Evaluation Method for Ultimate Flexural State of Prestressed Precast Reinforced Concrete Beam–Column Connection with Debonded Partial Tendon

Abstract

1. Introduction

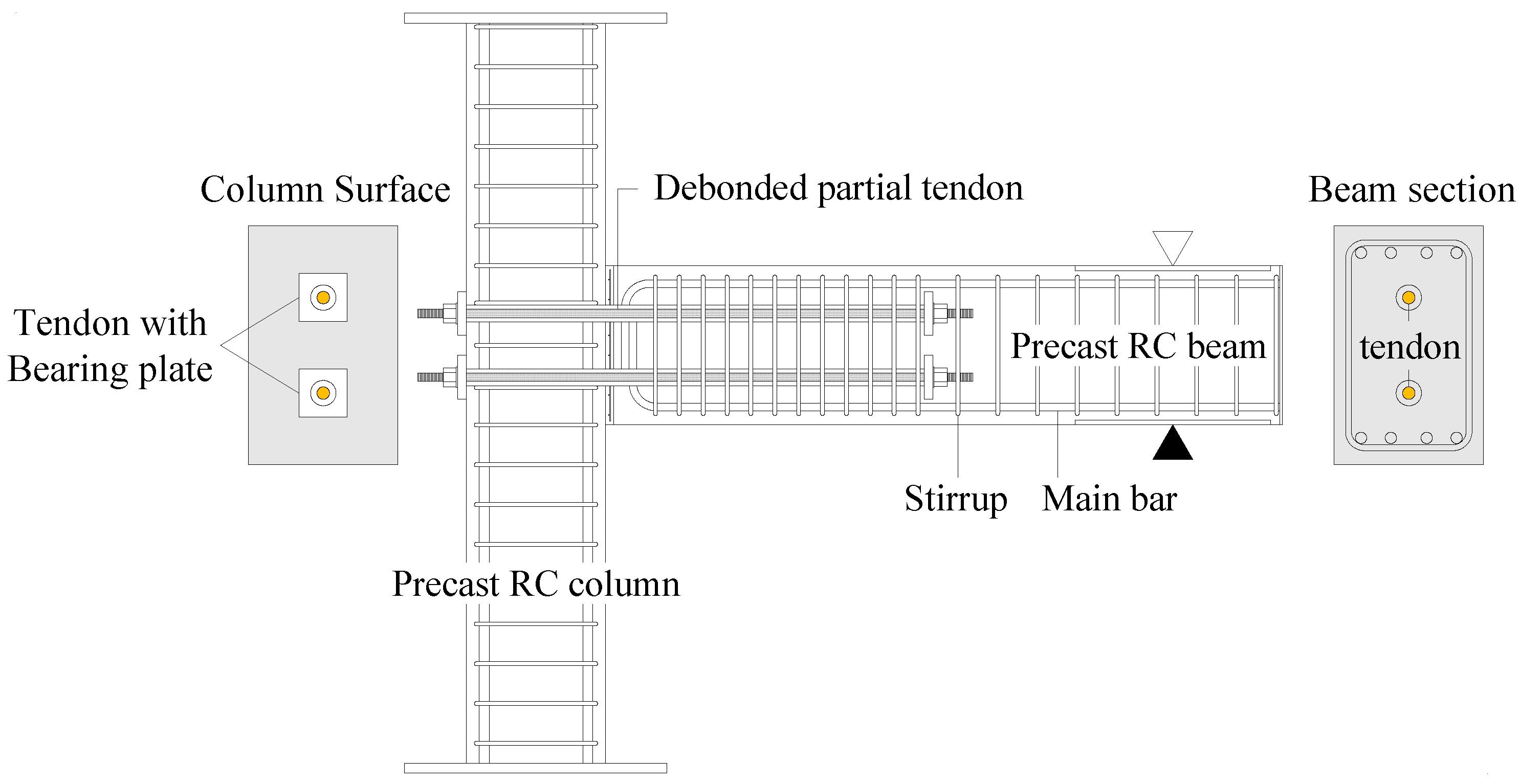

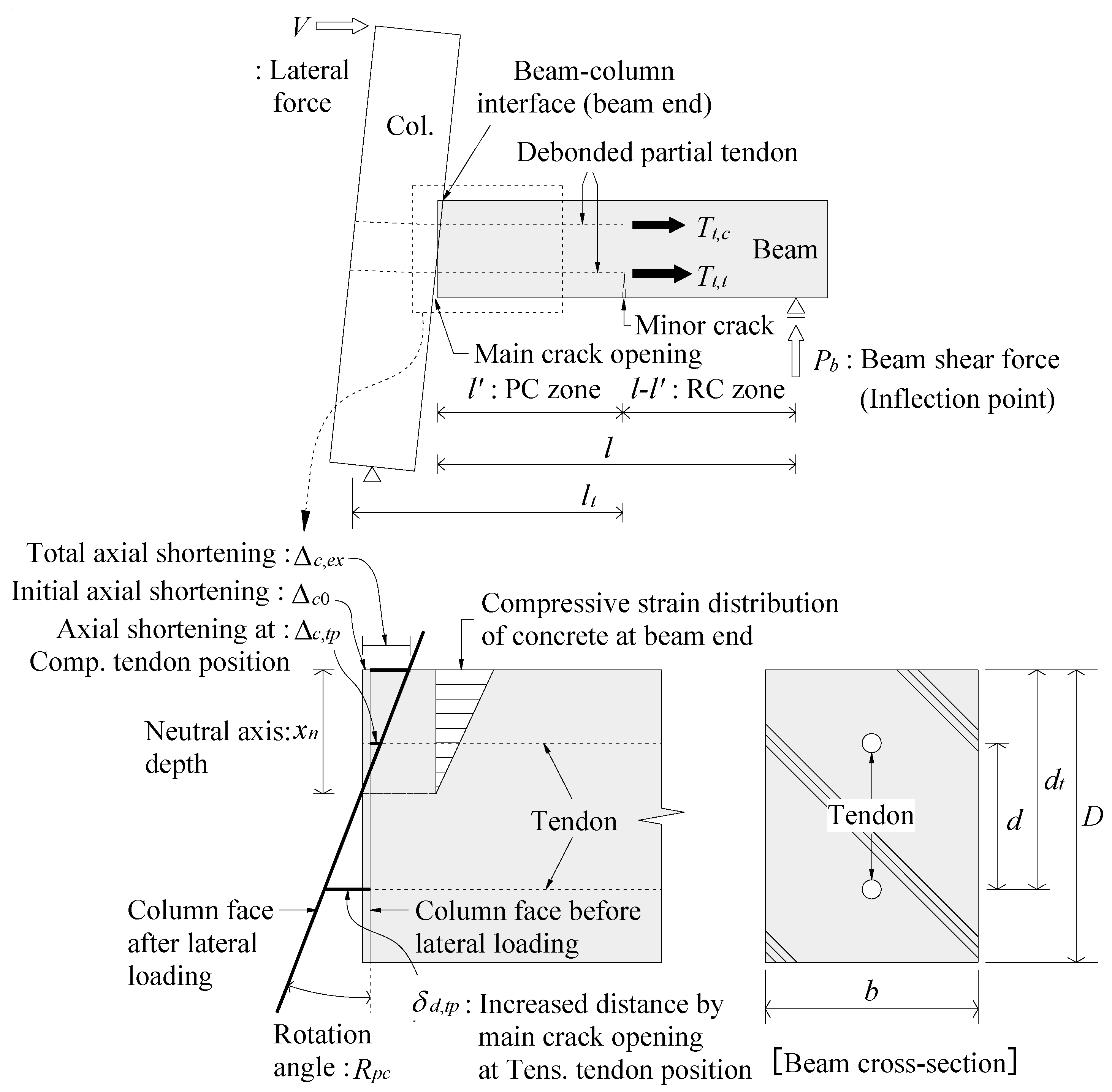

2. Model of Beam–Column Subassemblage

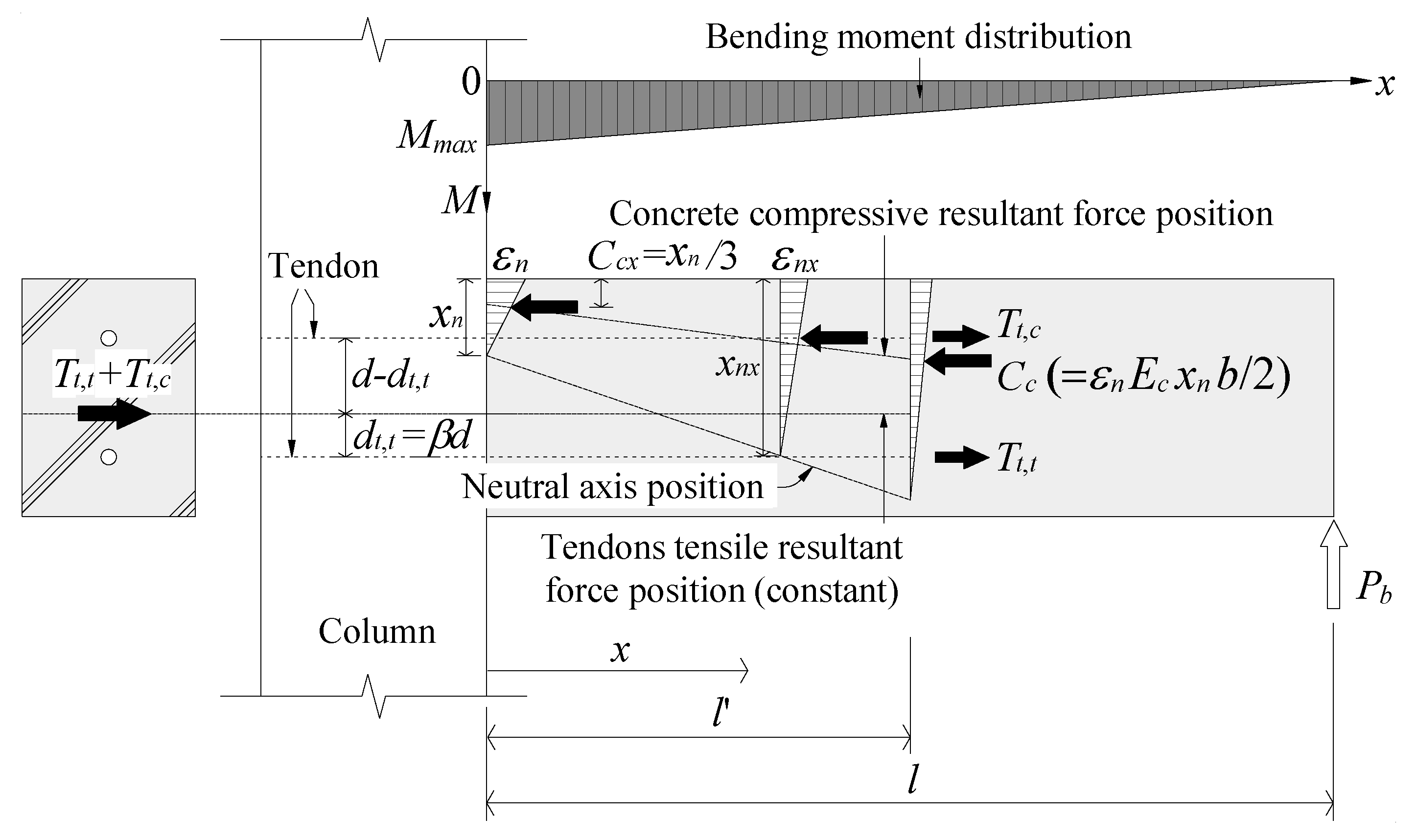

2.1. Model Outline

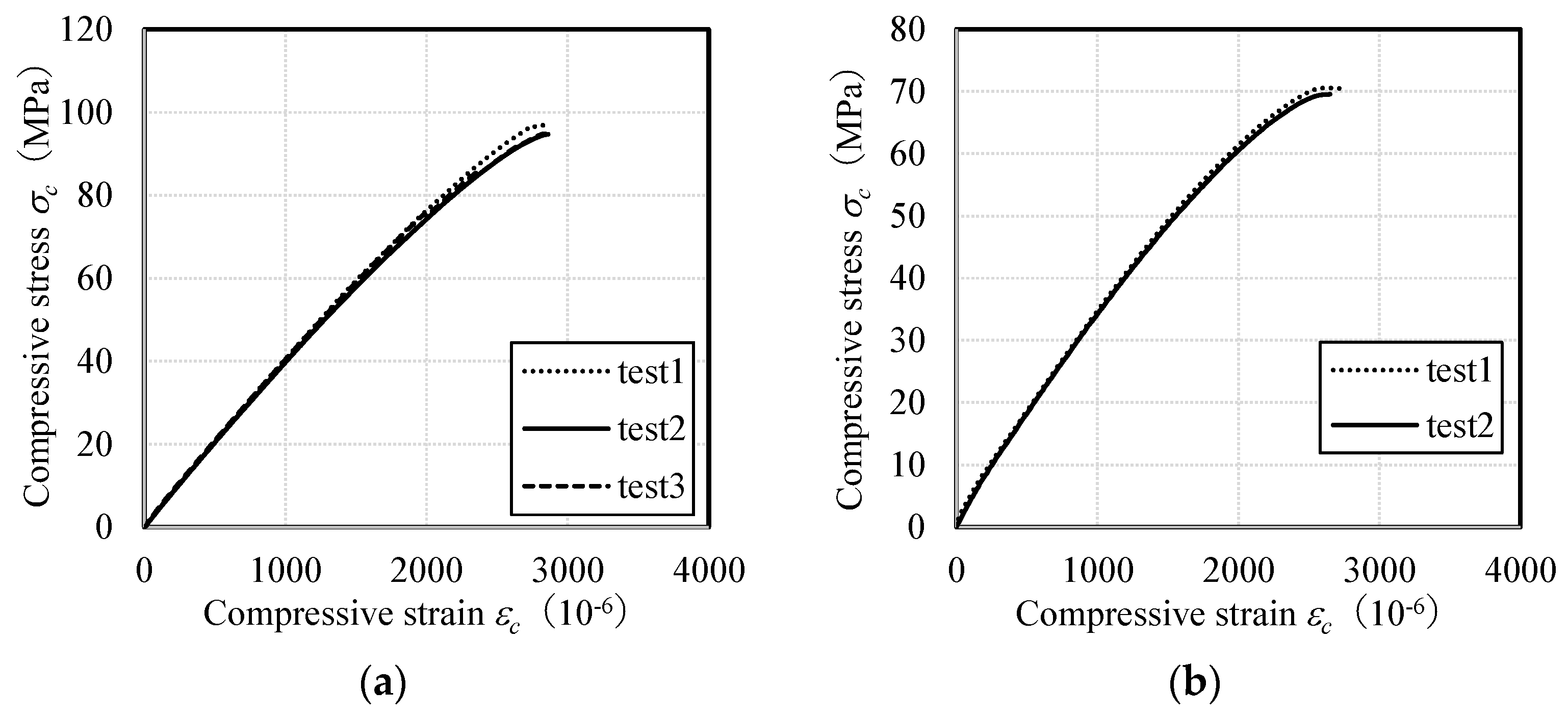

2.2. Constitutive Model of Concrete and Tendons

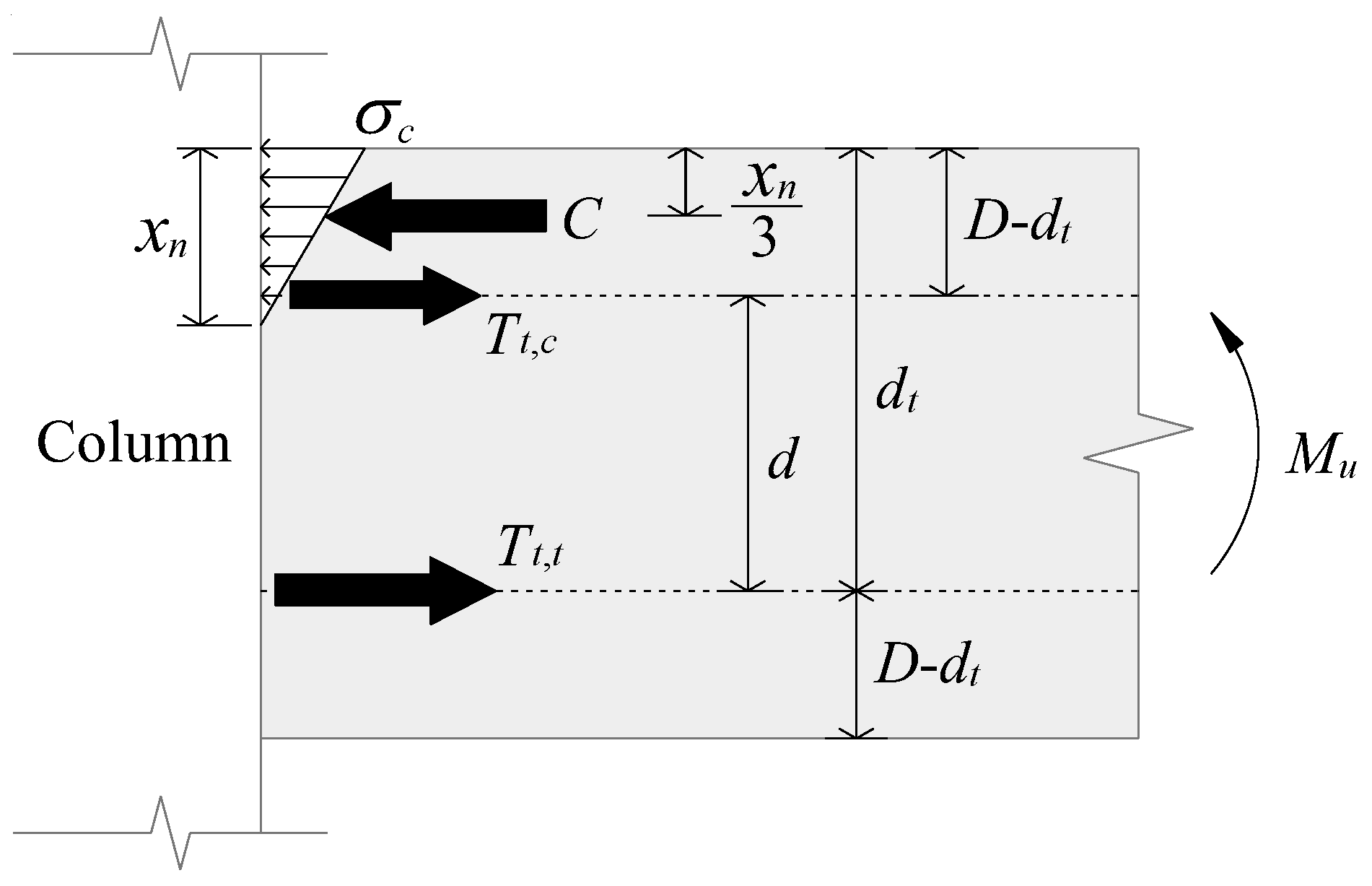

2.3. Force Equilibrium Condition

2.4. Deformation Compatibility Condition

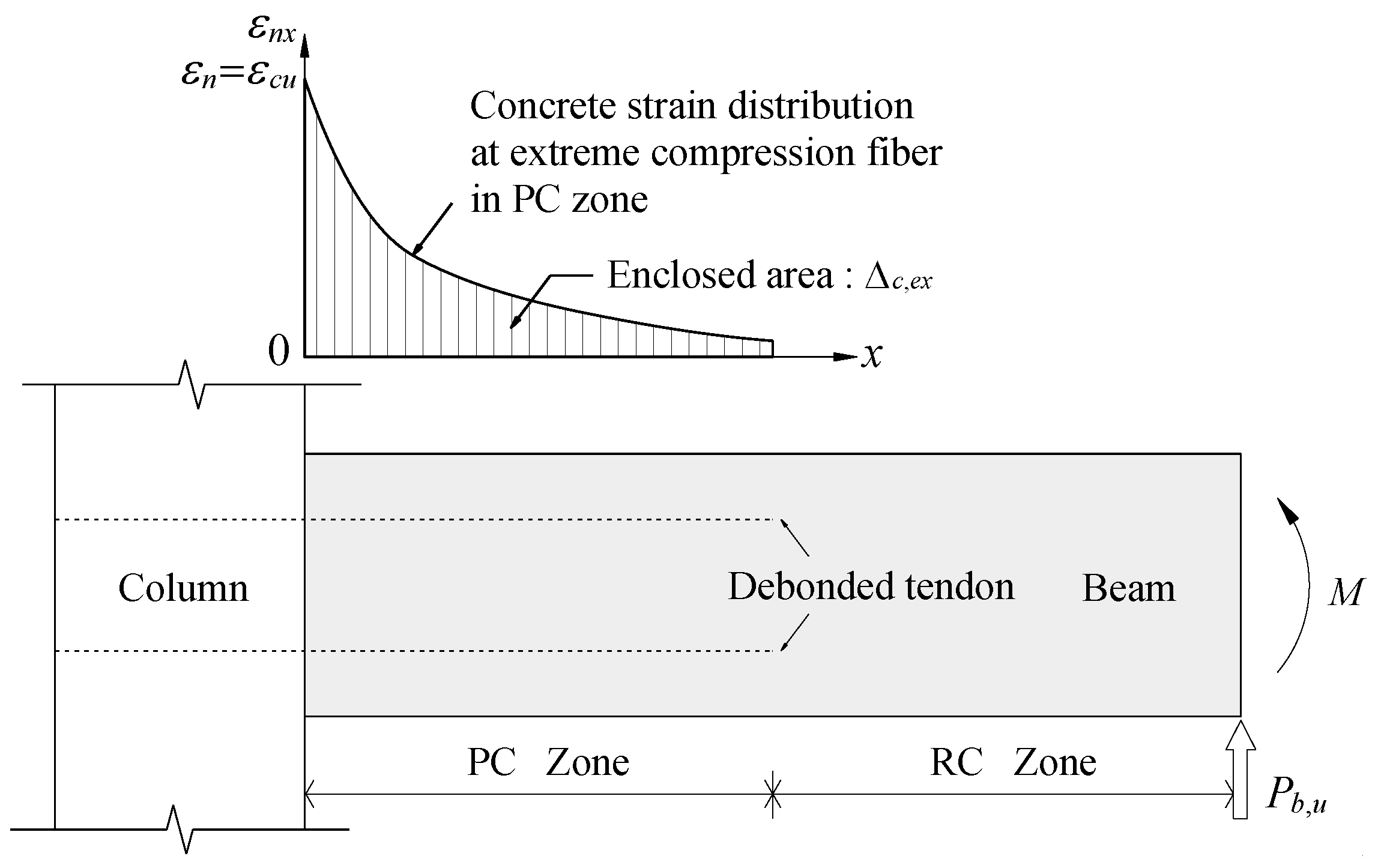

2.5. Evaluation of Concrete Axial Shortening Δc,ex

3. Evaluation of Ultimate Flexural Limit State

3.1. Bending Moment at Beam–Column Interface

3.2. Beam Deflection Angle

3.3. Iterative Evaluation Procedure

3.4. Simplified Evaluation Procedure

4. Verification of Evaluation Methods

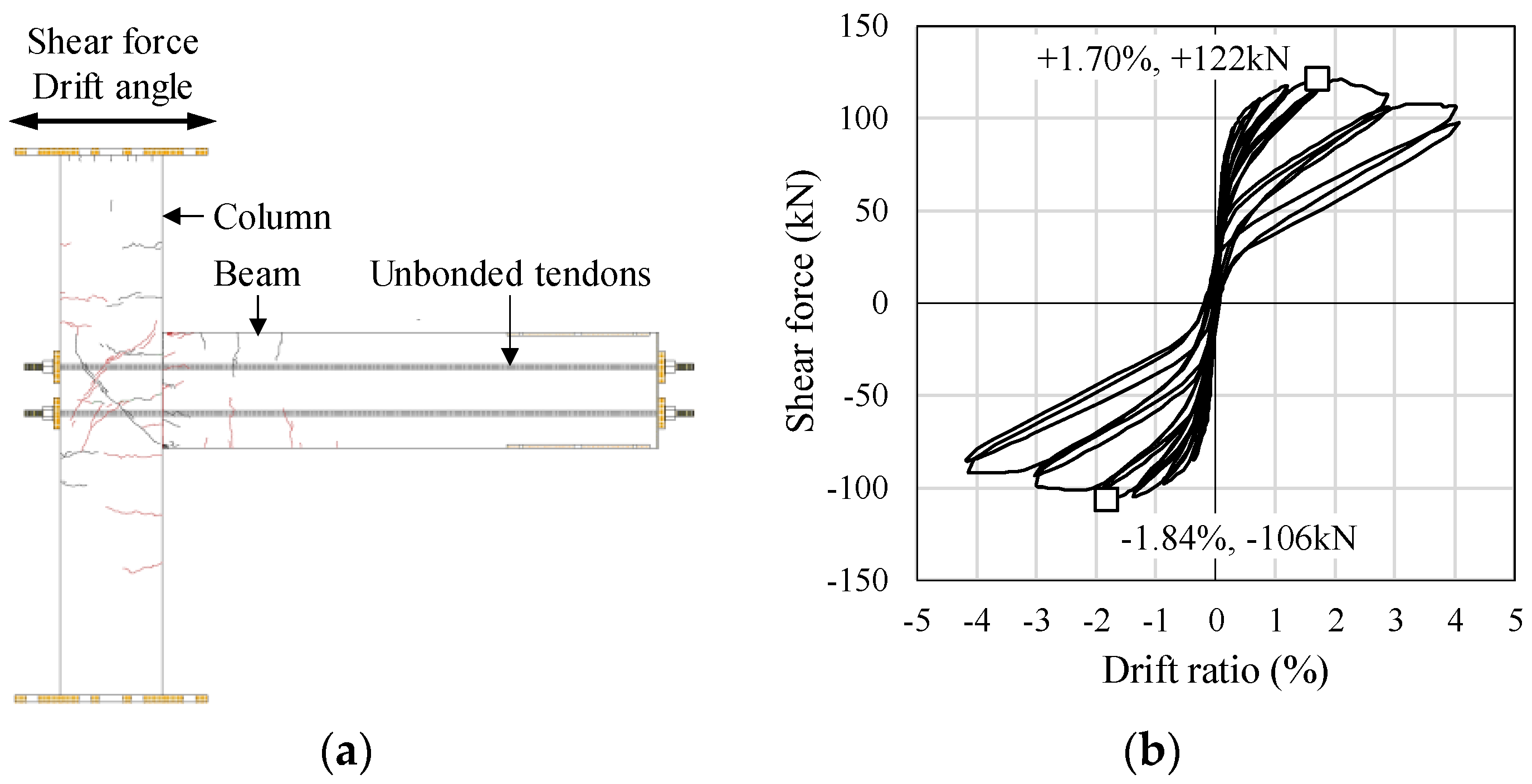

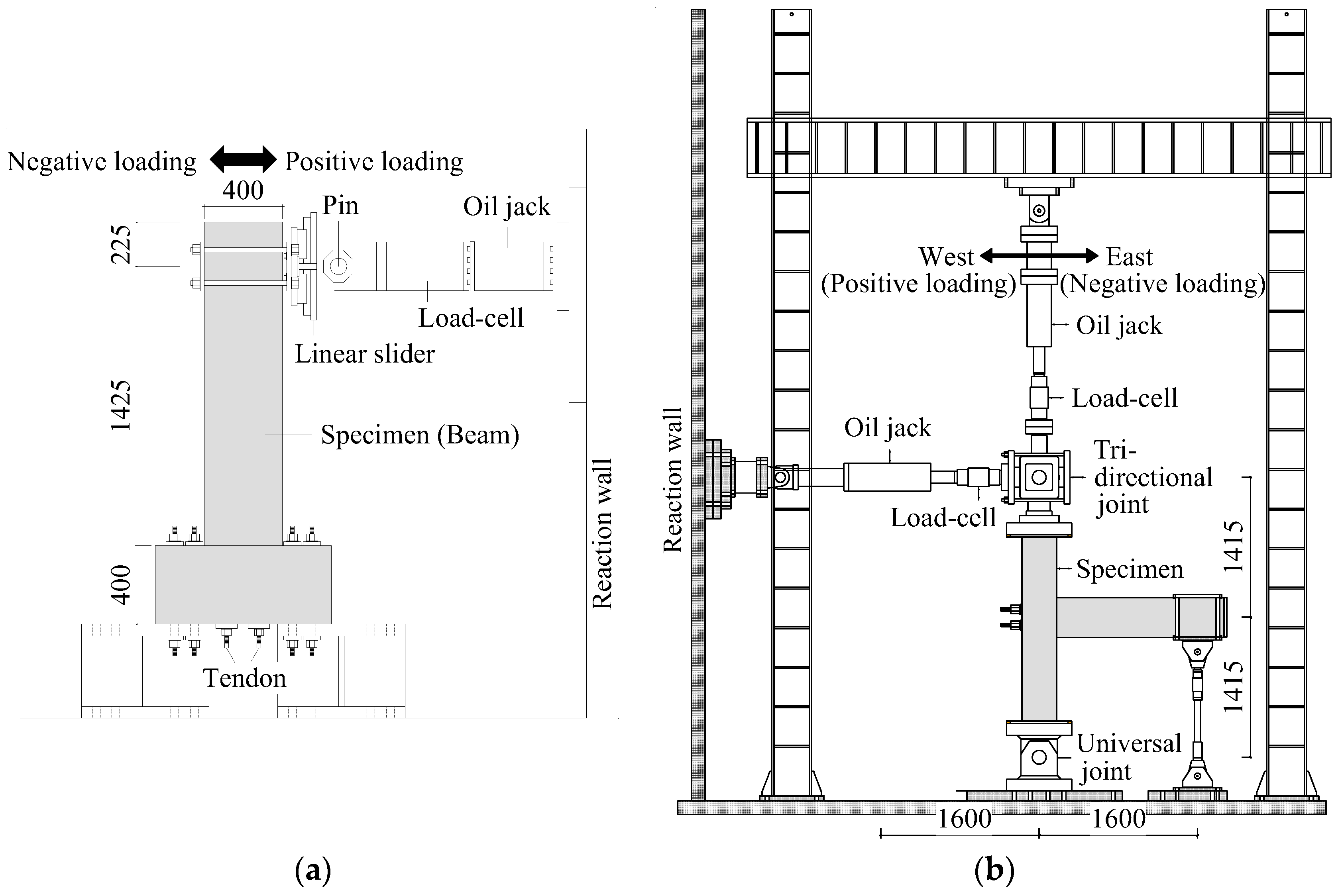

4.1. Outline of Previous Experiments

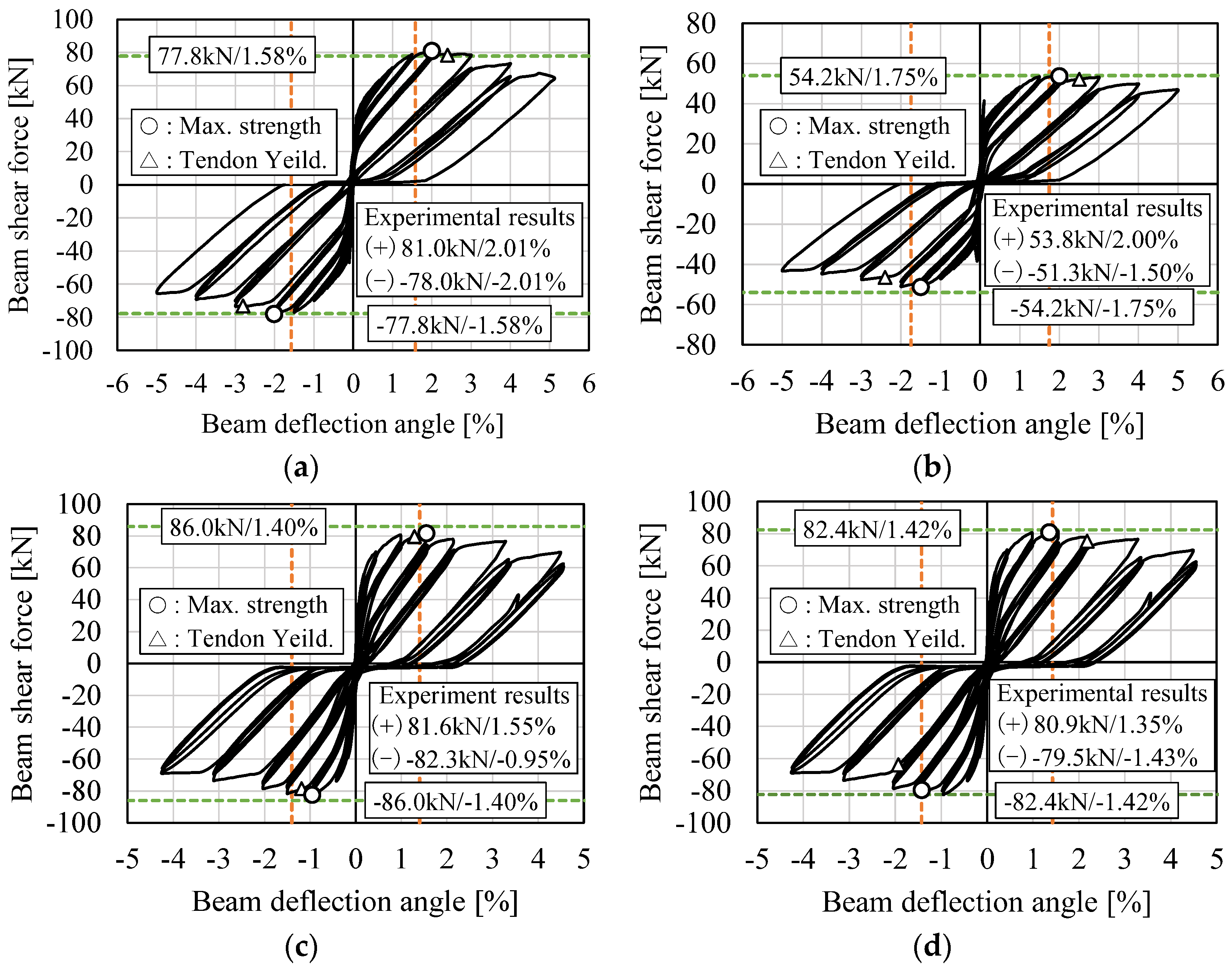

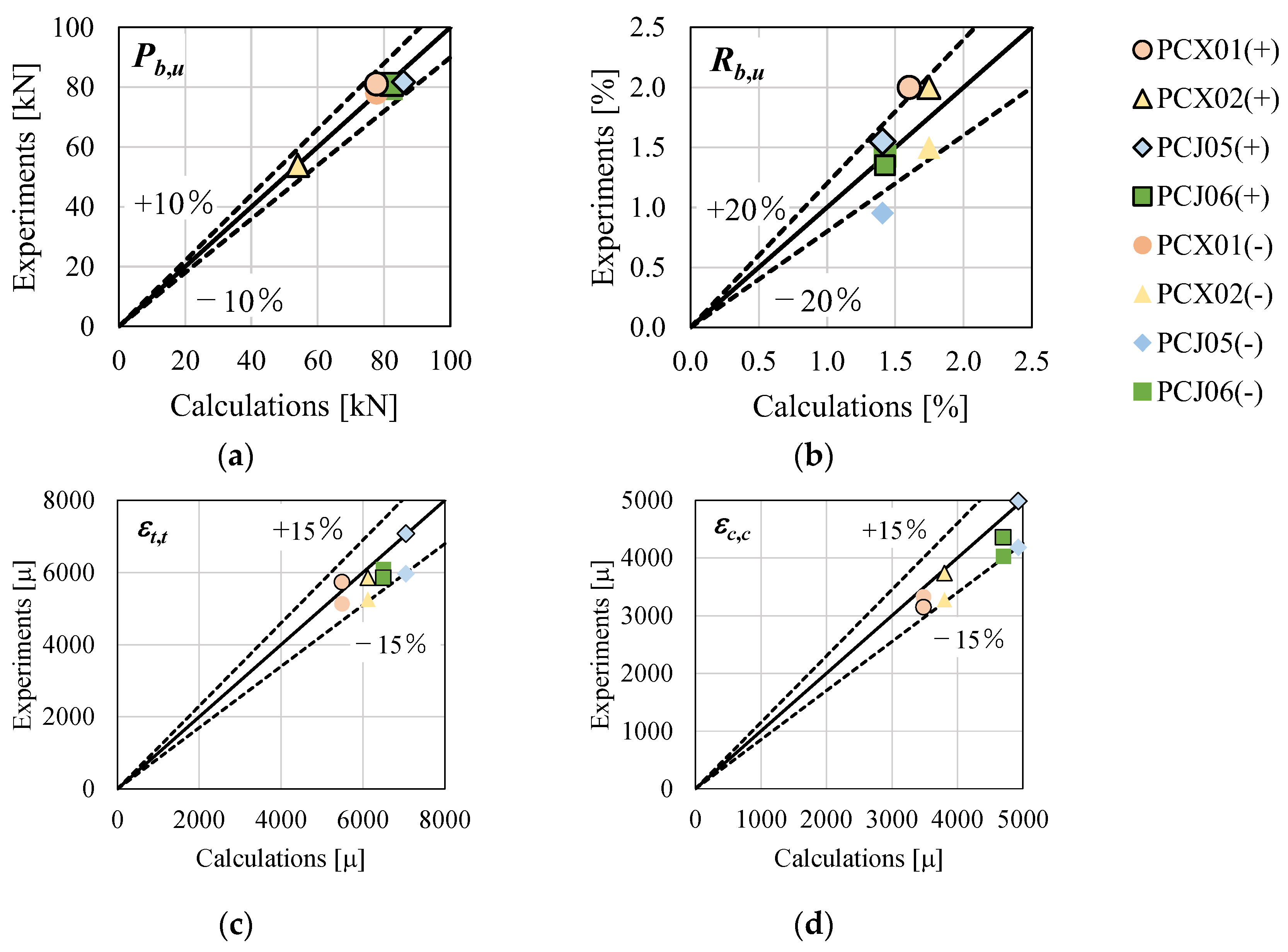

4.2. Comparison of Evaluation and Experimental Results

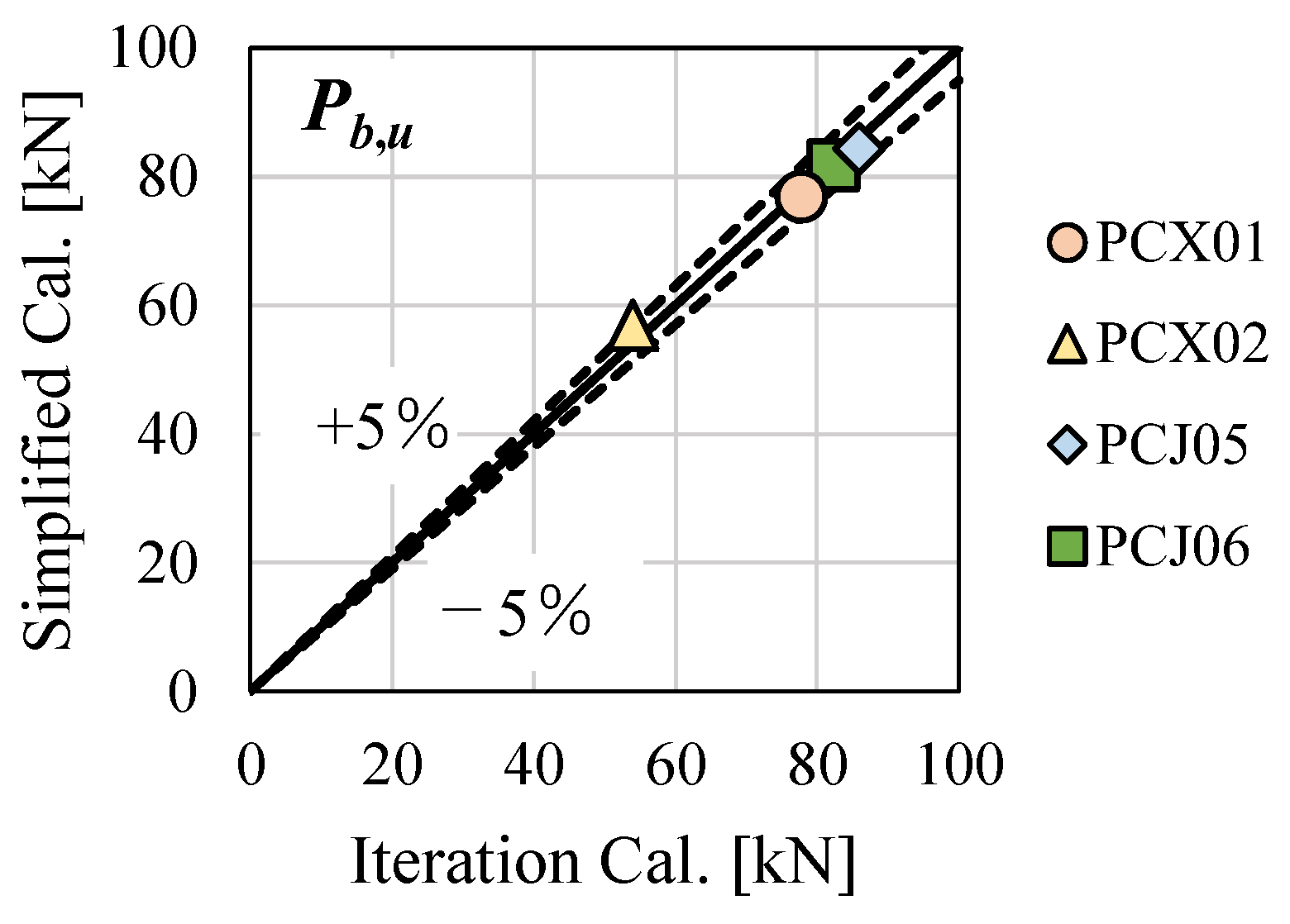

4.3. Verification of Simplified Method

5. Conclusions and Future Work

- The analytical model can more comprehensively and accurately consider the stress–strain distribution of concrete and tendons at each section of the PC beam, and also consider the unequal tensile forces of multiple partial tendons. However, the existing methods cannot evaluate the ultimate deformation of the connection or give the exact tendon strain at the ultimate state. Some other methods can only consider equal axial forces of multiple tendons or cannot be applied in the case of the partial tendons. Therefore, the proposed analytical model and methods are superior to most existing ones.

- The proposed evaluation method can reasonably evaluate the ultimate bending moment at the beam end, the corresponding beam deflection and the tendon strains with good accuracy. The evaluation errors for the ultimate bending moment were within 10%, and for the beam deflection angle the errors were almost less than 20%. With respect to the tendon strains, regardless of the tendon positions, the evaluation errors were within 15%. The good evaluation accuracy indicates the proposed analytical model can reflect the behavior of the PC beam–column connection properly.

- The iterative method using the iterative process is proposed, and then simplified to the direct method, which does not require the iterative calculation process, by means of the approximation of axial concrete shortening at the beam–column interface. The simplified method can give evaluations of similar accuracy as the iterative one by introducing the correction factor, which is therefore more suitable for engineering design.

- The self-centering and low-damage characteristics of the proposed PC connection are confirmed by cyclic loading tests. Through the comprehensive evaluation of the ultimate performance of the connection, the self-centering and low-damage characteristics could be guaranteed in strong earthquake by preventing concrete spalling or tendons yielding, while the bearing and deformation capacity of the connection could be fully utilized.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Park, R. Seismic design and construction of precast concrete buildings in New Zealand. PCI J. 2002, 47, 60–75. [Google Scholar] [CrossRef]

- Priestley, M.J. Overview of PRESSS Research Program. PCI J. 1991, 36, 50–57. [Google Scholar] [CrossRef]

- Yee, A.A. Social and environmental benefits of precast concrete technology. PCI J. 2001, 46, 14–19. [Google Scholar] [CrossRef]

- Shiohara, H.; Watanabe, F. The Japan PRESS precast concrete connection design. In Proceedings of the 12th World Conference of Earthquake Engineering, Aukland, New Zealand, 30 January 2000. [Google Scholar]

- Jaillon, L.; Poon, C.S. Sustainable construction aspects of using prefabrication in dense urban environment: A Hong Kong case study. Constr. Manag. Econ. 2008, 26, 953–966. [Google Scholar] [CrossRef]

- Bull, D.K.; Park, R. Seismic resistance of frames incorporating precast prestressed concrete beam shells. PCI J. 1986, 31, 54–93. [Google Scholar] [CrossRef]

- Alcocer, S.M.; Carranza, R.; Perez-Navarrete, D.; Martinez, R. Seismic tests of beam-to-column connections in a precast concrete frame. PCI J. 2002, 47, 70–89. [Google Scholar] [CrossRef]

- Parastesh, H.; Hajirasouliha, I.; Ramezani, R. A new ductile moment-resisting connection for precast concrete frames in seismic regions: An experimental investigation. Eng. Struct. 2014, 70, 144–157. [Google Scholar] [CrossRef]

- Guan, D.; Guo, Z.; Xiao, Q.; Zheng, Y. Experimental study of a new beam-to-column connection for precast concrete frames under reversal cyclic loading. Adv. Struct. Eng. 2016, 19, 529–545. [Google Scholar] [CrossRef]

- French, C.W.; Hafner, M.; Jayashankar, V. Connections between precast elements failure within connection region. J. Struct. Eng. 1989, 115, 3171–3192. [Google Scholar] [CrossRef]

- Nakaki, S.D.; Englekirk, R.E.; Plaehn, J.L. Ductile connectors for a precast concrete frame. PCI J. 1994, 39, 46–59. [Google Scholar] [CrossRef]

- Nzabonimpa, J.D.; Hong, W.-K.; Kim, J. Nonlinear finite element model for the novel mechanical beam-column joints of precast concrete-based frames. Comput. Struct. 2017, 189, 31–48. [Google Scholar] [CrossRef]

- Li, S.; Li, Q.; Zhang, H.; Jiang, H.; Yan, L.; Jiang, W. Experimental study of a fabricated confined concrete beam-to-column connection with end-plates. Constr. Build. Mater. 2018, 158, 208–216. [Google Scholar]

- Choi, H.K.; Choi, Y.C.; Choi, C.S. Development and testing of precast concrete beam-to-column connections. Eng. Struct. 2013, 56, 1820–1835. [Google Scholar] [CrossRef]

- Ghayeb, H.H.; Razak, H.A.; Sulong, N.H. Development and testing of hybrid precast concrete beam-to-column connections under cyclic loading. Constr. Build. Mater. 2017, 151, 258–278. [Google Scholar] [CrossRef]

- Cheok, G.S.; Lew, H.S. Performance of precast concrete beam-to-column connections subject to cyclic loading. PCI J. 1991, 36, 56–67. [Google Scholar] [CrossRef]

- Priestley, M.N.; Tao, J. Seismic response of precast prestressed concrete frames with partially debonded tendons. PCI J. 1993, 38, 58–69. [Google Scholar] [CrossRef]

- Priestley, M.N.; MacRae, G.A. Seismic tests of precast beam-to-column joint subassemblages with unbonded tendons. PCI J. 1996, 41, 64–81. [Google Scholar] [CrossRef]

- Cheok, G.S. A hybrid reinforced precast frame for seismic regions. PCI J. 1997, 42, 20–32. [Google Scholar]

- Wang, H.; Marino, E.M.; Pan, P.; Liu, H.; Nie, X.J. Experimental study of a novel precast prestressed reinforced concrete beam-to-column joint. Eng. Struct. 2018, 156, 68–81. [Google Scholar] [CrossRef]

- Jin, K.; Song, S.; Kitayama, K.; Hao, L. Detailed evaluation of the ultimate flexural states of beams in unbonded precast prestressed concrete frames. Bull. Earthq. Eng. 2019, 17, 1495–1519. [Google Scholar] [CrossRef]

- Jin, K.; Hao, L.; Kitayama, K. Direct evaluation method for load-deformation curve of precast prestressed concrete frame with different tendon forces. Bull. Earthq. Eng. 2021, 19, 3597–3626. [Google Scholar] [CrossRef]

- Priestley, M.J.; Sritharan, S.; Conley, J.R.; Pampanin, S. Preliminary results and conclusions from the PRESSS five-story precast concrete test building. PCI J. 1999, 44, 42–67. [Google Scholar] [CrossRef]

- Lu, X.; Cui, Y.; Liu, J.; Gao, W. Shaking table test and numerical simulation of a 1/2-scale self-centering reinforced concrete frame. Earthq. Eng. Struct. Dyn. 2015, 44, 1899–1917. [Google Scholar] [CrossRef]

- Rahman, M.A.; Sritharan, S. Performance-based seismic evaluation of two five-story precast concrete hybrid frame buildings. J. Struct. Eng. 2007, 133, 1489–1500. [Google Scholar] [CrossRef]

- Morgen, B.G.; Kurama, Y.C. Seismic response evaluation of posttensioned precast concrete frames with friction dampers. J. Struct. Eng. 2008, 134, 132–145. [Google Scholar] [CrossRef]

- Wang, H.; Marino, E.M.; Pan, P. Design, testing and finite element analysis of an improved precast prestressed beam-to-column joint. Eng. Struct. 2019, 199, 109661. [Google Scholar] [CrossRef]

- Song, S.; Kurimoto, K.; Jin, K.; Kitayama, K.; Kanemoto, K.; Tajima, Y. Seismic performance of unbonded precast prestressed reinforced concrete frame with different lengths of tendon. In Summaries of Technical Papers of Annual Meeting; Architectural Institute of Japan (AIJ): Kobe, Japan, 2014. [Google Scholar]

- Kurama, Y.C. Hybrid post-tensioned precast concrete walls for use in seismic regions. PCI J. 2002, 47, 36–59. [Google Scholar] [CrossRef]

- Holden, T.; Restrepo, J.; Mander, J.B. Seismic performance of precast reinforced and prestressed concrete walls. J. Struct. Eng. ASCE 2003, 129, 286–296. [Google Scholar] [CrossRef]

- Smith, B.J.; Kurama, Y.C.; McGinnis, M.J. Design and Measured Behavior of a Hybrid Precast Concrete Wall Specimen for Seismic Regions. J. Struct. Eng. ASCE 2011, 137, 1052–1062. [Google Scholar] [CrossRef]

- Sritharan, S.; Aaleti, S.; Henry, R.S.; Liu, K.-Y.; Tsai, K.-C. Precast concrete wall with end columns (PreWEC) for earthquake resistant design. Earthq. Eng. Struct. Dyn. 2015, 44, 2075–2092. [Google Scholar] [CrossRef]

- Gavridou, S.; Wallace, J.W.; Nagae, T.; Matsumori, T.; Tahara, K.; Fukuyama, K. Shake-Table Test of a Full-Scale 4-Story Precast Concrete Building. I: Overview and Experimental Results. J. Struct. Eng. 2017, 143, 04017034. [Google Scholar] [CrossRef]

- Twigden, K.; Henry, R.J.; Engineering, E. Shake table testing of unbonded post-tensioned concrete walls with and without additional energy dissipation. Soil Dyn. Earthq. Eng. 2019, 119, 375–389. [Google Scholar] [CrossRef]

- Kurama, Y.C.; Weldon, B.D.; Shen, Q.J. Experimental evaluation of posttensioned hybrid coupled wall subassemblages. J. Struct. Eng. 2006, 132, 1017–1029. [Google Scholar] [CrossRef]

- Weldon, B.D.; Kurama, Y.C. Experimental evaluation of posttensioned precast concrete coupling beams. J. Struct. Eng. 2010, 136, 1066–1077. [Google Scholar] [CrossRef]

- Midorikawa, M.; Azuhata, T.; Ishihara, T.; Wada, A.J.; Dynamics, S. Shaking table tests on seismic response of steel braced frames with column uplift. Earthq. Eng. Struct. Dyn. 2006, 35, 1767–1785. [Google Scholar] [CrossRef]

- Sause, R.; Ricles, J.; Roke, D.; Chancellor, N.; Gonner, N. Seismic performance of a self-centering rocking concentrically-braced frame. In Proceedings of the 9th US National and 10th Canadian Conference on Earthquake Engineering, Toronto, ON, Canada, 25 July 2010. [Google Scholar]

- Eatherton, M.R.; Ma, X.; Krawinkler, H.; Deierlein, G.G.; Hajjar, J.F. Quasi-Static Cyclic Behavior of Controlled Rocking Steel Frames. J. Struct. Eng. 2014, 140, 04014083. [Google Scholar] [CrossRef]

- Eatherton, M.R.; Hajjar, J.F. Hybrid simulation testing of a self-centering rocking steel braced frame system. Earthq. Eng. Struct. Dyn. 2014, 43, 1725–1742. [Google Scholar] [CrossRef]

- Christopoulos, C.; Filiatrault, A.; Uang, C.M.; Folz, B. Posttensioned energy dissipating connections for moment-resisting steel frames. J. Struct. Eng. ASCE 2002, 128, 1111–1120. [Google Scholar] [CrossRef]

- Garlock, M.M.; Ricles, J.M.; Sause, R.J. Experimental studies of full-scale posttensioned steel connections. J. Struct. Eng. 2005, 131, 438–448. [Google Scholar] [CrossRef]

- Kim, H.-J.; Christopoulos, C.J. Friction damped posttensioned self-centering steel moment-resisting frames. J. Struct. Eng. 2008, 134, 1768–1779. [Google Scholar] [CrossRef]

- Vasdravellis, G.; Karavasilis, T.L.; Uy, B. Finite element models and cyclic behavior of self-centering steel post-tensioned connections with web hourglass pins. Eng. Struct. 2013, 52, 1–16. [Google Scholar] [CrossRef]

- Ho, T.X.; Dao, T.N.; Aaleti, S.; van de Lindt, J.W.; Rammer, D.R. Hybrid system of unbonded post-tensioned CLT panels and light-frame wood shear walls. J. Struct. Eng. 2017, 143, 04016171. [Google Scholar] [CrossRef]

- Ganey, R.; Berman, J.; Akbas, T.; Loftus, S.; Dolan, J.D.; Sause, R.; Ricles, J.; Pei, S.; van de Lindt, J.; Blomgren, H.-E. Experimental Investigation of Self-Centering Cross-Laminated Timber Walls. J. Struct. Eng. 2017, 143, 04017135. [Google Scholar] [CrossRef]

- Iqbal, A.; Pampanin, S.; Palermo, A.; Buchanan, A.H. Performance and Design of LVL Walls Coupled with UFP Dissipaters. J. Earthq. Eng. 2015, 19, 383–409. [Google Scholar] [CrossRef]

- Iqbal, A.; Smith, T.; Pampanin, S.; Fragiacomo, M.; Palermo, A.; Buchanan, A.J. Experimental performance and structural analysis of plywood-coupled LVL walls. J. Struct. Eng. 2016, 142, 04015123. [Google Scholar] [CrossRef]

- Rosenboom, O.A.; Kowalsky, M.J. Reversed in-plane cyclic behavior of posttensioned clay brick masonry walls. J. Struct. Eng. 2004, 130, 787–798. [Google Scholar] [CrossRef]

- Hassanli, R.; ElGawady, M.A.; Mills, J.E. Experimental investigation of in-plane cyclic response of unbonded posttensioned masonry walls. J. Struct. Eng. 2016, 142, 04015171. [Google Scholar] [CrossRef]

- Ban, S.; Muguruma, H. Ultimate strength of post-tensioned unbonded beams, part 1: Study on bending behaviors of post-tensioned unbonded beams. Trans. Archit. Inst. Jpn. 1956, 60, 641–644. [Google Scholar]

- Morgen, B.G.; Kurama, Y.C. Seismic design of friction-damped precast concrete frame structures. J. Struct. Eng. -ASCE 2007, 133, 1501–1511. [Google Scholar] [CrossRef]

- Koshikawa, T. Moment and energy dissipation capacities of post-tensioned precast concrete connections employing a friction device. Eng. Struct. 2017, 138, 170–180. [Google Scholar] [CrossRef]

- Matsumora, M.; Koshikawa, T.; Kikuchi, M. Evaluation of ultimate strength and rotation angle for unbonded post-tensioned precast concrete beams by using section analysis. J. Struct. Constr. Eng. 2014, 79, 1005–1013. [Google Scholar] [CrossRef]

- El-Sheikh, M.T.; Sause, R.; Pessiki, S.; Lu, L.W. Seismic behavior and design of unbonded post-tensioned precast concrete frames. PCI J. 1999, 44, 54–71. [Google Scholar] [CrossRef]

- Tsuda, K. A study on the calculation method for flexural behavior of unbonded pre-stressed concrete beam. Struct. Const. Eng. 2015, 710, 659–668. [Google Scholar] [CrossRef]

- Stanton, J.F.; Nakaki, S.D. Design Guidelines for Precast Concrete Seismic Structural Systems; Department of Civil Engineering, University of Washington: Seattle, WA, USA, 2002. [Google Scholar]

- Hawileh, R.; Tabatabai, H.; Rahman, A.; Amro, A. Non-dimensional design procedures for precast, prestressed concrete hybrid frames. PCI J. 2006, 51, 110. [Google Scholar] [CrossRef]

- Nakaki, S.D.; Stanton, J.F.; Sritharan, S. An Overview of the PRESSS Five-Story Precast Test Building. PCI J. 1999, 44, 26–39. [Google Scholar] [CrossRef]

- Jin, K.; Ueno, A.; Baba, R.; Kitayama, K. Seismic performance of precast prestressed reinforced concrete frame with partial unbonded tendon. Proc. Jpn. Concr. Inst. 2020, 42, 397–402. [Google Scholar]

- Guidelines for Structural Design and Construction of Prestressed Concrete Buildings Based on Performance Evaluation Concept (Draft); Architectural Institute of Japan (AIJ): Tokyo, Japan, 2015.

- AIJ Standard for Structural Calculation of Reinforced Concrete Structures; Architectural Institute of Japan (AIJ): Tokyo, Japan, 2018.

- Sugano, S. Study on hysteretic characteristics of reinforced concrete members. Concr. J. 1973, 11, 1–9. [Google Scholar]

| Specimen | Beam | Concrete | Debonded Tendon | ||||||

|---|---|---|---|---|---|---|---|---|---|

| b × D (mm) | σB (MPa) | Et1 (MPa) | εte (%) | εty (%) | σty (MPa) | ΣAt (mm2) | l’ (mm) | λa | |

| PCJ05 | 250 × 400 | 90.1 | 2.0 × 105 | 0.46 | 0.70 | 1006.0 | 692.7 | 400 | 0.8 |

| PCJ06 | 70.8 | 0.46 | 0.70 | 1006.0 | 692.7 | 800 | 0.8 | ||

| PCX01 | 95.2 | 0.45 | 0.71 | 998.5 | 692.7 | 800 | 0.5 | ||

| PCX02 | 95.2 | 0.43 | 0.69 | 996.1 | 454.0 | 800 | 0.5 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, K.; Ota, R.; Hao, L.; Kitayama, K. Evaluation Method for Ultimate Flexural State of Prestressed Precast Reinforced Concrete Beam–Column Connection with Debonded Partial Tendon. Appl. Sci. 2023, 13, 2843. https://doi.org/10.3390/app13052843

Jin K, Ota R, Hao L, Kitayama K. Evaluation Method for Ultimate Flexural State of Prestressed Precast Reinforced Concrete Beam–Column Connection with Debonded Partial Tendon. Applied Sciences. 2023; 13(5):2843. https://doi.org/10.3390/app13052843

Chicago/Turabian StyleJin, Kiwoong, Riku Ota, Linfei Hao, and Kazuhiro Kitayama. 2023. "Evaluation Method for Ultimate Flexural State of Prestressed Precast Reinforced Concrete Beam–Column Connection with Debonded Partial Tendon" Applied Sciences 13, no. 5: 2843. https://doi.org/10.3390/app13052843

APA StyleJin, K., Ota, R., Hao, L., & Kitayama, K. (2023). Evaluation Method for Ultimate Flexural State of Prestressed Precast Reinforced Concrete Beam–Column Connection with Debonded Partial Tendon. Applied Sciences, 13(5), 2843. https://doi.org/10.3390/app13052843