Nutritional Value, Physical Properties, and Sensory Quality of Sugar-Free Cereal Bars Fortified with Grape and Apple Pomace

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Preparation of Dough and Baking Bars

2.3. Determination of Moisture

2.4. Determination of Polyphenol Content

2.5. Determination of Dietary Fibre Content

2.6. Determination of Mechanical Strength

2.7. Determination of Colour

2.8. Sensory Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. Chemical Analysis

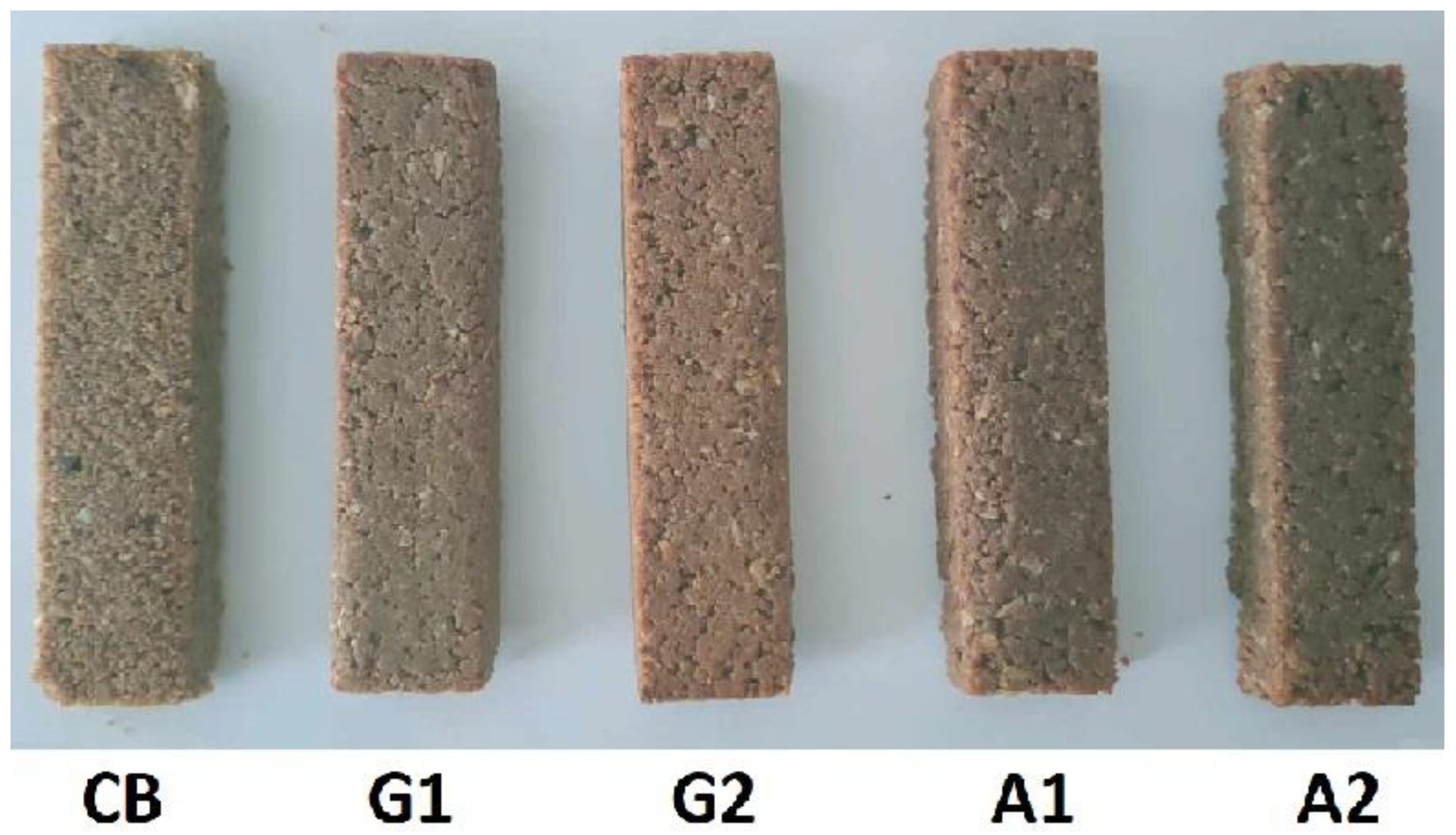

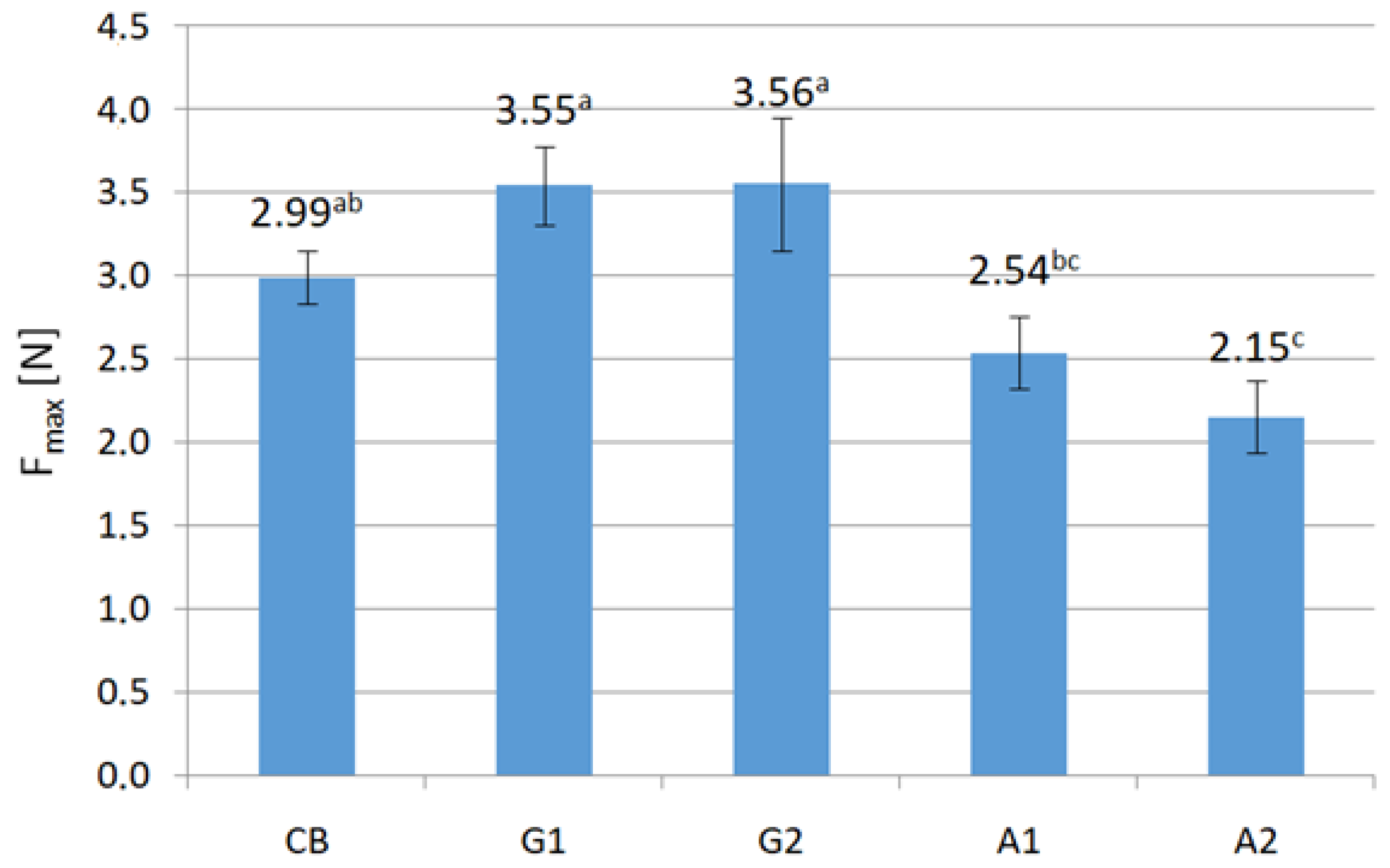

3.2. Analysis of Physical Properties

3.3. Colour Parameters

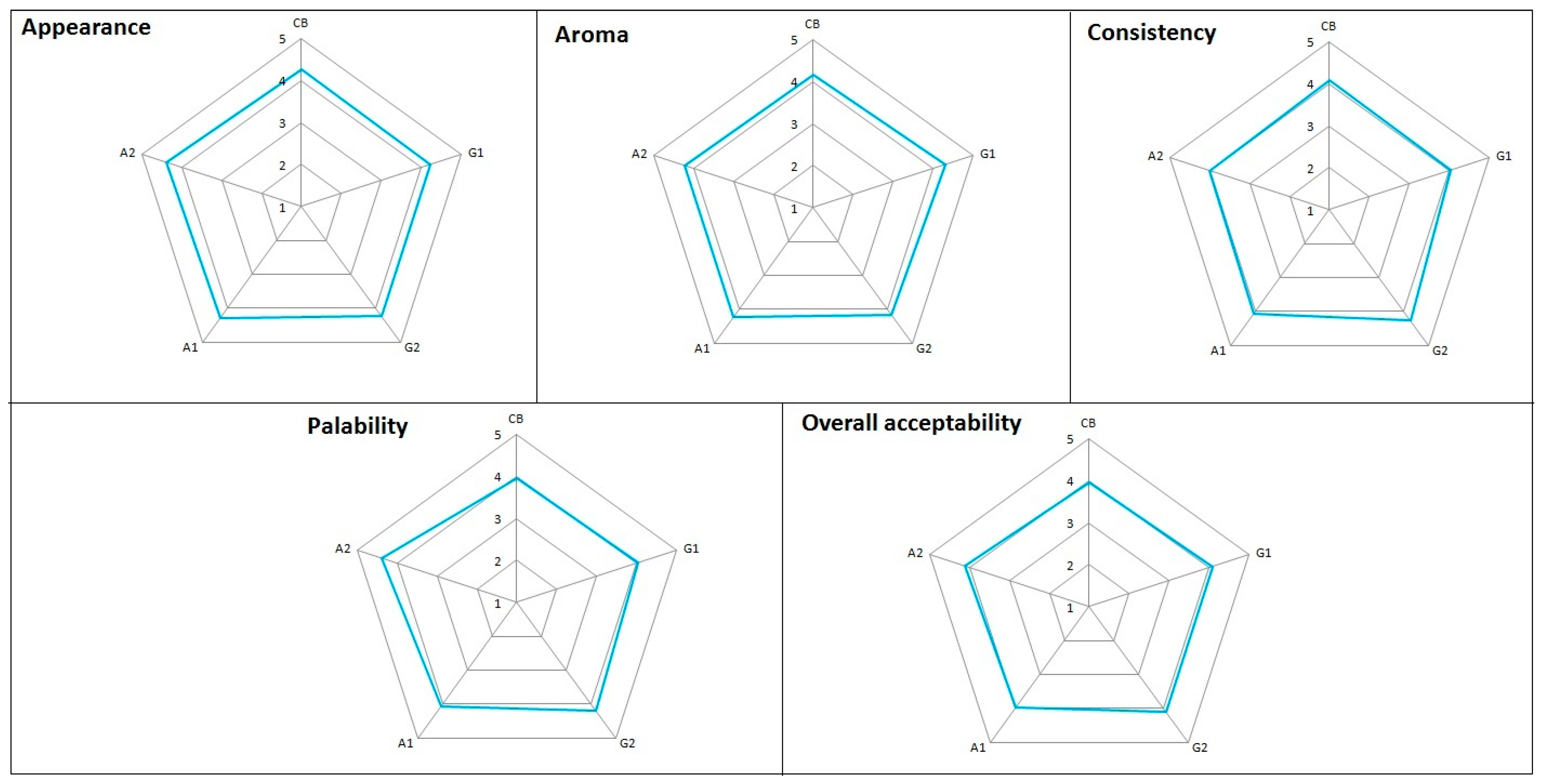

3.4. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bacchetti, T.; Turco, I.; Urbano, A.; Morresi, C.; Ferretti, G. Relationship of fruit and vegetable intake to dietary antioxidant capacity and markers of oxidative stress: A sex-related study. Nutrition 2019, 61, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Ambrosone, C.B.; McCullough, M.J.; Ahn, J.; Stevens, V.L.; Thun, M.J.; Hong, C.C. Oxidative stress-related genotypes, fruit and vegetable consumption and breast cancer risk. Carcinogenesis 2009, 30, 777–784. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Sun, L.; Yang, Y.; Gou, X.; Niu, P.; Guo, Y. Changes in the physicochemical properties, aromas and polyphenols of not from concentrate (NFC) apple juice during production. CYTA J. Food 2018, 16, 755–764. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, H.; Sun, R.; Zhao, Y.; Xing, R.; Yu, N.; Deng, T.; Ni, X.; Chen, Y. Volatolomics approach for authentication of not-from-concentrate (NFC) orange juice based on characteristic volatile markers using headspace solid phase microextraction (HS-SPME) combined with GC-MS. Food Control 2022, 136, 108856. [Google Scholar] [CrossRef]

- Bianchi, F.; Cervini, M.; Giuberti, G.; Rocchetti, G.; Lucini, L.; Simonato, B. Distilled grape pomace as a functional ingredient in vegan muffins: Effect on physicochemical, nutritional, rheological and sensory aspects. Int. J. Food Sci. Technol. 2022, 57, 4847–4858. [Google Scholar] [CrossRef]

- Monrad, J.K.; Suárez, M.; Motilva, M.J.; King, J.W.; Srinivas, K.; Howard, L.R. Extraction of anthocyanins and flavan-3-ols from red grape pomace continuously by coupling hot water extraction with a modified expeller. Food Res. Int. 2014, 65, 77–87. [Google Scholar] [CrossRef]

- Castellanos-Gallo, L.; Ballinas-Casarrubias, L.; Espinoza-Hicks, J.C.; Hernández-Ochoa, L.R.; Muñoz-Castellanos, L.N.; Zermeño-Ortega, M.R.; Borrego-Loya, A.; Salas, E. Grape pomace valorization by extraction of phenolic polymeric pigments: A review. Processes 2022, 10, 469. [Google Scholar] [CrossRef]

- Schieber, A.; Hilt, P.; Streker, P.; Endreß, H.U.; Rentschler, C.; Carle, R. A new process for the combined recovery of pectin and phenolic compounds from apple pomace. IFSET 2003, 4, 99–107. [Google Scholar] [CrossRef]

- Colin-Henrion, M.; Mehinagic, E.; Renard, C.M.; Richomme, P.; Jourjon, F. From apple to applesauce: Processing effects on dietary fibres and cell wall polysaccharides. Food Chem. 2009, 117, 254–260. [Google Scholar] [CrossRef]

- Tarko, T.; Duda-Chodak, A.; Bebak, A. Biological activity of selected fruit and vegetable pomaces. Food Sci. Technol. Qual. 2012, 19, 55–65. [Google Scholar] [CrossRef]

- Peričin, D.; Radulović-Popović, L.; Vaštag, Ž.; Mađarev-Popović, S.; Trivić, S. Enzymatic hydrolysis of protein isolate from hull-less pumpkin oil cake: Application of response surface methodology. Food Chem. 2009, 115, 753–757. [Google Scholar] [CrossRef]

- Hayta, M.; Özugur, G.; Etgü, H.; Seker, I.T. Effect of grape (Vitis vinifera L.) pomace on the quality, total phenolic content and anti-radical activity of bread. J. Food Process. Preserv. 2014, 38, 980–986. [Google Scholar] [CrossRef]

- Sarkis, J.R.; Michel, I.; Tessaro, I.C.; Marczak, L.D.F. Optimization of phenolics extraction from sesame seed cake. Sep. Purif. 2014, 122, 506–514. [Google Scholar] [CrossRef]

- Zardo, I.; de Espíndola Sobczyk, A.; Marczak, L.D.F.; Sarkis, J. Optimization of ultrasound assisted extraction of phenolic compounds from sunflower seed cake using response surface methodology. Waste Biomass Valorization 2019, 10, 33–44. [Google Scholar] [CrossRef]

- de Oliveira Filho, J.G.; Egea, M.B. Sunflower seed byproduct and its fractions for food application: An attempt to improve the sustainability of the oil process. J. Food Sci. 2021, 86, 1497–1510. [Google Scholar] [CrossRef]

- Ahlström, C.; Thuvander, J.; Rayner, M.; Mayer Labba, I.C.; Sandberg, A.S.; Östbring, K. Pilot-Scale Protein Recovery from Cold-Pressed Rapeseed Press Cake: Influence of Solids Recirculation. Processes 2022, 10, 557. [Google Scholar] [CrossRef]

- Rasane, P.; Jha, A.; Sabikhi, L.; Kumar, A.; Unnikrishnan, V.S. Nutritional advantages of oats and opportunities for its processing as value added foods-a review. J. Food Sci. Technol. 2015, 52, 662–675. [Google Scholar] [CrossRef]

- Sterna, V.; Zute, S.; Brunava, L. Oat grain composition and its nutrition benefice. Agric. Agric. Sci. Procedia 2016, 8, 252–256. [Google Scholar] [CrossRef]

- AACC (American Association of Cereal Chemistry). Approved Methods, 10th ed.; AACC: St. Paul, MN, USA, 2000; Available online: http://methods.aaccnet.org/toc.aspx (accessed on 14 April 2022).

- Lachowicz, S.; Bieniek, A.; Gil, Z.; Bielska, N.; Markuszewski, B. Phytochemical parameters and antioxidant activity of new cherry silverberry biotypes (Elaeagnus multiflora Thunb.). Eur. Food Res. Technol. 2019, 245, 1997–2005. [Google Scholar] [CrossRef]

- AOAC (Association of Official Analytical Chemists International). Official Methods, 21st ed.; AOAC: Rockville, MD, USA, 2019; Available online: https://www.aoac.org/official-methods-of-analysis-21st-edition-2019/ (accessed on 14 April 2022).

- Quiles, A.; Campbell, G.M.; Struck, S.; Rohm, H.; Hernando, I. Fiber from fruit pomace: A review of applications in cereal-based products. Food Rev. Int. 2018, 34, 162–181. [Google Scholar] [CrossRef]

- Znamirowska, A.; Kalicka, D.; Buniowska, M.; Rozek, P. Effect of dried apple powder additive on physical-chemical and sensory properties of yoghurt. Food Sci. Technol. Qual. 2018, 25, 71–80. [Google Scholar]

- Manzocco, L.; Romano, G.; Calligaris, S.; Nicoli, M.C. Modeling the effect of the oxidation status of the ingredient oil on stability and shelf life of low-moisture bakery products: The case study of crackers. Foods 2020, 9, 749. [Google Scholar] [CrossRef] [PubMed]

- Galić, K.; Ćurić, D.; Gabrić, D. Shelf life of packaged bakery goods—A review. Crit. Rev. Food Sci. Nutr. 2009, 49, 405–426. [Google Scholar] [CrossRef] [PubMed]

- Williamson, G.; Carughi, A. Polyphenol content and health benefits of raisins. Nutr. Res. 2010, 30, 511–519. [Google Scholar] [CrossRef] [PubMed]

- León, E.A.V.; Aldapa, C.A.G.; Rojas, J.A.; Torres, A.V.; Uribe, J.P.H.; Rodríguez, H.M.P.; Cortez, R.O.N. Phytochemical content and antioxidant activity of extruded products made from yellow corn supplemented with apple pomace powder. Food Sci. Technol. 2022, 42, e91221. [Google Scholar] [CrossRef]

- Valková, V.; Ďúranová, H.; Havrlentová, M.; Ivanišová, E.; Mezey, J.; Tóthová, Z.; Gabríny, L.; Kačániová, M. Selected physico-chemical, nutritional, antioxidant and sensory properties of wheat bread supplemented with apple pomace powder as a by-product from juice production. Plants 2022, 11, 1256. [Google Scholar] [CrossRef]

- Gumul, D.; Kruczek, M.; Ivanišová, E.; Słupski, J.; Kowalski, S. Apple pomace as an ingredient enriching wheat pasta with health-promoting compounds. Foods 2023, 12, 804. [Google Scholar] [CrossRef]

- Sobczak, P.; Nadulski, R.; Kobus, Z.; Zawiślak, K. Technology for apple pomace utilization within a sustainable development policy framework. Sustainability 2022, 14, 5470. [Google Scholar] [CrossRef]

- Vildan, E.Y.İ.Z.; Tontul, İ.; Türker, S. Edible coating of cereal bars using different biopolymers: Effect on physical and chemical properties during storage. GIDA 2020, 45, 1019–1029. [Google Scholar]

- Wiedemair, V.; Gruber, K.; Knöpfle, N.; Bach, K.E. Technological changes in wheat-based breads enriched with hemp seed press cakes and hemp seed grit. Molecules 2022, 27, 1840. [Google Scholar] [CrossRef]

- Sandini, M.B.; Biz, A.P.; Bertolo, A.P.; Bagatini, L.; Riego, E.; Cavalheiro, D. Enriched cereal bars with wine fermentation biomass. J. Sci. Food Agric. 2020, 101, 542–547. [Google Scholar]

- Carvalho, V.S.; Conti-Silva, A.C. Cereal bars produced with banana peel flour: Evaluation of acceptability and sensory profile. J. Sci. Food Agric. 2018, 98, 134–139. [Google Scholar] [CrossRef]

- Eyiz, V.; Tontul, İ.; Türker, S. The effect of edible coatings on physical and chemical characteristics of fruit bars. J. Food Meas. Charact. 2020, 14, 1775–1783. [Google Scholar] [CrossRef]

- Usman, M.; Ahmed, S.; Mehmood, A.; Bilal, M.; Patil, P.J.; Akram, K.; Farooq, U. Effect of apple pomace on nutrition, rheology of dough and cookies quality. J. Food Sci. Technol. 2020, 57, 3244–3251. [Google Scholar] [CrossRef] [PubMed]

- Acun, S.; Gül, H. Effects of grape pomace and grape seed flours on cookie quality. Qual. Assur. Saf. 2014, 6, 81–88. [Google Scholar] [CrossRef]

| Sample | Component [g] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Oatmeal Flakes | Barley Flakes | Rye Flakes | Sesame Seeds | Sunflower Seeds | Almonds | Pumpkin Seeds | Coconut Chips | Peanut Cream | Fresh Bananas | Sultanas | Grape Pomace | Apple Pomace | |

| CB | 140 | 20 | 20 | 10 | 10 | 10 | 10 | 10 | 70 | 180 | 50 | - | - |

| G1 | 140 | 20 | 20 | 10 | 10 | 10 | 10 | 10 | 70 | 180 | 40 | 10 | - |

| G2 | 140 | 20 | 20 | 10 | 10 | 10 | 10 | 10 | 70 | 180 | 30 | 20 | - |

| A1 | 140 | 20 | 20 | 10 | 10 | 10 | 10 | 10 | 70 | 180 | 40 | - | 10 |

| A2 | 140 | 20 | 20 | 10 | 10 | 10 | 10 | 10 | 70 | 180 | 30 | - | 20 |

| Sample | Moisture [%] | TPC [mg/g] | IDF [%] | SDF [%] | TDF [%] |

|---|---|---|---|---|---|

| CB | 16.28 ± 0.62 e | 1.21 ± 0.02 b | 12.23 ± 0.11 a | 5.11 ± 0.08 c | 17.34 ± 0.19 ab |

| G1 | 18.13 ± 0.07 d | 1.00 ± 0.03 a | 11.60 ± 0.07 b | 5.44 ± 0.06 b | 17.04 ± 0.13 b |

| G2 | 19.50 ± 0.36 c | 1.04 ± 0.05 a | 10.84 ± 0.11 c | 5.45 ± 0.04 b | 16.29 ± 0.15 c |

| A1 | 21.17 ± 0.37 b | 1.03± 0.01 a | 12.26 ± 0.12 a | 5.36 ± 0.04 b | 17.62 ± 0.17 a |

| A2 | 23.64 ± 0.23 a | 0.94 ± 0.05 a | 11.54 ± 0.05 b | 5.75 ± 0.07 a | 17.30 ± 0.11 ab |

| Sample | L* | a* | b* | ΔE |

|---|---|---|---|---|

| CB | 33.98 ± 6.57 | 7.49 ± 2.00 | 18.61 ± 2.65 a | |

| G1 | 36.10 ± 2.77 | 8.67 ± 0.57 | 17.78 ± 1.58 abc | 2.56 |

| G2 | 37.40 ± 0.82 | 9.22 ± 0.81 | 16.28 ± 0.73 ab | 4.48 |

| A1 | 35.78 ± 0.76 | 8.20 ± 0.30 | 15.17 ± 0.75 c | 3.95 |

| A2 | 36.96 ± 0.65 | 8.32 ± 0.33 | 14.82 ± 0.98 bc | 4.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blicharz-Kania, A.; Vasiukov, K.; Sagan, A.; Andrejko, D.; Fifowska, W.; Domin, M. Nutritional Value, Physical Properties, and Sensory Quality of Sugar-Free Cereal Bars Fortified with Grape and Apple Pomace. Appl. Sci. 2023, 13, 10531. https://doi.org/10.3390/app131810531

Blicharz-Kania A, Vasiukov K, Sagan A, Andrejko D, Fifowska W, Domin M. Nutritional Value, Physical Properties, and Sensory Quality of Sugar-Free Cereal Bars Fortified with Grape and Apple Pomace. Applied Sciences. 2023; 13(18):10531. https://doi.org/10.3390/app131810531

Chicago/Turabian StyleBlicharz-Kania, Agata, Kostiantyn Vasiukov, Agnieszka Sagan, Dariusz Andrejko, Weronika Fifowska, and Marek Domin. 2023. "Nutritional Value, Physical Properties, and Sensory Quality of Sugar-Free Cereal Bars Fortified with Grape and Apple Pomace" Applied Sciences 13, no. 18: 10531. https://doi.org/10.3390/app131810531

APA StyleBlicharz-Kania, A., Vasiukov, K., Sagan, A., Andrejko, D., Fifowska, W., & Domin, M. (2023). Nutritional Value, Physical Properties, and Sensory Quality of Sugar-Free Cereal Bars Fortified with Grape and Apple Pomace. Applied Sciences, 13(18), 10531. https://doi.org/10.3390/app131810531