Abstract

Expansive soils exhibit pronounced behaviors of swelling, shrinkage, and over-consolidation, leading to significant engineering challenges. To address these issues, this study investigated the influence of different cementation solution concentrations on the swelling and mechanical properties of microbially induced calcium carbonate precipitation (MICP)-treated expansive soils. Additionally, a series of wet–dry cycling experiments were conducted to analyze the performance degradation of the MICP-treated soils under cyclic environmental conditions. The results showed that as the cementation solution concentration increased, the free swell ratio and unconfined swell ratio of the soil samples decreased by 39.29% and 71%, respectively. The unconfined compressive strength, cohesion, and internal friction angle of the MICP-treated soils also exhibited significant improvements, with increases of 391.67%, 33.76%, and 91.67%, respectively. A cementation solution concentration of 1 M was found to be the optimal for achieving substantial enhancements in the soil properties. However, under continuous wet–dry cycling, the mechanical properties of the MICP-treated soils experienced degradation, with the unconfined compressive strength decreasing by up to 62.24%. These findings highlight the potential of MICP as an effective and eco-friendly technique for stabilizing expansive soils.

1. Introduction

Expansive soils, notably characterized by their high contents of montmorillonite and illite minerals, exhibit pronounced behaviors of swelling, shrinkage, and over-consolidation [1]. These properties can lead to significant engineering challenges, including uneven settlement, slope instability, and pavement heaving [2]. These detrimental effects have led to the metaphorical characterization of expansive soils as the “cancer of highways” [3]. The extensive distribution of these soils, coupled with the often concealed and long-term nature of the associated issues, results in global annual repair costs amounting to billions of dollars [4]. Consequently, the development of effective soil improvement techniques is essential for the rational and sustainable utilization of expansive soils.

To address the challenges posed by expansive soils, researchers have extensively investigated a variety of physical and chemical stabilization techniques [5]. Physical stabilization methods typically involve the incorporation of non-expansive fillers, such as fine sand, crushed stone, or fibers, to reduce the montmorillonite and illite mineral contents, thereby suppressing the swelling and shrinkage behavior while simultaneously improving mechanical properties [6,7]. For instance, Huang et al. [8] demonstrated the effectiveness of basalt fiber in enhancing the stability of expansive soils. Their findings indicated that the addition of 4% basalt fiber significantly mitigated swelling and shrinkage while also enhancing the mechanical properties of the soil. Similarly, Blayi et al. [9] reported that the inclusion of rock powder, fine sand, and gravel improved both the stability and mechanical performance of expansive soils. However, it is important to note that the effectiveness of physical stabilization is somewhat limited and is primarily suitable for soils with low expansiveness.

In contrast, chemical stabilization approaches focus on modifying the internal particle structure of expansive soils or inducing gel-like precipitations to enhance their swelling and shrinkage characteristics [10,11]. The previous studies [12,13] have shown that the addition of lime and cement positively influences the engineering properties and swelling–shrinkage behavior of expansive soils. For instance, Mohamed et al. [14] effectively improved the swelling–shrinkage properties and enhanced the compressive and shear strength of expansive soils through various mixtures, including 6% lime with 12% zeolite, 1% cement with 10% fly ash, and sawdust ash. Furthermore, Zhou et al. [15] identified an optimal improvement in expansive soils with the incorporation of 0.6% cationic polyacrylamide. While these chemical methods can effectively reduce swelling and shrinkage, they often raise concerns regarding energy consumption and environmental pollution [16].

In recent years, microbially induced calcium carbonate precipitation (MICP) has emerged as a promising and eco-friendly technique for soil improvement [17]. MICP leverages the interaction between specific microorganisms and expansive soils to facilitate the formation of calcium carbonate precipitates, which subsequently alters the internal structure and mineral composition of the soil [18]. Numerous studies have demonstrated the effectiveness of MICP in enhancing various properties of expansive soils, including material properties, swelling rates, and mechanical characteristics [19,20]. For instance, Osinubi et al. [21] utilized MICP technology to treat the natural soil, resulting in significant improvements in key properties such as Atterberg limits and linear shrinkage, with optimal performance being achieved at a specific bacteria-to-cementation reagent ratio. Similarly, Chittoori et al. [22] reported that MICP treatment led to substantial increases in both the compressive and shear strength of expansive soils. These findings underscore the potential of MICP as a viable solution for mitigating the challenges posed by expansive soil behavior [23]. However, certain environmental conditions can adversely affect the performance of MICP-treated soils. In regions with hot and humid climates, such as Guangxi and Yunnan provinces in China, cyclic wet–dry conditions can lead to a decline in the bearing capacity of MICP-treated expansive soil bases [24]. This phenomenon poses challenges for the long-term stability and effectiveness of MICP applications in these regions [25]. Additionally, it is important to note that the natural concentration of calcium ions in expansive soils is often low, necessitating the addition of an appropriate calcium source to enhance the production of calcium carbonate precipitates [26]. Despite the promising results of MICP, there is currently limited research focused on determining the optimal concentration of the cementation solution required for the effective MICP treatment of expansive soils.

This study aimed to investigate the influence of different cementation solution concentrations on the physical, swelling, and mechanical properties of MICP-treated expansive soils. Furthermore, a series of wet–dry cycling experiments were conducted to analyze the performance degradation of the MICP-treated expansive soils under cyclic environmental conditions. The findings of this study contribute to the development of sustainable and eco-friendly soil stabilization techniques for expansive soil-prone regions, providing insights into the long-term performance of MICP-treated soils under varying environmental conditions.

2. Materials and Methods

2.1. Materials

The expansive soil samples used in this study were collected from a construction site in Guangxi province, China. Surface soils exhibiting potential rainfall-induced weathering were systematically excluded, with all test specimens extracted from the primary expansive clay layer (1.5–2.0 m depth). The soil samples were yellowish-brown in color and had a relatively high natural moisture content (27.3%). The physical properties and swelling potential of the expansive soil were determined, as presented in Table 1 and Table 2.

Table 1.

Physical properties of the expansive soil.

Table 2.

Swelling potential of the expansive soil.

The MICP process was facilitated by Sporosarcina pasteurii (ATCC11859), a common ureolytic bacteria widely used in MICP applications. The bacterial culture was activated and cultivated on Petri dishes prior to the experiments. The cultivation conditions for the bacterial strain are presented in Table 3. After the cultivation was completed, the optical density (OD600) of the bacterial suspension was measured, and the suspension was considered ready for use when the OD600 value reached 1.0. The bacterial suspension was then stored at 4 °C to avoid potential mutations from repeated subculturing.

Table 3.

Cultivation conditions for Sporosarcina pasteurii.

2.2. Sample Preparation

The expansive soil samples were first air-dried, crushed, and sieved through a 2 mm mesh to prepare the soil for the stabilization experiments. To mitigate the potential impact of insufficient natural calcium ion concentration in the expansive soil, cementation solutions with different concentrations were prepared. Specifically, five cementation solution concentrations were investigated: 0 M, 0.5 M, 0.75 M, 1.0 M, 1.25 M, and 1.5 M. The molar ratio of urea to calcium chloride (CaCl2) was maintained at 1:1 in all the cementation solutions, as recommended in previous studies.

The MICP treatment was conducted using a mixing method. The bacterial suspension and the cementation solution were added to the expansive soil in a 1:1 ratio by mass and thoroughly mixed until the soil moisture content reached the target value. Based on previous studies that determined the optimal moisture content for maximizing compaction density and performance of expansive soils, all soil improvement tests in this work were consistently conducted at a fixed target moisture content of 21.9% to ensure experimental repeatability and result comparability.

The MICP-treated soil samples with different cementation solution concentrations (0 M, 0.5 M, 0.75 M, 1.0 M, 1.25 M, and 1.5 M) were labeled as S-0, S-1, S-2, S-3, S-4, and S-5, respectively. After the mixing, the MICP-treated soil samples were placed in a temperature- and humidity-controlled curing chamber (temperature of 25 °C and relative humidity of 95%) and cured for 7 days to allow for the completion of the MICP process.

The cured soil samples were then subjected to various physical, swelling, and mechanical property tests, as described in the following sections.

2.3. Test Methods

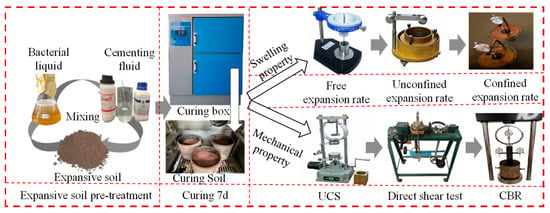

The overall test procedure, encompassing the preparation of soil samples, application of MICP treatment, and subsequent testing for swelling properties and mechanical properties, is systematically illustrated in Figure 1.

Figure 1.

Experimental protocol flowchart.

All the swelling and mechanical property tests were performed on the MICP-treated expansive soil samples with different cementation solution concentrations, as well as the untreated control sample (S-0). The results were analyzed to evaluate the effectiveness of the MICP treatment and the influence of the cementation solution concentration on the soil properties. In addition, each experimental sample was set up with 3 parallel samples.

2.3.1. Swelling Property Tests

The swelling behavior of MICP-treated expansive soils was evaluated through free swelling and unconfined swelling tests performed in accordance with ASTM D4546(B) [29]. Meanwhile, the confined swelling property was measured during the CBR test, following ASTM D1883 [30].

The soil samples were placed in a free expansion instrument and consolidometer and saturated with water. The free and vertical swell deformation was recorded over time until no further expansion was observed, ensuring a thorough assessment of the free swelling and unconfined swelling potential.

2.3.2. Mechanical Property Tests

The mechanical properties of the MICP-treated expansive soil samples were evaluated through unconfined compressive strength (UCS), direct shear, and California bearing ratio (CBR) tests.

The UCS test was conducted in accordance with ASTM D2166 [31]. Cylindrical soil samples were prepared and tested under axial compression until failure. The maximum compressive strength was recorded as the UCS.

The shear strength of the MICP-treated expansive soil samples was evaluated through direct shear tests, following ASTM D3080 [32]. The specimens were placed in the direct shear apparatus and subjected to a series of normal stresses (50 kPa, 100 kPa, and 150 kPa) to determine the shear strength parameters, namely the cohesion (c) and the angle of internal friction (φ).

The CBR test was performed following the procedures outlined in ASTM D1883 [30]. Soil samples were compacted in a CBR mold and soaked in water for 96 h, and the confined swelling property was measured during the test. Subsequently, the samples were subjected to a penetration test. The CBR value was calculated as the ratio of the test load to the standard load, expressed as a percentage.

2.3.3. Scanning Electron Microscopy Test

In this study, a scanning electron microscopy (SEM) was employed to examine the microstructural variations between untreated expansive soil (S-0) and soil treated with a 1.0 M cementing solution (S-3). Standard soil specimens (8 × 8 × 15 mm3) were prepared and freeze-dried under liquid nitrogen vacuum to preserve their original pore structure. For SEM observation, samples were sputter-coated with metal and mounted on the specimen stage. Microstructural characterization was performed at 15 kV accelerating voltage and 50× magnification. These observations effectively revealed the microscale mechanism of soil structure improvement through cementation.

2.3.4. Wet–Dry Cycling Tests

To analyze the performance degradation of the MICP-treated expansive soil under cyclic environmental conditions, a series of wet–dry cycling tests were conducted. The soil sample treated with a 1.0 M cementation solution (S-3) was selected for the wet–dry cycling tests, which is the optimal binder concentration determined by the swelling characteristics and mechanical performance tests of the improved soil. In addition, the untreated control sample (S-0) were selected as the control group.

The wet–dry cycling test procedure was as follows:

- Prepare test specimens from the S-0 and S-3 soil sample.

- Dry the soil specimens in a 60 °C oven for 23 h, followed by 1 h of resting in a 25 °C oven.

- Submerge the soil specimens in water for 23 h, followed by 1 h of resting in a 25 °C oven.

- Repeat steps 2 and 3 to complete 0, 3, 6, 9, 12, and 15 wet–dry cycles.

- After each specified number of wet–dry cycles, measure the mass loss, volume deformation, UCS, and shear strength of the soil specimens.

The wet–dry cycling test was designed to simulate the cyclic environmental conditions, particularly the wet–dry cycles, experienced by the MICP-treated expansive soil in regions with hot and humid climates in China. The test results were used to evaluate the long-term performance and durability of the MICP-treated expansive soil under these challenging environmental conditions.

3. Results and Discuss

3.1. Swelling Characteristics of Treated Soils

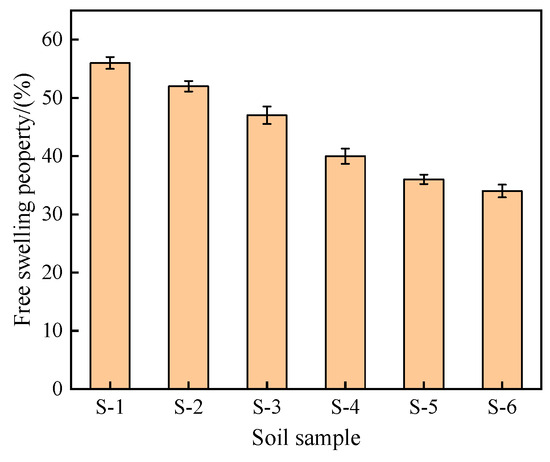

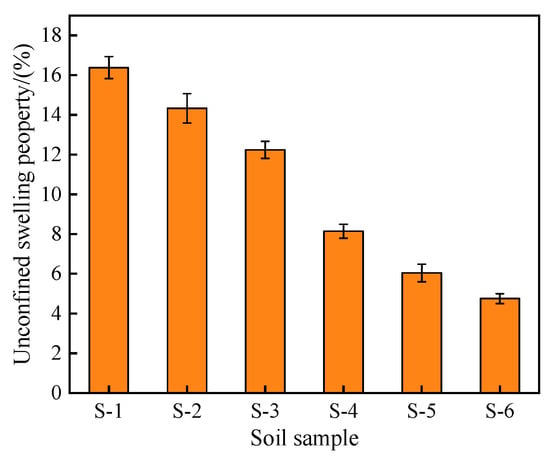

The results of the free swell tests and confined swell tests for the soil samples are presented in Figure 2 and Figure 3, respectively. These results reveal that as the cementation solution concentration increased, the free swell ratio of the soil samples decreased from 56% for S-0 to 34% for S-5, a reduction of 39.29%. Similarly, the unconfined swell ratio decreased from 16.38% for S-0 to 4.75% for S-5, a reduction of 71%.

Figure 2.

Free swell rate test results.

Figure 3.

Unconfined swell ratio test results.

The free swell ratio and unconfined swell ratio both exhibited a decreasing trend, with a more rapid decline at lower cementation solution concentrations and a more gradual decline at higher concentrations. Specifically, for the soil samples S-0 to S-3 (cementation solution concentration less than 1 M), the free swell ratio and unconfined swell ratio decreased by 28.57% and 50.31%, respectively. In contrast, for the soil samples S-3 to S-5 (cementation solution concentration greater than 1 M), the decreases in the free swell ratio and confined swell ratio were only 10.72% and 20.69%, respectively.

These results suggest that a cementation solution concentration of 1 M is effective in reducing the swelling potential of the expansive soil. The reduction in swelling characteristics can be attributed to the precipitation of calcium carbonate induced by the Sporosarcina pasteurii bacteria and the cementation solution. The CaCO3 precipitation fills the pore spaces and alters the internal particle structure of the expansive soil, effectively improving its water-induced swelling behavior.

Moreover, the significant decrease in swelling ratios, especially at lower cementation solution concentrations, indicates that the MICP treatment enhances the soil’s resistance to volume changes upon wetting. This improvement is crucial for mitigating the adverse effects of swelling in expansive soils, such as uneven settlement and structural failures.

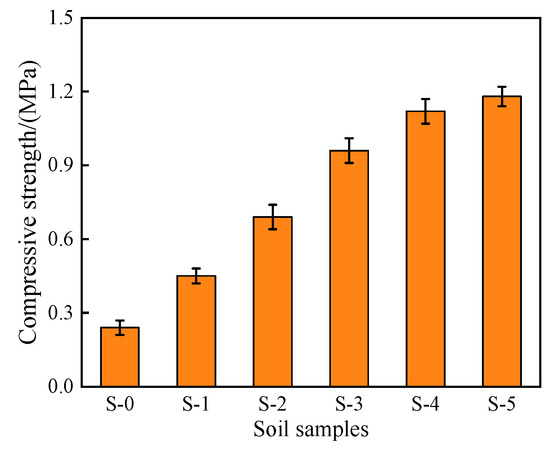

3.2. Mechanical Properties of Treated Soils

The UCS test results for the S-0 to S-5 soil samples are shown in Figure 4. As the cementation solution concentration increased, the UCS increased from 0.24 MPa to 1.18 MPa, an increase of 391.67%. The rate of change in the UCS exhibited a rapid increase at first, followed by a slower increase. The S-3 soil sample, corresponding to a cementation solution concentration of 1 M, was the turning point for the change in the compaction characteristics of the MICP-treated expansive soil. When the cementation solution concentration was less than 1 M (S-0 to S-3), the UCS increased from 0.24 MPa to 0.96 MPa, an increase of 300%. When the cementation solution concentration was greater than 1 M (S-3 to S-5), the UCS increased from 0.96 MPa to 1.18 MPa, an increase of 91.67%.

Figure 4.

Compression test results.

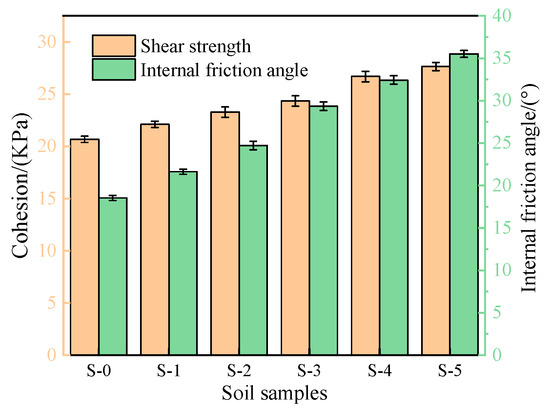

The direct shear test results for the S-0 to S-5 soil samples are shown in Figure 5. As the cementation solution concentration increased, the cohesion increased from 20.67 kPa to 27.65 kPa, an increase of 33.76%, and the internal friction angle increased from 18.53° to 35.52°, an increase of 91.67%. The rate of change in the cohesion and internal friction angle exhibited a rapid increase at first, followed by a slower increase. The S-3 soil sample, corresponding to a cementation solution concentration of 1 M, was the turning point for the change in the compaction characteristics of the MICP-treated expansive soil. When the cementation solution concentration was less than 1 M (S-0 to S-3), the increases in cohesion and the internal friction angle were 17.77% and 58.33%, respectively. When the cementation solution concentration was greater than 1 M (S-3 to S-5), the increases in cohesion and the internal friction angle were 15.99% and 33.34%, respectively.

Figure 5.

Shear test results.

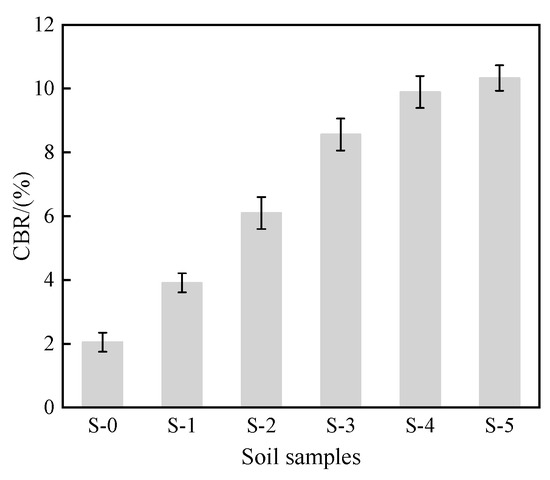

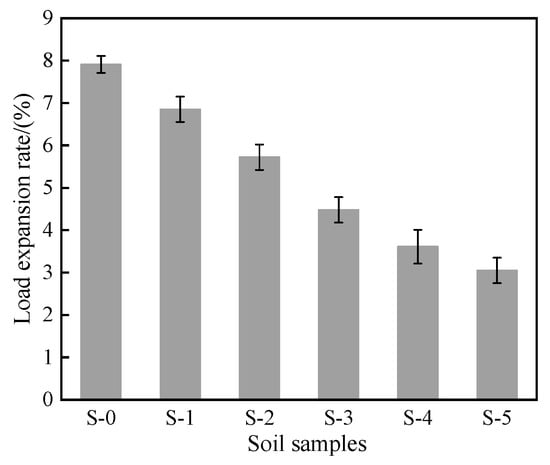

The CBR test results for the S-0 to S-5 soil samples are shown in Figure 6 and Figure 7. The CBR value increased from 2.05% to 10.33%, an increase of 403.90%. A minimum value point occurred at a cementation solution concentration of 1 M, with the S-3 soil sample having a CBR value of 8.56%, which already meets the requirement for the highway subgrade filler CBR value in China. The load expansion rate results show that the S-1 to S-5 soil samples had a significantly lower load expansion rate compared to the S-0 soil sample, with a reduction of ranging from 13.40% to 61.44%. The overall change rate of the load expansion rate for the S-0 to S-5 soil samples exhibited a rapid decrease at first, followed by a slower decrease. When the cementation solution concentration was greater than 1 M, the decrease in the load expansion rate slowed down significantly.

Figure 6.

CBR value results.

Figure 7.

Load expansion rate test results.

These results indicate that the mechanical properties of the expansive soil were significantly improved after MICP treatment. This is likely due to the formation of calcium carbonate precipitates through the interaction between Sporosarcina pasteurii, the cementation solution, and the expansive soil. Some of the precipitates were adsorbed onto the surrounding fine particles, forming aggregates, while others filled the pores between the soil particles [33]. This resulted in a more compact internal structure, with reduced voids and increased particle interlocking and frictional effects, allowing the improved soil to withstand higher stresses.

Furthermore, the substantial increase in UCS, cohesion, and the internal friction angle, along with the significant reduction in the load expansion rate, highlights the effectiveness of MICP treatment in enhancing the load-bearing capacity and stability of expansive soils. The findings suggest that a cementation solution concentration of 1 M is optimal for achieving significant mechanical property improvements.

3.3. Discussion

The application of microbially induced carbonate precipitation (MICP) technology demonstrates significant potential for improving the expansive characteristics and mechanical properties of expansive soils. This finding aligns with previous studies which reported substantial enhancements in soil mechanical parameters through microbial treatment. For instance, Tian et al. [34] observed a 33.5% increase in soil cohesion (from 29.52 kPa to 39.41 kPa) and a 46.94% improvement in the internal friction angle (from 20.13° to 29.58°). Similarly, Chittoori and Neupane [20] documented a 252% enhancement in unconfined compressive strength (UCS), with values increasing from 0.25 MPa to 0.88 MPa.

Notably, some discrepancies exist between the improvement levels reported in these studies and our current findings. These variations may be attributed to differences in the mineralogical composition of expansive soils across geographical regions.

Furthermore, it is important to recognize that the efficacy of microbial soil modification can be influenced by multiple factors, including the bacterial solution concentration and curing conditions (temperature, duration, and pH) [35]. While the present study primarily examines the effect of cementation solution concentration while maintaining constant bacterial solution concentrations and curing parameters, future investigations should systematically evaluate the impacts of these additional variables to optimize the MICP treatment process.

3.4. Microscopic Mechanism of MICP-Treated Expansive Soil

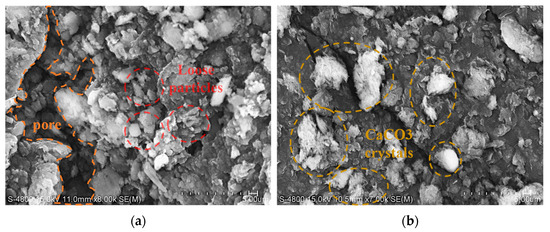

The MICP treatment was further investigated at the microscopic level to understand the mechanism by which it improves the properties of expansive soil. Scanning electron microscopy (SEM) was employed to examine the microstructural changes in the untreated soil (S-0) and the soil treated with a 1.0 M cementation solution (S-3).

Figure 8a presents the SEM images of the untreated soil sample (S-0). The soil particles exhibit a dispersed and block structure, characteristic of expansive soils. The pore spaces between the particles are relatively large, allowing for the penetration of water and the subsequent swelling of the soil. In contrast, the SEM images of the MICP-treated soil sample (S-3) shown in Figure 8b reveal a markedly different microstructure. The soil particles are bound together by the precipitation of calcium carbonate, forming a denser and more agglomerated structure. The pore spaces between the particles are significantly reduced, with the CaCO3 filling the voids and cementing the soil grains together. CaCO3 enhances the soil stability by binding particles together and adsorbing onto expansive soil surfaces while also modifying their contact behavior.

Figure 8.

SEM images of (a) the untreated soil sample (S-0); (b) the MICP-treated soil sample (S-3).

The CaCO3 precipitation has a twofold effect on the expansive soil properties. First, the cementation of the soil particles reduces the overall porosity and permeability of the soil, limiting the ingress of water and the subsequent swelling of the soil. Second, the CaCO3 precipitates act as a bonding agent, improving the overall strength and stability of the soil structure. Therefore, the microscopic evidence provided by the SEM analysis supports the observed improvements in the swelling and mechanical properties of the MICP-treated expansive soil, as discussed in the previous sections.

4. Performance Degradation of MICP-Treated Soil Under Wet–Dry Cycling

4.1. Degradation of Mechanical Properties

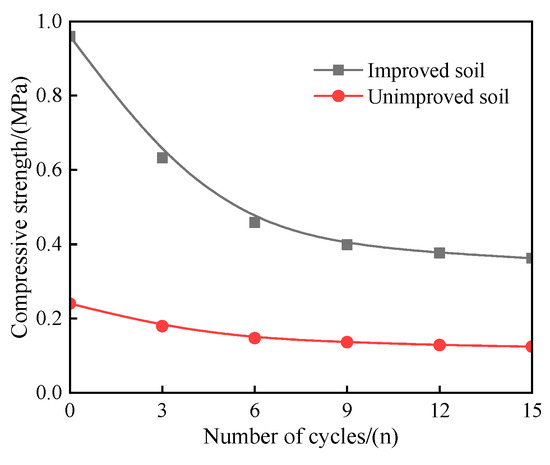

The results of the UCS tests conducted on the specimens after various wet–dry cycling intervals are presented in Figure 9. The results show that the UCS of the MICP-treated soil samples gradually decreased with an increasing number of wet–dry cycles, exhibiting a trend of a rapid initial decline followed by a more gradual reduction. After nine cycles of wet–dry exposure, the UCS of the specimens tended to stabilize. When the specimens were subjected to 15 wet–dry cycles, the UCS decreased from the initial value of 0.96 MPa to 0.36 MPa, representing a total degradation of 62.24%. However, even after 15 cycles, the UCS of the MICP-treated soil remained above the minimum requirement of 0.35 MPa specified in the Chinese standards. The majority of the UCS degradation, 93.87% of the total, occurred within the first nine wet–dry cycles, where the UCS decreased from 0.96 MPa to 0.39 MPa, a reduction of 58.43%. Meanwhile, the UCS of the untreated expansive soil decreased from 0.24 MPa to 0.12 MPa, representing a total degradation of 50%. Although this degradation rate was notably lower than that of the treated soil, the final strength of untreated soil fell significantly below the standard requirement of 0.35 MPa.

Figure 9.

Degradation of UCS results.

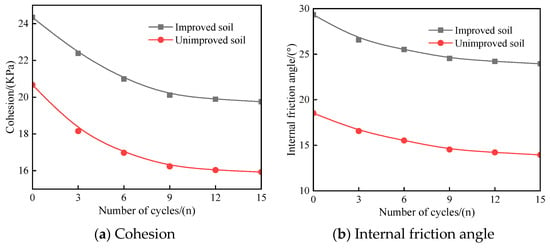

The results of the direct shear tests on the specimens after wet–dry cycling are shown in Figure 10. Similarly to the UCS results, the shear strength parameters, namely the cohesion (c) and the angle of internal friction (φ), gradually decreased with an increasing number of wet–dry cycles, also exhibiting a rapid initial decline followed by a more gradual reduction. After 15 wet–dry cycles, the cohesion of the MICP-treated soil samples decreased from 24.34 kPa to 19.74 kPa, a total degradation of 18.92%, while the angle of internal friction decreased from 29.34° to 21.54°, a total degradation of 26.59%. The degradation rate was most pronounced during the first nine wet–dry cycles, with the cohesion decreasing from 24.34 kPa to 20.11 kPa (91.86% of the total degradation) and the angle of internal friction decreasing from 29.34° to 22.45° (88.37% of the total degradation). Despite experiencing greater degradation in cohesion and internal friction angle under wet–dry cycles than untreated soil, the improved soil maintained its superior shear strength—surpassing untreated soil by 23.9% in cohesion and 71.8% in internal friction angle after 15 cycles.

Figure 10.

Degradation of shear strength results.

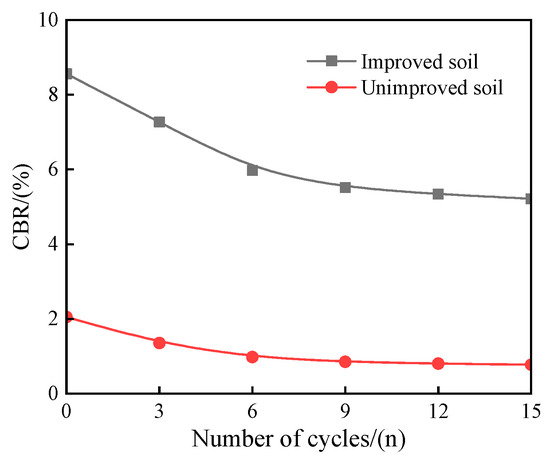

The results of the CBR tests after wet–dry cycling are presented in Figure 11. The CBR value of the MICP-treated soil samples also decreased with an increasing number of wet–dry cycles, following a similar trend of a rapid initial decline and a more gradual reduction. After 15 wet–dry cycles, the CBR value decreased from 8.56% to 5.21%, a total degradation of 39.05%. The majority of the CBR degradation, 91.14% of the total, occurred within the first nine wet–dry cycles, where the CBR value decreased from 8.56% to 5.51%. Meanwhile, the CBR of the untreated expansive soil decreased from 2.05% to 0.77%, representing a total degradation of 62.43%, and the final strength of untreated soil fell significantly below the standard requirement.

Figure 11.

Degradation of CBR results.

These results indicate that the wet–dry cycling had a significant negative impact on the mechanical properties of the MICP-treated expansive soil. The degradation of the mechanical properties, including then UCS, shear strength, and CBR, followed a trend of a rapid initial decline followed by a more gradual reduction. After nine wet–dry cycles, the degradation of the mechanical properties tended to stabilize.

Using untreated expansive soil as a control, the experimental results demonstrate significantly less mechanical property degradation after wet–dry cycles compared to the improved soil. This difference primarily stems from the untreated soil’s initially poor mechanical properties, which leave little room for further deterioration. Importantly, even after cyclic wet–dry exposure, the treated soil maintains mechanical properties substantially superior to those of untreated expansive soil.

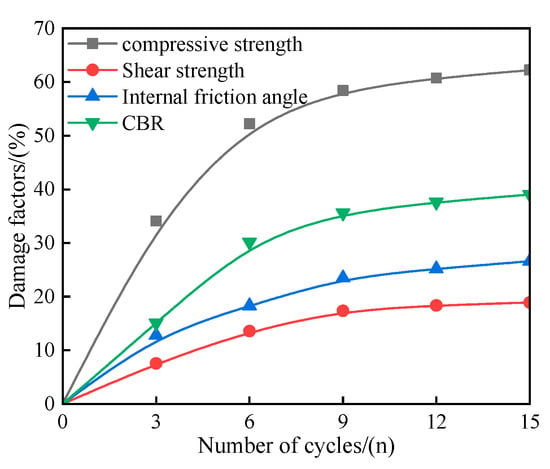

To further analyze the degradation patterns of the various mechanical parameters, the concept of a damage factor was introduced. The damage factor (DV) was calculated using Equation (1), based on the initial and post-wet–dry cycling mechanical property values. The total degradation (DS) and degradation rate (VS) were then determined using Equations (2) and (3), respectively, as suggested in the literature. The damage factor curves for the different mechanical properties are presented in Figure 12.

where DV represents the damage factor; S denotes the mechanical property value after wet–dry cycling; S0 indicates the initial mechanical property value; DS signifies total degradation; VS refers to the degradation rate; a is the number of wet–dry cycles; and f(x) represents the degradation curve for various parameters.

Figure 12.

Damage factor curves of mechanical properties.

The total degradation areas for the UCS, angle of internal friction, cohesion, and CBR were calculated to be 710.02, 413.95, 279.24, and 198.89, respectively. The corresponding degradation rates were 3.12, 2.84, 2.49, and 1.97, respectively. These results indicate that the wet–dry cycling had the most significant impact on the unconfined compressive strength of the MICP-treated soil, followed by the CBR, while the shear strength parameters were the least affected.

4.2. Mass Loss

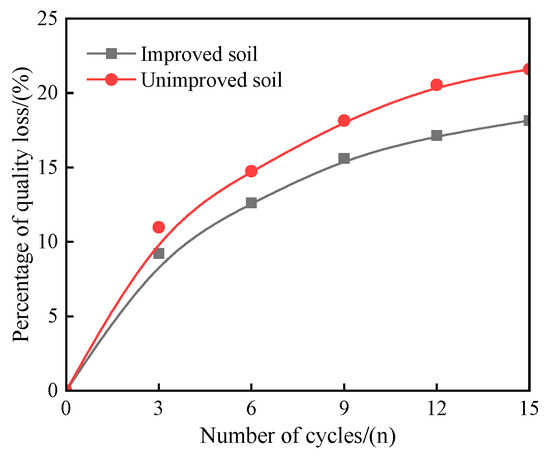

The results of the mass loss tests conducted on the untreated and MICP-treated soil specimens after various wet–dry cycling intervals are presented in Figure 13. The results show that the mass loss rate of the specimens increased with the number of wet–dry cycles, exhibiting a trend of a rapid initial increase followed by a more gradual reduction.

Figure 13.

Loss of quality.

After 15 wet–dry cycles, the total mass loss of the MICP-treated soil specimens was 18.15%. However, the majority of the mass loss, 86% of the total, occurred within the first nine wet–dry cycles, where the mass loss rate reached 15.61%. Furthermore, after 15 drying–wetting cycles, the stabilized expansive soil showed an 15.97% lower mass loss rate than the untreated soil.

This behavior can be attributed to the mechanism of mass loss during the wet–dry cycling. When the specimens were submerged in water, the water flow caused the erosion and transportation of some soil particles from the internal structure of the specimens. Additionally, the loose surface particles were also carried away by the water solution, leading to the observed mass loss. After the initial rapid mass loss during the first nine wet–dry cycles, the rate of mass loss gradually decreased. This can be explained by the stabilization of the soil structure, where the remaining particles became more tightly bound together due to the MICP treatment, reducing the susceptibility to further mass loss.

4.3. Volume Expansion

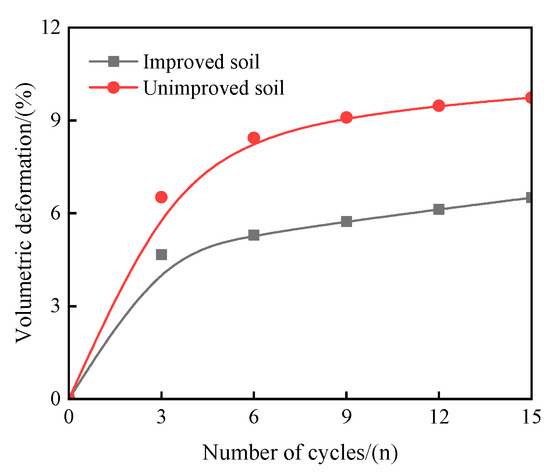

The results of the volume expansion tests conducted on the MICP-treated soil specimens after various wet–dry cycling intervals are presented in Figure 14. The results show that the volume expansion of the specimens increased with the number of wet–dry cycles, exhibiting a rapid initial increase followed by a more gradual reduction.

Figure 14.

Volume expansion behavior.

After 15 wet–dry cycles, the total volume expansion of the MICP-treated soil specimens was 6.53%. However, the majority of the volume expansion, 71.36% of the total, occurred within the first three wet–dry cycles, where the volume expansion reached 4.66%. Furthermore, after 15 drying–wetting cycles, the stabilized expansive soil exhibited a 33.20% reduction in its volumetric expansion rate compared to the untreated soil.

This behavior can be attributed to the changes in the soil microstructure during the wet–dry cycling. Initially, the MICP treatment had effectively reduced the swelling potential of the expansive soil by altering the internal particle structure and reducing the pore spaces, as observed in the earlier microscopic analysis. However, the subsequent wet–dry cycles caused the progressive degradation of the MICP-induced cementation, leading to an increase in the volume expansion of the soil. After the initial rapid volume expansion during the first three wet–dry cycles, the rate of volume expansion gradually decreased. This can be explained by the stabilization of the soil structure, where the remaining cementation bonds became more resistant to the effects of wet–dry cycling, limiting further volume expansion.

5. Conclusions

This study comprehensively investigated the influence of different cementation solution concentrations on the swelling and mechanical properties of MICP-treated expansive soils. Based on the experimental results, the following main conclusions can be drawn:

- MICP treatment can significantly improve the swelling characteristics of expansive soils. As the cementation solution concentration increased, the free swell ratio and unconfined swell ratio of the soil samples both exhibited a decreasing trend. When the cementation solution concentration reached 1 M, the swelling properties of the soil samples were substantially suppressed. This can be attributed to the precipitation of calcium carbonate during the MICP process, which fills the pore spaces between soil particles and alters the internal structure, thereby enhancing the anti-swelling performance.

- MICP treatment also significantly enhanced the mechanical properties of the expansive soil. As the cementation solution concentration increased, the unconfined compressive strength, cohesion, and internal friction angle of the soil samples all exhibited notable improvements. When the cementation solution concentration reached 1 M, the mechanical properties of the soil samples were significantly enhanced, meeting the technical requirements for highway subgrade fill materials. This is primarily due to the filling and cementing effects of the calcium carbonate precipitates, which strengthen the inter-particle bonding within the soil.

- Under continuous wet–dry cycling, the mechanical properties of the MICP-treated soil samples experienced degradation. The unconfined compressive strength showed the most significant reduction, decreasing by 62.24%. The decreases in cohesion and internal friction angle were relatively smaller, at 18.92% and 26.59%, respectively. The CBR value also decreased by 39.05%. This performance degradation mainly occurred within the first nine wet–dry cycles, after which it tended to stabilize. This is likely due to the partial dissolution and loss of the calcium carbonate precipitates under the repeated wet–dry cycles, leading to a reduction in the strength and stiffness of the MICP-treated soil.

In summary, MICP technology can effectively improve the performance of expansive soils, but in regions with hot and humid climates, the mechanical properties of the treated soil samples may undergo a certain degree of degradation under long-term wet–dry cycling. Therefore, further optimization of the MICP method is needed to enhance its durability under complex environmental conditions, providing a more reliable solution for the engineering construction in expansive soil-prone regions.

Author Contributions

Conceptualization, F.H. and B.J.; methodology, S.W.; software, S.W.; validation, F.H., B.J. and F.Z.; formal analysis, F.Z.; investigation, F.Z.; resources, X.L.; data curation, X.L.; writing—original draft preparation, B.J.; writing—review and editing, B.J. and F.H.; visualization, X.L.; supervision, S.W.; project administration, F.Z.; funding acquisition, S.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Research Project of Chongqing Education Commission of China (Grant numbers: KJQN202305802, KJQN202403413), Chongqing Natural Science Foundation (Grant number: CSTB2024NSCQ-MSX0006).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this paper will be made available by the authors by request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mehmood, M.; Guo, Y.; Liu, Y.; Wang, L.; Nie, W.; Uge, B.U.; Ali, S.; Chen, X.; Zhao, Y. Experimental study on the engineering characteristics of expansive soil improved conjointly using enzyme induced carbonate precipitation and eggshell powder. Soils Found. 2025, 65, 101567. [Google Scholar] [CrossRef]

- Irakoze, D.; Abongo, K.; Waweru, S. Performance of Expansive Soil blended with Waste Marble Dust and Natural Pozzolana for Road Subgrade. Eng. Technol. Appl. Sci. Res. 2025, 15, 21068–21075. [Google Scholar] [CrossRef]

- Luo, P.; Ma, M. Failure Mechanisms and Protection Measures for Expansive Soil Slopes: A Review. Sustainability 2024, 16, 5127. [Google Scholar] [CrossRef]

- Xu, S.; Ma, E.; Lai, J.; Yang, Y.; Liu, H.; Yang, C.; Hu, Q. Diseases failures characteristics and countermeasures of expressway tunnel of water-rich strata: A case study. Eng. Fail. Anal. 2022, 134, 106056. [Google Scholar] [CrossRef]

- Zada, U.; Jamal, A.; Iqbal, M.; Eldin, S.M.; Almoshaogeh, M.; Bekkouche, S.R.; Almuaythir, S. Recent advances in expansive soil stabilization using admixtures: Current challenges and opportunities. Case Stud. Constr. Mater. 2023, 18, e01985. [Google Scholar] [CrossRef]

- Tiwari, N.; Satyam, N.; Puppala, A.J. Strength and durability assessment of expansive soil stabilized with recycled ash and natural fibers. Transp. Geotech. 2021, 29, 100556. [Google Scholar] [CrossRef]

- Al-Gharbawi, A.S.; Najemalden, A.M.; Fattah, M.Y. Expansive soil stabilization with lime, cement, and silica fume. Appl. Sci. 2022, 13, 436. [Google Scholar] [CrossRef]

- Huang, Z.; Sun, H.-Y.; Dai, Y.-M.; Hou, P.-B.; Zhou, W.-Z.; Bian, L.-L. A study on the shear strength and dry-wet cracking behaviour of waste fibre-reinforced expansive soil. Case Stud. Constr. Mater. 2022, 16, e01142. [Google Scholar] [CrossRef]

- Blayi, R.A.; Sherwani, A.F.H.; Mahmod, F.H.R.; Ibrahim, H.H. Influence of rock powder on the geotechnical behaviour of expansive soil. Int. J. Geosynth. Ground Eng. 2021, 7, 14. [Google Scholar] [CrossRef]

- Liu, C.; Lu, K.; Wu, Z.; Liu, X.; Garg, A.; Qin, Y.; Mei, G.; Lv, C. Expansive soil improvement using industrial bagasse and low-alkali ecological cement. Constr. Build. Mater. 2024, 423, 135806. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, C.; Zhang, Z.; Zhang, Z.; Kou, J.; Jing, Z. Study on Engineering Characteristics and Mechanism of Expansive Soil Improved by Lime-zeolite Powder. Acad. J. Archit. Geotech. Eng. 2024, 6, 54–61. [Google Scholar]

- Jangid, A.K.; Khatti, J.; Grover, K.S. Effect of multicollinearity in assessing the compaction and strength parameters of lime-treated expansive soil using artificial intelligence techniques. Multiscale Multidiscip. Model. Exp. Des. 2025, 8, 68. [Google Scholar] [CrossRef]

- Por, S.; Nishimura, S.; Likitlersuang, S. Deformation characteristics and stress responses of cement-treated expansive clay Under confined one-dimensional swelling. Appl. Clay Sci. 2017, 146, 316–324. [Google Scholar] [CrossRef]

- Mohamed, A.A.M.S.; Yuan, J.; Al-Ajamee, M.; Dong, Y.; Ren, Y.; Hakuzweyezu, T. Improvement of expansive soil characteristics stabilized with sawdust ash, high calcium fly ash and cement. Case Stud. Constr. Mater. 2023, 18, e01894. [Google Scholar] [CrossRef]

- Zhou, S.; Shi, M.; Chen, W.; Zhang, Y.; Wang, W.; Zhang, H.; Li, D. Improved geotechnical behavior of an expansive soil amended with cationic polyacrylamide. J. Renew. Mater. 2021, 9, 1941–1957. [Google Scholar] [CrossRef]

- Ahmad, S.; Ghazi, M.S.A.; Syed, M.; Al-Osta, M.A. Utilization of fly ash with and without secondary additives for stabilizing expansive soils: A review. Results Eng. 2024, 22, 102079. [Google Scholar] [CrossRef]

- Li, J.; Hou, Q.; Zhang, X.; Zhang, X. Microbial-Induced Mineral Carbonation: A Promising Approach for Improving Carbon Sequestration and Performance of Steel Slag for Its Engineering Utilization. Dev. Built Environ. 2025, 21, 100615. [Google Scholar] [CrossRef]

- Liu, Z.; Beng, J.; Wu, Y.; Nie, K.; Dang, Y.; Yao, Y.; Li, J.; Fang, M. Microbial induced calcite precipitation for improving low-cohesive soil: Mechanisms, methods and macroscopic properties. Low-Carbon Mater. Green Constr. 2024, 2, 30. [Google Scholar] [CrossRef]

- Wei, R.; Xiao, J.; Wu, S.; Cai, H.; Wang, Z. Effectiveness of microbially induced calcite precipitation for treating expansive soils. Adv. Civ. Eng. Mater. 2021, 10, 350–361. [Google Scholar] [CrossRef]

- Chittoori, B.; Neupane, S. Evaluating the application of microbial induced calcite precipitation technique to stabilize expansive soils. In Proceedings of the Civil Infrastructures Confronting Severe Weathers and Climate Changes Conference, Hangzhou, China, 23–25 July 2018; pp. 10–19. [Google Scholar]

- Osinubi, K.; Eberemu, A.; Gadzama, E.; Ijimdiya, T. Plasticity characteristics of lateritic soil treated with Sporosarcina pasteurii in microbial-induced calcite precipitation application. SN Appl. Sci. 2019, 1, 825. [Google Scholar] [CrossRef]

- Chittoori, B.C.; Rahman, T.; Burbank, M. Microbial-facilitated calcium carbonate precipitation as a shallow stabilization alternative for expansive soil treatment. Geotechnics 2021, 1, 558–572. [Google Scholar] [CrossRef]

- Li, J.; Bi, W.; Yao, Y.; Liu, Z. State-of-the-Art review of utilization of microbial-induced calcite precipitation for improving moisture-dependent properties of unsaturated soils. Appl. Sci. 2023, 13, 2502. [Google Scholar] [CrossRef]

- Huang, W.; Mou, Y.; Li, Y.; Zhao, B.; Li, J.; Wu, X.; Zhou, M. Study on durability of MICP treated cohesive soils Under dry–wet cycle and freeze–thaw cycle. Arab. J. Geosci. 2022, 15, 422. [Google Scholar] [CrossRef]

- Liu, S.; Wen, K.; Armwood, C.; Bu, C.; Li, C.; Amini, F.; Li, L. Enhancement of MICP-treated sandy soils against environmental deterioration. J. Mater. Civ. Eng. 2019, 31, 04019294. [Google Scholar] [CrossRef]

- Tang, C.S.; Liu, B.; Vahedifard, F.; Jiang, N.J.; Zhu, C.; Shen, Z.T.; Pan, X.H.; Cheng, Q.; Shi, B. Enhancing soil resilience to climatic wetting-drying cycles through a bio-mediated approach. J. Geophys. Res. Earth Surf. 2024, 129, e2023JF007573. [Google Scholar] [CrossRef]

- ASTM D698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D4546-21; Standard Test Methods for One-Dimensional Swell or Collapse of Soils. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D1883-21; Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2024.

- ASTM D3080; Standard Test Method for Direct Shear Test of Soils Under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2023.

- Li, X.; Zhang, C.; Xiao, H.; Jiang, W.; Qian, J.; Li, Z. Reducing Compressibility of the Expansive Soil by Microbiological-Induced Calcium Carbonate Precipitation. Adv. Civ. Eng. 2021, 2021, 8818771. [Google Scholar] [CrossRef]

- Tian, X.; Xiao, H.; Li, Z.; Li, Z.; Su, H.; Ouyang, Q. Experimental study on the strength characteristics of expansive soils improved by the MICP method. Geofluids 2022, 2022, 3089820. [Google Scholar] [CrossRef]

- Tang, C.-S.; Yin, L.-Y.; Jiang, N.-J.; Zhu, C.; Zeng, H.; Li, H.; Shi, B. Factors affecting the performance of microbial-induced carbonate precipitation (MICP) treated soil: A review. Environ. Earth Sci. 2020, 79, 94. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).