Optimization of Exposed Aggregate Concrete Mix Proportions for High Skid Resistance and Noise Reduction Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Orthogonal Experimental Design Scheme

2.3. Specimen Preparation and Test Methods

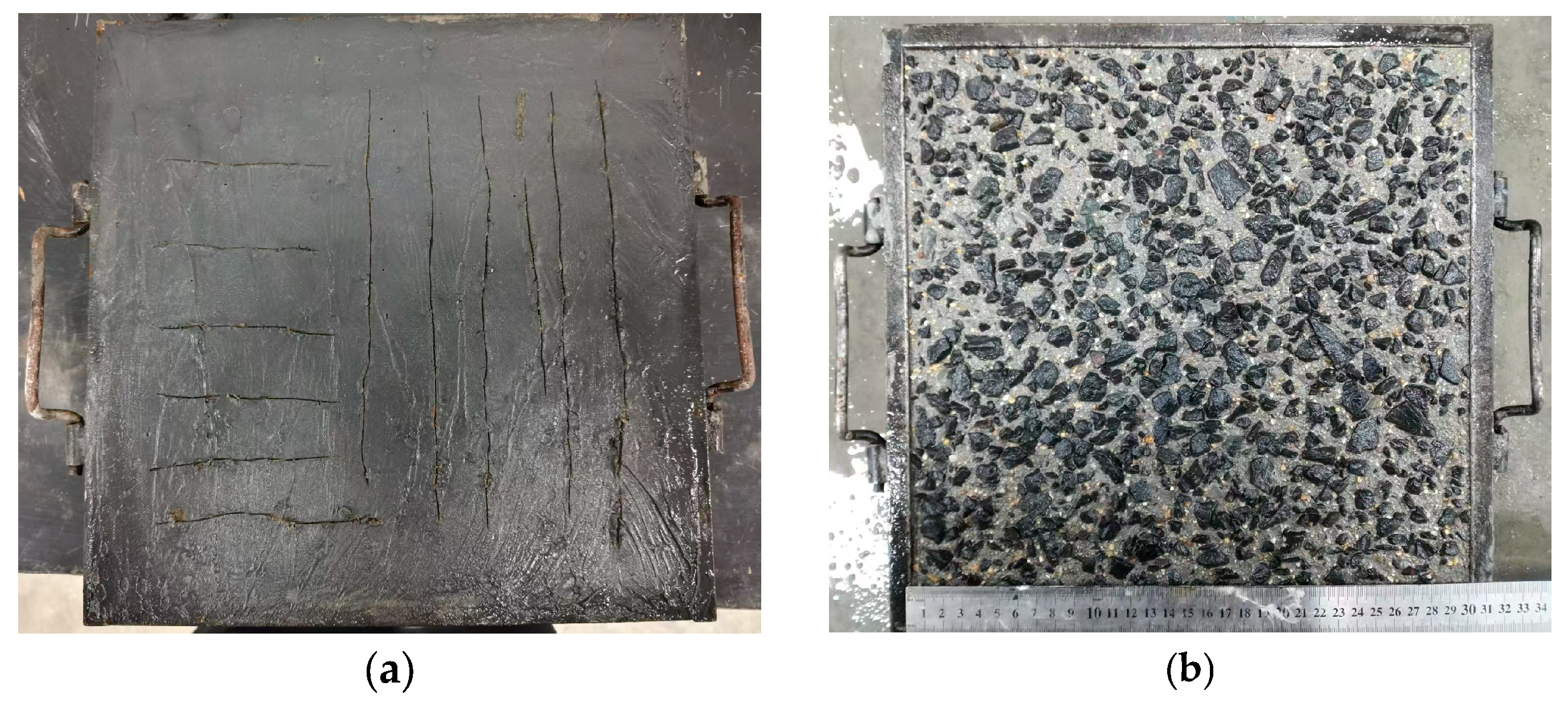

2.3.1. Specimen Preparation

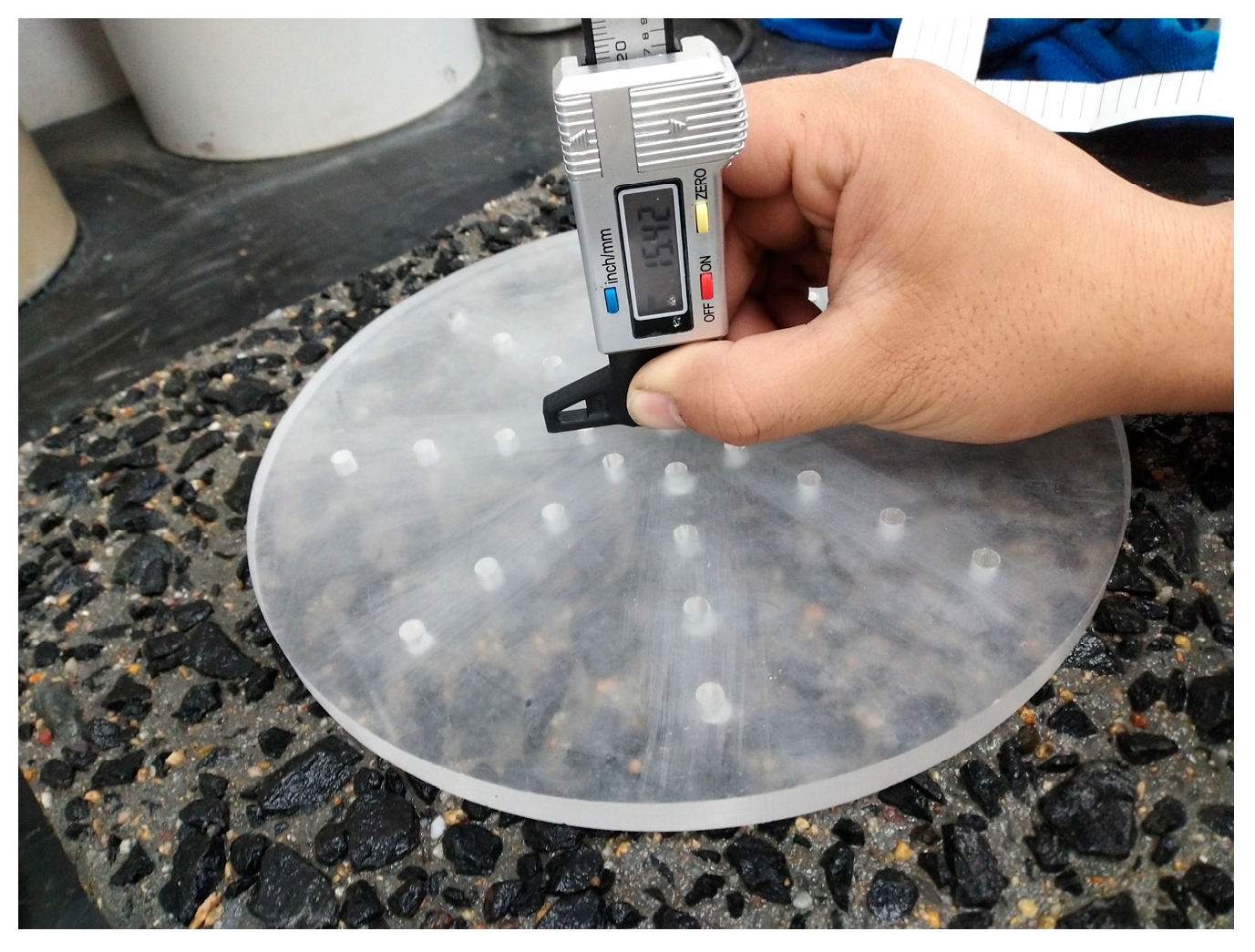

2.3.2. Exposed Aggregate Depth Test

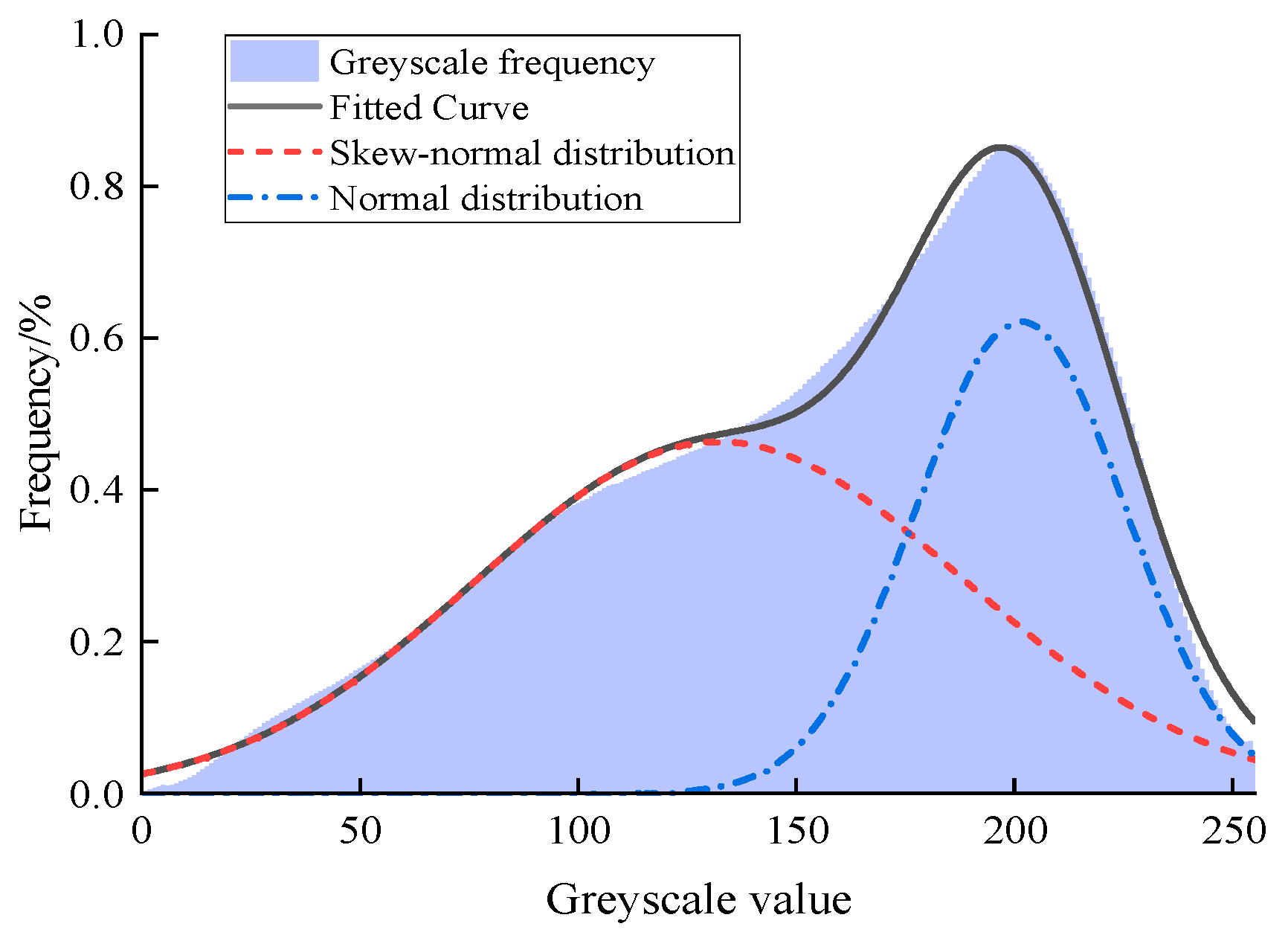

2.3.3. Exposed Aggregate Area Ratio Analysis

2.3.4. Skid Resistance Performance Test

2.3.5. Noise Reduction Performance Test

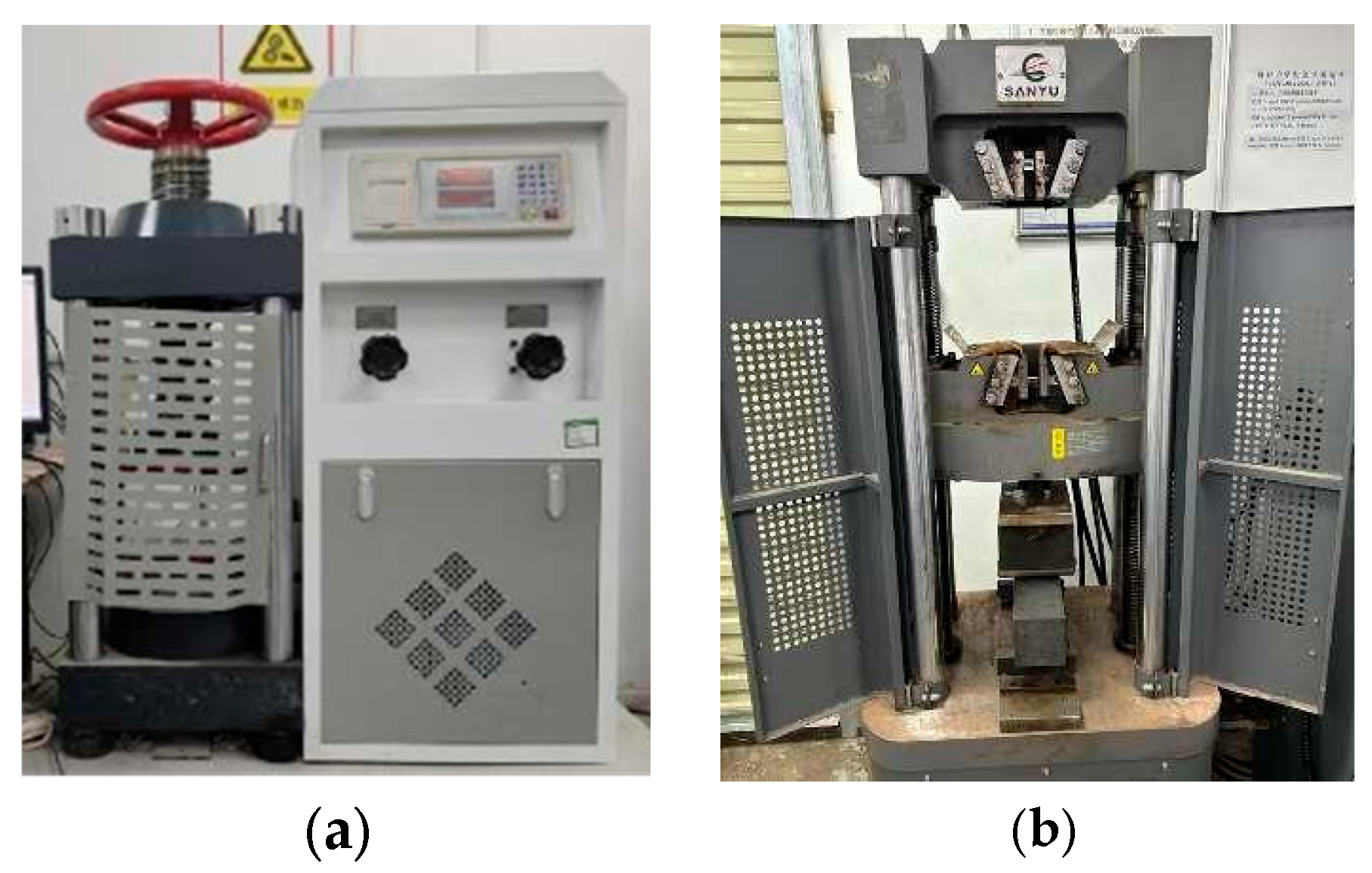

2.3.6. Mechanical Properties Test

3. Test Results

3.1. Analysis of Orthogonal Test Results

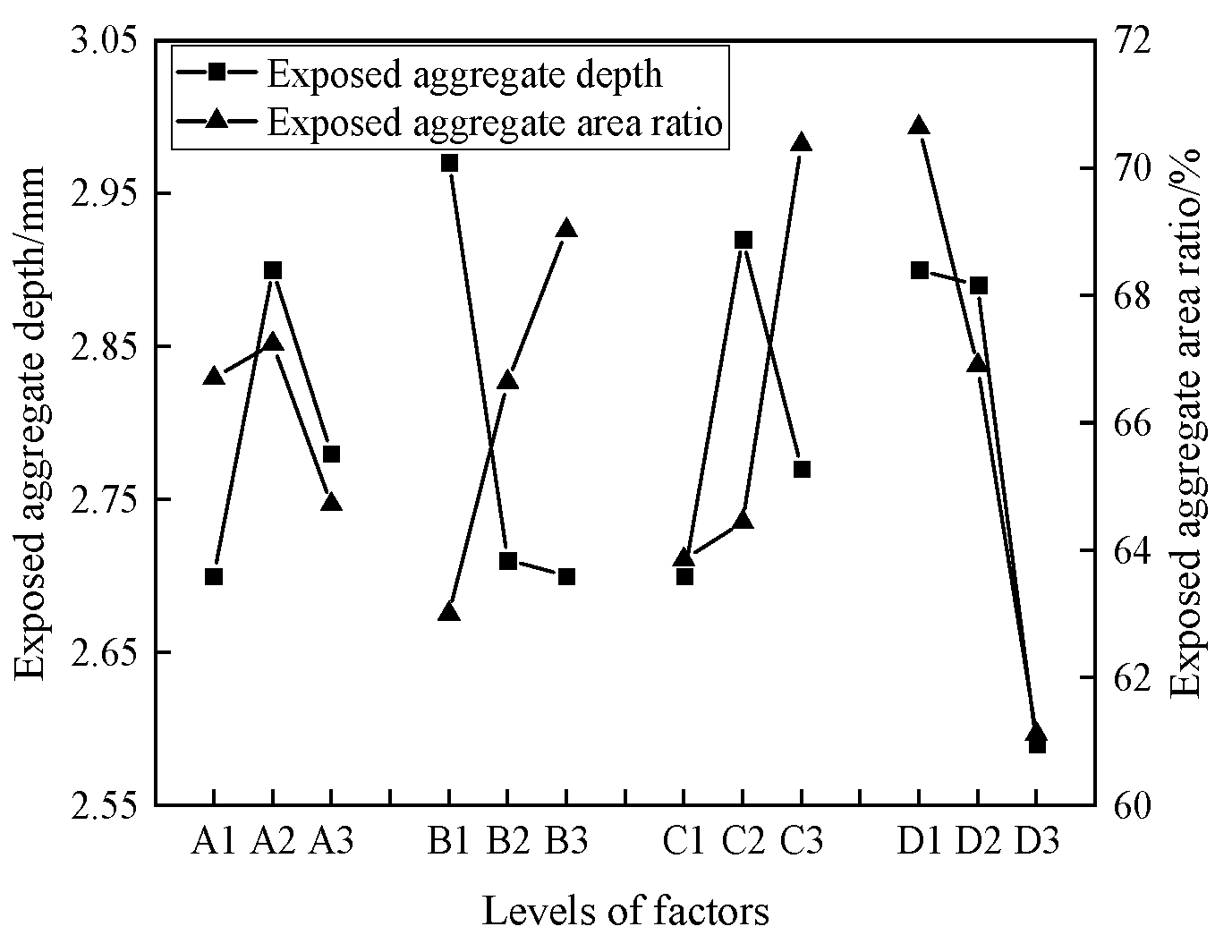

3.2. Variation Patterns of Various Factors on Surface Texture Characteristics

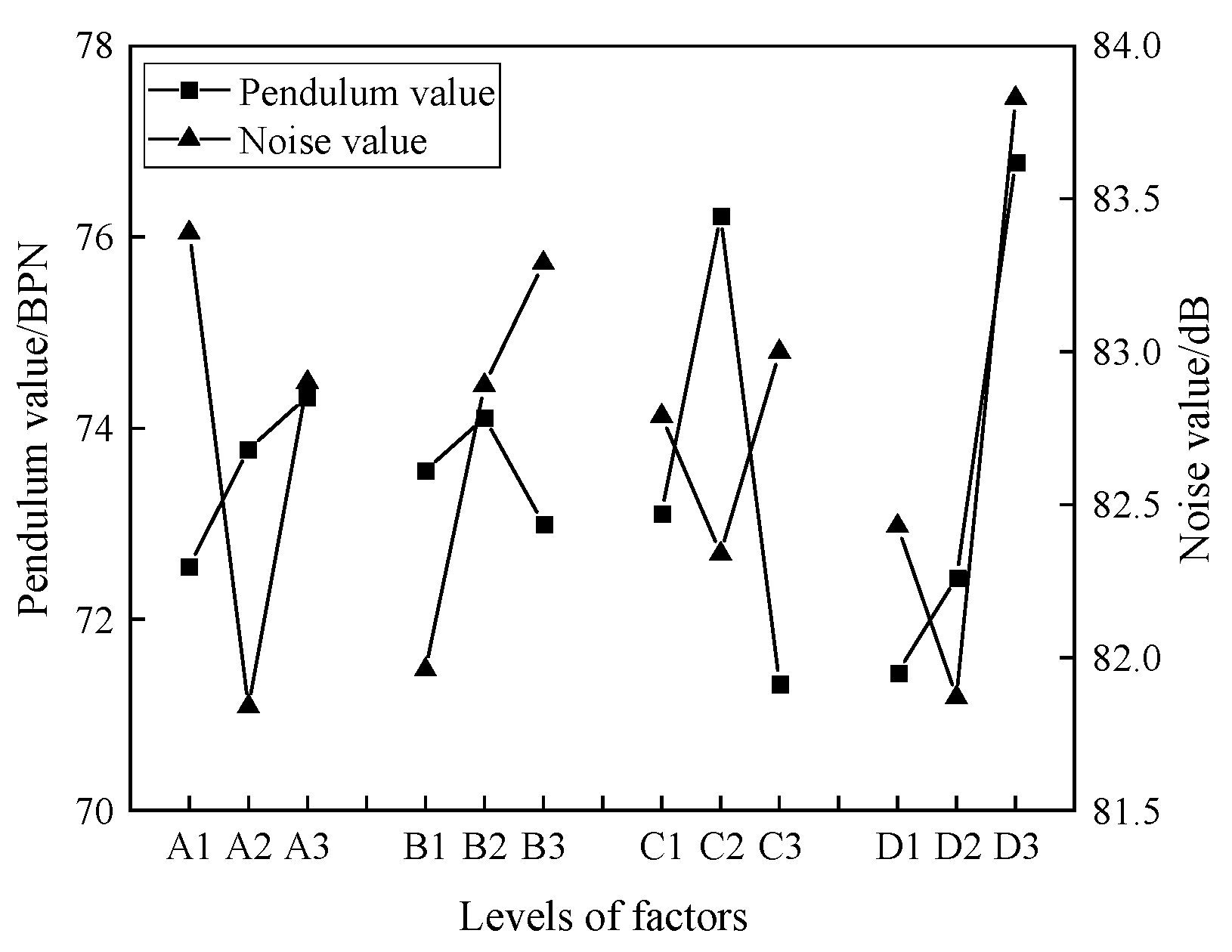

3.3. Variation Patterns of Various Factors on SRNR Performance

3.3.1. Variation Patterns of Various Factors on Skid Resistance Performance

3.3.2. Variation Patterns of Various Factors on Noise Reduction Performance

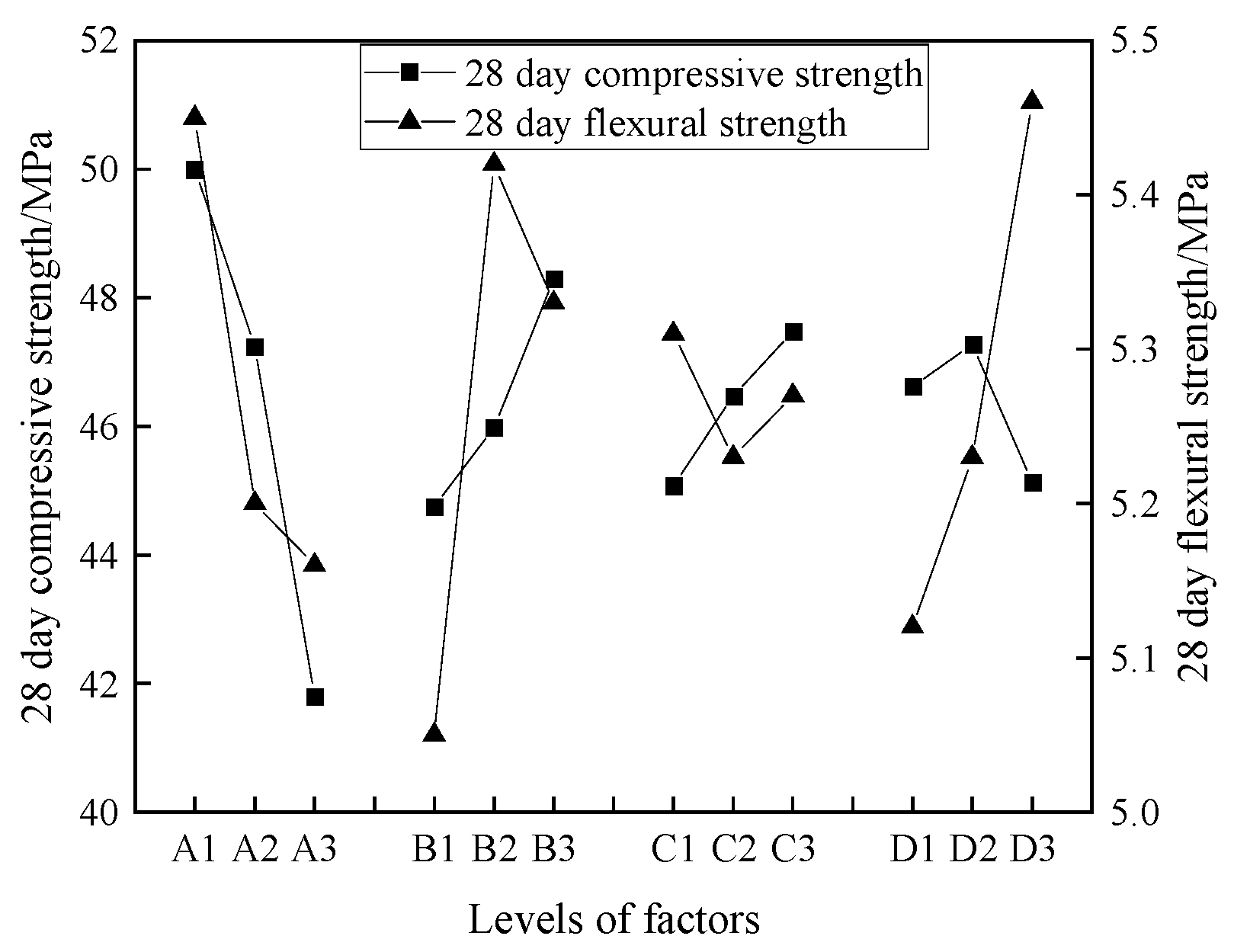

3.4. Variation Patterns of Various Factors on Mechanical Properties

4. Discussion

4.1. Optimisation of Mix Proportions

4.2. Verification of Optimal Mix Proportions

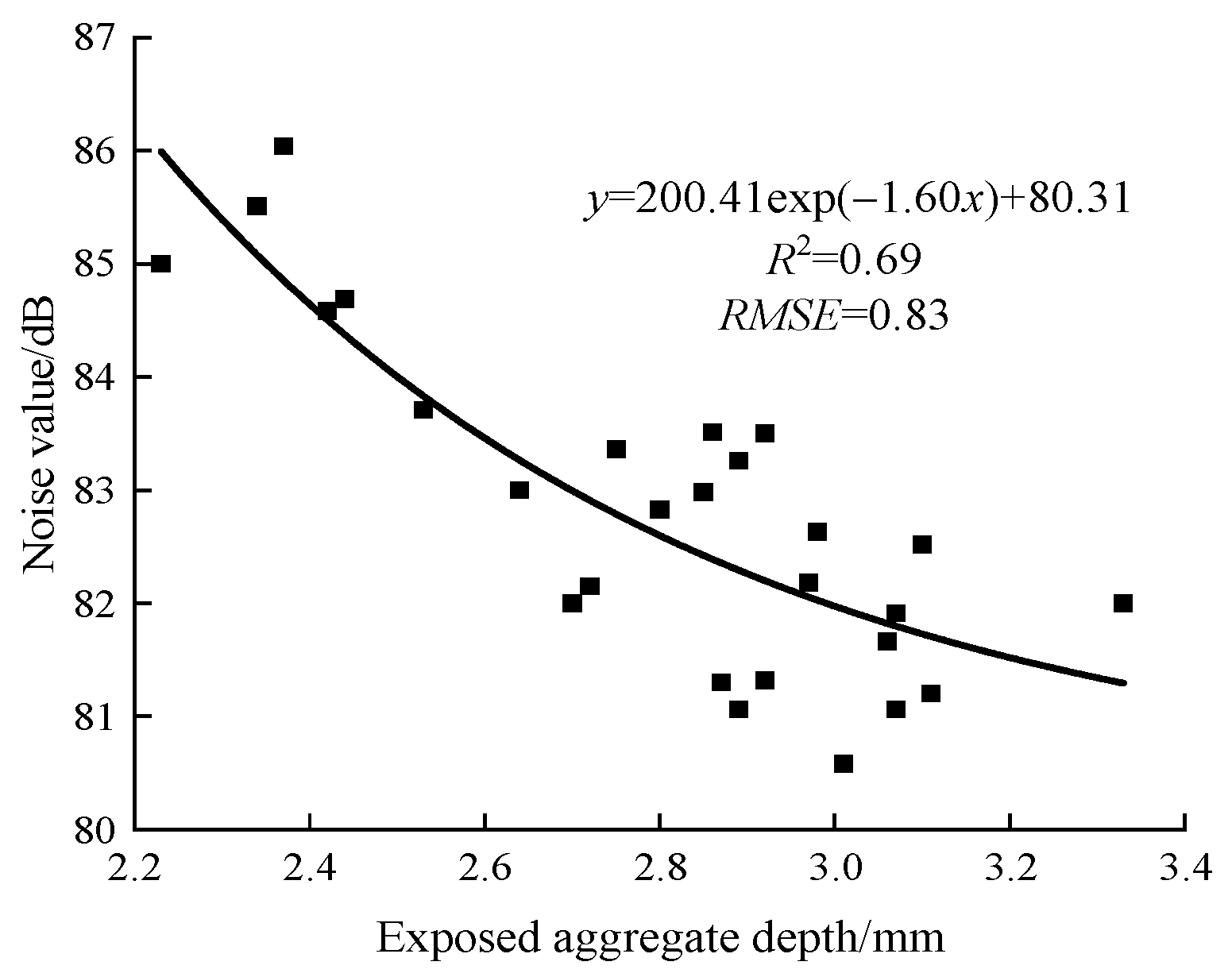

4.3. Correlation Analysis of SRNR Performance

5. Conclusions

- (1)

- The proportion of aggregates > 9.5 mm is the most significant factor affecting the surface texture characteristics and SRNR performance of EAC. When the proportion of aggregates > 9.5 mm is 70%, both the exposed aggregate depth and the exposed aggregate area ratio of EAC decrease significantly. Therefore, the proportion of aggregates > 9.5 mm should not be too high during mix design.

- (2)

- The optimal mix proportions of EAC are as follows: water–binder ratio of 0.43, sand ratio of 31%, coarse aggregate volume ratio of 42%, and proportion of aggregates > 9.5 mm of 50%. Compared with ordinary grooved concrete, the optimal mix proportions of EAC increase the pendulum value by 31.5% and reduce the noise value by 6.48 dB. The frequency range of noise reduction is mainly concentrated between 1.5 kHz and 4.0 kHz, which belongs to the mid-high frequency range that is more sensitive to the human ear.

- (3)

- There is a high correlation between noise value and exposed aggregate depth, as well as between pendulum value and exposed aggregate area ratio. Specifically, as the exposed aggregate depth increases, the noise value gradually decreases and stabilizes, showing an inverse exponential function relationship. On the other hand, as the exposed aggregate area ratio increases, the pendulum value first decreases, then increases, and finally decreases again, exhibiting a cubic polynomial relationship.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fang, J.; Tu, J.; Wu, K. Analysis of skid resistance and noise characteristics for varieties of concrete pavement. Adv. Mater. Sci. Eng. 2020, 1, 7427314. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, J.; Lai, J.; Shi, X.; Xu, Z. Skid resistance of cement concrete pavement in highway tunnel: A review. Constr. Build. Mater. 2023, 406, 133235. [Google Scholar] [CrossRef]

- Wen, B.; Cao, D. Statistical analysis of traffic accidents and skid resistance of expressway pavement. HTRD 2006, 23, 72–75. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, B.; He, J.; Xiang, D.; Yi, L. Traffic risk analysis of ponding sections on freeways based on driving dynamics. J. Transp. Inf. Saf. 2019, 37, 9–17. [Google Scholar] [CrossRef]

- Kassomenos, P.; Vogiatzis, K.; Coelho, J. Critical issues on environmental noise: Editorial. Sci. Total Environ. 2014, 482, 399–400. [Google Scholar] [CrossRef]

- Miera-Dominguez, H.; Lastra-González, P.; Indacoechea-Vega, I.; Castro-Fresno, D.; Van Loon, R.; van Blokland, G.; Muresn, B.; Blanc, J. Development and validation of a new asphalt mixture to reduce tyre-road contact noise in interurban areas. Constr. Build. Mater. 2024, 453, 139025. [Google Scholar] [CrossRef]

- Zhu, B.; Hu, D.; Liao, F.; Chen, J.; Su, B.; Wu, J.; Wang, Y. A Fast Approach to Optimize Tread Pattern Shape for Tire Noise Reduction. Appl. Sci. 2023, 13, 10256. [Google Scholar] [CrossRef]

- Ouis, D. Annoyance from road traffic noise: A review. J. Environ. Psychol. 2001, 21, 101–120. [Google Scholar] [CrossRef]

- Wegman, F. The future of road safety: A worldwide perspective. IATSS Res. 2017, 40, 66–71. [Google Scholar] [CrossRef]

- Cai, Z.; He, Z.; Tian, B.; Qiu, Z. Study on effecting depth of aggregate exposing solvent. Highw. Eng. 2018, 43, 66–69+100. [Google Scholar] [CrossRef]

- Cai, Z.; He, Z.; Wang, Z.; Yu, D.; Hou, Z.; Zhang, Y.; Zhang, B. Study on the amount of cleaning of exposed-aggregate concrete pavement. Concrete 2018, 3, 149–152. [Google Scholar] [CrossRef]

- Wei, L. Study on surface characteristics of exposed aggregate concrete pavement. Low Temp. Archit. Technol. 2016, 38, 17–19. [Google Scholar] [CrossRef]

- Kim, Y.K.; Kim, J.H.; Rith, M.; Lee, S.W. Optimisation of mixture design and surface texture for low-noise exposed aggregate concrete pavements. Int. J. Pavement Eng. 2020, 23, 950–956. [Google Scholar] [CrossRef]

- Yan, Q.; Li, X.; Tian, B.; Hou, Z.; Xie, J. Research on mix proportion design of low noise exposed-aggregate cement concrete. Constr. Technol. 2015, 44, 63–66. [Google Scholar] [CrossRef]

- Chhay, L.; Kim, J.; Lee, S.W. Mean texture depth estimation of exposed aggregate concrete pavement surface texture based on photogrammetry technique. Int. J. Civ. Eng. 2024, 22, 1717–1729. [Google Scholar] [CrossRef]

- Yang, L.; Chen, J.; Zhang, B.; Li, J.; Wang, F. Research on long-term anti-sliding performance of exposed aggregate cement concrete. J. Traffic Eng. 2020, 20, 1–6. [Google Scholar] [CrossRef]

- Chen, W.; Shen, P. Research on development and pavement performances of aggregate exposing concrete. Highway 2013, 58, 45–52. [Google Scholar] [CrossRef]

- Hu, L.; Yun, D.; Gao, J.; Tang, C. Monitoring and optimizing the surface roughness of high friction exposed aggregate cement concrete in exposure process. Constr. Build. Mater. 2020, 230, 117005. [Google Scholar] [CrossRef]

- Rith, M.; Kim, Y.K.; Lee, S.W. Characterization of long-term skid resistance in exposed aggregate concrete pavement. Constr. Build. Mater. 2020, 256, 119423. [Google Scholar] [CrossRef]

- Han, S.; Dong, Y.; Chen, H.; Zhang, D.; Lu, X.; Shi, Y. Noise reduction performance of exposed-aggregate cement concrete pavement. J. Traffic Transp. Eng. 2005, 5, 32–34. [Google Scholar] [CrossRef]

- Zhao, D.; Zhang, P.; Tian, B.; Huang, Z.; Li, L. Study on the wear behavior of three-dimensional morphology of anti-sliding structure of cement concrete pavement. New Build. Mater. 2023, 50, 117–122. [Google Scholar] [CrossRef]

- Hablovicova, B.; Krivanek, V.; Markova, P. Comparison of exposed aggregate cement concrete surface and stone mastic asphalt surface noise emissions by close-proximity method. Appl. Sci. 2021, 11, 10359. [Google Scholar] [CrossRef]

- JTG/T F30-2014; Technical Guidelines for Construction of Highway Cement Concrete Pavements. Ministry of Transportation of PRC: Beijing, China, 2014.

- Liu, Y.; Liu, M.; Qu, L.; Wang, F. Factor analysis affect the surface structure of exposed-aggregate cement concrete pavement. Concrete 2016, 2, 157–160. [Google Scholar] [CrossRef]

- Šernas, O.; Zofka, A.; Vaitkus, A.; Gražulytė, J. The effect of exposed aggregate concrete gradation on the texture characteristics and durability. Constr. Build. Mater. 2020, 261, 119921. [Google Scholar] [CrossRef]

- Hu, S. Study on mix proportion of slipform paving of tunnel exposed aggregate cement concrete pavement. Commun. Sci. Technol. Heilongjiang 2022, 45, 113–117. [Google Scholar] [CrossRef]

- Xiao, Y. Application of exposed aggregate concrete pavement in road tunnel construction. Transp. World 2023, 36, 154–156. [Google Scholar] [CrossRef]

- Jang, G. Analysis of construction techniques for high skid resistance and low noise exposed aggregate cement concrete pavement. Transp. World 2024, 17, 65–67. [Google Scholar] [CrossRef]

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Ministry of Transportation of PRC: Beijing, China, 2011.

- Yin, F.; Cheng, X. Key construction control technology of exposed aggregate cement concrete. Highw. Transp. Inn. Mong. 2007, 6, 15–16. [Google Scholar] [CrossRef]

- Zha, X.; Liu, L.; Bai, L.; Han, X. Image recognition method of asphalt-aggregate ratio for asphalt mixture. J. Traffic Transp. Eng. 2013, 13, 1–6+14. [Google Scholar] [CrossRef]

- JTG 3450-2019; Field Test Methods of Highway Subgrade and Pavement. Ministry of Transportation of PRC: Beijing, China, 2019.

- Mai, J.; Meng, X.; Li, L.; Zhao, L.; He, J. Study on denoising and sound absorption performance of drainage asphalt pavement based on indoor tire accelerated falling method. J. Highw. Transp. Res. Dev. 2022, 39, 17–24. [Google Scholar] [CrossRef]

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. Ministry of Transportation of PRC: Beijing, China, 2020.

- Panagouli, O.K.; Kokkalis, A.G. Skid resistance and fractal structure of pavement surface. Chaos Soliton. Fract. 1998, 9, 493–505. [Google Scholar] [CrossRef]

- Han, D.; Wang, L.; Guo, P.; Lu, W.; Yang, X. Review of principles and research on noise reduction technology for dense-graded rubber asphalt pavements. J. Chang. Univ. Sci. Technol. (Nat. Sci. Ed.) 2024, 21, 61–78+106. [Google Scholar] [CrossRef]

- Huang, Z.; Zang, X.; Chen, B.; Yu, J.; Chen, F. Influence of tyre contact configuration distribution on noise reduction characteristics of asphalt pavement. Sci. Technol. Eng. 2018, 18, 123–128. [Google Scholar] [CrossRef]

- JTG D40-2011; Specifications for Design of Highway Cement Concrete Pavement. Ministry of Transportation of PRC: Beijing, China, 2011.

- Guo, C.; Shen, G.; Wang, X.; Li, L. Analysis of asphalt-rubber pavement noise spectrum with close-proximity trailer method. China J. Highw. Transp. 2012, 25, 22–28. [Google Scholar] [CrossRef]

- Dong, S.; Han, S.; Xu, J.; Su, H.; Niu, D.; Chen, D.; Jia, M.; Wang, W. Review of methods for three-dimensional reconstruction and evaluation of asphalt pavement textures. China J. Highw. Transp. 2025, 38, 60–84. [Google Scholar] [CrossRef]

- Asteris, P.G.; Skentou, A.D.; Bardhan, A.; Samui, P.; Pilakoutas, K. Predicting concrete compressive strength using hybrid ensembling of surrogate machine learning models. Cement Concrete Res. 2021, 145, 106449. [Google Scholar] [CrossRef]

- Jamhiri, B.; Jalal, F.E.; Chen, Y. Hybridizing multivariate robust regression analyses with growth forecast in evaluation of shear strength of zeolite-alkali activated sands. Multiscale Multi. Mod. 2022, 5, 317–335. [Google Scholar] [CrossRef]

- Naser, A.H.; Badr, A.H.; Henedy, S.N.; Ostrowski, K.A.; Imran, H. Application of multivariate adaptive regression splines (mars) approach in prediction of compressive strength of eco-friendly concrete. Case Stud. Constr. Mat. 2022, 17, e01262. [Google Scholar] [CrossRef]

| Levels | Factors | |||

|---|---|---|---|---|

| A Water–Binder Ratio | B Sand Ratio/% | C Coarse Aggregate Volume Ratio/% | D Proportion of Aggregates >9.5 mm/% | |

| 1 | 0.40 | 28 | 40 | 30 |

| 2 | 0.43 | 31 | 42 | 50 |

| 3 | 0.46 | 34 | 44 | 70 |

| Test Number | Factors | |||

|---|---|---|---|---|

| A | B | C | D | |

| 1 | 0.40 | 28 | 40 | 30 |

| 2 | 0.40 | 31 | 42 | 50 |

| 3 | 0.40 | 34 | 44 | 70 |

| 4 | 0.43 | 28 | 42 | 70 |

| 5 | 0.43 | 31 | 44 | 30 |

| 6 | 0.43 | 34 | 40 | 50 |

| 7 | 0.46 | 28 | 44 | 50 |

| 8 | 0.46 | 31 | 40 | 70 |

| 9 | 0.46 | 34 | 42 | 30 |

| Test Number | Exposed Aggregate Depth/mm | Exposed Aggregate Area Ratio/% | Pendulum Value/BPN | Noise Value/dB | 28-day Compressive Strength/MPa | 28-day Flexural Strength/MPa |

|---|---|---|---|---|---|---|

| 1 | 2.88 | 65.53 | 70.00 | 82.44 | 47.42 | 5.13 |

| 2 | 2.84 | 66.03 | 74.67 | 82.37 | 50.69 | 5.53 |

| 3 | 2.38 | 68.54 | 73.00 | 85.38 | 51.86 | 5.70 |

| 4 | 3.00 | 57.13 | 79.67 | 81.84 | 44.57 | 5.13 |

| 5 | 2.89 | 76.23 | 70.00 | 82.02 | 48.29 | 5.20 |

| 6 | 2.81 | 68.34 | 71.67 | 81.66 | 48.86 | 5.27 |

| 7 | 3.03 | 66.33 | 71.00 | 81.59 | 42.27 | 4.90 |

| 8 | 2.40 | 57.67 | 77.67 | 84.28 | 38.97 | 5.53 |

| 9 | 2.92 | 70.17 | 74.33 | 82.82 | 44.15 | 5.03 |

| Test Indicators | Factors | ||||

|---|---|---|---|---|---|

| A | B | C | D | ||

| Exposed aggregate depth/mm | k1 | 2.70 | 2.97 | 2.70 | 2.90 |

| k2 | 2.90 | 2.71 | 2.92 | 2.89 | |

| k3 | 2.78 | 2.70 | 2.77 | 2.59 | |

| range | 0.20 | 0.27 | 0.22 | 0.31 | |

| Exposed aggregate area ratio/% | k1 | 66.70 | 63.00 | 63.85 | 70.64 |

| k2 | 67.24 | 66.64 | 64.44 | 66.90 | |

| k3 | 64.72 | 69.02 | 70.37 | 61.11 | |

| range | 2.51 | 6.02 | 6.52 | 9.53 | |

| Pendulum value/BPN | k1 | 72.56 | 73.56 | 73.11 | 71.44 |

| k2 | 73.78 | 74.11 | 76.22 | 72.44 | |

| k3 | 74.33 | 73.00 | 71.33 | 76.78 | |

| range | 1.78 | 1.11 | 4.89 | 5.33 | |

| Noise value/dB | k1 | 83.39 | 81.96 | 82.79 | 82.43 |

| k2 | 81.84 | 82.89 | 82.34 | 81.87 | |

| k3 | 82.90 | 83.29 | 83.00 | 83.83 | |

| range | 1.55 | 1.33 | 0.66 | 1.96 | |

| 28-day compressive strength/MPa | k1 | 49.99 | 44.75 | 45.08 | 46.62 |

| k2 | 47.24 | 45.98 | 46.47 | 47.27 | |

| k3 | 41.80 | 48.29 | 47.47 | 45.13 | |

| range | 8.19 | 3.54 | 2.39 | 2.14 | |

| 28-day flexural strength/MPa | k1 | 5.45 | 5.05 | 5.31 | 5.12 |

| k2 | 5.20 | 5.42 | 5.23 | 5.23 | |

| k3 | 5.16 | 5.33 | 5.27 | 5.46 | |

| range | 0.30 | 0.37 | 0.08 | 0.33 | |

| Test Indicators | Factors | |||

|---|---|---|---|---|

| A | B | C | D | |

| Pendulum value | 0.46 | 31 | 42 | 70 |

| Noise value | 0.43 | 28 | 42 | 50 |

| 28-day compressive strength | 0.40 | 34 | 44 | 50 |

| 28-day flexural strength | 0.40 | 31 | 40 | 70 |

| Test Indicators | Technical Requirements | EAC | Grooved Concrete |

|---|---|---|---|

| Exposed aggregate depth/mm | 2~3 | 2.89 | / |

| Exposed aggregate area ratio/% | 65~75 | 68.75 | / |

| Pendulum value/BPN | / | 77.56 | 58.98 |

| Noise value/dB | / | 81.53 | 88.01 |

| 28-day compressive strength/MPa | ≥40 | 47.81 | 43.23 |

| 28-day flexural strength/MPa | ≥5 | 5.35 | 5.12 |

| Slump/mm | 10~30 | 14 | 23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zha, X.; Wu, C.; Luo, R.; Liu, Y. Optimization of Exposed Aggregate Concrete Mix Proportions for High Skid Resistance and Noise Reduction Performance. Appl. Sci. 2025, 15, 5881. https://doi.org/10.3390/app15115881

Zha X, Wu C, Luo R, Liu Y. Optimization of Exposed Aggregate Concrete Mix Proportions for High Skid Resistance and Noise Reduction Performance. Applied Sciences. 2025; 15(11):5881. https://doi.org/10.3390/app15115881

Chicago/Turabian StyleZha, Xudong, Chengzhi Wu, Runzhou Luo, and Yaqiang Liu. 2025. "Optimization of Exposed Aggregate Concrete Mix Proportions for High Skid Resistance and Noise Reduction Performance" Applied Sciences 15, no. 11: 5881. https://doi.org/10.3390/app15115881

APA StyleZha, X., Wu, C., Luo, R., & Liu, Y. (2025). Optimization of Exposed Aggregate Concrete Mix Proportions for High Skid Resistance and Noise Reduction Performance. Applied Sciences, 15(11), 5881. https://doi.org/10.3390/app15115881