Acoustic Emission and Infrared Radiation Temperature Characteristics of Coal with Varying Bedding Planes Under Uniaxial Compression

Abstract

1. Introduction

2. Materials and Methods

2.1. Coal Specimen

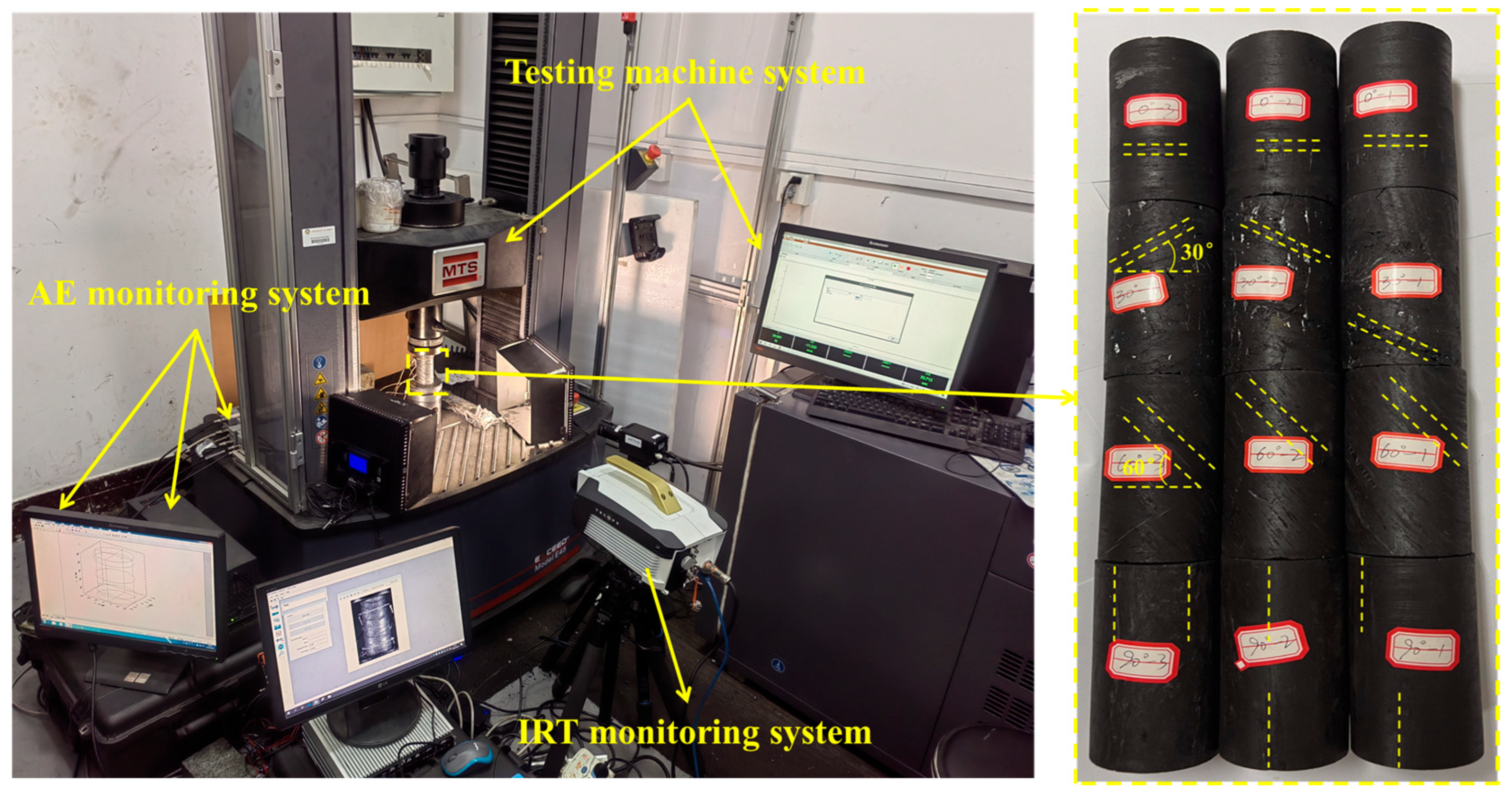

2.2. Testing System

2.3. Experimental Methods

3. Results and Analysis

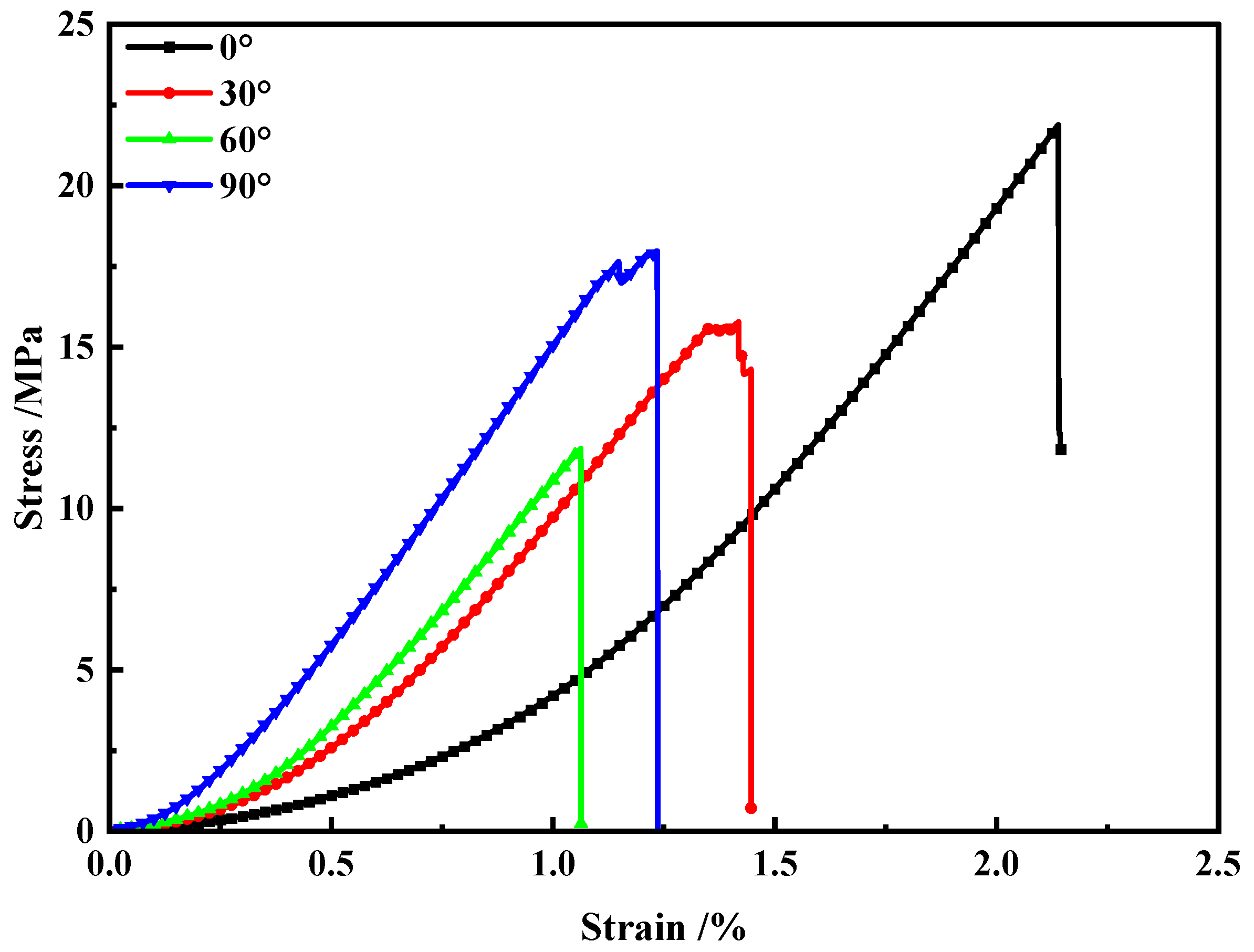

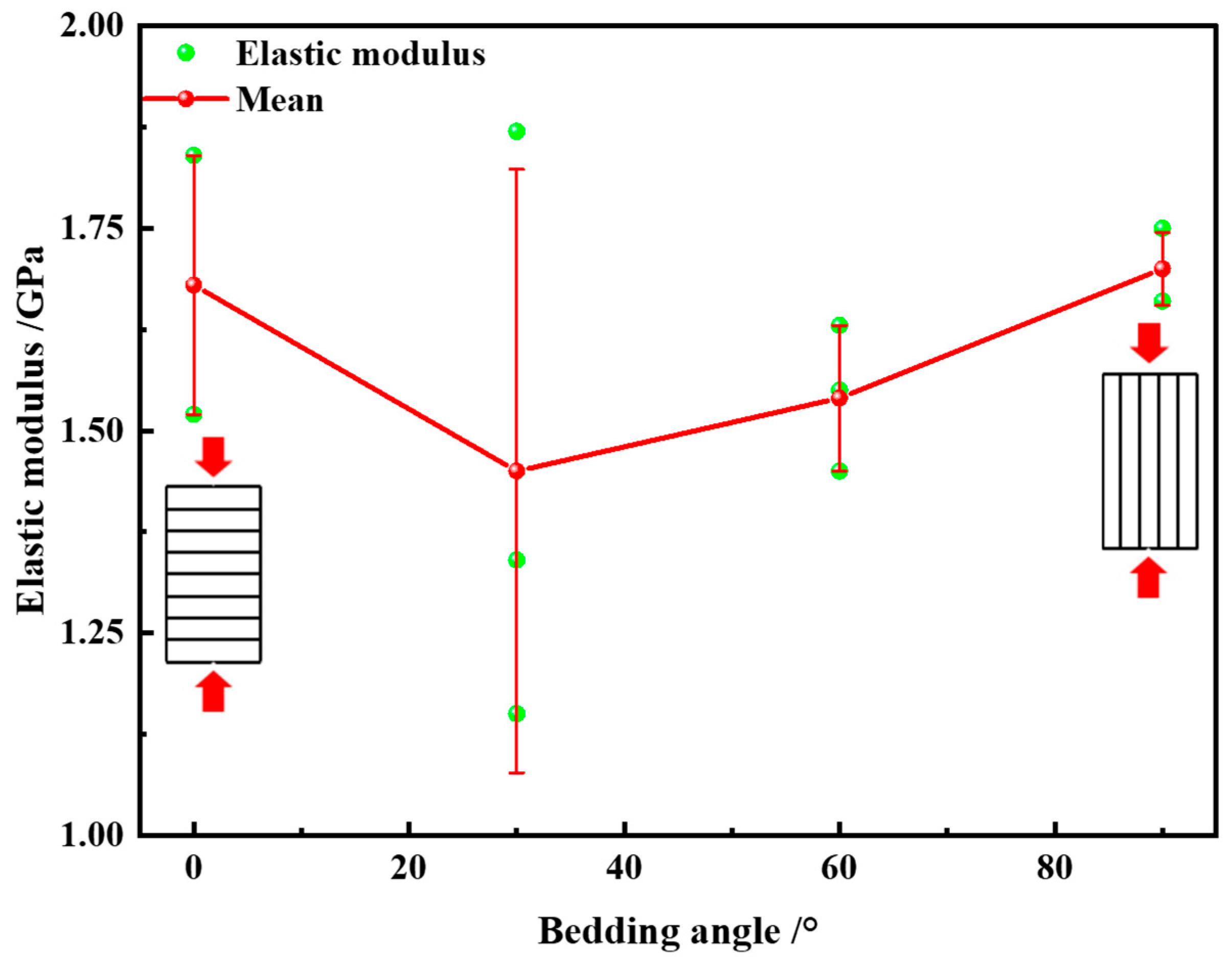

3.1. Deformation Characteristics

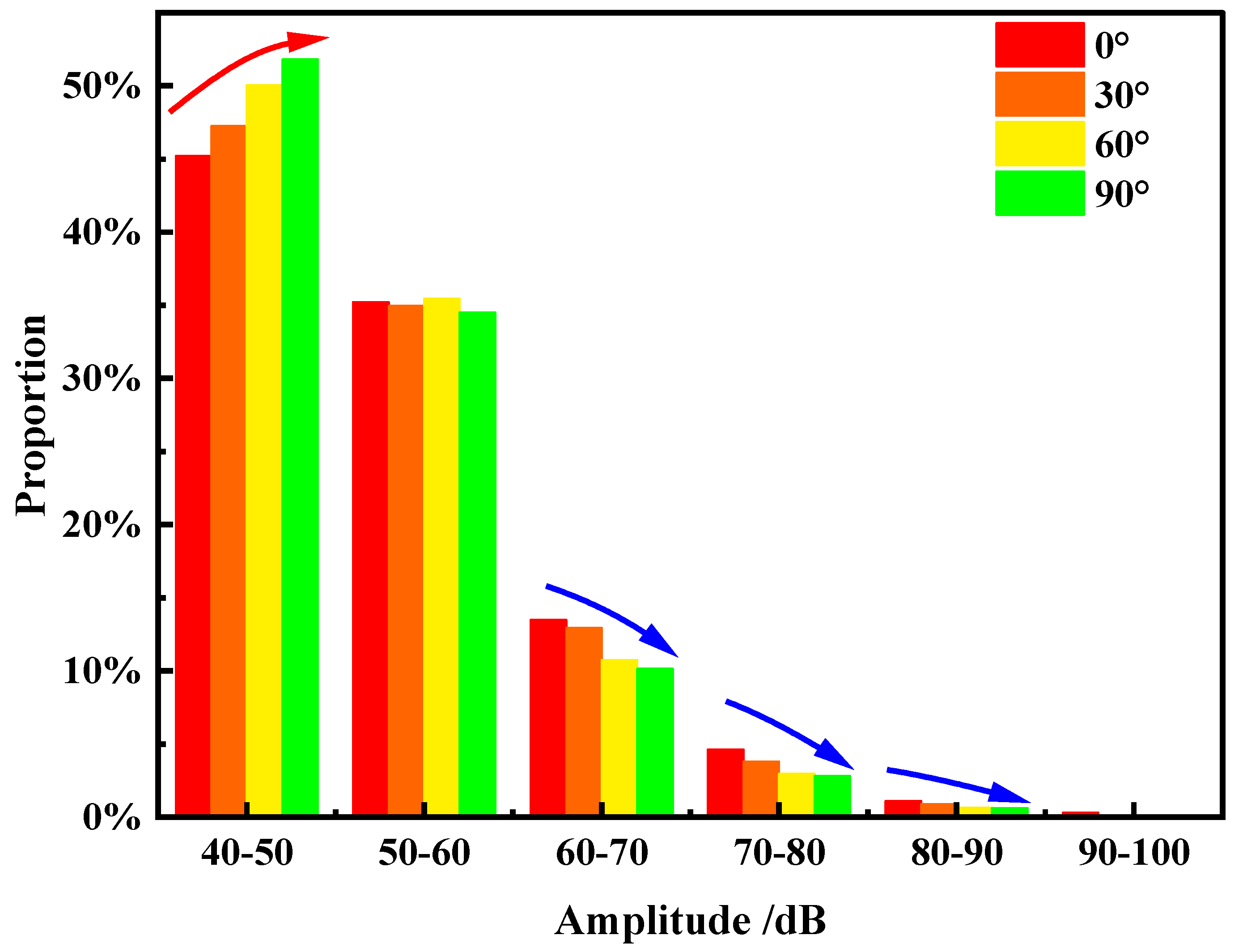

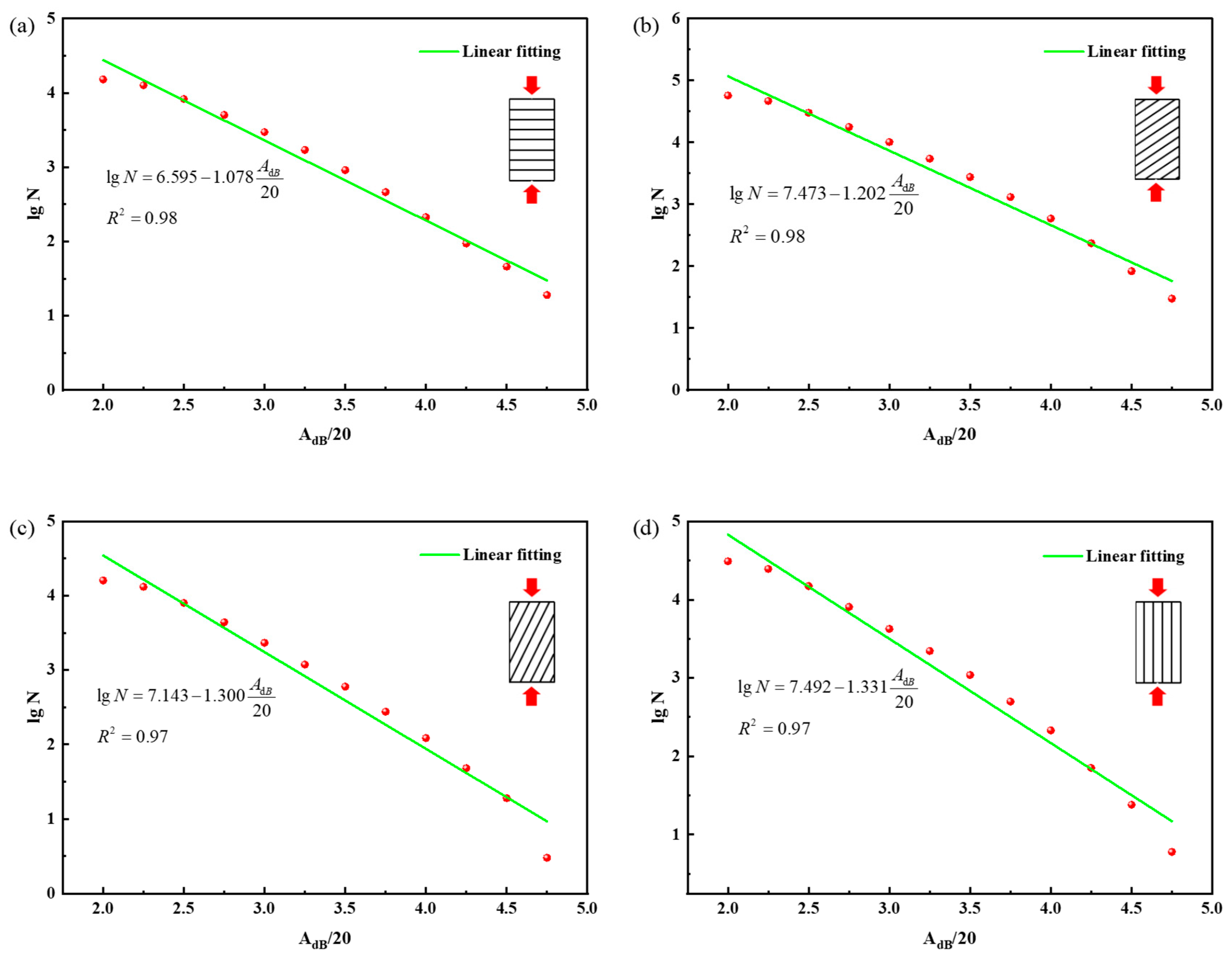

3.2. AE Evolution

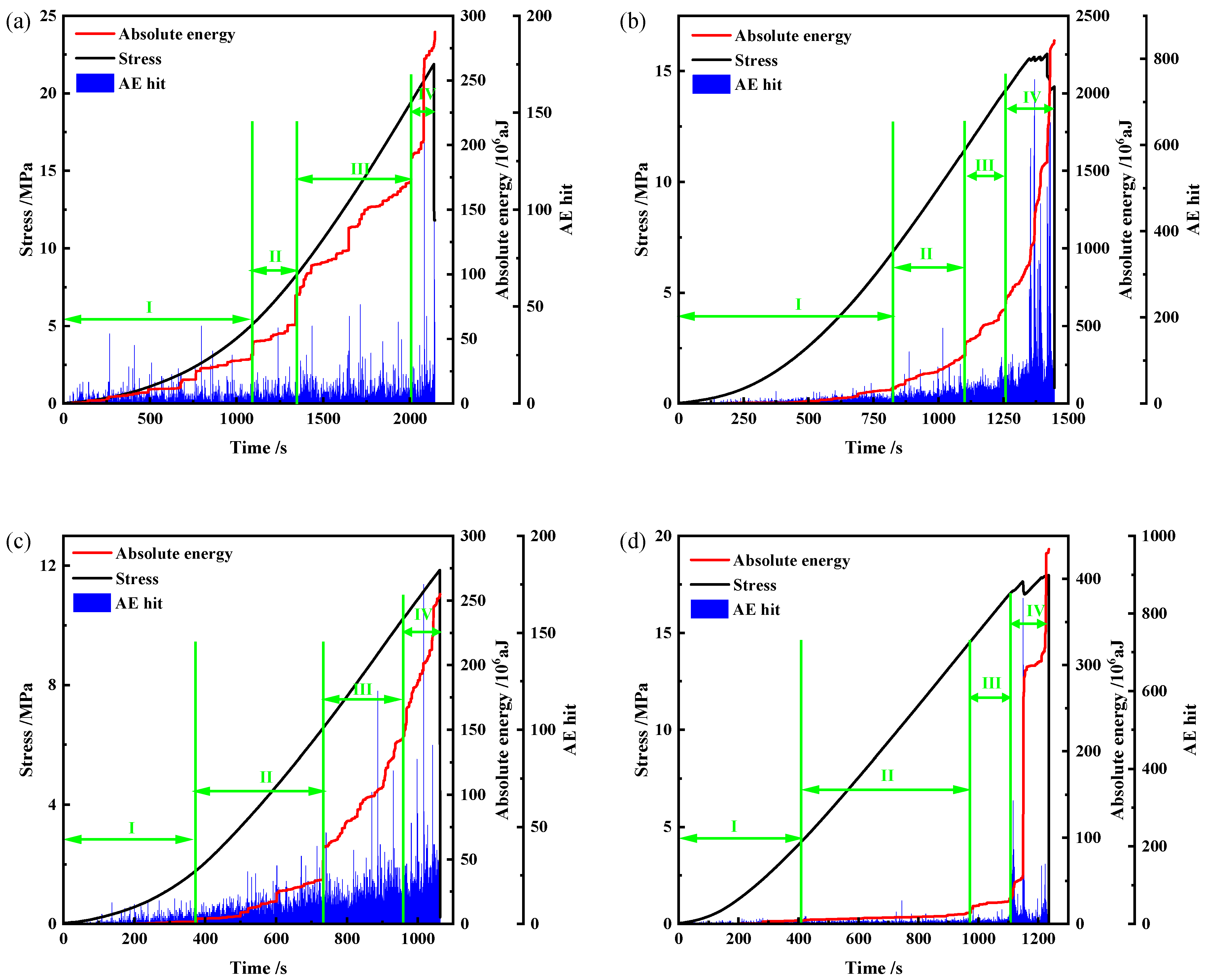

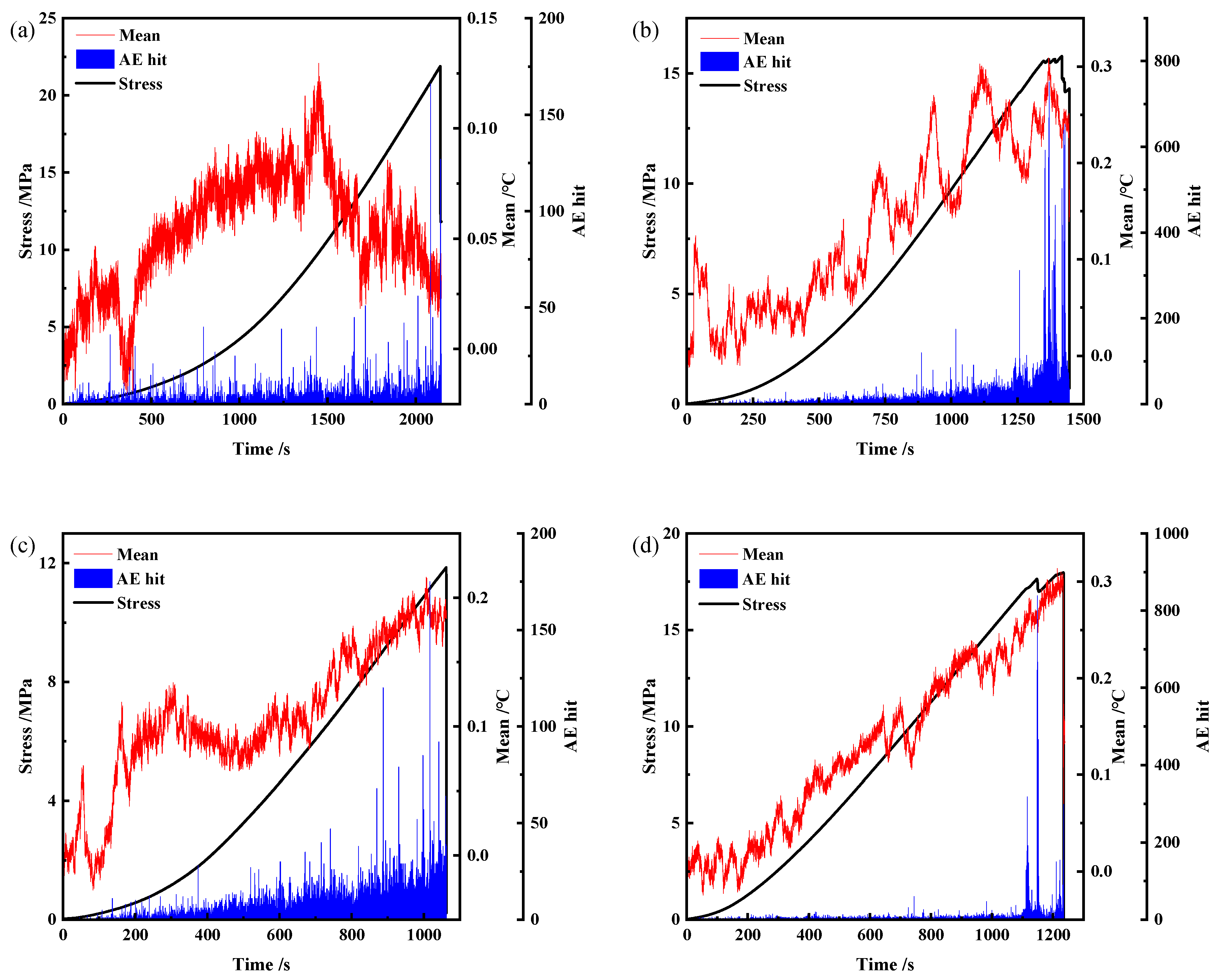

3.3. IRT Evolution

4. Discussions

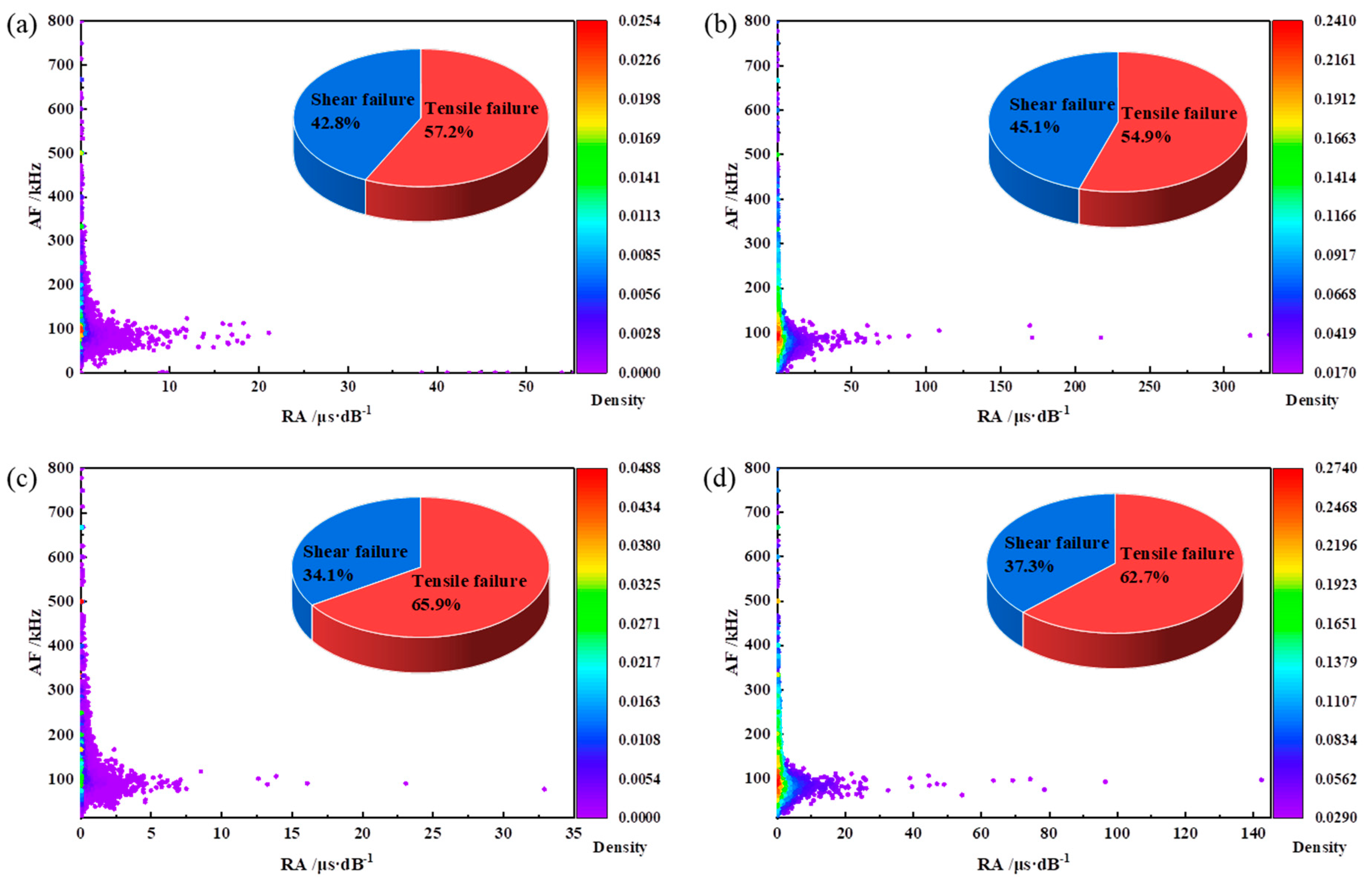

4.1. Microfailure Mechanism

4.2. Correlation Between AE and IRT

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gu, D.Z.; Yan, Y.G.; Zhang, Y.; Wang, E.Z.; Cao, Z.G. Experimental Study and Numerical Simulation for Dynamic Response of Coal Pillars in Coal Mine Underground Reservoir. Meitan Xuebao/J. China Coal Soc. 2016, 41, 1589–1597. [Google Scholar] [CrossRef]

- Gu, D.Z. Theory Framework and Technological System of Coal Mine Underground Reservoir. Meitan Xuebao/J. China Coal Soc. 2015, 40, 239–246. [Google Scholar] [CrossRef]

- Gu, D.; Cao, Z.; Li, J.; Wu, B.; Zhang, Y.; Jiang, B.; Guo, Q.; Wang, H.; Wu, Y.; Shi, X.; et al. Original Experimental Platform System and Application of Underground Coal Mine Reservoirs. Meitan Xuebao/J. China Coal Soc. 2024, 49, 100–113. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhao, G.F.; Jiang, Y.; Elsworth, D.; Huang, Y. Effects of Bedding on the Dynamic Indirect Tensile Strength of Coal: Laboratory Experiments and Numerical Simulation. Int. J. Coal Geol. 2014, 132, 81–93. [Google Scholar] [CrossRef]

- Kim, H.; Cho, J.W.; Song, I.; Min, K.B. Anisotropy of Elastic Moduli, P-Wave Velocities, and Thermal Conductivities of Asan Gneiss, Boryeong Shale, and Yeoncheon Schist in Korea. Eng. Geol. 2012, 147–148, 68–77. [Google Scholar] [CrossRef]

- Kim, K.Y.; Zhuang, L.; Yang, H.; Kim, H.; Min, K.B. Strength Anisotropy of Berea Sandstone: Results of X-Ray Computed Tomography, Compression Tests, and Discrete Modeling. Rock Mech. Rock Eng. 2016, 49, 1201–1210. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, S.; Jiang, Y.; Wang, K.; Huang, Y. Dynamic Tensile Strength of Coal under Dry and Saturated Conditions. Rock Mech. Rock Eng. 2016, 49, 1709–1720. [Google Scholar] [CrossRef]

- Viljoen, J.; Campbell, Q.P.; le Roux, M.; Hoffman, J.W. The Influence of Bedding-Plane Orientation on the Degradation Characteristics of a South African Waterberg Coal. Int. J. Coal Prep. Util. 2017, 37, 179–194. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, J.; Hou, Q.; Yu, B.; Li, M.; Niu, Q. Anisotropic Characteristics of Low-Rank Coal Fractures in the Fukang Mining Area, China. Fuel 2018, 211, 182–193. [Google Scholar] [CrossRef]

- Liu, C.; Yin, G.; Li, M.; Shang, D.; Deng, B.; Song, Z. Deformation and Permeability Evolution of Coals Considering the Effect of Beddings. Int. J. Rock Mech. Min. Sci. 2019, 117, 49–62. [Google Scholar] [CrossRef]

- Ju, M.; Li, J.; Li, J.; Zhao, J. Loading Rate Effects on Anisotropy and Crack Propagation of Weak Bedding Plane-Rich Rocks. Eng. Fract. Mech. 2020, 230, 106983. [Google Scholar] [CrossRef]

- Maruvanchery, V.; Kim, E. Effects of a High Temperature (500 °C) on the Fracture Processes in Calcite-Cemented Sandstone Along Bedding-Plane Orientations. Rock Mech. Rock Eng. 2020, 53, 955–966. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, Y.; Sun, Z.; Lu, C. Effects of Bedding Planes on the Fracture Characteristics of Coal under Dynamic Loading. Eng. Fract. Mech. 2021, 250, 107761. [Google Scholar] [CrossRef]

- Zhou, J.; Zhao, Y.; Paneiro, G.; Liu, W.; Wang, X.; Wang, H.; Gao, Y.; Han, C.; Zhang, X. Loading Rate and Bedding Plane Coupled Effect Study on Coal Failure under Uniaxial Compression: Acoustic Emissions and Energy Dissipation Analysis. Geofluids 2022, 2022, 9028178. [Google Scholar] [CrossRef]

- Shi, X.; Zhao, Y.; Yao, W.; Gong, S.; Danesh, N.N. Dynamic Tensile Failure of Layered Sorptive Rocks: Shale and Coal. Eng. Fail. Anal. 2022, 138, 106346. [Google Scholar] [CrossRef]

- Khalili, M.; Fahimifar, A.; Shobeiri, H. The Effect of Bedding Planes on the Bending Strength of Rock-like Material and Evaluation of the Crack Propagation Mechanism. Theor. Appl. Fract. Mech. 2023, 127, 104061. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Y.; Zhang, X.; Sun, Z.; Gao, Y.; Jiang, Y. Effects of Anisotropy on Strength and Deformability of Anthracite Under High Confinement. Rock Mech. Rock Eng. 2023, 56, 2157–2183. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Y.; Gao, Y.; Sun, Z.; Liu, B.; Jiang, Y. Energy Evolution of Anthracite Considering Anisotropy Under High Confining Pressure: An Experimental Investigation. Rock Mech. Rock Eng. 2023, 56, 6735–6759. [Google Scholar] [CrossRef]

- Mashhadiali, N.; Molaei, F. Theoretical and Experimental Investigation of a Shear Failure Model for Anisotropic Rocks Using Direct Shear Test. Int. J. Rock Mech. Min. Sci. 2023, 170, 105561. [Google Scholar] [CrossRef]

- Sun, Z.; Zhao, Y.; Gao, Y.; Elmo, D.; Gao, S.; Wang, X. Effect of Size and Anisotropy on Fracture Process Zone of Coal: An Experiment and Numerical Simulation. Eng. Fract. Mech. 2024, 306, 110227. [Google Scholar] [CrossRef]

- Huang, L.; Li, B.; Wu, B.; Li, C.; Wang, J.; Cai, H. Study on the Extension Mechanism of Hydraulic Fractures in Bedding Coal. Theor. Appl. Fract. Mech. 2024, 131, 104431. [Google Scholar] [CrossRef]

- Zhang, G.; Zhao, Y.; Sun, Y.; Gong, Z. Energy Evolution and Infrared Radiation Characteristics of Different Bedded Coal under Uniaxial Compression. Meitan Kexue Jishu/Coal Sci. Technol. 2024, 52, 48–59. [Google Scholar] [CrossRef]

- Huang, L.; Li, B.; Li, C.; Wu, B.; Wang, J. Research on Anisotropic Characteristics and Energy Damage Evolution Mechanism of Bedding Coal under Uniaxial Compression. Energy 2024, 301, 131659. [Google Scholar] [CrossRef]

- Tang, X.; Xu, F.; Bi, Y.; Bi, R.; Guo, Y.; Huo, N. Mechanical and Permeability Characteristics of Gas-Bearing Coal Under Various Bedding Angles. Processes 2025, 13, 176. [Google Scholar] [CrossRef]

- Ma, S.; He, J.; Xiong, D.; Zhu, R.; Qu, Z.; Fang, D. Fracture Evolution Behavior of Deep Coal with Bedding Planes: An in-Situ ΜCT Study Based on Deep Learning. Opt. Laser Technol. 2025, 189, 113149. [Google Scholar] [CrossRef]

- Sun, Z.; Zhao, Y.; Gao, Y.; Wang, X.; Wang, H.; Liu, B.; Jiang, Y. Effects of Bedding Characteristics on Crack Propagation of Coal under Mode II Loading: Laboratory Experiment and Numerical Simulation. J. Rock Mech. Geotech. Eng. 2025, 17, 1037–1052. [Google Scholar] [CrossRef]

- Seredin, V.V.; Khrulev, A.S. Variations of Temperature in Specimens of Rocks and Geomaterials under Failure. J. Min. Sci. 2016, 52, 683–688. [Google Scholar] [CrossRef]

- Jiang, Y.; Lu, Y.; Zhao, Y.; Song, Y.; Tao, L. Multiparameter Monitoring Experiments for Instability Destruction of Coal Samples. Yanshilixue Yu Gongcheng Xuebao/Chin. J. Rock Mech. Eng. 2012, 31, 667–674. [Google Scholar]

- Gao, Y.; Zhao, Y.; Wang, H.; Liu, B.; Hartlieb, P.; Gao, S. Loaded Failure Characteristics of Anthracite Derived from Microwave Irradiation: Acoustic Emission Evaluation. Rock Mech. Rock Eng. 2023, 56, 8809–8831. [Google Scholar] [CrossRef]

- Wu, L.; Wang, J. Infrared Radiation Features of Coal and Rocks under Loading. Int. J. Rock Mech. Min. Sci. 1998, 35, 969–976. [Google Scholar] [CrossRef]

- Rankin, B.A.; Blunck, D.L.; Monfort, J.; Kiel, B.V.; Gore, J.P. Infrared Radiation and Acoustic Characteristics of Combustion Instabilities in Turbulent Premixed Flames. J. Propuls. Power 2012, 28, 862–865. [Google Scholar] [CrossRef]

- Pieczyska, E.A.; Tobushi, H.; Takeda, K.; Stróz, D.; Ranachowski, Z.; Kulasiński, K.; Kúdela, S.; Luckner, J. Martensite Transformation Bands Studied in TiNi Shape Memory Alloy by Infrared and Acoustic Emission Techniques. Kov. Mater. 2012, 50, 309–318. [Google Scholar] [CrossRef]

- Xu, H.; Ma, L.; Cao, K.; Khan, N.M.; Hussain, S.; Niu, D.; Alarifi, S.S.; Bacha, S. Precursors of Cyclic Loading and Unloading Sandstone Failure Based on “Acoustic-Thermal” Loading–Unloading Response Ratio. Sustainability 2023, 15, 10158. [Google Scholar] [CrossRef]

- Yin, S.; Li, Z.; Wang, E.; Liu, Y.; Niu, Y.; Yang, H. Damage Status and Failure Precursors of Different Coal Impact Types Based on Comprehensive Monitoring of Infrared Radiation and Acoustic Emission. Appl. Sci. 2024, 14, 8792. [Google Scholar] [CrossRef]

- Chang, L.; Chen, L.; Zhang, M.; Li, D.; Li, Y. Experimental Study on Infrared Radiation and Crack Evolution Characteristics during the Failure Process of Rocks with Pre-Set Crack. Infrared Phys. Technol. 2024, 138, 105236. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, Y.; Hua, X.; Ling, C.; Wang, X. Failure Characteristic and Acoustic Emission Spatio-Temporal Evolution of Coal under Different Cyclic Loading Rates. Energy Sci. Eng. 2023, 11, 2039–2051. [Google Scholar] [CrossRef]

- Shang, D.; Zhang, S.; Jiang, Y.; Wang, X.; Zhang, J.; Liu, J.; Wang, Y. Elucidating the Rate-Dependent Shear Failure Mechanism in Cement Fractures Based on Multi-Parameter Acoustic Emission Analysis. J. Build. Eng. 2025, 111, 113161. [Google Scholar] [CrossRef]

- Burud, N.B.; Chandra Kishen, J.M. Application of Generalized Logistic Equation for B-Value Analysis in Fracture of Plain Concrete Beams under Flexure. Eng. Fract. Mech. 2019, 210, 228–246. [Google Scholar] [CrossRef]

- Liang, Y.; Yang, Y.; Xin, G.; Zou, Q.; Ran, Q.; Qin, D. Mechanical Properties and Crack Propagation Characteristics of Mudstone under Different Loading Frequencies. Eng. Fract. Mech. 2025, 316, 110863. [Google Scholar] [CrossRef]

- Ma, L.; Sun, H. Spatial-Temporal Infrared Radiation Precursors of Coal Failure under Uniaxial Compressive Loading. Infrared Phys. Technol. 2018, 93, 144–153. [Google Scholar] [CrossRef]

- Lou, Q.; He, X. Experimental Study on Infrared Radiation Temperature Field of Concrete under Uniaxial Compression. Infrared Phys. Technol. 2018, 90, 20–30. [Google Scholar] [CrossRef]

- Zhang, G.; Yu, Y.; Zhang, W. Experimental Investigation of the Acoustic Emission and Energy Evolution of Bedded Coal under Uniaxial Compression. Sci. Rep. 2025, 15, 12578. [Google Scholar] [CrossRef]

- De Smedt, M.; Andreev, K.; Shetty, N.; Verstrynge, E. Effectiveness of Acoustic Emission Parameters to Monitor the Crack Formation in Refractories—Case Study on Castables of Different Brittleness. J. Eur. Ceram. Soc. 2019, 39, 5423–5432. [Google Scholar] [CrossRef]

- Botvina, L.R.; Bolotnikov, A.I.; Sinev, I.O.; Beletsky, E.N. Acoustic Emission, Damage and Fracture Mechanisms of Structural Steel under Mixed-Mode Loading. Eng. Fract. Mech. 2023, 292, 109635. [Google Scholar] [CrossRef]

- Zhao, Y.; Jiang, Y. Acoustic Emission and Thermal Infrared Precursors Associated with Bump-Prone Coal Failure. Int. J. Coal Geol. 2010, 83, 11–20. [Google Scholar] [CrossRef]

| Specimen No. | Density g/cm3 | Compressive Strength MPa | Mean MPa | Elastic Modulus GPa | Mean GPa |

|---|---|---|---|---|---|

| S-0-1 | 1.25 | 22.23 | 25.50 | 1.84 | 1.68 |

| S-0-2 | 1.26 | 34.35 | 1.68 | ||

| S-0-3 | 1.24 | 19.77 | 1.52 | ||

| S-30-1 | 1.26 | 15.92 | 18.41 | 1.87 | 1.45 |

| S-30-2 | 1.23 | 19.29 | 1.15 | ||

| S-30-3 | 1.26 | 20.03 | 1.34 | ||

| S-60-1 | 1.32 | 13.35 | 12.38 | 1.45 | 1.54 |

| S-60-2 | 1.22 | 11.70 | 1.55 | ||

| S-60-3 | 1.30 | 12.07 | 1.63 | ||

| S-90-1 | 1.26 | 17.90 | 16.81 | 1.66 | 1.70 |

| S-90-2 | 1.27 | 14.67 | 1.75 | ||

| S-90-3 | 1.22 | 17.85 | 1.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Liu, B.; Wang, S.; Pang, B. Acoustic Emission and Infrared Radiation Temperature Characteristics of Coal with Varying Bedding Planes Under Uniaxial Compression. Appl. Sci. 2025, 15, 9554. https://doi.org/10.3390/app15179554

Wu Y, Liu B, Wang S, Pang B. Acoustic Emission and Infrared Radiation Temperature Characteristics of Coal with Varying Bedding Planes Under Uniaxial Compression. Applied Sciences. 2025; 15(17):9554. https://doi.org/10.3390/app15179554

Chicago/Turabian StyleWu, Yang, Bin Liu, Shirui Wang, and Bo Pang. 2025. "Acoustic Emission and Infrared Radiation Temperature Characteristics of Coal with Varying Bedding Planes Under Uniaxial Compression" Applied Sciences 15, no. 17: 9554. https://doi.org/10.3390/app15179554

APA StyleWu, Y., Liu, B., Wang, S., & Pang, B. (2025). Acoustic Emission and Infrared Radiation Temperature Characteristics of Coal with Varying Bedding Planes Under Uniaxial Compression. Applied Sciences, 15(17), 9554. https://doi.org/10.3390/app15179554