Durability Assessment of Recycled Aggregate HVFA Concrete

Abstract

1. Introduction

- Nat, as reference;

- Nat + FA with HVFA added at equal amounts as cement;

- Rec, by replacing the 100% of Nat with Rec;

- Rec + FA with HVFA.

2. Materials and Methods

2.1. Materials

2.2. Mixture Proportions

3. Preparation and Testing of Specimens

3.1. Compression Tests

3.2. Carbonation Depth

3.3. Chloride Penetration

3.4. Corrosion Tests

4. Results and Discussion

4.1. Compression Tests

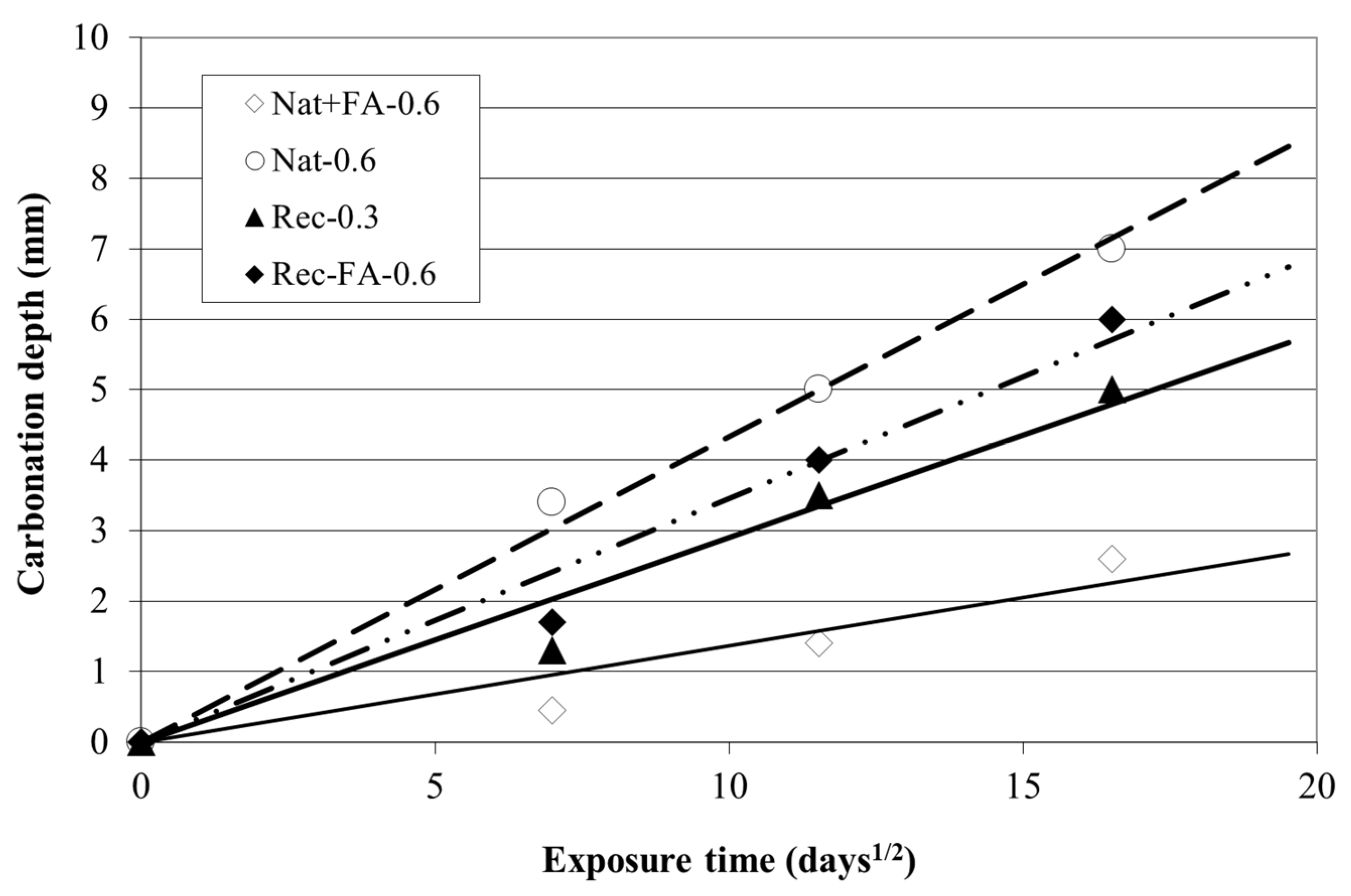

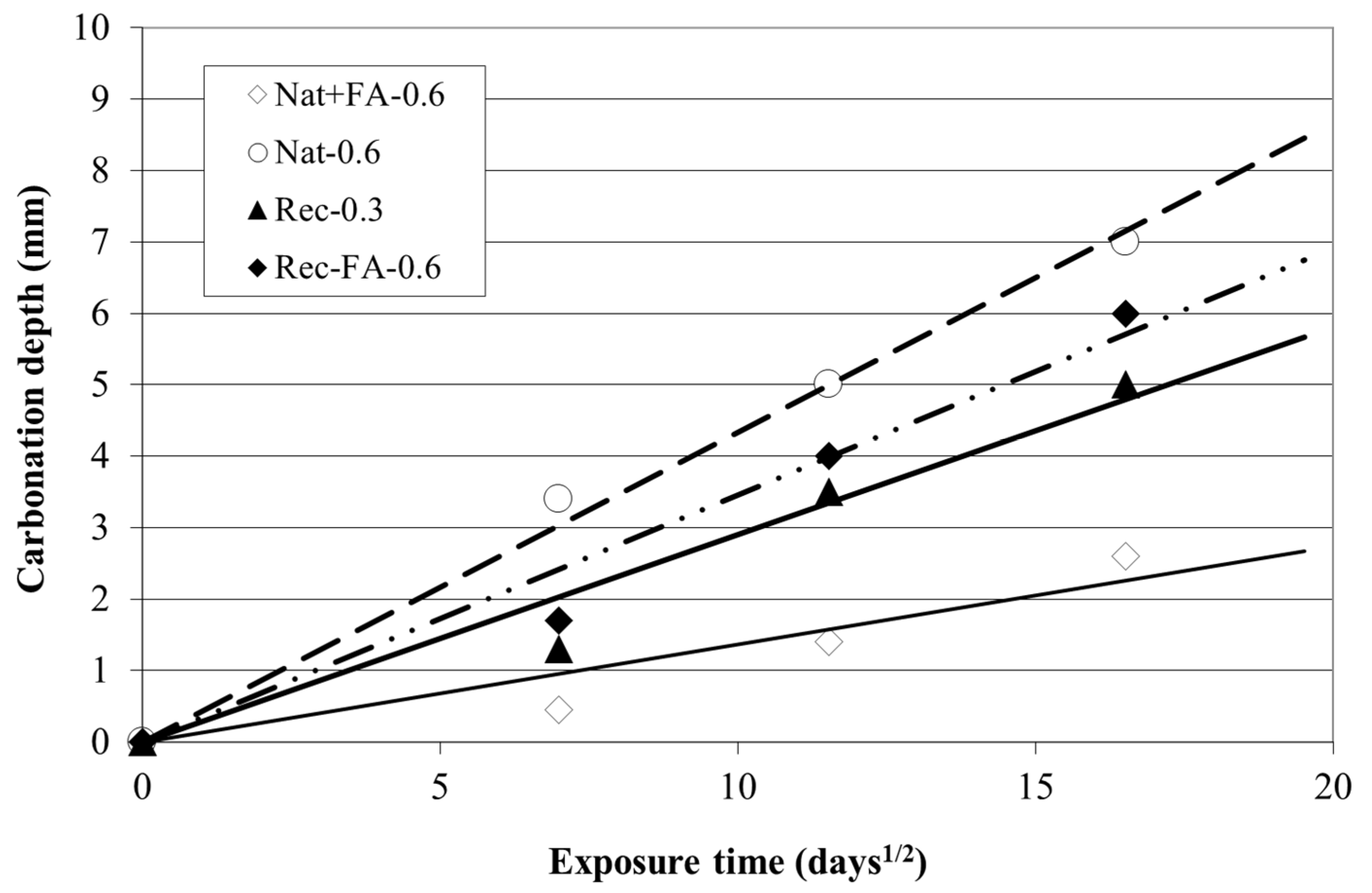

4.2. Carbonation Depth

4.3. Chloride Penetration

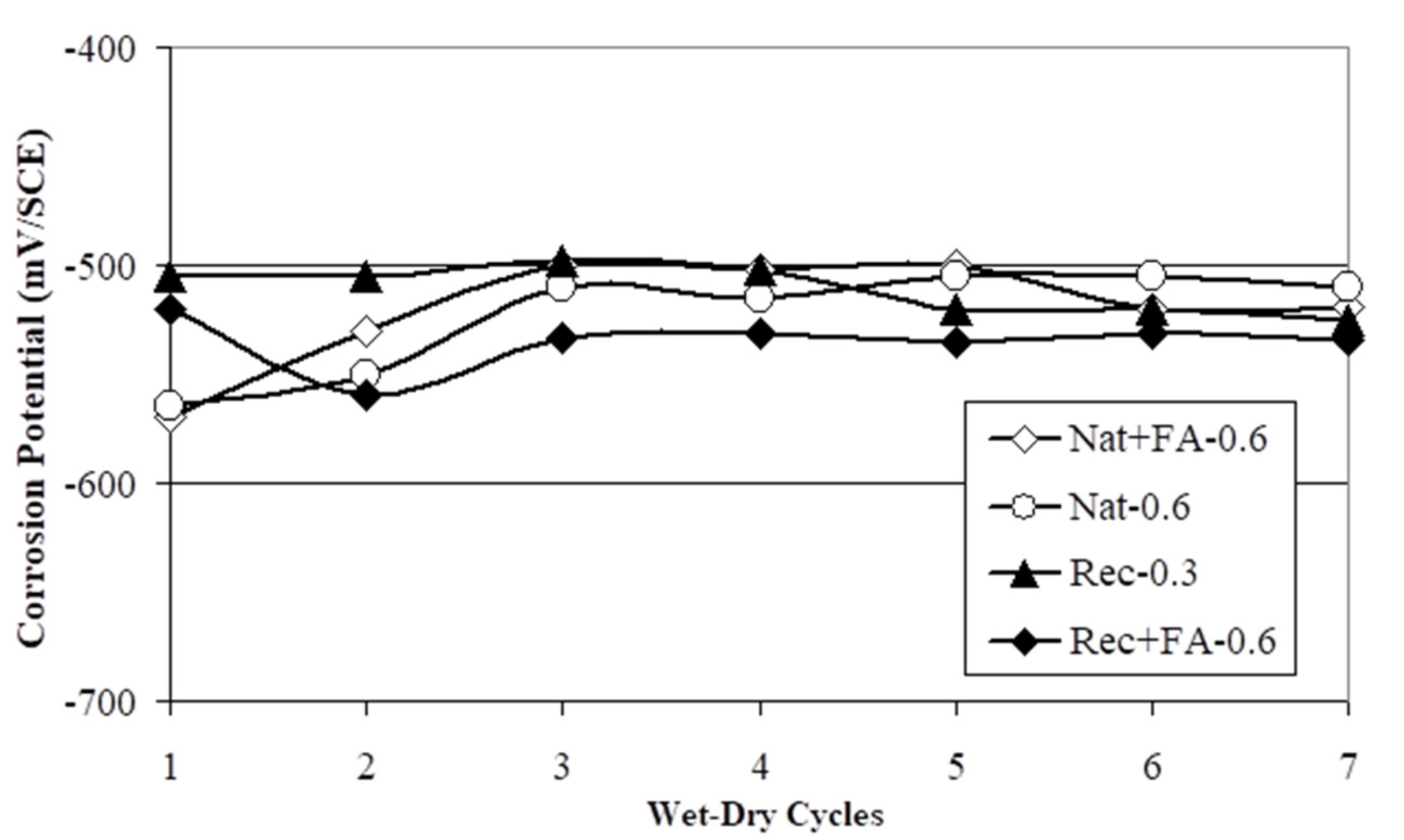

4.4. Corrosion Tests

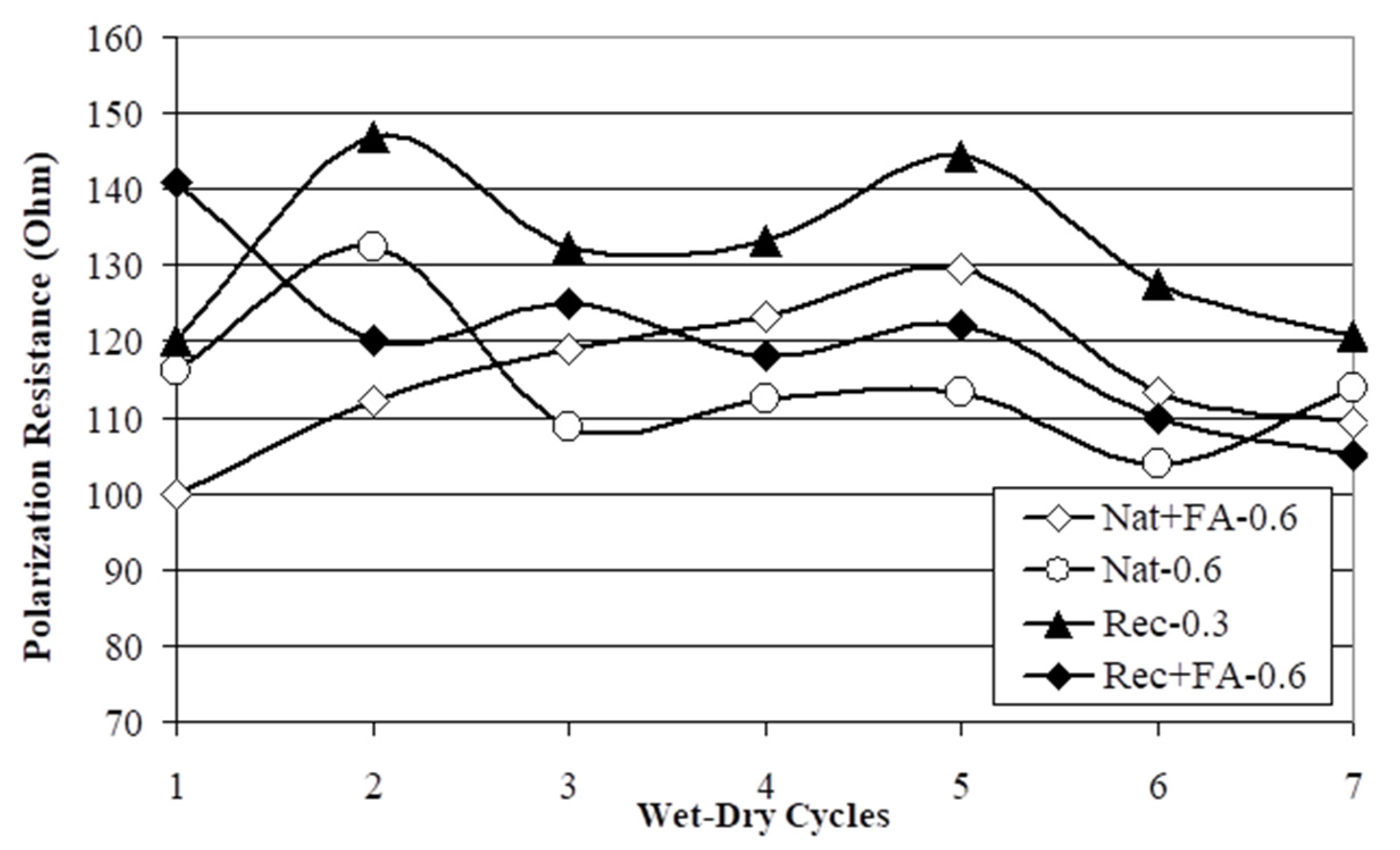

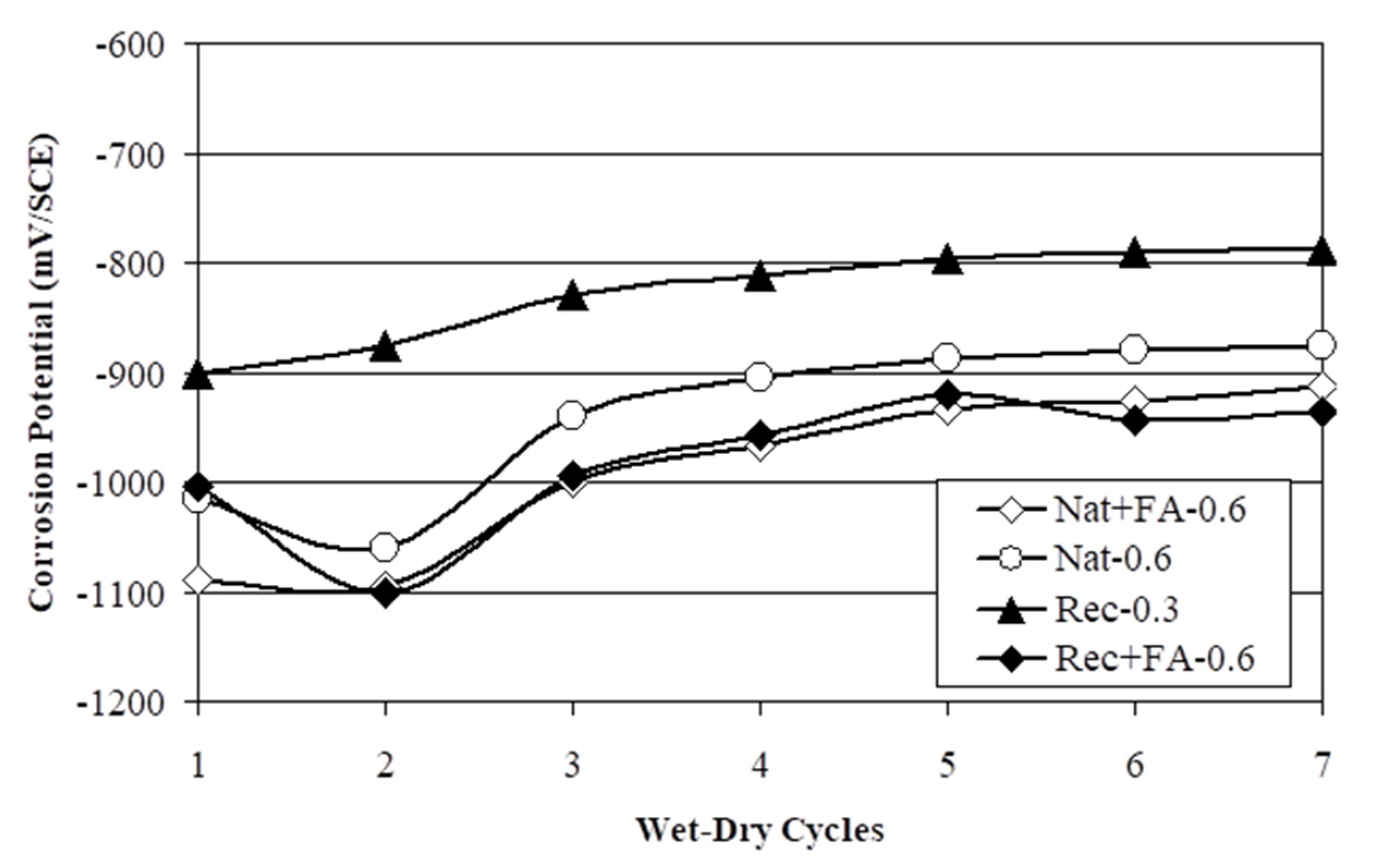

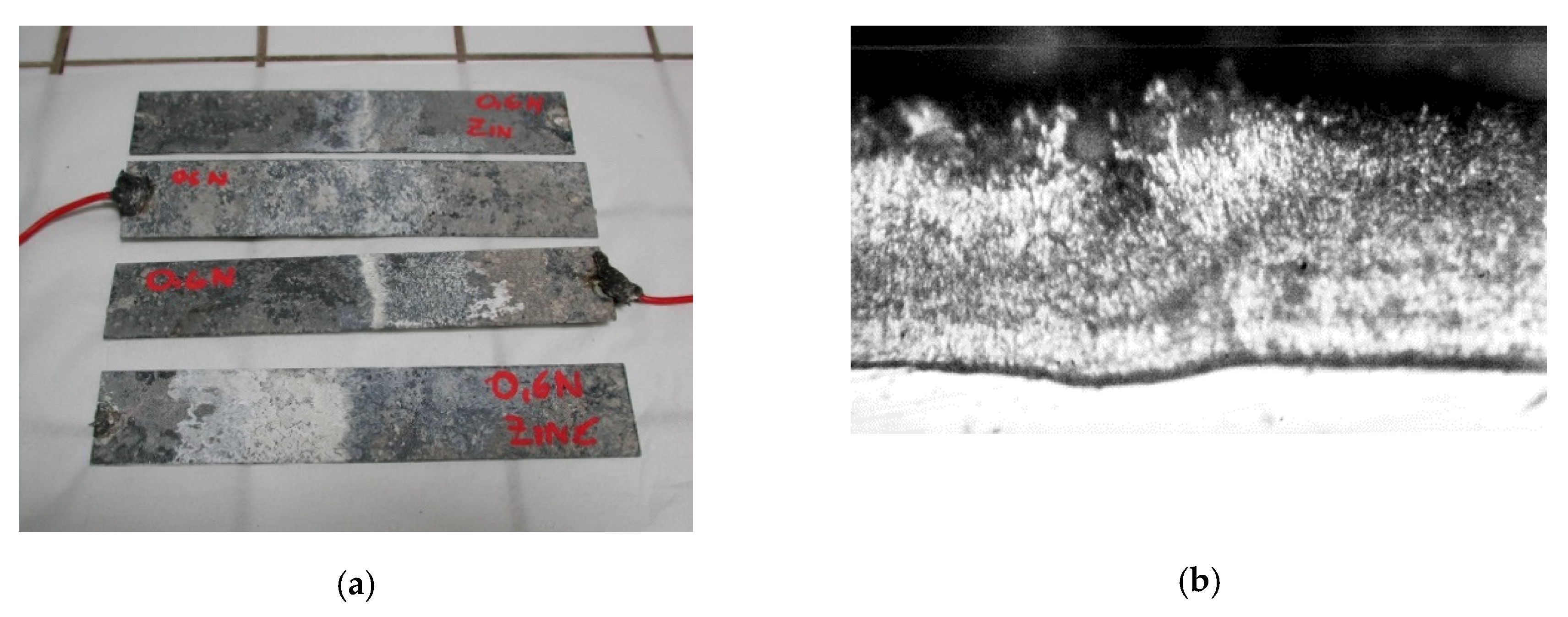

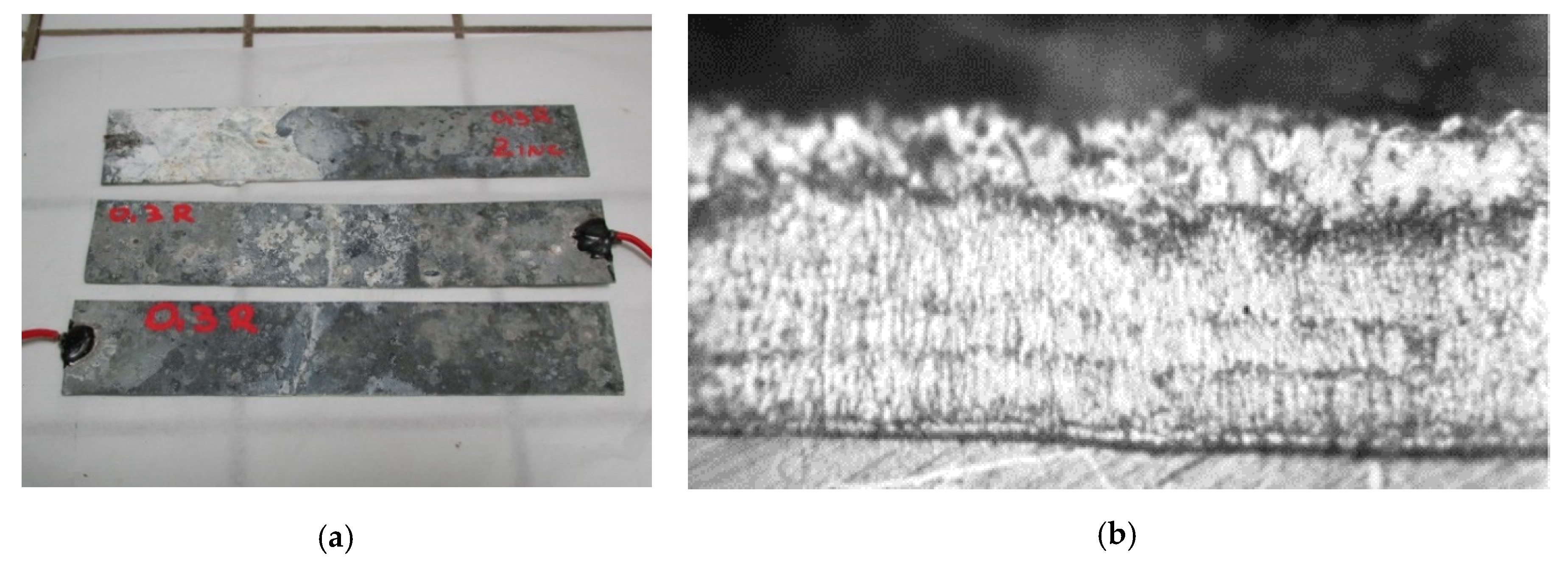

4.4.1. Bare Steel Plates

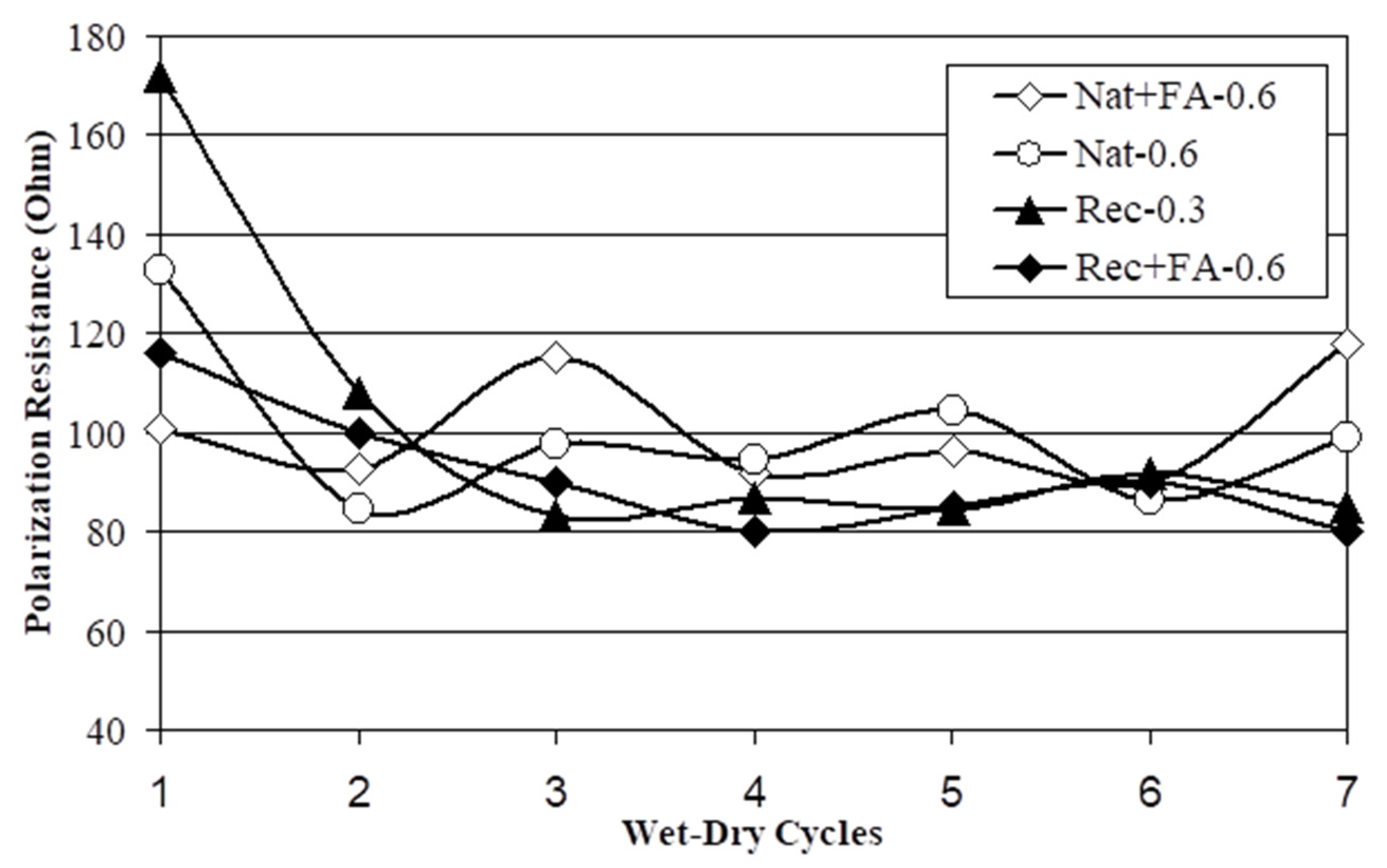

4.4.2. Galvanized Steel Plates

5. Conclusions

- The use of recycled aggregate fractions (up to 15 mm) proved to be suitable for manufacturing structural concrete, even when employed in total replacement of fine and coarse natural aggregates.

- If natural aggregates are substituted by recycled ones, fly ash is added to the mixture in partial substitution of cement, and the w/c is decreased with the aid of a superplasticizer, the compressive strength is equal or even greater than that of natural aggregate concrete.

- The use of fly ash proved to be very effective in reducing carbonation and Cl penetration depths in concrete, even if recycled instead of virgin aggregate was used.

- When the concrete cover was cracked, the addition of fly ash and the use of recycled aggregates (Rec + FA-0.6) did not reduced the corrosion resistance of steel reinforcement, while it appeared very effective to protect the galvanized steel reinforcement.

- An improved attention to the sustainability issue in concrete manufacturing, promoted by using recycled aggregate and high-volume fly ash, did not cause bad side effects on durability performance of reinforced concrete specimens under testing.

Author Contributions

Funding

Conflicts of Interest

References

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Siddique, R. Performance characteristics of high-volume class F fly ash concrete. Cem. Concr. Res. 2004, 34, 487–493. [Google Scholar] [CrossRef]

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical properties and mechanical behaviour of concrete made with recycled aggregates and fly ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- Mobili, A.; Giosue`, C.; Corinaldesi, V.; Tittarelli, F. Bricks and Concrete Wastes as Coarse and Fine Aggregates in Sustainable Mortars. Adv. Mater. Sci. Eng. 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Faella, C.; Lima, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Mechanical and durability performance of sustainable structural concretes: An experimental study. Cem. Concr. Compos. 2016, 71, 85–96. [Google Scholar] [CrossRef]

- Singh, N.; Kumar, P.; Goyal, P. Reviewing the behaviour of high volume fly ash based self compacting concrete. J. Build. Eng. 2019, 26, 100882. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Palaniraj Saravanakumar, P.; Dhinakaran, G. Durability aspects of HVFA-based recycled aggregate concrete. Mag. Concr. Res. 2014, 66, 186–195. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water absorption and electrical resistivity of concrete with recycled concrete aggregates and fly ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Optimizing recycled concrete containing high volume of fly ash in terms of the embodied energy and chloride ion resistance. J. Clean. Prod. 2018, 194, 735–750. [Google Scholar] [CrossRef]

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Use of recycled concrete aggregate in fly-ash concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Combined influence of recycled concrete aggregates and high contents of fly ash on concrete properties. Constr. Build. Mater. 2017, 157, 554–572. [Google Scholar] [CrossRef]

- Wei, Y.; Chai, J.; Qin, Y.; Xu, Z.; Zhang, X. Performance evaluation of green-concrete pavement material containing selected C&D waste and FA in cold regions. J. Mater. Cycles Waste Manag. 2019, 21, 1550–1562. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Li, S.; Zhao, Y.; Qin, Y. Resistance of recycled aggregate concrete containing low- and high-volume fly ash against the combined action of freeze–thaw cycles and sulfate attack. Constr. Build. Mater. 2018, 166, 23–34. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Etxeberria, M. Residue strength, water absorption and pore size distributions of recycled aggregate concrete after exposure to elevated temperatures. Cem. Concr. Compos. 2014, 53, 73–82. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Effect of mineral admixtures on properties of recycled aggregate concrete at high temperature. Constr. Build. Mater. 2018, 184, 361–373. [Google Scholar] [CrossRef]

- Ren, Q.; Wu, Y.; Zhang, X.; Wang, Y. Effects of fly ash on the mechanical and impact properties of recycled aggregate concrete after exposure to high temperature. Eur. J. Environ. Civ. Eng. 2019, 1–17. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Qureshi, Z.A.; Shaheen, N.; Ali, S. Bio-mineralized self-healing recycled aggregate concrete for sustainable infrastructure. Sci. Total Environ. 2020, 703, 135007. [Google Scholar] [CrossRef]

- Carević, V.; Ignjatović, I.; Dragaš, J. Model for practical carbonation depth prediction for high volume fly ash concrete and recycled aggregate concrete. Constr. Build. Mater. 2019, 213, 194–208. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S.P. Carbonation resistance and microstructural analysis of Low and High Volume Fly Ash Self Compacting Concrete containing Recycled Concrete Aggregates. Constr. Build. Mater. 2016, 127, 828–842. [Google Scholar] [CrossRef]

- Kurda, R.; De Brito, J.; Silvestre, J.D. Carbonation of concrete made with high amount of fly ash and recycled concrete aggregates for utilization of CO2. J. Co2 Util. 2019, 29, 12–19. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. CONCRETop method: Optimization of concrete with various incorporation ratios of fly ash and recycled aggregates in terms of quality performance and life-cycle cost and environmental impacts. J. Clean. Prod. 2019, 226, 642–657. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. A comparative study of the mechanical and life cycle assessment of high-content fly ash and recycled aggregates concrete. J. Build. Eng. 2020, 29, 101173. [Google Scholar] [CrossRef]

- Stambaugh, N.D.; Bergman, T.L.; Srubar, W.V. Numerical service-life modeling of chloride-induced corrosion in recycled-aggregate concrete. Constr. Build. Mater. 2018, 161, 236–245. [Google Scholar] [CrossRef]

- Revathi, P.; Nikesh, P. Effect of Fly-Ash on Corrosion Resistance Characteristics of Rebar Embedded in Recycled Aggregate Concrete. J. Inst. Eng. India Ser. A 2018, 99, 473–483. [Google Scholar] [CrossRef]

- Gurdián, H.; García-Alcocel, E.; Baeza-Brotons, F.; Garcés, P.; Zornoza, E. Corrosion Behavior of Steel Reinforcement in Concrete with Recycled Aggregates, Fly Ash and Spent Cracking Catalyst. Materials 2014, 7, 3176–3197. [Google Scholar] [CrossRef] [PubMed]

- UNI EN 12390-1:2012. Prova Sul Calcestruzzo Indurito—Parte 1: Forma, Dimensioni ed Altri Requisiti per Provini e per Casseforme; Ente Nazionale Italiano di Unificazione: Milan, Italy, 2012. [Google Scholar]

- UNI EN 12390-3:2019. Prove sul Calcestruzzo Indurito—Parte 3: Resistenza alla Compressione dei Provini; Ente Nazionale Italiano di Unificazione: Milan, Italy, 2019. [Google Scholar]

- CPC-18. Measurement of hardened concrete carbonation depth. Mater. Struct. 1988, 21, 453–455. [Google Scholar] [CrossRef]

| Oxide (%) | CEM II/A-L 42.5 R | Fly Ash |

|---|---|---|

| SiO2 | 29.7 | 59.9 |

| Al2O3 | 3.7 | 22.9 |

| Fe2O3 | 1.8 | 4.7 |

| TiO2 | 0.1 | 0.9 |

| CaO | 59.3 | 3.1 |

| MgO | 1.1 | 1.6 |

| SO3 | 3.2 | 0.3 |

| K2O | 0.8 | 2.2 |

| Na2O | 0.3 | 0.6 |

| Loss on Ignition (L.o.I.) | 11.6 | 3.3 |

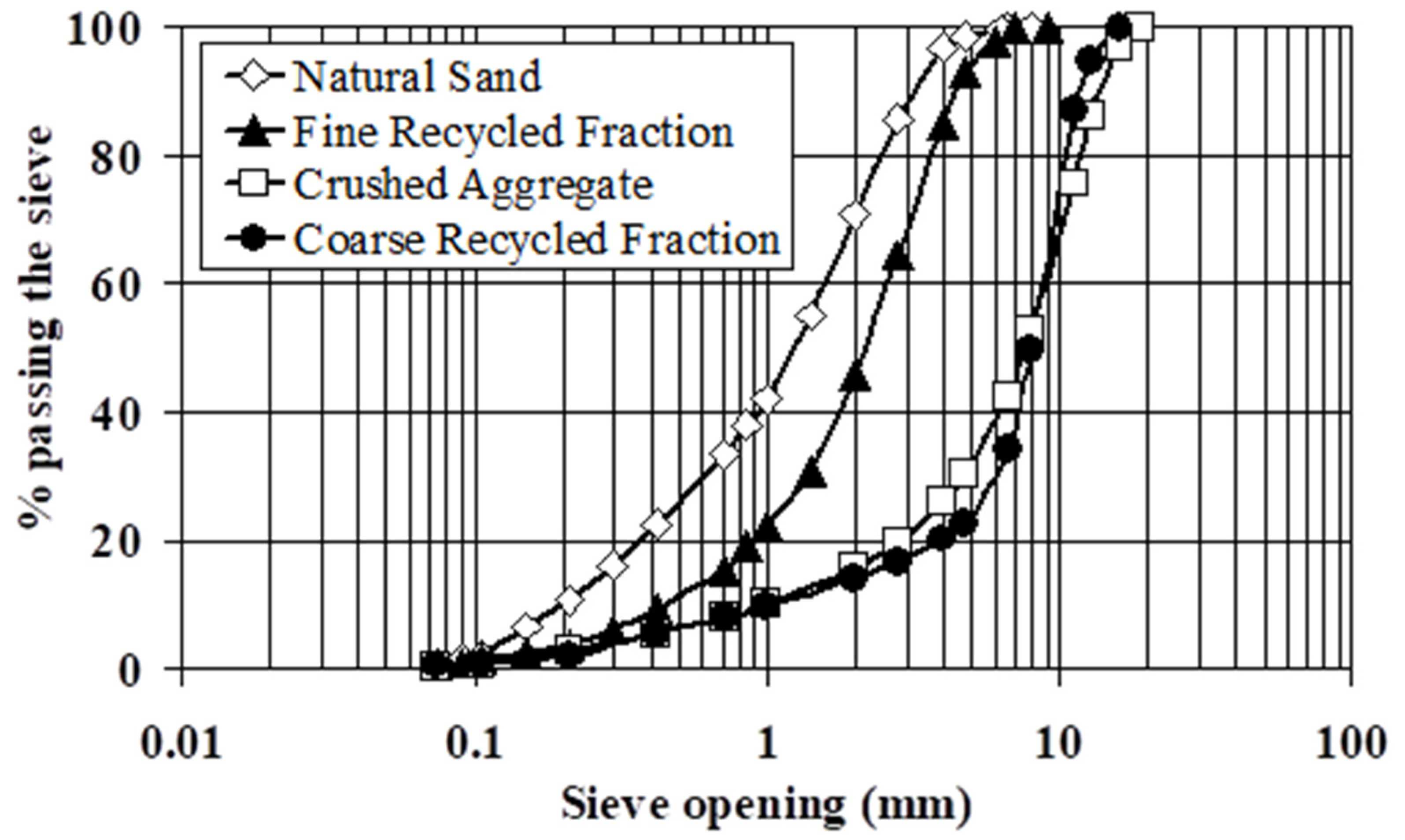

| Aggregate Fractions | Bulk Density (SSD), kg/m3 | Water Absorption, % | Passing 75 μm, % |

|---|---|---|---|

| Natural Sand | 2620 | 3 | 0.9 |

| Crushed Aggregate | 2680 | 2 | 0.2 |

| Fine Recycled Fraction | 2150 | 10 | 0.5 |

| Coarse Recycled Fraction | 2320 | 8 | 0.3 |

| Nat-0.6 | Nat + FA-0.6 | Rec-0.3 | Rec + FA-0.6 | |

|---|---|---|---|---|

| Water/Cement | 0.6 | 0.6 | 0.3 | 0.6 |

| Water/Binder | 0.6 | 0.3 | 0.3 | 0.3 |

| Water | 250 | 250 | 180 | 180 |

| Cement | 420 | 420 | 600 | 300 |

| Fly ash | - | 420 | - | 300 |

| Superplasticizer | - | 8.4 | 6.0 | 5.4 |

| Natural sand | 290 | - | - | - |

| Fine recycled aggregate | - | - | 125 | 125 |

| Crushed aggregate | 1280 | 1280 | - | - |

| Coarse recycled aggregate | - | - | 1030 | 1030 |

| Nat-0.6 | Nat + FA-0.6 | Rec-0.3 | Rec + FA-0.6 | |

|---|---|---|---|---|

| D (cm2∙s−1∙10−6) | 1.90 | 0.87 | 0.72 | 0.46 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corinaldesi, V.; Donnini, J.; Giosué, C.; Mobili, A.; Tittarelli, F. Durability Assessment of Recycled Aggregate HVFA Concrete. Appl. Sci. 2020, 10, 6454. https://doi.org/10.3390/app10186454

Corinaldesi V, Donnini J, Giosué C, Mobili A, Tittarelli F. Durability Assessment of Recycled Aggregate HVFA Concrete. Applied Sciences. 2020; 10(18):6454. https://doi.org/10.3390/app10186454

Chicago/Turabian StyleCorinaldesi, Valeria, Jacopo Donnini, Chiara Giosué, Alessandra Mobili, and Francesca Tittarelli. 2020. "Durability Assessment of Recycled Aggregate HVFA Concrete" Applied Sciences 10, no. 18: 6454. https://doi.org/10.3390/app10186454

APA StyleCorinaldesi, V., Donnini, J., Giosué, C., Mobili, A., & Tittarelli, F. (2020). Durability Assessment of Recycled Aggregate HVFA Concrete. Applied Sciences, 10(18), 6454. https://doi.org/10.3390/app10186454