Innovative Spiral Vibrating Screen for High-Quality Cubical Crushed Stone: Design and Validation

Abstract

1. Introduction

- -

- Provide a theoretical justification for the optimal operating parameters of the spiral vibrating screen;

- -

- Experimentally verify its screening efficiency under various vibration modes;

- -

- Perform a comparative analysis of the spiral screen and conventional screening devices (flat and drum types);

- -

- Assess the energy and environmental efficiency of the proposed design.

2. Materials and Methods

2.1. Experimental Setup

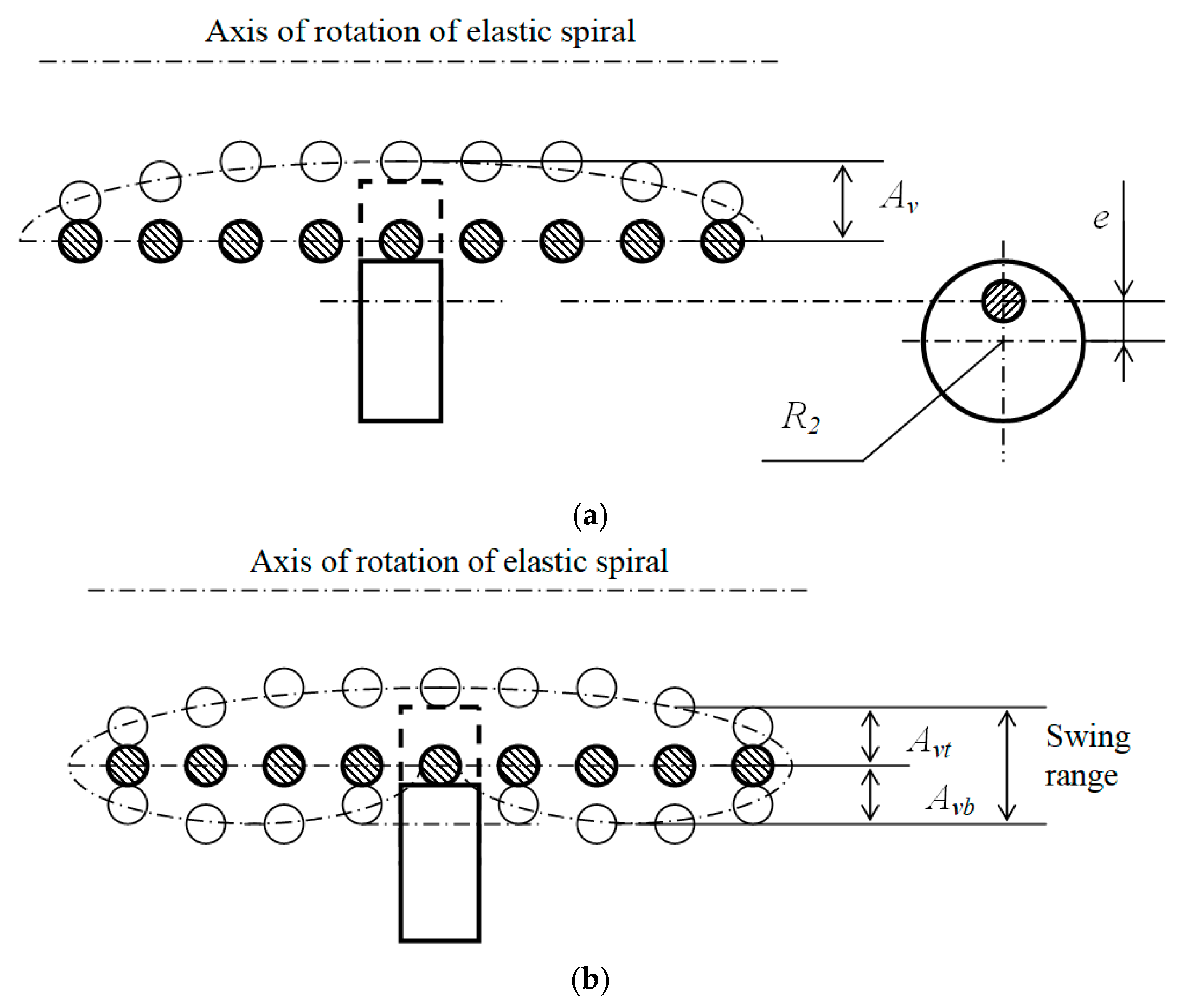

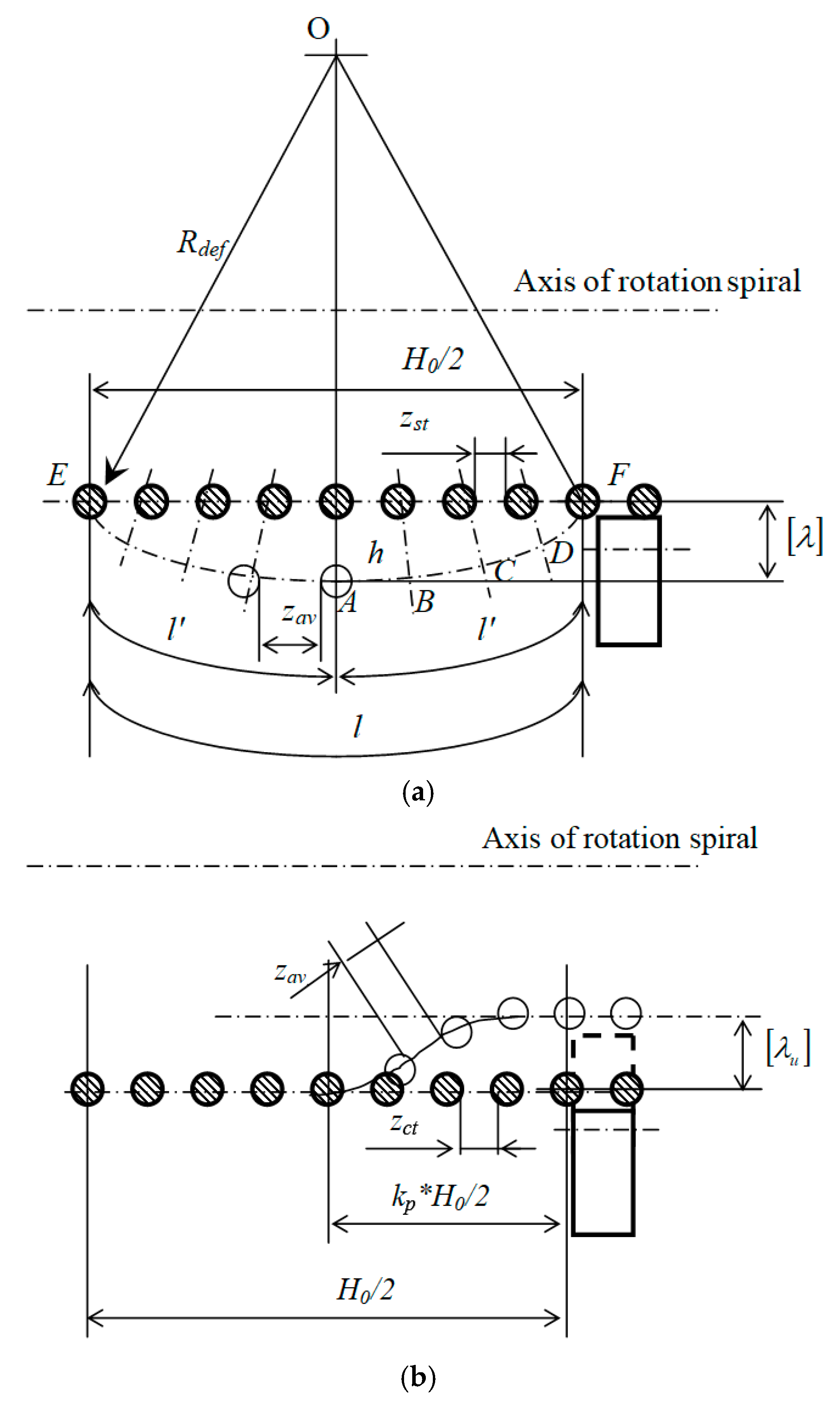

2.2. Mathematical Model

2.3. Experimental Procedure

- −

- The screening efficiency was evaluated using the coefficient Ks, calculated as follows:

- −

- Where m1 is the mass of the material that passed through the sieve surface (undersize fraction), and m0 is the total mass of the feed sample. Values of Ks close to 1 indicate high screening efficiency.

- −

- Particle shape coefficient (cubicality)—the proportion of particles with a length-to-width ratio not exceeding 1.8.

- −

- Specific energy consumption per ton of screened material, kWh/t.

- -

- Cubical particle content—the proportion of grains in the sample with an aspect ratio l/b ≤ 1.8, determined in accordance with GOST 8269.0-97 and EN 933-3:2012.

- -

- Shape coefficient (Kf)—the ratio of the maximum to the minimum dimension of a single particle (Kf = Lmax/Lmin). Values of Kf ≤ 1.35 correspond to cubical aggregates according to standards.

2.4. Data Processing and Statistical Analysis

3. Results

3.1. Performance of the Spiral Vibrating Screen

- -

- The screening efficiency Ks reached 93–95% at the nominal capacity.

- -

- The proportion of cubical particles (according to the criterion l/b ≤ 1.8) ranged from 82% to 86%, depending on the excitation frequency and feed rate.

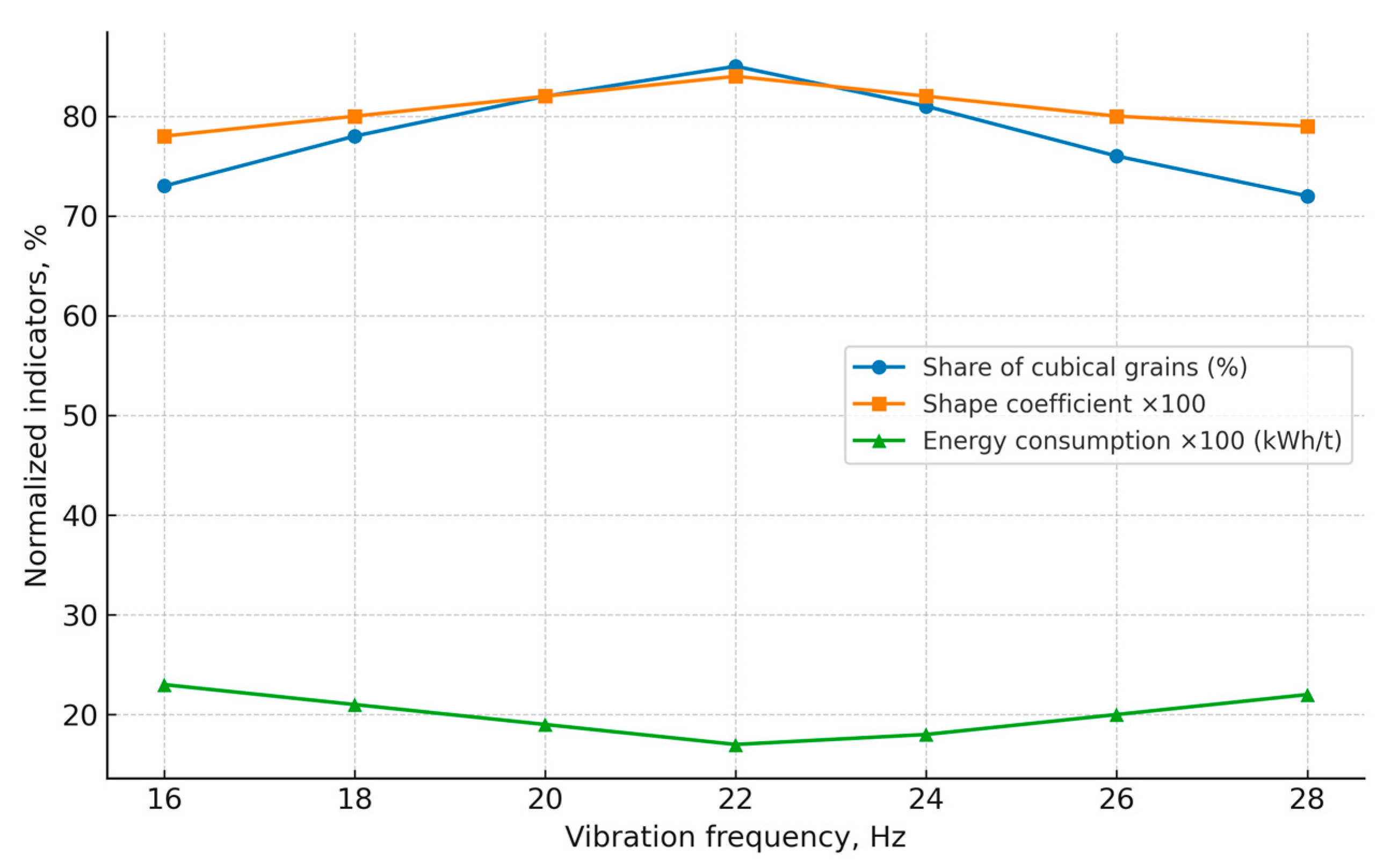

3.2. Influence of Vibration Frequency and Amplitude

3.3. Comparative Analysis with Conventional Screens

3.4. Energy Efficiency and Environmental Impact

4. Discussion

5. Conclusions

- -

- Increase in the proportion of cubical particles to 84–86% due to the original spiral screen surface design and excitation of complex vibrations.

- -

- Reduction in specific energy consumption by 18–26% compared to conventional screens.

- -

- Stable operation of the unit over a wide range of loads and vibration frequencies.

- -

- Adaptability of the design to different fractions and types of materials.

- -

- Confirmed originality and practical applicability of the design, protected by patents.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Bozhyk, D.; Sokur, M.; Biletskyi, V. Determining the rational operating parameters for granite crushing to obtain cubiform crushed stone. Min. Miner. Depos. 2022, 16, 18–25. [Google Scholar] [CrossRef]

- Rabat, O.Z.; Salmanova, A.N. Experimental research of characteristics of crushers with cycloidal motion of working bodies. Periód. Tchê Quím. 2018, 15, 627–639. [Google Scholar] [CrossRef]

- Zhang, H.; Su, Y.; Cheng, C.; Tan, B.; Zhang, W.; Li, L. Optimisation of gradation based on fractal dimension for large-size graded crushed stone. Road Mater. Pavement Des. 2025, 1–17. [Google Scholar] [CrossRef]

- Cherniaiev, O.; Anisimov, O.; Saik, P.; Lozynskyi, V.; Adamchuk, A. Influence of mineral raw material processing on the qualitative and quantitative indicators of crushed stone production. Coll. Res. Pap. Natl. Min. Univ. 2023, 74, 69–86. [Google Scholar] [CrossRef]

- GOST 8267-93; Crushed Stone and Gravel of Solid Rocks for Construction Works—Specifications. Interstate Council for Standardization, Metrology and Certification: Moscow, Russia, 1993. Available online: https://online.zakon.kz/Document/?doc_id=30015052 (accessed on 15 August 2025).

- EN 12620:2002+A1:2008; Aggregates for Concrete. European Committee for Standardization: Brussels, Belgium, 2008. Available online: https://standards.iteh.ai/catalog/standards/cen/27c8e34e-993f-4b1a-989f-8a3263dbe9fb/en-12620-2002a1-2008 (accessed on 17 August 2025).

- ASTM C33/C33M-24a; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- Makinde, O.A.; Ramatsetse, B.I.; Mpofu, K. Review of vibrating screen development trends: Linking the past and the future in mining machinery industries. Int. J. Miner. Process. 2015, 145, 17–22. [Google Scholar] [CrossRef]

- Robben, C.; Wotruba, H. Sensor-based ore sorting technology in mining—Past, present and future. Minerals 2019, 9, 523. [Google Scholar] [CrossRef]

- Duan, X.; Zhang, C. Analysis on current technical status and development of tumbler screening machines in China and abroad. Appl. Mech. Mater. 2015, 743, 26–29. [Google Scholar] [CrossRef]

- Moraes, M.; Galéry, R.; Mazzinghy, D. A review of process models for wet fine classification with high frequency screens. Powder Technol. 2021, 390, 226–236. [Google Scholar] [CrossRef]

- Qin, G.; Sun, L.; Liu, Y.; Zhang, X.; Jing, X.; Ji, Q. Current status and prospects of mineral sorting technology research at home and abroad. E3S Web Conf. 2024, 573, 02015. [Google Scholar] [CrossRef]

- Li, Z.; Jia, P.; Li, K.; Tong, X.; Wu, Z. Study on screening performance and parameter optimization of vibrating-dewatering screen. Adv. Mech. Eng. 2021, 13, 16878140211046580. [Google Scholar] [CrossRef]

- Yelemes, D.Y.; Kalieva, A.D. Technological features of acid activation of clay rocks of the Zhalgyztyube deposit. Key Eng. Mater. 2012, 531–532, 346–350. [Google Scholar] [CrossRef]

- Surashev, N.; Dudkin, M.; Yelemes, D.; Kalieva, A. The planetary vibroexciter with elliptic inner race. Adv. Mater. Res. 2013, 694–697, 229–232. [Google Scholar] [CrossRef]

- Shanmugam, B.; Vardhan, H.; Raj, M.; Kaza, M.; Sah, R.; Hanumanthappa, H. Investigation on the operational parameters of screening coal in the vibrating screen using Taguchi L27 technique. Int. J. Coal Prep. Util. 2021, 42, 3282–3291. [Google Scholar] [CrossRef]

- Li, H.; Mu, G.; Zhang, H.; Wu, H.; Liu, F.; Sun, Z.; Zhang, Q.; Wang, Y.; Wang, Y.; Li, X.; et al. Design and testing of a mechanized brush-screen cooperative vibration harvester for mudflat-buried shellfish based on the discrete element method. Front. Mar. Sci. 2023, 10, 1134888. [Google Scholar] [CrossRef]

- Hafez, A.; Liu, Q.; Finkbeiner, T.; Alouhali, R.; Moellendick, T.; Santamarina, C. The effect of particle shape on discharge and clogging. Sci. Rep. 2021, 11, 3309. [Google Scholar] [CrossRef]

- Li, Y.; Fan, H.; Xu, Y.; Cui, T.; Su, Y.; Qiao, M.; Han, S.; Qian, J.; Zheng, Z. CFD-DEM investigation of particle dispersion degree on a novel vibrating screen. Powder Technol. 2022, 405, 117497. [Google Scholar] [CrossRef]

- Hu, H.; Li, Y.; Lu, Y.; Li, Y.; Song, G.; Wang, X. Numerical study of flow field and particle motion characteristics on raw coal vertical roller mill circuits. Miner. Eng. 2024, 206, 108997. [Google Scholar] [CrossRef]

- Lyu, Z.; Zhou, S. Research on spatial Lissajous trajectory vibrating screen. Adv. Mech. Eng. 2019, 11, 1687814019872851. [Google Scholar] [CrossRef]

- Duan, C.; Yuan, J.; Pan, M.; Huang, T.; Jiang, H.; Zhao, Y.; Qiao, J.; Wang, W.; Yu, S.; Lu, J. Variable elliptical vibrating screen: Particles kinematics and industrial application. Int. J. Min. Sci. Technol. 2021, 31, 951–959. [Google Scholar] [CrossRef]

- Saeidmehr, A.; Steel, P.; Samavati, F. Systematic review using a spiral approach with machine learning. Syst. Rev. 2024, 13, 32. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Zhao, L.; Li, H.; Liu, C.; Hu, E.; Li, Y.; Hou, Q. DEM study of particles flow on an industrial-scale roller screen. Adv. Powder Technol. 2020, 31, 4445–4456. [Google Scholar] [CrossRef]

- Elemes, D.E.; Surashev, N. Innovative Patents on Vibrating Screens and Devices. Nos. 23420, 23421, 23422, 26656, 27371 (IPC B07B 1/22), 2010–2013. Available online: https://kz.patents.su/metka/grohot (accessed on 15 August 2025).

- Arifuzzaman, S.; Dong, K.; Yu, A. Process model of vibrating screen based on DEM and physics-informed machine learning. Powder Technol. 2022, 409, 117869. [Google Scholar] [CrossRef]

- EN 933-3:2012; Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape: Flakiness Index. European Committee for Standardization: Brussels, Belgium, 2012. Available online: https://standards.iteh.ai/catalog/standards/cen/0ccc19d3-9861-4d02-b943-5f166e7cf6d6/en-933-3-2012 (accessed on 15 August 2025).

- GOST 8269.0–97; Mountainous Rock Road Metal and Gravel, Industrial Waste Products for Construction Works—Methods of Physical and Mechanical Tests. Interstate Council for Standardization, Metrology and Certification: Moscow, Russia, 1998. Available online: https://www.russiangost.com/p-19969-gost-82690-97.aspx (accessed on 15 August 2025).

- Shkut, A. Research on the dynamics of transitional regimes in an inertial screen with two motor vibrators. Coll. Res. Pap. Natl. Min. Univ. 2023, 75, 203–210. [Google Scholar] [CrossRef]

- Pylypaka, S.; Volina, T.; Hropost, V.; Babka, V.; Hryshchenko, I. Determination of the form of a spiral spring in a free state. ScienceRise 2023, 12, 46–51. [Google Scholar] [CrossRef]

- Practical Maintenance. Construction, Working and Maintenance of Electric Vibrators and Vibrating Screens. 2018. Available online: https://practicalmaintenance.net/wp-content/uploads/Construction-Working-and-Maintenance-of-Vibrators-and-Vibrating-Screens.pdf (accessed on 15 August 2025).

- Ecoverse. Trommel Screen Drums: Everything You Need to Know. 2023. Available online: https://www.ecoverse.net/blog/trommel-screen-drums-everything-you-need-to-know/ (accessed on 15 August 2025).

- Edge Innovate. Trommel Screens—The Ultimate Guide. 2023. Available online: https://edgeinnovate.com/trommel-screens-the-ultimate-guide/ (accessed on 15 August 2025).

- Yamada, M.; Seko, W.; Yanai, T.; Ninomiya, K.; Seki, M. Slanted, asymmetric microfluidic lattices as size-selective sieves for continuous particle/cell sorting. Lab. Chip 2017, 17, 304–314. [Google Scholar] [CrossRef]

| № | Property | Value | Test Method/Standard |

|---|---|---|---|

| 1 | Rock type | Granite | GOST 8269.0-97 |

| 2 | Density, g/cm3 | 2.65 | GOST 8269.0-97 |

| 3 | Water absorption, % | 0.35 | GOST 8269.0-97 |

| 4 | Compressive strength, MPa | 138 | GOST 8269.0-97 |

| 5 | Flakiness index, % | 22 | GOST 8269.0-97 |

| № | Parameter | Spiral Vibrating Screen | Flat Screen | Drum Screen |

|---|---|---|---|---|

| 1 | Capacity, t/h | 5.0 | 4.0 | 4.3 |

| 2 | Installed power, kW | 5.5 | 6.0 | 5.8 |

| 3 | Vibration frequency, Hz | 5–10 | 12–16 | 3–5 |

| 4 | Inclination angle of the working surface, ° | 12 | 20 | — |

| 5 | Screen surface material | Spring steel | Steel | Steel |

| № | Parameter | Value | Note |

|---|---|---|---|

| 1 | Material name | Crushed stone, 5–20 mm fraction | Granite, fractionated |

| 2 | Bulk density, kg/m3 | 1400–1500 | Moisture content 0.5–1.0% |

| 3 | True density, kg/m3 | 2600–2700 | According to GOST 8269.0 |

| 4 | Moisture content, % | 0.7 | Controlled within ±0.2 |

| 5 | Shape coefficient (elongation) | 1.5–2.0 | Before screening |

| 6 | Content of flat and elongated particles, % | 28–32 | Before screening, according to GOST 8269.0 |

| 7 | Compressive strength, MPa | 120–140 | According to GOST 8269.0 |

| 8 | Volume yield of cubical particles, % | 56–58 | Before screening, according to GOST 8269.0 |

| № | Screen Operating Mode (Frequency/Amplitude) | Percentage of Cubical Particles, % | Percentage of Flaky Particles, % | Shape Coefficient (Kf) | σ (Cubical Particles), % | Note |

|---|---|---|---|---|---|---|

| 1 | 16 Hz/1.5 mm | 78 | 14 | 1.48 | 1.6 | Low amplitude, moderate frequency |

| 2 | 18 Hz/2.0 mm | 81 | 11 | 1.39 | 1.4 | Optimal mode |

| 3 | 20 Hz/2.5 mm | 84 | 9 | 1.33 | 1.2 | Maximum selectivity |

| 4 | 22 Hz/3.0 mm | 86 | 8 | 1.28 | 1.5 | Peak efficiency |

| 5 | 24 Hz/3.5 mm | 83 | 10 | 1.35 | 1.7 | Onset of shape destabilization |

| 6 | 26 Hz/4.0 mm | 79 | 13 | 1.42 | 1.8 | Deterioration due to resonant vibrations |

| № | Parameter | Flat Screen | Drum Screen | Spiral Vibrating Screen |

|---|---|---|---|---|

| 1 | Share of cubiform grains, % | 75–80 | 78–82 | 90–92 |

| 2 | Uniformity of fraction distribution, % | ±5 | ±6–7 | ±3 |

| 3 | Energy consumption, kWh/t | 1.35 | 1.40 | 1.20 |

| 4 | Operating frequency, Hz | 12–16 [31] | 3–5 [32,33] | 16–26 (adjustable) |

| 5 | Inclination angle, ° | 15–25 [31] | - | 12 |

| 6 | Screen surface material | Steel (GOST) | Perforated steel [33] | Spring steel |

| 7 | Drive type | Inertial | Drum with motor-reducer | Cam–eccentric |

| № | Type of Screen | Power Consumption, kWh/t | Reduction Relative to Baseline, % |

|---|---|---|---|

| 1 | Flat | 1.35 | — |

| 2 | Drum | 1.40 | — |

| 3 | Spiral | 1.20 | 11.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yelemes, D.; Yessentay, D.; Rustemov, I.; Bekturganova, N.; Shogelova, N.; Kazhetaev, A.; Kossenko, I. Innovative Spiral Vibrating Screen for High-Quality Cubical Crushed Stone: Design and Validation. Appl. Sci. 2025, 15, 10339. https://doi.org/10.3390/app151910339

Yelemes D, Yessentay D, Rustemov I, Bekturganova N, Shogelova N, Kazhetaev A, Kossenko I. Innovative Spiral Vibrating Screen for High-Quality Cubical Crushed Stone: Design and Validation. Applied Sciences. 2025; 15(19):10339. https://doi.org/10.3390/app151910339

Chicago/Turabian StyleYelemes, Darkhan, Dauren Yessentay, Ilyas Rustemov, Neila Bekturganova, Nazym Shogelova, Arlan Kazhetaev, and Irina Kossenko. 2025. "Innovative Spiral Vibrating Screen for High-Quality Cubical Crushed Stone: Design and Validation" Applied Sciences 15, no. 19: 10339. https://doi.org/10.3390/app151910339

APA StyleYelemes, D., Yessentay, D., Rustemov, I., Bekturganova, N., Shogelova, N., Kazhetaev, A., & Kossenko, I. (2025). Innovative Spiral Vibrating Screen for High-Quality Cubical Crushed Stone: Design and Validation. Applied Sciences, 15(19), 10339. https://doi.org/10.3390/app151910339