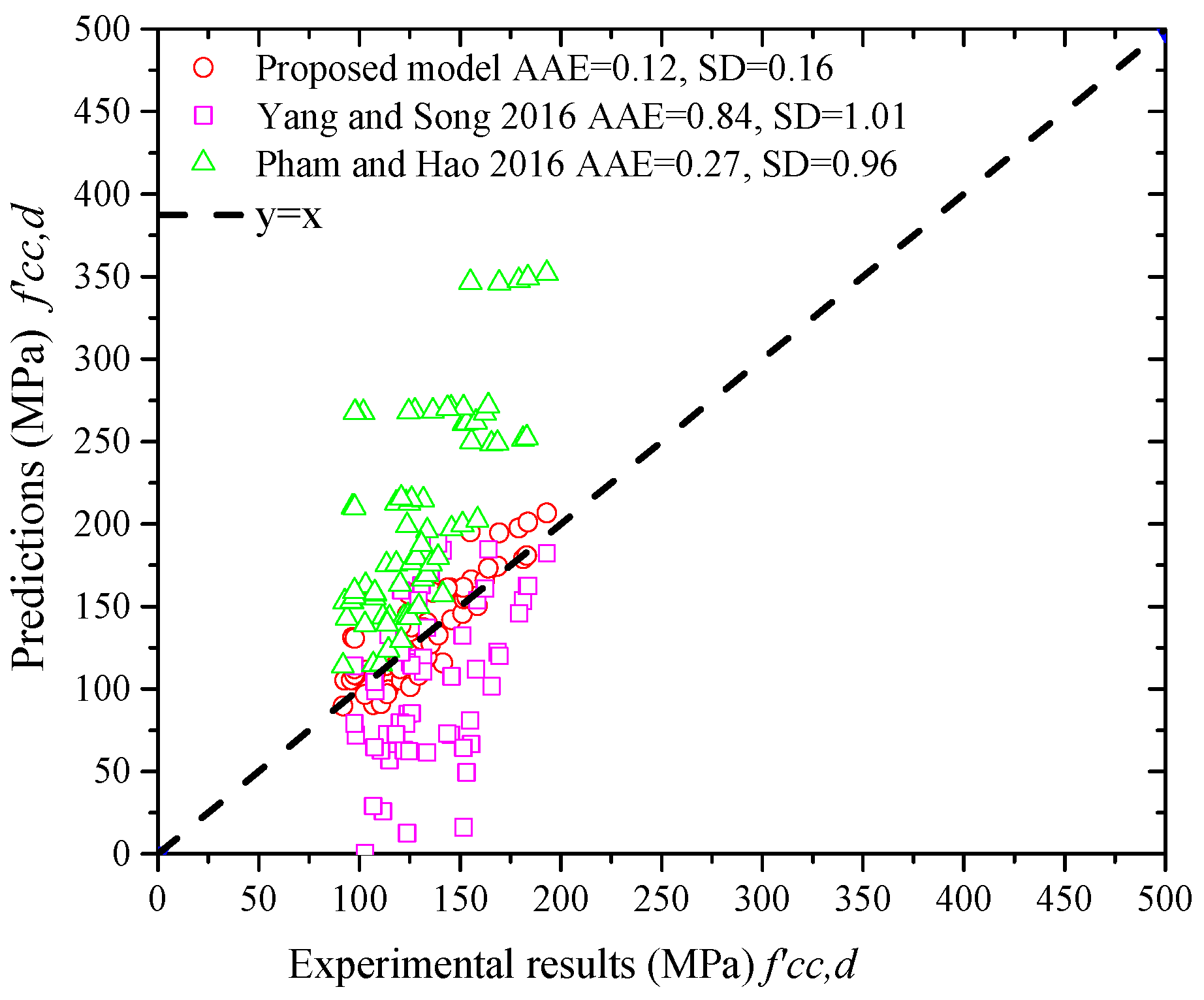

5.2. Dynamic Compressive Strength Model for FCHC

6. Conclusions

- (1)

- The compressive strength and the corresponding strain increase with an increase in the strain rate for both FRP-confined and unconfined high-strength concrete.

- (2)

- The increase in the FRP confinement ratio leads to an increase in the dynamic increase factor of FCHC, regardless of the type of FRP jacket. The efficiency of the FRP is not proportional to the FRP confinement ratio. For FCHC with the same type of FRP jacket, the DIF of the three-layer FRP-confined specimen is the smallest and the dynamic increment factor is the largest for the one-layer FRP-confined specimen. This is due to the confinement lag effect in the confined concrete under dynamic loadings. Namely, dynamic compression leads to failure of the concrete, but the failure is not necessarily developed timely in the FRP jacket.

- (3)

- Given the same FRP confinement condition, the DIF of the AFRP-confined high-strength concrete is the largest, indicating that AFRP-confined high-strength concrete has a favorable impact resistance. This is due to the larger FRP hoop strain efficiency for the AFRP.

- (4)

- The energy absorption of confined concrete increases with an increase in the strain rate.

- (5)

- The proposed modified design-oriented strength model can provide close predictions to the dynamic compressive strength of FCHC and is more accurate than the existing dynamic strength models for FCHC.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Qin, R.Y.; Lau, D.; Tam, L.H.; Liu, T.J.; Zou, D.J.; Zhou, A. Experimental investigation on interfacial defect criticality of FRP-confined concrete columns. Sensors 2019, 19, 468. [Google Scholar] [CrossRef] [PubMed]

- Xia, L.P.; Zheng, Y. Deep embedment (DE) FRP shear strengthening of concrete bridge slabs under loads close to supports. Appl. Sci. 2018, 8, 721. [Google Scholar] [CrossRef]

- Li, G.H.; Zhao, J.; Wang, Z.K. Fatigue behavior of glass fiber-reinforced polymer bars after elevated temperatures exposure. Materials 2018, 11, 1028. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.Z.; Zheng, Y.; Taylor, S.E. Finite-element investigation of the structural behavior of basalt fiber reinforced polymer (BFRP)- reinforced self-compacting concrete (SCC) decks slabs in Thompson Bridge. Polymers 2019, 10, 678. [Google Scholar] [CrossRef] [PubMed]

- Gong, J.W.; Zou, X.X.; Shi, H.; Jiang, C.; Li, Z.C. Numerical investigation of the nonlinear composite action of FRP-concrete hybrid beams/decks. Appl. Sci. 2018, 8, 2031. [Google Scholar] [CrossRef]

- Liang, H.J.; Li, S.; Lu, Y.Y.; Yang, T. Reliability study on FRP composites exposed to wet-dry cycles. Appl. Sci. 2018, 8, 892. [Google Scholar] [CrossRef]

- Yu, Q.Q.; Gao, R.X.; Gu, X.L.; Zhao, X.L.; Chen, T. Bond behavior of CFRP-steel double-lap joints exposed to marine atmosphere and fatigue loading. Eng. Struct. 2018, 175, 76–85. [Google Scholar] [CrossRef]

- Fang, H.; Zou, F.; Liu, W.Q.; Wu, C.; Bai, Y. Hui, D. Mechanical performance of concrete pavement reinforced by CFRP grids for bridge deck applications. Compos. Part B Eng. 2017, 110, 313–335. [Google Scholar] [CrossRef]

- Zeng, J.J.; Gao, W.Y.; Liu, F. Interfacial Behavior and Debonding Failures of Full-Scale CFRP-Strengthened H-Section Steel Beams. Compos. Struct. 2018, 201, 540–552. [Google Scholar] [CrossRef]

- Guo, Y.C.; Gao, W.Y.; Zeng, J.J.; Ni, X.Y.; Peng, K.D. Compressive behavior of FRP ring-confined concrete in circular columns: Effects of specimen size and a new design-oriented stress-strain model. Constr. Build. Mater. 2019, 201, 350–368. [Google Scholar] [CrossRef]

- Wei, Y.; Cheng, X.Y.; Wu, G.; Duan, M.J.; Wang, L.B. Experimental investigations of concrete-filled steel tubular columns confined with high-strength steel wire. Adv. Struct. Eng. 2019, 22. [Google Scholar] [CrossRef]

- Zhou, Y.W.; Zhang, Y.W.; Sui, L.L.; Xing, F.; Hu, J.J.; Li, P.D. Behavior and modeling of FRP-confined ultra-lightweight cement composites under monotonic axial compression. Compos. Part B Eng. 2019, 162, 289–302. [Google Scholar] [CrossRef]

- Bai, Y.L.; Dai, J.G.; Mohammad, M.; Lin, G.; Mei, S.J. Stiffness-based design-oriented compressive stress-strain model for large-rupture-strain (LRS) FRP-confined concrete. Compos. Struct. 2019, 223, 110953. [Google Scholar] [CrossRef]

- Li, P.D.; Wu, Y.F.; Zhou, Y.W.; Xing, F. Stress-strain model for FRP-confined concrete subject to arbitrary load path. Compos. Part B Eng. 2019, 163, 9–25. [Google Scholar] [CrossRef]

- Wang, W.Q.; Sheikh, M.N.; Albaali, A.Q.; Hadi, M.N.S. Compressive behaviour of partially FRP confined concrete: Experimental observations and assessment of the stress-strain models. Constr. Build. Mater. 2018, 192, 785–797. [Google Scholar] [CrossRef]

- Zeng, J.J.; Guo, Y.C.; Li, L.J.; Chen, W.P. Behavior and three-dimensional finite element modeling of circular concrete columns partially wrapped with FRP strips. Polymers 2018, 10, 253. [Google Scholar] [CrossRef]

- Wang, D.Y.; Wang, Z.Y.; Yu, T.; Li, H. Seismic performance of CFRP-retrofitted large-scale rectangular RC columns under lateral loading in different directions. Compos. Struct. 2018, 192, 475–488. [Google Scholar] [CrossRef]

- Chen, G.M.; Zhang, J.J.; Jiang, T.; Lin, C.J. Compressive behavior of CFRP-confined recycled aggregate concrete in different-sized circular sections. J. Compos. Constr. 2018, 22, 04018021. [Google Scholar] [CrossRef]

- Zeng, J.J.; Guo, Y.C.; Li, L.J.; Chen, W.P. Stress-strain behavior of concrete in circular columns partially wrapped with FRP strips. Compos. Struct. 2018, 200, 810–828. [Google Scholar] [CrossRef]

- Smith, S.T.; Kim, S.J.; Zhang, H.W. Behavior and effectiveness of FRP wrap in the confinement of large concrete cylinders. J. Compos. Constr. 2010, 14, 573–582. [Google Scholar] [CrossRef]

- Zeng, J.J.; Lin, G.; Teng, J.G.; Li, L.J. Behavior of large-scale FRP-confined rectangular RC columns under axial compression. Eng. Struct. 2018, 174, 629–645. [Google Scholar] [CrossRef]

- Del Zoppo, M.; Di Ludovico, M.; Balsamo, A.; Prota, A. Comparative analysis of existing RC columns jacketed with CFRP or FRCC. Polymers 2018, 10, 361. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.W.; Zheng, B.W.; Zhao, D.B.; Dang, L.J.; Sui, L.L.; Li, P.D.; Xing, F. Cyclic bond behaviors between corroded steel bar and concrete under the coupling effects of hoop FRP confinement and sustained loading. Compos. Struct. 2019, 224, 110991. [Google Scholar] [CrossRef]

- Feng, P.; Cheng, S.; Bai, Y.; Ye, L.P. Load-strain model for steel-concrete-FRP concrete columns in axial compression. J. Compos. Constr. 2016, 20, 04016017. [Google Scholar]

- Zeng, J.J.; Lv, J.F.; Lin, G.; Guo, Y.C.; Li, L.J. Compressive behavior of double-tube concrete columns with an outer square FRP tube and an inner circular high-strength steel tube. Constr. Build. Mater. 2018, 184, 668–680. [Google Scholar] [CrossRef]

- Teng, J.G.; Yu, T.; Wong, Y.L.; Dong, S.L. Hybrid FRP-concrete-steel tubular columns: Concept and behavior. Constr. Build. Mater. 2007, 21, 846–854. [Google Scholar] [CrossRef]

- Fam, A.Z.; Rizkalla, S.H. Behavior of axially loaded concrete-filled circular fiber reinforced polymer tubes. ACI Struct. J. 2001, 98, 280–289. [Google Scholar]

- Li, Y.L.; Teng, J.G.; Zhao, X.L.; Raman, R.K.S. Theoretical model for seawater and sea sand concrete-filled circular FRP tubular stub columns under axial compression. Eng. Struct. 2018, 160, 71–84. [Google Scholar] [CrossRef]

- Yu, T.; Lin, G.; Zhang, S.S. Compressive behavior of FRP-confined concrete-encased steel columns. Compos. Struct. 2016, 154, 493–506. [Google Scholar] [CrossRef]

- Yang, H.; Song, H.; Zhang, S. Experimental investigation of the behavior of aramid fiber reinforced polymer confined concrete subjected to high strain-rate compression. Constr. Build. Mater. 2015, 95, 143–151. [Google Scholar] [CrossRef]

- Yang, H.; Song, H. Dynamic compressive behavior of FRP-confined concrete under impact and a new design-oriented strength model. Polym. Polym. Compos. 2016, 24, 127–131. [Google Scholar]

- Xiong, B.B.; Demartino, C.; Xiao, Y. High-strain rate compressive behavior of CFRP confined concrete: Large diameter SHPB tests. Constr. Build. Mater. 2019, 95, 143–151. [Google Scholar] [CrossRef]

- Liu, C.; Pang, L.; Chen, W.L. SHPB Test of High-Strength Concrete. In Proceedings of the International Conference on Material Engineering & Application, Shanghai, China, 12–13 November 2016. [Google Scholar]

- Abbas, H.; Almusallam, T.; Al-Salloum, Y. Improving the impact resistance of reinforced concrete. Adv. Mater. Res. 2014, 919–921, 1924–1929. [Google Scholar] [CrossRef]

- Hao, Y.; Hao, H.; Jiang, G.P.; Zhou, Y. Experimental confirmation of some factors influencing dynamic concrete compressive strengths in high-speed impact tests. Cem. Concr. Res. 2013, 52, 63–70. [Google Scholar] [CrossRef]

- Chen, D.; Liu, F.; Yang, F.; Jin, L.; Feng, W.H.; Lv, J.B.; Luo, Q.Z. Dynamic compressive and splitting tensile response of unsaturated polyester polymer concrete material at different curing ages. Constr. Build. Mater. 2018, 177, 477–498. [Google Scholar] [CrossRef]

- Ross, C.A.; Tedesco, J.W.; Kuennen, S.T. Effects of strain-rate on concrete strength. ACI Mater. J. 1995, 92, 37–47. [Google Scholar]

- Xiao, S.Y.; Li, H.N.; Monteiro, P. Influence of strain rates and loading histories on the compressive damage behaviour of concrete. Mag. Concr. Res. 2011, 63, 915–926. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, R.; Shen, L.M.; Poon, C.S. Compressive behaviour of recycled aggregate concrete under impact loading. Cem. Concr. Res. 2015, 71, 46–55. [Google Scholar] [CrossRef]

- Guo, Y.C.; Xie, J.H.; Zheng, Y.W.; Li, J.L. Effects of steel slag as fine aggregate on static and impact behaviours of concrete. Constr. Build. Mater. 2018, 192, 194–201. [Google Scholar] [CrossRef]

- Liu, F.; Chen, G.F.; Li, L.J.; Guo, Y.C. Study of impact performance of rubber reinforced concrete. Constr. Build. Mater. 2012, 36, 604–616. [Google Scholar] [CrossRef]

- Li, W.G.; Luo, Z.Y.; Long, C.; Wu, C.Q.; Duan, W.H.; Shah, S.P. Effects of nanoparticle on the dynamic behaviors of recycled aggregate concrete under impact loading. Mater. Des. 2016, 112, 58–66. [Google Scholar] [CrossRef]

- Bischoff, P.H.; Perry, S.H. Compressive behavior of concrete at high strain rates. Mater. Struct. 1991, 24, 425–450. [Google Scholar] [CrossRef]

- Hao, Y.; Hao, H. Dynamic compressive behaviour of spiral steel fibre reinforced concrete in split Hopkinson pressure bar tests. Constr. Build. Mater. 2013, 48, 521–532. [Google Scholar] [CrossRef]

- Wu, Z.M.; Shi, C.J.; He, W.; Huang, D.H. Static and dynamic compressive properties of ultra-high performance concrete (UHPC) with hybrid steel fiber reinforcements. Cem. Concr. Compos. 2017, 79, 148–157. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Xie, A.Y.; Qi, Y.Z. Experimental study on dynamic mechanical properties and constitutive model of basalt fiber reinforced concrete. Constr. Build. Mater. 2017, 152, 154–167. [Google Scholar] [CrossRef]

- Li, W.G.; Luo, Z.; Wu, C.Q.; Duan, W.H. Impact performances of steel tube-confined recycled aggregate concrete (STCRAC) after exposure to elevated temperatures. Cem. Concr. Compos. 2018, 86, 87–97. [Google Scholar] [CrossRef]

- Mirmomeni, M.; Heidarpour, A.; Zhao, X.L.; Al-Mahaidi, R.; Packer, J.A. Size-dependency of concrete-filled steel tubes subject to impact loading. Int. J. Impact Eng. 2017, 100, 90–101. [Google Scholar] [CrossRef]

- Deng, Y.; Tuan, C.Y. Flexural behaviour of concrete-filled circular steer tubes under high strain-rate impact loading. J. Struct. Eng. 2012, 138, 449–456. [Google Scholar] [CrossRef]

- Shan, J.H.; Chen, R.; Zhang, W.X.; Xiao, Y.; Lu, F.Y. Behavior of concrete filled tubes and confined concrete filled tubes under high speed impact. Adv. Struct. Eng. 2007, 10, 209–218. [Google Scholar] [CrossRef]

- Xiao, Y.; Shen, Y. Impact behaviors of CFT and CFRP confined CFT stub columns. J. Compos. Constr. 2012, 16, 662–670. [Google Scholar]

- Pham, T.M.; Hao, H. Axial impact resistance of FRP-confined concrete. J. Compos. Constr. 2016, 21. [Google Scholar] [CrossRef]

- ASTM C469. Standard Test Method for Static Modulus of Elasticity and Poisson Ratio of Concrete in Compression; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM D3039. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials (D3039M); ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Teng, J.G.; Jiang, T.; Lam, L.; Luo, Y.Z. Refinement of a design-oriented stress-strain model for FRP-confined concrete. J. Compos. Constr. 2009, 13, 269–278. [Google Scholar] [CrossRef]

- Zeng, J.J.; Guo, Y.C.; Gao, W.Y.; Li, J.Z.; Xie, J.H. Behavior of partially and fully FRP-confined circularized square columns under axial compression. Constr. Build. Mater. 2017, 152, 319–332. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress–strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Lin, G.; Yu, T.; Teng, J.G. Design-oriented stress-strain model for concrete under combined FRP-steel confinement. J. Compos. Constr. 2015, 20, 04015084. [Google Scholar] [CrossRef]

- Pham, T.; Hadi, M.N.S. Confinement model for FRP confined normal- and high-strength concrete circular columns. Constr. Build. Mater. 2014, 69, 83–90. [Google Scholar] [CrossRef]

- The Fib Model Code for Concrete Structures 2010; International Federation for Structural Concrete: Lausanne, Switzerland, 2010.

- Hao, Y.; Hao, H. Influence of the concrete DIF model on the numerical predictions of RC wall responses to blast loadings. Eng. Struct. 2014, 73, 24–38. [Google Scholar] [CrossRef]

| 477.8 | 172.0 | 560.07 | 1190.1 | 5.0 | 71.2 | 0.0023 | 44.7 |

| Specimen | Tensile Strength (MPa) | Rupture Strain (%) | Modulus of Elasticity (GPa) | |||

|---|---|---|---|---|---|---|

| Test | Average | Test | Average | Test | Average | |

| S-A-1 | 2288.2 | 2350.7 | 1.33 | 1.32 | 172 | 177.7 |

| S-A-2 | 2533.5 | 1.42 | 178.4 | |||

| S-A-3 | 2230.5 | 1.22 | 182.8 | |||

| S-B-1 | 949.2 | 890.2 | 1.66 | 1.6 | 57.2 | 56.6 |

| S-B-2 | 910.5 | 1.62 | 56.2 | |||

| S-B-3 | 850.1 | 1.51 | 56.3 | |||

| S-C-1 | 4004.5 | 4021.8 | 1.66 | 1.67 | 241.2 | 241.3 |

| S-C-2 | 4080.9 | 1.69 | 241.5 | |||

| S-C-3 | 3980.1 | 1.65 | 241.2 | |||

| Specimen | or Test Average | or Test Average | FRP Hoop Rupture Strain Test Average | Modulus of Elasticity Test Average | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| S-0-1 | 70.55 | 71.21 | N.A. | 0.0023 | 0.0023 | N.A. | −0.0008 | −0.0007 | N.A. | 46.75 | 44.70 |

| S-0-2 | 71.87 | 0.0023 | −0.0007 | 44.31 | |||||||

| S-0-3 | 63.54 | 0.0024 | −0.0007 | 43.03 | |||||||

| S-B1-1 | 75.41 | 75.96 | 1.07 | 0.0030 | 0.0030 | 1.30 | −0.0013 | −0.0021 | 0.13 | 41.33 | 41.48 |

| S-B1-2 | 74.01 | 0.0031 | −0.0028 | 40.25 | |||||||

| S-B1-3 | 78.47 | 0.0030 | −0.0022 | 42.86 | |||||||

| S-B2-1 | 80.25 | 80.32 | 1.13 | 0.0031 | 0.0035 | 1.53 | −0.0028 | −0.0028 | 0.18 | 39.69 | 41.38 |

| S-B2-2 | 80.38 | 0.0039 | −0.0027 | 43.06 | |||||||

| S-B2-3 | 68.41 | 0.0030 | −0.0035 | 49.36 | |||||||

| S-B3-1 | 93.12 | 93.25 | 1.31 | 0.0079 | 0.0075 | 3.26 | −0.0132 | −0.0133 | 0.83 | 41.93 | 41.08 |

| S-B3-2 | 90.45 | 0.0070 | −0.0126 | 39.33 | |||||||

| S-B3-3 | 96.18 | 0.0077 | −0.0140 | 41.97 | |||||||

| S-A1-1 | 77.32 | 94.01 | 1.32 | 0.0038 | 0.0109 | 4.73 | −0.0052 | −0.0150 | 1.14 | 44.40 | 40.55 |

| S-A1-2 | 97.96 | 0.0115 | −0.0163 | 41.75 | |||||||

| S-A1-3 | 90.06 | 0.0102 | −0.0136 | 39.95 | |||||||

| S-A2-1 | 115.41 | 127.66 | 1.79 | 0.0138 | 0.0170 | 7.39 | −0.0131 | −0.0192 | 1.45 | 42.86 | 39.45 |

| S-A2-2 | 129.04 | 0.0171 | −0.0193 | 38.14 | |||||||

| S-A2-3 | 128.41 | 0.0169 | −0.0190 | 37.34 | |||||||

| S-A3-1 | 170.96 | 164.67 | 2.31 | 0.0192 | 0.0192 | 8.35 | −0.0194 | −0.0186 | 1.41 | 47.28 | 39.69 |

| S-A3-2 | 162.42 | 0.0176 | −0.0179 | 36.24 | |||||||

| S-A3-3 | 160.64 | 0.0209 | −0.0134 | 35.56 | |||||||

| S-C1-1 | 105.39 | 105.83 | 1.49 | 0.0114 | 0.0115 | 5.00 | −0.0130 | −0.0129 | 0.77 | 39.74 | 39.04 |

| S-C1-2 | 99.26 | 0.0114 | −0.0126 | 37.78 | |||||||

| S-C1-3 | 112.84 | 0.0116 | −0.0132 | 39.60 | |||||||

| S-C2-1 | 150.31 | 149.43 | 2.10 | 0.0198 | 0.0191 | 8.30 | −0.0161 | −0.0160 | 0.96 | 35.92 | 38.87 |

| S-C2-2 | 126.64 | 0.0152 | −0.0138 | 38.71 | |||||||

| S-C2-3 | 148.54 | 0.0183 | −0.0158 | 41.97 | |||||||

| S-C3-2 | 192.36 | 197.71 | 2.78 | 0.0183 | 0.0212 | 9.22 | −0.0150 | −0.0153 | 0.92 | 42.22 | 38.68 |

| S-C3-3 | 203.06 | 0.0241 | −0.0156 | 35.14 | |||||||

| Specimen | FRP Thickness | Launch Pressure (MPa) | Projectile Velocity | Strain Rate | Failure Pattern | |||

|---|---|---|---|---|---|---|---|---|

| D-0-1 | 0 | 0.30 | 4.398 | 31.81 | 61.51 | 0.0162 | 0.86 | A |

| D-0-2 | 0 | 0.40 | 5.608 | 52.02 | 73.55 | 0.0220 | 1.03 | B |

| D-0-3 | 0 | 0.40 | 5.930 | 62.05 | 78.27 | 0.0252 | 1.10 | B |

| D-0-4 | 0 | 0.45 | 6.411 | 84.24 | 87.64 | 0.0275 | 1.23 | B |

| D-0-5 | 0 | 0.50 | 7.083 | 120.94 | 99.75 | 0.0301 | 1.40 | B |

| D-B1-1 | 0.169 | 0.40 | 5.042 | 11.47 | 91.81 | 0.0079 | 1.21 | A |

| D-B1-2 | 0.169 | 0.50 | 6.190 | 34.67 | 106.83 | 0.0168 | 1.41 | A |

| D-B1-3 | 0.169 | 0.60 | 7.101 | 46.97 | 110.72 | 0.0195 | 1.46 | B+C |

| D-B1-4 | 0.169 | 0.70 | 9.569 | 88.52 | 114.38 | 0.0383 | 1.51 | B+C |

| D-B1-5 | 0.169 | 0.70 | 9.820 | 112.93 | 120.72 | 0.0458 | 1.59 | B+C |

| D-B2-1 | 0.338 | 0.50 | 6.239 | 24.46 | 102.70 | 0.0134 | 1.28 | A |

| D-B2-2 | 0.338 | 0.60 | 7.570 | 46.81 | 113.85 | 0.0188 | 1.42 | A |

| D-B2-3 | 0.338 | 0.70 | 9.161 | 69.56 | 125.23 | 0.0298 | 1.56 | B+C |

| D-B2-4 | 0.338 | 0.80 | 10.775 | 97.80 | 129.46 | 0.0423 | 1.61 | B+C |

| D-B2-5 | 0.338 | 0.90 | 11.061 | 128.31 | 141.35 | 0.0526 | 1.76 | B+C |

| D-B3-1 | 0.507 | 0.45 | 5.958 | 16.03 | 103.05 | 0.0146 | 1.11 | A |

| D-B3-2 | 0.507 | 0.60 | 8.405 | 45.59 | 120.21 | 0.0198 | 1.29 | A |

| D-B3-3 | 0.507 | 0.70 | 9.308 | 65.16 | 131.65 | 0.0289 | 1.41 | A |

| D-B3-4 | 0.507 | 0.70 | 9.569 | 76.61 | 133.60 | 0.0373 | 1.43 | A |

| D-B3-5 | 0.507 | 0.90 | 11.089 | 103.89 | 135.45 | 0.0462 | 1.45 | B+C |

| D-B3-6 | 0.507 | 0.95 | 11.296 | 121.87 | 139.15 | 0.0483 | 1.49 | B+C |

| D-A1-1 | 0.167 | 0.40 | 4.746 | 17.58 | 93.73 | 0.0082 | 1.00 | A |

| D-A1-2 | 0.167 | 0.50 | 6.503 | 30.24 | 111.64 | 0.0102 | 1.19 | A |

| D-A1-3 | 0.167 | 0.55 | 7.595 | 40.02 | 114.97 | 0.0173 | 1.22 | A |

| D-A1-4 | 0.167 | 0.60 | 7.919 | 42.26 | 121.97 | 0.0216 | 1.30 | B+C |

| D-A1-5 | 0.167 | 0.70 | 8.984 | 51.59 | 124.04 | 0.0289 | 1.32 | B+C |

| D-A2-1 | 0.334 | 0.50 | 7.340 | 22.03 | 123.69 | 0.0177 | 0.97 | A |

| D-A2-2 | 0.334 | 0.60 | 7.998 | 34.24 | 133.66 | 0.0190 | 1.05 | A |

| D-A2-3 | 0.334 | 0.70 | 9.242 | 51.92 | 145.76 | 0.0231 | 1.14 | A |

| D-A2-4 | 0.334 | 0.80 | 10.124 | 65.04 | 151.13 | 0.0251 | 1.18 | B+C |

| D-A2-5 | 0.334 | 0.85 | 10.931 | 78.90 | 158.57 | 0.0324 | 1.24 | B+C |

| D-A3-1 | 0.501 | 0.70 | 9.640 | 27.68 | 155.50 | 0.0212 | 0.94 | A |

| D-A3-2 | 0.501 | 0.90 | 11.028 | 37.98 | 165.50 | 0.0272 | 1.00 | A |

| D-A3-3 | 0.501 | 0.95 | 11.540 | 45.82 | 168.63 | 0.0320 | 1.02 | B+C |

| D-A3-4 | 0.501 | 1.00 | 12.059 | 60.73 | 181.23 | 0.0328 | 1.10 | B+C |

| D-A3-5 | 0.501 | 1.05 | 12.236 | 65.87 | 183.10 | 0.0343 | 1.11 | B+C |

| D-C1-1 | 0.167 | 0.50 | 6.563 | 13.41 | 113.43 | 0.0094 | 1.07 | A |

| D-C1-2 | 0.167 | 0.55 | 6.962 | 21.89 | 118.39 | 0.0178 | 1.12 | A |

| D-C1-3 | 0.167 | 0.70 | 9.004 | 49.95 | 126.05 | 0.0266 | 1.19 | B+C |

| D-C1-4 | 0.167 | 0.75 | 9.265 | 67.47 | 128.25 | 0.0315 | 1.21 | B+C |

| D-C1-5 | 0.167 | 0.80 | 10.479 | 100.68 | 130.81 | 0.0340 | 1.24 | B+C |

| D-C2-1 | 0.334 | 0.70 | 8.936 | 21.13 | 151.77 | 0.0178 | 1.02 | A |

| D-C2-2 | 0.334 | 0.80 | 9.631 | 28.54 | 153.23 | 0.0233 | 1.03 | A |

| D-C2-3 | 0.334 | 0.85 | 9.888 | 50.22 | 157.92 | 0.0254 | 1.06 | A |

| D-C2-4 | 0.334 | 0.90 | 10.914 | 78.10 | 162.18 | 0.0266 | 1.09 | B+C |

| D-C2-5 | 0.334 | 0.95 | 11.778 | 96.86 | 163.95 | 0.0336 | 1.10 | B+C |

| D-C3-1 | 0.501 | 0.80 | 10.282 | 29.98 | 155.05 | 0.0211 | 0.78 | A |

| D-C3-2 | 0.501 | 0.85 | 10.411 | 42.73 | 169.43 | 0.0222 | 0.86 | A |

| D-C3-3 | 0.501 | 0.90 | 11.441 | 53.91 | 179.11 | 0.0247 | 0.91 | A |

| D-C3-4 | 0.501 | 1.00 | 12.221 | 62.70 | 183.68 | 0.0259 | 0.93 | A |

| D-C3-5 | 0.501 | 1.05 | 13.149 | 74.87 | 192.95 | 0.0269 | 0.98 | B+C |

| Specimen Size d × h/mm | FRP Type | FRP Thickness | Impact Pressure (MPa) | Strain Rate | ||||

|---|---|---|---|---|---|---|---|---|

| 150 × 75 | - | 0 | 0.3 | 22.9 | 76.9 | 62.2 | 0.8 | |

| 150 × 75 | - | 0 | 0.3 | 20.4 | 76.9 | 72.7 | 0.9 | |

| 150 × 75 | - | 0 | 0.3 | 20.2 | 76.9 | 69.1 | 0.9 | |

| 150 × 75 | - | 0 | 0.7 | 50.3 | 76.9 | 82 | 1.1 | |

| 150 × 75 | - | 0 | 0.7 | 43.5 | 76.9 | 82.4 | 1.1 | |

| 150 × 75 | - | 0 | 0.7 | 45.3 | 76.9 | 87.6 | 1.1 | |

| 150 × 75 | - | 0 | 1.0 | 76.6 | 76.9 | 96.3 | 1.3 | |

| 150 × 75 | - | 0 | 1.0 | 72.3 | 76.9 | 86.8 | 1.1 | |

| 150 × 75 | - | 0 | 1.0 | 70.3 | 76.9 | 98.1 | 1.3 | |

| 150 × 75 | CFRP | 0.167 | 0.3 | 4.2 | 110.4 | 92.6 | 0.8 | |

| 150 × 75 | CFRP | 0.167 | 0.3 | 4 | 110.4 | 96.5 | 0.9 | |

| 150 × 75 | CFRP | 0.167 | 0.3 | 4.4 | 110.4 | 95.9 | 0.9 | |

| 150 × 75 | CFRP | 0.167 | 0.7 | 46.1 | 110.4 | 98.3 | 0.9 | |

| 150 × 75 | CFRP | 0.167 | 0.7 | 43.3 | 110.4 | 107.5 | 1.0 | |

| 150 × 75 | CFRP | 0.167 | 0.7 | 48.9 | 110.4 | 97.5 | 0.9 | |

| Xiong et al. [32] | 150 × 75 | CFRP | 0.167 | 1.0 | 57.6 | 110.4 | 108 | 1.0 |

| 150 × 75 | CFRP | 0.167 | 1.0 | 60.4 | 110.4 | 107.5 | 1.0 | |

| 150 × 75 | CFRP | 0.167 | 1.0 | 65.5 | 110.4 | 97.5 | 1.0 | |

| 150 × 75 | CFRP | 0.167 | 1.0 | 65.5 | 110.4 | 97.5 | 1.0 | |

| 150 × 75 | CFRP | 0.334 | 0.3 | 3.2 | 131.1 | 97.5 | 0.7 | |

| 150 × 75 | CFRP | 0.334 | 0.3 | 3.5 | 131.1 | 96.6 | 0.7 | |

| 150 × 75 | CFRP | 0.334 | 0.3 | 2.8 | 131.1 | 97.6 | 0.7 | |

| 150 × 75 | CFRP | 0.334 | 0.7 | 42.2 | 131.1 | 123.1 | 0.9 | |

| 150 × 75 | CFRP | 0.334 | 0.7 | 40 | 131.1 | 118.3 | 0.9 | |

| 150 × 75 | CFRP | 0.334 | 0.7 | 36.7 | 131.1 | 124.7 | 1.0 | |

| 150 × 75 | CFRP | 0.334 | 1.0 | 55 | 131.1 | 131.7 | 1.0 | |

| 150 × 75 | CFRP | 0.334 | 1.0 | 56.7 | 131.1 | 125.9 | 1.0 | |

| 150 × 75 | CFRP | 0.334 | 1.0 | 60.6 | 131.1 | 120.8 | 0.9 | |

| 150 × 75 | CFRP | 0.501 | 0.3 | 3 | 147.4 | 102 | 0.7 | |

| 150 × 75 | CFRP | 0.501 | 0.3 | 3.1 | 147.4 | 98.1 | 0.7 | |

| 150 × 75 | CFRP | 0.501 | 0.3 | 2.8 | 147.4 | 97.6 | 0.7 | |

| 150 × 75 | CFRP | 0.501 | 0.7 | 5.7 | 147.4 | 127.6 | 0.9 | |

| 150 × 75 | CFRP | 0.501 | 0.7 | 6.5 | 147.4 | 136.5 | 0.9 | |

| 150 × 75 | CFRP | 0.501 | 0.7 | 4.1 | 147.4 | 124.4 | 0.8 | |

| 150 × 75 | CFRP | 0.501 | 1.0 | 34.4 | 147.4 | 145.5 | 1.0 | |

| 150 × 75 | CFRP | 0.501 | 1.0 | 32.2 | 147.4 | 151.6 | 1.0 | |

| 150 × 75 | CFRP | 0.501 | 1.0 | 34.6 | 147.4 | 143.7 | 1.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Z.; Duan, Z.; Guo, Y.; Li, X.; Zeng, J. Behavior of Fiber-Reinforced Polymer-Confined High-Strength Concrete under Split-Hopkinson Pressure Bar (SHPB) Impact Compression. Appl. Sci. 2019, 9, 2830. https://doi.org/10.3390/app9142830

Xie Z, Duan Z, Guo Y, Li X, Zeng J. Behavior of Fiber-Reinforced Polymer-Confined High-Strength Concrete under Split-Hopkinson Pressure Bar (SHPB) Impact Compression. Applied Sciences. 2019; 9(14):2830. https://doi.org/10.3390/app9142830

Chicago/Turabian StyleXie, Zhihong, Zhijian Duan, Yongchang Guo, Xiang Li, and Junjie Zeng. 2019. "Behavior of Fiber-Reinforced Polymer-Confined High-Strength Concrete under Split-Hopkinson Pressure Bar (SHPB) Impact Compression" Applied Sciences 9, no. 14: 2830. https://doi.org/10.3390/app9142830

APA StyleXie, Z., Duan, Z., Guo, Y., Li, X., & Zeng, J. (2019). Behavior of Fiber-Reinforced Polymer-Confined High-Strength Concrete under Split-Hopkinson Pressure Bar (SHPB) Impact Compression. Applied Sciences, 9(14), 2830. https://doi.org/10.3390/app9142830