1. Introduction

Engineering education under Industry 4.0 requires competence-based training that combines safety, efficiency, and rapid feedback [

1,

2,

3]. In welding and particularly in SMAW, entry-level practice in workshops entails non-trivial risks (arc radiation, fumes, burns) and high consumable usage, which constrains early practice time and instructor supervision. Immersive simulation has therefore been investigated as a preparatory stage that transfers basic psychomotor training to a safe, repeatable environment prior to workshop practice. Haptic-enabled VR is especially relevant to SMAW because it affords tactile cues for electrode angle, arc ignition, and sticking key sources of novice error. However, most existing simulators emphasize MIG/MAG or TIG processes and operate on closed, proprietary platforms with limited curricular adaptability. As summarized in

Table 1, these features differentiate commercial systems from the present work, which introduces a locally developed, SMAW-specific, haptic-integrated VR prototype embedded into mechanical engineering education.

In this context, virtual reality (VR) simulators have emerged as promising solutions, offering controlled environments for repetitive practice without material wastage or exposure to dangers [

8].

Despite the proliferation of VR-based welding simulators, many existing systems suffer from limitations on haptic feedback [

9,

10]. These gaps make it more difficult to effectively transfer skills from simulation to real-world scenarios. Furthermore, a significant portion of the available simulators in the market are expensive and they might be difficult to adapt to local educational curricula [

8].

At the School of Mechanical Engineering of the Pontificia Universidad Católica de Valparaíso (PUCV), students often begin welding courses with limited experience and confidence, leading to high levels of material waste and extended training times.

This work introduces the development and preliminary validation of a locally produced VR welding simulator enhanced with a haptic device, developed using Unity 3D, and adapted to replicate the physical environment of the welding laboratory at PUCV. A custom 3D-printed electrode holder was integrated into the system to replicate a real one, allowing for more realistic control during practice [

11]. The simulation includes interactive elements such as spark effects, visual feedback for arc ignition, bead growth logic, and electrode-sticking mechanics.

1.1. Welding Education and the Role of Engineering Schools in Industry 4.0

Modern engineering education must align with the demands of Industry 4.0, including automation, digital manufacturing, and cyber–physical systems. Immersive training environments offer significant advantages in this transition, enabling early familiarization with real-world industrial tasks through simulated experiences [

12,

13]. For welding, which is still a core skill in many mechanical and manufacturing careers, such simulators allow progressive learning, where students can build confidence before facing the constraints of real machines and dangerous environments.

In the context of Chilean universities, including the Pontificia Universidad Católica de Valparaíso (PUCV), traditional Shielded Metal Arc Welding (SMAW) training continues to rely heavily on manual practice in physical laboratories. These workshops are characterized by frequent electrode consumption, substantial scrap generation, and exposure to high temperatures and fumes.

The recent literature suggests that immersive virtual reality (VR) technologies can provide effective alternatives by offering controlled, safe, and repeatable environments for skill acquisition. In particular, the integration of haptic feedback devices allows learners to experience tactile interactions such as electrode resistance and collision events—which are key factors in developing fine motor coordination for welding tasks [

14]. Engineering schools play a pivotal role in fostering these technological innovations by incorporating simulation-based learning as a complement to traditional workshop instruction. Universities in Asia and Europe have already begun integrating such systems into their curricula, often accompanied by digital twins, automated assessment tools, and AI-enhanced analytics to support competency-based education [

12,

15]. In Latin America, however, adoption remains limited due to cost, lack of local development capabilities, and dependency on foreign commercial products. This creates an urgent need for institutions to develop autonomous, cost-effective, and contextually relevant educational technologies [

16].

The SMAW simulator developed at PUCV addresses this gap through a locally driven initiative that combines Unity 3D and a commercial haptic device to deliver an accessible and scalable training platform. By replicating the university’s own laboratory layout and welding procedures, the system offers students a familiar but enhanced training experience. It allows them to practice arc ignition, electrode manipulation, and travel speed control without consuming materials or exposing themselves to risks.

This development seeks to modernize engineering education by incorporating advanced technologies and promoting interdisciplinary innovation. Moreover, it contributes to the broader goal of preparing engineers capable of navigating the complexities of Industry 4.0 environments, as the global demand for skilled welders grows, particularly in sectors such as construction, shipbuilding, and renewable energy infrastructure [

17,

18].

1.2. The Importance of Psychomotor Skill Development in SMAW Training

In the context of Shielded Metal Arc Welding (SMAW), psychomotor skill development is critical, as welding is not only a cognitive task but a complex motor activity that requires fine control of hand movements, visual tracking, and real-time feedback processing [

3]. The mastery of these psychomotor abilities directly impacts the quality of the welds and the safety of the operator, especially in high-risk industrial environments. The lack of such skill development can result in poor quality joints, increased material waste, and greater risk of accidents due to improper handling or contact with material at a high temperature [

19].

SMAW training inherently involves repetitive tasks that demand precision, coordination, and muscle memory, particularly in maintaining the arc, adjusting travel speed, and managing electrode angles across different welding positions (1 G to 6 G) [

20]. Psychomotor training via simulation aligns well with the constructivist learning theory, where learners build knowledge through interaction and sensory engagement [

21,

22]. According to Chan et al., 2022, the inclusion of visuo-haptic interfaces in virtual welding systems fosters spatial awareness and dexterity, enhancing task retention and technical performance in subsequent physical tasks [

8].

However, traditional workshop instruction often faces challenges that limit the effectiveness of skill acquisition, like insufficient equipment, the high cost of consumables (electrodes, base metals), safety risks, and the lack of real-time individualized feedback from instructors, especially when supervising multiple students simultaneously.

Evidence supports the integration of immersive technologies (such as haptic and virtual simulators) to bridge this gap. Virtual reality (VR) and augmented reality (AR) applications, particularly those embedded with haptic feedback systems, have demonstrated effectiveness in developing psychomotor competence without incurring the material and safety liabilities of real welding practice [

8,

23].

These simulation learning tools offer scalable training pathways that can support individualized feedback loops, frequent repetitions without material consumption, and practice under varying weld positions and difficulty levels. These capabilities make them indispensable in preparing students for industrial environments where psychomotor proficiency is not optional, but foundational to occupational performance and safety [

24].

1.3. Motivation: A Locally Developed Haptic VR Simulator for Mechanical Engineering at PUCV

The motivation for this project arises from the need to modernize welding education within the School of Mechanical Engineering at Pontificia Universidad Católica de Valparaíso (PUCV), ensuring alignment with the skill demands of Industry 4.0. Currently, training in Shielded Metal Arc Welding (SMAW) at the university is based on theoretical practice and direct practice in the workshop, where students handle electrodes, welding machines, and consumables. While this last immersive approach has high pedagogical value, it presents significant challenges: high consumable and material usage, increased energy demand, accelerated wear of workshop equipment, and the risks associated with the nature of the process, for example, exposure to harmful gases and high temperatures. Additionally, novice welders often require extended time to master tasks like maintaining a stable arc, which leads to frequent arc extinguishing, electrical overloading of machines, and in some cases, electrical shutdowns. These issues increase operational costs and limit training throughput, particularly in large groups of students where machine availability and instructor supervision are constrained.

Commercial VR welding simulators have demonstrated effectiveness in bridging early-stage training gaps by allowing safe, repetitive practice without the risks or costs of live welding [

25]. However, their acquisition costs remain high, and many commercial systems are closed platforms restricting customization [

25,

26]. In contrast a locally developed haptic VR simulator represents a strategic solution, enabling the university to leverage existing resources (Unity 3D for simulation development, a commercially available haptic device, and in-house CAD and mechanical design capabilities) to produce a tailored, sustainable, and adaptable training tool.

A locally developed and modular architecture ensures scalability and sustainability, so the system has been designed to incorporate future upgrades, like automated weld quality assessment modules, integration with head-mounted VR displays, and extensions to other welding processes such as Gas Metal Arc Welding (GMAW) and Tungsten Inert Gas (TIG). The idea of embedding the simulator into the welding curriculum arises from the perspective that this tool will allow next generations of engineering students to benefit from continuous technological and pedagogical improvements without dependency on costly industrial systems [

26]. This approach reinforces the role of universities not only as adopters but also as producers of educational technology, fostering national capacity-building in technical education [

27].

In line with this vision, [

8] demonstrated that virtual reality welding simulators can be developed using affordable, off-the-shelf components to achieve interactivity and realism without the prohibitive costs of commercial systems. Their approach shows that low-cost VR platforms can train psychomotor skills and integrate safety procedures, reinforcing the feasibility of creating accessible and customizable solutions within academic environments [

28]. This evidence supports the strategic decision to pursue a locally developed haptic VR simulator at PUCV, leveraging similar cost-effective principles while expanding capabilities through haptic feedback integration.

Despite the progress of VR- and AR-based welding simulators worldwide, several gaps remain. Most existing systems are designed for MIG/MAG or TIG processes, prioritize commercial closed architectures, and provide limited adaptability for integration into local curricula. Moreover, the validation of such technologies in Latin American higher education environments is scarce. Few studies address SMAW-specific training with low-cost, haptic-integrated platforms that can be customized to institutional needs.

Building on these considerations, this study is guided by the following research question: Can a low-cost, locally developed haptic VR simulator for SMAW effectively support psychomotor skill development and confidence-building as a complementary tool to traditional welding practice in engineering education?

The simulator is therefore conceived not as a replacement for workshop practice, but as a preparatory and complementary tool aimed at building confidence and basic psychomotor coordination in early training stages.

2. Materials and Methods

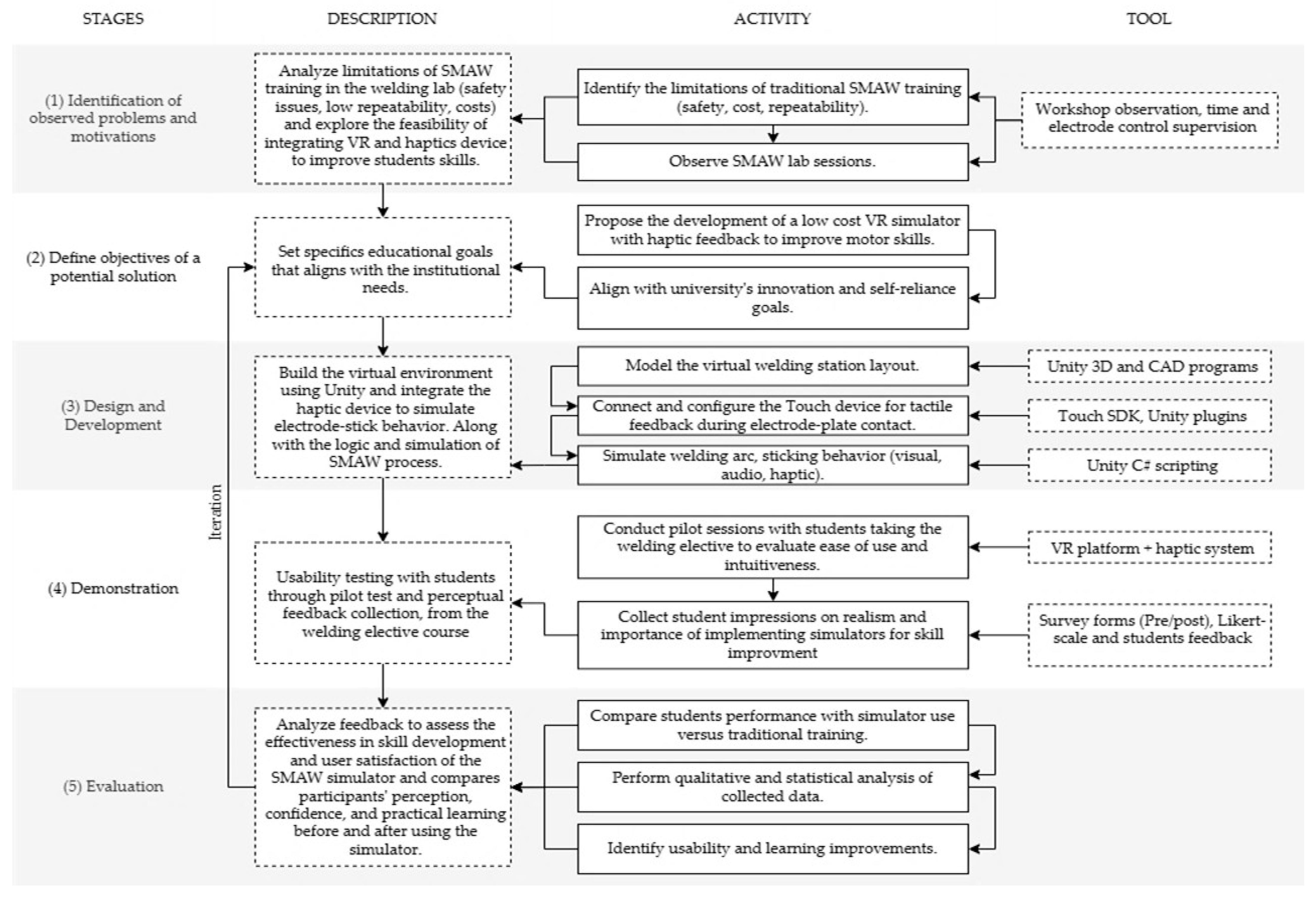

This research proposes the development of a haptic virtual reality simulator that imitates the conditions of a Shielded Metal Arc Welding (SMAW) workshop and aims to enhance the psychomotor training of mechanical engineering students at the Pontificia Universidad Católica de Valparaiso. To guide the research and development process, the Design Science Research Methodology (DSRM) was used, as it offers a structured framework for building and evaluating innovative technological solutions. The process followed these five key stages: (1) Identification of observed problems and motivations; (2) definition of objectives for a potential solution; (3) design and development of the simulator; (4) demonstration through student interaction; and (5) evaluation based on user perception.

Figure 1 shows the stages, activities, and tools needed to carry out this project.

During the initial stage of the research, observations were conducted in the Mechanical Engineering School laboratory workshop at PUCV to analyze the students’ experience and difficulties during SMAW (Shielded Metal Arc Welding) training. These included a poor control of arc length, difficulties in keeping the arc ignited, the electrode getting stuck in the work-plate and a lack of consistency in travel speed, factors that directly affect weld quality [

29]. This environment also presented limitations such as safety risks, high material consumption, and limited repetition opportunities. Given these constraints, the feasibility of integrating virtual reality and haptic feedback technology was explored to enhance students’ psychomotor training in a controlled and repeatable environment.

The opportunity to design a simulator that replicates the physical workshop virtually emerged, aligning with the university’s strategic goal of promoting technological autonomy and innovative tools using available resources. To do so, objectives were defined to guide the development, focusing on improving motor skills related to electrode handling, specifically when the electrode sticks to the work plate.

In the design and development phase, Unity 3D, an open-source game engine, was used to model a virtual replica of the welding station at the university. A haptic device, called “Touch” by 3D Systems, was integrated to simulate physical resistance when the electrode makes improper contact with the metal plate, emulating the sticking. The welding process was developed to provide visual, audio and haptic cues that respond dynamically to the student’s input.

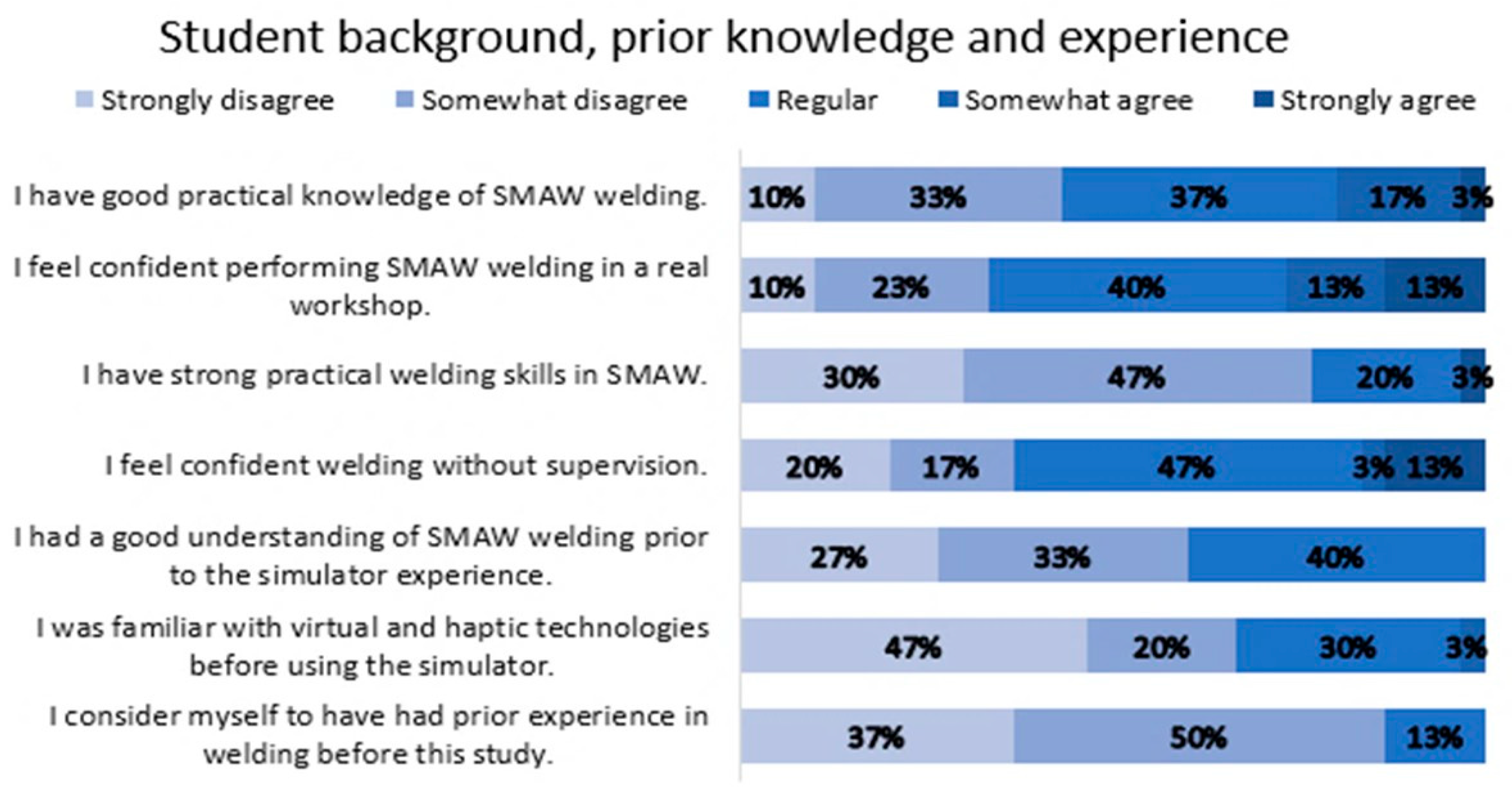

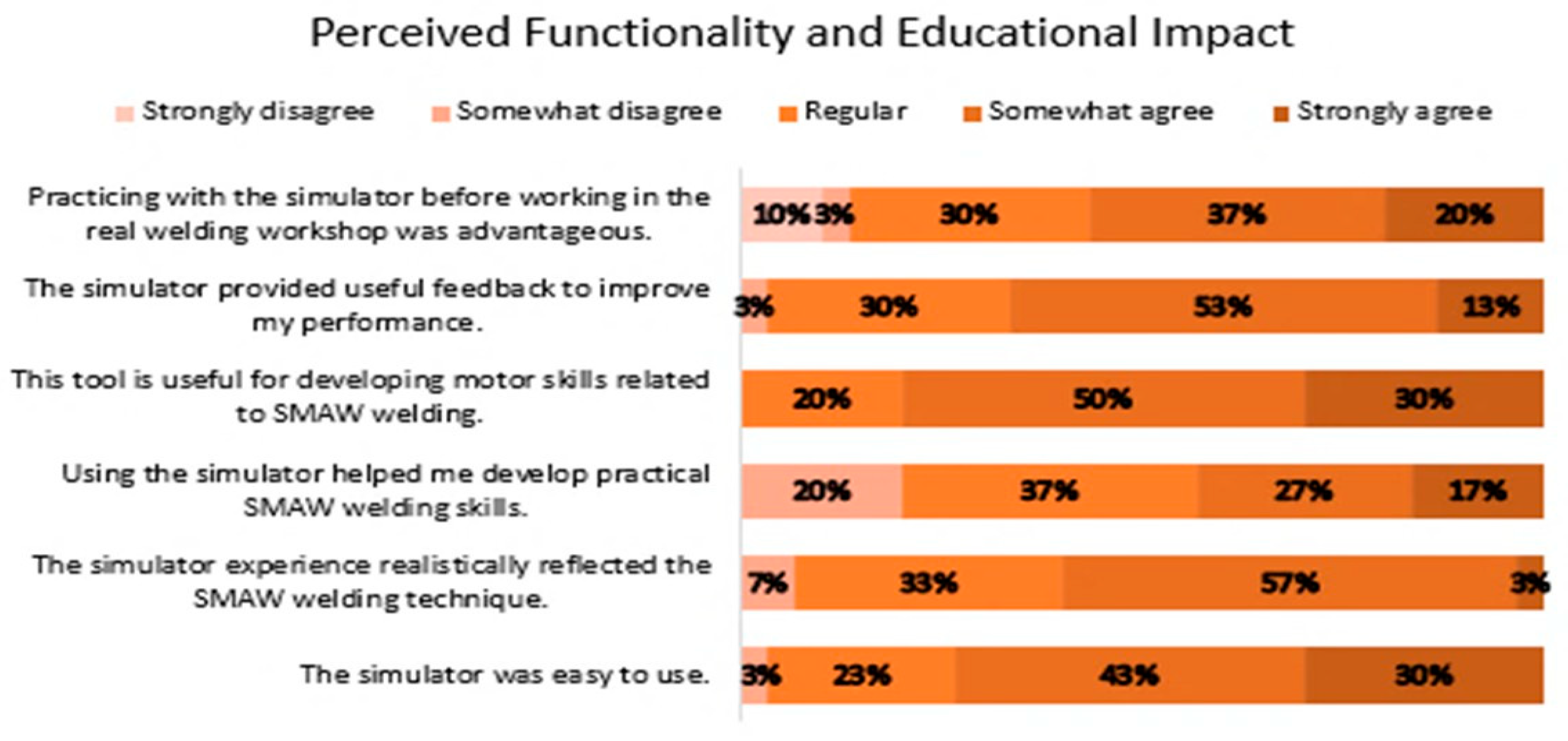

With the system in place, pilot sessions were conducted with students from the welding elective course and surveys were conducted for people that work in the university and have had more than a year of welding. The students interacted with the simulator in controlled conditions, and their feedback was collected using pre- and post-surveys that focused on ease of use, perceived realism, and potential for improving welding skills in general. The final stage consisted of evaluating the simulator’s impact based on student performance, confidence, and engagement. Qualitative and quantitative analyses were performed to compare learning outcomes before and after using the simulator and insights were drawn on how the virtual tool complemented traditional training, especially in early-stage instruction where safety and repetition are critical.

3. SMAW Simulator Development Workflow

3.1. Conceptual Design of the Simulator and Requirement Definition

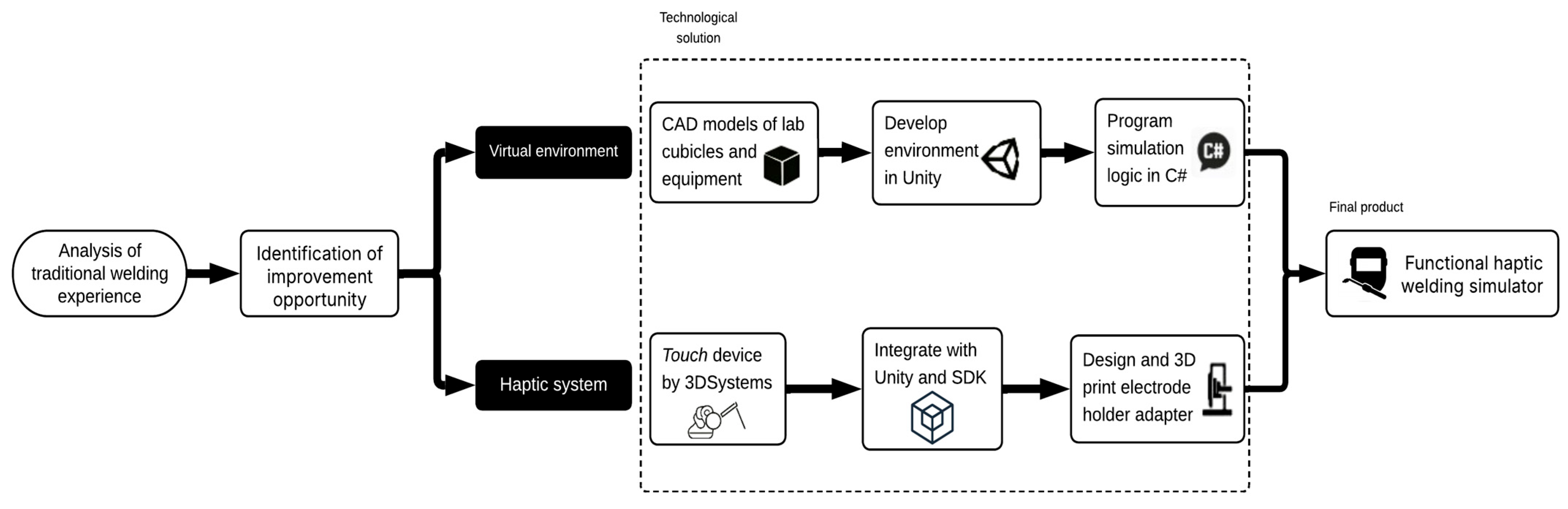

For the development of the SMAW simulator, a structured workflow was defined as illustrated in

Figure 2. After the analysis of the traditional welding experience and the identification of the opportunities, the workflow is divided into three main stages: Development of technological solutions, user validation, and the respective evaluations. These last two topics are covered in the following chapters.

The technological solution consisted of a virtual reality welding simulator with haptic feedback. To do so, two development tracks were defined: one for the integration of a haptic system and another for the construction of the virtual environment. In the haptic system track, a Touch device from 3DSystems was used, as shown in

Figure 3, to simulate tactile feedback during electrode–plate interactions and movement control of the electrode holder. This last one was designed so it can adapt to the Touch device, and 3D-printed to emulate the geometry of a real welding tool (see

Figure 3).

The use of additive manufacturing in this stage follows the principles described by Chong et al., 2018, where 3D-printed components enhance realism and conceptual understanding by enabling rapid prototyping of custom teaching aids, as well as facilitating iterative design adjustments in response to user feedback [

30]. The printed electrode holder was coupled to the Touch and then its virtual model was integrated into the simulation environment, allowing for accurate spatial alignment between the physical haptic device and its digital counterpart and contributing to higher immersion [

30].

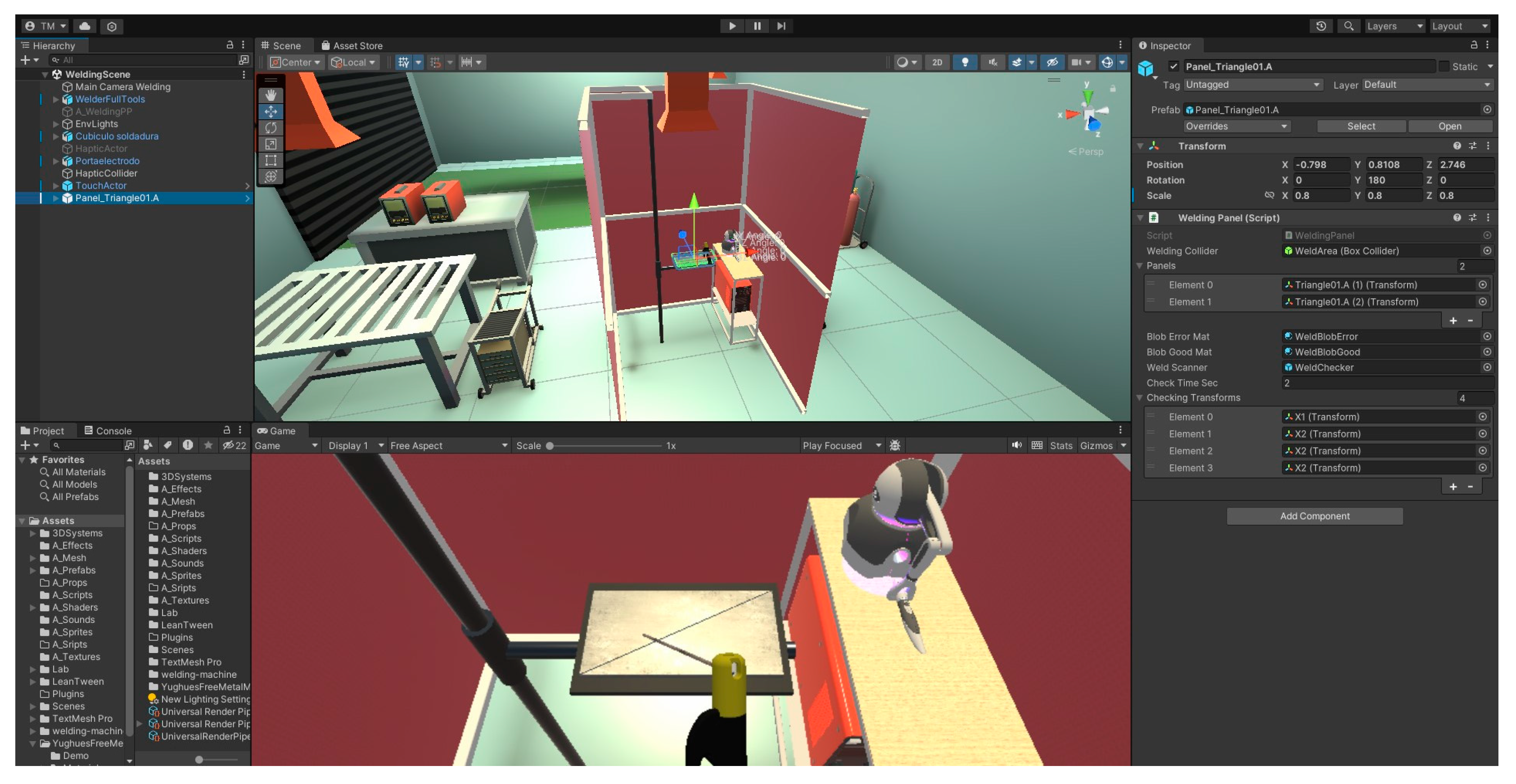

Unity3D version 2022.3 was selected as the development engine due to its 3D rendering capabilities and support for custom plugins. The Haptics Direct Unity SDK was used to bridge communication between the Touch device and the virtual simulation. Additional modeling was conducted using Autodesk Inventor to create accurate representations of the welding lab cubicles, tools, and test workpieces, which were then imported into the Unity environment.

From a functional perspective, the simulator was required to reproduce key elements of the welding process, such as sticking behavior when an improper arc distance is maintained and audio–visual feedback including arc sound, sparks, and weld bead formation. These interactions were programmed using C# within Unity to allow dynamic responses to user input.

3.2. Development of the Virtual Environment and Haptic Integration (Unity 3D, Haptic Interaction)

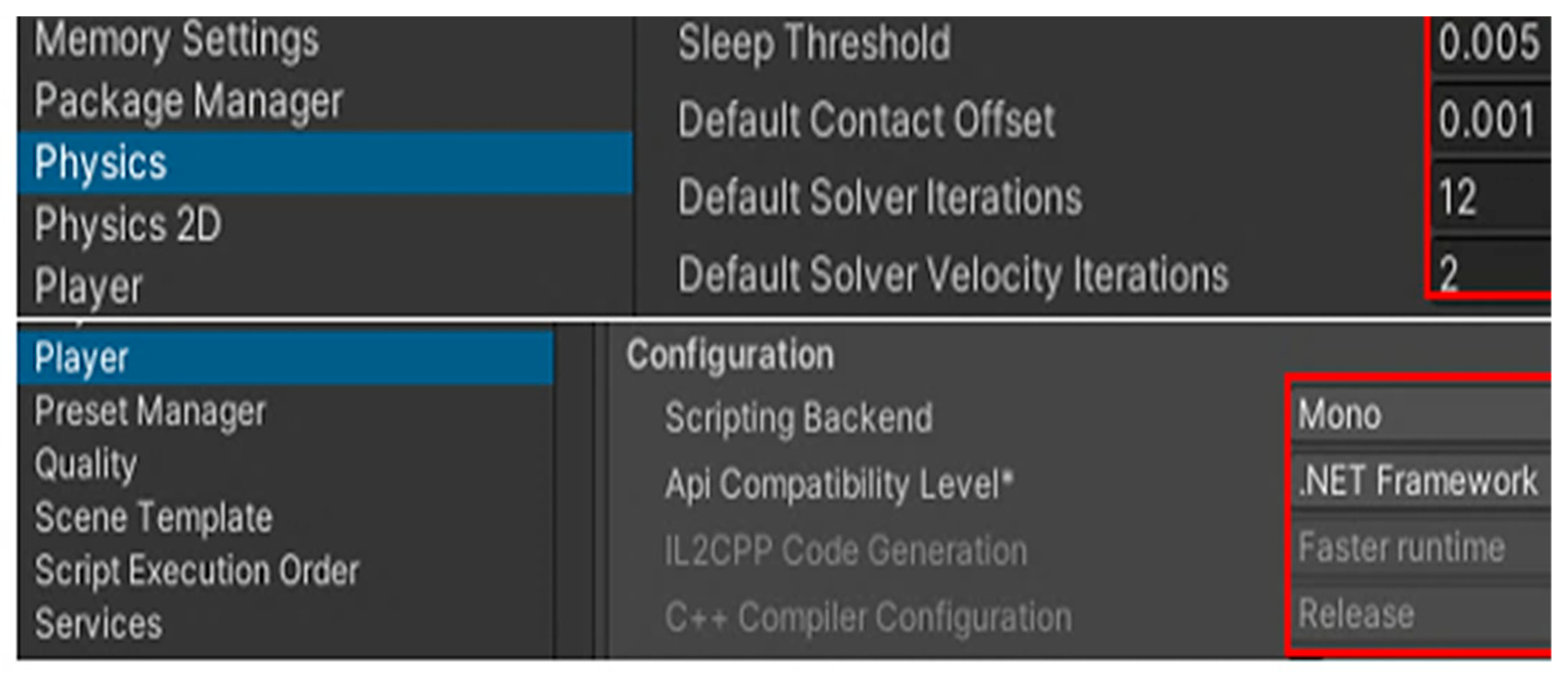

The development of the virtual welding environment began with the installation and configuration of Unity 3D. The 2022.3 version was used and then the physics and player configuration were adjusted to ensure low-latency input handling and accurate collision detection as shown in

Figure 4.

Specifically, the default contact offset, solver iterations, and solver velocity iterations were adjusted as specified by the haptic device supplier. The Api Compatibility level was changed from .NET Standard 2.1 to .NET Framework for a better library compatibility as this option is ideal for developments that require complex native libraries.

The following steps were taken to ensure the correct performance of the Touch haptic device:

Driver Installation: The official Touch drivers were installed onto the used computer to enable communication between the device and the operating system.

SDK Importation: The Haptics Direct Unity SDK (plugin) was imported into the project as a new asset so it can be initialized, tested, and used in the scenes.

Once the device has been integrated and is functioning properly, the development of the virtual environment begins. The main scene consists of nine elements, described in

Table 2.

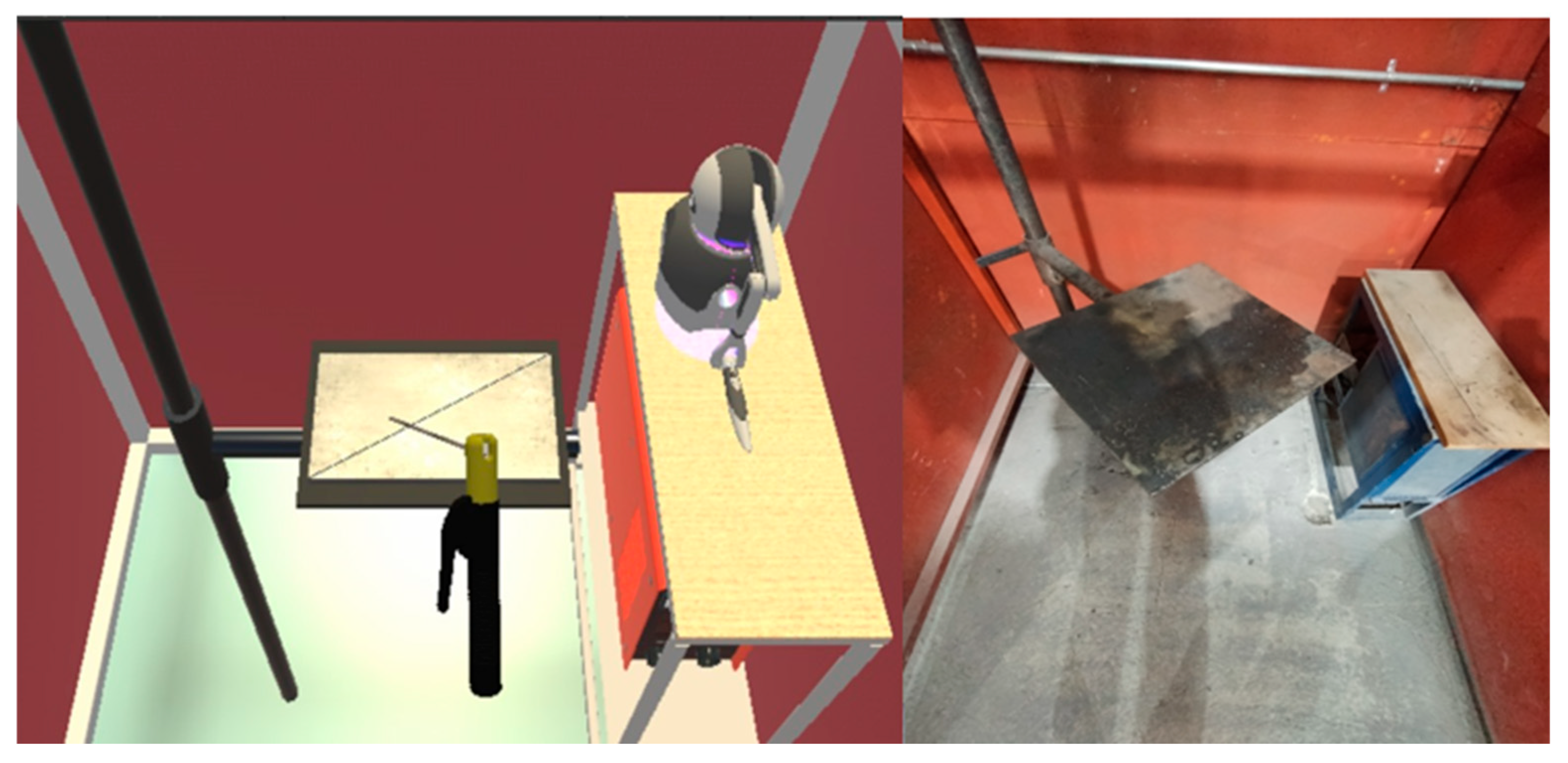

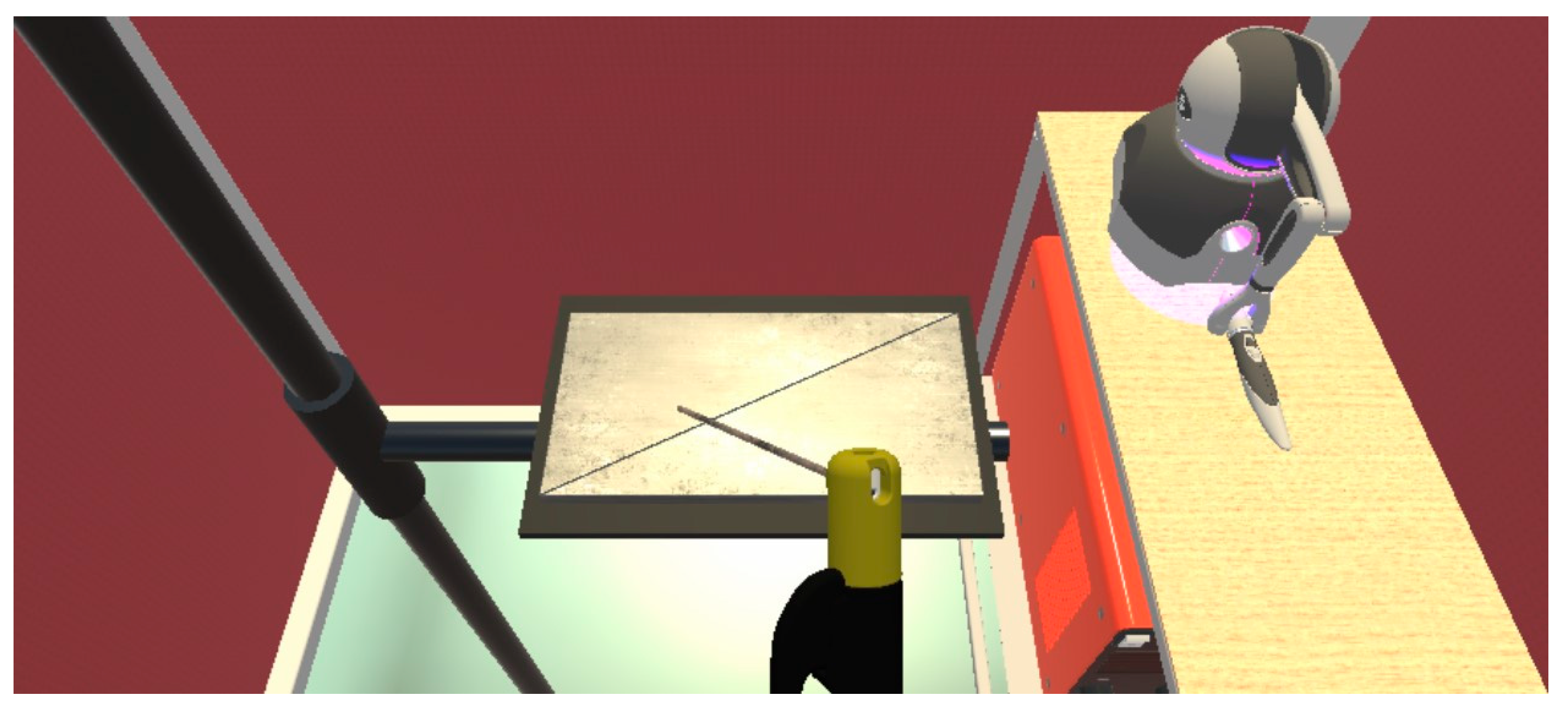

The main camera shows the user’s point of view and remains static throughout the simulation. Its position emulates the visual perspective of a welder inside a real welding booth in the university laboratory;

Figure 5 shows the comparison of the real cabinet and the virtual one.

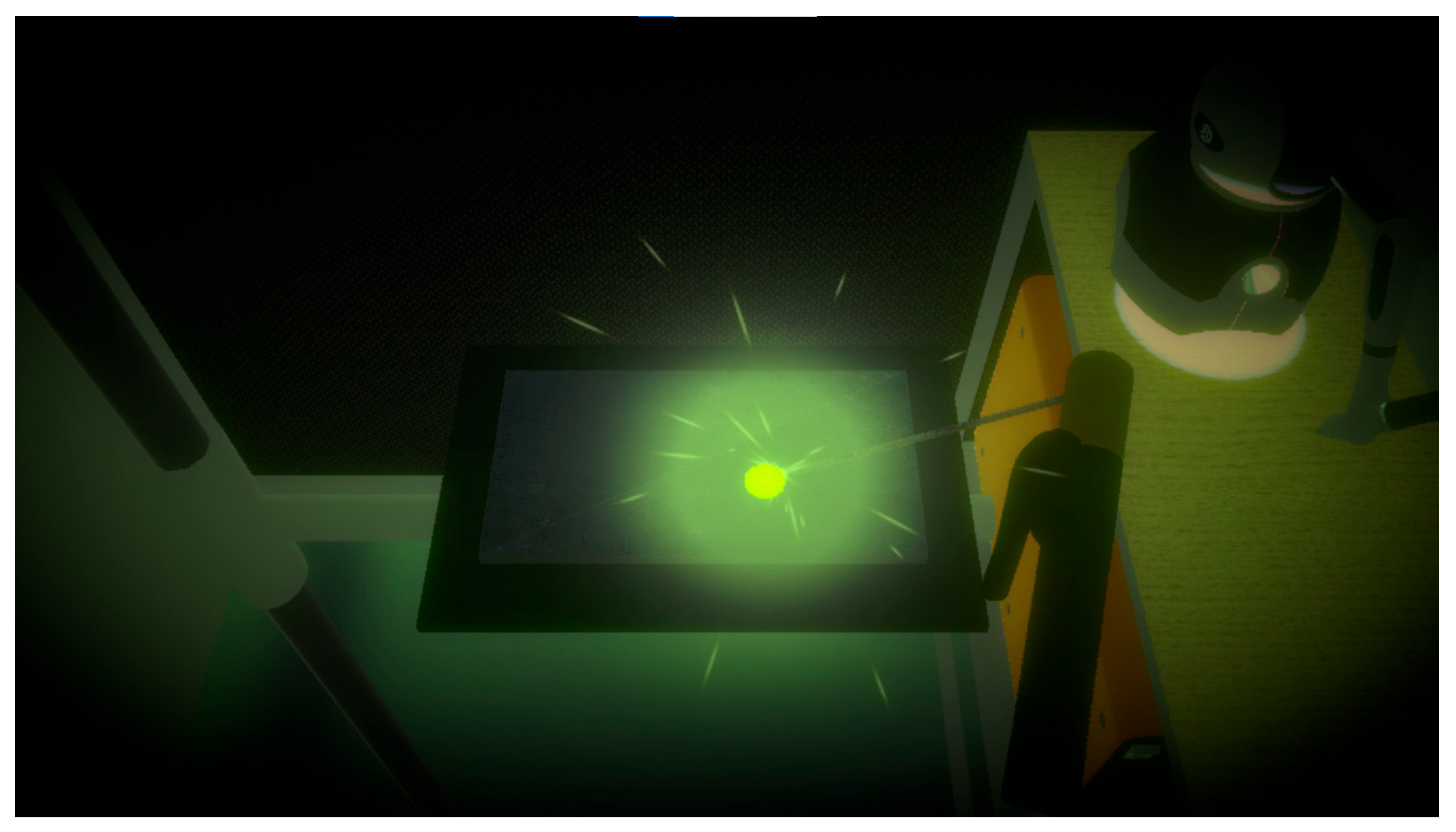

The arc light effect is a visual effect that is activated only when the arc is properly ignited, this is achieved through programming. It emits a subtle greenish glow that mimics the darkened filter of a welding helmet once the arc is activated, as shown in

Figure 6.

The ambient lights add realism to the scene, providing illumination and depth to the virtual environment. The welding cabinet (cubicle) is a CAD-modeled structure based on the real one that is placed at the university workshop (

Figure 5). It is composed of a welding table, a welding machine, a workpiece material, the booth walls, and a storage cabinet where a virtual model of the Touch device is placed. The haptic actor is an imaginary volume that has functionalities and the HapticPlugin script in it, that allows interaction with the touch device in Unity. It manages the Touch physics, the visual mesh, and the collision mesh that allows them to interact with other objects.

The electrode holder is a virtual model that has its mesh, light effect, and spark particle system, which activate when a proper arc is ignited. The haptic collider enables the interaction between the electrode and the workpiece material, while also initiating the weld bead protocol, triggering particle effects and making a hole (visual mask) if the electrode is held too long in a same spot. A digital counterpart of the real haptic device (Touch device model) is placed in a cabinet to track movement in real time and provide visual orientation to the user.

Lastly, the workpiece material is the welding surface and consists of three main components (see

Figure 7):

The visible work panel where the weld cord is deposited (workpiece).

An invisible object that contains the material controller script that manages collider interaction and physical properties.

A bounding volume that defines the area within the welding process can occur (WeldBox).

3.3. Simulation of the SMAW Process: Modeling, Logic, and Feedback

To understand how the simulation works, its logic and the chain of command of the scripts, it is necessary to know how the electrode moves, what the arc ignition and welding activation protocol is, how the weld bases and visuals are generated, and the structure of communication between scripts.

The movement of the virtual electrode holder in the simulator is directly controlled by the physical manipulation of the haptic stylus (Haptic pen) from the Touch device. This is achieved through real-time acquisition of the pen’s spatial position and orientation. Each simulation frames a script call function to retrieve the stylus’s cartesian coordinates. This information is then used to update the position and rotation of the virtual model, providing smooth movements with a low latency.

For the arc ignition, a set of logical conditions were applied. The user must satisfy a series of interaction-based criteria within the virtual environment

Physical contact and positioning: The collider must have touched the work surface (panel) and then positioned inside the WeldBox so the first condition is triggered.

Surface detection and layer checking: For each frame, a ray is cast from the electrode tip to determine whether it is hitting the workpiece or something else. Only when the ray detects a welding layer is the arc ignition possible.

Upon successful arc ignition, the particle system responsible for the visual effect of the spark, audio, and lighting effects is triggered.

If any of the conditions are no longer satisfied, the system immediately stops welding. This method tries to replicate the real interaction of the arc ignition in a real SMAW process: approach the workpiece until it is touched, ignite the arc, and move away from it just enough so that the arc is maintained.

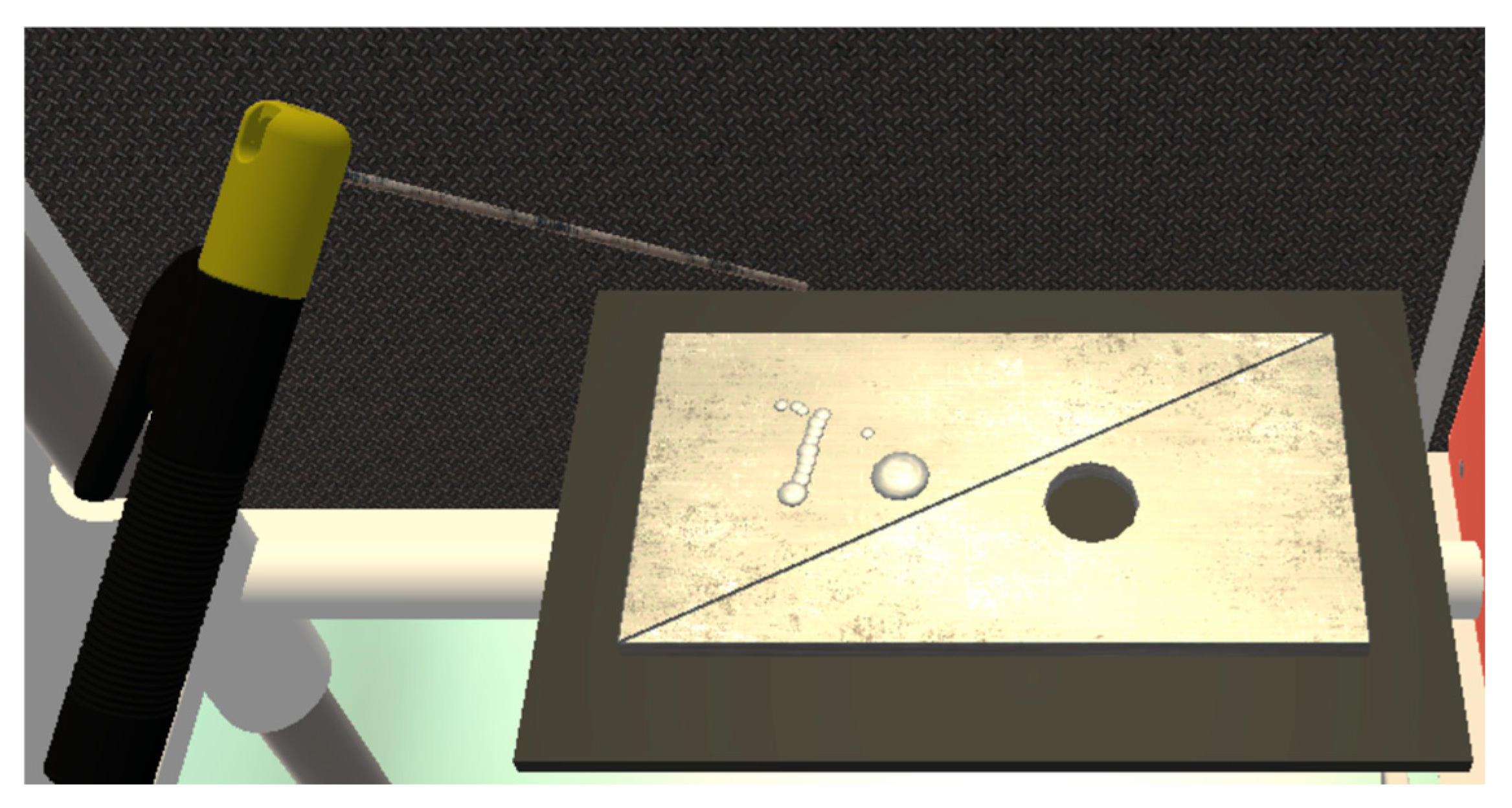

To generate the weld bead, 3D objects, referred to as “blobs”, are dynamically instantiated. They are created and scaled along the user’s welding path. Once the system detects that the electrode is correctly positioned and the welding conditions are met, a new blob is instantiated at the point of contact of the ray cast and the workpiece. The scale of the blob grows over time if the user remains in the same spot, and new ones are generated, forming a continuous weld bead, as the electrode moves (

Figure 8). If the electrode is held too long in the same spot, the blob size will increase to a point where, if it exceeds a defined threshold, the code replaces the blob with a “hole mask” that visually represents a burn-through in the workpiece, as shown in

Figure 8.

Multiple forms of feedback are triggered during welding to enhance a better simulation: The particle effects (sparks) activate when the arc is ignited properly, along with the arc light and the arc welding sound. Also, the tip of the electrode and the blobs change colors based on welding conditions (hot/cold) and cooling delays. And the haptic device provides physical resistance to contact with the workpiece when attempting to ignite the arc.

Code Structure and Communication Between Scripts

There are five codes that make up the main architecture of the project, where each script is responsible for a specific layer of the interaction and simulation logic.

As shown in

Table 3, the core manager of the simulation is the WeldingHandle script. It orchestrates the welding process by managing the arc ignition, bead creation, and feedback effects, and it uses a ray cast emitted from the tip of the virtual electrode to detect collisions with designated layers. A layer for existing weld blobs and a layer for weldable surfaces (workpiece) were created and if a valid surface is detected, the impact data is stored. Then, once the three conditions mentioned earlier are met, the welding start method is triggered, activating the visuals and audio effects during the process.

The HapticPlugin script interfaces directly with the haptic device, retrieving the position, orientation, and velocity of the physical stylus each frame, and then it converts the signals into Unity coordinates and updates the position and interaction state of the virtual electrode holder. If an interaction with the workpiece has been made, the HapticCollider and HapticMaterial scripts are called. The HapticMaterial manages the physical properties of the workpiece, such as stiffness, dampness and a constant force in the negative Y direction that will activate on contact and is responsible for the sticky feeling of the virtual electrode. Both the collider and the material haptic scripts trigger events and update the forces upon collision.

The appearance and behavior of the weld bead is managed by the WeldingBlobSet script, that makes the transition from hot to cool, controls glow effects, and the blob’s color. So, when the haptic stylus contacts the workpiece, the collision is detected and processed by HapticCollider, which then calls into the HapticPlugin to update the force feedback and interaction state. If welding is initiated, WeldingHandle triggers visual and audio effects and creates the weld bead (blobs) that will change in color thanks to WeldingBlobSet.

3.4. Structure and Flow of Evaluation Strategy

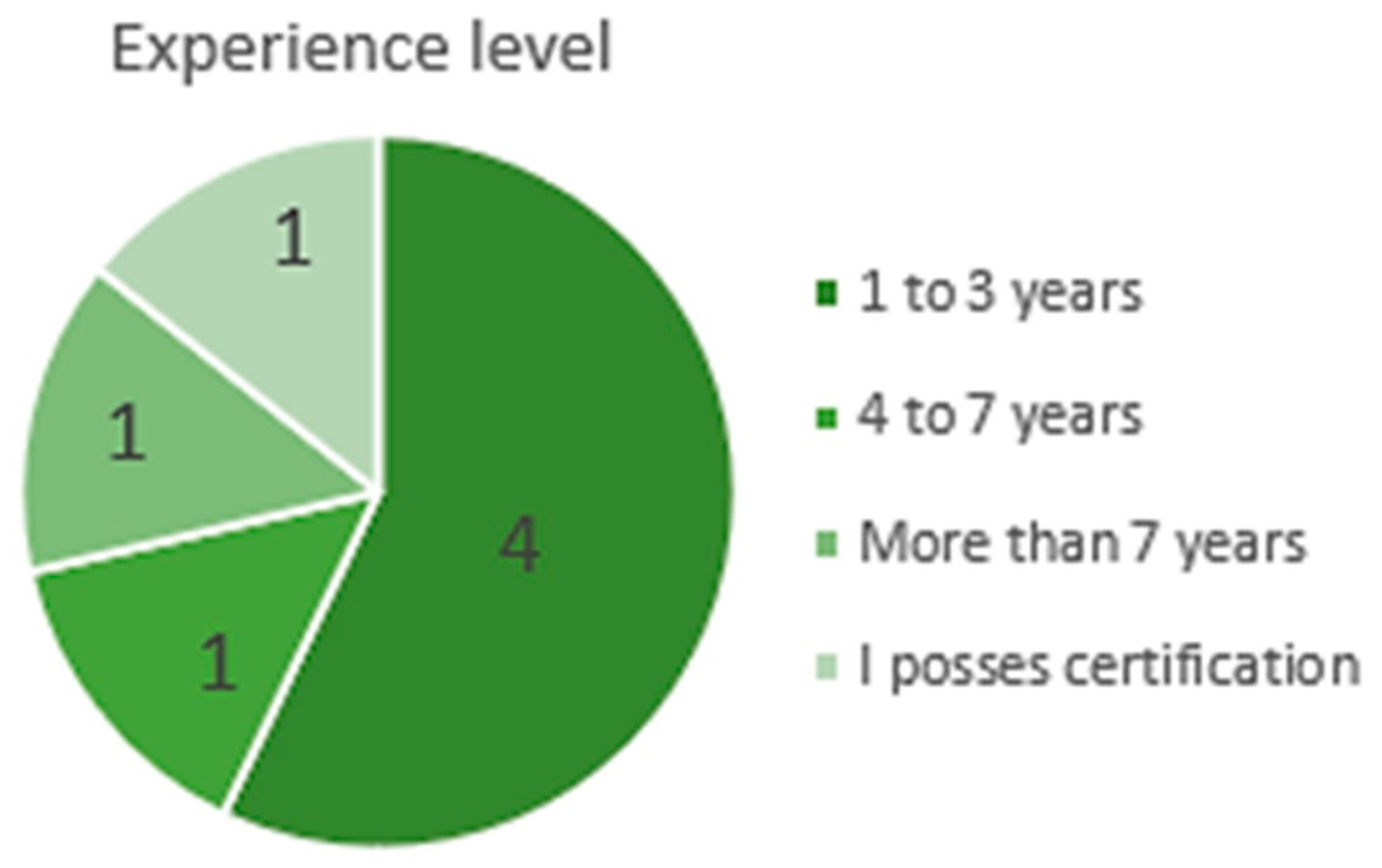

Two types of survey were conducted (see

Figure 9) via google forms. A user satisfaction survey was conducted with student participants from the welding elective course, who were becoming familiar with the welding world for the first time, and another survey was conducted with people that work in the university and have at least one year of experience with welding processes.

The satisfaction evaluation focused on gathering both quantitative and qualitative data regarding students’ perceptions about the simulator, the skill development, and the potential impact on real welding performance. It was administered in two stages: before and after simulator usage. This way, using a Likert scale, open-ended responses and comparative judgment tasks, a contrastive analysis of changes is possible. The primary objectives of these evaluations were as follows:

Measure student perception and confidence before and after the simulator.

Compare the simulator experience to traditional welding practice to perceive advantages, limitations, and suggestions for improvement.

Evaluate user satisfaction, identifying beneficial features for learning and components to get better.

Determine the simulator’s impact on safety and improve the precision in handling the electrode.

Collect feedback for iterative design improvements and for future integration into educational programs.

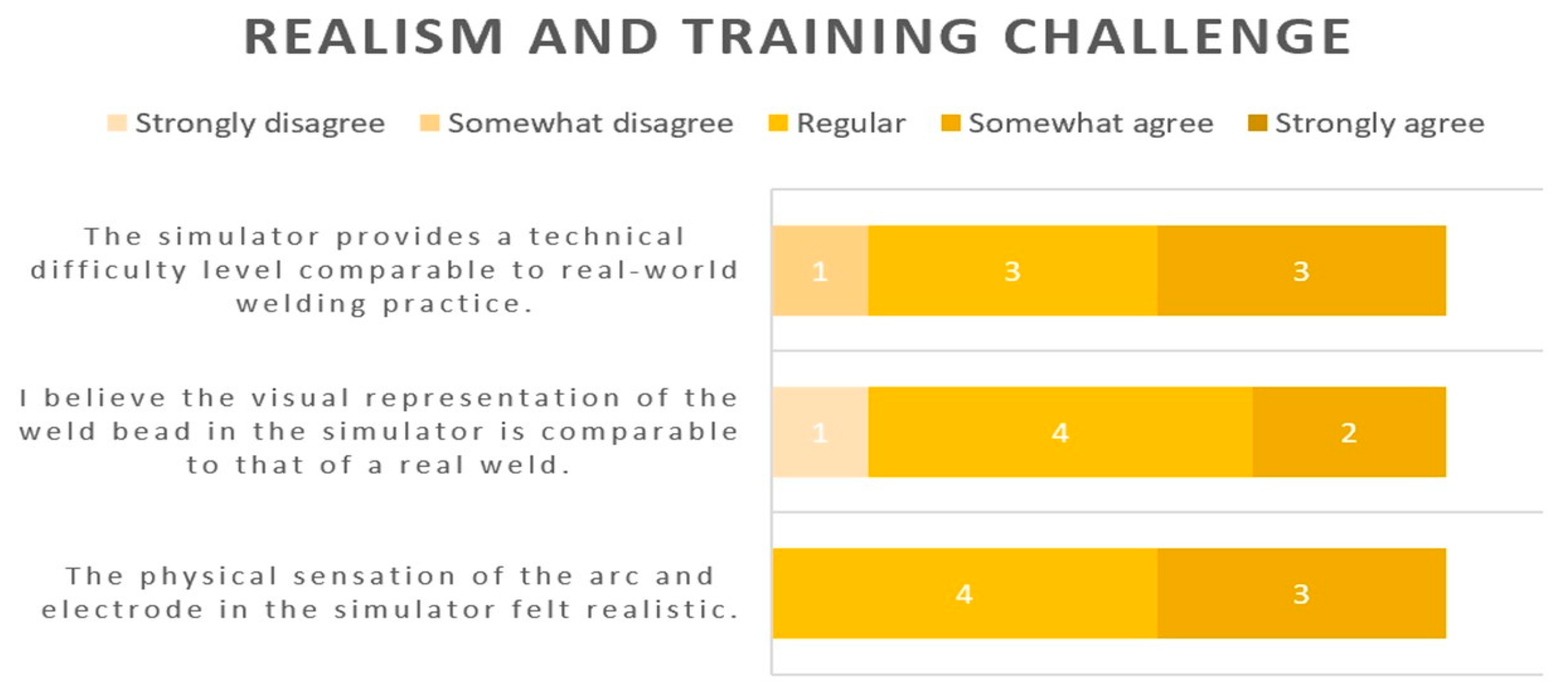

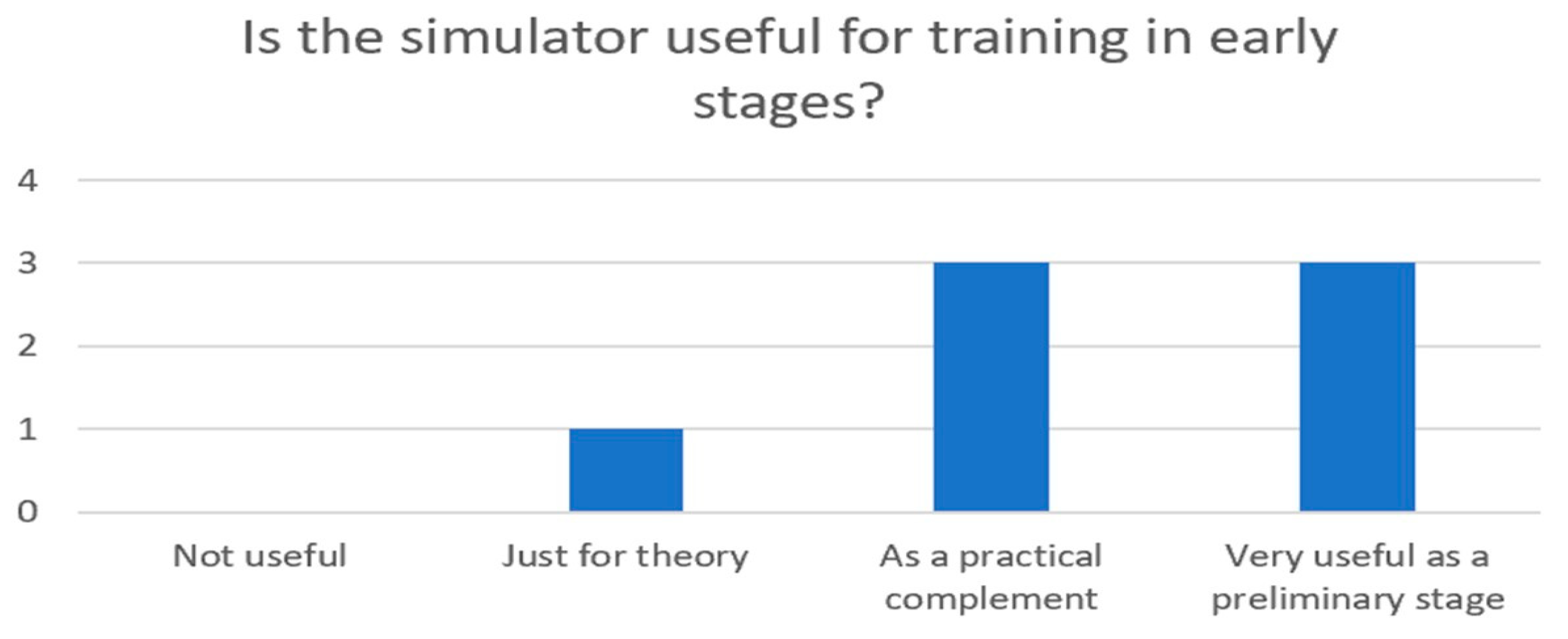

On the other hand, the validation survey was designed to collect expert feedback from individuals with experience or certification, assessing realism, practical usefulness and potential educational value, focusing on the following:

Haptics, visual realism, and how realistic the arc sensation and weld bead appearance are compared to real welding.

Perceived usefulness of the simulator as a tool to complement real welding practice.

Technical challenges and how difficult it is using the simulator compared to using a real welder.

Need for automatic feedback and qualitative insights to identify weaknesses and propose improvements.

5. Discussion

The development and implementation of the haptic virtual reality welding simulator at the Mechanical Engineering School at PUCV has shown promising outcomes aligned with the project’s original objectives—enhancing early welding training through immersive simulation, promoting psychomotor skill development, and improving student confidence in a controlled environment.

In comparison with existing commercial solutions, the proposed simulator presents several distinctive features. Systems such as Soldamatic (Seabery, Huelva, Spain), Lincoln Electric VR trainers, and Fronius platforms are predominantly designed for MIG/MAG or TIG welding processes and are based on proprietary, closed architectures that restrict adaptation to local curricula. In contrast, the present prototype is specifically oriented toward SMAW training, a process that remains essential in Latin American engineering education yet is underrepresented in commercial simulators. Furthermore, the system integrates haptic feedback to replicate electrode manipulation and sticking phenomena, which are typically overlooked in existing tools. Its Unity-based modular architecture also provides an open and extensible environment, allowing future integration of automated feedback mechanisms, augmented reality components, and compatibility with immersive head-mounted displays. While commercial platforms currently offer more advanced graphical fidelity and automated scoring features, the originality of this work lies in demonstrating the feasibility of a locally developed, SMAW-specific, haptic-integrated training system that combines contextual relevance with architectural flexibility, reinforcing its applicability within higher education settings.

These distinctive design choices were also reflected in the evaluation outcomes. Students highlighted the usefulness of the simulator for practicing arc ignition and controlling electrode sticking, which directly relates to the SMAW-specific focus of the system. Expert feedback confirmed that, although the fidelity of haptic force remains limited, the inclusion of tactile cues for electrode manipulation represents a valuable step which is not present in many commercial solutions. In addition, the modular Unity-based architecture was perceived as advantageous by instructors, as it allows adaptation to evolving curricular needs. Taken together, these findings illustrate that the originality of the system is not limited to its design but is supported by user perceptions of its pedagogical value.

The comparison between simulator and real workshop performance (

Figure 16 and

Table 4) provides additional insights into the pedagogical value and current limitations of the prototype. Students achieved shorter and more consistent arc maintenance times in the simulator (mean 10.07 s) compared to real SMAW practice (mean 17.17 s), where variability was considerably higher. This outcome can be interpreted in two ways. On the one hand, it suggests that the simulator may facilitate a faster initial learning curve by offering a controlled and low-stress environment that reduces cognitive load. On the other hand, it also indicates that the current implementation simplifies task complexity, since factors such as electrode consumption, thermal distortions, and visual obstructions were not reproduced. While this limits the fidelity of skill transfer, it also reinforces the simulator’s role as a preparatory tool that lowers the entry barrier for novices. This finding aligns with [

32], who reported that VR-assisted welding training reduced anxiety and supported early-stage coordination, but highlighted the need for iterative improvements in realism to ensure transferability to workshop practice.

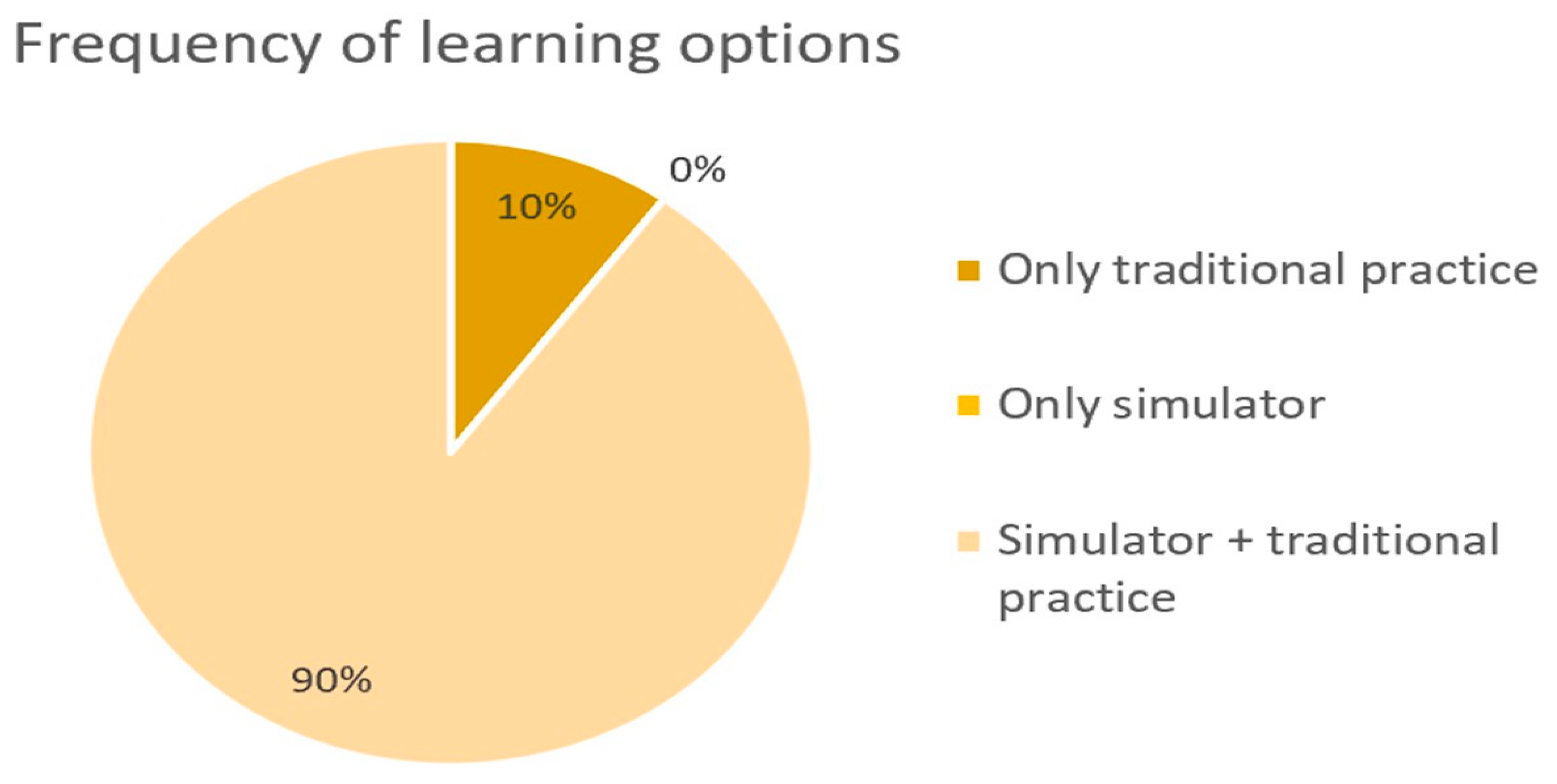

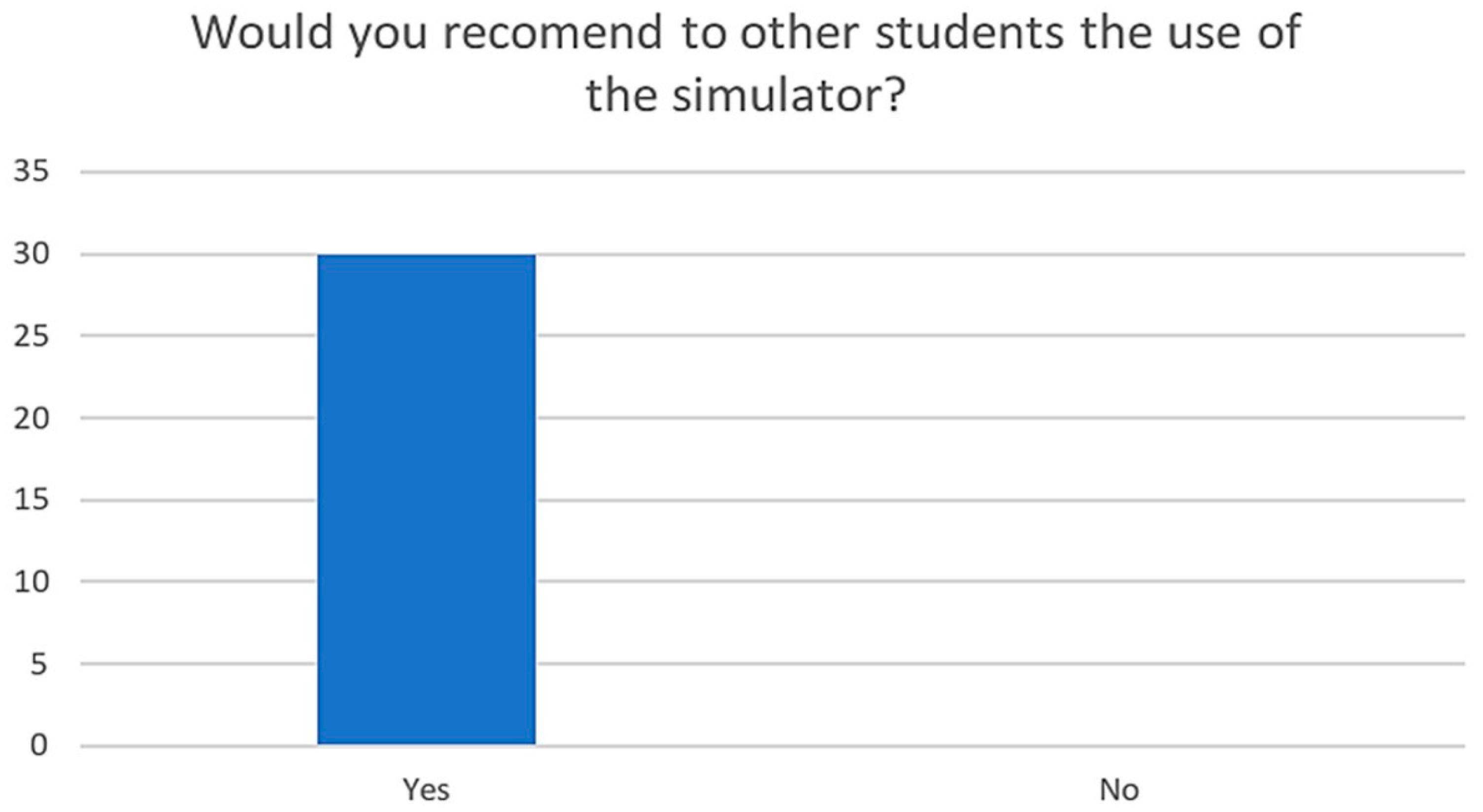

Survey data and performance observations indicate that the simulator could contribute positively to student learning, especially in terms of building confidence, improving psychomotor coordination, and offering a safe space to practice. The virtual environment allowed repeated attempts without material waste or safety risks, enabling learners to focus on motor skills such as arc ignition and electrode control. This supports Checa and Bustillo’s, 2020, conclusions regarding the affective and cognitive advantages of immersive environments in technical education [

25]. Furthermore, the students’ unanimous recommendation to extend simulator use reinforces its perceived value, despite some limitations in real-time feedback, automated evaluation or realism.

These findings are consistent with those reported in previous studies on VR- and AR-based welding education. For example, [

32] observed that students trained with VR modules experienced reduced anxiety and improved arc control during early stages, like the confidence gains identified in our surveys. [

33] demonstrated that AR-integrated SMAW modules achieved high validity and practicality, which parallels the positive acceptance and usability ratings obtained in our study. Conversely, [

34] emphasized the importance of iterative development cycles to enhance realism and fidelity, reinforcing our own observation that limitations in haptic feedback and electrode consumption constrain the simulator’s transferability. Taken together, these comparisons suggest that while the present prototype remains preliminary, its observed benefits in confidence, psychomotor coordination, and student preference for hybrid training are aligned with international evidence on immersive welding education.

From both technical and instructional standpoints, the simulator lays a strong foundation for future development. Its modular and adaptable architecture enables future extensions such as real-time feedback systems, visual quality assessment algorithms, and immersive VR integration. This scalability is a crucial feature, also highlighted in studies like Tran et al. (2023), who demonstrated the long-term adaptability of VR systems for welding instruction [

10]. In this regard, the iterative continuous improvement approach described by [

34], in their WELD-VR project, provides a relevant framework for guiding the evolution of our prototype. Their methodology—based on repeated testing, feedback collection from students, and close collaboration between technical and pedagogical teams—mirrors the refinement process already applied in our simulator and reinforces the value of structured, cyclical enhancement to address usability and pedagogical challenges over time [

34]. Likewise, Yunus et al., 2025, reported that an augmented reality-integrated SMAW learning module with 3D simulation achieved high validity (93%), practicality (84%), and moderate effectiveness, underscoring that immersive and interactive tools can significantly enhance welding training outcomes when aligned with pedagogical objectives [

33].

Educationally, it could be formally embedded in welding curricula as a complementary tool that prepares students cognitively and physically for the demands of the workshop. This preparation is especially valuable in settings where equipment access, safety, or instructor time are limited. The findings of Sjölie et al. highlight the flexibility and applicability of VR laboratories across multiple educational levels—from vocational schools to postgraduate training—which directly supports the versatility of our simulator. Just as their virtual environments have been adapted to metallurgy, welding processes, and remote learning contexts, our system could be scaled to support diverse user groups, including industry professionals seeking upskilling and students with varying learning needs [

34].

However, several limitations must be acknowledged. The study was based on a relatively small sample of 30 mechanical engineering students and 7 professional welders. Although the students represent the entire cohort of the elective welding course at PUCV, the small sample restricts the statistical generalizability of the findings. This sample was homogeneous, consisting only of novices, which limits insights into skill transfer among learners with varying levels of prior experience. The evaluation relied primarily on perception-based surveys, focusing on confidence and usability, with limited inclusion of objective performance-based metrics such as weld quality or defect detection. These decisions were made to start an exploratory investigation of this developed prototype, aimed at validating feasibility within institutional constraints.

Another important limitation lies in the technical scope. The simulator currently lacks automated performance scoring, providing feedback mainly through visual (sparks, bead growth) and auditory cues. Electrode consumption was not implemented, as modifying the haptic stylus could compromise device integrity and warranty. Furthermore, only one haptic unit was available, meaning that training could only be performed individually, reducing scalability in larger classes. However, welding courses at the university are currently organized in smaller groups, which makes it feasible to integrate the simulator into the class schedule, as only a limited number of students train per session. This arrangement increases the practicality of the current prototype for classroom use. Nevertheless, the long-term solution would be the acquisition of additional units, allowing multiple students to practice simultaneously and thereby enhancing scalability. While these constraints do not diminish the value of the prototype as a pedagogical tool, they highlight the importance of cautious interpretation of the results and the need for iterative improvements.

Despite these limitations, the simulator’s potential for educational inclusion is significant. Though not yet tested with students with cognitive or physical disabilities, the simulator’s controlled and customizable environment could support differentiated instruction in future research. Such an approach has been proposed as a critical development area for immersive learning environments yet remains underexplored in welding education (D. Checa and A. Bustillo) [

25]. Expanding the simulator’s adaptability could enable its use beyond traditional technical training, opening possibilities for inclusive education across various learner profiles [

34].

Future iterations could implement automatic evaluation algorithms and extend functionality to other welding techniques such as GMAW or TIG. Moreover, although it is often assumed that simulators reduce the cost of consumables and physical equipment degradation, few studies provide robust cost–benefit analyses. Future work should consider quantifying the return on investment (ROI) of the simulator compared to traditional training modalities at the university, which would support institutional decision-making and budget planning.

Overall, the simulator developed in this project demonstrates how universities can leverage their own resources to produce high-impact educational tools aligned with Industry 4.0, and lays the groundwork for expanding equitable, effective, and technology-enhanced training in technical education.

6. Conclusions

This work presented the design, development, and preliminary validation of a functional prototype of a haptic virtual reality simulator for Shielded Metal Arc Welding (SMAW), developed within a university context to strengthen the training of mechanical engineering students. The simulator was conceived as an accessible and scalable educational tool to address key challenges in early-stage welding instruction.

Findings from student surveys and observation suggest that the simulator may contribute positively to the acquisition of psychomotor skills, support user confidence and help to reduce anxiety during initial welding experiences. Participants reported satisfactory usability and instructional value, positioning the tool as a complementary aid to traditional hands-on training rather than a substitute. From an educational perspective, the simulator has the potential to enable more inclusive, safer and resource-efficient teaching strategies, particularly in contexts where material costs, safety, and access to equipment are constraints. Technologically, the system integrates Unity 3D with a commercial haptic device to build a modular architecture that can evolve over time. The simulator’s software and hardware integration were designed with scalability in mind, supporting future upgrades such as automatic weld quality evaluation, deeper interaction tracking, and compatibility with head-mounted VR systems.

These findings are reinforced by the results obtained in the study by Rojas Catalán et al., 2025, where the integration of technologies, like immersive VR environments, demonstrated significant improvements in operator training, situational awareness, and fault prevention in industrial contexts [

35]. Likewise, the validation work of Prasetya et al., 2023 on a VR-based SMAW learning environment showed that virtual modules—supported by structured development models and evaluated through expert and student feedback—can achieve content, design, and technical validity, leading to greater student engagement and more effective conceptual understanding aligning with Industry 4.0 paradigms, offering repeatable, controlled, and measurable learning experiences [

36].

Future developments should extend the simulator’s capabilities to include additional welding processes such as GMAW and TIG, broadening its applicability across diverse training needs. Inspired by the findings of Lorenzo et al., 2016, the system could also be adapted to support learners with cognitive or physical disabilities, incorporating immersive, structured, feedback-driven environments that have proven effective in enhancing social and emotional skills in children with autism spectrum disorders [

37]. This adaptation would enable the simulator to serve not only conventional technical education but also inclusive education programs, providing customized scenarios that facilitate skill acquisition and knowledge transfer to real-world contexts. Such technology represents a promising step toward modernizing technical education through immersive and interactive tools, empowering institutions to train the next generation of engineers, while also expanding their social value by addressing specialized educational needs with greater safety and engagement. Nevertheless, its current validation remains preliminary, and further development and systematic evaluation—incorporating objective performance metrics, larger and more diverse cohorts, and longitudinal studies—are required before its effectiveness in improving welding skill acquisition can be fully confirmed.

From a scientific perspective, this study contributes a modular Unity–haptic architecture and an exploratory validation approach that expands the body of research on immersive welding education. It demonstrates how SMAW-specific tactile interactions, such as electrode sticking, can be modeled and assessed within a flexible virtual environment. From a practical perspective, the prototype illustrates a viable pathway for integrating accessible, scalable, and sustainable training tools into engineering curricula. By reducing risks and material consumption while improving student confidence and readiness, the simulator addresses pressing pedagogical challenges in early-stage SMAW instruction. Taken together, these contributions underline the broader relevance of locally developed immersive technologies for advancing both educational innovation and industrial skill preparedness in the context of Industry 4.0.