Tribological and Thermal Transport of Ag-Vegetable Nanofluids Prepared by Laser Ablation

Abstract

1. Introduction

2. Materials and Methods

2.1. Nanofluids Preparation

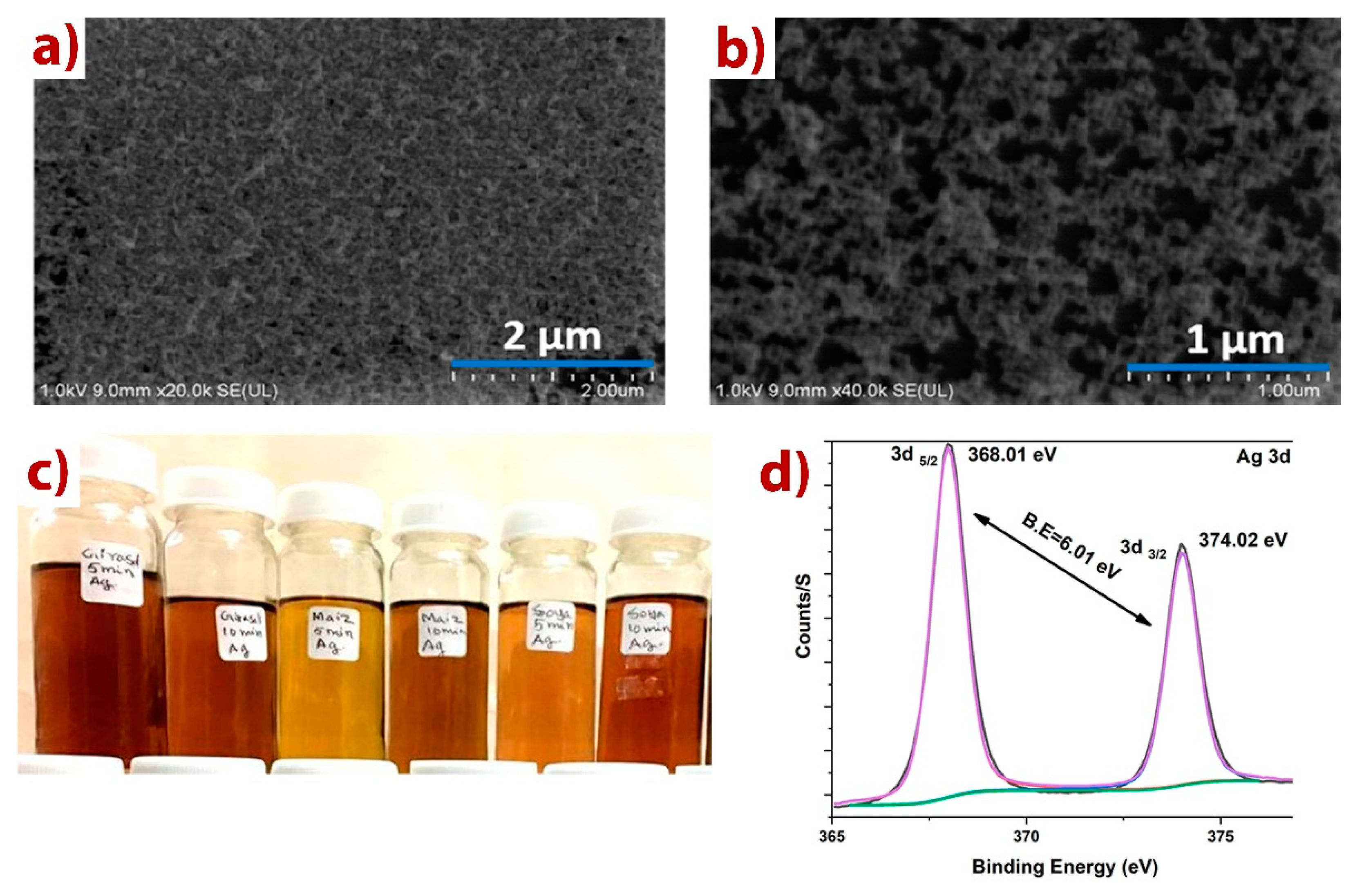

2.2. Morphology by SEM

2.3. Thermal Conductivity Characterization

2.4. Tribological Experimentation

3. Results

3.1. ICP-OES/Elemental Composition Analysis

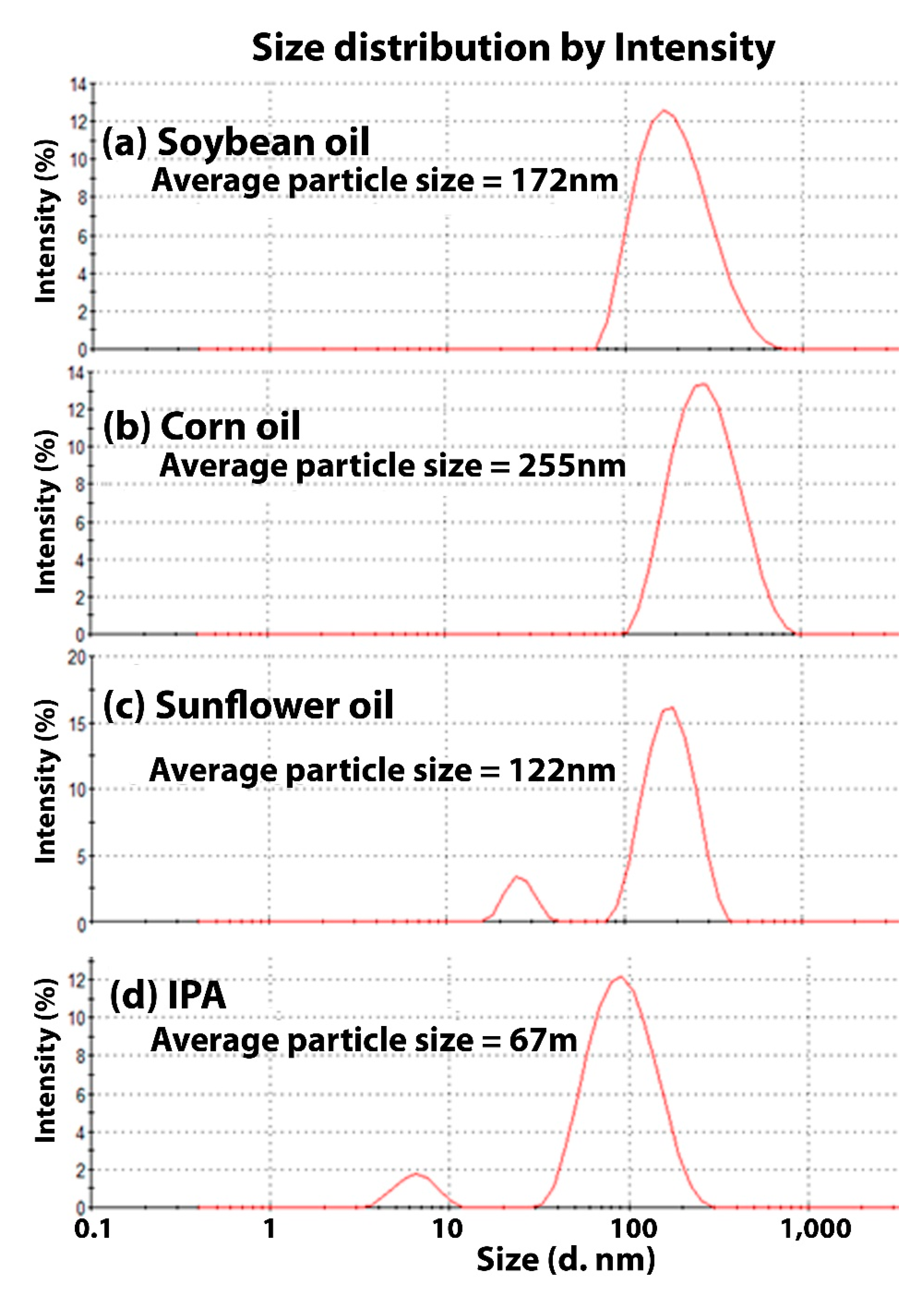

3.2. DLS Analysis/Average Size Determination by DLS

4. Results and Discussion

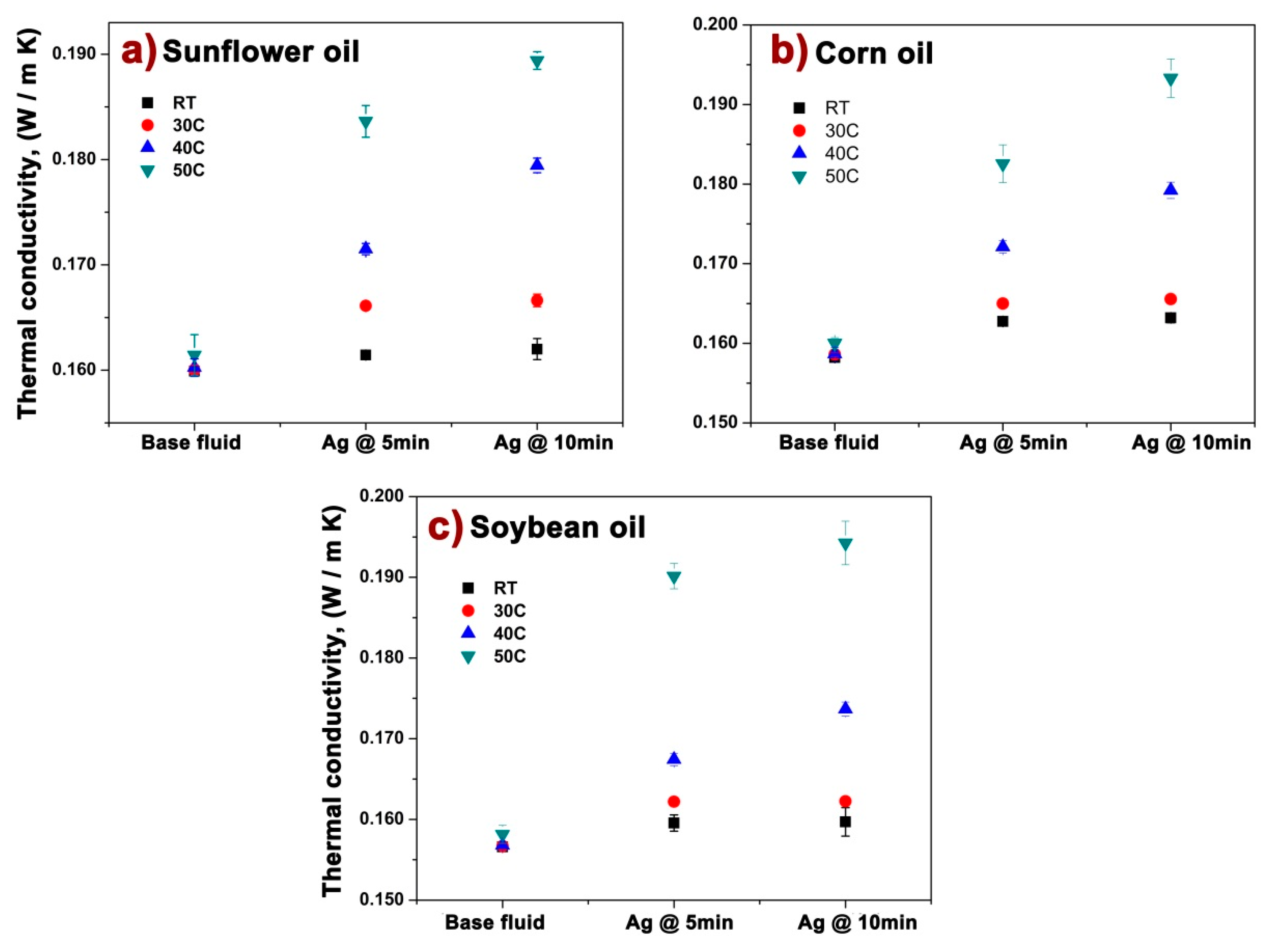

4.1. Thermal Performance

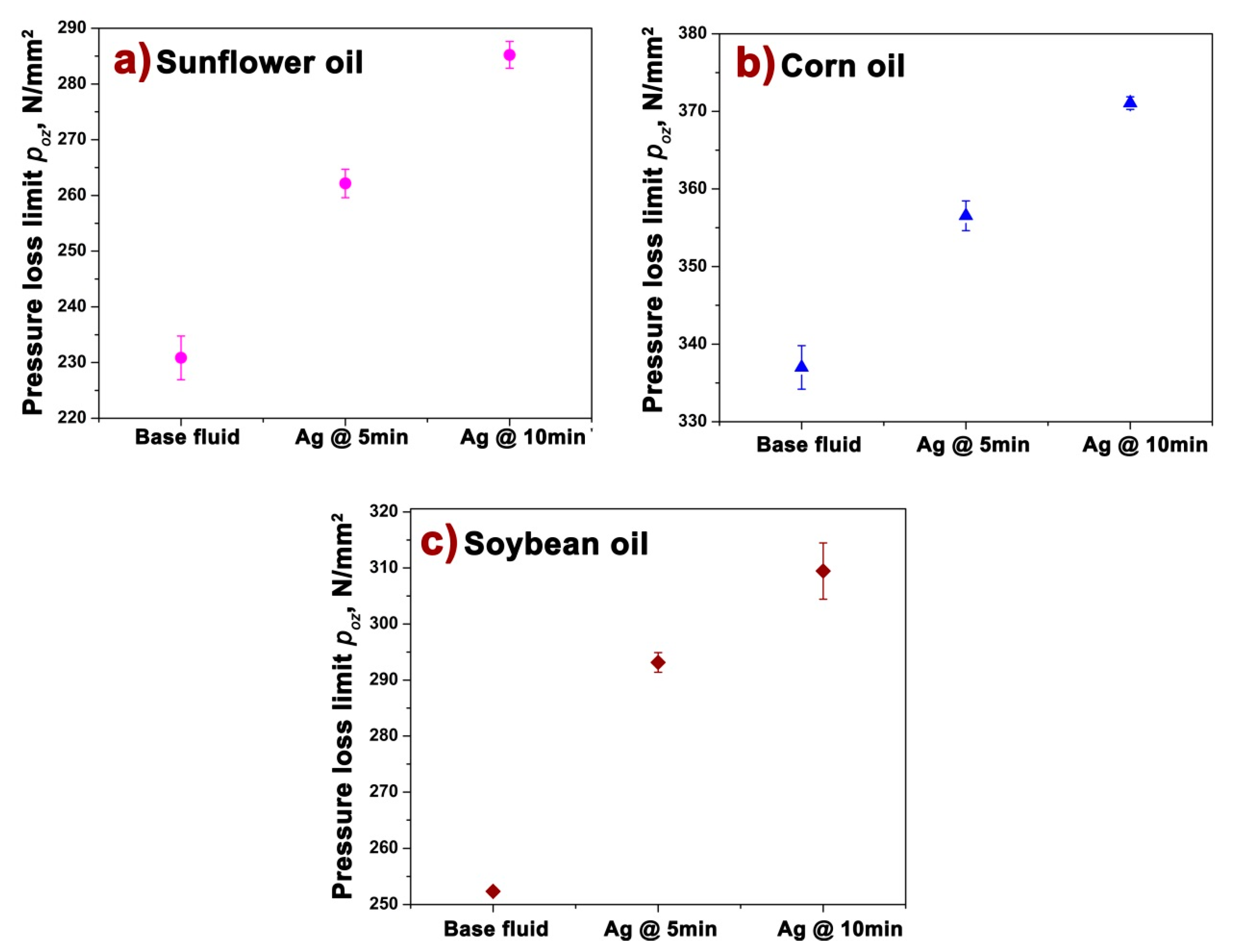

4.2. Tribological Performance

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Taha-Tijerina, J.; Aviña, K.; Diabb, J.M. Tribological and Thermal Transport Performance of SiO2-Based Natural Lubricants. Lubricants 2019, 7, 71. [Google Scholar] [CrossRef]

- Belluco, W.; De Chiffre, L. Surface integrity and part accuracy in reaming and tapping stainless steel with new vegetable based cutting oils. Tribol. Int. 2002, 35, 865–870. [Google Scholar] [CrossRef]

- Das, A.; Patel, S.K.; Das, S.R. Performance comparison of vegetable oil based nanofluids towards machinability improvement in hard turning of HSLA steel using minimum quantity lubrication. Mech. Ind. 2019, 20, 506. [Google Scholar] [CrossRef]

- Zubir, B.; Abdul, M.Z.; Abd, A.F.; Said, M.S. The effect of cutting fluid condition on surface roughness in turning of alloy steel. In Advanced Engineering for Processes and Technologies; Ismail, A., Abu Bakar, M., Öchsner, A., Eds.; Springer: Cham, Switzerland, 2019; pp. 297–305. [Google Scholar]

- Taha-Tijerina, J.J. Thermal transport and Challenges on Nanofluids Performance. In Microfluidics and Nanofluidics; Kandelousi, M.S., Ed.; InTech: Rijeka, Croatia, 2018; pp. 215–256. [Google Scholar]

- Altavilla, C.; Sarno, M.; Ciambelli, P.; Senatore, A.; Petrone, V. New “chimie douce” approach to the synthesis of hybrid nanosheets of MoS2 on CNT and their anti-friction and anti-wear properties. Nanotechnology 2013, 24, 125601. [Google Scholar] [CrossRef]

- Shashidhara, Y.M.; Jayaram, S.R. Vegetable oils as a potential cutting fluid-An evolution. Tribol. Int. 2010, 43, 1073–1081. [Google Scholar] [CrossRef]

- Koh, M.Y.; Ghazi, T.I.M.; Idris, A. Synthesis of palm based biolubricant in an oscillatory flow reactor (OFR). Ind. Crops Prod. 2014, 52, 567–574. [Google Scholar] [CrossRef]

- Heikal, E.K.; Elmelawy, M.S.; Khalil, S.A.; Elbasuny, N.M. Manufacturing of environment friendly biolubricants from vegetable oils. Egypt. J. Pet. 2017, 26, 53–59. [Google Scholar] [CrossRef]

- Krolczyk, G.M.; Maruda, R.W.; Krolczyk, J.B.; Wojciechowski, S.; Mia, M.; Nieslony, P.; Budzik, G. Ecological trends in machining as a key factor in sustainable production—A review. Clean. Prod. 2019, 218, 601–615. [Google Scholar] [CrossRef]

- Xavior, M.A.; Adithan, M. Determining the influence of cutting fluids on tool wear and surface roughness during turning of AISI 304 austenitic stainless steel. J. Mater. Process. Technol. 2009, 209, 900–909. [Google Scholar] [CrossRef]

- Benedicto, E.; Carou, D.; Rubio, E.M. Technical, Economic and Environmental Review of the Lubrication/Cooling Systems used in Machining Processes. Procedia Eng. 2017, 184, 99–116. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Maldonado-Cortés, D.; Taha-Tijerina, J. Eco-Friendly Nanoparticle Additives for Lubricants and Their Tribological Characterization. In Handbook of Ecomaterials; Torres Martínez, L.M., Kharissova, O.V., Kharisov, B.I., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–21. [Google Scholar]

- Taha-Tijerina, J.; Narayanan, T.N.; Avali, S.; Ajayan, P.M. 2D Structures-based Energy Management Nanofluids. In Proceedings of the ASME 2012 International Mechanical Engineering Congress & Exposition IMECE, Houston, TX, USA, 9–15 November 2012. IMECE 2012-87890. [Google Scholar]

- Nagendramma, P.; Kumar, P. Eco-Friendly Multipurpose Lubricating Greases from Vegetable Residual Oils. Lubricants 2015, 3, 628–636. [Google Scholar] [CrossRef]

- Karmakar, G.; Ghosh, P.; Sharma, B. Chemically Modifying Vegetable Oils to Prepare Green Lubricants. Lubricants 2017, 5, 44. [Google Scholar] [CrossRef]

- Liu, Z.; Sharma, B.K.; Erhan, S.Z.; Biswas, A.; Wang, R.; Schuman, T.P. Oxidation and low temperature stability of polymerized soybean oil-based lubricants. Thermochim. Acta 2015, 601, 9–16. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Franco, J.M.; Spikes, H.A.; Gallegos, C. Low-temperature flow behaviour of vegetable oil-based lubricants. Ind. Crops Prod. 2012, 37, 383–388. [Google Scholar] [CrossRef]

- Erhan, S.Z.; Sharma, B.K.; Perez, J.M. Oxidation and low temperature stability of vegetable oil-based lubricants. Ind. Crops Prod. 2006, 24, 292–299. [Google Scholar] [CrossRef]

- Reeves, C.J.; Siddaiah, A.; Menezes, P.L. A Review on the Science and Technology of Natural and Synthetic Biolubricants. J. Bio- Tribo-Corrosion 2017, 3, 11. [Google Scholar] [CrossRef]

- Somashekaraiah, R.; Gnanadhas, D.P.; Kailas, S.V.; Chakravortty, D. Eco-Friendly, Non-Toxic Cutting Fluid for Sustainable Manufacturing and Machining Processes. Tribol. Online 2016, 11, 556–567. [Google Scholar] [CrossRef]

- Kumar, N. Oxidative stability of biodiesel: Causes, effects and prevention. Fuel 2017, 190, 328–350. [Google Scholar] [CrossRef]

- Fox, N.J.; Stachowiak, G.W. Vegetable oil-based lubricants-A review of oxidation. Tribol. Int. 2007, 40, 1035–1046. [Google Scholar] [CrossRef]

- Syahrullail, S.; Kamitani, S.; Shakirin, A. Performance of vegetable oil as lubricant in extreme pressure condition. Procedia Eng. 2013, 68, 172–177. [Google Scholar] [CrossRef]

- Tripathi, A.; Vinu, R. Characterization of Thermal Stability of Synthetic and Semi-Synthetic Engine Oils. Lubricants 2015, 3, 54–79. [Google Scholar] [CrossRef]

- Zainal, N.A.; Zulkifli, N.W.M.; Gulzar, M.; Masjuki, H.H. A review on the chemistry, production, and technological potential of bio-based lubricants. Renew. Sustain. Energy Rev. 2018, 82, 80–102. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Sarno, M.; Senatore, A.; Spina, D.; Mustafa, W.A.A. A Tribochemical Boost for Cu Based Lubricant Nano-Additive. Key Eng. Mater. 2019, 813, 292–297. [Google Scholar] [CrossRef]

- Kumar, K.; Ravi, M. Past and Current Status of Eco-Friendly Vegetable Oil Based Metal Cutting Fluids. Mater. Today Proc. 2017, 4, 3786–3795. [Google Scholar] [CrossRef]

- Rapeti, P.; Pasam, V.K.; Rao, K.M.; Revuru, R.S. Performance evaluation of vegetable oil based nano cutting fluids in machining using grey relational analysis-A step towards sustainable manufacturing. J. Clean. Prod. 2018, 172, 2862–2875. [Google Scholar] [CrossRef]

- Wagner, H.; Luther, R.; Mang, T. Lubricant base fluids based on renewable raw materials: Their catalytic manufacture and modification. Appl. Catal. A Gen. 2001, 221, 429–442. [Google Scholar] [CrossRef]

- Abdalla, H.S.; Patel, S. The performance and oxidation stability of sustainable metalworking fluid derived from vegetable extracts. Proc. Inst. Mech Eng. Part. B J. Eng. Manuf. 2006, 220, 2027–2040. [Google Scholar] [CrossRef]

- Mannekote, J.K.; Kailas, S.V. The Effect of Oxidation on the Tribological Performance of Few Vegetable Oils. J. Mater. Res. Technol. 2012, 1, 91–95. [Google Scholar] [CrossRef]

- Barcikowski, S.; Amendola, V.; Marzun, G.; Rehbock, C.; Reichenberger, S.; Zhang, D.; Gökce, B. Handbook of Laser Synthesis of Colloids; Universität Duisburg-Essen: Duisburg, Germany, 2016; 150p. [Google Scholar]

- Yang, G. Laser Ablation in Liquids: Principles and Applications in the Preparation of Nanomaterials; Pan Standford Publishing: Singapore, 2012. [Google Scholar]

- Zhang, D.; Gökce, B.; Barcikowski, S. Laser Synthesis and Processing of Colloids: Fundamentals and Applications. Chem. Rev. 2017, 117, 3990–4103. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, J.; Li, P.; Tian, Z.; Liang, C. Recent Advances in Surfactant-Free, Surface-Charged, and Defect- Rich Catalysts Developed by Laser Ablation and Processing in Liquids. ChemNanoMat 2017, 3, 512–533. [Google Scholar] [CrossRef]

- Johny, J.; Sepulveda, G.S.; Krishnan, B.; Avellaneda, D.; Shaji, S. Nanostructured SnS2 Thin Films from Laser Ablated Nanocolloids: Structure, Morphology, Optoelectronic and Electrochemical Properties. ChemPhysChem 2018, 19, 2902–2914. [Google Scholar] [CrossRef] [PubMed]

- Kozuka, H.; Yamano, A.; Fujita, M.; Uchiyama, H. Aqueous dip-coating route to dense and porous silica thin films using silica nanocolloids with an aid of polyvinylpyrrolidone. J. Sol-Gel Sci. Technol. 2012, 61, 381–389. [Google Scholar] [CrossRef]

- Zuñiga-Ibarra, V.A.; Shaji, S.; Krishnan, B.; Johny, J.; Sharma, K.S.; Avellaneda, D.A.; Martinez, J.A.A.; Roy, T.K.D.; Ramos-Delgado, N.A. Synthesis and characterization of black TiO2 nanoparticles by pulsed laser irradiation in liquid. Appl. Surf. Sci. 2019, 483, 156–164. [Google Scholar] [CrossRef]

- Shaji, S.; Vinayakumar, V.; Krishnan, B.; Johny, J.; Sharma, K.S.; Flores, J.M.; Sepulveda, S.; Avellaneda, D.A.; Castillo, G.A.; Aguilar, J.A. Copper antimony sulfide nanoparticles by pulsed laser ablation in liquid and their thin film for photovoltaic application. Appl. Surf. Sci. 2019, 476, 94–106. [Google Scholar] [CrossRef]

- Rodriguez-Vela, D.L.; Krishnan, B.; Aguilar-Martinez, J.A.; Loredo, S.L.; Shaji, S. AgSb(SxSe1-x)2 thin films by rapid thermal processing of Sb2 S3-Ag-Se thin films for photovoltaic applications. Phys. Status Solidi 2016, 13, 47–52. [Google Scholar]

- Ganguly, S.; Das, P.; Bose, M.; Das, T.K.; Mondal, S.; Das, A.K.; Das, N.C. Sonochemical green reduction to prepare Ag nanoparticles decorated graphene sheets for catalytic performance and antibacterial application. Ultrason. Sonochem. 2017, 39, 577–588. [Google Scholar] [CrossRef]

- Lokhande, A.C.; Babar, P.T.; Karade, V.C.; Jang, J.S.; Lokhande, V.C.; Lee, D.J.; Kim, I.C.; Patole, S.P.; Qattan, I.A.; Lokhande, C.D.; et al. A viable green route to produce Ag nanoparticles for antibacterial and electrochemical supercapacitor applications. Mater. Today Chem. 2019, 14, 100181. [Google Scholar] [CrossRef]

- Szczerek, M.; Tuszynski, W. A method for testing lubricants under conditions of scuffing. Part, I. Presentation of the method. Tribotest 2002, 8, 273–284. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Taha-Tijerina, J.; García, A.; Maldonado, D.; Nájera, A.; Cantú, P.; Ortiz, D. Thermal transport and tribological properties of nanogreases for metal-mechanic applications. Wear 2015, 332–333, 1322–1326. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Peña-Paras, L.; Narayanan, T.N.; Garza, L.; Lapray, C.; Gonzalez, J.; Palacios, E.; Molina, D.; García, A.; Maldonado, D.; et al. Multifunctional nanofluids with 2D nanosheets for thermal and tribological management. Wear 2013, 302, 1241–1248. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Taha-Tijerina, J.; García, A.; Maldonado, D.; González, J.A.; Molina, D.; Palacios, E.; Cantú, P. Antiwear and Extreme Pressure Properties of Nanofluids for Industrial Applications. Tribol. Trans. 2014, 57, 1072–1076. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.; Castaños-Guitrón, B.; Peña-Parás, L.; Tovar-Padilla, M.; Alvarez-Quintana, J.; Maldonado-Cortés, D. Impact of silicate contaminants on tribological and thermal transport performance of greases. Wear 2019, 426–427, 862–867. [Google Scholar] [CrossRef]

- Kanakkillam, S.S.; Shaji, S.; Krishnan, B.; Vazquez-Rodriguez, S.; Martinez, J.A.A.; Palma, M.I.M.; Avellaneda, D.A. Nanoflakes of zinc oxide:cobalt oxide composites by pulsed laser fragmentation for visible light photocatalysis. Appl. Surf. Sci. 2020, 501, 144223. [Google Scholar] [CrossRef]

- LotfizadehDehkordi, B.; Kazi, S.N.; Hamdi, M.; Ghadimi, A.; Sadeghinezhad, E.; Metselaar, H.S.C. Investigation of viscosity and thermal conductivity of alumina nanofluids with addition of SDBS. Heat Mass Transf. 2013, 49, 1109–1115. [Google Scholar] [CrossRef]

- Taha-Tijerina, J.J.; Narayanan, T.N.; Tiwary, C.S.; Lozano, K.; Chipara, M.; Ajayan, P.M. Nanodiamond-based thermal fluids. ACS Appl. Mater. Interfaces 2014, 6, 4778–4785. [Google Scholar] [CrossRef] [PubMed]

- Taha-Tijerina, J.; Narayanan, T.N.; Gao, G.; Rohde, M.; Tsentalovich, D.A.; Pasquali, M.; Ajayan, P.M. Electrically insulating thermal nano-oils using 2D fillers. ACS Nano 2012, 6, 1214–1220. [Google Scholar] [CrossRef]

- Jang, S.P.; Choi, S.U.S. Role of Brownian motion in the enhanced thermal conductivity of nanofluids. Appl. Phys. Lett. 2004, 84, 4316. [Google Scholar] [CrossRef]

- Azmi, W.H.; Sharma, K.V.; Mamat, R.; Najafi, G.; Mohamad, M.S. The enhancement of effective thermal conductivity and effective dynamic viscosity of nanofluids—A review. Renew. Sust. Energ. Rev. 2016, 53, 1046–1058. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of Nanoparticles in Lubricating Oil: A Critical Review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

| Materials | Properties | ||||

|---|---|---|---|---|---|

| Vegetable Fluids | Density @ 20 °C (g/cm3) | Viscosity @ 24 °C (m Pa s) | Viscosity @ 40 °C (m Pa s) | Viscosity @ 100 °C (m Pa s) | Refractive Index |

| Soybean Oil | 0.9604 | 54.3 | 32.93 | 6.79 | 1.47 |

| Corn Oil | 0.9100 | 52.3 | 30.8 | 6.57 | 1.40 |

| Sunflower Oil | 0.9197 | 68.0 | 40.05 | 8.65 | 1.70 |

| Parameters | ITEePib Polish Method |

|---|---|

| Time | 18 s |

| Temperature (°C) | 24 ± 1 |

| Velocity (RPM) | 500 |

| Applied Force (N) | 0–7200 (linear increment) |

| Pure | Ag | ||

|---|---|---|---|

| 5 min | 10 min | ||

| COF-µ | |||

| Soybean Oil | 0.0385 ± 0.0009 | 0.0365 ± 0.0004 | 0.0345 ± 0.0004 |

| Corn Oil | 0.0485 ± 0.0006 | 0.0467 ± 0.0004 | 0.0445 ± 0.0003 |

| Sunflower Oil | 0.0437 ± 0.0005 | 0.0402 ± 0.0003 | 0.0372 ± 0.0003 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taha-Tijerina, J.; Shaji, S.; Sharma Kanakkillam, S.; Mendivil Palma, M.I.; Aviña, K. Tribological and Thermal Transport of Ag-Vegetable Nanofluids Prepared by Laser Ablation. Appl. Sci. 2020, 10, 1779. https://doi.org/10.3390/app10051779

Taha-Tijerina J, Shaji S, Sharma Kanakkillam S, Mendivil Palma MI, Aviña K. Tribological and Thermal Transport of Ag-Vegetable Nanofluids Prepared by Laser Ablation. Applied Sciences. 2020; 10(5):1779. https://doi.org/10.3390/app10051779

Chicago/Turabian StyleTaha-Tijerina, Jaime, Sadasivan Shaji, Sreed Sharma Kanakkillam, Maria Isabel Mendivil Palma, and Karla Aviña. 2020. "Tribological and Thermal Transport of Ag-Vegetable Nanofluids Prepared by Laser Ablation" Applied Sciences 10, no. 5: 1779. https://doi.org/10.3390/app10051779

APA StyleTaha-Tijerina, J., Shaji, S., Sharma Kanakkillam, S., Mendivil Palma, M. I., & Aviña, K. (2020). Tribological and Thermal Transport of Ag-Vegetable Nanofluids Prepared by Laser Ablation. Applied Sciences, 10(5), 1779. https://doi.org/10.3390/app10051779