Microbial Control by High Pressure Processing for Shelf-Life Extension of Packed Meat Products in the Cold Chain: Modeling and Case Studies

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Meat Products Preparation

2.2. High Pressure Processing

2.3. Storage Conditions

2.4. Microbiological Analysis

2.5. pH Measurement

2.6. Instrumental Color Analysis

2.7. Instrumental Texture Analysis

2.8. Sensory Evaluation

2.9. Data Analysis

2.10. Remaining Shelf Life Determination—Cold Chain Management

2.11. Statistical Analysis

3. Results and Discussion

3.1. Preliminary Experiments for Selection of HP Treatment Conditions

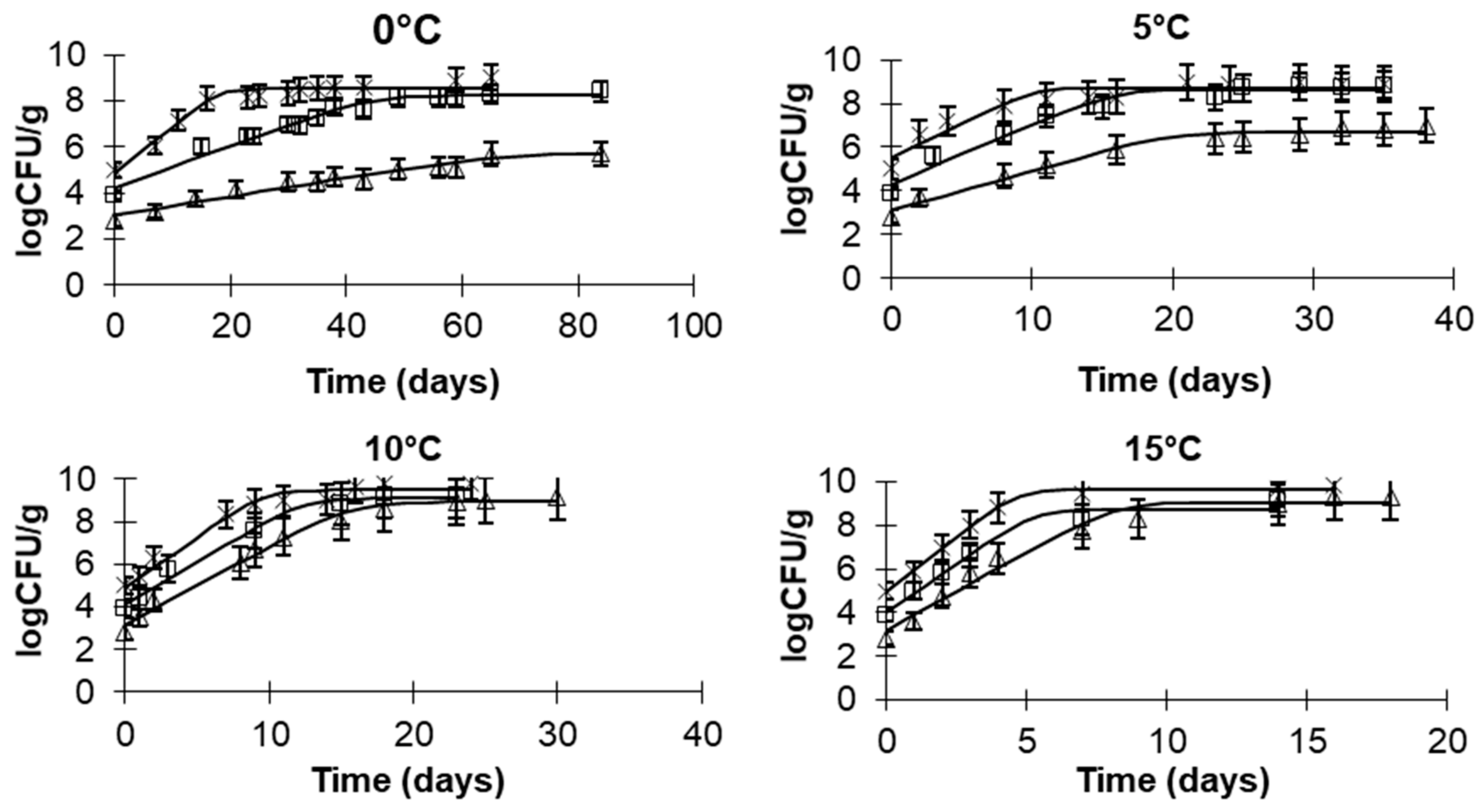

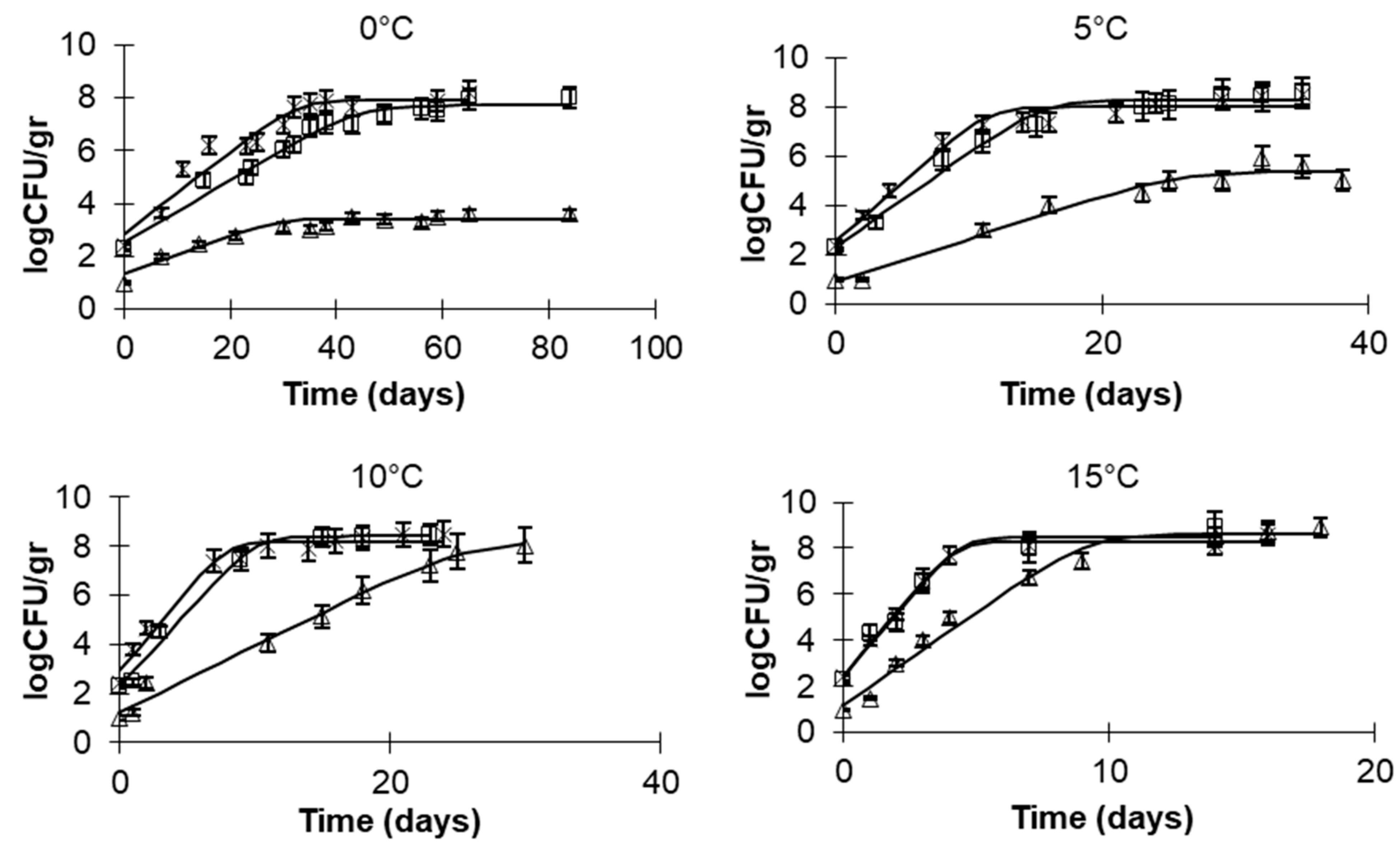

3.2. Effect of HP Treatment on Microbial Growth of Bratwurst Sausages

3.3. Effect of HP Treatment on Microbial Growth of Sliced Cooked Ham

3.4. Effect of HP Treatment on Microbial Growth of Sliced Cooked Turkey

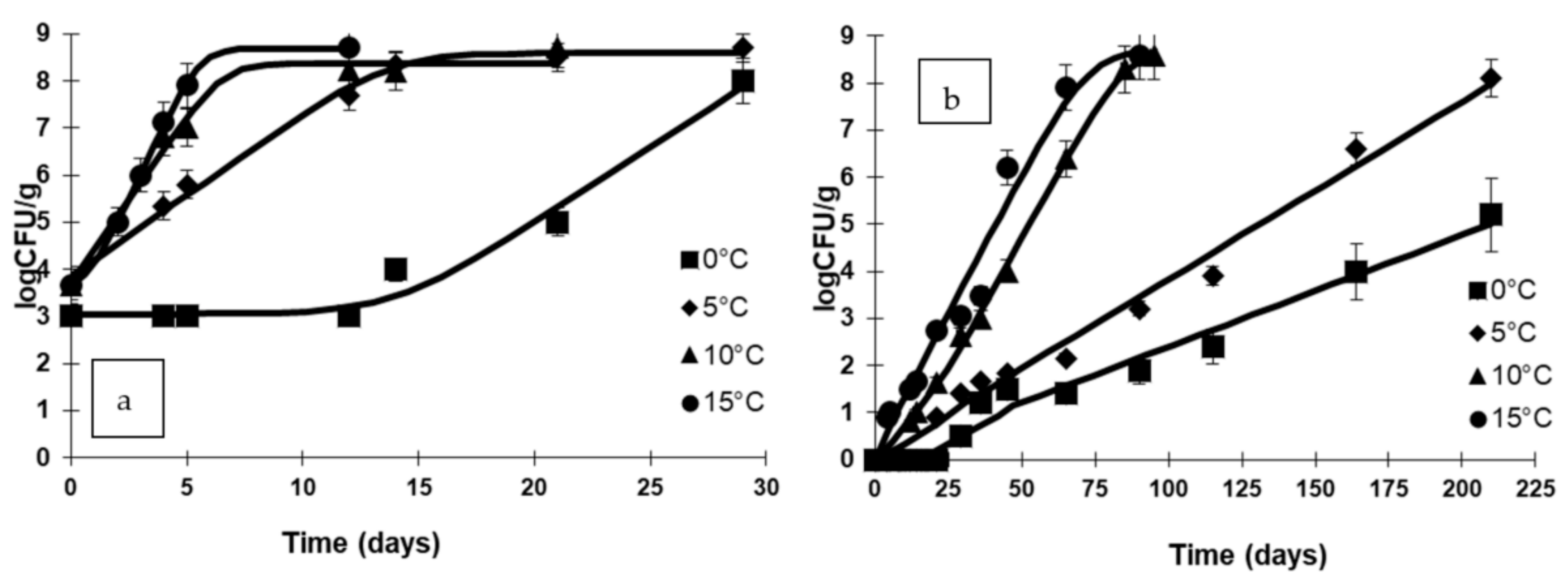

3.5. Effect of HP Treatment on Microbial Growth of Cooked Ham Cubes

3.6. Effect of Storage Temperature on Meat Products Microbial Growth Rate Constants

3.7. Effect of HP Treatment on pH Values of Meat Products

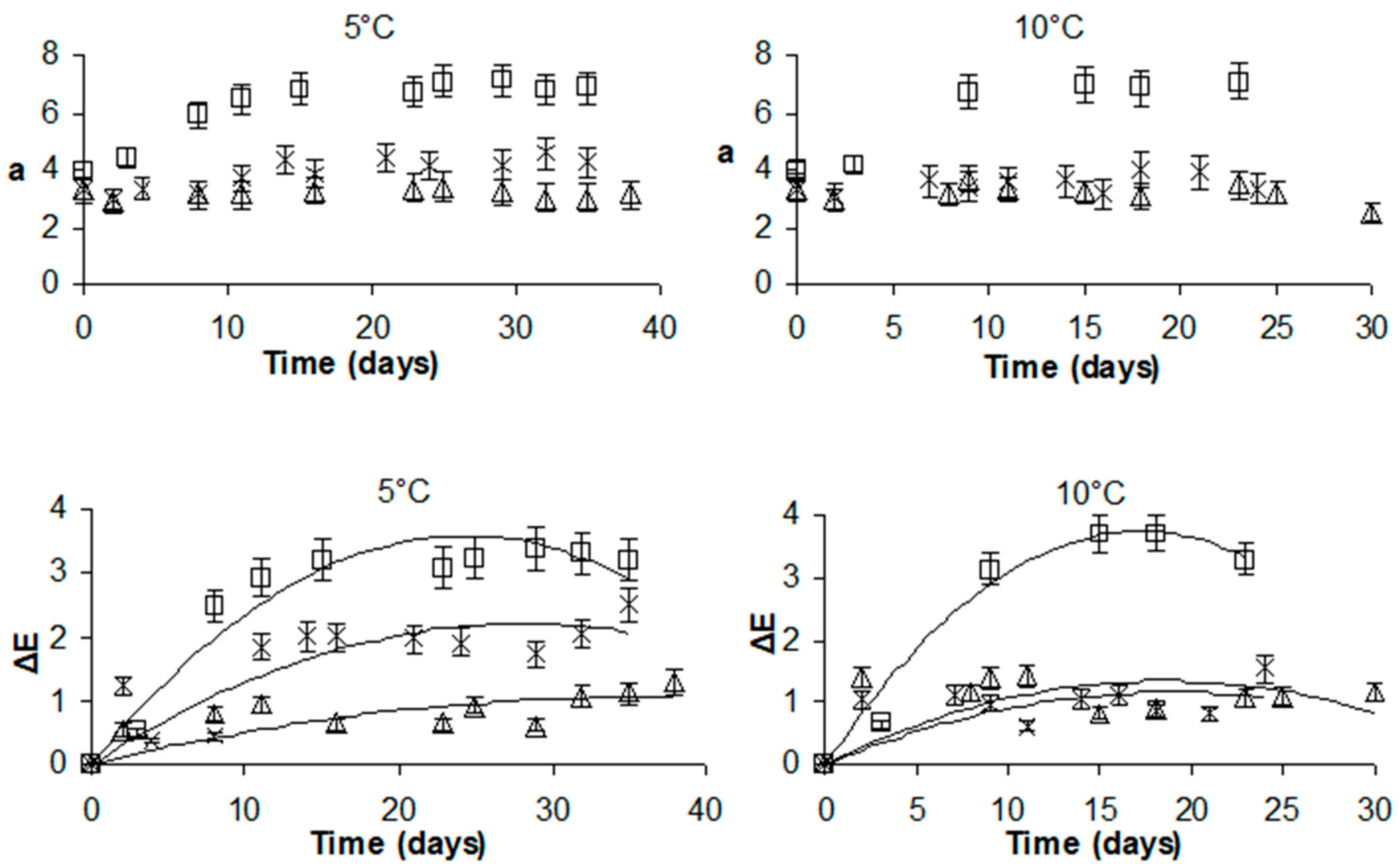

3.8. Effect of HP Treatment on Color of Meat Products

3.9. Effect of HP Treatment on Texture of Meat Products

3.10. Effect of HP Treatment on Organoleptic Properties of Meat Products

3.11. Effect of HP Treatment on Shelf Life of Meat Products

3.12. Consumers’ Acceptance of HP Treated Sliced Cooked Ham

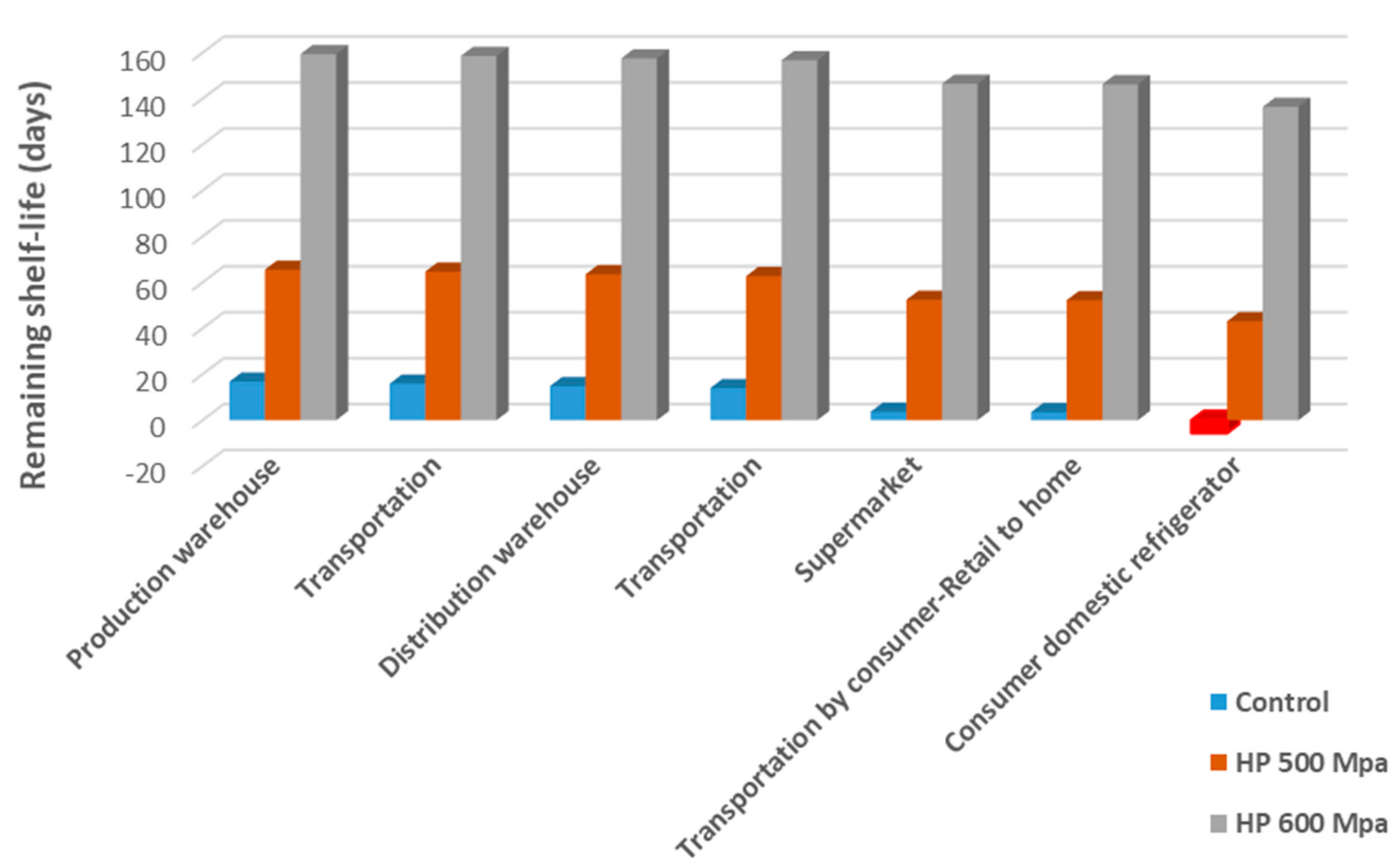

3.13. Cold Chain Management of HP Treated Meat Products

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nastasijevic, I.; Lakicevic, B.; Petrović, Z. Cold Chain Management in Meat Storage, Distribution and Retail: A Review. IOP Conf. Ser. Earth Environ. Sci. 2017, 85, 012022. [Google Scholar] [CrossRef]

- Rahman, S. Nitrites in Food Preservation. In Handbook of Food Preservation; Shafiur Rahman, M., Ed.; CRC Press, Inc.: Boca Raton, FL, USA, 1999; pp. 421–436. [Google Scholar]

- Holley, R.A. Brochothrix. In Encyclopedia of Food Microbiology, 2nd ed.; Batt, C.A., Tortorello, M.L., Eds.; Academic Press: London, UK, 1981; pp. 331–334. [Google Scholar]

- Andersen, H.J.; Bertelson, G.; Skibsted, L.H. Salt effect on acid-catalyzed autoxidation of oxymyoglobin. Acta Chem. Scand. 1988, A42, 226. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.H.; Cassens, R.G. Nitrite binding sites on myoglobin. J. Food Sci. 1976, 41, 969. [Google Scholar] [CrossRef]

- Gassiot, M.; Masoliver, P. Commercial high pressure processing of ham and other sliced meat products at Esteban Espuña, SA. In Case Studies in Novel Food Processing Technologies: Innovations in Processing, Packaging, and Predictive Modelling; Doona, C.J., Kustin, K., Feeherry, F.E., Eds.; Woodhead Publishing: Sawston/Cambridge, UK, 2010; pp. 21–33. [Google Scholar]

- Pottier, L.; Villamonte, G.; de Lamballerie, M. Applications of high pressure for healthier foods. Curr. Opin. Food Sci. 2017, 16, 21–27. [Google Scholar] [CrossRef]

- Tonello-Samson, C. High Pressure Processing Commercial Developments: Global Market, Equipment and Applications in the Meat Industry. Eur. Symp. Food Saf. 2017. [Google Scholar] [CrossRef]

- Hiperbaric—Blog: Global Trends in High Pressure Processing (HPP) for 2019. Available online: https://blog.hiperbaric.com/en/global-trends-in-hpp-for-2019 (accessed on 29 December 2020).

- Cheftel, J.C. Review: High-pressure, microbial inactivation and food preservation. Food Sci. Technol. Intern. 1995, 1, 75–90. [Google Scholar] [CrossRef]

- Sukmanov, V.; Hanjun, M.; Li, Y.-P. Effect of high pressure processing on meat and meat products. A review. Ukr. Food J. 2019, 8, 448–469. [Google Scholar] [CrossRef]

- Katsaros, G.J.; Alexandrakis, Z.S.; Taoukis, P.S. Kinetic assessment of high pressure inactivation of different plant origin pectinmethylesterase enzymes. Food Eng. Rev. 2017, 9, 170–189. [Google Scholar] [CrossRef]

- Jofré, A.; Aymerich, T.; Grèbol, N.; Garriga, M. Efficiency of high hydrostatic pressure at 600 MPa against food-borne microorganisms by challenge tests on convenience meat products. LWT 2009, 42, 924–928. [Google Scholar] [CrossRef]

- Slongo, A.P.; Rosenthal, A.; Quaresma Camargo, L.M.; Deliza, R.; Mathias, S.P.; Falcão de Aragão, G.M. Modeling the growth of lactic acid bacteria in sliced ham processed by high hydrostatic pressure. LWT 2009, 42, 303–306. [Google Scholar] [CrossRef]

- O’Neill, C.M.; Cruz-Romero, M.C.; Duffy, G.; Kerry, J.P. Shelf life extension of vacuum-packed salt reduced frankfurters and cooked ham through the combined application of high pressure processing and organic acids. Food Pack. Shelf. Life 2018, 17, 120–128. [Google Scholar] [CrossRef]

- Hayman, M.M.; Baxter, I.; O’Riordan, P.J.; Stewart, C.M. Effects of high-pressure processing on the safety, quality, and shelf life of ready-to-eat meats. J. Food Prot. 2004, 67, 1709–1718. [Google Scholar] [CrossRef] [PubMed]

- Diez, A.M.; Santos, E.M.; Jaime, I.; Rovira, J. Effectiveness of combined preservation methods to extend the shelf life of Morcilla de Burgos. Meat Sci. 2009, 81, 171–177. [Google Scholar] [CrossRef] [PubMed]

- Pietrasik, Z.; Gaudette, N.J.; Johnston, S.P. The impact of high hydrostatic pressure on the functionality and consumer acceptability of reduced sodium naturally cured wieners. Meat Sci. 2017, 129, 127–134. [Google Scholar] [CrossRef]

- Garriga, M.; Grèbol, N.; Aymerich, M.T.; Monfort, J.M.; Hugas, M. Microbial inactivation after high-pressure processing at 600 MPa in commercial meat products over its shelf life. Innov. Food Sci. Emerg. Technol. 2004, 5, 451–457. [Google Scholar] [CrossRef]

- Huang, M.; Moreira, R.G.; Murano, E. Use of hydrostatic pressure to produce high quality and safe fresh pork sausage. J. Food Process. Preserv. 1999, 23, 265–284. [Google Scholar] [CrossRef]

- Cacace, F.; Bottani, E.; Rizzi, A.; Vignali, G. Evaluation of the economic and environmental sustainability of high pressure processing of foods. Innov. Food Sci. Emerg. 2020, 60, 102281. [Google Scholar] [CrossRef]

- Peleg, M. Texture Profile Analysis Parameters Obtained by an Instron Universal Testing Machine. J. Food Sci. 1976, 41, 721–722. [Google Scholar] [CrossRef]

- Baranyi, J.; Roberts, T.A. A dynamic approach to predicting bacterial growth in food. Int. J. Food Microbiol. 1994, 23, 277–294. [Google Scholar] [CrossRef]

- Gogou, E.; Katsaros, G.; Derens, E.; Alvarez, G.; Taoukis, P.S. Cold chain database development and application as a tool for the cold chain management and food quality evaluation. Int. J. Refrig. 2015, 52, 109–121. [Google Scholar] [CrossRef]

- Koutsoumanis, K.; Taoukis, P.S.; Nychas, G.J.E. Development of a Safety Monitoring and Assurance System for chilled food products. Int. J. Food Microbiol. 2005, 100, 253–260. [Google Scholar] [CrossRef] [PubMed]

- Cayré, M.E.; Garro, O.; Vignolo, G. Effect of storage temperature and as permeability of packaging film on the growth of lactic acid bacteria and Brochothrix thermosphacta in cooked meat emulsions. Food Microbiol. 2005, 22, 505–512. [Google Scholar] [CrossRef]

- Borch, E.; Kant-Muermans, M.L.; Blixt, Y. Bacterial spoilage of meat and cured meat products. Int. J. Food Microbiol. 1996, 33, 103–120. [Google Scholar] [CrossRef]

- Korkeala, H.J.; Björkroth, K.J. Spoilage and contamination of vacuum-packaged cooked sausages: A review. J. Food Prot. 1997, 60, 724–731. [Google Scholar] [CrossRef] [Green Version]

- Sofos, J.N. Microbial growth and its control in meat, poultry and fish. In Quality Attributes and Their Measurement in Meat, Poultry, and Fish Products; Pearson, A.M., Dutson, T.R., Eds.; Blackie Academic and Professional: Glasgow, UK, 1994; pp. 359–403. [Google Scholar]

- Hitchener, B.J.; Egan, A.F.; Rogers, P.J. Characteristics of lactic acid bacteria isolated from vacuum-packaged beef. J. Appl. Bacter. 1982, 52, 31–37. [Google Scholar] [CrossRef]

- García-Lopéz, M.L.; Prieto, M.; Otero, A. The Microbiology of Meat and Poultry; Davies, A., Board, R., Eds.; Blackie Academic and Professional: London, UK, 1998; pp. 1–34. [Google Scholar]

- Eakes, B.D.; Blumer, N.N.; Monroe, R.J. Effect of nitrate and nitrite on color and flavor of country-style ham. J. Food Sci. 1975, 40, 973–976. [Google Scholar] [CrossRef]

- Yuste, J.; Mor-Mur, M.; Capellas, M.; Pla, R. Listeria innocua and aerobic mesophiles during chill storage of inoculated mechanically recovered poultry meat treated with high hydrostatic pressure. Meat Sci. 1999, 53, 251–257. [Google Scholar] [CrossRef]

- Jimenez-Colmenero, F.; Fernandez, P.; Carballo, J.; Fernandez-Martin, F. High-pressure-cooked low-fat pork and chicken batters as affected by salt levels and cooking temperature. J. Food Sci. 1998, 63, 656–659. [Google Scholar] [CrossRef]

- Mor-Mur, Μ.; Yuste, J. High pressure processing applied to cooked sausage manufacture: Physical properties and sensory analysis. Meat Sci. 2003, 65, 1187–1191. [Google Scholar] [CrossRef]

- Dong, Q.; Tu, K.; Guo, Y.; Yang, J.; Wang, H.; Chen, Y. The effect of sodium nitrite on the textural properties of cooked sausage during cold storage. J. Texture Stud. 2007, 38, 537–554. [Google Scholar] [CrossRef]

- Taoukis, P.S.; Labuza, T.P.; Saguy, I.S. Kinetics of food deterioration and shelf life prediction. In Handbook of Food Engineering Practice; Valentas, K.J., Rotstein, E., Singh, R.P., Eds.; CRC: New York, NY, USA, 2007. [Google Scholar]

| Process Conditions | Sliced Cooked Ham | Sliced Cooked Turkey | Bratwurst Sausages | |||

|---|---|---|---|---|---|---|

| Organoleptic Scoring | Total Viable Count at t = 0 min (log CFU/g) | Organoleptic Scoring | Total Viable Count at t = 0 min (log CFU/g) | Organoleptic Scoring | Total Viable Count at t = 0 min (log CFU/g) | |

| Untreated | 9 | 3.7 | 9 | 2.9 | 9 | 4.2 |

| 400 MPa—25 °C—10 min | 8.5 | 3.1 | 8.5 | 2.6 | 8.5 | 3.0 |

| 500 MPa—25 °C—5 min | 8.5 | 3.0 | 8.5 | 2.4 | 8.5 | 2.5 |

| 500 MPa—25 °C—10 min | 7.5 | 2.2 | 7.5 | 2.0 | 7.5 | 2.1 |

| 600 MPa—25 °C—5 min | 8.5 | N.D. | 8.5 | 1.0 | 8.5 | 1.5 |

| 600 MPa—25 °C—10 min | 7 | N.D. | 7 | N.D. | 7 | N.D. |

| 700 MPa—25 °C—5 min | 6.5 | N.D. | 6.5 | N.D. | 6.5 | N.D. |

| Storage Temperature | Control Samples | Nitrite Enriched Samples | HP-Treated Samples | |||

|---|---|---|---|---|---|---|

| TVC | LAB | TVC | LAB | TVC | LAB | |

| 0 °C | 0.197 ± 0.008 | 0.149 ± 0.011 | 0.092 ± 0.006 | 0.118 ± 0.012 | 0.040 ± 0.007 | 0.071 ± 0.006 |

| 5 °C | 0.303 ± 0.031 | 0.505 ± 0.092 | 0.273 ± 0.041 | 0.454 ± 0.067 | 0.180 ± 0.010 | 0.174 ± 0.024 |

| 10 °C | 0.474 ± 0.081 | 0.651 ± 0.053 | 0.403 ± 0.087 | 0.607 ± 0.104 | 0.364 ± 0.014 | 0.241 ± 0.019 |

| 15 °C | 0.998 ± 0.138 | 1.368 ± 0.107 | 0.886 ± 0.099 | 1.334 ± 0.134 | 0.725 ± 0.093 | 0.803 ± 0.083 |

| Ea (kJ/mol) | 69.3 | 89.8 | 94.1 | 101.4 | 123.2 | 100.9 |

| Growth Rate Constants (days−1) for Lactic Acid Bacteria (LAB) | |||||||

|---|---|---|---|---|---|---|---|

| Storage Temperature | Sliced Cooked Ham | Sliced Cooked Turkey | Cooked Ham Cubes | ||||

| Control | HP 500 MPa | HP 600 MPa | Control | HP 600 MPa | Control | HP 600 MPa | |

| 0 °C | 0.109 ± 0.007 | 0.096 ± 0.011 | 0.024 ± 0.006 | 0.188 ± 0.031 | 0.025 ± 0.004 | 0.260 ± 0.012 | 0.083 ± 0.009 |

| 5 °C | 0.249 ± 0.024 | 0.115 ± 0.030 | 0.037 ± 0.004 | 0.300 ± 0.062 | 0.061 ± 0.010 | 0.418 ± 0.106 | 0.094 ± 0.018 |

| 10 °C | 0.509 ± 0.107 | 0.347 ± 0.027 | 0.154 ± 0.020 | 0.390 ± 0.071 | 0.150 ± 0.026 | 0.536 ± 0.097 | 0.158 ± 0.031 |

| 15 °C | 0.652 ± 0.122 | 0.532 ± 0.083 | 0.227 ± 0.039 | 0.535 ± 0.088 | 0.207 ± 0.041 | 1.143 ± 0.240 | 0.245 ± 0.057 |

| Ea (kJ/mol) | 79.8 | 81.5 | 106 | 44.5 | 94.2 | 61.1 | 49.2 |

| Meat Products Organoleptic Deterioration Rates | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Storage Temperature | Sliced Cooked Ham | Sliced Cooked Turkey | Cooked Ham Cubes | Bratwurst Sausages | ||||||

| Control | HP 500 MPa | HP 600 MPa | Control | HP 600 MPa | Control | HP 600 MPa | Control | Nitrite Enriched | HP 600 MPa | |

| 0 °C | 0.116 ± 0.007 | 0.069 ± 0.011 | 0.018 ± 0.004 | 0.185 ± 0.019 | 0.018 ± 0.005 | 0.357 ± 0.025 | 0.060 ± 0.009 | 0.208 ± 0.018 | 0.115 ± 0.024 | 0.039 ± 0.010 |

| 5 °C | 0.217 ± 0.014 | 0.083 ± 0.018 | 0.027 ± 0.008 | 0.294 ± 0.048 | 0.044 ± 0.007 | 0.556 ± 0.104 | 0.068 ± 0.012 | 0.259 ± 0.023 | 0.156 ± 0.022 | 0.072 ± 0.017 |

| 10 °C | 0.357 ± 0.027 | 0.250 ± 0.020 | 0.111 ± 0.019 | 0.385 ± 0.087 | 0.106 ± 0.023 | 0.714 ± 0.130 | 0.114 ± 0.029 | 0.383 ± 0.041 | 0.325 ± 0.051 | 0.203 ± 0.028 |

| 15 °C | 0.833 ± 0.120 | 0.385 ± 0.037 | 0.167 ± 0.034 | 0.556 ± 0.091 | 0.147 ± 0.033 | 1.667 ± 0.147 | 0.179 ± 0.034 | 0.585 ± 0.082 | 0.458 ± 0.060 | 0.335 ± 0.039 |

| Ea (kJ/mol) | 83 | 82 | 107 | 47 | 94 | 63 | 50 | 45.6 | 63.7 | 97.7 |

| Shelf Life (Days) of Meat Products | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Storage Temperature | Sliced Cooked Ham | Sliced Cooked Turkey | Cooked Ham Cubes | Bratwurst Sausages | ||||||

| Control | HP 500 MPa | HP 600 MPa | Control | HP 600 MPa | Control | HP 600 MPa | Control | Nitrite Enriched | HP 600 MPa | |

| 0 °C | 43 | 73 | 286 | 27 | 275 | 14 | 84 | 35 | 49 | 113 |

| 5 °C | 23 | 60 | 187 | 17 | 114 | 9 | 74 | 13 | 16 | 51 |

| 10 °C | 14 | 20 | 45 | 13 | 47 | 7 | 44 | 10 | 12 | 28 |

| 15 °C | 6 | 13 | 30 | 9 | 34 | 3 | 28 | 5 | 5 | 9 |

| Days | Sliced Cooked Ham | Sliced Cooked Turkey | |||

|---|---|---|---|---|---|

| Control | HP 500 MPa | HP 600 MPa | Control | HP 600 MPa | |

| Recommended handling conditions throughout the whole chain (cold chain at 4 °C) | 2.0 | 50 | 192 | 1.5 | 168 |

| Representative profile (Figure 8) | 3.5 | 52 | 201 | 2.0 | 176 |

| Best case t–T profile scenario (Figure 8) | 6.0 | 55 | 212 | 3.5 | 180 |

| Worst case t–T profile scenario (Figure 8) | 1.5 | 49 | 189 | −1.0 | 162 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katsaros, G.; Taoukis, P. Microbial Control by High Pressure Processing for Shelf-Life Extension of Packed Meat Products in the Cold Chain: Modeling and Case Studies. Appl. Sci. 2021, 11, 1317. https://doi.org/10.3390/app11031317

Katsaros G, Taoukis P. Microbial Control by High Pressure Processing for Shelf-Life Extension of Packed Meat Products in the Cold Chain: Modeling and Case Studies. Applied Sciences. 2021; 11(3):1317. https://doi.org/10.3390/app11031317

Chicago/Turabian StyleKatsaros, George, and Petros Taoukis. 2021. "Microbial Control by High Pressure Processing for Shelf-Life Extension of Packed Meat Products in the Cold Chain: Modeling and Case Studies" Applied Sciences 11, no. 3: 1317. https://doi.org/10.3390/app11031317

APA StyleKatsaros, G., & Taoukis, P. (2021). Microbial Control by High Pressure Processing for Shelf-Life Extension of Packed Meat Products in the Cold Chain: Modeling and Case Studies. Applied Sciences, 11(3), 1317. https://doi.org/10.3390/app11031317