Abstract

In this study, a sustainable mortar mixture is developed using renewable by-products for the enhancement of mechanical properties and fracture behavior. A high-volume of fly ash—a by-product of coal combustion—is used to replace Portland cement while waste by-products from the production of engineered bamboo composite materials are used to obtain bamboo fibers and to improve the fracture toughness of the mixture. The bamboo process waste was ground and size-fractioned by sieving. Several mixes containing different amounts of fibers were prepared for mechanical and fracture toughness assessment, evaluated via bending tests. The addition of bamboo fibers showed insignificant losses of strength, resulting in mixtures with compressive strengths of 55 MPa and above. The bamboo fibers were able to control crack propagation and showed improved crack-bridging effects with higher fiber volumes, resulting in a strain-softening behavior and mixture with higher toughness. The results of this study show that the developed bamboo fiber-reinforced mortar mixture is a promising sustainable and affordable construction material with enhanced mechanical properties and fracture toughness with the potential to be used in different structural applications, especially in developing countries.

1. Introduction

The construction industry is a major consumer of energy and raw materials and contributes immensely to environmental pollution, especially to greenhouse gas (GHG) emissions [1]. Since the 1970s, annual GHG emissions have steadily increased and reached 53.5 GtCO2e in 2017 [2]. Within the construction industry, concrete is the dominant building material with a global production of 20 × 1012 kg per annum which exceeds the amount of all other construction materials combined. With an increase in the demand for new infrastructure demonstrated by developing countries, the use of Portland cement (PC), the main component in concrete, has been rising rapidly [3]. Accordingly, the global use of PC has increased from 2.22 to 4.10 Gt/year within the past decade. The production of PC accounts for ~5% of the global anthropogenic CO2 emissions [4]. Moreover, concrete is commonly reinforced with steel, whose production involves high energy emissions and consumption of fossil fuels that additionally contributes to CO2 emissions. Furthermore, the fast pace of development in many developing countries has led to an increased demand for reinforced concrete for housing and infrastructure projects. Unfortunately, the majority of developing countries lack the resources to produce their own cement and steel for the production of reinforced concrete elements which forces them to import the majority of their needs from highly industrialized countries, and as a result of the import surge, trade deficits, economic slow-downs, and loss of jobs are prominent in those countries. Besides the economic challenges from the cement and steel import, environmental issues also need to be addressed. The construction industry is facing an urgent need for the use of sustainable materials incorporating locally available renewable resources as well as industrial by-products with lower environmental impacts.

One potential material is fly ash, a by-product of the combustion of coal, oil and biomass. Fly ash contains Silicon dioxide (SiO2) and Aluminum oxide (Al2O3) as major components that can contribute to the hydration of cement. Furthermore, low-cost and renewable materials such as bamboo and wood can be found in abundant supply in many developing countries, where the bamboo and wood industry produce a large number of waste products. Replacement of cement with by-products such as fly ash or bamboo and wood waste can enable the reduction of the carbon footprint associated with the cement industry and improve the mechanical and thermal properties of the developed formulations. Other performance aspects such as the ductility of these mixes could be further enhanced via the use of other renewable materials such as natural fibers to avoid the brittle failure that is characteristic of plain concrete.

Previous studies [5,6,7,8,9,10,11] revealed improvements in the mechanical properties and durability of concrete mixtures, in which PC was partially replaced with wood ash or fly ash. Substituting aggregates with wood process waste such as wood chips, flax or hemp was also shown to enhance the mechanical or thermal properties of concrete mixtures [11,12,13,14,15,16,17,18]. Further research on fiber-reinforced concrete reported that the addition of synthetic fibers—such as polypropylene (PP), polyethylene (PE), polyvinyl alcohol (PVA)—or steel fibers could increase the fire resistance, ductility, tensile strength, impact resistance and toughness of concrete mixtures [19,20,21,22]. However, synthetic fibers, which are mainly derived from petroleum-based sources, and steel fibers require energy-intensive and expensive production processes. In contrast, natural fibers, such as those obtained from wood and bamboo industry by-products, can provide a low-cost and sustainable alternative for the construction industry. Challenges of resource scarcity and the negative environmental impacts of synthetic fiber production have led many researchers to search for alternative, green, sources of fibers for the production of fiber-reinforced concrete. Natural fibers represent a sustainable source of raw materials from renewable resources and can help to alleviate the need for synthetic fibers. While there is growing interest in the use of wood fibers to enhance the mechanical behavior and fracture toughness of concrete [23,24,25], there has so far been relatively little investigation of the use of bamboo fibers for this purpose. Only a few studies [26,27,28,29,30] investigated the performance of bamboo fiber-reinforced concrete and mortar mixtures through a series of mechanical tests. The bamboo fibers in those studies were obtained from bamboo forests and were subsequently processed as fibers for concrete mixtures. Furthermore, the studies showed that only concrete’s tensile property had obvious improvement when bamboo fibers were added, while the enhancement to the compression property and flexural property was not obvious. The studies on the application of bamboo fiber-reinforced concrete and mortar mixtures are rather limited. Both bamboo fibers and fly ash present a great opportunity as sustainable and affordable replacements for cement and steel for developing countries. Bamboo belongs to the botanical family of grasses and shows high resistance to tensile stresses. The tensile strength of natural bamboo is superior to that of wood. This attribute marks bamboo as an attractive option to incorporate into fiber-reinforced concrete, especially in developing countries where demand for reinforced concrete is growing rapidly [31,32,33]. Bamboo is a gigantic grass, which belongs to the angiosperms (seed-bearing vascular plants) group and monocotyledon (flowering plants) subgroup. Bamboo attains maturity in 3 to 5 years, in favorable contrast to wood, which takes at least 20 years, depending on the species [34]. The growth behavior of bamboo culm and the extreme wind loads it has to sustain during its life cycle require a precise mechanical adaptation to the environment. Therefore, material optimization has to be achieved effectively from the bamboo fibers and their cell structures. This results in an optimized microstructure with superior material performance when compared to various wood species. Furthermore, bamboo can directly address global warming as it rapidly grows and sequesters carbon in biomass and soil faster than almost any wood species. The main components of bamboo culms are cellulose, hemicellulose and lignin. The minor components are resins, tannins, waxes and mineral salts. However, the percentage of each component differs from species to species and depends on the conditions of bamboo growth and the age of the bamboo, as well as the location of the section on the culm [31,34]. In general, cellulose in bamboo culms accounts for more than 50% of the bamboo chemical components. After cellulose, lignin is the next largest component, and normally accounts for more than 20% of the bamboo’s mass. Bamboo displays a round-shaped cell cross-section, in contrast to the nearly rectangular and relatively large cells of wood species. Furthermore, bamboo culms have a particular multi-layered cell wall structure with alternating thick and thin layers of fibers, unlike the typical three-layered cell wall of wood species which have a structure with a dominating middle layer [34,35,36].

In recent years various methods have been developed to employ bamboo through new processing technologies for the fabrication of high-performance bamboo-composite materials in such a way that the inherent mechanical capacities of the fibers are retained, while the durability issues, specifically water absorption, swelling, shrinking and chemical resistance, of the composite could be enhanced for application as structural elements in buildings [31,32,33,37]. The bamboo-composite materials display high mechanical properties and have been used as either reinforcement in concrete, replacing steel or as structural elements in the form of a beam or column. However, the process through which natural bamboo culms transform into bamboo-composite materials employs only certain sections of the culms and therefore the remaining parts usually become part of the waste of the production process which can be safely utilized for applications as sustainable and affordable fibers in fiber-reinforced mortar.

Therefore, the objective of this study is to develop a sustainable and affordable mortar mixture incorporating by-products and renewable materials (i.e., fly ash and bamboo fibers) that show improved mechanical properties and fracture behavior and could be employed for the construction of low-cost and low-rise housing solutions in developing countries. The developed mixture was characterized via compression, splitting and bending tests, whereby the fracture properties including toughness and absorption energy were also assessed. The findings generated through this work set the foundation for further research on bamboo fibers and bamboo-reinforced concrete and mortar mixtures for structural applications.

2. Materials and Methodology

2.1. Bamboo Plant

There are about 1200 species of bamboo under some 90 genera. The physical and mechanical properties of bamboo culms are correlated with the specific gravity and the fiber content. Therefore, the physical and mechanical properties of bamboo differ from species to species and even within the same species or same culm, due to changes in chemical composition as well as specific gravity [38]. For the purpose of this study Dendrocalamus asper, known as Petung Putih bamboo, was selected from a bamboo forest on the Java island of Indonesia. Dendrocalamus asper is widely used for low-rise and low-cost housing across Indonesia.

2.1.1. Bamboo Fibers

A new processing technology was developed to process bamboo culms into fibers that were suitable for use in a novel engineered bamboo composite materials [33]. Accordingly, the fibers were obtained by processing entire bamboo culms. They were then added to epoxy resin and fabricated into high-tensile-strength bamboo composite materials by using a hot-press fabrication method. The process yielded an engineered bamboo composite material, which was then cut into different sizes to be used in concrete as reinforcement in place of steel bars in previous studies [39,40].

Throughout this process, some portions of the fibers are not used and remain as the waste by-products of the fabrication process. This study adopts the use of these waste portions of these fibers to reinforce the mortar matrix. In an earlier study [37], the mechanical properties of Dendrocalamus asper bamboo from Indonesia were investigated with respect to culm physical properties including culm diameter, wall thickness, height, moisture content and specific density. Correlations were drawn between the culm’s physical properties and the resulting mechanical properties, including tensile strength, modulus of rupture and modulus of elasticity in flexure and tension.

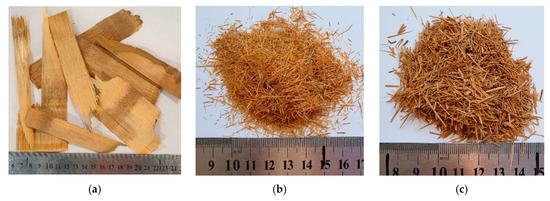

Bamboo fibers were ground and sieved with a sieve tower using sieve sizes of 1 mm and 500, 300 and 125 µm. The final bamboo fibers used in this study were those remained in the 500 µm and 300 µm sieves (Figure 1) and are referred to as “500 µm” and “300 µm” fibers throughout this study, respectively. Bigger and smaller sieves were used for a better separation of the fiber sizes. This ensured more constant fiber sizes and avoided clogging of the 500-micron sieves with bigger fibers. Trail mixes with 212 µm fibers showed no promising results and were therefore not considered in this article.

Figure 1.

Bamboo fibers. (a) Raw waste material; (b) 300 µm-diameter fibers after grinding and sieving; and (c) 500 µm-diameter fibers after grinding and sieving.

2.1.2. Bamboo Fiber Treatment

A variety of treatments to improve the durability and the bonding of natural fibers embedded in concrete and mortar matrix are available, with different levels of complexity including but not limited to cement surface coating, lime surface coating, cement–lime coating and oil impregnation [41,42,43,44]. For the present study, two treatments were selected for the bamboo fibers. To enhance the durability, lignin was partially removed by simply heating the bamboo fibers in water at 85 °C for 72 h and drying them at 80 °C for 24 h [45]. In addition, the bond between the fibers and the mortar matrix was improved by an alkaline treatment, which involved the stirring of the bamboo fibers in a lime (Ca(OH)2) solution for 2 h. The solution contained 40 g of lime per liter of water. This suspension was stirred repeatedly during the entire treatment duration to avoid the sedimentation of the fibers and any undissolved lime particles. After the lime treatment, the bamboo fibers were dried at 80 °C for 24 h. This treatment is known to modify the surface of the fibers and improve their mechanical strength [45].

2.1.3. Characterization of the Bamboo Fiber Geometry

The fiber geometry was assessed by microscopy, during which a total of 200 fibers within each size category were measured with an optical microscope and analyzed with the Zeiss software “ZEN 2 (Blue edition). Table 1 presents the mean value of the length and diameter as well as the standard deviation obtained from these microscopy measurements. The mean value is calculates by whereby the standard deviation is calculated by . The intentionally chosen simplified manufacturing and sieving process leads to the relatively high standard deviation of the fibers, but allows replication with minimal equipment and labor costs, especially in developing countries with limited access to such facilities. The average density of the bamboo fibers used in this study was 840 kg/m3 and was obtained from [31].

Table 1.

Geometry of the bamboo fibers.

2.2. Mortar Mixtures

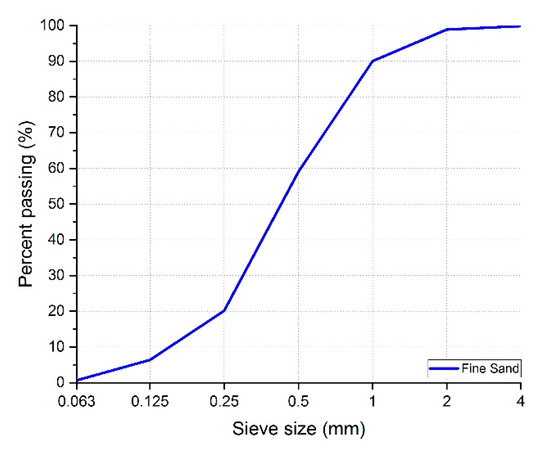

A mortar mixture containing 547 kg/m3 of Ordinary Portland cement, CEM I, according to Singapore Standard SS EN 197-1 [46] and 656 kg/m3 of fly ash Class C, according to ASTM C 618 [47], was used as a control mixture. Different contents of bamboo fibers (4, 6, and 8% by volume of the concrete) were added to investigate the resulting mechanical and fracture behavior. Fine sand with a maximum grain size of 2 mm was used as aggregates. The sieve curve of the sand is shown in Figure 2. To adjust the workability of the mixtures, a superplasticizer (ACE 8538, BASF), was added to the mixture. To ensure a constant mix procedure and fiber distribution trail mixes were prepared to evaluate mixing time and the amount of superplasticizer needed to achieve good workability. At first Cement, Fly Ash and aggregates were mixed for 90 s before water containing superplasticizer was added and mixed for 5 min. Finally, the bamboo fibers were gradually added and the constituents were mixed for another 3 min before filled into the molds. To evaluate the workability of the mixtures a flow table test was carried out according to ASTM C1437 [48]. All mixtures showed a spread of more than 255 mm diameter (maximum diameter of the flow table test apparatus according to [49]) and therefore could be filled well in the molds and compacted.The compositions of all mixtures used in this study are provided in Table 2.

Figure 2.

Particle size distribution of the fine aggregates used in this study.

Table 2.

Compositions of mortar mixtures.

2.3. Test Procedure

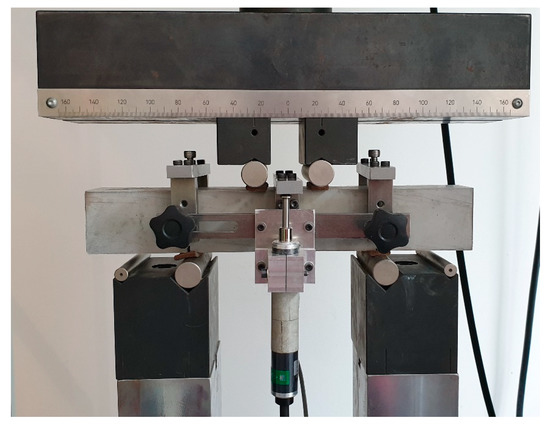

The experimental program included compressive and splitting tensile tests for the mechanical characterization of the prepared mixtures. A four-point bending test was also used to evaluate the post-cracking behavior of the bamboo fiber mixtures. These were assessed on 50 mm cubes and beams with dimensions of 50 × 50 × 300 mm. Compression tests were performed at a loading rate of 55 kN/min, following the ASTM C109 standard [50]. Splitting tests were performed in accordance to ASTM C496 [51], at a loading rate of 1.0 mm/min. Four-point bending tests were performed according to ASTM C1609 [52] on prisms with a span, L, of 150 mm. The load was applied in the 1/3 points at a rate of 0.2 mm/min. The deflection of the beam was measured with two Linear Variable Differential Transducers (LVDTs) at the mid-span (Figure 3).

Figure 3.

Four-point bending test performed according to ASTM C1609 [52].

With the recorded load–deflection data at hand, the load at the limit of proportionality, Fmax, and the corresponding modulus of rupture (MOR) could be assessed according to the RILEM TC 162-TDF [53] recommendation. According to the RILEM recommendation, the limit of proportionality is equal to the maximum load recorded up to 0.05 mm. The modulus of rupture, corresponding to the maximum force in a four-point bending test, can be calculated by the following expression:

where b, h and l are the width, height and span of the tested specimens and equal to 50 mm, 50 mm and 150 mm respectively.

MOR = Fmax l/(b h2) (MPa)

The density as well as the compressive and tensile splitting tests were evaluated on three specimens after 28 days of curing. The notation throughout this study was chosen as XXX-YP, where XXX referred to the bamboo fiber diameter in microns and Y referred to the volumetric fiber content. Therefore, notation 300-6P referred to the mixture containing 6 V% (volume %) of bamboo fibers with a nominal diameter of 300 m.

3. Results and Discussion

3.1. Mechanical Properties

3.1.1. Density and Compressive Strength

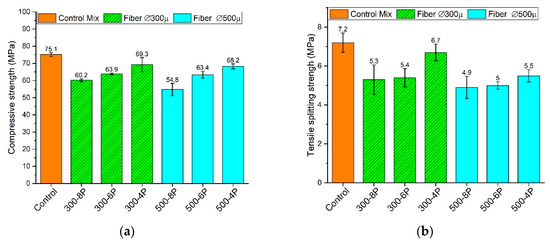

The control mix exhibited a density of 2132 kg/m3, which was slightly higher than the mixes containing fibers. The addition of bamboo fibers had little effect on the density, revealing a reduction ranging between 0.7% and 2.5%, as shown in Table 3. In terms of performance, the control mixture achieved the highest 28-day compressive strength of 75.1 MPa, as shown in Figure 4. The inclusion of fibers led to a reduction in strength, which was directly correlated with the number of bamboo fibers added to the mix design as shown in Table 3. Accordingly, higher fiber contents resulted in lower compressive strengths. This behavior can be attributed to the difference in the compressive strength and E-modulus of the bamboo fibers and the cement matrix. A previous study of the authors on different grades of the bamboo culms revealed a compressive strength between 43.2 and 68.4 MPa and an E-modulus between 18.1 and 28.2 GPa [31]. The incorporated bamboo fibers reduce the overall strength of the matrix resulting in a higher loss of strength with increasing fiber content which is in compliance with the findings of other researchers [20,54,55]. In addition, a study of Li et al. on natural fibers found that air pockets were formed at some of the fibers resulting in a reduced compressive strength compared to the control mixture [56]. Furthermore, a lower aspect ratio, thicker and longer fibers (i.e., “500 m” batch), generally indicated a greater reduction in the compressive strength than thinner and shorter fibers (i.e., “300 m” batch), which was also found in [54]. In this respect, the reduction of the compressive strength for the 4 V% to 8 V% of fibers was within a range of 7.8–19.9% for the 300 m fibers and 9.1–27% for the 500 m fibers (see Figure 4 and Table 3). An average compressive strength of 60.2 MPa was recorded for the 8 V% mixture with 300 m fibers, while the corresponding figure was 54.8 MPa for the 8 V% mixture with 500 m fibers. Although a slight reduction in strength was observed, the overall findings reveal the comparable performance of the bamboo fiber reinforced mortar mixtures with those of commonly used mix designs for structural members in similar studies [20,31,54].

Table 3.

Physical and mechanical properties of the Bamboo Fiber-reinforced mortar mixtures.

Figure 4.

Compressive strength (a) and splitting tensile strength (b) of the bamboo fiber-reinforced mortar mixtures.

3.1.2. Splitting Tensile Strength

The control mixture showed a splitting tensile strength of 7.2 MPa. Similar to the trends observed in the compressive strength results, the splitting tensile strength of the samples with 8/6/4 V% of fibers was reduced by 6.9/25.0/26.4% for the 300 m fibers and 23.6/30.6/31.9% for the 500 m fibers (see Figure 4 and Table 3). It is worth noting that the splitting test setup compression is applied to a small area along the specimen resulting in tensile stress (lateral force) within the matrix which causes splitting. The splitting tensile strength is the maximum load before cracks appear and therefore the crack bridging behavior of the fibers is not considered in this test. This is investigated with bending tests and discussed later on. According to [57], the tensile strength of a mortar matrix can be assumed to be in the range of 10% of the compressive strength which matches the results obtained in this study.

3.1.3. Flexural Tensile Behavior

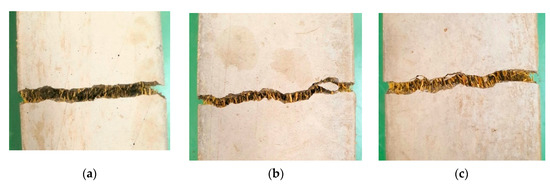

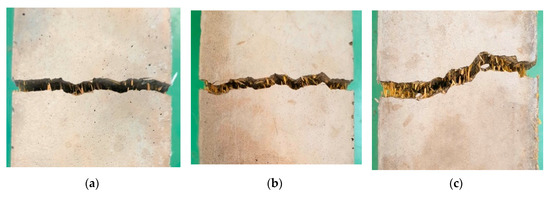

The control mix showed linear elastic behavior up to the peak load, which was followed by an abrupt failure, resulting in complete separation of the specimens into two parts. In contrast, the bamboo fiber mixtures exhibited improved post-crack behavior, resulting in a strain-softening behavior, where a single crack occurred within the central third of the prismatic samples. This effect can be seen in Figure 5 and Figure 6 where the pictures of the tested specimens taken after the bending tests are shown for both sets of samples containing 300 m and 500 m fibers. Within these figures, it is possible to visualize the fibers bridging the developed crack, which was much more evident as the fiber content increased from 4 V% to 8 V%.

Figure 5.

Photographs of test samples after bending tests involving 300 m fibers. Fiber content: (a) 4 V%, (b) 6 V% and (c) 8 V%.

Figure 6.

Photographs of test samples after bending tests involving 500 m fibers. Fiber content: (a) 4 V%, (b) 6 V% and (c) 8 V%.

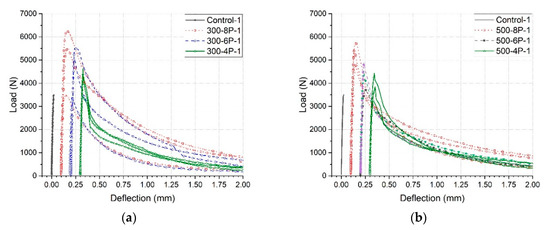

The load–deflection behaviors of all test specimens are shown in Figure 7. Test results with different fiber contents are plotted with an offset of 0.1 mm from each other for better visual comparison. Both fiber groups involving the use of 300 m and 500 m fibers, revealed similar trends, during which 8 V% mixtures exhibited the highest peak load and the mixtures with 4 V% the lowest. Furthermore, the bamboo fibers were able to bridge the developing crack, resulting in a strain-softening behavior in all bamboo mixtures. The post-crack behavior was more pronounced for mixtures with higher fiber contents, which was in line with the findings with Aydin Serdar and Hameed et.al. where it was shown that a higher fiber content results in a higher load-carrying capacity due to the crack bridging behavior of the fibers [58,59].

Figure 7.

Bending test results of mixtures with 4 V%, 6 V% and 8 V% of (a) 300 m fibers and (b) 500 m fibers.

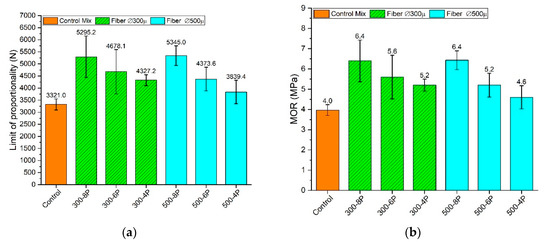

3.1.4. Fracture Properties and Toughness

The limit of proportionality and the modulus of rupture are shown in Figure 8. It should be noted that one out of the 3 samples of the 300 m with 8 V% and 6 V% exhibited a significantly lower bending performance as can be seen in Figure 7. This resulted in a high standard variation shown in Figure 8. Samples with the 500 m fiber batch revealed a lower modulus of rupture compared to those containing 300 m fibers. These values were around 0.0%, 7.7% and 13.0% lower for the 8/6/4 V% fibers specimens, respectively. These findings were in agreement with ACI 544.1R-96, where a lower MOR was reported with decreasing aspect ratio of the fibers [60]. Longer and thinner fibers exhibit a higher bond within a concrete or mortar matrix resulting in a higher pull-out resistance compared to shorter and thicker fibers as shown which was also found by other researchers in [55,61].

Figure 8.

Bending test assessment: (a) limit of proportionality Fmax; (b) modulus of rupture.

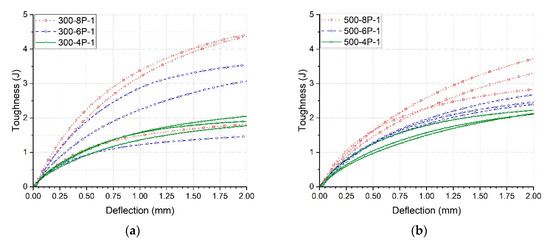

The toughness was calculated as the area under the load–deflection curve and expressed as energy in Joules. Accordingly, the resulting cumulative energy up to 2 mm deflection is shown in Figure 9 and Figure 10. As expected, a higher fiber content resulted in higher toughness. Thicker and longer fibers, as found in the 500 m batch, showed an overall reduction in toughness when compared to the smaller and shorter fibers in the 300 m batch. This is explained due to the higher bridge bearing capacity of the mixtures with a higher amount of fibers and a higher pull-out resistance for fibers with a higher aspect ratio as discussed earlier and shown in [59,61].

Figure 9.

Cumulative toughness of the bamboo fiber reinforced specimens up to 2 mm deflection: (a) 300 m batch; (b) 500 m batch evaluated from the four-point bending test according to ASTM C1609 [52].

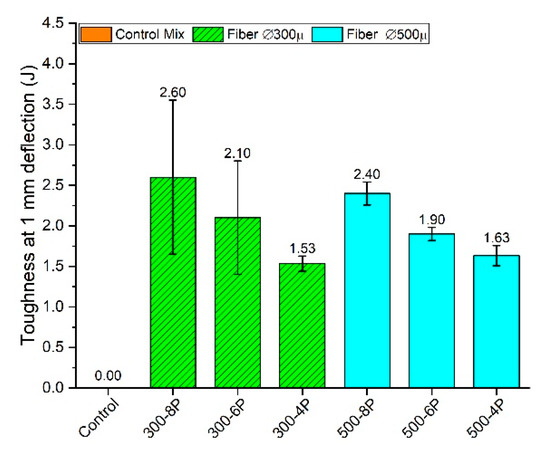

Figure 10.

Toughness of the mixtures at 1 mm deflection measured according to RILEM RC 162-TDF [53].

To characterize the post-cracking behavior of the different mixes, two toughness parameters were evaluated in accordance with RILEM RC 162-TDF [53]. The toughness values at a mid-span deflection of span/150, which corresponded to 1 mm deflection, and the toughness at a mid-span deflection of span/75 (2 mm deflection) were evaluated. The corresponding results, presented in Figure 10 and Table 4, revealed that a higher fiber content enhanced the ductility and toughness of the prepared mixes. The toughness values of the 300 m fiber specimens at 1 mm deflection were 40.0% and 73.3% higher for the 6 V% and 8 V% mixes when compared to 4 V% mixes, respectively. Assessing the 500 m fiber batch, an increase of 16% and 47% increase in toughness was recorded for the 8 V% and 6 V% mixes when compared to 4 V% mixes, respectively (see Figure 10). Furthermore, the results of the mixes containing 500 m fibers showed lower energy up to both 1.0 mm and 2.0 mm deflection when compared to the 300 m fiber results and showed the influence of the aspect ratio of the fibers on the bond strength of the specimen which is in compliance with findings in [55,61]. The high standard deviation of the 300 m with 8 V% and 6 V% is the result of the lower bending performance of one out of three tested specimens shown in Figure 7.

Table 4.

Flexural strength and toughness parameters of the four-point bending test.

4. Conclusions

This study focused on the development of a sustainable and affordable mortar mixture consisting of a high amount of fly ash (656 kg/m3) and varying contents of bamboo fibers (4/6/8 V%) from waste by-products of engineered bamboo-composite fabrication. The bamboo fibers, obtained from bamboo composite production waste, were categorized into two groups of 300 m and 500 m and were incorporated at three different volumes of 4/6/8 V% within each mix. The mechanical performance of the developed formulations was assessed via the measurement of the mechanical and fracture properties. From these results, the following conclusions can be drawn:

The addition of 4/6/8 V% of bamboo fibers has a reasonably modest effect on the compressive strength of the mixtures. Compared to the control mixture without fibers, the reduction of the compressive strength of the mixtures with 300 m fibers is between 7.8% and 19.9%, with larger fiber volume fractions corresponding to a greater reduction of strength.

- The mixtures with 500 m fibers were reduced in compressive strength between 9.1% and 27.0% by the same range of 4/6/8 V% of fiber content. The reduction of the compressive strength for both the 300 m and 500 m fibers could be related to the lower mechanical properties of the bamboo fibers as well as the influence of their aspect ratio.

- The compressive strengths of the mixtures with 8 V% of fibers were shown to be 60.2 MPa and 54.6 MPa for the 300 m and 500 m mixtures, respectively, and is within a reasonable range for use in structural members.

- The splitting tensile strength of the bamboo fiber-reinforced mixtures displays a reduction of between 6.9% and 31.9% compared to the control mixture depending on the fiber volume and aspect ratio. The mixtures containing the 500 m fibers (lower aspect ratio) show lower strength in comparison with the 300 m mixtures.

- All bamboo fiber-reinforced mortar mixtures display a strain-softening behavior. The mixtures with 8 V% of fibers show better crack-bridging effects than those with lower volume fractions, resulting in higher residual strength.

- The toughness of the mixtures was evaluated at a mid-span deflection of L/150. The 300 m fiber mixtures show values of 2.6, 2.1 and 1.5 Joule for 8, 6 and 4 V% of fibers respectively, whereas the 500 m mixtures show, in general, lower toughness of 2.40, 1.90 and 1.63 Joule.

- Mixtures containing 300 m fibers demonstrate an overall enhanced mechanical performance and post-crack behavior compared to the mixtures with 500 m fibers as a result of the higher bond strength due to their higher aspect ratio.

The findings emerging from this study demonstrate the suitability of using natural bamboo fibers, obtained from process waste, to improve the ductility of high-volume fly ash mortar. The resulting formulations can enable the development of a sustainable and low-cost mixture for structural members. These results can be utilized for the construction of low-cost and low-rise housing units in developing countries, especially in Southeast Asia, Latin and Central America, where there is access to bamboo and low-cost cementitious materials with low demand for ductility. Further studies on the durability of bamboo fibers and the replacement of steel reinforcement with engineered bamboo composites and natural bamboo fiber members are being performed to broaden the application range of these materials on a larger scale.

Author Contributions

Conceptualization, M.M.; Methodology, M.M.; Validation, M.M.; Formal analysis, M.M.; Investigation, M.M., A.J., and N.S.; Resources: M.M., A.J., and N.S.; Data curation, M.M., A.J., and N.S.; Writing—original draft preparation, M.M.; Writing—review and editing, A.J.; N.S.; H.K.T.; C.U. Visualization, M.M.; Supervision, H.K.T. and C.P.O.; Project administration, M.M. and A.J.; Funding acquisition, M.M., A.J., and N.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the Republic of Singapore’s National Research Foundation through a grant to the Berkeley Education Alliance for Research in Singapore (BEARS) for the Singapore-Berkeley Building Efficiency and Sustainability in the Tropics (SinBerBEST) Program. BEARS has been established by the University of California, Berkeley, as a center for intellectual excellence in research and education in Singapore. The research was conducted at the Future Cities Laboratory at the Singapore-ETH Centre, which was established collaboratively between ETH Zurich and Singapore’s National Research Foundation (FI 370074016) 766 under its Campus for Research Excellence and Technological Enterprise program.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Nations, U. Emission Gap Report 2018; UNEP DTU Partnership; 2018; Available online: https://core.ac.uk/reader/189891060 (accessed on 30 August 2020).

- Krausmann, F.; Gingrich, S.; Eisenmenger, N.; Erb, K.-H.; Haberl, H.; Fischer-Kowalski, M. Growth in global materials use, GDP and population during the 20th century. Ecol. Econ. 2009, 68, 2696–2705. [Google Scholar] [CrossRef]

- Boden, T.; Marland, G.; Andres, R. Global, Regional, and National Fossil-Fuel CO2 Emissions; Carbon Dioxide Information Analysis Center, Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2013. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of wood ash in concrete manufacturing. Resour. Conserv. Recycl. 2012, 67, 27–33. [Google Scholar] [CrossRef]

- Cheah, C.B.; Ramli, M. The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: An overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Mahmood, Y.A. Ash from timber waste as cement replacement material. Cem. Concr. Compos. 2002, 24, 219–222. [Google Scholar] [CrossRef]

- Guo, Z.; Jiang, T.; Zhang, J.; Kong, X.; Chen, C.; Lehman, D.E. Mechanical and durability properties of sustainable self-compacting concrete with recycled concrete aggregate and fly ash, slag and silica fume. Constr. Build. Mater. 2020, 231, 117115. [Google Scholar] [CrossRef]

- Uthaman, S.; Vishwakarma, V.; George, R.P.; Ramachandran, D.; Kumari, K.; Preetha, R.; Premila, M.; Rajaramand, R.; KamachiMudali, U.; Amarendra, G. Enhancement of strength and durability of fly ash concrete in seawater environments: Synergistic effect of nanoparticles. Constr. Build. Mater. 2018, 187, 448–459. [Google Scholar] [CrossRef]

- Velandia, D.F.; Lynsdale, C.J.; Provis, J.L.; Ramirez, F. Effect of mix design inputs, curing and compressive strength on the durability of Na2SO4-activated high volume fly ash concretes. Cem. Concr. Compos. 2018, 91, 11–20. [Google Scholar] [CrossRef]

- Singh, N.; Kumar, P.; Goyal, P. Reviewing the behaviour of high volume fly ash based self compacting concrete. J. Build. Eng. 2019, 26, 100882. [Google Scholar] [CrossRef]

- Bederina, M.; Marmoret, L.; Mezreb, K.; Khenfer, M.M.; Bali, A.; Quéneudec, M. Effect of the addition of wood shavings on thermal conductivity of sand concretes: Experimental study and modelling. Constr. Build. Mater. 2007, 21, 662–668. [Google Scholar] [CrossRef]

- Coatanlem, P.; Jauberthie, R.; Rendell, F. Lightweight wood chipping concrete durability. Constr. Build. Mater. 2006, 20, 776–781. [Google Scholar] [CrossRef]

- Guo, A.; Aamiri, O.B.; Satyavolu, J.; Sun, Z. Impact of thermally modified wood on mechanical properties of mortar. Constr. Build. Mater. 2019, 208, 413–420. [Google Scholar] [CrossRef]

- Akkaoui, A.; Caré, S.; Vandamme, M. Experimental and micromechanical analysis of the elastic properties of wood-aggregate concrete. Constr. Build. Mater. 2017, 134, 346–357. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Mazzoli, A.; Siddique, R. Characterization of lightweight mortars containing wood processing by-products waste. Constr. Build. Mater. 2016, 123, 281–289. [Google Scholar] [CrossRef]

- Taoukil, D.; Sick, F.; Mimet, A.; Ezbakhe, H.; Ajzoul, T. Moisture content influence on the thermal conductivity and diffusivity of wood–concrete composite. Constr. Build. Mater. 2013, 48, 104–115. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Development and characterization of thermal insulation materials from renewable resources. Constr. Build. Mater. 2019, 214, 685–697. [Google Scholar] [CrossRef]

- Hager, I.; Zdeb, T.; Krzemień, K. The impact of the amount of polypropylene fibres on spalling behaviour and residual mechanical properties of Reactive Powder Concretes. MATEC Web Conf. 2013, 6, 02003. [Google Scholar] [CrossRef]

- Bencardino, F.; Rizzuti, L.; Spadea, G.; Swamy, R.N. Experimental evaluation of fiber reinforced concrete fracture properties. Compos. Part B Eng. 2010, 41, 17–24. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, K.-Q.; Yu, J.-T.; Xu, S.-L. Structural behaviors of ultra-high performance engineered cementitious composites (UHP-ECC) beams subjected to bending-experimental study. Constr. Build. Mater. 2018, 177, 102–115. [Google Scholar] [CrossRef]

- Pan, Z.; Wu, C.; Liu, J.; Wang, W.; Liu, J. Study on mechanical properties of cost-effective polyvinyl alcohol engineered cementitious composites (PVA-ECC). Constr. Build. Mater. 2015, 78, 397–404. [Google Scholar] [CrossRef]

- Li, M.; Khelifa, M.; Khennane, A.; El Ganaoui, M. Structural response of cement-bonded wood composite panels as permanent formwork. Compos. Struct. 2019, 209, 13–22. [Google Scholar] [CrossRef]

- Fonseca, C.S.; Silva, M.F.; Mendes, R.F.; Hein, P.R.G.; Zangiacomo, A.L.; Savastano, H., Jr.; Tonoli, G.H.D. Jute fibers and micro/nanofibrils as reinforcement in extruded fiber-cement composites. Constr. Build. Mater. 2019, 211, 517–527. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Li, M.; Zhou, S.; Guo, X. Effects of alkali-treated bamboo fibers on the morphology and mechanical properties of oil well cement. Constr. Build. Mater. 2017, 150, 619–625. [Google Scholar] [CrossRef]

- Dewi, S.M.; Wijaya, M.N. The use of bamboo fiber in reinforced concrete beam to reduce crack. AIP Conf. Proc. 2017, 1887, 020003. [Google Scholar]

- Zhang, X.; Pan, J.Y.; Yang, B. Experimental study on mechanical performance of bamboo fiber reinforced concrete. Appl. Mech. Mater. 2012, 174, 1219–1222. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, Z.; Chen, G.W. Experimental research on bamboo fiber reinforced concrete. Appl. Mech. Mater. 2013, 357, 1045–1048. [Google Scholar] [CrossRef]

- Terai, M.; Minami, K. Basic Study on Mechanical Properties of Bamboo Fiber Reinforced Concrete. Glob. Think. Struct. Eng. Recent Achiev. 2012, 8, 17–24. [Google Scholar]

- Javadian, A. Composite Bamboo and its Application as Reinforcement in Structural Concrete. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2017. [Google Scholar]

- Rahman, N.; Shing, L.W.; Simon, L.; Philipp, M.; Alireza, J.; Ling, C.S.; Wuan, L.H.; Valavan, S.; Nee, S.S. Enhanced bamboo composite with protective coating for structural concrete application. Energy Procedia 2017, 143, 167–172. [Google Scholar] [CrossRef]

- Hebel, D.E.; Javadian, A.; Heisel, F.; Schlesier, K.; Griebel, D.; Wielopolski, M. Process-controlled optimization of the tensile strength of bamboo fiber composites for structural applications. Compos. Part B Eng. 2014, 67, 125–131. [Google Scholar] [CrossRef]

- Liese, W. The Anatomy of Bamboo Culms; BRILL: Boston, MA, USA, 1998. [Google Scholar]

- Liese, W. Bamboos Biology, Silvics, Properties, Utilization (Schriftenreihe der GTZ, no. No 180); Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ): Eschborn, Germany, 1985; p. 132. [Google Scholar]

- Wang, X.; Keplinger, T.; Gierlinger, N.; Burgert, I. Plant material features responsible for bamboo’s excellent mechanical performance: A comparison of tensile properties of bamboo and spruce at the tissue, fibre and cell wall levels. Ann. Bot. 2014, 114, 1627–1635. [Google Scholar] [CrossRef]

- Javadian, A.; Smith, I.F.C.; Saeidi, N.; Hebel, D.E. Mechanical Properties of Bamboo Through Measurement of Culm Physical Properties for Composite Fabrication of Structural Concrete Reinforcement. Front. Mater. 2019, 6, 15. [Google Scholar] [CrossRef]

- Ray, K.A.; Mondal, S.; Das, S.K.; Ramachandrarao, P. Bamboo—A functionally graded composite-correlation between microstructure and mechanical strength. J. Mater. Sci. 2005, 40, 5249–5253. [Google Scholar] [CrossRef]

- Javadian, A.; Wielopolski, M.; Smith, I.F.; Hebel, D.E. Bond-behavior study of newly developed bamboo-composite reinforcement in concrete. Constr. Build. Mater. 2016, 122, 110–117. [Google Scholar] [CrossRef]

- Grüner Stahl—Hochfeste Naturfaserverbundwerkstoffe für strukturelle Anwendungen in der Industrie. In Projekt abschlussbericht KTI-Commission for Technology and Innovation; ETH Zurich, Empa Dubendorf: Bern, Switzerland, 2016; Volume 1.

- Xu, R.; He, T.; Da, Y.; Liu, Y.; Li, J.; Chen, C. Utilizing wood fiber produced with wood waste to reinforce autoclaved aerated concrete. Constr. Build. Mater. 2019, 208, 242–249. [Google Scholar] [CrossRef]

- Bederina, M.; Gotteicha, M.; Belhadj, B.; Dheily, R.M.; Khenfer, M.M.; Queneudec, M. Drying shrinkage studies of wood sand concrete—Effect of different wood treatments. Constr. Build. Mater. 2012, 36, 1066–1075. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Traore, Y.B.; Messan, A.; Hannawi, K.; Gerard, J.; Prince, W.; Tsobnang, F. Effect of oil palm shell treatment on the physical and mechanical properties of lightweight concrete. Constr. Build. Mater. 2018, 161, 452–460. [Google Scholar] [CrossRef]

- SS-EN197-1—Cement: Compositoin, Specification and Conformity Criteria for Common Cements; Enterprise Singapore: Singapore, 2011.

- ASTM C618-19 Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C1437-07—Standard Test Method for Flow of Hydraulic Cement Mortar; ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM C230/C230M—Standard Specification for Flow Table for Use in Tests of Hydraulic Cement; ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM C109, Compressive Strength of Hydraulic Cement Mortars; ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM C496, Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C1609, Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete; ASTM International: West Conshohocken, PA, USA, 2011.

- Vandewalle, L. RILEM TC 162-TDF: Test and design methods for steel fibre reinforced concrete. Mater. Struct. 2000, 33, 3–5. [Google Scholar]

- Yazıcı, Ş.; İnan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 2007, 21, 1250–1253. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, H.; Wang, G.; Yu, Z.; Shi, S.Q. Tensile properties of bamboo in different sizes. J. Wood Sci. 2015, 61, 552–561. [Google Scholar] [CrossRef]

- Li, Z.; Wang, L.; Wang, X. Compressive and flexural properties of hemp fiber reinforced concrete. Fibers Polym. 2004, 5, 187–197. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Syed, Z.I.; Najm, O.F. Splitting Tensile Strength of Sustainable self-consolidating Concrete. Procedia Eng. 2016, 145, 1218–1225. [Google Scholar] [CrossRef]

- Aydın, S. Effects of fiber strength on fracture characteristics of normal and high strength concrete. Period. Polytech. Civ. Eng. 2013, 57, 191–200. [Google Scholar] [CrossRef]

- Hameed, R.; Turatsinze, A.; Duprat, F.; Sellier, A. Metallic fiber reinforced concrete: Effect of fiber aspect ration on the flexural properties. ARPN J. Eng. Appl. Sci. 2009, 4, 67–72. [Google Scholar]

- ACI 544.1R-96: Report on Fiber Reinforced Concrete; ACI World Headquarters: Farmington Hills, MI, USA, 2002.

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Constr. Build. Mater. 2011, 25, 575–581. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).