From Apple By-Product to Shortbread Cookies: Drying Conditions and Their Impact on Product Quality

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Drying Processes

2.3. Drying Kinetics and Mathematical Modeling

2.4. Particle Size Characterization Following the Grinding Process

2.5. Cookies Preparations

2.6. Water Content and Activity

2.7. Basic Composition

2.8. Color Evaluation

2.9. Cutting Test

2.10. Sensory Assessment

2.11. Statistical Evaluation

3. Results

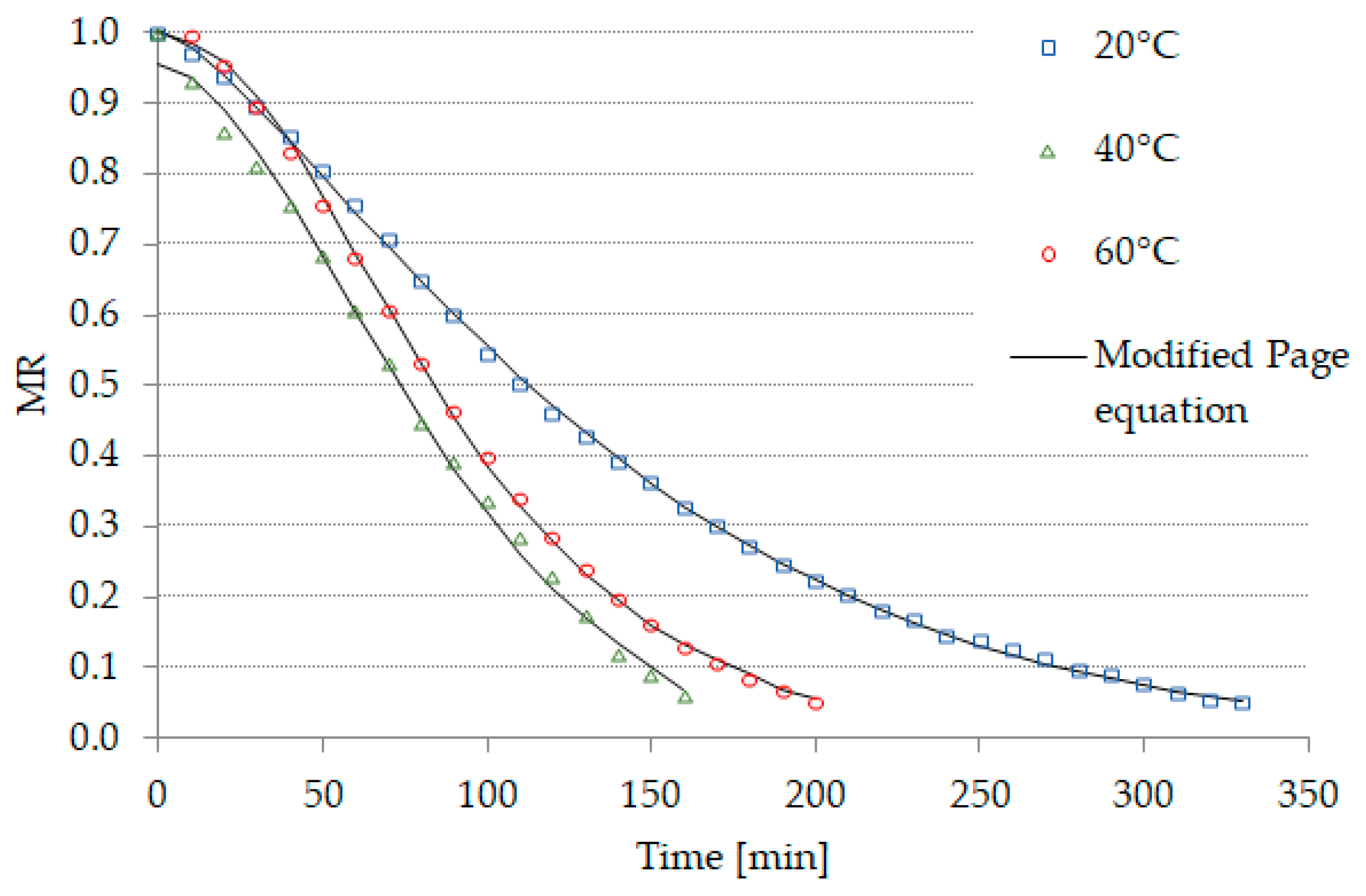

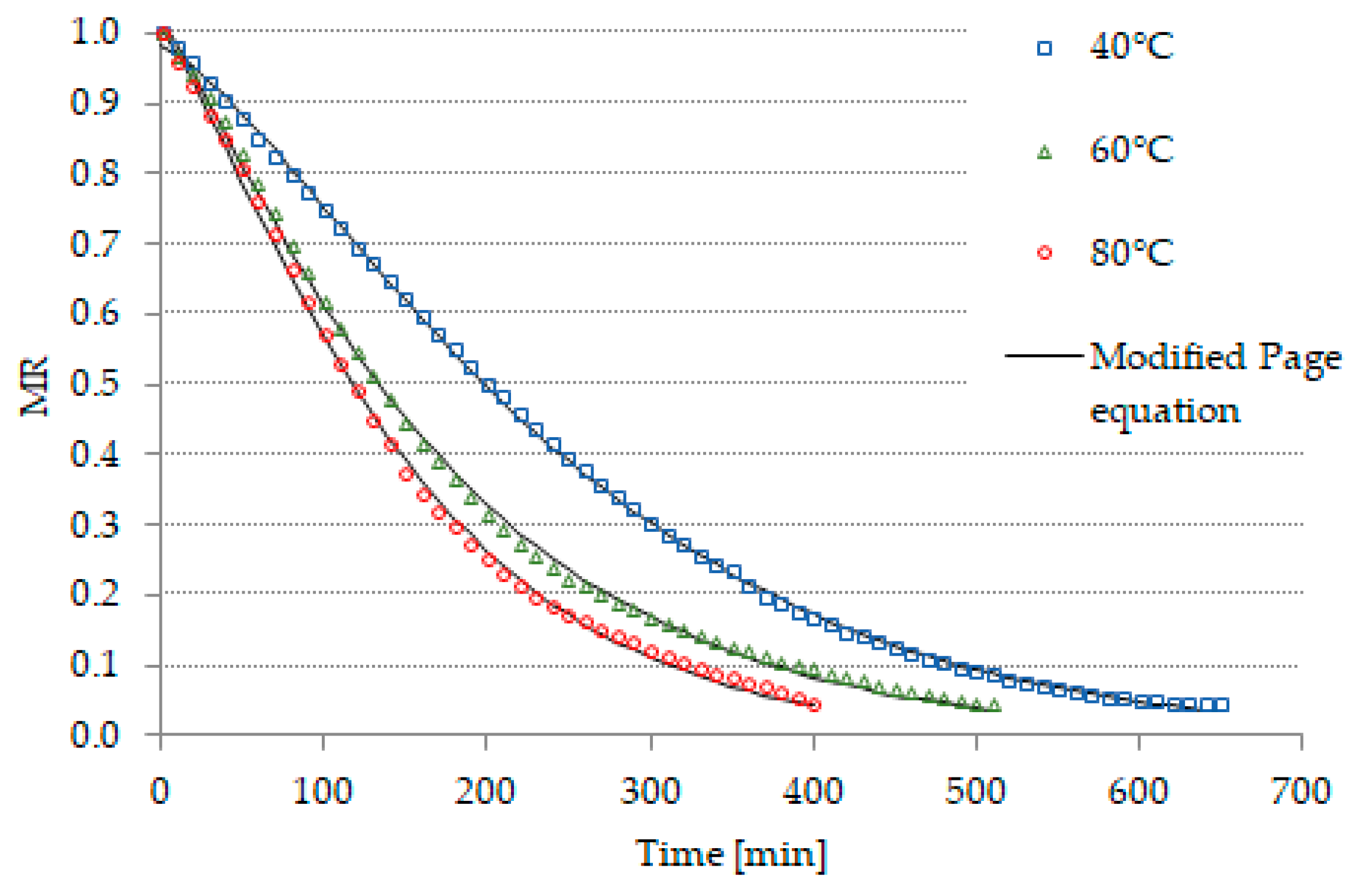

3.1. Modeling Drying Kinetics of Apple By-Product

3.2. Particle Size of Ground ABP

3.3. Basic Composition of Pomace and Cookies

3.4. Color of Apple By-Products and Enriched Cookies

3.5. Hardness of Cookies

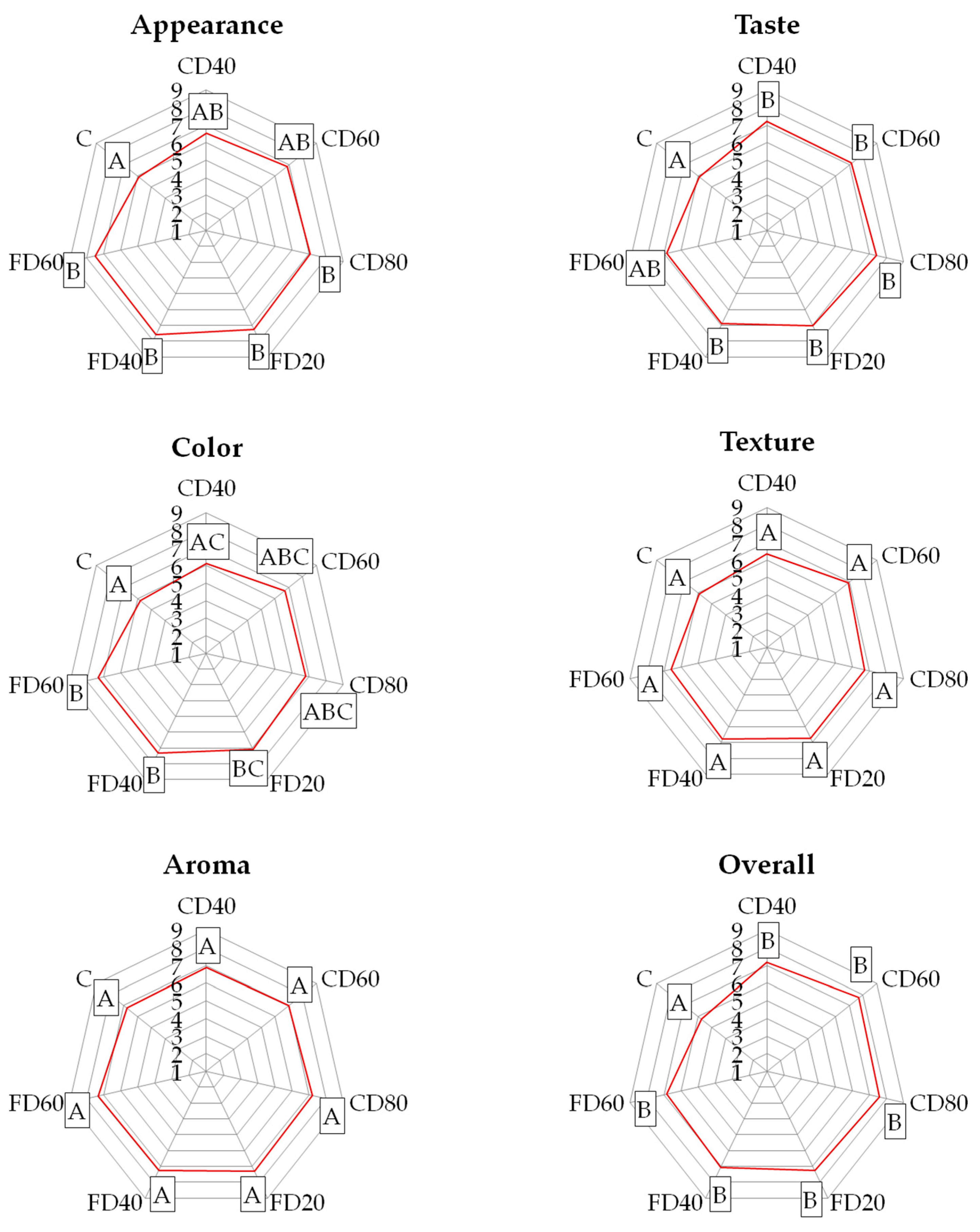

3.6. Sensory Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Majerska, J.; Michalska, A.; Figiel, A. A review of new directions in managing fruit and vegetable processing by-products. Trends Food Sci. Technol. 2019, 88, 207–219. [Google Scholar] [CrossRef]

- Krajewska, A.; Dziki, D. Enrichment of cookies with fruits and their by-products: Chemical composition, antioxidant properties, and sensory changes. Molecules 2023, 28, 4005. [Google Scholar] [CrossRef]

- Gómez, M.; Braojos, M.; Fernández, R.; Parle, F. Utilization of by-products from the fruit and vegetable processing industry in pasta production. Appl. Sci. 2025, 15, 2189. [Google Scholar] [CrossRef]

- Tańska, M.; Roszkowska, B.; Czaplicki, S.; Borowska, E.J.; Bojarska, J.; Dąbrowska, A. Effect of fruit pomace addition on shortbread cookies to improve their physical and nutritional values. Plant Foods Hum. Nutr. 2016, 71, 307–313. [Google Scholar] [CrossRef] [PubMed]

- Theagarajan, R.; Malur Narayanaswamy, L.; Dutta, S.; Moses, J.A.; Chinnaswamy, A. Valorisation of grape pomace (cv. muscat) for development of functional cookies. Int. J. Food Sci. Technol. 2019, 54, 1299–1305. [Google Scholar] [CrossRef]

- Tarko, T.; Duda-Chodak, A.; Bebak, A. Biological activity of selected fruit and vegetable pomaces. Zywn. Nauk. Technol. Jakosc/Food. Sci. Technol. Qual. 2012, 19, 55–65. [Google Scholar] [CrossRef]

- Llavata, B.; Picinelli, A.; Simal, S.; Cárcel, J.A. Cider apple pomace as a source of nutrients: Evaluation of the polyphenolic profile, antioxidant and fiber properties after drying process at different temperatures. Food Chem. X 2022, 15, 100403. [Google Scholar] [CrossRef]

- Kaur, N.; Aggarwal, P.; Kaur, S. Phytochemical profile and techno-functional properties of black carrot (Daucus carota) pomace powder for the formulation of nutraceutical tablets: An impact of drying methods. Biomass Convers. Biorefinery 2024, 14, 23473–23483. [Google Scholar] [CrossRef]

- Zhong, C.; Zu, Y.; Zhao, X.; Li, Y.; Ge, Y.; Wu, W.; Zhang, Y.; Li, Y.; Guo, D. Effect of Superfine Grinding on Physicochemical and Antioxidant Properties of Pomegranate Peel. Int. J. Food Sci. Technol. 2015, 51, 212–221. [Google Scholar] [CrossRef]

- Antal, T.; Kerekes, B. Investigation of Hot Air- and Infrared-Assisted Freeze-Drying of Apple. J. Food Process. Preserv. 2016, 40, 257–269. [Google Scholar] [CrossRef]

- Wang, L.; Wen, H.; Yang, N.; Li, H. Effect of Vacuum Freeze Drying and Hot Air Drying on Dried Mulberry Fruit Quality. PLoS ONE 2023, 18, e0283303. [Google Scholar] [CrossRef]

- Barbosa, J.; Borges, S.; Amorim, M.; Pereira, M.J.; Oliveira, A.; Pintado, M.E.; Teixeira, P. Comparison of Spray Drying, Freeze Drying and Convective Hot Air Drying for the Production of a Probiotic Orange Powder. J. Funct. Foods 2015, 17, 340–351. [Google Scholar] [CrossRef]

- Ratti, C. Hot Air and Freeze-Drying of High-Value Foods: A Review. J. Food Eng. 2001, 49, 311–319. [Google Scholar] [CrossRef]

- Kittibunchakul, S.; Temviriyanukul, P.; Chaikham, P.; Kemsawasd, V. Effects of Freeze Drying and Convective Hot-Air Drying on Predominant Bioactive Compounds, Antioxidant Potential and Safe Consumption of Maoberry Fruits. LWT–Food Sci. Technol. 2023, 184, 114992. [Google Scholar] [CrossRef]

- Krajewska, A.; Dziki, D.; Yilmaz, M.A.; Özdemir, F.A. Broccoli Pomace: Effect of Drying Methods and Temperature on the Grinding Process and Physicochemical Properties. Int. Agrophysics 2024, 38, 423–436. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Yi, J.; Jin, X.; Li, X.; Feng, S.; Bi, J. Freeze-drying of fruits and vegetables in food industry: Effects on phytochemicals and bioactive properties attributes—A comprehensive review. Food Rev. Int. 2023, 39, 6611–6629. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Hu, L. High efficient freeze-drying technology in food industry. Crit. Rev. Food Sci. Nutr. 2022, 62, 3370–3388. [Google Scholar] [CrossRef] [PubMed]

- Stratta, L.; Capozzi, L.C.; Franzino, S.; Pisano, R. Economic analysis of a freeze-drying cycle. Processes 2020, 8, 1399. [Google Scholar] [CrossRef]

- Rocha Parra, A.F.; Sahagún, M.; Ribotta, P.D.; Ferrero, C.; Gómez, M. Particle size and hydration properties of dried apple pomace: Effect on dough viscoelasticity and quality of sugar-snap cookies. Food Bioprocess Technol. 2019, 12, 1083–1092. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K. Evaluation of Drying Models of Apple (Var. McIntosh) Dried in a Convective Dryer. Int. J. Food Sci. Technol. 2010, 45, 891–898. [Google Scholar] [CrossRef]

- Naseem, Z.; Bhat, N.A.; Mir, S.A. Valorisation of apple pomace for the development of high-fibre and polyphenol-rich wheat flour cookies. Sci. Rep. 2024, 14, 25912. [Google Scholar] [CrossRef]

- Tulej, W.; Głowacki, S. Modeling of the Drying Process of Apple Pomace. Appl. Sci. 2022, 12, 1434. [Google Scholar] [CrossRef]

- Demiray, E.; Yazar, J.G.; Aktok, Ö.; Çulluk, B.; Çalişkan Koç, G.; Pandiselvam, R. The Effect of Drying Temper ature and Thickness on the Drying Kinetic, Antioxidant Activity, Phenolic Compounds, and Color Values of Apple Slices. J. Food Qual. 2023, 2023, 7426793. [Google Scholar] [CrossRef]

- Rurush, E.; Alvarado, M.; Palacios, P.; Flores, Y.; Rojas, M.L.; Miano, A.C. Drying Kinetics of Blueberry Pulp and Mass Transfer Parameters: Effect of Hot Air and Refractance Window Drying at Different Temperatures. J. Food Eng. 2022, 320, 110929. [Google Scholar] [CrossRef]

- Skinner, R.C.; Gigliotti, J.C.; Ku, K.M.; Tou, J.C. A comprehensive analysis of the composition, health benefits, and safety of apple pomace. Nutr. Rev. 2018, 76, 893–909. [Google Scholar] [CrossRef] [PubMed]

- Motevali, A.; Younji, S.; Chayjan, R.A.; Aghilinategh, N.; Banakar, A. Drying kinetics of dill leaves in a convective dryer. Int. Agrophysics 2013, 27, 39–47. [Google Scholar] [CrossRef]

- Chabane, F.; Moummi, N.; Brima, A. An Experimental Study and Mathematical Modeling of Solar Drying of Moisture Content of the Mint, Apricot, and Green Pepper. Energy Sources Part A Recovery Util. Environ. Eff. 2023, 45, 4697–4711. [Google Scholar] [CrossRef]

- Page, G.E. Factors Influencing the Maximum Rates of Air Drying Shelled Corn in Thin Layers. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 1949. [Google Scholar]

- Babalis, S.J.; Papanicolaou, E.; Kyriakis, N.; Belessiotis, V.G. Evaluation of thin-layer drying models for describing drying kinetics of figs (Ficus carica). J. Food Eng. 2006, 75, 205–214. [Google Scholar] [CrossRef]

- Henderson, S.M.; Pabis, S. Grain drying theory (I) temperature effect on drying coefficient. J. Agric. Eng. Res. 1961, 6, 169–174. [Google Scholar]

- Isa, J.; Majasan, O.I.; Jimoh, K.A. Mathematical modelling of the drying characteristics of milled sorghum residue. J. Eng. Res. Rep. 2021, 21, 1–17. [Google Scholar] [CrossRef]

- Wang, C.; Singh, R. Use of variable equilibrium moisture content in modeling rice drying. Trans. ASAE (Am. Soc. Agric. Eng.) 1978, 11, 668–672. [Google Scholar]

- Kohli, D.; Singh Champawat, P.; Kumar Jain, S.; Dayal Mudgal, V.; Chand Shahi, N. Mathematical modelling for drying kinetics of asparagus roots (Asparagus racemosus L.) and determination of energy consumption. Biointerface Res. Appl. Chem. 2022, 12, 3572–3589. [Google Scholar] [CrossRef]

- Wagner, C.E.; Richter, J.K.; Ikuse, M.; Ganjyal, G.M. Classification of select functional dietary fiber ingredients based on quantitative properties and latent qualitative criteria. J. Food Sci. 2024, 89, 6098–6112. [Google Scholar] [CrossRef]

- Krajewska, A.; Dziki, D. Utilization of pear pomace as a functional additive in biscuit production: Physicochemical and sensory evaluation. Int. Agrophysics 2025, 39, 53–60. [Google Scholar] [CrossRef]

- American Association of Cereal Chemistry (AACC). American Association of Cereal Chemistry Approved Methods, 10th ed.; American, Association of Cereal Chemistry (AACC): St. Paul, MN, USA, 2021; Available online: http://methods.aaccnet.org/toc.aspx (accessed on 25 May 2023).

- Association of Official Analytical Chemists International (AOAC). Official Methods, 20th ed.; (AOAC International Rockville, Maryland, USA). Available online: https://www.aoac.org/official-methods-of-analysis/ (accessed on 29 July 2020).

- Wichchukit, S.; O’Mahony, M. The 9-point hedonic scale and hedonic ranking in food science: Some reappraisals and alternatives. J. Sci. Food Agric. 2015, 95, 2167–2178. [Google Scholar] [CrossRef]

- Kingsly, A.R.P.; Singh, D.B. Drying kinetics of pomegranate arils. J. Food Eng. 2007, 79, 741–744. [Google Scholar] [CrossRef]

- Cavalcanti-Mata, M.E.R.M.; Duarte, M.E.M.; Lira, V.V.; de Oliveira, R.F.; Costa, N.L.; Oliveira, H.M.L. A New approach to the traditional drying models for the thin-layer drying kinetics of chickpeas. J. Food Process Eng. 2020, 43, e13569. [Google Scholar] [CrossRef]

- Simal, S. Use of exponential, Page’s and diffusional models to simulate the drying kinetics of kiwi fruit. J. Food Eng. 2004, 66, 323–328. [Google Scholar] [CrossRef]

- Topal, M.E.; Şahin, B.; Vela, S. Artificial Neural Network Modeling Techniques for Drying Kinetics of Citrus Medica Fruit during the Freeze-Drying Process. Processes 2024, 12, 1362. [Google Scholar] [CrossRef]

- Delfiya, D.S.A.; Prashob, K.; Murali, S.; Alfiya, P.V.; Samuel, M.P.; Pandiselvam, R. Drying kinetics of food materials in infrared radiation drying: A review. J. Food Process Eng. 2022, 45, e13810. [Google Scholar] [CrossRef]

- Krajewska, A.; Dziki, D.; Yilmaz, M.A.; Özdemir, F.A. Physicochemical properties of dried and powdered pear pomace. Molecules 2024, 29, 742. [Google Scholar] [CrossRef]

- Fante, L.; Noreña, C.P.Z. Quality of hot air dried and freeze-dried of garlic (Allium sativum L.). J. Food Sci. Technol. 2015, 52, 211–220. [Google Scholar] [CrossRef]

- Belorio, M.; Sahagún, M.; Gómez, M. Influence of flour particle size distribution on the quality of maize gluten-free cookies. Foods 2019, 8, 83. [Google Scholar] [CrossRef]

- Chen, Y.M.; Wan, J.Q.; Huang, M.Z.; Ma, Y.W.; Wang, Y.; Lv, H.L.; Yang, J. Influence of drying temperature and duration on fiber properties of unbleached wheat straw pulp. Carbohydr. Polym. 2011, 85, 759–764. [Google Scholar] [CrossRef]

- Cantero, L.; Salmerón, J.; Miranda, J.; Larretxi, I.; Fernández-Gil, M.D.P.; Bustamante, M.Á.; Matias, S.; Navarro, V.; Simón, E.; Martínez, O. Performance of apple pomace for gluten-free bread manufacture: Effect on physicochemical characteristics and nutritional value. Appl. Sci. 2022, 12, 5934. [Google Scholar] [CrossRef]

- Rana, S.; Rana, A.; Gupta, S.; Bhushan, S. Varietal Influence on phenolic constituents and nutritive characteristics of pomace obtained from apples grown in Western Himalayas. J. Food Sci. Technol. 2021, 58, 166–174. [Google Scholar] [CrossRef] [PubMed]

- Lyu, F.; Luiz, S.F.; Azeredo, D.R.P.; Cruz, A.G.; Ajlouni, S.; Ranadheera, C.S. Apple pomace as a functional and healthy ingredient in food products: A review. Processes 2020, 8, 319. [Google Scholar] [CrossRef]

- Usman, M.; Ahmed, S.; Mehmood, A.; Bilal, M.; Patil, P.J.; Akram, K.; Farooq, U. Effect of apple pomace on nutrition, rheology of dough and cookies quality. J. Food Sci. Technol. 2020, 57, 3244–3251. [Google Scholar] [CrossRef] [PubMed]

- Suresh, A.; Shobna; Salaria, M.; Morya, S.; Khalid, W.; Afzal, F.A.; Khan, A.A.; Safdar, S.; Khalid, M.Z.; Mukonzo Kasongo, E.L. Dietary fiber: An unmatched food component for sustainable health. Food Agric. Immunol. 2024, 35, 2384420. [Google Scholar] [CrossRef]

- Gowman, A.C.; Picard, M.C.; Rodriguez-Uribe, A.; Misra, M.; Khalil, H.; Thimmanagari, M.; Mohanty, A.K. Physicochemical Analysis of Apple and Grape Pomaces. BioResources 2019, 14, 3210–3230. [Google Scholar] [CrossRef]

- Parisi, S.; Luo, W. Maillard reaction and processed foods—Main chemical products. In Chemistry of Maillard Reactions in Processed Foods; SpringerBriefs in Molecular Science; Springer International Publishing: Cham, Switzerland, 2018; pp. 53–59. [Google Scholar] [CrossRef]

- Lin, L.; Sun, Y.; Zhang, P. Color development kinetics of maillard reactions. Ind. Eng. Chem. Res. 2021, 60, 3495–3501. [Google Scholar] [CrossRef]

- Aradwad, P.P.; Thirumani Venkatesh, A.K.; Mani, I. Infrared drying of apple (Malus domestica) slices: Effect on drying and color kinetics, texture, rehydration, and microstructure. J. Food Process Eng. 2023, 46, e14218. [Google Scholar] [CrossRef]

- Fontana, M.; Murowaniecki Otero, D.; Pereira, A.M.; Santos, R.B.; Gularte, M.A. Grape pomace flour for incorporation into cookies: Evaluation of nutritional, sensory and technological characteristics. J. Culin. Sci. Technol. 2024, 22, 850–869. [Google Scholar] [CrossRef]

- Yang, L.; Wang, S.; Zhang, W.; Zhang, H.; Guo, L.; Zheng, S.; Du, C. Effect of black soybean flour particle size on the nutritional, texture and physicochemical characteristics of cookies. LWT-Food Sci Technol. 2022, 164, 113649. [Google Scholar] [CrossRef]

- Oyinloye, T.M.; Yoon, W.B. Effect of freeze-drying on quality and grinding process of food produce: A review. Processes 2020, 8, 354. [Google Scholar] [CrossRef]

- Ando, Y.; Nei, D. Comparison of potato void structures dried by air-drying, freeze-drying, and microwave-vacuum-drying, and the physical properties of powders after grinding. Food Bioprocess Technol. 2023, 16, 447–458. [Google Scholar] [CrossRef]

- Jose, M.; Himashree, P.; Sengar, A.S.; Sunil, C.K. Valorization of food industry by-product (pineapple pomace): A study to evaluate its effect on physicochemical and textural properties of developed cookies. Meas. Food 2022, 6, 100031. [Google Scholar] [CrossRef]

- Zlatanović, S.; Kalušević, A.; Micić, D.; Laličić-Petronijević, J.; Tomić, N.; Ostojić, S.; Gorjanović, S. Functionality and storability of cookies fortified at the industrial scale with up to 75% of apple pomace flour produced by dehydration. Foods 2019, 8, 561. [Google Scholar] [CrossRef] [PubMed]

- Nishinari, K.; Fang, Y.; Rosenthal, A. Human oral processing and texture profile analysis parameters: Bridging the gap between the sensory evaluation and the instrumental measurements. J. Texture Stud. 2019, 50, 369–380. [Google Scholar] [CrossRef] [PubMed]

| Number | Model | Equation | |

|---|---|---|---|

| 1 | Newton [27] | Equation (2) | |

| 2 | Page [28] | Equation (3) | |

| 3 | Modified Page [29] | Equation (4) | |

| 4 | Handerson and Pabis [30] | Equation (5) | |

| 5 | Logarythmic [31] | Equation (6) | |

| 6 | Wang and Singh [32] | Equation (7) | |

| 7 | Logistic [33] | Equation (8) |

| Model | Sample | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 20 °C | 40 °C | 60 °C | |||||||

| R2 | RMSE | χ2 | R2 | RMSE | χ2 | R2 | RMSE | χ2 | |

| 1 | 0.971 | 0.015 | 1.488 × 10−4 | 0.928 | 0.040 | 1.687 × 10−3 | 0.939 | 0.025 | 6.665 × 10−4 |

| 2 | 0.999 | 0.002 | 3.673 × 10−8 | 0.999 | 0.001 | 5.214 × 10−7 | 0.994 | 0.003 | 7.490 × 10−6 |

| 3 | 0.999 | 0.001 | 3.253 × 10−8 | 0.999 | 0.001 | 3.596 × 10−7 | 0.996 | 0.002 | 3.407 × 10−6 |

| 4 | 0.986 | 0.007 | 6.208 × 10−5 | 0.959 | 0.023 | 5.706 × 10−4 | 0.954 | 0.019 | 3.973 × 10−4 |

| 5 | 0.995 | 0.002 | 6.803 × 10−6 | 0.982 | 0.010 | 1.146 × 10−4 | 0.996 | 0.002 | 2.880 × 10−6 |

| 6 | 0.995 | 0.003 | 2.823 × 10−6 | 0.975 | 0.014 | 2.164 × 10−4 | 0.996 | 0.002 | 3.032 × 10−6 |

| 7 | 0.889 | 0.059 | 3.867 × 10−3 | 0.836 | 0.092 | 9.629 × 10−3 | 0.846 | 0.033 | 1.177 × 10−3 |

| Model | Sample | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 20 °C | 40 °C | 60 °C | |||||||

| R2 | RMSE | χ2 | R2 | RMSE | χ2 | R2 | RMSE | χ2 | |

| 1 | 0.977 | 0.017 | 2.865 × 10−3 | 0.989 | 0.007 | 4.582 × 10−5 | 0.983 | 0.009 | 8.646 × 10−5 |

| 2 | 0.999 | 0.001 | 1.262 × 10−7 | 0.998 | 0.001 | 1.137 × 10−7 | 0.999 | 0.001 | 8.163 × 10−7 |

| 3 | 0.999 | 0.001 | 4.923 × 10−8 | 0.999 | 0.001 | 7.248 × 10−7 | 0.998 | 0.001 | 7.819 × 10−7 |

| 4 | 0.987 | 0.009 | 8.920 × 10−5 | 0.996 | 0.003 | 7.497 × 10−6 | 0.992 | 0.005 | 2.184 × 10−5 |

| 5 | 0.996 | 0.003 | 8.279 × 10−6 | 0.996 | 0.002 | 5.094 × 10−6 | 0.995 | 0.003 | 9.923 × 10−6 |

| 6 | 0.998 | 0.001 | 1.164 × 10−6 | 0.995 | 0.003 | 1.031 × 10−5 | 0.984 | 0.002 | 5.983 × 10−6 |

| 7 | 0.987 | 0.009 | 9.543 × 10−5 | 0.996 | 0.003 | 7.663 × 10−6 | 0.902 | 0.055 | 3.237 × 10−3 |

| Temperature of Heating Plates | Model | Coefficient | |||

|---|---|---|---|---|---|

| a | k (min−1) | n | b | ||

| 20 °C | 1 | 0.006850 | |||

| 2 | 0.001149 | 1.353876 | |||

| 3 | 1.005718 | 0.001231 | 1.341492 | ||

| 4 | 1.106479 | 0.007606 | |||

| 5 | 1.246105 | 0.005374 | −0.183377 | ||

| 6 | −0.005222 | 0.000007 | |||

| 7 | 0.000024 | 0.000001 | −0.999980 | ||

| 40 °C | 1 | 0.009664 | |||

| 2 | 0.000338 | 1.716085 | |||

| 3 | 1.015958 | 0.000425 | 1.670972 | ||

| 4 | 1.169251 | 0.011266 | |||

| 5 | 1.440053 | 0.006628 | −0.330720 | ||

| 6 | −0.006998 | 0.000011 | |||

| 7 | 0.000020 | 0.000001 | −0.999984 | ||

| 60 °C | 1 | 0.010988 | |||

| 2 | 0.000827 | 1.572410 | |||

| 3 | 0.955788 | 0.000400 | 1.719416 | ||

| 4 | 1.100717 | 0.012184 | |||

| 5 | 2.26321 | 0.00353 | −1.24166 | ||

| 6 | −0.007381 | 0.000009 | |||

| 7 | 0.000015 | 0.000001 | −0.999987 | ||

| Drying Conditions | Model | Coefficient | |||

|---|---|---|---|---|---|

| a | k (min−1) | n | b | ||

| 40 °C | 1 | 0.003927 | |||

| 2 | 0.000669 | 1.313040 | |||

| 3 | 0.983331 | 0.000535 | 1.349242 | ||

| 4 | 1.096148 | 0.004305 | |||

| 5 | 1.193991 | 0.003190 | −0.142006 | ||

| 6 | −0.002976 | 0.000002 | |||

| 7 | −210.9870 | 0.004000 | −193.4260 | ||

| 60 °C | 1 | 0.005529 | |||

| 2 | 0.002061 | 1.185464 | |||

| 3 | 1.024774 | 0.002629 | 1.144678 | ||

| 4 | 1.077641 | 0.005963 | |||

| 5 | 1.094867 | 0.005518 | −0.030441 | ||

| 6 | −0.004255 | 0.000005 | |||

| 7 | −3102.390 | 0.010000 | −2879.800 | ||

| 80 °C | 1 | 0.006409 | |||

| 2 | 0.001833 | 1.243122 | |||

| 3 | 1.010475 | 0.002049 | 1.223719 | ||

| 4 | 1.083984 | 0.006959 | |||

| 5 | 1.129610 | 0.005937 | −0.069461 | ||

| 6 | −0.004989 | 0.000007 | |||

| 7 | 0.000027 | 0.000001 | −0.999977 | ||

| Drying Method | Drying Temperature (°C) | d10 (µm) | d50 (µm) | d90 (µm) | Span |

|---|---|---|---|---|---|

| FD | 20 | 45.59 ± 0.46 a | 182.12 ± 1.34 b | 315.84 ± 2.37 a | 1.48 ± 0.00 ab |

| 40 | 43.47 ± 1.33 a | 176.37 ± 1.14 a | 314.43 ± 1.92 a | 1.54 ± 0.02 bc | |

| 60 | 43.57 ± 1.03 a | 173.63 ± 1.97 a | 315.38 ± 7.64 a | 1.57 ± 0.04 c | |

| CD | 40 | 54.13 ± 1.22 b | 188.75 ± 1.72 c | 333.73 ± 1.30 c | 1.48 ± 0.01 a |

| 60 | 55.01 ± 0.24 b | 189.30 ± 0.91 c | 328.93 ± 1.27 bc | 1.45 ± 0.01 a | |

| 80 | 53.01 ± 0.86 b | 188.81 ± 2.58 c | 323.79 ± 1.69 ab | 1.43 ± 0.01 a |

| DM | DT | Fat | Ash | Protein | IDF | SDF | TDF | Carbohydrates |

|---|---|---|---|---|---|---|---|---|

| CABP | - | 2.72 ± 0.06 a | 1.45 ± 0.03 a | 4.20 ± 0.03 a | 27.22 ± 0.12 b | 10.92 ± 0.26 a | 37.14 ± 0.22 b | 54.50 |

| CD | 40 | 2.67 ± 0.09 a | 1.42 ± 0.03 a | 4.21 ± 0.12 a | 29.47 ± 0.36 c | 11.79 ± 0.11 b | 39.44 ± 0.46 c | 52.26 |

| 60 | 2.75 ± 0.11 a | 1.48 ± 0.04 a | 4.19 ± 0.14 a | 26.79 ± 0.16 b | 10.83 ± 0.08 ab | 37.63 ± 0.23 b | 53.96 | |

| 80 | 2.70 ± 0.07 a | 1.46 ± 0.02 a | 4.14 ± 0.05 a | 25.39 ± 0.12 a | 10.20 ± 0.50 a | 35.59 ± 0.62 a | 56.10 | |

| FD | 20 | 2.68 ± 0.08 a | 1.44 ± 0.02 a | 4.10 ± 0.06 a | 26.30 ± 0.18 ab | 11.46 ± 0.25 b | 37.76 ± 0.11 b | 54.03 |

| 40 | 2.69 ± 0.05 a | 1.45 ± 0.03 a | 4.20 ± 0.13 a | 25.25 ± 0.49 a | 11.55 ± 0.11 b | 36.80 ± 0.40 ab | 54.85 | |

| 60 | 2.75 ± 0.04 a | 1.46 ± 0.02 a | 4.18 ± 0.06 a | 25.87 ± 0.44 a | 11.94 ± 0.26 b | 37.81 ± 0.18 b | 53.81 |

| DM | DT | Fat | Ash | Protein | IDF | SDF | TDF | Carbohydrates |

|---|---|---|---|---|---|---|---|---|

| CC | - | 24.82 ± 0.04 A | 0.36 ± 0.02 A | 8.69 ± 0.73 B | 2.99 ± 0.02 A | 3.58 ± 0.07 A | 6.57 ± 0.09 A | 59.56 |

| CD | 40 | 24.44 ± 0.28 A | 0.50 ± 0.01 AB | 7.67 ± 0.04 A | 6.72 ± 0.31 D | 5.03 ± 0.19 C | 11.75 ± 0.14 E | 55.64 |

| 60 | 24.66 ± 0.03 A | 0.44 ± 0.02 B | 7.60 ± 0.11 A | 5.20 ± 0.12 B | 4.79 ± 0.40 BC | 9.99 ± 0.28 BC | 57.31 | |

| 80 | 24.29 ± 0.35 A | 0.52 ± 0.02 AB | 7.67 ± 0.26 A | 6.02 ± 0.05 C | 4.54 ± 0.13 BC | 10.56 ± 0.08 D | 56.96 | |

| FD | 20 | 24.44 ± 0.28 A | 0.51 ± 0.03 AB | 7.61 ± 0.08 A | 5.61 ± 0.31 BC | 4.72 ± 0.17 BC | 10.33 ± 0.15 CD | 57.11 |

| 40 | 24.72 ± 0.12 A | 0.51 ± 0.03 AB | 7.62 ± 0.23 A | 5.46 ± 0.09 B | 4.35 ± 0.04 B | 9.82 ± 0.10 B | 57.34 | |

| 60 | 24.60 ± 0.43 A | 0.59 ± 0.18 B | 7.48 ± 0.06 A | 5.69 ± 0.07 BC | 4.51 ± 0.15 BC | 10.20 ± 0.08 BCD | 57.13 |

| DM | DT | L* | a* | b* |

|---|---|---|---|---|

| CABP | - | 79.99 ± 0.13 d | 4.21 ± 0.19 b | 22.48 ± 0.31 b |

| CD | 40 | 74.18 ± 0.53 c | 9.78 ± 0.08 d | 27.57 ± 0.35 e |

| 60 | 72.63 ± 0.41 b | 9.62 ± 0.08 d | 23.60 ± 0.34 c | |

| 80 | 67.40 ± 0.58 a | 8.90 ± 0.12 c | 24.54 ± 0.41 d | |

| FD | 20 | 80.04 ± 0.33 d | 4.26 ± 0.15 b | 22.54 ± 0.26 b |

| 40 | 80.19 ± 0.57 d | 3.61 ± 0.15 a | 21.14 ± 0.07 a | |

| 60 | 80.41 ± 0.31 d | 3.48 ± 0.28 a | 20.72 ± 0.06 a |

| DM | DT | L* | a* | b* | Cutting Force [N] |

|---|---|---|---|---|---|

| CC | - | 75.15 ± 0.06 D | 5.08 ± 0.01 A | 26.59 ± 0.02 A | 39.14 ± 2.32 BC |

| CD | 40 | 60.74 ± 0.16 A | 13.65 ± 0.32 D | 28.76 ± 0.60 BC | 31.62 ± 2.78 A |

| 60 | 60.70 ± 0.72 A | 13.30 ± 0.40 D | 28.45 ± 0.30 B | 32.54 ± 3.16 A | |

| 80 | 60.02 ± 0.35 A | 12.41 ± 0.27 C | 28.12 ± 0.63 B | 34.62 ± 2.16 AB | |

| FD | 20 | 65.05 ± 0.34 C | 11.54 ± 0.06 B | 30.21 ± 0.47 E | 42.60 ± 1.29 CD |

| 40 | 64.36 ± 0.09 BC | 11.29 ± 0.44 B | 29.79 ± 0.07 DE | 41.08 ± 1.95 CD | |

| 60 | 64.25 ± 0.39 B | 11.35 ± 0.56 B | 29.39 ± 0.21 CD | 45.38 ± 2.36 D |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krajewska, A.; Dziki, D.; Sobota, A. From Apple By-Product to Shortbread Cookies: Drying Conditions and Their Impact on Product Quality. Appl. Sci. 2025, 15, 10667. https://doi.org/10.3390/app151910667

Krajewska A, Dziki D, Sobota A. From Apple By-Product to Shortbread Cookies: Drying Conditions and Their Impact on Product Quality. Applied Sciences. 2025; 15(19):10667. https://doi.org/10.3390/app151910667

Chicago/Turabian StyleKrajewska, Anna, Dariusz Dziki, and Aldona Sobota. 2025. "From Apple By-Product to Shortbread Cookies: Drying Conditions and Their Impact on Product Quality" Applied Sciences 15, no. 19: 10667. https://doi.org/10.3390/app151910667

APA StyleKrajewska, A., Dziki, D., & Sobota, A. (2025). From Apple By-Product to Shortbread Cookies: Drying Conditions and Their Impact on Product Quality. Applied Sciences, 15(19), 10667. https://doi.org/10.3390/app151910667