Factors Affecting the Yield in Formation of Fat-Derived Fragrance Compounds by Yarrowia lipolytica Yeast

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Strains and Culture Mediums

2.3. Culture Conditions

2.4. Gamma-Decalactone Extraction and Quantification

2.5. Hexanal Extraction and Quantification

2.6. Measurement of Lipase Activity

2.7. Measurement of Lipoxygenase Activity

2.8. Determination of Biomass

2.9. Statistical Analysis

3. Results

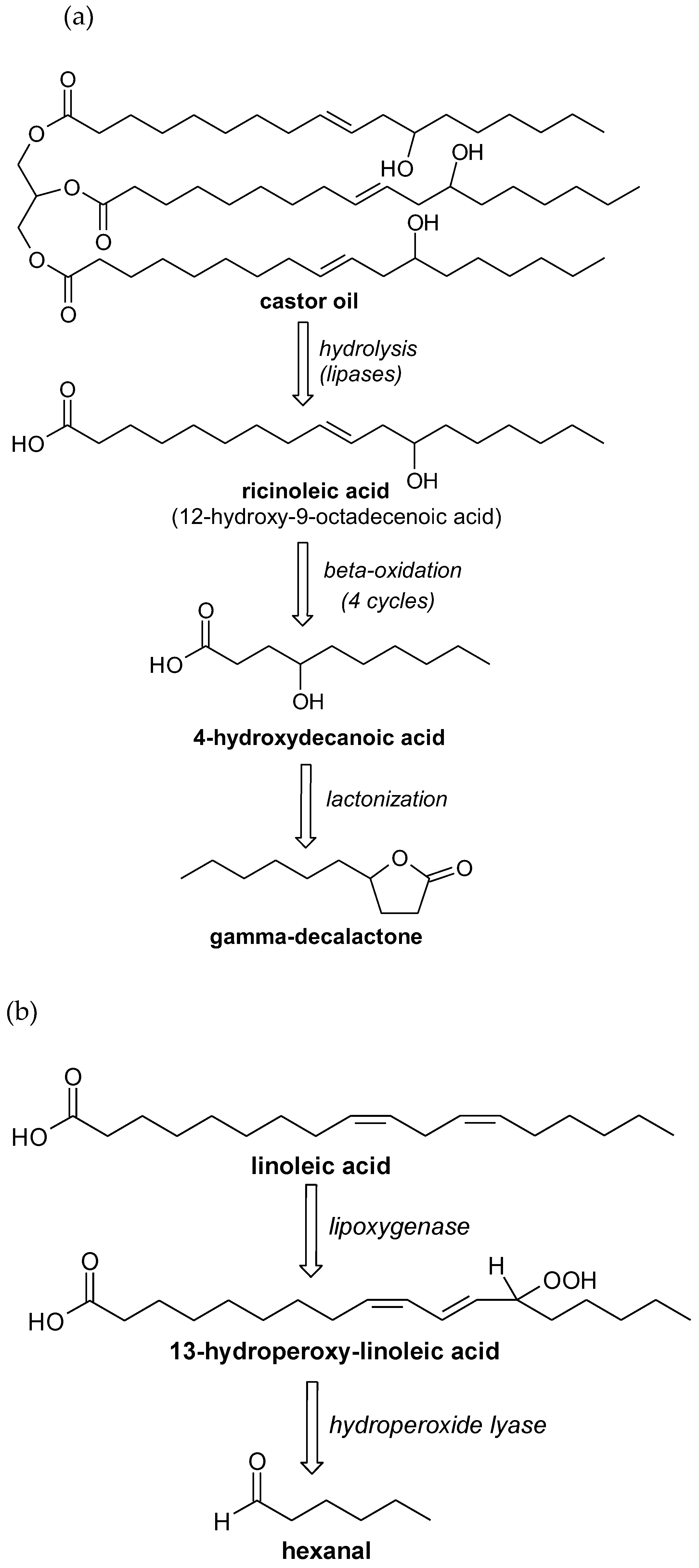

3.1. The Analysis of the Conditions for Gamma-Decalactone Biosynthesis

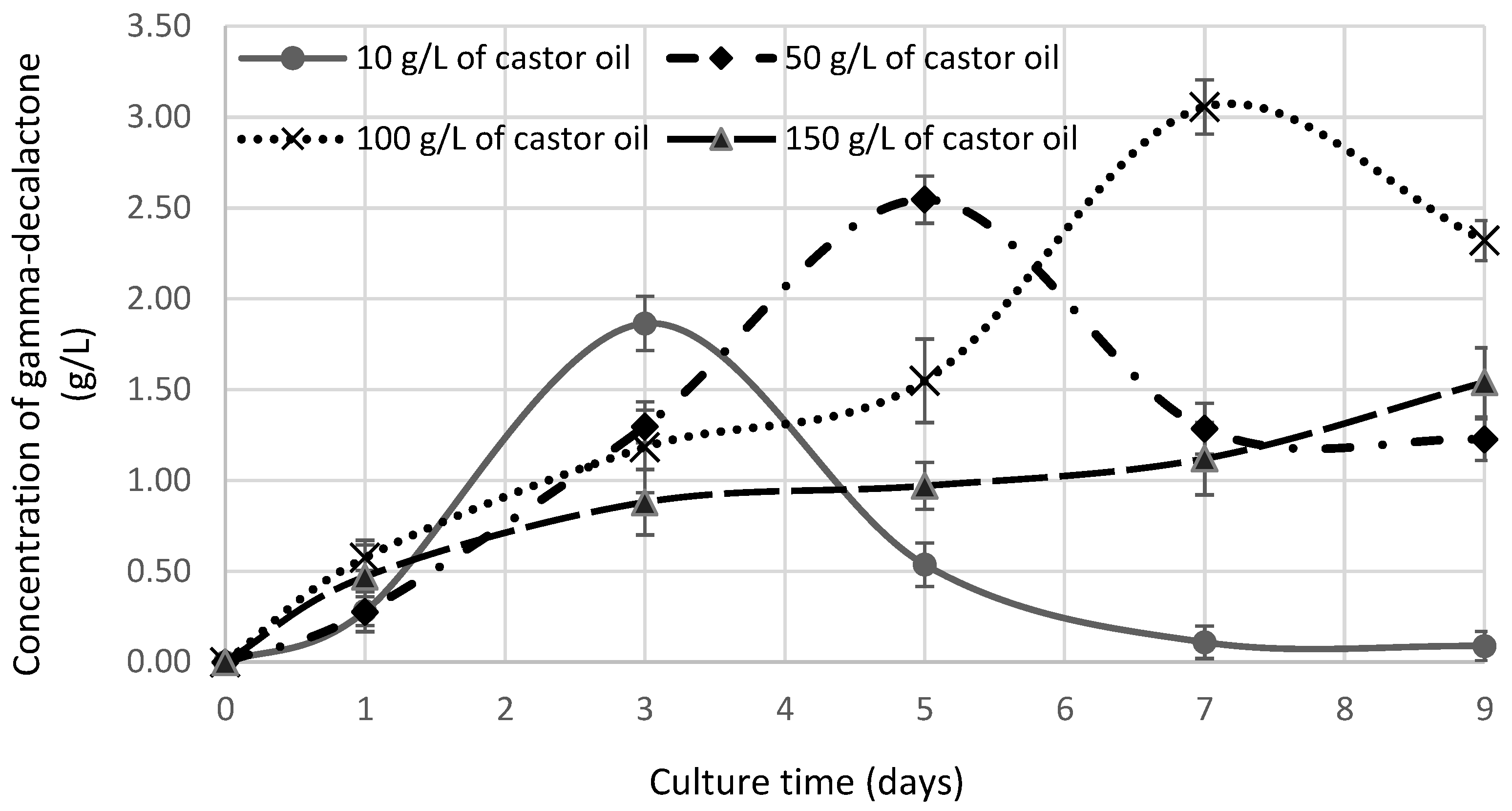

3.1.1. The Influence of Castor Oil Concentration on Gamma-Decalactone Production

3.1.2. Effect of Heptane Presence on Gamma-Decalactone Production

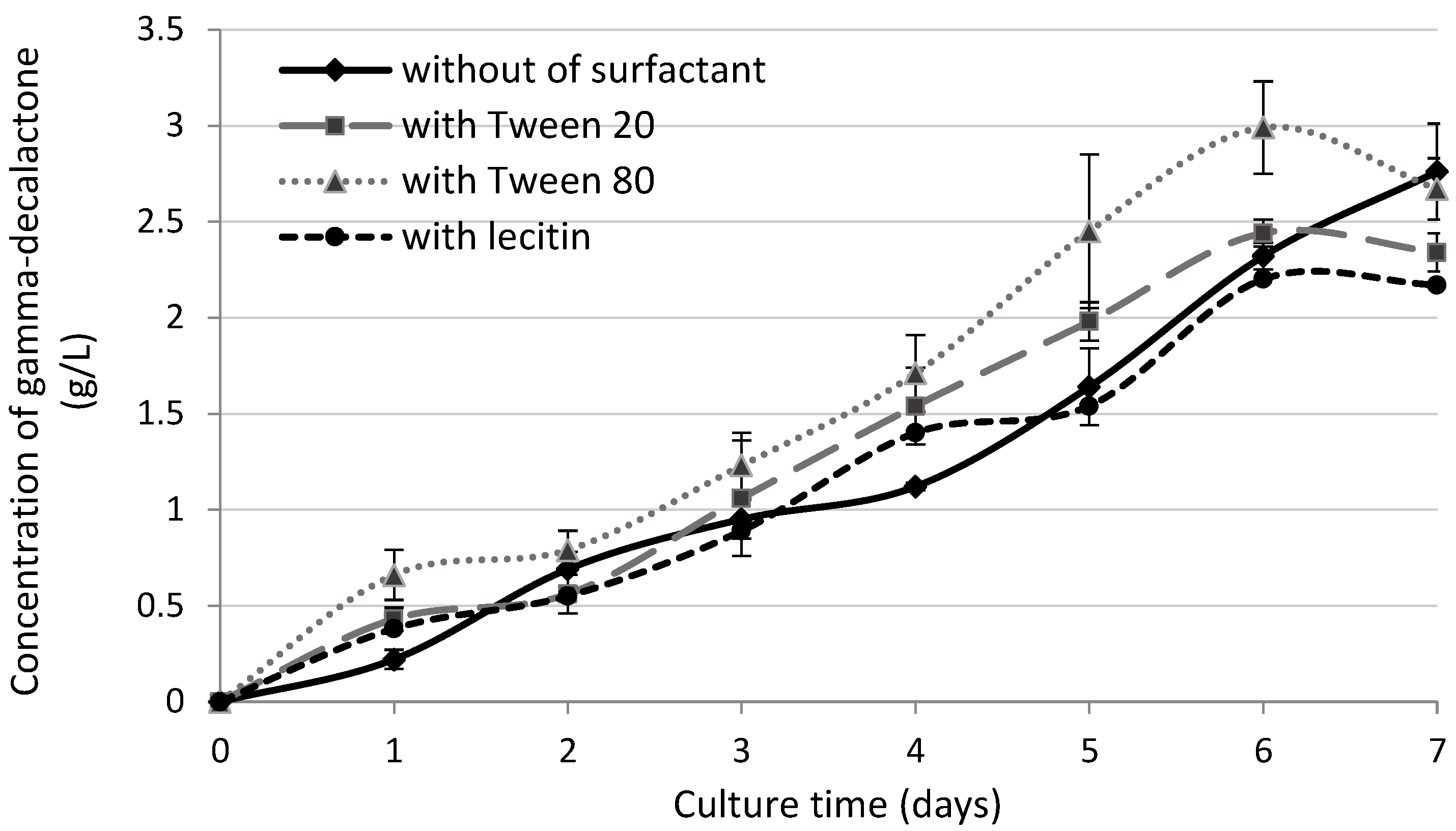

3.1.3. Effect of Surfactant Presence on Gamma-Decalactone Production

3.1.4. Effect of the Emulsification of the Medium on Gamma-Decalactone Production

3.1.5. Effect of Inoculum Size on Gamma-Decalactone Concentration

3.2. The Analysis of the Selected Conditions for Hexanal Biosynthesis

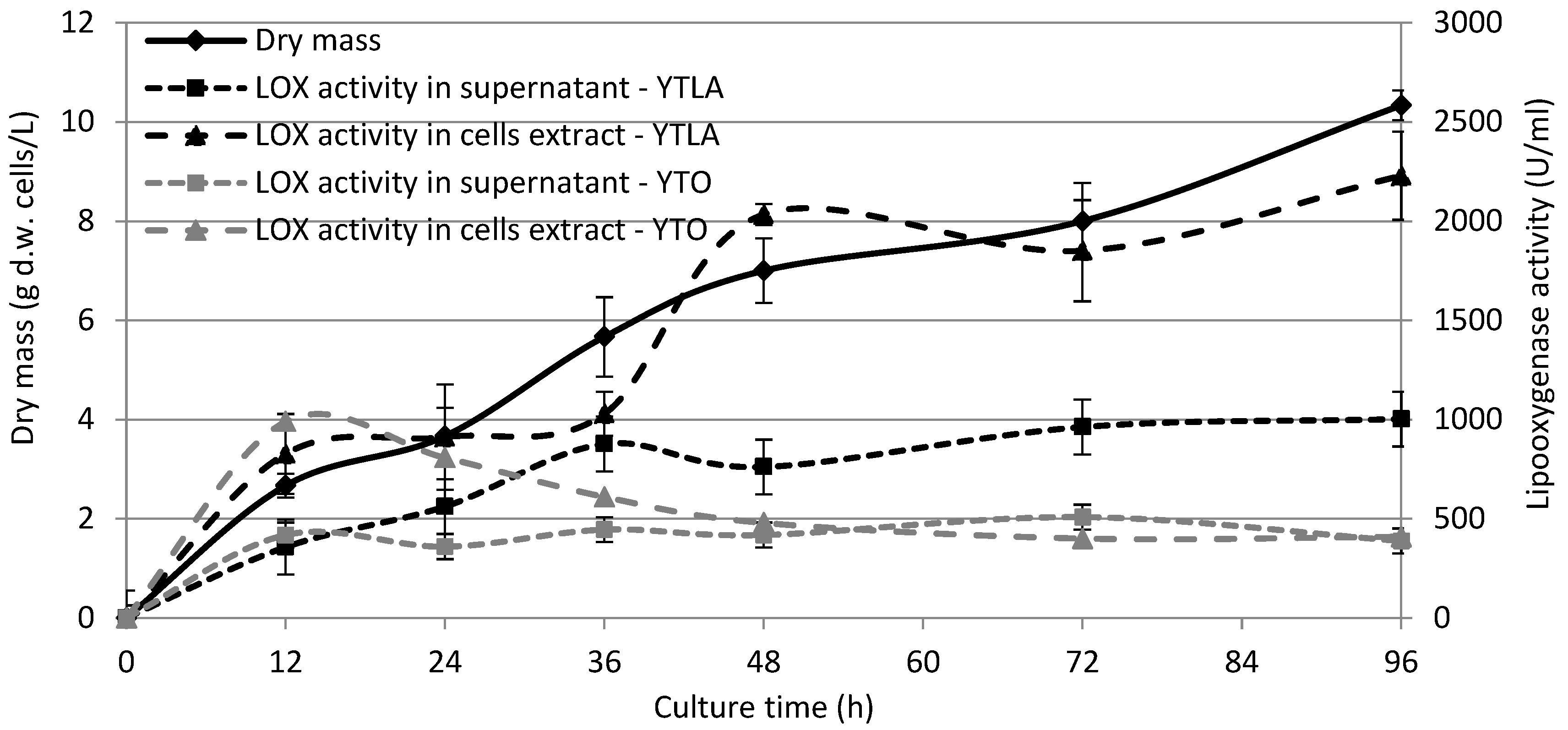

3.2.1. Lipooxygenase Activity and Hexanal Production in the Cellular Extract and Supernatant

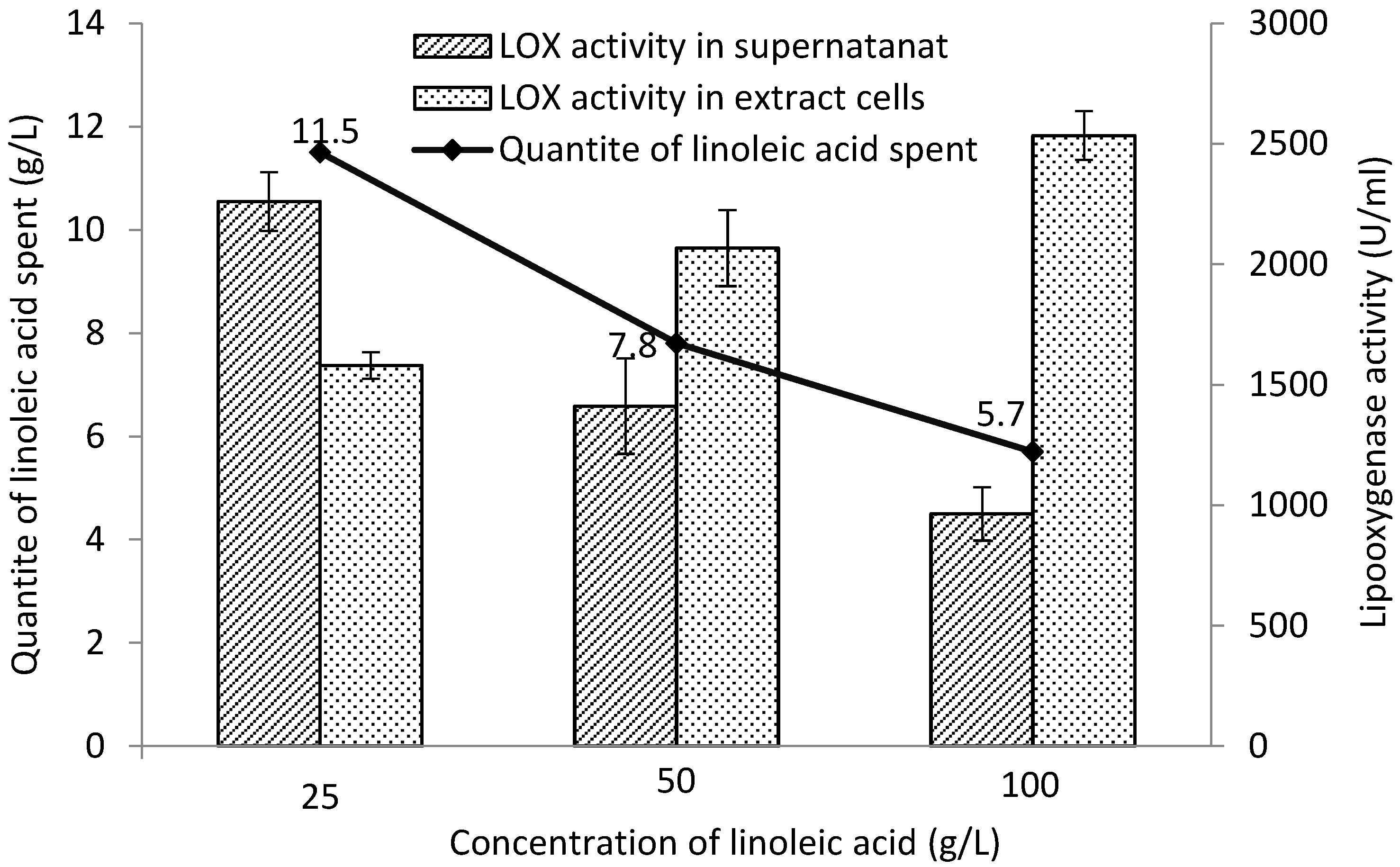

3.2.2. Effect of Linoleic Acid Concentration on Lipoxygenase Activity and Hexanal Production

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GDL | gamma-decalactone; |

| LOX | lipoxygenase; |

| HPL | hydroperoxide lyase; |

| CAGR | compound annual growth rate; |

| GRAS | generally recognized as safe; |

| FDA | Food and Drug Administration; |

| OD | optical density |

References

- Madzak, C. Engineering Yarrowia lipolytica for use in biotechnological applications: A review of major achievements and recent innovations. Mol. Biotechnol. 2018, 60, 621–635. [Google Scholar] [CrossRef]

- Yaguchi, A.; Spagnuolo, M.; Blenner, M. Engineering yeast for utilization of alternative feedstocks. Curr. Opin. Biotechnol. 2018, 53, 122–129. [Google Scholar] [CrossRef]

- Papanikolaou, S.; Diamantopoulou, P.; Blanchard, F.; Lambrinea, E.; Chevalot, I.; Stoforos, N.G.; Rondags, E. Physiological characterization of a novel wild-type Yarrowia lipolytica strain grown on glycerol: Effects of cultivation conditions and mode on polyols and citric acid production. Appl. Sci. 2020, 10, 7373. [Google Scholar] [CrossRef]

- Zinjarde, S.S. Food-related applications of Yarrowia lipolytica. Food Chem. 2014, 152, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, F.A.G.; Colen, G.; Takahashi, J.A. Yarrowia lipolytica and its multiple applications in the biotechnological industry. Sci. World J. 2014, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Groenewald, M.; Boekhout, T.; Neuvéglise, C.; Gaillardin, C.; van Dijck, P.W.M.; Wyss, M. Yarrowia lipolytica: Safety assessment of an oleaginous yeast with a great industrial potential. Crit. Rev. Microbiol. 2014, 40, 187–206. [Google Scholar] [CrossRef] [PubMed]

- Globe Newswire: Food Flavors Market to Reach USD 19.72 Billion By 2026. Available online: https://www.globenewswire.com/news-release/2019/10/10/1928250/0/en/Food-Flavors-Market-To-Reach-USD-19-72-Billion-By-2026-Reports-And-Data.html (accessed on 10 September 2021).

- Share & Trends Analysis Report 2019–2025. Flavors and Fragrances Market Size. Available online: https://www.grandviewresearch.com/industry-analysis/flavors-fragrances-market (accessed on 10 September 2021).

- Paulino, B.N.; Sales, A.; Felipe, L.; Pastore, G.M.; Molina, G.; Bicas, J.L. Recent advances in the microbial and enzymatic production of aroma compounds. Curr. Opin. Food Sci. 2021, 37, 98–106. [Google Scholar] [CrossRef]

- Janssens, L.; de Pooter, H.L.; Vandamme, E.J.; Schamp, N.M. Production of flavours by microorganisms. Process Biochem. 1992, 27, 195–215. [Google Scholar] [CrossRef]

- Krings, U.; Berger, R.G. Biotechnological production of flavours and fragrances. Appl. Microbiol. Biotechnol. 1998, 49, 1–8. [Google Scholar] [CrossRef]

- Vandamme, E.J.; Soetaert, W. Bioflavours and fragrances via fermentation and biocatalysis. J. Chem. Technol. Biotechnol. 2002, 77, 1323–1332. [Google Scholar] [CrossRef]

- Aguedo, M.; Ly, M.H.; Belo, I.; Teixeira, J.A.; Belin, J.M.; Waché, Y. The use of enzymes and microorganisms for the production of aroma compounds from lipids. Food Technol. Biotechnol. 2004, 42, 327–336. [Google Scholar] [CrossRef]

- Silva, R.; Coelho, E.; Aguiar, T.Q.; Domingues, L. Microbial biosynthesis of lactones: Gaps and opportunities towards sustainable production. Appl. Sci. 2021, 11, 8500. [Google Scholar] [CrossRef]

- Schrader, J.; Etschmann, M.M.W.; Sell, D.; Hilmer, J.M.; Rabenhorst, J. Applied biocatalysis for the synthesis of natural flavour compounds—Current industrial processes and future prospects. Biotechnol. Lett. 2004, 26, 463–472. [Google Scholar] [CrossRef]

- Burdock, G.A. Fenaroli’s Handbook of Flavor Ingredients, 6th ed.; CRC Press/Taylor & Francis Group: Boca Raton, FL, USA, 2010. [Google Scholar]

- Gopinath, M.; Vijayakumar, L.; Dhanasekar, R.; Viruthagiri, T. Microbial biosynthesis of γ-decalactone and its applications—A review. Glob. J. Biotechnol. Biochem. 2008, 3, 60–68. [Google Scholar]

- Blin-Perrin, C.; Molle, D.; Duffose, L.; Le-Quere, J.L.; Viel, C.; Mauvais, G.; Feron, G. Metabolism of ricinoleic acid into γ-decalactone: β-oxidation and long chain acyl intermedtaies of ricinoleic acid in the genus Sporidiobolus sp. FEMS Microbiol. Lett. 2000, 188, 69–74. [Google Scholar] [CrossRef]

- Romero-Guido, C.; Belo, I.; Ta, T.M.N.; Cao-Hoang, L.; Alchihab, M.; Gomes, N.; Thonart, P.; Teixeira, J.A.; Destain, J.; Waché, Y. Biochemistry of lactone formation in yeast and fungi and its utilisation for the production of flavor and fragrance compounds. Appl. Microbiol. Biotechnol. 2011, 89, 535–547. [Google Scholar] [CrossRef]

- Krzyczkowska, J.; Phan-Thi, H.; Waché, Y. Lactone formation in yeast and fungi. In Fungal Metabolites; Mérillon, M., Ramawat, K.G., Eds.; Springer: Cham, Switzerland, 2017; pp. 461–498. [Google Scholar] [CrossRef]

- Waché, Y.; Aguedo, M.; LeDall, M.T.; Nicaud, J.M.; Belin, J.M. Optimization of Yarrowia lipolytica’s β-oxidation pathway for γ-decalactone production. J. Mol. Catal. B Enzym. 2002, 19–20, 347–351. [Google Scholar] [CrossRef]

- Mitsuhashi, K.; Iimori, M. Method for Producing Lactone. U.S. Patent 7,129,067 B2, 31 October 2006. [Google Scholar]

- Lee, S.L.; Lin, S.J.; Chou, C.C. Production of γ-decalactone by Sporobolomyces odorus in jar fermentors as affected by pH, areation and fed-batch technique. J. Ferment. Bioeng. 1995, 80, 195–199. [Google Scholar] [CrossRef]

- Lee, S.L.; Cheng, H.Y.; Chen, W.C.; Chou, C.C. Effect of physical factors on the production of γ-decalactone by immobilized cells of Sporidiobolus salmonicolor. Process Biochem. 1999, 34, 845–850. [Google Scholar] [CrossRef]

- Alchihab, M.; Destain, J.; Aguedo, M.; Majad, L.; Ghalfi, H.; Wathelet, J.P.; Thonart, P. Production of γ-decalactone by a psychrophilic and mesophilic strain of the yeast Rhodotorula aurantica. Appl. Biochem. Biotechnol. 2009, 158, 41–50. [Google Scholar] [CrossRef]

- Waché, Y.; Husson, F.; Feron, G.; Belin, J.M. Yeast as an efficient biocatalyst for the production of lipid-derived flavours and fragrances. Antonie Van Leeuwenhoek 2006, 89, 405–416. [Google Scholar] [CrossRef] [PubMed]

- Akacha, N.B.; Gargouri, M. Microbial and enzymatic technologies used for the production of natural aroma compounds: Synthesis, recovery modeling, and bioprocesses. Food Bioprod. Process. 2015, 94, 675–706. [Google Scholar] [CrossRef]

- Fukushige, H.; Hildebrand, D.F. A Simple and efficient system for green note compound biogenesis by use of certain lipoxygenase and hydroperoxide lyase sources. J. Agric. Food Chem. 2005, 53, 6877–6882. [Google Scholar] [CrossRef] [PubMed]

- Schörken, U.; Kempers, P. Lipid biotechnology: Industrially relevant production processes. Eur. J. Lipid Sci. Technol. 2009, 111, 627–645. [Google Scholar] [CrossRef]

- Buchhaupt, M.; Guder, J.C.; Etschmann, M.M.W.; Schrader, J. Synthesis of green note aroma compounds by biotransformation of fatty acids using yeast cells coexpressing lipoxygenase and hydroperoxide lyase. Appl. Microbiol. Biotechnol. 2012, 93, 159–168. [Google Scholar] [CrossRef]

- Vogel, A.I.; Furniss, B.S.; Tatchell, A.R.; Hannaford, A.J.; Smith, P.W.G. Vogel’s Textbook of Practical Organic Chemistry, 5th ed.; Prentice Hall: New York, NY, USA, 1996. [Google Scholar]

- Gomes, M.; Aguedo, M.; Teixeira, J.; Belo, I. Oxygen mass transfer in a biphasic medium: Influence on the biotransformation of methyl ricinoleate into γ-decalactone by the yeast Yarrowia lipolytica. Biochem. Eng. J. 2007, 35, 380–386. [Google Scholar] [CrossRef] [Green Version]

- Fickers, P.; Benetti, P.H.; Waché, Y.; Marty, A.; Mauersberger, S.; Smit, M.S.; Nicaud, J.M. Hydrophobic substrate utilisation by the yeast Yarrowia lipolytica, and its potential applications. FEMS Yeast Res. 2005, 5, 527–543. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karlova, I.; Sjöblom, J. Surfactants used in food industry: A Review. J. Dispers. Sci. Technol. 2009, 30, 1363–1383. [Google Scholar] [CrossRef]

- Małajowicz, J.; Nowak, D.; Fabiszewska, A.U.; Iuliano, A. Comparison of gamma-decalactone biosynthesis by yeast Yarrowia lipolytica MTLY40-2p and W29 in batch-cultures. Biotechnol. Biotechnol. Equip. 2020, 34, 330–340. [Google Scholar] [CrossRef]

- Fabiszewska, A.U.; Białecka-Florjańczyk, E. Factors influencing synthesis of extracellular lipases by Yarrowia lipolytica in medium containing vegetable oils. J. Microbiol. Biotechnol. Food Sci. 2014, 3, 231–237. [Google Scholar] [CrossRef] [Green Version]

- Gomes, N.; Braga, A.; Teixeira, J.A.; Belo, I. Impact of lipase-mediated hydrolysis of castor oil on γ-decalactone production by Yarrowia lipolytica. J. Am. Oil Chem. Soc. 2013, 90, 1131–1137. [Google Scholar] [CrossRef] [Green Version]

- Groguenin, A.; Waché, Y.; Garcia, E.E.; Aguedo, M.; Husson, F.; LeDall, M.T.; Nicaud, J.M.; Belin, J.M. Genetic engineering of the β-oxidation pathway in the yeast Yarrowia lipolytica to increase the production of aroma compounds. J. Mol. Catal. B Enzym. 2004, 28, 75–79. [Google Scholar] [CrossRef]

- Gomes, N.; Teixeira, J.A.; Belo, I. The use of methyl ricinoleate in lactone production by Yarrowia lipolytica: Aspects of bioprocess operation that influence the overall performance. Biocatal. Biotransformations 2010, 28, 227–234. [Google Scholar] [CrossRef]

- Try, S.; De-Coninck, J.; Voilley, A.; Chunhieng, T.; Waché, Y. Solid state fermentation for the production of γ-decalactones by Yarrowia lipolytica. Process Biochem. 2018, 64, 9–15. [Google Scholar] [CrossRef]

- Braga, A.; Belo, I. Biotechnological production of γ-decalactone, a peach like aroma, by Yarrowia lipolytica. World J. Microbiol. Biotechnol. 2016, 32, 169. [Google Scholar] [CrossRef] [Green Version]

- Waché, Y.; Aguedo, M.; Choquet, A.; Gatfield, I.L.; Nicaud, J.M.; Belin, J.M. Role of β-oxidation enzymes in γ-decalactone production by the yeast Yarrowia lipolytica. Appl. Environ. Microbiol. 2001, 67, 5700–5704. [Google Scholar] [CrossRef] [Green Version]

- Davis, K.E.R.; Joseph, S.J.; Janssen, P.H. Effects of growth medium, inoculum size, and incubation time on culturability and isolation of soil bacteria. Appl. Environ. Microbiol. 2005, 71, 826–834. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.X.; Yue, Q.Y.; Gao, B.Y.; Wang, Y.; Li, Q.; Zhan, P.D. Research on microbial lipid production from potato starch wastewater as culture medium by Lipomyces starkeyi. Water Sci. Technol. 2013, 67, 1802–1808. [Google Scholar] [CrossRef]

- Bisakowski, B.; Atwal, A.S.; Kermasha, S. Characterization of lipoxygenase activity from a partially purified enzymic extract from Morchella esculenta. Process Biochem. 2000, 36, 1–7. [Google Scholar] [CrossRef]

- Bisakowski, B.; Kermasha, S.; Schuepp, C. Partial purification and some properties of lipoxygenase from Saccharomyces cerevisiae. World J. Microbiol. Biotechnol. 1995, 11, 494–496. [Google Scholar] [CrossRef] [PubMed]

- Márczy, J.S.Z.; Németh, A.S.Z.; Samu, Z.; Háger-Veress, A.; Szajáni, B. Production of hexanal from hydrolyzed sunflower oil by lipoxygenase and hydroperoxid lyase enzymes. Biotechnol. Lett. 2002, 24, 1673–1675. [Google Scholar] [CrossRef]

- Bourel, G.; Nicaud, J.M.; Nthangeni, B.; Santiago-Gomez, P.; Belin, J.M.; Husson, F. Fatty acid hydroperoxide lyase of green bell pepper: Cloning in Yarrowia ipolytica and biogenesis of volatile aldehydes. Enzym. Microb. Technol. 2004, 35, 293–299. [Google Scholar] [CrossRef]

- Schade, F.; Thompson, J.E.; Legge, R.L. Use of a plant-derived enzyme template for the production of the green-note volatile hexanal. Biotechnol. Bioeng. 2003, 84, 265–273. [Google Scholar] [CrossRef] [PubMed]

| Culture Time | Medium | Concentration of GDL L (g/L) | Lipolytic Activity (U/mL) | Biomass Yield X (gd.w./L) | Conversion Yield of GDL Per Biomass Formed YL/X (g/gd.w.) | Specific Rate of GDL Production qL (g/gd.w./h) |

|---|---|---|---|---|---|---|

| 3rd day | non-emulsfied | 2.02 ± 0.06 a | 0.13 ± 0.02 a | 21.85 ± 2.99 c | 0.092 a | 0.0013 b |

| emulsified | 1.66 ± 0.08 a | 1.46 ± 0.18 c | 8.48 ± 0.87 a | 0.196 c | 0.0027 d | |

| 7th day | non-emulsfied | 3.21 ± 0.14 b | 0.23 ± 0.04 b | 22.03 ± 3.08 c | 0.146 b | 0.0009 a |

| emulsified | 5.25 ± 0.10 c | 0.26 ± 0.05 b | 18.58 ± 1.55 b | 0.283 d | 0.0017 c |

| Inoculum Volume (mL/100 mL of Medium) | Concentration of Gamma-Decalactone (g/L) | ||||

|---|---|---|---|---|---|

| Culture Time (days) | |||||

| 1 | 2 | 3 | 5 | 7 | |

| 0.25 mL | 0.15 ± 0.02 | 0.48 ± 0.02 | 0.67 ± 0.01 | 1.00 ± 0.11 | 1.92 ± 0.14 |

| 0.5 mL | 0.14 ± 0.01 | 0.31 ± 0.03 | 0.45 ± 0.04 | 1.32 ± 0.14 | 2.10 ± 0.04 |

| 1 mL | 0.13 ± 0.04 | 0.45 ± 0.03 | 0.57 ± 0.02 | 1.71 ± 0.07 | 3.01 ± 0.15 |

| 2 mL | 0.11 ± 0.03 | 0.25 ± 0.09 | 0.64 ± 0.07 | 0.97 ± 0.01 | 1.29 ± 0.06 |

| 5 mL | 0.08 ± 0.01 | 0.21 ± 0.07 | 0.58 ± 0.10 | 0.95 ± 0.06 | 1.37 ± 0.08 |

| Culture Time (h) | Concentration of Hexanal (mg/L) | |

|---|---|---|

| Cellular Extract | Supernatant | |

| 12 | 120.14 ± 12.22 | 10.86 ± 2.01 |

| 24 | 137.09 ± 22.12 | 21.71 ± 2.33 |

| 36 | 281.07 ± 17.54 | 10.31 ± 1.87 |

| 48 | 352.09 ± 22.69 | 7.89 ± 0.87 |

| 72 | 290.46 ± 8.98 | 3.19 ± 0.65 |

| 96 | 241.32 ± 23.78 | 3.54 ± 1.03 |

| Concentration of Linoleic Acid (g/L) | Concentration of Hexanal (mg/L) | |

|---|---|---|

| Cellular Extract | Supernatant | |

| 25 | 38.68 ± 4.87 | 8.32 ± 2.22 |

| 50 | 163.82 ± 19.98 | 47.10 ± 8.81 |

| 100 | 189.44 ± 29.23 | 15.40 ± 4.46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Małajowicz, J.; Kozłowska, M. Factors Affecting the Yield in Formation of Fat-Derived Fragrance Compounds by Yarrowia lipolytica Yeast. Appl. Sci. 2021, 11, 9843. https://doi.org/10.3390/app11219843

Małajowicz J, Kozłowska M. Factors Affecting the Yield in Formation of Fat-Derived Fragrance Compounds by Yarrowia lipolytica Yeast. Applied Sciences. 2021; 11(21):9843. https://doi.org/10.3390/app11219843

Chicago/Turabian StyleMałajowicz, Jolanta, and Mariola Kozłowska. 2021. "Factors Affecting the Yield in Formation of Fat-Derived Fragrance Compounds by Yarrowia lipolytica Yeast" Applied Sciences 11, no. 21: 9843. https://doi.org/10.3390/app11219843

APA StyleMałajowicz, J., & Kozłowska, M. (2021). Factors Affecting the Yield in Formation of Fat-Derived Fragrance Compounds by Yarrowia lipolytica Yeast. Applied Sciences, 11(21), 9843. https://doi.org/10.3390/app11219843