Tribological Investigation on the Friction and Wear Behaviors of Biogenic Lubricating Greases in Steel–Steel Contact

Abstract

1. Introduction

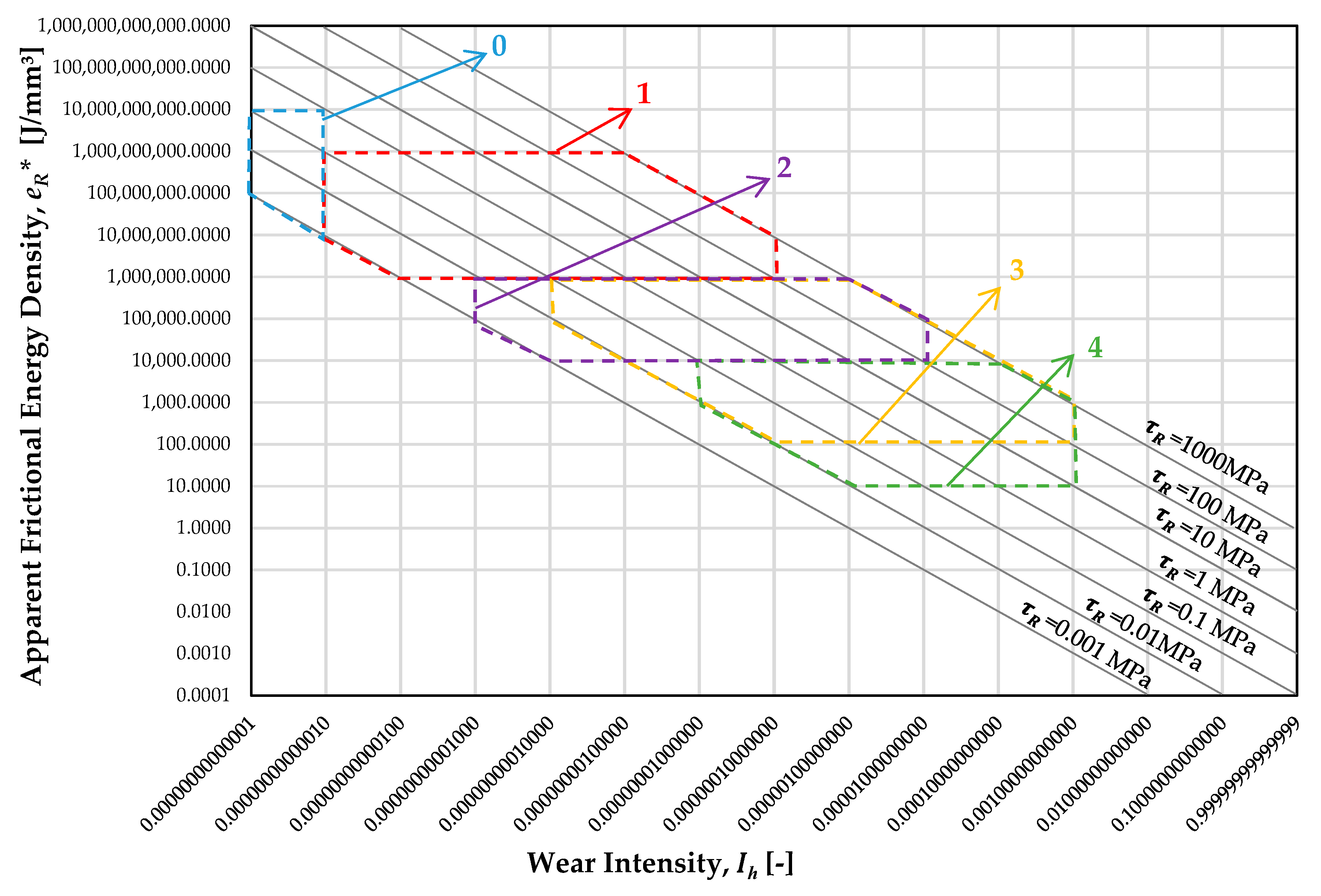

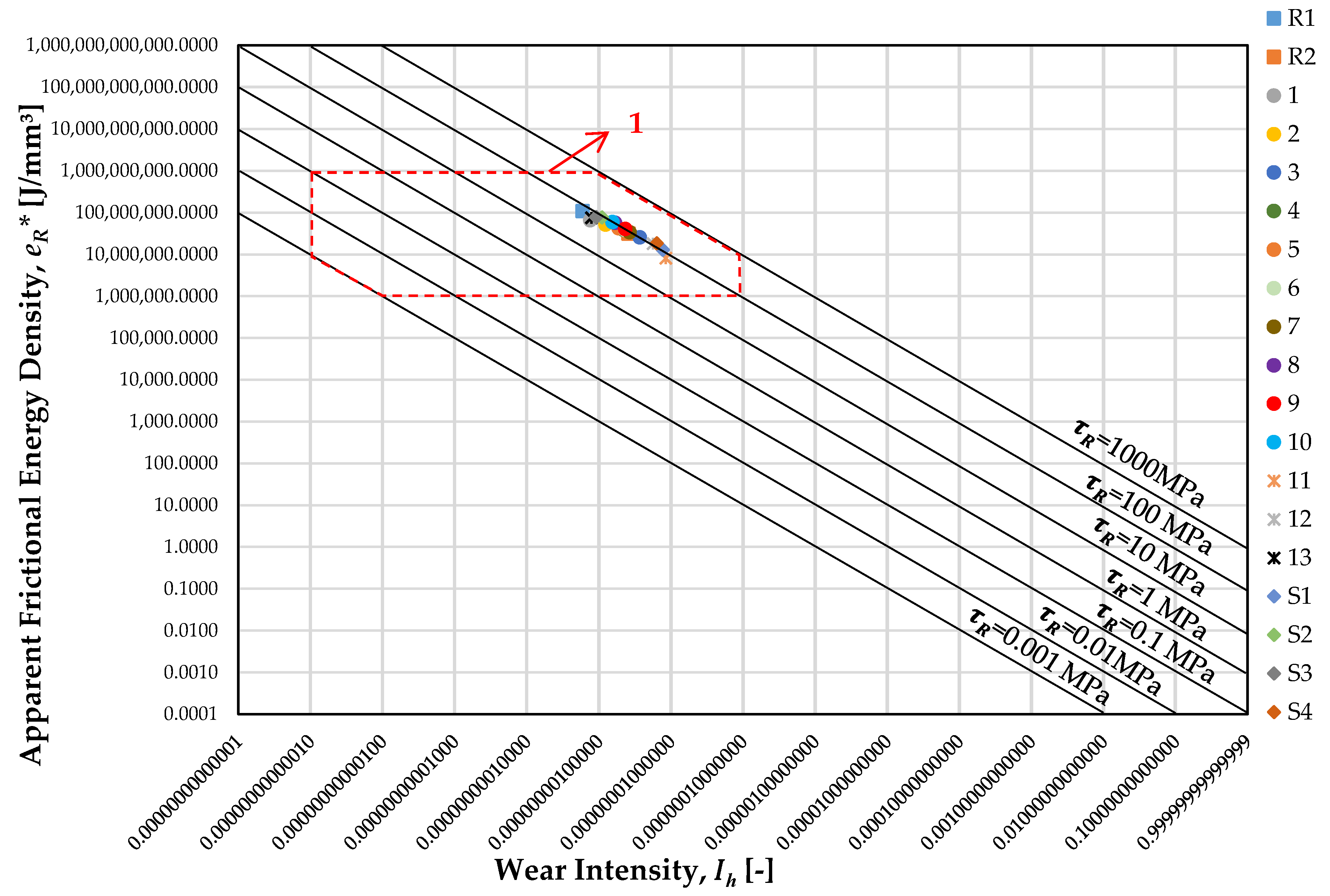

2. Energy-Based Wear Model and Apparent Friction Energy Density

3. Experimental Section

3.1. Materials

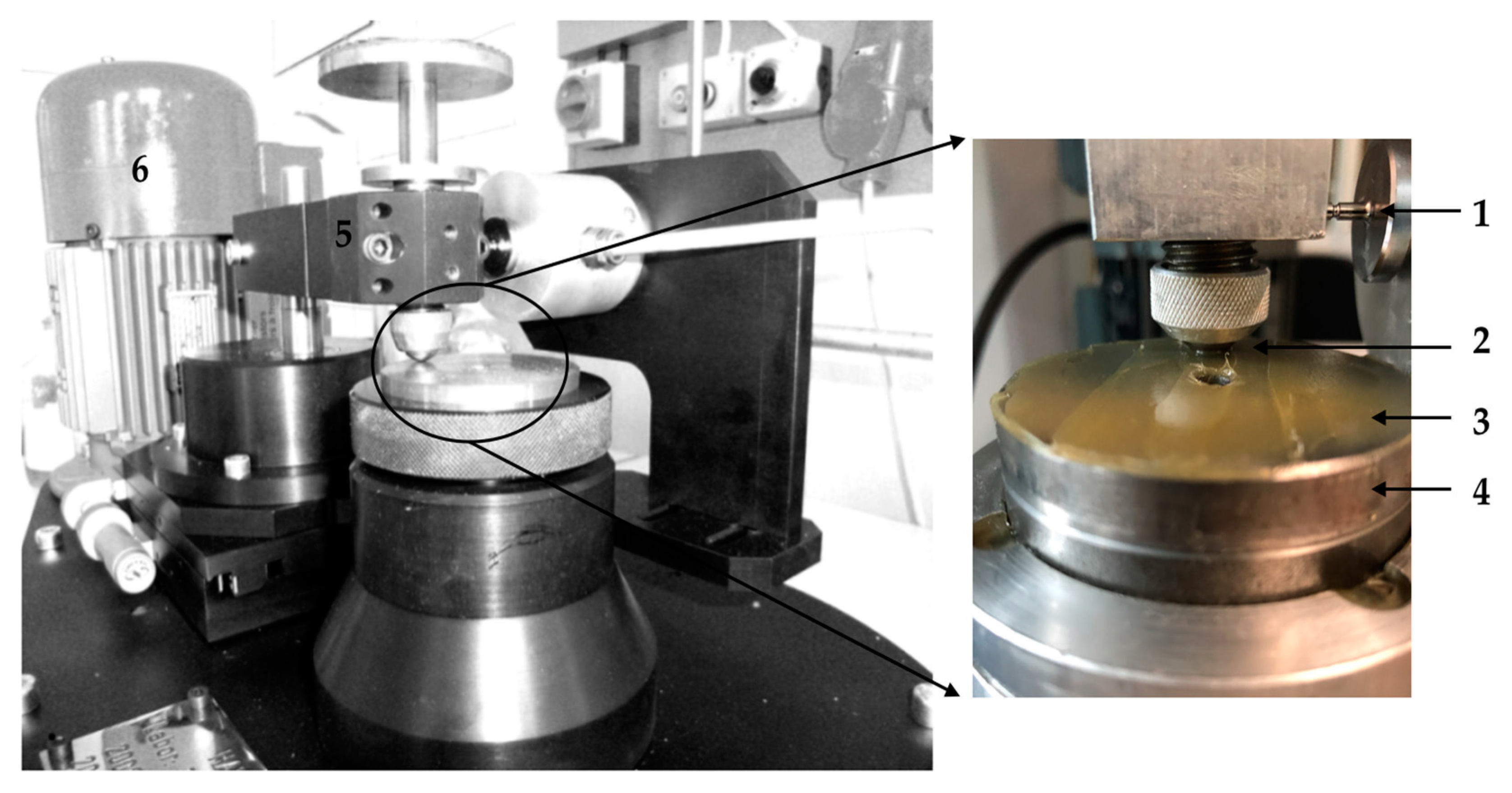

3.2. Tribological Tests on the Ball-on-Disc Tribometer

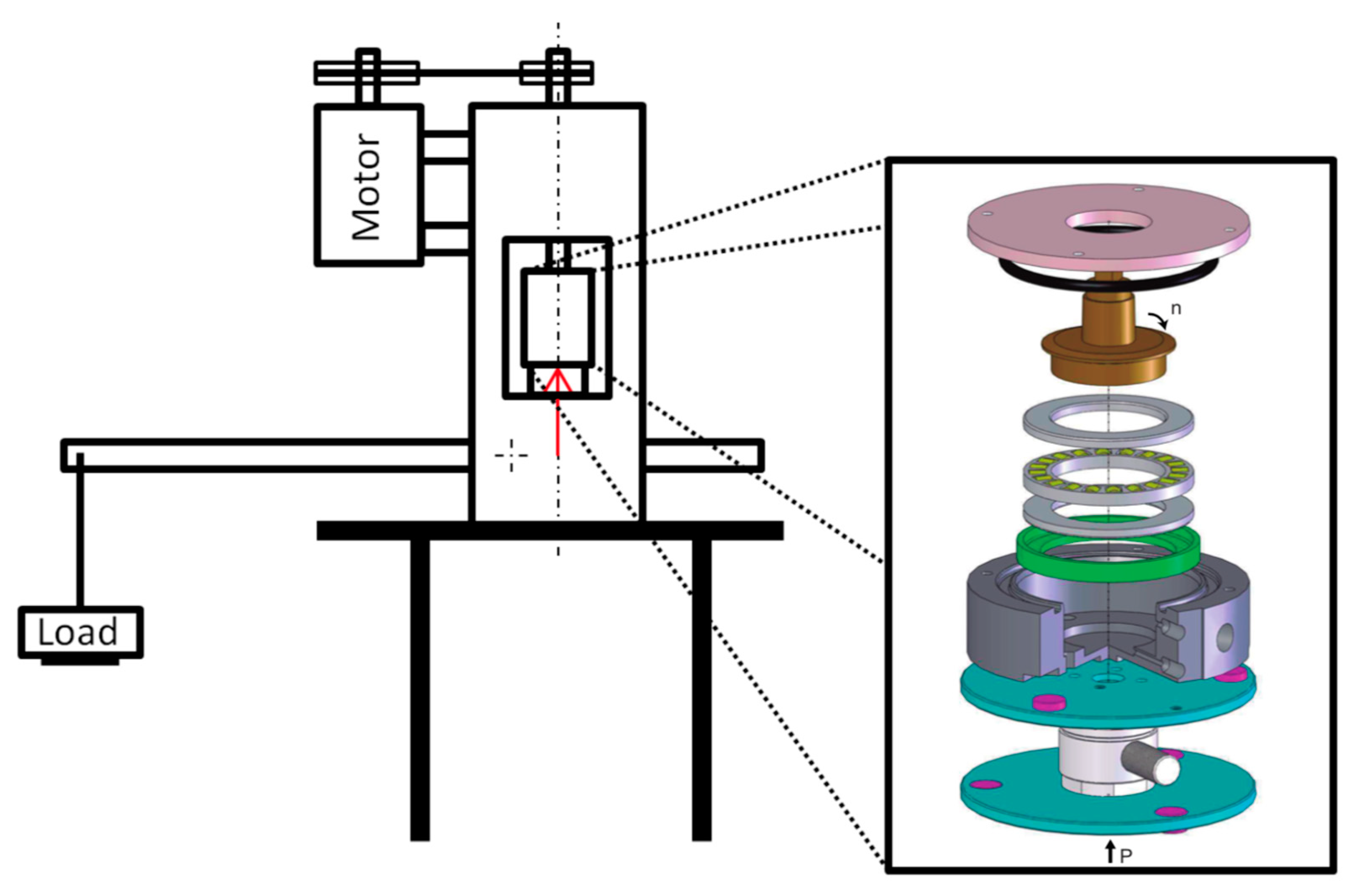

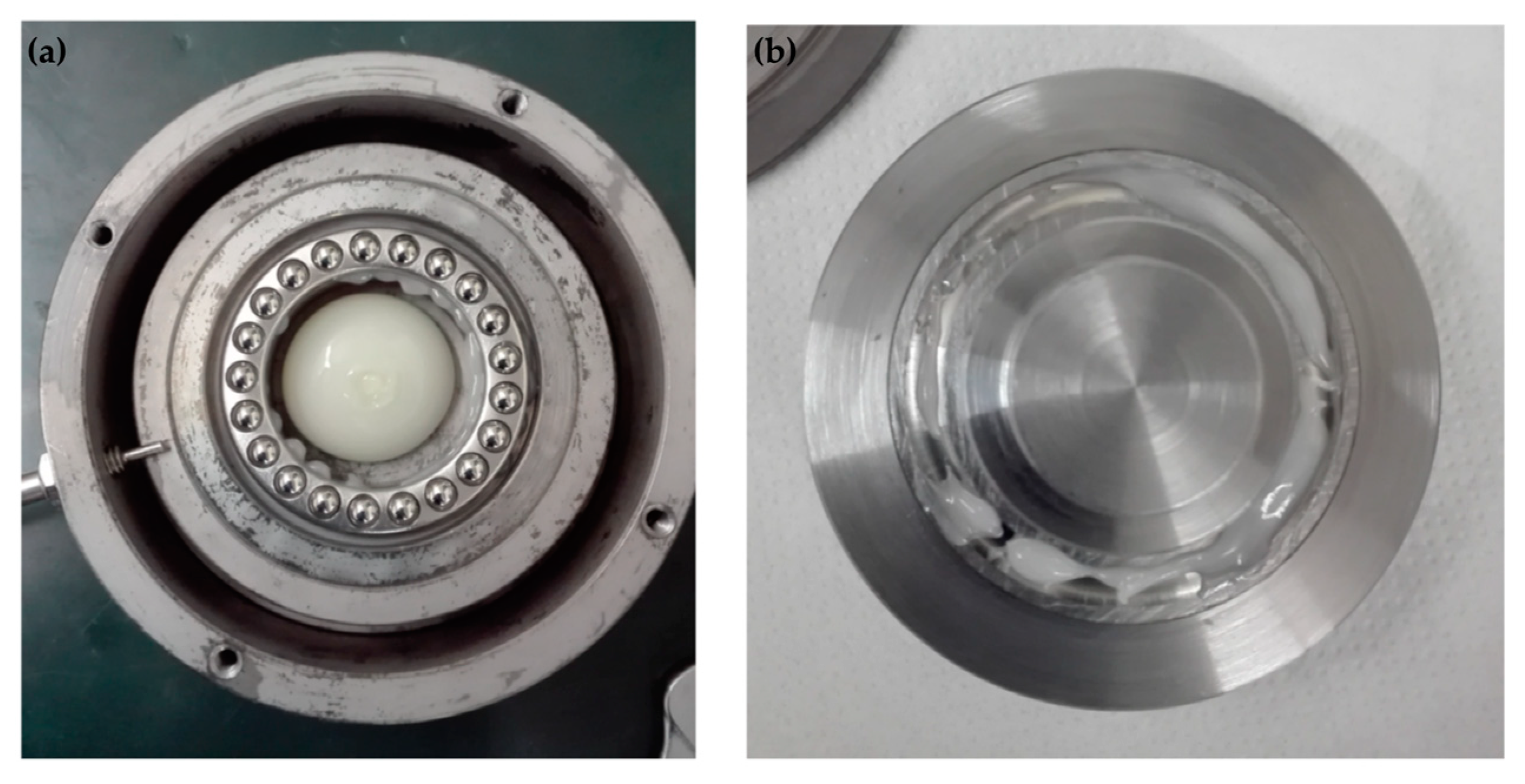

3.3. Rolling Bearing’s Friction Torque Tests

3.3.1. Power Loss Tests

- The machine was loaded with 5 kg (load on the bearing ≈1000 N) and the motor was started, with the speed increasing to 500 rpm for 5 min.

- The load was increased to 25 kg (5 kN) and the speed was set at 100 rpm.

- Temperature stabilization was undertaken (less than 1 °C degree variation in a time window of 10 min).

- The friction torque was measured five times at constant operating conditions.

- The rotational speed was increased. Steps 3 and 4 were repeated to reach the required rotational speed.

- The test was stopped.

3.3.2. Wear Tests

3.3.3. Grease Volume

4. Results and Discussion

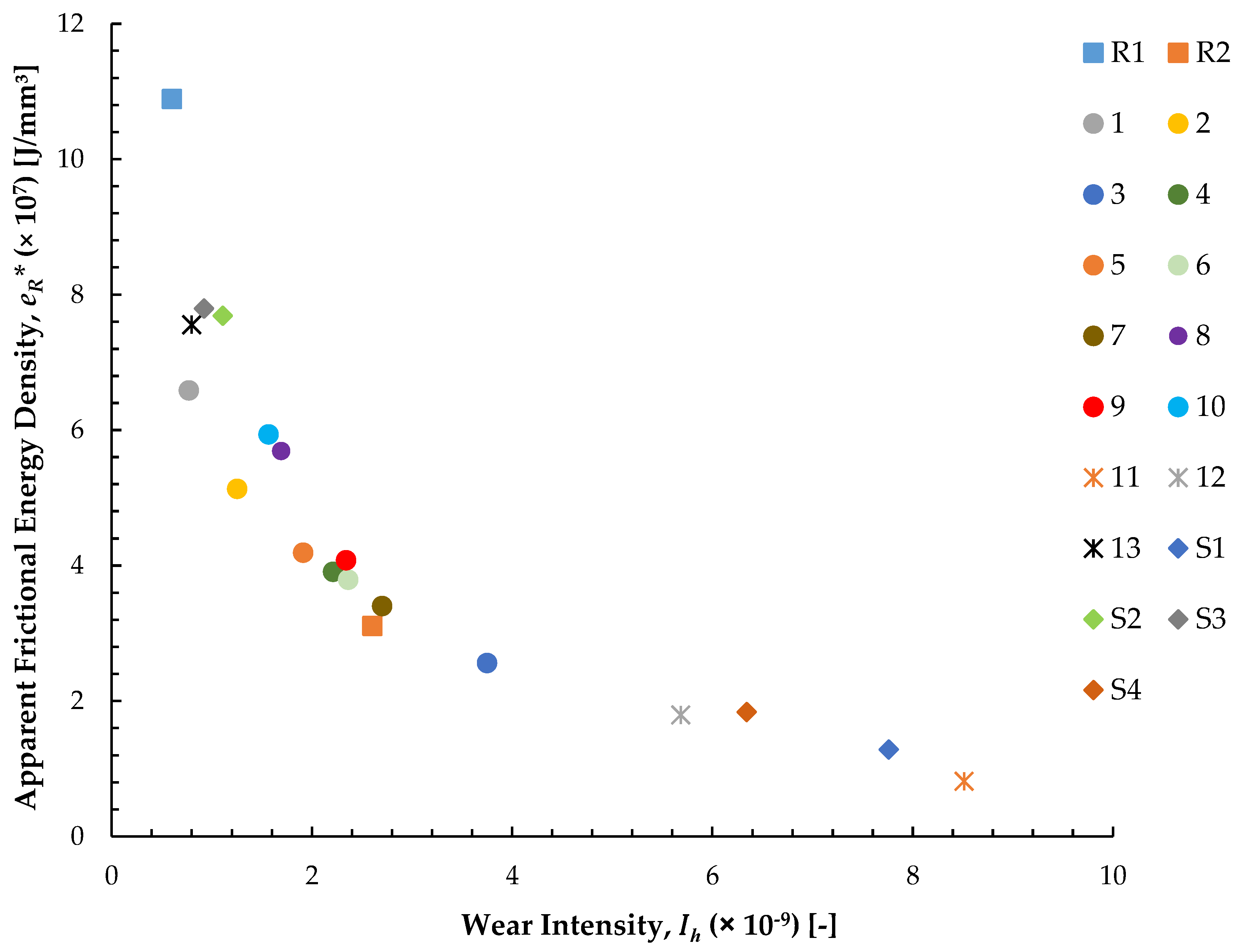

4.1. Apparent Friction Energy Density

4.2. Rolling Bearings Test Results

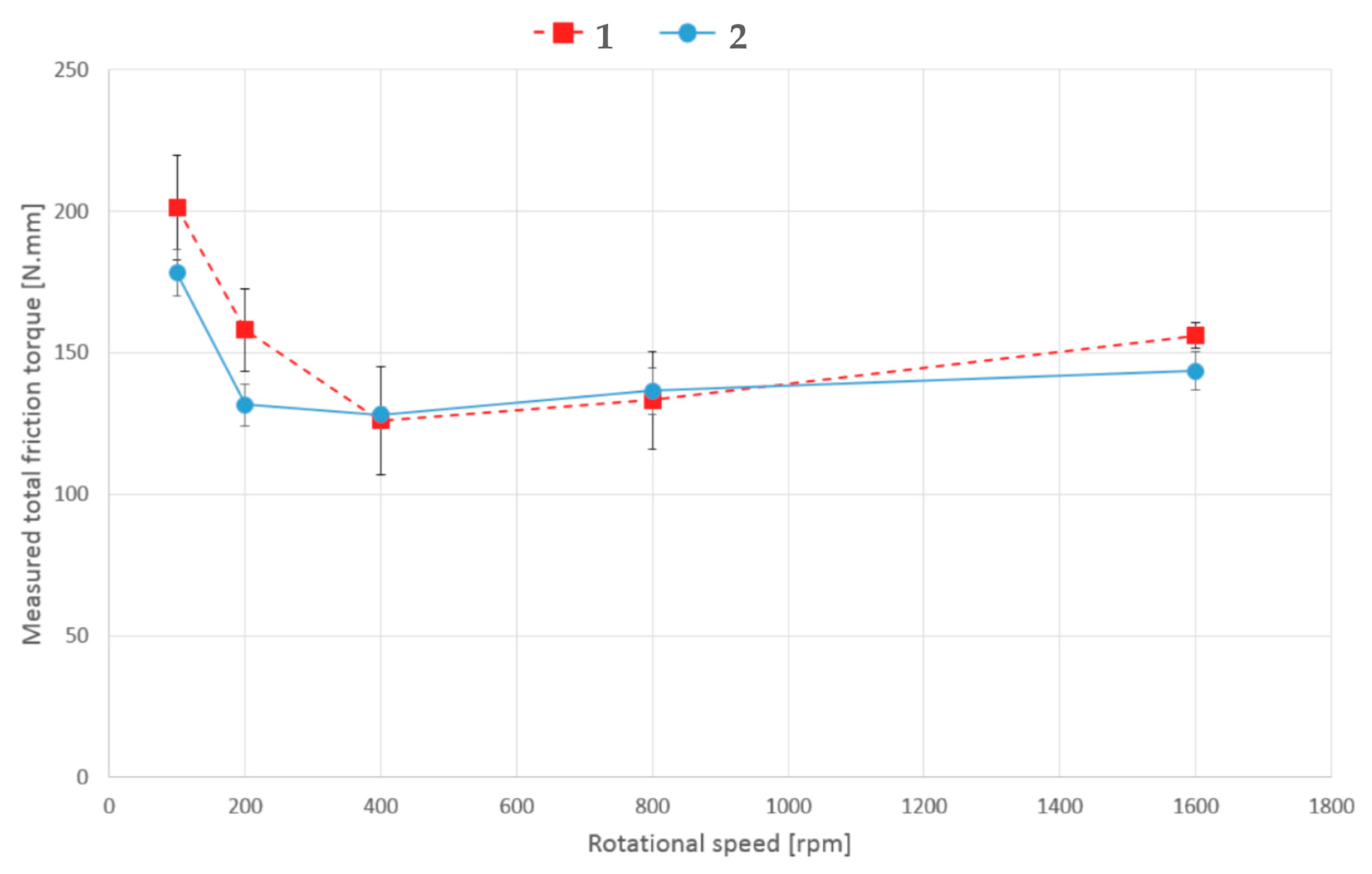

4.2.1. Power Loss Tests

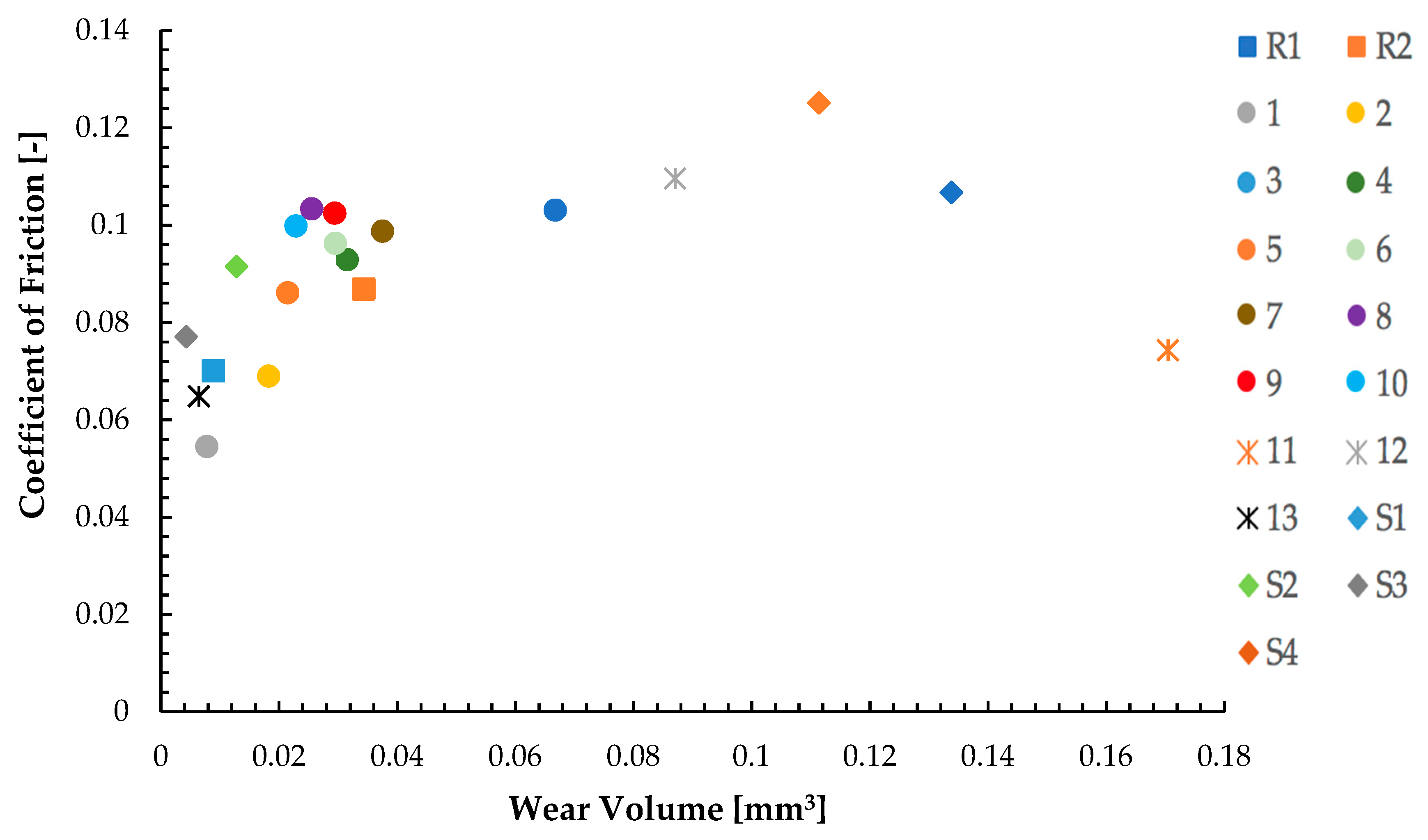

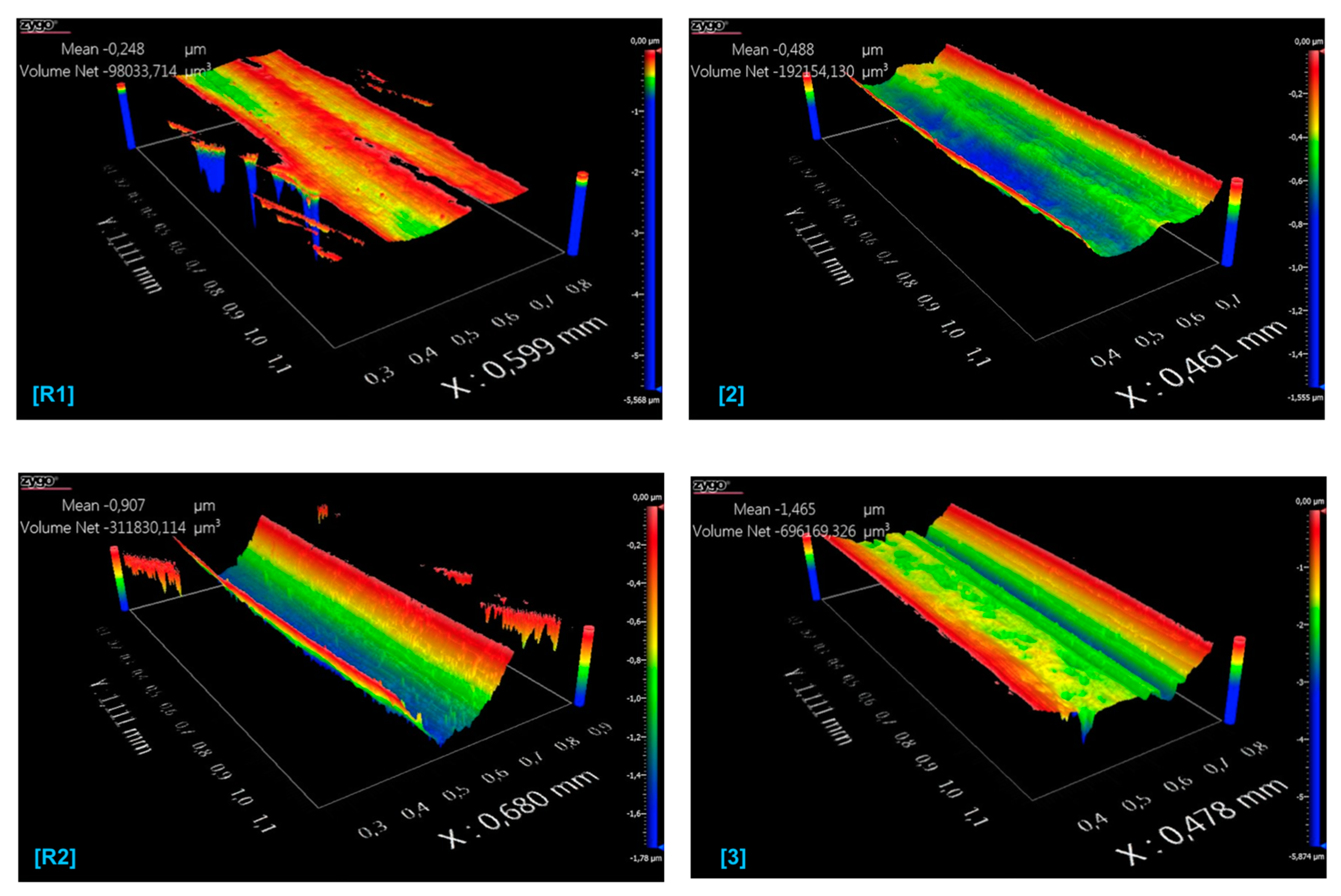

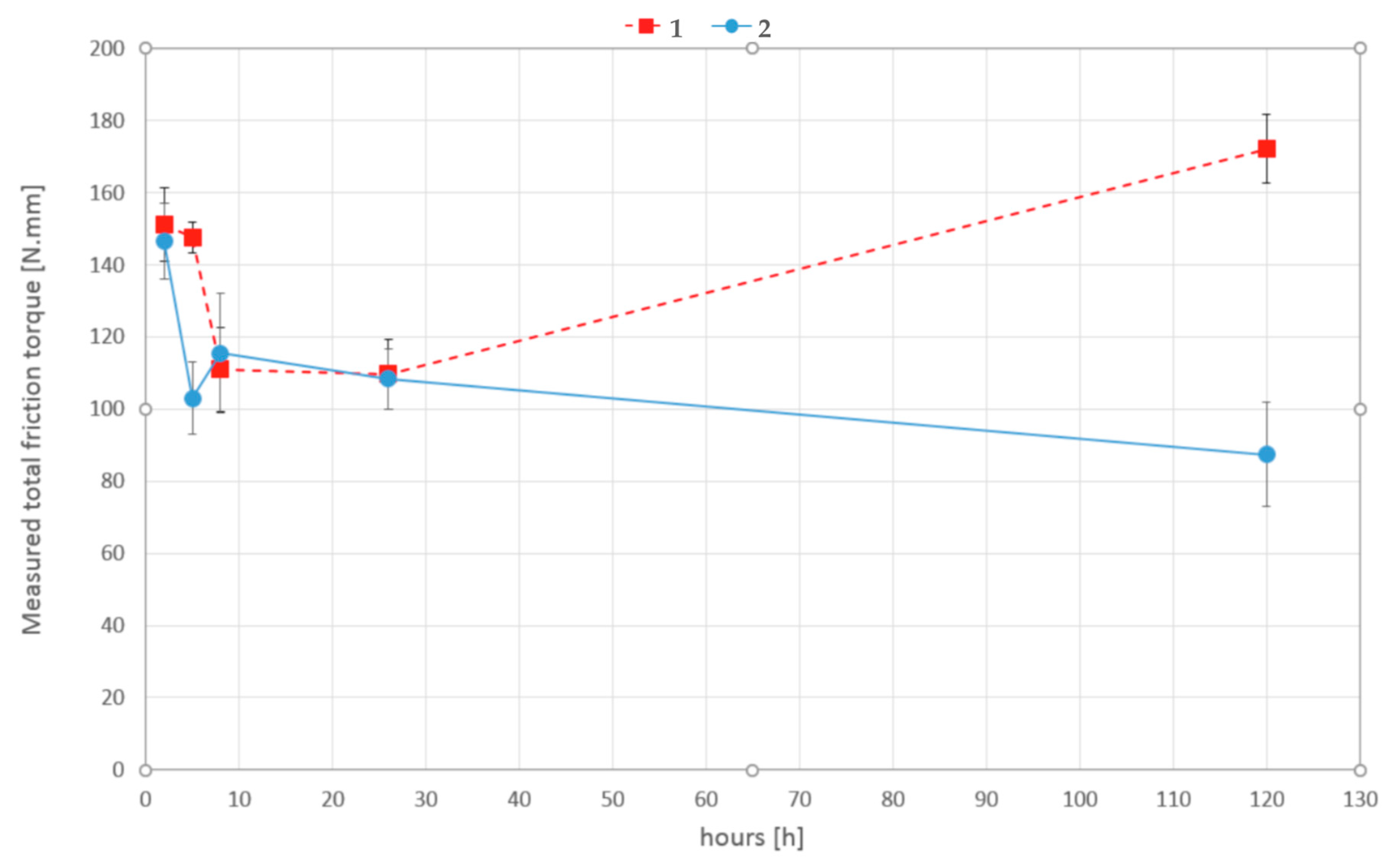

4.2.2. Wear Tests

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bartz, J.W. Lubricants and the environment. Tribol. Int. 1998, 31, 35–47. [Google Scholar] [CrossRef]

- Wilson, B. Lubricants and functional fluids from renewable resources. Ind. Lubr. Tribol. 1998, 50, 6–15. [Google Scholar] [CrossRef]

- Boyde, S. Green lubricants. Environmental benefits and impacts of lubrication. Green Chem. 2002, 4, 293–307. [Google Scholar] [CrossRef]

- Erhan, S.Z.; Asadauskas, S. Lubricant basestocks from vegetable oils. Ind. Crops Prod. 2000, 11, 277–282. [Google Scholar] [CrossRef]

- Adhvaryu, A.; Erhan, S.Z. Epoxidized soybean oil as a potential source of high-temperature lubricants. Ind. Crops Prod. 2002, 15, 247–254. [Google Scholar] [CrossRef]

- Adhvaryu, A.; Erhan, S.Z.; Perez, J.M. Tribological studies of thermally and chemically modified vegetable oils for use as environmentally friendly lubricants. Wear 2004, 257, 359–367. [Google Scholar] [CrossRef]

- Erhan, S.Z.; Sharma, B.K.; Perez, J.M. Oxidation and low temperature stability of vegetable oil-based lubricants. Ind. Crops Prod. 2006, 24, 292–299. [Google Scholar] [CrossRef]

- Adhvaryu, A.; Sung, C.; Erhan, S.Z. Fatty acids and antioxidant effects on grease microstructures. Ind. Crops Prod. 2005, 21, 285–291. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Valencia, C.; Franco, J.M.; Gallegos, C. Viscosity Modification of High-Oleic Sunflower Oil with Polymeric Additives for the Design of New Biolubricant Formulations. Environ. Sci. Technol. 2009, 43, 2060–2065. [Google Scholar] [CrossRef]

- Quinchia, L.A.; Delgado, M.A.; Valencia, C.; Franco, J.M.; Gallegos, C. Viscosity modification of different vegetable oils with EVA copolymer for lubricant applications. Ind. Crops Prod. 2010, 32, 607–612. [Google Scholar] [CrossRef]

- García-Zapateiro, L.A.; Delgado, M.A.; Franco, J.M.; Valencia, C.; Ruiz-Méndez, M.V.; Garcés, R.; Gallegos, C. Oleins as a source of estolides for biolubricant applications. Grasas y Aceites 2010, 61, 171–174. [Google Scholar]

- Sánchez, R.; Franco, J.M.; Delgado, M.A.; Valencia, C.; Gallegos, C. Effect of thermo-mechanical processing on the rheology of oleogels potentially applicable as biodegradable lubricating greases. Chem. Eng. Res. Des. 2008, 86, 1073–1082. [Google Scholar] [CrossRef]

- Sánchez, R.; Franco, J.M.; Delgado, M.A.; Valencia, C.; Gallegos, C. Development of new green lubricating greases formulations based on cellulosic derivatives and castor oil. Green Chem. 2009, 11, 686–693. [Google Scholar] [CrossRef]

- Sánchez, R.; Franco, J.M.; Kuhn, E.; Fiedler, M. Tribological characterization of green lubricating greases formulated with castor oil and different biogenic thickener agents: A comparative experimental study. Ind. Lubr. Tribol. 2011, 63, 446–452. [Google Scholar] [CrossRef]

- Sánchez, R.; Franco, J.M.; Delgado, M.A.; Valencia, C.; Gallegos, C. Thermal and mechanical characterization of cellulosic derivatives-based oleogels potentially applicable as bio-lubricating greases: Influence of ethyl cellulose molecular weight. Carbohydr. Polym. 2011, 83, 151–158. [Google Scholar] [CrossRef]

- Sánchez, R.; Stringari, G.B.; Franco, J.M.; Delgado, M.A.; Valencia, C.; Gallegos, C. Use of chitin, chitosan and acylated derivatives as thickener agents of vegetable oils for bio lubricant applications. Carbohydr. Polym. 2011, 85, 705–714. [Google Scholar] [CrossRef]

- Alfonso, J.E.M.; Yañez, R.; Valencia, C.; Franco, J.M.; Díaz, M.J. Optimization of the Methylation Conditions of Kraft Cellulose Pulp for Its Use As a Thickener Agent in Biodegradable Lubricating Greases. Ind. Eng. Chem. Res. 2009, 48, 6765–6771. [Google Scholar] [CrossRef]

- Núñez, N.; Alfonso, J.E.M.; Valencia, C.; Sánchez, M.C.; Franco, J.M. Rheology of new green lubricating grease formulations containing cellulose pulp and its methylated derivative as thickener agents. Ind. Crops Prod. 2012, 37, 500–507. [Google Scholar] [CrossRef]

- Sánchez, R. Rheological and mechanical properties of oleogels based on castor oil and cellulosic derivatives potentially applicable as bio-lubricating greases: Influence of cellulosic derivatives concentration ratio. J. Ind. Eng. Chem. 2011, 17, 705–711. [Google Scholar] [CrossRef]

- Acar, N.; Franco, J.M.; Kuhn, E. On the shear-induced structural degradation of lubricating greases and associated activation energy: An experimental rheological study. Tribol. Int. 2020, 144, 106105. [Google Scholar] [CrossRef]

- Kuhn, E. Friction and wear of a grease lubricated contact—An energetic approach. In Tribology: Fundamentals and Advancements; Gegner, J., Ed.; InTech: London, UK, 2013; ISBN 978-953-51-1135-1. [Google Scholar]

- Fleischer, G.; Gröger, H.; Thum, H. Verschleiß und Zuverlässigkeit; VEB Verlag Technik: Berlin, Germany, 1980. [Google Scholar]

- Fleischer, G. Zum Energetischen Niveau von Reibpaarungen. In Schmierungstechnik 16; VEB Verlag Technik: Berlin, Germany, 1985. [Google Scholar]

- Sequard-base, J.; Lenauer, C.; Lazarev, V.; Gavrilov, K.; Doikin, A.; Vorlaufer, G. A Modified Energy-Based Model for Describing Wear Processes Applied to an Internal Combustion Engine. Int. J. Comp. Methods Exp. Meas. 2015, 3, 150–164. [Google Scholar] [CrossRef]

- Brinkschulte, L.; Mattes, J.; Geimer, M. An approach to wear simulation of hydrostatic drives to improve the availability of mobile machines. In Proceedings of the 11th International Fluid Power Conference, Aachen, Germany, 19–21 March 2018. [Google Scholar]

- Bartel, D.; Bobach, L.; Illner, T.; Deters, L. Simulating transient wear characteristics of journal bearings subjected to mixed friction. J. Eng. Tribol. 2012, 226, 1095–1108. [Google Scholar] [CrossRef]

- Lang, J.; Knoll, G.; Schönen, R.; Jaitner, D.; Schiffgens, H.J.; Schlüter, S. Simulation of a High-Pressure Fuel Pump under Thermo-Elastohydrodynamic Conditions; Springer Fachmedien: Wiesbaden, Germany, 2018. [Google Scholar] [CrossRef]

- Foko, F.; Heimes, J.; Magyar, B.; Sauer, B. Reibenergiebasierte verschleisssimulation für radialwellendichtringe. In Proceedings of the Gft-Conference, Göttingen, Germany, 23–25 September 2019. [Google Scholar]

- Kučera, M.; Chotčborský, R. Analysis of the process of abrasive wear under experimental conditions. Sci. Agric. Bohem. 2013, 44, 102–106. [Google Scholar] [CrossRef]

- Kučera, M.; Pršan, J.; Kostoláni, P. A systemic approach to testing the tribological properties of selected materials of agricultural machines. J. Cent. Eur. Agric. 2014, 15, 146–159. [Google Scholar] [CrossRef]

- Kuhn, E. Tribological stress of lubricating greases in the light of system entropy. Lubricants 2016, 4, 37. [Google Scholar] [CrossRef]

- Kuhn, E. Correlation between system entropy and structural changes in lubricating grease. Lubricants 2015, 3, 332–345. [Google Scholar] [CrossRef]

- Kragelski, I.P.; Dobicin, M.N.; Kombalov, V.S. Reibung und Verschleiß; Technik: Verl, Germany, 1982. [Google Scholar]

- Kuhn, E. Zur Tribologie der Schmierfette: Eine Energetische Betrachtungsweise des Reibungs-und Verschleißprozesses; Expert Verl: Renningen, Germany, 2017. [Google Scholar]

- Borrero-López, A.M.; Valencia, C.; Franco, J.M. Rheology of lignin-based chemical oleogels prepared using diisocyanate crosslinkers: Effect of the diisocyanate and curing kinetics. Eur. Polym. J. 2017, 89, 311–323. [Google Scholar] [CrossRef]

- Triviño, E.C.; Valencia, C.; Delgado, M.A.; Franco, J.M. Modification of alkali lignin with poly (ethylene glycol) diglycidyl ether to be used as a thickener in bio-lubricant formulations. Polymers 2018, 10, 670. [Google Scholar] [CrossRef]

- Cousseau, T.; Graça, B.; Campos, A.; Seabra, J. Experimental measuring procedure for the friction torque in rolling bearings. Lubr. Sci. 2010, 22, 133–147. [Google Scholar] [CrossRef]

- Cousseau, T.; Graça, B.; Campos, A.; Seabra, J. Friction torque in grease lubricated thrust ball bearings. Tribol. Int. 2011, 44, 523–531. [Google Scholar] [CrossRef]

- Gonçalves, D.; Cousseau, T.; Gama, A.; Campos, A.V.; Seabra, J.H.O. Friction torque in thrust roller bearings lubricated with greases, their base oils and bleed-oils. Tribol. Int. 2016. [Google Scholar] [CrossRef]

- Gonçalves, D.; Pinho, S.; Graça, B.; Campos, A.V.; Seabra, J.H.O. Friction torque in thrust ball bearings lubricated with polymer greases of different thickener content. Tribol. Int. 2016, 96, 87–96. [Google Scholar] [CrossRef]

- Available online: www.tricocorp.com/product/direct-reading-ferrograph/ (accessed on 31 May 2018).

- SKF. Evolution online and G morales-espejel. using a friction model as an engineering tool. Evol. SKF 2006, 2, 27–30. [Google Scholar]

- SKF. SKF General Catalogue; SKF: Schweinfurt, Germany, 2003. [Google Scholar]

- Available online: http://www.plus-sci.co.kr/image/ana/predict-dli/pdf/ferrography_overview.pdf (accessed on 20 December 2019).

- Available online: https://pdfs.semanticscholar.org/17d4/b8224be1a7df01929af300874e6f5017f18c.pdf (accessed on 20 December 2019).

- Available online: https://wearcheck.com/virtual_directories/Literature/Techdoc/WCA001.htm (accessed on 20 December 2019).

| Range | Friction State | Wear State | Process Parameter | ||

|---|---|---|---|---|---|

| 0 | Fluid friction (rheological deformation and shear) | Zero wear | 1010–107 | 100–10−3 | <10−13 |

| 1 | Fluid friction/mixed friction (rheological and elastic deformation and shear) | Solid body wear level 1 | 109–106 | 103–10−3 | 10−13–10−7 |

| 2 | Mixed friction (rheological and plastic deformation and shear) | Solid body wear level 2 | 106–104 | 103–10−3 | 10−11–10−5 |

| 3 | Solid friction (elastic and plastic deformation and shear) | Solid body wear level 3 | 106–102 | 103–10−2 | 10−10–10−3 |

| 4 | Solid friction (separating deformation and shear) | Solid body wear level 4 | 104–101 | 103–10−2 | 10−8–10−3 |

| Grease Sample (Code) | Base Oil | Substance of Content |

|---|---|---|

| R1 | Synthetic ester | Lithium/calcium soap |

| R2 | HOSO 1 | Lithium-12-hydroxystearate |

| 1 | HOSO and castor oil | Beeswax, glyceryl monostearate, and cetyl alcohol |

| 2 | HOSO and castor oil | Glyceryl monostearate, cetyl alcohol, and sorbitan monostearate |

| 3 | HOSO and glycerol | Cellulose ether |

| 4 | HOSO | Isoprene derivative |

| 5 | HOSO | Lignosulfonate |

| 6 | HOSO | Natural cellulose fibers, 18 µm |

| 7 | HOSO | Corncob grits, 80–120 µm |

| 8 | HOSO | Natural cellulose, 20–40 µm |

| 9 | HOSO | Natural wood pulp from softwood, 70–150 µm |

| 10 | HOSO | Natural cellulose fibers, 120 µm |

| 11 | HOSO and castor oil | Ethyl cellulose, carnauba wax, and cetyl alcohol |

| 12 | Castor oil, HOSO and MCT oil (triglyceride of C8/C10 fatty acids) | Polyhydroxybutyric acid and ethyl cellulose |

| 13 | Glycerol and sorbitan monooleate | Chitosan, glyceryl monostearate, and calcium phosphates |

| S1 | Castor oil | Lignin/PEGDGE 2 (weight ratio of 1/0.25) |

| S2 | Castor oil | Lignin/PEGDGE (weight ratio of 1/1) |

| S3 | Castor oil | Lignin/HMDI 3 (weight ratio of 1/2) |

| S4 | Castor oil | Lignin/HMDI (weight ratio of 1/1) |

| Parameter | TBB 51107 |

|---|---|

| Mean diameter (mm) | 43.5 |

| Number of rolling elements | 21 |

| Height (mm) | 12 |

| Composite roughness (nm) | 155 |

| Rotational speed (rpm) | 100, 200, 400, 800, 1600 |

| Axial Load (N) | 5 kN (2.08 GPa) |

| Temperature (°C) | Controlled at 50 °C |

| Load | Speed | Temperature | Time |

|---|---|---|---|

| 5 kN | 200 rpm | 50 °C | 120 h |

| Identification | Power Loss Tests | Wear Tests | ||

|---|---|---|---|---|

| Sample | 1 | 2 | 1 | 2 |

| Bearing Load (kN) | 5 | 5 | 5 | 5 |

| Number of cycles | 250–300 k | 250–300 k | 1440 k | 1440 k |

| Ferrometry | ||||

| Large Particles Index (DL) | 67.7 | 17.7 | 86.0 | 57.1 |

| Small Particles Index (DS) | 17.7 | 5.1 | 30.7 | 17.7 |

| Particle Concentration Index (CPUC) | 85.4 | 22.8 | 116.7 | 74.8 |

| Severity of Wear Index (ISUC) | 4270.0 | 287.3 | 6453.5 | 2947.1 |

| Ferrography | ||||

| Normal Wear | Strong | Medium | Strong | Strong |

| Severe Wear | Strong | Strong | Medium | Medium |

| Fatigue Wear Particles | Medium | Medium | Medium | Medium |

| Adhesion Wear Particles | Fair | Fair | Fair | Fair |

| Friction Polymers | Fair | Fair | Fair | Fair |

| Black Oxides | Medium | Fair | Strong | Strong |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acar, N.; Franco, J.M.; Kuhn, E.; Gonçalves, D.E.P.; Seabra, J.H.O. Tribological Investigation on the Friction and Wear Behaviors of Biogenic Lubricating Greases in Steel–Steel Contact. Appl. Sci. 2020, 10, 1477. https://doi.org/10.3390/app10041477

Acar N, Franco JM, Kuhn E, Gonçalves DEP, Seabra JHO. Tribological Investigation on the Friction and Wear Behaviors of Biogenic Lubricating Greases in Steel–Steel Contact. Applied Sciences. 2020; 10(4):1477. https://doi.org/10.3390/app10041477

Chicago/Turabian StyleAcar, Nazli, José M. Franco, Erik Kuhn, David E. P. Gonçalves, and Jorge H. O. Seabra. 2020. "Tribological Investigation on the Friction and Wear Behaviors of Biogenic Lubricating Greases in Steel–Steel Contact" Applied Sciences 10, no. 4: 1477. https://doi.org/10.3390/app10041477

APA StyleAcar, N., Franco, J. M., Kuhn, E., Gonçalves, D. E. P., & Seabra, J. H. O. (2020). Tribological Investigation on the Friction and Wear Behaviors of Biogenic Lubricating Greases in Steel–Steel Contact. Applied Sciences, 10(4), 1477. https://doi.org/10.3390/app10041477