Reviews on Corrugated Diaphragms in Miniature Fiber-Optic Pressure Sensors

Abstract

1. Introduction

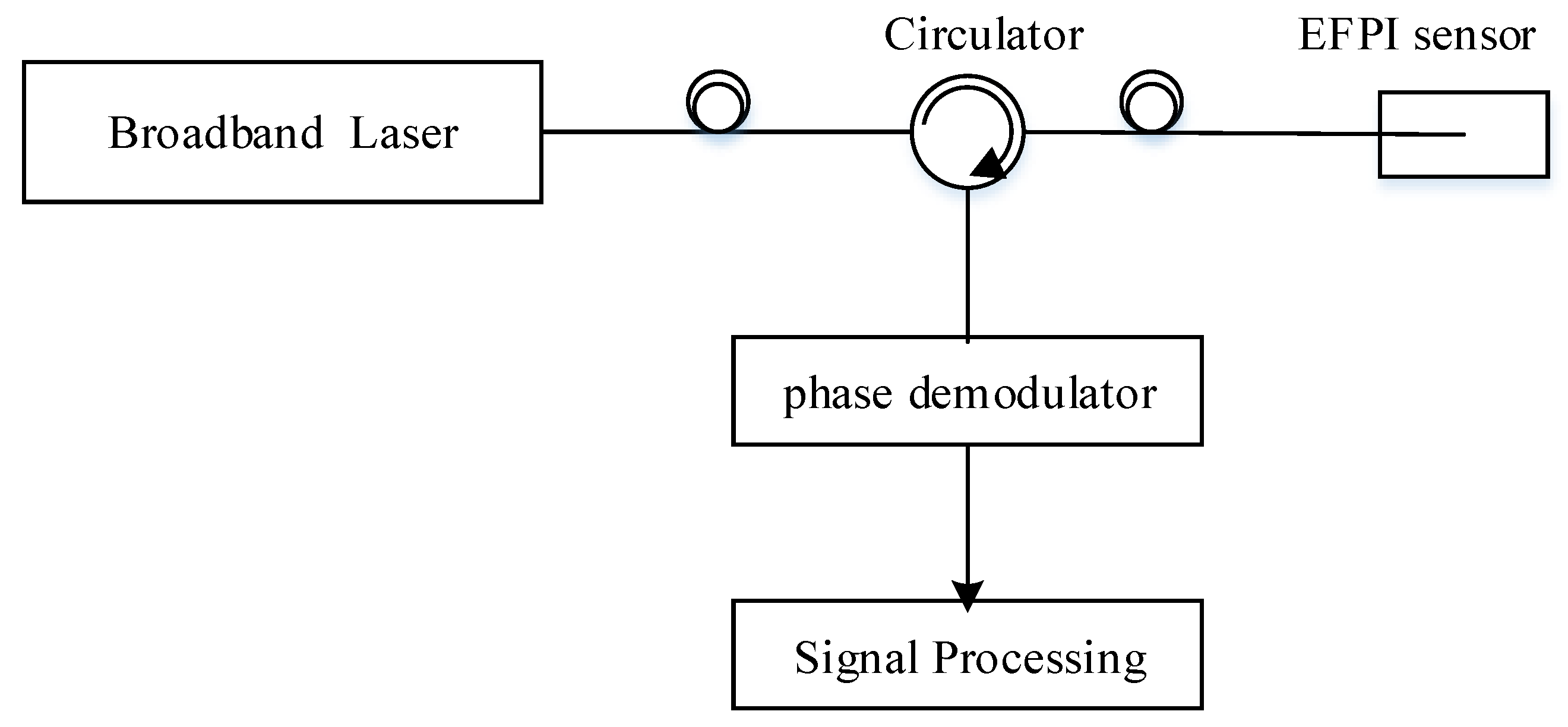

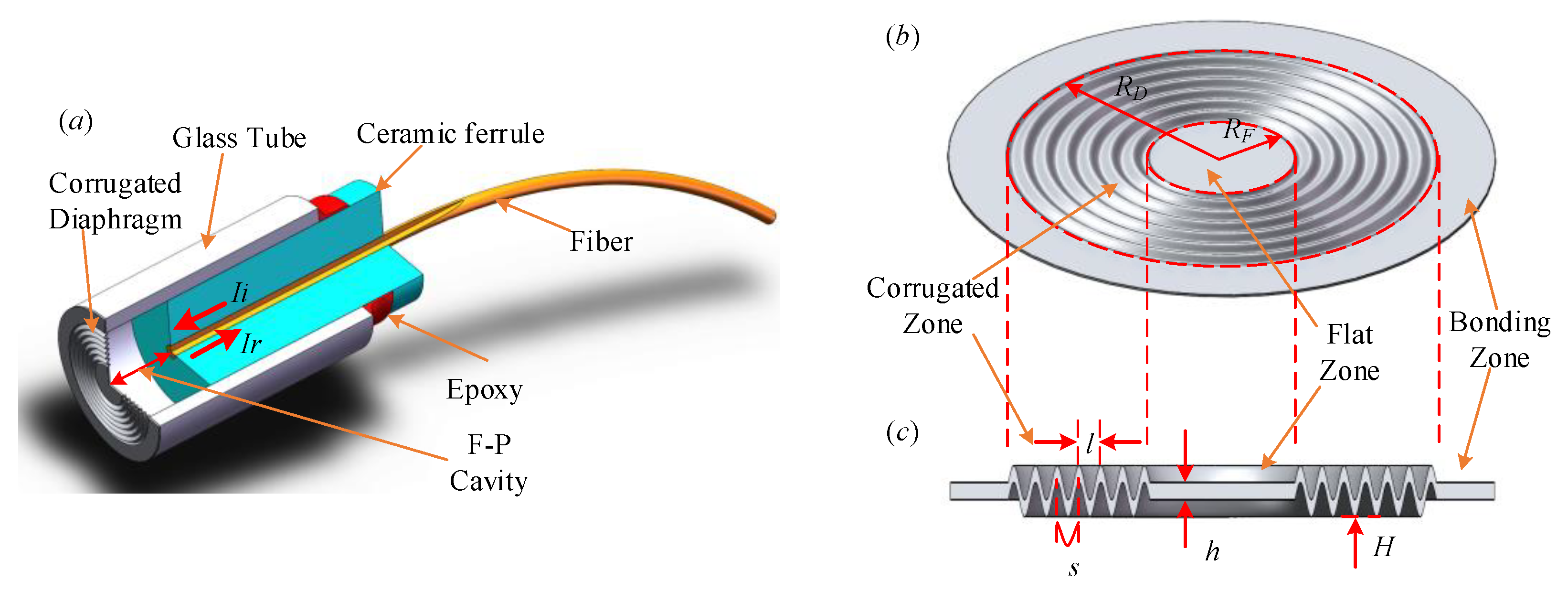

2. The Principles of Operation of Miniature Fiber-Optic Pressure Sensors

2.1. The Basic Principles of EFPI Pressure Sensors

2.2. Demodulation Methods of EFPI Sensors

2.2.1. Intensity demodulation

2.2.2. Phase demodulation

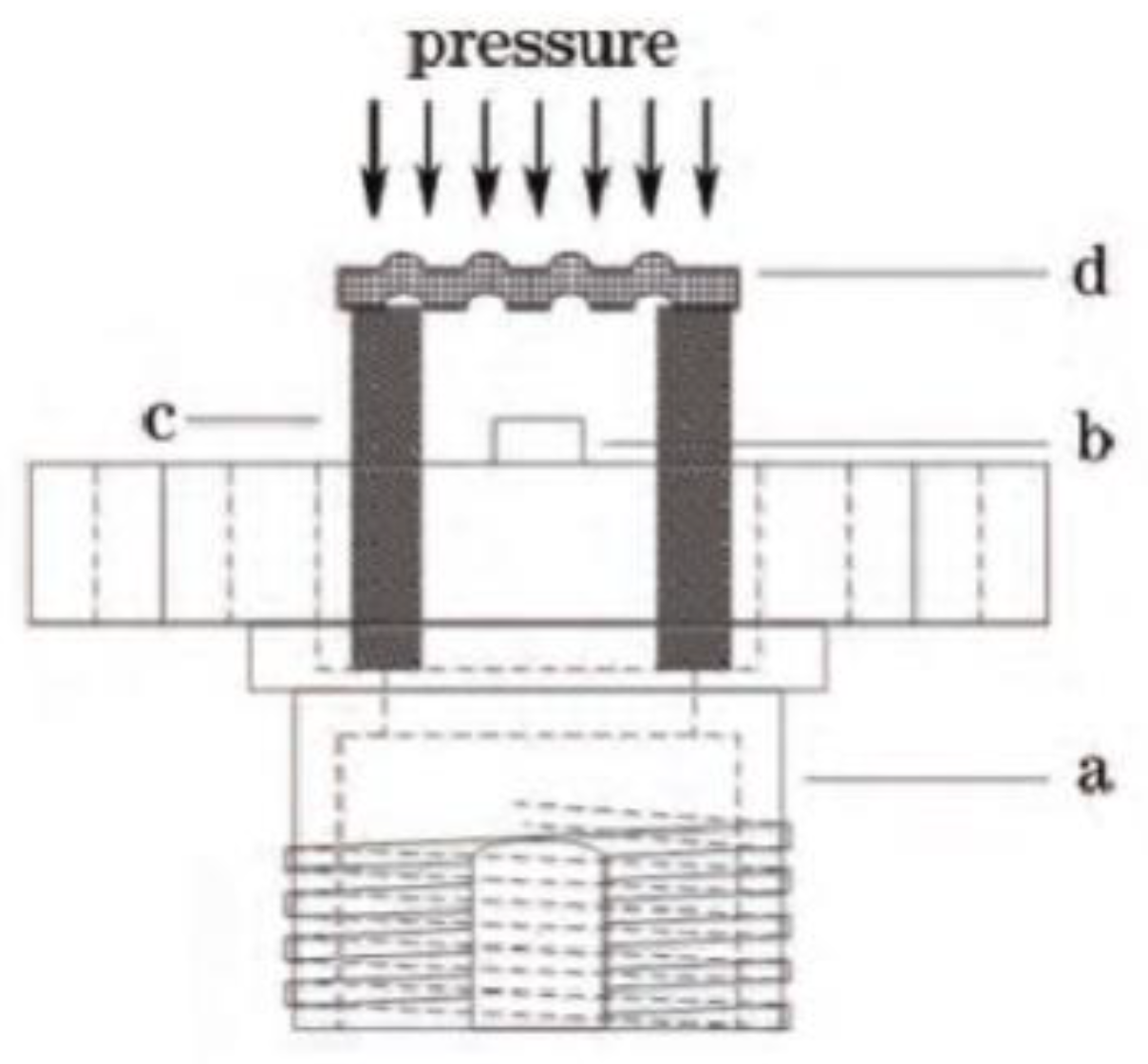

3. The Mechanical Properties of Diaphragms

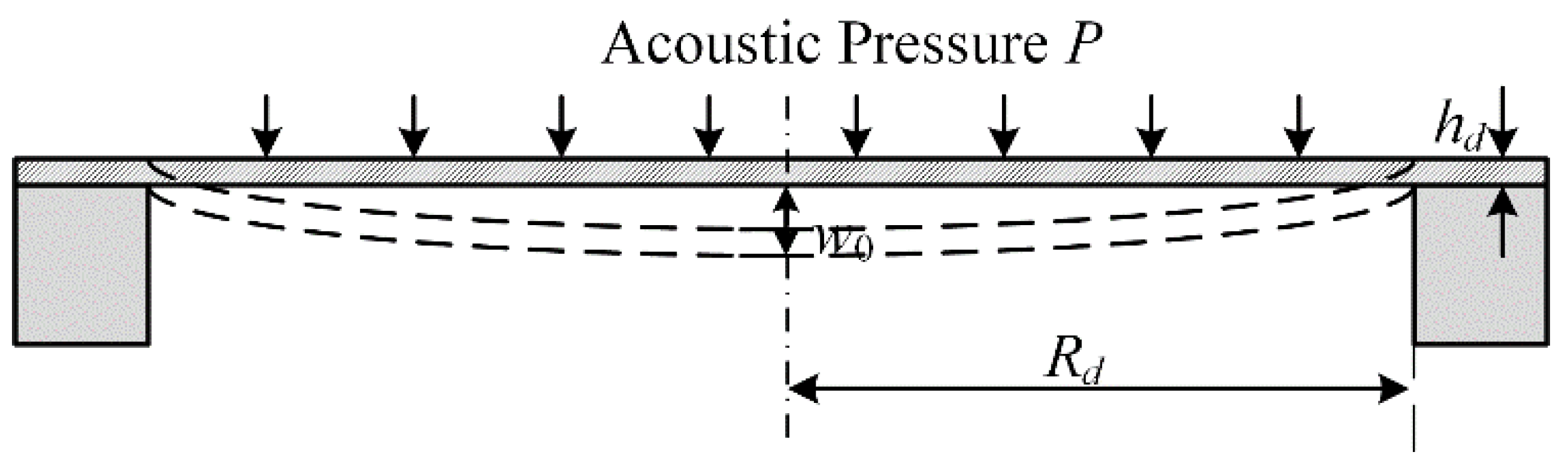

3.1. Mechanical Properties of the FD

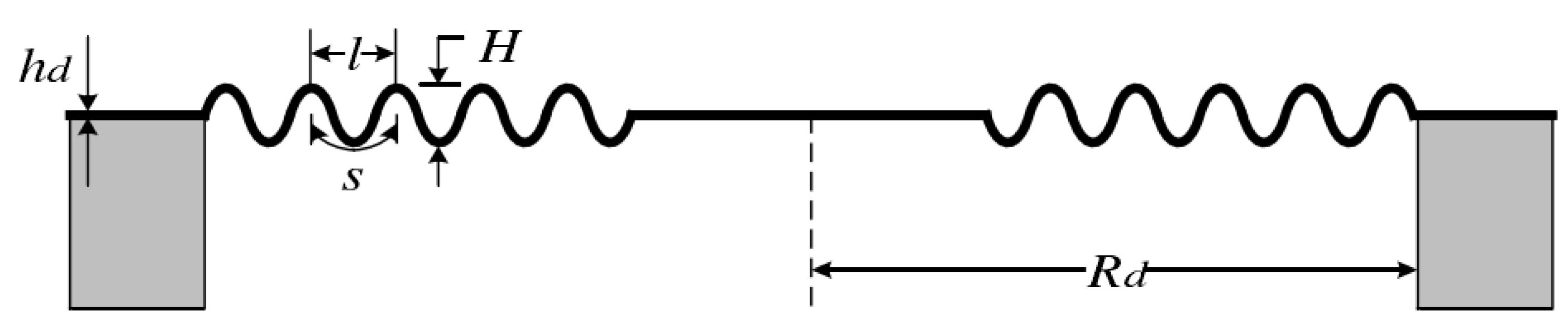

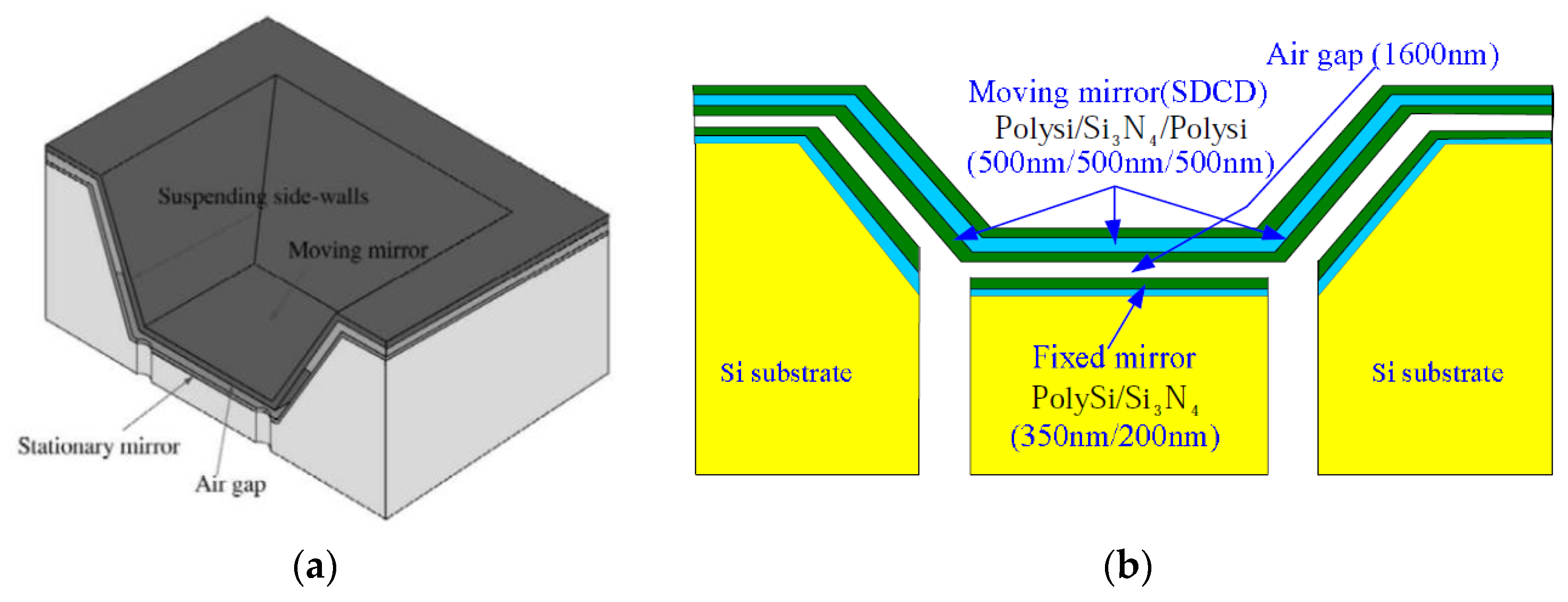

3.2. Mechanical Properties of the SCD

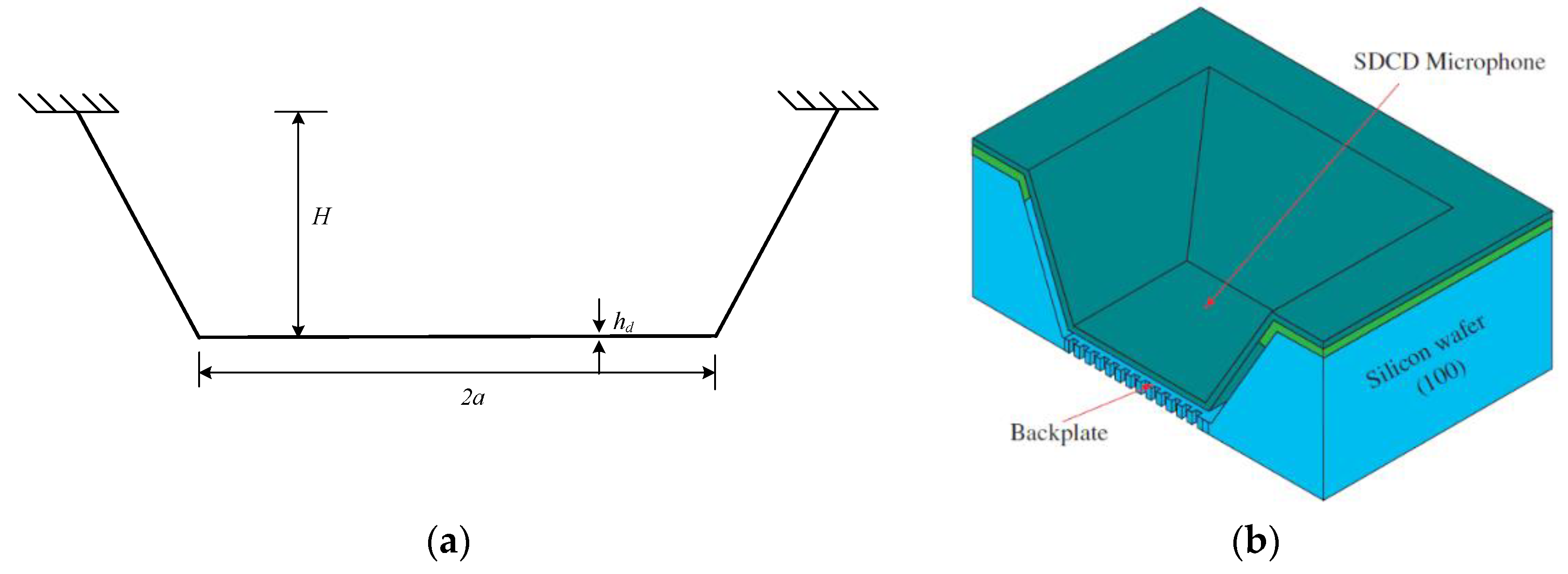

3.3. Mechanical Properties of the single deep corrugated diaphragm (SDCD)

3.4. Influences on the Performance of the Sensor

4. The Application of CDs in Miniature Fiber-Optic Pressure Sensors

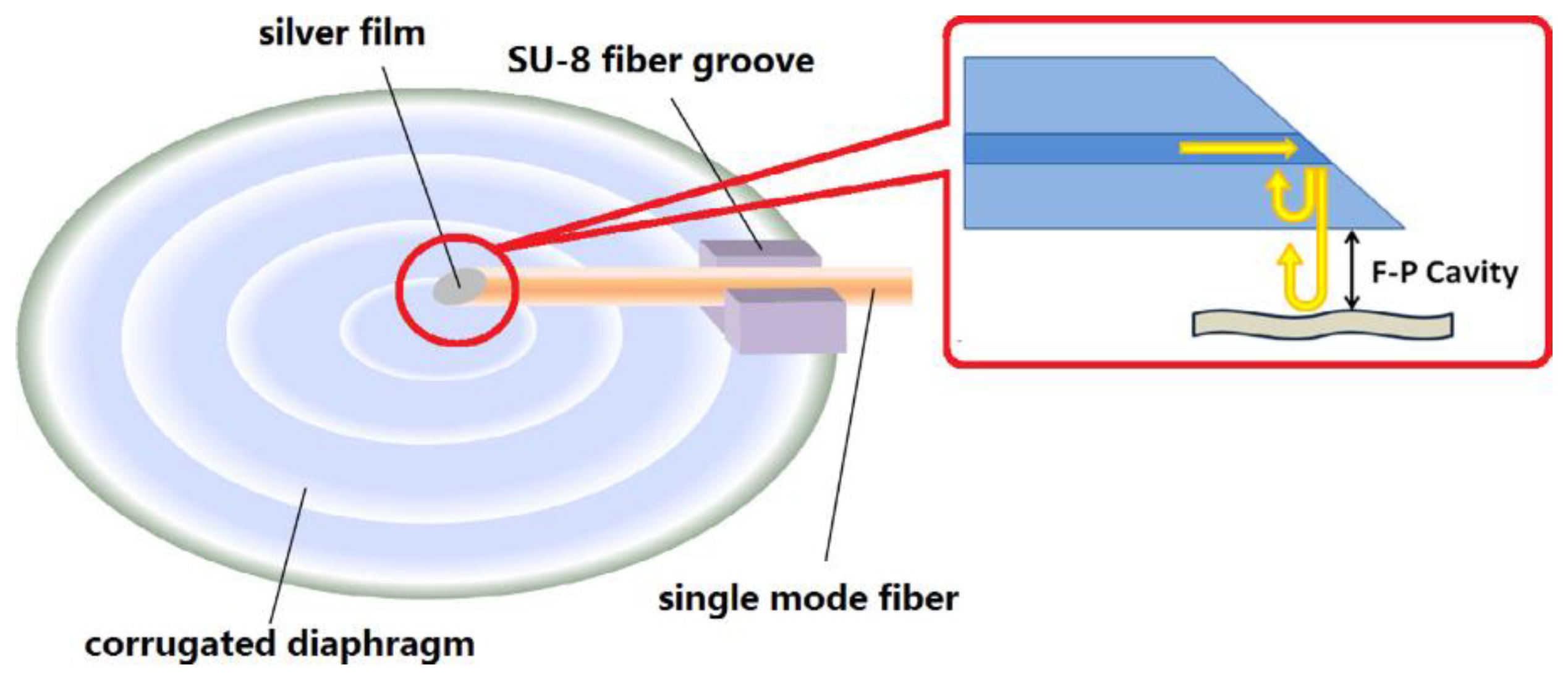

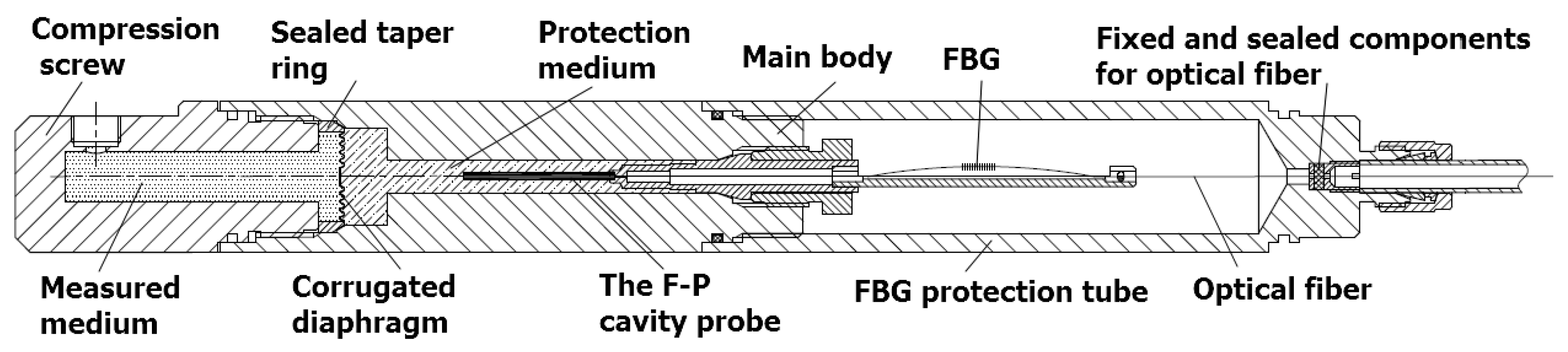

4.1. In the Miniature Fiber-Optic Static Pressure Sensors

4.2. In the Miniature Fiber-Optic Acoustic Pressure Sensors

5. Conclusions

- The fabrication of CDs: At present, almost all CDs are fabrication by MEMS technology, including photolithography, thin film technology, etching technology, and so on. Some of the processing parameters are difficult to control accurately, which makes the center area of the CD uneven, resulting in a reduction in the accuracy and consistency of the CD, and seriously affecting the performance of the sensor. It could be said that the manufacturing technology is currently the main factor that limits the practical application of the CD-based miniature fiber-optic pressure sensor.

- The bonding method of the sensor: At present, most components of the CD-based miniature fiber-optic pressure sensor are fixed by curing glue. Due to the large thermal expansion coefficient of the curing gel, the sensor’s performance is greatly affected by temperature, and the length of the F-P cavity will be changed during the use, which makes the temperature-pressure crossover sensitivity of the sensor large, limiting the high temperature performance of the sensor.

- The packaging of the sensor: At present, MEMS devices mainly use chip-level packaging, that is, dicing before releasing, which can avoid damage to the diaphragm in dicing process, but this method cannot be mass-produced, and the size of the product is large with high cost.

- For the existing problems, the following improvements can be made:

- Develop more suitable and easy-to-control MEMS technology to reduce the difficulty of controlling technological parameters and improve the accuracy and consistency of the CD.

- Develop new diaphragm materials, design new structures of diaphragm and sensor to improve the performance of diaphragm-based pressure sensors to meet the needs of different application environments.

- Consider the packaging of the sensor according to the actual situation, select the appropriate bonding method, and use wafer-level packaging which releases the diaphragm first and then performs dicing, so as to improve the production efficiency.

- Consider the integration of a temperature sensor with the pressure sensor to compensate for the influence of temperature change on the performance of the sensor.

Author Contributions

Funding

Conflicts of Interest

References

- Qiao, X.G.; Shao, Z.H.; Bao, W.J.; Rong, Q.Z. Fiber-optic ultrasonic sensors and applications. Acta Phys. Sin. 2017, 66, 074205. [Google Scholar] [CrossRef]

- Zhou, W.; Hou, W.; Zhang, H. Development and Application of Fiber-optic Pressure Sensor in Medical Field. Zhongguo Yi Liao Qi Xie Za Zhi 2018, 42, 354–356. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.N. Study on the Optical Fiber EFPI Sensor System and Its Applications in Gas and Oil Well. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2008. [Google Scholar]

- Wooler, J.P.; Crickmore, R.I. Fiber-optic microphones for battlefield acoustics. Appl. Opt. 2007, 46, 2486–2491. [Google Scholar] [CrossRef]

- López-Higuera, J.M.; Jones, J.D.C.; López-Amo, M.; Santos, J.L.; Krisch, H.; Niermann, B.; Gedikli, A.; Tenderenda, T.; Nasilowski, T. Advanced photonic vortex flowmeter with interferometer sensor for measurement of wide dynamic range of medium velocity at high temperature and high pressure. In Proceedings of the 23rd International Conference on Optical Fibre Sensors, Santander, Spain, 2–6 June 2014. [Google Scholar]

- Jindal, S.K.; Raghuwanshi, S.K.; Kumar, A. Realization of MOEMS pressure sensor using mach zehnder interferometer. J. Mech. Sci. Technol. 2015, 29, 3831–3839. [Google Scholar] [CrossRef]

- Thondagere, C.; Kaushalram, A.; Srinivas, T.; Hegde, G. Mathematical modeling of optical MEMS differential pressure sensor using waveguide Bragg gratings embedded in Mach Zehnder interferometer. J. Opt. 2018, 20, 085802. [Google Scholar] [CrossRef]

- Liu, L.; Lu, P.; Wang, S.; Liao, H. A Novel Acoustic Sensor Based on a PP/PET Diaphragm. In Proceedings of the 2015 Opto-Electronics and Communications Conference (Oecc), Shanghai, China, 28 June–2 July 2015. [Google Scholar]

- Liao, H.; Lu, P.; Liu, D.; Liu, L.; Zhang, J. Demodulation Of Diaphragm Based Fiber-optic Acoustic Sensor Using with Symmetric 3 × 3 Coupler. In Proceedings of the 2017 Opto-Electronics and Communications Conference (OECC) and Photonics Global Conference (PGC), Singapore, 31 July–4 Aug 2017. [Google Scholar]

- Ma, J.; Yu, Y.; Jin, W. Demodulation of diaphragm based acoustic sensor using Sagnac interferometer with stable phase bias. Opt. Express 2015, 23, 29268–29278. [Google Scholar] [CrossRef]

- Fu, X.; Lu, P.; Ni, W.; Liu, L.; Liao, H.; Liu, D.; Zhang, J. Intensity Demodulation Based Fiber Sensor for Dynamic Measurement of Acoustic Wave and Lateral Pressure Simultaneously. IEEE Photonics J. 2016, 8, 1–13. [Google Scholar] [CrossRef]

- Li, X.; Zhen, S.; Qian, K.; Liang, X.; Wang, X.; Shi, J.; Wu, X.; Yu, B. A heat-resistance and high-sensitivity acoustic pressure sensor based on aluminum-polyimide diaphragm. Sens. Actuators A Phys. 2018, 279, 75–78. [Google Scholar] [CrossRef]

- Han, M.; Wang, X.W.; Xu, J.C.; Cooper, K.L.; Wang, A.B. Diaphragm-based extrinsic Fabry-Perot interferometric optical fiber sensor for acoustic wave detection under high background pressure. Opt. Eng. 2005, 44. [Google Scholar] [CrossRef]

- Chen, L.H.; Chan, C.C.; Yuan, W.; Goh, S.K.; Sun, J. High performance chitosan diaphragm-based fiber-optic acoustic sensor. Sens. Actuators A Phys. 2010, 163, 42–47. [Google Scholar] [CrossRef]

- Gong, Z.; Chen, K.; Zhou, X.; Yang, Y.; Zhao, Z.; Zou, H.; Yu, Q. High-Sensitivity Fabry-Perot Interferometric Acoustic Sensor for Low-Frequency Acoustic Pressure Detections. J. Lightwave Technol. 2017, 35, 5276–5279. [Google Scholar] [CrossRef]

- Liu, B. Research on the Key Technologies of Micro Fiber Acoustic Sensor Based on Fabry-Perot Interferometer. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Wang, A.L. Research on the Influence of Corrugated Structure on The Performance of Diaphragm-based EFPI Fiber Acoustic Sensor. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Rao, Y.J.; Jackson, D.A. Prototype fiber-optic-based pressure probe with built-in temperature compensation with signal recovery by coherence reading. Appl. Opt. 1993, 32, 7110–7113. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhu, J.L.; Li, Z.Y.; W, M. Optical Fiber Fabry-Perot Pressure Sensor Using Corrugated Diaphragm. Acta Optica Sinica 2016, 36, 0306002:1–0306002:5. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, M.; Chen, L.; Ni, X.; Ni, H. An optical fiber Fabry–Perot pressure sensor using corrugated diaphragm and angle polished fiber. Opt. Fiber Technol. 2017, 34, 42–46. [Google Scholar] [CrossRef]

- Zhao, Z.-S.; Liao, Y.; Grattan, K.T.; Wang, W.; Jiang, D.; Zhang, W.; Wei, L.; Zhao, W.; Zhao, Q.; Wang, H.; et al. Design of fiber optic F-P cavity pressure sensor based on corrugated diaphragm. In Proceedings of the AOPC 2017: Fiber Optic Sensing and Optical Communications, Beijing, China, 4–6 June 2017. [Google Scholar]

- Dagang, G.; Po, S.N.C.; Hock, F.T.E.; Rongming, L. Design and Optimization of Dual Optical Fiber MEMS Pressure Sensor for Biomedical Applications. J. Phys. Conf. Ser. 2006, 34, 1073–1078. [Google Scholar] [CrossRef]

- Sharawi, A.A.; Aouf, M.; Kareem, G.; Elhag Osman, A.H. Sensitivity Improvement of Micro-diaphragm Deflection for Pulse Pressure Detection. In International Conference on Advanced Intelligent Systems and Informatics; Springer: Cham, Switzerland, 2018; pp. 137–151. [Google Scholar]

- Gong, K. Study on Fabrication of Fiber-Optic Sensor Based on Film by MEMS Technology and Its Application. Master’s Thesis, Anhui University, Hefei, China, 2015. [Google Scholar]

- Cheng, J.M. The Design and Experimental Study of Interferometric Microstructure Fiber Optic Sensor. Master’s Thesis, Anhui University, Hefei, China, 2018. [Google Scholar]

- Liu, B.; Zhou, H.; Liu, L.; Wang, X.; Shan, M.; Jin, P.; Zhong, Z. An Optical Fiber Fabry-Perot Microphone Based on Corrugated Silver Diaphragm. IEEE Trans. Instrum. Meas. 2018, 67, 1994–2000. [Google Scholar] [CrossRef]

- Lu, X.; Wu, Y.; Gong, Y.; Rao, Y. A Miniature Fiber-Optic Microphone Based on an Annular Corrugated MEMS Diaphragm. J. Lightwave Technol. 2018, 36, 5224–5229. [Google Scholar] [CrossRef]

- Tian, J.; Zhang, Q.; Fink, T.; Li, H.; Peng, W.; Han, M. Tuning operating point of extrinsic Fabry-Perot interferometric fiber-optic sensors using microstructured fiber and gas pressure. Opt. Lett. 2012, 37, 4672–4674. [Google Scholar] [CrossRef]

- Chen, J.; Chen, D.; Geng, J.; Li, J.; Cai, H.; Fang, Z. Stabilization of optical Fabry-Perot sensor by active feedback control of diode laser. Sens. Actuators A Phys. 2008, 148, 376–380. [Google Scholar] [CrossRef]

- Wang, A.; May, R.G.; Wang, A.; Xiao, H.; Deng, J.; Huo, W.; Wang, Z. SCIIB pressure sensors for oil extraction applications. In Proceedings of the Harsh Environment Sensors II, Boston, MA, USA, 8 December 1999; pp. 29–35. [Google Scholar]

- Zhang, G.; Yu, Q.; Song, S. An investigation of interference/intensity demodulated fiber-optic Fabry-Perot cavity sensor. Sens. Actuators A Phys. 2004, 116, 33–38. [Google Scholar] [CrossRef]

- Murphy, K.A.; Gunther, M.F.; Vengsarka, A.M.; Claus, R.O. Quadrature phase-shifted, extrinsic Fabry-Perot optical fiber sensors. Opt. Lett. 1991, 16, 273–275. [Google Scholar] [CrossRef] [PubMed]

- Dahlem, M.; Santos, J.L.; Ferreira, L.A.; Araújo, F.M. Passive interrogation of low-finesse Fabry-Perotcavities using fiber Bragg gratings. IEEE Photonics Technol. Lett. 2001, 13, 990–992. [Google Scholar] [CrossRef]

- Schmidt, M.; Fürstenau, N. Fiber-optic extrinsic Fabry-Perot interferometer sensors with three-wavelength digital phase demodulation. Opt. Lett. 1999, 24, 599–601. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y. High-resolution interrogation technique for fiber optic extrinsic Fabry–Perot interferometric sensors by the peak-to-peak method. Appl. Opt. 2008, 47, 925–932. [Google Scholar] [CrossRef] [PubMed]

- Mei, J.; Xiao, X.; Yang, C. High-resolution and large dynamic range fiber extrinsic Fabry-Perot sensing by multi-extrema-tracing technique. Appl. Opt. 2015, 54. [Google Scholar] [CrossRef]

- Jiang, Y. Fourier Transform White-Light Interferometry for the Measurement of Fiber-Optic Extrinsic Fabry-Perot Interferometric Sensors. IEEE Photonics Technol. Lett. 2008, 20, 75–77. [Google Scholar] [CrossRef]

- Rao, Y.J.; Wang, X.J.; Zhu, T.; Zhou, C.X. Demodulation algorithm for spatial-frequency-division-multiplexed fiber-optic Fizeau strain sensor networks. Opt. Lett. 2006, 31, 700–702. [Google Scholar] [CrossRef]

- Wang, W.; Hu, Z.; Jiang, P.; Li, G.; Hu, Y. Breaking through the intensity restriction of the asymmetric fiber Bragg grating based Fabry-Perot sensitivity enhancement system. In Proceedings of the 7th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Smart Structures and Materials for Manufacturing and Testing, Harbin, China, 26–29 April 2014. [Google Scholar]

- Wang, F.; Xie, J.; Hu, Z.; Xiong, S.; Luo, H.; Hu, Y. Interrogation of Extrinsic Fabry-Perot Sensors Using Path-Matched Differential Interferometry and Phase Generated Carrier Technique. J. Lightwave Technol. 2015, 33, 2392–2397. [Google Scholar] [CrossRef]

- Jerman, J.H. The Fabrication and Use Of Micromachined Corrugated Silicon Diaphragms. Sens. Actuators A Phys. 1990, 23, 988–992. [Google Scholar] [CrossRef]

- Scheeper, P.R.; Olthuis, W.; Bergveld, P. The Design, Fabrication, and Testing of Corrugated Silicon Nitride Diaphragms. J. Microelectromech. Syst. 1994, 3, 36–42. [Google Scholar] [CrossRef]

- Beeby, S.; Ensel, G.; Kraft, M. MEMS Mechanical Sensors; Artech House: Norwood, MA, USA, 2004. [Google Scholar]

- Zou, Q.B.; Liu, L.T.; Li, Z.J. Study of Corrugated Diaphragms Used in Silicon Condenser Microphones. Chin. J. Semicond. 1996, 17, 907–913. [Google Scholar]

- Wang, W.J.; Lin, R.M.; Li, X.; Guo, D.G. Study of single deeply corrugated diaphragms for high-sensitivity microphones. J. Micromech. Microeng. 2003, 13, 184–189. [Google Scholar] [CrossRef]

- Wang, W.J.; Lin, R.M.; Zou, Q.B.; Li, X.X. Modeling and characterization of a silicon condenser microphone. J. Micromech. Microeng. 2004, 14, 403–409. [Google Scholar] [CrossRef]

- Akkaya, O.C.; Akkaya, O.; Digonnet, M.J.F.; Kino, G.S.; Solgaard, O. Modeling and Demonstration of Thermally Stable High-Sensitivity Reproducible Acoustic Sensors. J. Microelectromech. Syst. 2012, 21, 1347–1356. [Google Scholar] [CrossRef]

- Spiering, V.L.; Bouwstra, S.; Spiering, R.M.E.J. On-chip decoupling zone for package-stress reduction. Sens. Actuators A Phys. 1993, 39, 149–156. [Google Scholar] [CrossRef]

- Offereins, H.L.; Sandmaier, H.; Folkmer, B.; Steger, U.; Lang, W. Stress free assembly technique for a silicon based pressure sensor. Proceedings of TRANSDUCERS ’91: 1991 International Conference on Solid-State Sensors and Actuators. Digest of Technical Papers, San Francisco, CA, USA, 24–27 June 1991; pp. 986–989. [Google Scholar]

- Spiering, V.L.; Bouwstra, S.; Burger, J.F.; Elwenspoek, M. Membranes fabricated with a deep single corrugation for package stress reduction and residual stress relief. J. Micromech. Microeng. 1993, 3, 242–246. [Google Scholar] [CrossRef]

- El-Fatatry, A.; Guo, D.G.; Wang, W.J.; Lin, R. Extrinsic Fabry-Perot pressure sensor using single deeply corrugated diaphragm technique. In Proceedings of the MOEMS and Miniaturized Systems IV, San Jose, CA, USA, 24 January 2004. [Google Scholar]

- Chen, J.; Liu, L.T.; Li, Z.J.; Tan, Z.M.; Xu, Y.; Ma, J. On the single-chip condenser miniature microphone using DRIE and backside etching techniques. Sens. Actuators A Phys. 2003, 103, 42–47. [Google Scholar] [CrossRef]

- Huang, C.H.; Lee, C.H.; Hsieh, T.M.; Tsao, L.C.; Wu, S.; Liou, J.C.; Wang, M.Y.; Chen, L.C.; Yip, M.C.; Fang, W. Implementation of the CMOS MEMS condenser microphone with corrugated metal diaphragm and silicon back-plate. Sensors 2011, 11, 6257–6269. [Google Scholar] [CrossRef]

- Feixiang, K.; Jianmin, M.; Oberhammer, J. A Ruthenium-Based Multimetal-Contact RF MEMS Switch with a Corrugated Diaphragm. J. Microelectromech. Syst. 2008, 17, 1447–1459. [Google Scholar] [CrossRef]

- Ke, F.X.; Miao, J.M.; Wang, Z.H. Ohmic series radio-frequency microelectromechanical system switch with corrugated diaphragm. J. Micro/Nanolithogr. MEMS 2009, 8, 021122. [Google Scholar] [CrossRef]

- Ke, F.; Miao, J.; Wang, Z. A wafer-scale encapsulated RF MEMS switch with a stress-reduced corrugated diaphragm. Sens. Actuators A Phys. 2009, 151, 237–243. [Google Scholar] [CrossRef]

- Ge, Y.X.; Wang, M.; Yan, H.T. Optical MEMS pressure sensor based on a mesa-diaphragm structure. Opt. Express 2008, 16, 21746–21752. [Google Scholar] [CrossRef]

- Wang, W.J.; Lin, R.M.; Sun, T.T.; Guo, D.G.; Ren, Y. Performance-enhanced Fabry-Perot microcavity structure with a novel non-planar diaphragm. Microelectron. Eng. 2003, 70, 102–108. [Google Scholar] [CrossRef]

- Wang, W.J.; Lin, R.M.; Ren, Y.; Sun, T.T.; Guo, D.G. Fabry-Perot microcavity pressure sensor with a novel single deeply corrugated diaphragm. Microw. Opt. Technol. Lett. 2003, 39, 240–243. [Google Scholar] [CrossRef]

- Kilic, O.; Digonnet, M.; Kino, G.; Solgaard, O. External fibre Fabry-Perot acoustic sensor based on a photonic-crystal mirror. Meas. Sci. Technol. 2007, 18, 3049–3054. [Google Scholar] [CrossRef]

| Type | Measurement Range | Temperature | Sensitivity | Accuracy | Application |

|---|---|---|---|---|---|

| JUMO 404366 | 0~60MPa | −20~80 °C | —— | general | |

| Rao [18] | 0~1MPa | 32~42 °C | 22.3 rad/bar | ±0.15% | |

| Chen [19] | 0~0.1 MPa | 25 °C | 518 μm/MPa | 1.05% | |

| Zhu [20] | 0~0.1 MPa | 15~65 °C | 706.64 μm /MPa | good | |

| JUMO 402050 | 0~6 MPa | -30~200 °C | —— | high temperature | |

| Zhao [21] | 0~69 MPa | 25~100 °C | 211 nm/MPa | good | |

| JUMO 404327 | 0~0.1 MPa | -20~80 °C | —— | medical | |

| Wang [22] | 0~20 kPa | —— | —— | <2% | |

| Amr [23] | 0~40 kPa 1 | —— | 16 μm/MPa 1 | —— |

| Type | Dynamic Range | Frequency Response | Sensitivity | MDP | Temperature |

|---|---|---|---|---|---|

| B&K 4192 | 19~162 dB | 3.15 Hz~20 kHz | 12.5 mV/Pa | —— | −30~300 °C |

| Gong [24] | —— | —— | 7.3374 mV/Pa | 115.04 μPa/Hz1/2 | —— |

| Wang [17] 1 | 9.17~76.58 dB | 80~1000 Hz | 83.24 nm/Pa | 57.45 μPa/Hz1/2 | —— |

| Wang [17] 2 | 63.6~130.94 dB | 31.5~800 Hz | 3.31 nm/Pa | 1514.22 μPa/Hz1/2 | —— |

| Liu [26] | 12.77~77.65 dB | 63~1000 Hz | 52 nm/Pa | 86.97 μPa/Hz1/2 | —— |

| Lu [27] | ~165 mPa | 20Hz~20 kHz | 2.23 V/Pa | 2.97 μPa/Hz1/2 | —— |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Deng, H.; Zheng, G.; Shan, M.; Zhong, Z.; Liu, B. Reviews on Corrugated Diaphragms in Miniature Fiber-Optic Pressure Sensors. Appl. Sci. 2019, 9, 2241. https://doi.org/10.3390/app9112241

Li H, Deng H, Zheng G, Shan M, Zhong Z, Liu B. Reviews on Corrugated Diaphragms in Miniature Fiber-Optic Pressure Sensors. Applied Sciences. 2019; 9(11):2241. https://doi.org/10.3390/app9112241

Chicago/Turabian StyleLi, Honglin, Hui Deng, Guangqi Zheng, Mingguang Shan, Zhi Zhong, and Bin Liu. 2019. "Reviews on Corrugated Diaphragms in Miniature Fiber-Optic Pressure Sensors" Applied Sciences 9, no. 11: 2241. https://doi.org/10.3390/app9112241

APA StyleLi, H., Deng, H., Zheng, G., Shan, M., Zhong, Z., & Liu, B. (2019). Reviews on Corrugated Diaphragms in Miniature Fiber-Optic Pressure Sensors. Applied Sciences, 9(11), 2241. https://doi.org/10.3390/app9112241