Insights on the Potential of Carob Powder (Ceratonia siliqua L.) to Improve the Physico-Chemical, Biochemical and Nutritional Properties of Wheat Durum Pasta

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

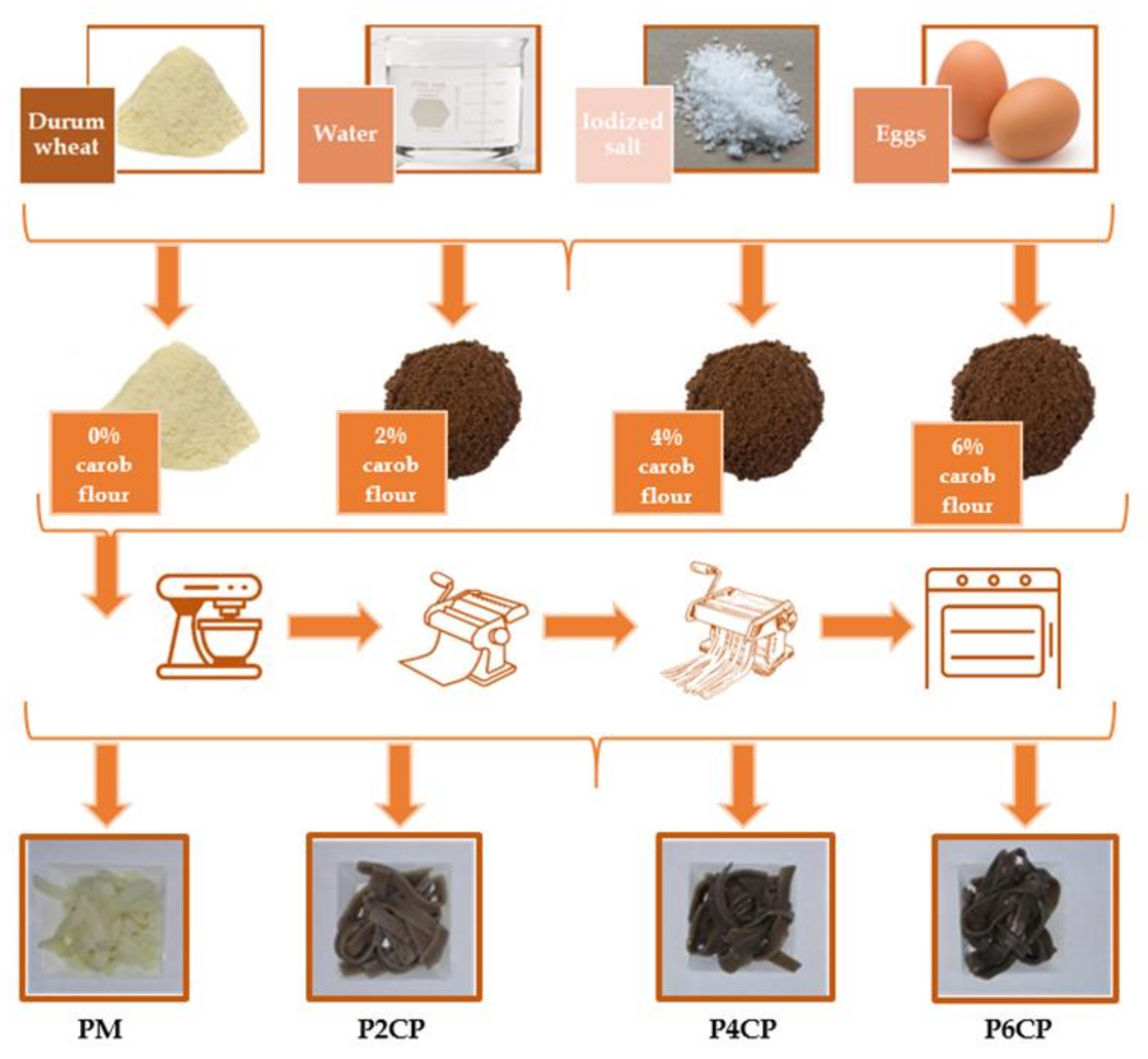

2.2. Pasta Preparation

2.3. Rheological Properties of the Dough

2.4. Extraction of Polyphenolic Compounds

2.5. Determination of Total Phenolic Content and Polyphenolic Compounds Profile

2.6. Determination of Total Titratable Acidity (TTA)

2.7. Determination of Moisture Content

2.8. Determination of Compression Resistance

2.9. Determination of Protein and Fiber Content

2.10. Sensory Evaluation

2.11. Statistical Analysis

3. Results and Discussion

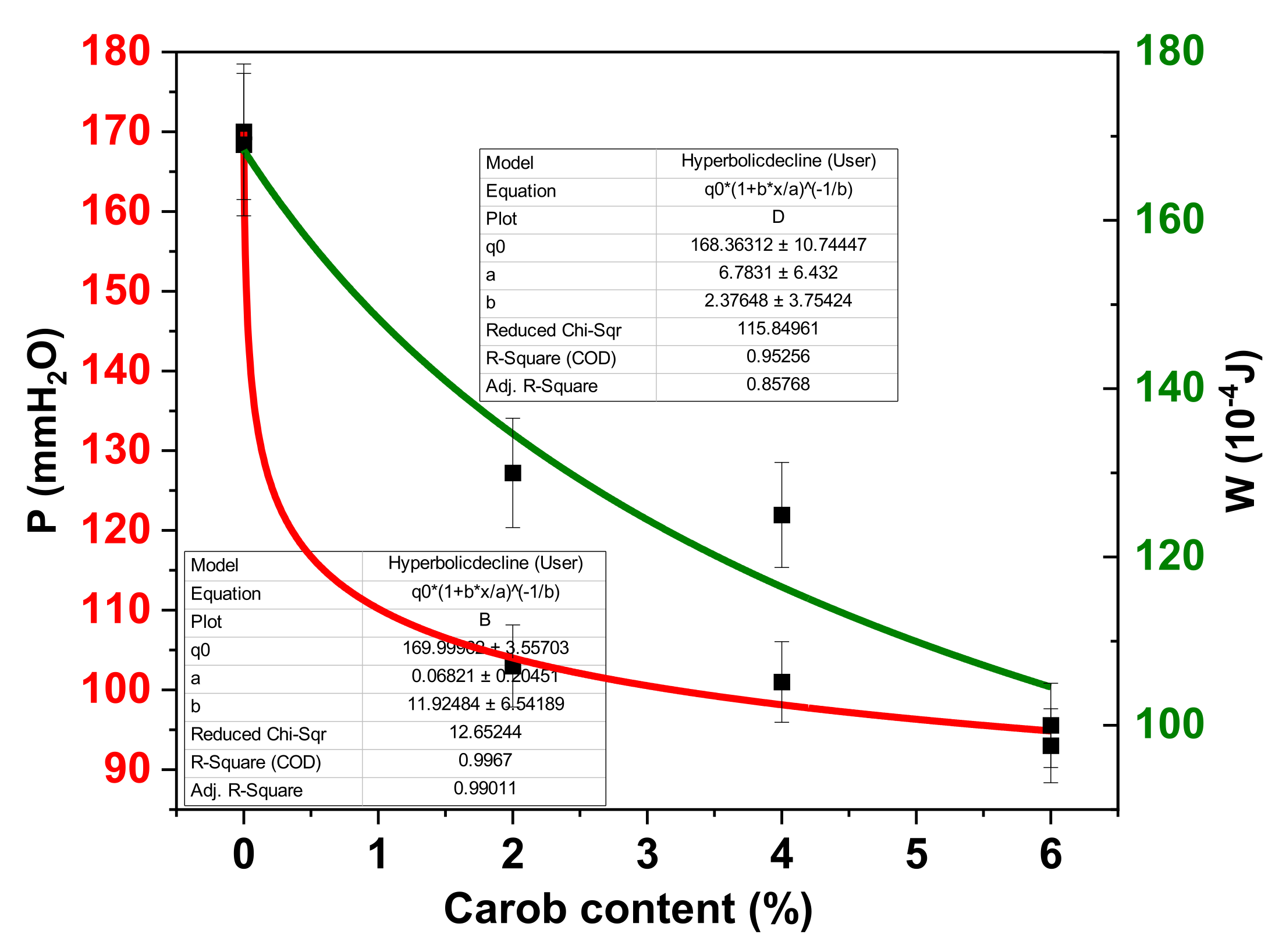

3.1. Dough Rheological Properties

3.2. Physical and Chemical Properties

3.3. Compression Resistance

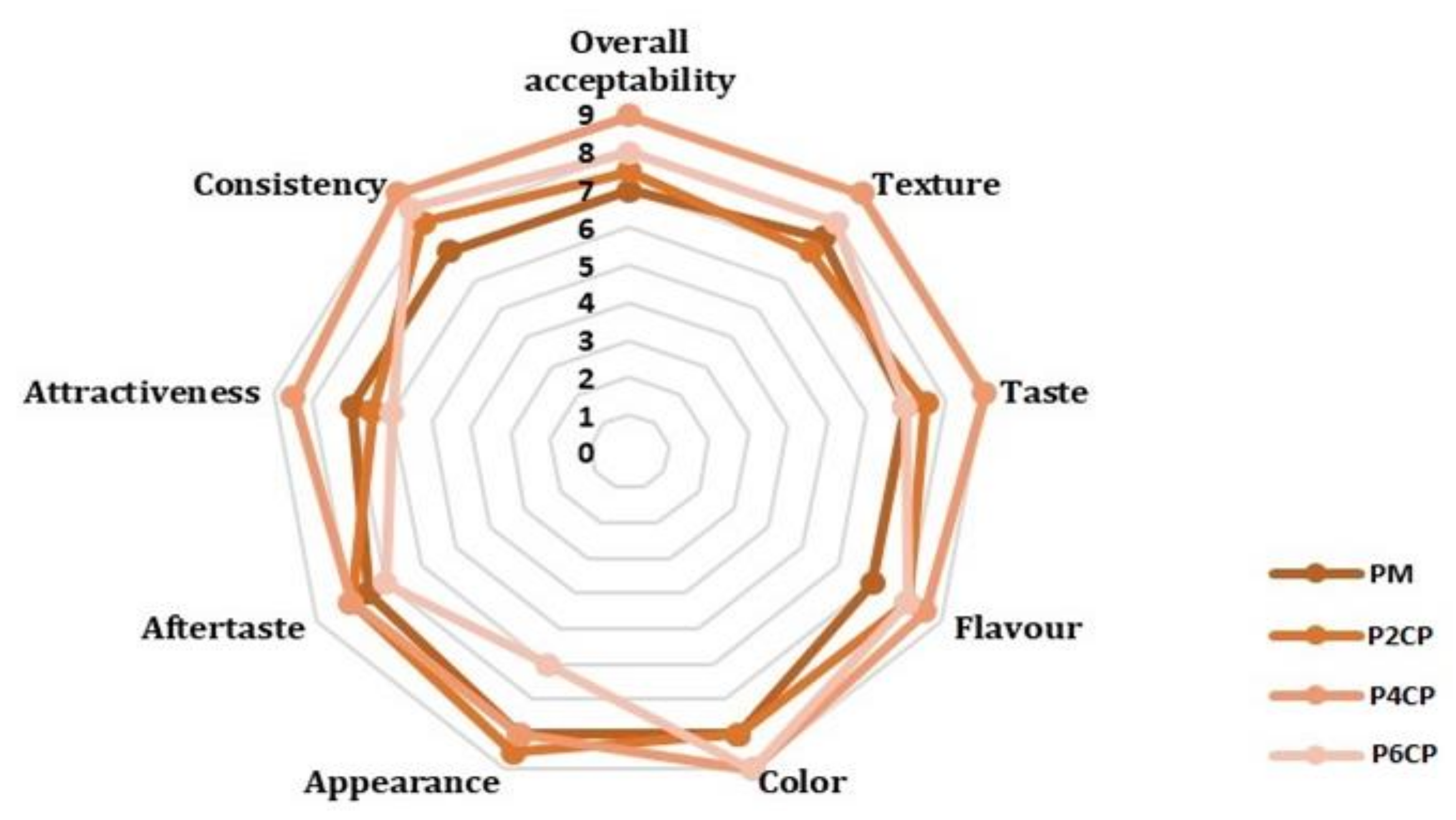

3.4. Sensory Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaur, G.; Sharma, S.; Nagi, H.P.S.; Ranote, P.S. Enrichment of pasta with different plant proteins. J. Food Sci. Technol. 2013, 50, 1000–1005. [Google Scholar] [CrossRef]

- Fuad, T.; Prabhasankar, P. Role of Ingredients in Pasta Product Quality: A Review on Recent Developments. Crit. Rev. Food Sci. Nutr. 2010, 50, 787–798. [Google Scholar] [CrossRef]

- IPO. 2019. Available online: https://internationalpasta.org/annual-report/ (accessed on 5 March 2023).

- Falciano, A.; Sorrentino, A.; Masi, P.; Di Pierro, P. Development of Functional Pizza Base Enriched with Jujube (Ziziphus jujuba) Powder. Foods 2022, 11, 1458. [Google Scholar] [CrossRef] [PubMed]

- Statista Global Consumer Survey. Available online: https://www.statista.com/chart/19776/gcs-pasta-consumption/ (accessed on 6 October 2020).

- Montalbano, A.; Tesoriere, L.; Diana, P.; Barraja, P.; Carbone, A.; Spano, V.; Parrino, B.; Attanzio, A.; Livrea, M.A.; Cascioferro, S.; et al. Quality characteristics and in vitro digestibility study of barley flour enriched ditalini pasta. LWT 2016, 72, 223–228. [Google Scholar] [CrossRef]

- Abdel-Aal, E.-S.M.; Young, J.C.; Rabalski, I. Anthocyanin Composition in Black, Blue, Pink, Purple, and Red Cereal Grains. J. Agric. Food Chem. 2006, 54, 4696–4704. [Google Scholar] [CrossRef]

- Spinelli, S.; Padalino, L.; Costa, C.; Del Nobile, M.A.; Conte, A. Food by-products to fortified pasta: A new approach for optimization. J. Clean. Prod. 2019, 215, 985–991. [Google Scholar] [CrossRef]

- Fares, C.; Menga, V. Effects of toasting on the carbohydrate profile and antioxidant properties of chickpea (Cicer arietinum L.) flour added to durum wheat pasta. Food Chem. 2012, 131, 1140–1148. [Google Scholar] [CrossRef]

- Lorusso, A.; Verni, M.; Montemurro, M.; Coda, R.; Gobbetti, M.; Rizzello, C.G. Use of fermented quinoa flour for pasta making and evaluation of the technological and nutritional features. LWT 2017, 78, 215–221. [Google Scholar] [CrossRef]

- Rizzello, C.G.; Verni, M.; Koivula, H.; Montemurro, M.; Seppa, L.; Kemell, M.; Katina, K.; Coda, R.; Gobbetti, M. Influence of fermented faba bean flour on the nutritional, technological and sensory quality of fortified pasta. Food Funct. 2017, 8, 860–871. [Google Scholar] [CrossRef]

- Boroski, M.; de Aguiar, A.C.; Boeing, J.S.; Rotta, E.M.; Wibby, C.L.; Bonafé, E.G.; de Souza, N.E.; Visentainer, J.V. Enhancement of pasta antioxidant activity with oregano and carrot leaf. Food Chem. 2011, 125, 696–700. [Google Scholar] [CrossRef]

- Teterycz, D.; Sobota, A.; Zarzycki, P.; Latoch, A. Legume flour as a natural colouring component in pasta production. J. Food Sci. Technol. 2020, 57, 301–309. [Google Scholar] [CrossRef] [PubMed]

- Testa, M.; Malandrino, O.; Santini, C.; Supino, S. Chapter 6—Nutraceutical and functional value of carob-based products The LBG Sicilia Srl Case Study. In Case Studies on the Business of Nutraceuticals, Functional and Super Foods; Woodhead Publishing Series in Consumer Science & Strategy Market; Woodhead Publishing: Sawston, UK, 2023; pp. 107–120. ISBN 9780128214084. [Google Scholar]

- Ortega, N.R.; Marcia, A.; Romero, M.; Reguant, J.; Motilva, M.J. Matrix composition effect on the digestibility of carob flour phenols by an in-vitro digestion model. Food Chem. 2011, 124, 65–71. [Google Scholar] [CrossRef]

- Azab, A. Carob (Ceratonia siliqua): Health, medicine and chemistry. Eur. Chem. Bull. 2017, 610, 456–469. [Google Scholar] [CrossRef]

- Boublenza, I.; Lazouni, H.A.; Ghaffari, L.; Ruiz, K.; Fabiano-Tixier, A.S.; Chemat, F. Influence of Roasting on Sensory, Antioxidant, Aromas, and Physicochemical Properties of Carob Pod Powder (Ceratonia siliqua L.). J. Food Qual. 2017, 2017, 1–10. [Google Scholar] [CrossRef]

- Papaefstathiou, E.; Agapiou, A.; Giannopoulos, S.; Kokkinofta, R. Nutritional characterization of carobs and traditional carob products. Food Sci. Nutr. 2018, 6, 2151–2161. [Google Scholar] [CrossRef]

- Tsatsaragkou, K.; Yiannopoulos, S.; Kontogiorgi, A.; Poulli, E.; Krokida, M.; Mandala, L. Effect of Carob Flour Addition on the Rheological Properties of Gluten-Free Breads. Food Bioproc. Tech. 2014, 7, 868–876. [Google Scholar] [CrossRef]

- Ayaz, F.A.; Torun, H.; Glew, R.H.; Bak, Z.D.; Chuang, L.T.; Presley, J.M.; Andrews, R. Nutrient content of carob pod (Ceratonia siliqua L.) flour prepared commercially and domestically. Plant Foods Hum. Nutr. 2009, 64, 286–292. [Google Scholar] [CrossRef]

- Bengoechea, C.; Romero, A.; Villanueva, A.; Moreno, G.; Alaiz, M.; Millán, F.; Puppo, M.C. Composition and structure of carob (Ceratonia siliqua L.) germ proteins. Food Chem. 2008, 107, 675–683. [Google Scholar] [CrossRef]

- Biner, B.; Gubbuk, H.; Karhan, M.; Aksu, M.; Pekmezci, M. Sugar profiles of the pods of cultivated and wild types of carob bean (Ceratonia siliqua L.) in Turkey. Food Chem. 2007, 100, 1453–1455. [Google Scholar] [CrossRef]

- Durazzo, A.; Turfani, V.; Narducci, V.; Azzini, E.; Maiani, G.; Carcea, M. Nutritional characterisation and bioactive components of commercial carobs flours. Food Chem. 2014, 153, 109–113. [Google Scholar] [CrossRef]

- Kumazawa, S.H.K.; Taniguchi, M.A.S.A.T.; Suzuki, Y.A.S.; Shimura, M.A.S.; Kwon, M.I.U.N.K.; Nakayama, T.S.N. Antioxidant activity of polyphenols in carob pods. J. Agricult. Food Chem. 2002, 50, 373–377. [Google Scholar] [CrossRef] [PubMed]

- Germec, M.; Turhan, I.; Karhan, M.; Demirci, A. Ethanol production via repeated-batch fermentation from carob pod extract by using Saccharomyces cevisiae in biofilm reactor. Fuel 2015, 161, 304–311. [Google Scholar] [CrossRef]

- Haddarah, A.; Ismail, A.; Bassal, A.; Hamieh, T.; Ioannou, I.; Ghoul, M. Morphological and chemical variability of Lebanese carob varieties. Eur. Sci. J. 2013, 9, 353–369. [Google Scholar]

- Biernacka, B.; Dziki, D.; Gawlik-Dziki, U.; Roozy, R.; Siastala, M. Physical, sensorial, and antioxidant properties of common wheat pasta enriched with carob fiber. LWT 2017, 77, 186–192. [Google Scholar] [CrossRef]

- Seczyk, L.; Swieca, M.; Gawlik-Dziki, U. Effect of carob (Ceratonia siliqua L.) flour on the antioxidant potential, nutritional quality, and sensory characteristics of fortified durum wheat pasta. Food Chem. 2016, 194, 637–642. [Google Scholar] [CrossRef] [PubMed]

- Gaita, C.; Alexa, E.; Moigradean, D.; Conforti, F.; Poiana, M.A. Designing of high value-added pasta formulas by incorporation of grape pomace skins. Rom. Biotechnol. Lett. 2020, 25, 1607–1614. [Google Scholar] [CrossRef]

- Gruber, W.; Sarkar, A. Chapter 8—Durum Wheat Milling. In American Associate of Cereal Chemists International, Durum Wheat, 2nd ed.; Sissons, M., Abecassis, J., Marchylo, B., Carcea, M., Eds.; AACC International Press: Washington, DC, USA, 2012; pp. 139–159. [Google Scholar]

- Hellin, P.; Escarnot, E.; Mingeot, D.; Gofflot, S.; Sinnaeve, G.; Lateur, M.; Godin, B. Multiyear evaluation of the agronomical and technological properties of a panel of spelt varieties under different cropping environments. J. Cereal Sci. 2023, 109, 103615. [Google Scholar] [CrossRef]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventos, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Meth. Enzymol. 1999, 299, 152–178. [Google Scholar]

- Abdel-Hameed, E.S.; Bazaid, S.A.; Salman, M.S. Characterization of the phytochemical constituents of Taif rose and its antioxidant and anticancer activities. Biomed Res. Int. 2013, 2013, 1–13. [Google Scholar] [CrossRef]

- Rios, M.B.; Iriondo-DeHond, A.; Iriondo-DeHond, M.; Herrera, T.; Velasco, D.; Gomez-Alonso, S.; Callejo, M.J.; Dolores del Castillo, M. Effect of Coffee Cascara Dietary Fiber on the Physicochemical, Nutritional and Sensory Properties of a Gluten-Free Bread Formulation. Molecules 2020, 25, 1358. [Google Scholar] [CrossRef]

- ISO 712:2009 Cereals and Cereal Products–Determination of Moisture Content–Reference Method. Available online: https://www.sis.se/api/document/preview/911751/ (accessed on 15 December 2021).

- Heeger, A.; Kosinska-Cagnazzo, A.; Cantergiani, E.; Andlauer, W. Bioactives of coffee cherry pulp and its utilisation for production of Cascara beverage. Food Chem. 2017, 221, 969–975. [Google Scholar] [CrossRef] [PubMed]

- Calculator de Calorii—Numararea Caloriilor—Klorii. Available online: https://klorii.ro/ (accessed on 8 March 2023).

- Yazar, G.; Duvarci, O.; Tavman, S.; Kokini, J.L. Non-linear rheological behavior of gluten-free flour doughs and correlations of LAOS parameters with gluten-free bread properties. J. Cereal Sci. 2017, 74, 28–36. [Google Scholar] [CrossRef]

- Dube, N.M.; Xu, F.; Zhao, R. The efficacy of sorghum flour addition on dough rheological properties and bread quality: A short review. Grain Oil Sci. Technol. 2022, 4, 164–171. [Google Scholar]

- Sibanda, T.; Ncube, T.; Ngoromani, N. Rheological properties and bread making quality of white grain sorghum-wheat flour composites. Int. Food Sci. Nutr. Eng. 2015, 5, 176–182. [Google Scholar]

- Arribas, C.; Cabellos, B.; Cuadrado, C.; Guillamón, E.; Pedrosa, M.M. Cooking Effect on the Bioactive Compounds, Texture, and Color Properties of Cold-Extruded Rice/Bean-Based Pasta Supplemented with Whole Carob Fruit. Foods 2020, 9, 415. [Google Scholar] [CrossRef]

- Bchir, B.; Karoui, R.; Danthine, S.; Blecker, C.; Besbes, S.; Attia, H. Date, Apple, and Pear By-Products as Functional Ingredients in Pasta: Cooking Quality Attributes and Physicochemical, Rheological, and Sensorial Properties. Foods 2022, 11, 1393. [Google Scholar] [CrossRef] [PubMed]

- Mandala, I.; Polaki, A.; Yanniotis, S. Influence of frozen storage on bread enriched with different ingredients. J. Food Eng. 2009, 92, 137–145. [Google Scholar] [CrossRef]

- Gopalakrishnan, J.; Menon, R.; Padmaja, G.; Sajeev, M.S.; Moorthy, S.N. Nutritional and Functional Characteristics of Protein-Fortified Pasta from Sweet Potato. Food Sci. Nutr. 2011, 2, 944–955. [Google Scholar] [CrossRef]

- Zhu, F.; Li, J. Physicochemical and sensory properties of fresh noodles fortified with ground linseed (Linum usitassimum). LWT 2019, 101, 847–853. [Google Scholar] [CrossRef]

- Makris, D.P.; Kefalas, P. Carob pods (Ceratonia siliqua L.) As a source of polyphenolic antioxidants. Food Technol. Biotechnol. 2004, 42, 105–108. [Google Scholar]

- Issaoui, M.; Flamini, G.; Delgado, A. Sustainability Opportunities for Mediterranean Food Products through New Formulations Based on Carob Flour (Ceratonia siliqua L.). Sustainability 2021, 13, 8026. [Google Scholar] [CrossRef]

- Aydin, S.; Ozdemir, Y. Development and Characterization of Carob Flour Based Functional Spread for Increasing Use as Nutritious Snack for Children. J. Food Qual. 2017, 2017, 1–7. [Google Scholar] [CrossRef]

- Sebecic, B.; Vedrina-Dragojevic, I.; Vitali, D.; Hecimovic, M.; Dragicevic, I. Raw Materials in Fibre Enriched Biscuits Production as Source of Total Phenols. Agric. Conspec. Sci. 2007, 72, 265–270. [Google Scholar]

- Bastida, S.; Sánchez-Muniz, F.J.; Olivero, R.; Pérez-Olleros, L.; Ruiz-Roso, B.; Jiménez-Colmenero, F. Antioxidant activity of Carob fruit extracts in cooked pork meat systems during chilled and frozen storage. Food Chem. 2009, 116, 748–754. [Google Scholar] [CrossRef]

- Bissar, S.; Ozcan, M.M. Determination of quality parameters and gluten free macaron production from carob fruit and sorghum. Int. J. Gastron. Food Sci. 2022, 27, 100460. [Google Scholar] [CrossRef]

- Brassesco, M.E.; Brandao, T.R.S.; Silva, C.L.M.; Pintado, M. Carob bean (Ceratonia siliqua L.): A new perspective for functional food. Trends Food Sci. Technol. 2021, 114, 310–322. [Google Scholar] [CrossRef]

- Tolve, R.; Pasini, G.; Vignale, F.; Favati, F.; Simonato, B. Effect of Grape Pomace Addition on the Technological, Sensory, and Nutritional Properties of Durum Wheat Pasta. Foods 2020, 9, 354. [Google Scholar] [CrossRef]

- Frühbauerova, M.; Cervenka, L.; Hajek, T.; Pouzar, M.; Palarcík, J. Bioaccessibility of phenolics from carob (Ceratonia siliqua L.) pod powder prepared by cryogenic and vibratory grinding. Food Chemistry 2022, 377, 131968. [Google Scholar] [CrossRef]

- Benković, M.; Bosiljkov, T.; Semić, A.; Ježek, D.; Srečec, S. Influence of Carob Flour and Carob Bean Gum on Rheological Properties of Cocoa and Carob Pastry Fillings. Foods 2019, 8, 66. [Google Scholar] [CrossRef]

- Rayas-Duarte, P.; Mock, C.M.; Satterlee, L.D. Quality of spaghetti containing buckwheat, amaranth, and lupin flours. Cereal Chem. 1996, 73, 381–387. [Google Scholar]

- Marinelli, V.; Padalino, L.; Nardiello, D.; Del Nobile, M.A.; Conte, A. New approach to enrich pasta with polyphenols from grape marc. J. Chem. 2015, 2015, 1–8. [Google Scholar] [CrossRef]

- Chen, J.; Rosenthal, A. Modifying food texture. In Volume 1: Novel Ingredients and Processing Techniques; Woodhead Publishing: Cambridge, UK, 2015; pp. 3–22. [Google Scholar]

| Type | Coding | Percentage (%) of Carob Flour Used in the Pasta Formulations |

|---|---|---|

| Control sample | PM | 0 |

| Sample with 2% carob flour | P2CP | 2 |

| Sample with 4% carob flour | P4CP | 4 |

| Sample with 6% carob flour | P6CP | 6 |

| Parameter | PM | P2CP | P4CP | P6CP |

|---|---|---|---|---|

| P (mmH2O) | 170 ± 0.15 a | 103 ± 0.09 b | 101 ± 0.03 b | 93 ± 0.01 c |

| L (mm) | 22 ± 0.05 a | 33 ± 0.12 b | 33 ± 0.09 b | 27 ± 0.06 c |

| G (mm) | 10.4 ± 0.11 a | 12.8 ± 0.13 b | 12.8 ± 0.07 b | 11.6 ± 0.05 c |

| W (10–4 J) | 169 ± 0.25 a | 130 ± 0.28 b | 125 ± 0.21 c | 100 ± 0.14 d |

| P/L | 7.73 ± 0.13 a | 3.12 ± 0.09 b | 3.06 ± 0.18 b | 3.44 ± 0.05 b |

| Parameter | 2 Hours | |||

|---|---|---|---|---|

| PM | P2CP | P4CP | P6CP | |

| Titratable acidity (%) | 2.21 ± 0.015 a | 1.80 ± 0.010 b | 1.42 ± 0.015 c | 1.21 ± 0.015 d |

| Protein content (%) | 14.03 ± 0.058 c | 14.17 ± 0.153 bc | 14.30 ± 0.100 ab | 14.45 ± 0.050 a |

| Moisture (%) | 30.23 ± 0.257 c | 32.03 ± 0.057 b | 33.07 ± 0.057 b | 35.87 ± 0.152 a |

| TPC (µg GAE/g) | 239.07 ± 0.010 d | 311.53 ± 0.025 c | 406.80 ± 0.100 b | 461.10 ± 0.100 a |

| Fiber (%) * | 2.00 | 2.04 | 2.08 | 2.12 |

| Compound | Ion Mode | Polyphenolic Compounds (µg/g d.s.) | |||

|---|---|---|---|---|---|

| PM | P2CP | P4CP | P6CP | ||

| Gallic acid | 169 | nd | nd | 6.97 ± 0.07 a | 31.44 ± 0.18 b |

| Protocatechuic acid | 153 | nd | nd | 19.93 ± 0.16 a | 51.14 ± 0.08 b |

| Caffeic acid | 179 | nd | nd | 0.86 ± 0.05 a | 8.56 ± 0.11 b |

| Epicatechin | 289 | nd | nd | 17.15 ± 0.13 a | 24.31 ± 0.17 b |

| p-Coumaric acid | 163 | nd | nd | 0.30 ± 0.03 a | 0.30 ± 0.09 a |

| Ferulic acid | 193 | nd | nd | nd | 0.23 ± 0.13 a |

| Rutin | 609 | nd | nd | 1.07 ± 0.06 a | 1.41 ± 0.16 b |

| Rosmarinic acid | 359 | nd | nd | nd | 224.24 ± 0.32 a |

| Resveratrol | 227 | nd | nd | nd | 0.85 ± 0.07 a |

| Quercetin | 301 | nd | 0.54 ± 0.02 a | 11.49 ± 0.11 b | 243.66 ± 0.25 c |

| Kaempferol | 285 | nd | nd | 63.76 ± 0.17 a | 231.51 ± 0.32 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lupu, M.I.; Canja, C.M.; Padureanu, V.; Boieriu, A.; Maier, A.; Badarau, C.; Padureanu, C.; Croitoru, C.; Alexa, E.; Poiana, M.-A. Insights on the Potential of Carob Powder (Ceratonia siliqua L.) to Improve the Physico-Chemical, Biochemical and Nutritional Properties of Wheat Durum Pasta. Appl. Sci. 2023, 13, 3788. https://doi.org/10.3390/app13063788

Lupu MI, Canja CM, Padureanu V, Boieriu A, Maier A, Badarau C, Padureanu C, Croitoru C, Alexa E, Poiana M-A. Insights on the Potential of Carob Powder (Ceratonia siliqua L.) to Improve the Physico-Chemical, Biochemical and Nutritional Properties of Wheat Durum Pasta. Applied Sciences. 2023; 13(6):3788. https://doi.org/10.3390/app13063788

Chicago/Turabian StyleLupu, Mirabela Ioana, Cristina Maria Canja, Vasile Padureanu, Adriana Boieriu, Alina Maier, Carmen Badarau, Cristina Padureanu, Catalin Croitoru, Ersilia Alexa, and Mariana-Atena Poiana. 2023. "Insights on the Potential of Carob Powder (Ceratonia siliqua L.) to Improve the Physico-Chemical, Biochemical and Nutritional Properties of Wheat Durum Pasta" Applied Sciences 13, no. 6: 3788. https://doi.org/10.3390/app13063788

APA StyleLupu, M. I., Canja, C. M., Padureanu, V., Boieriu, A., Maier, A., Badarau, C., Padureanu, C., Croitoru, C., Alexa, E., & Poiana, M.-A. (2023). Insights on the Potential of Carob Powder (Ceratonia siliqua L.) to Improve the Physico-Chemical, Biochemical and Nutritional Properties of Wheat Durum Pasta. Applied Sciences, 13(6), 3788. https://doi.org/10.3390/app13063788