Microstructural Changes Influencing the Magnetoresistive Behavior of Bulk Nanocrystalline Materials

Abstract

1. Introduction

- The (partial) immiscibility of both phases is a prerequisite for the appearance of granular GMR. The solid solution forming Fe–Pt did not show GMR behavior. Regarding the systems in focus of this publication, the solubility of Cu and Co and vice versa is smaller than 1 at% at 900 K [14]. The same is true for Cu–Fe below ~1000 K [15].

- A peak in GMR occurs for ferromagnetic volume fractions between 15% and 25%. This was found to be universal for all systems showing granular GMR. Within the Cu–Fe-series, the highest GMR was found for Fe20Cu80 (in vol%).

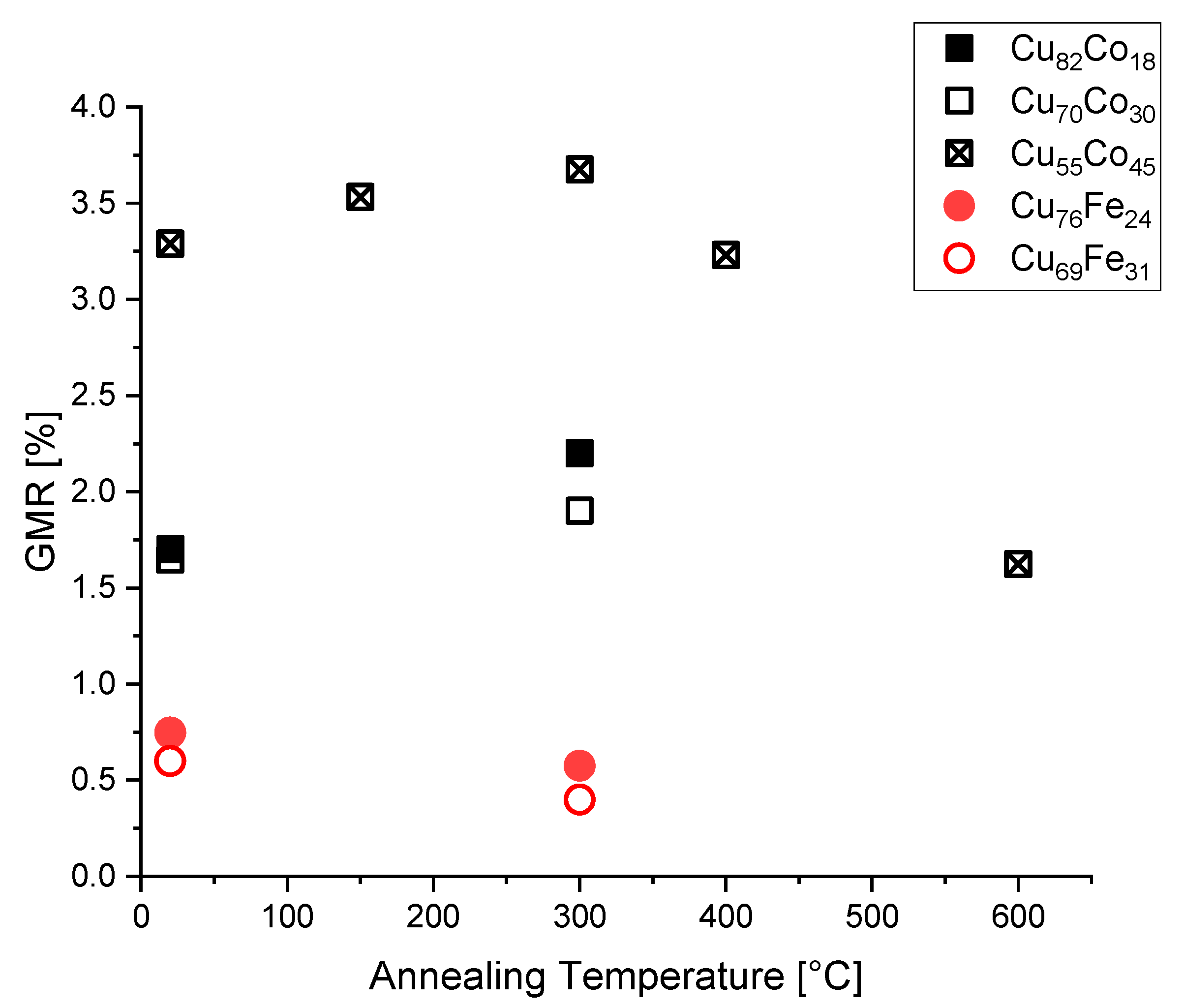

- The strength of GMR is affected by subsequent thermal treatments of the magnetron sputtered material. GMR is slightly larger for the Fe–Ag-system and for the Co–Ag-system after thermal treatment between 200 °C to 330 °C (depending on the chosen system) for 15 min and decreases again for even higher temperatures. For the Fe–Cu system, the maximum value was already found in the as-deposited state.

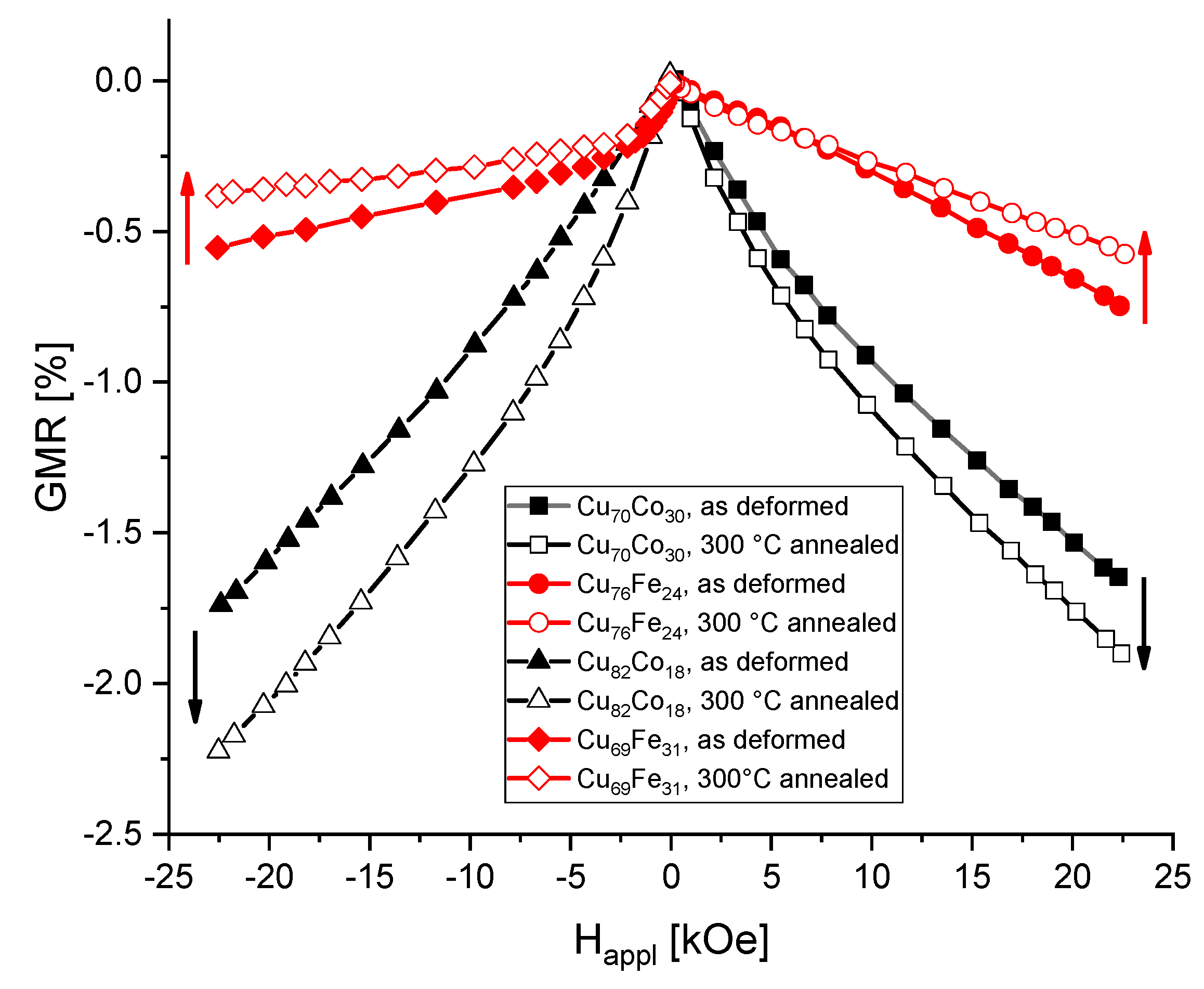

- A reduction of the saturation field for GMR is found for annealed materials. This has to be seen in connection with reduced fields for saturating the magnetization, found in hysteresis measurements, and the dependence of GMR on the magnetized state of the material. The same reductions in magnetization saturation fields were found for annealed HPT-deformed materials [16].

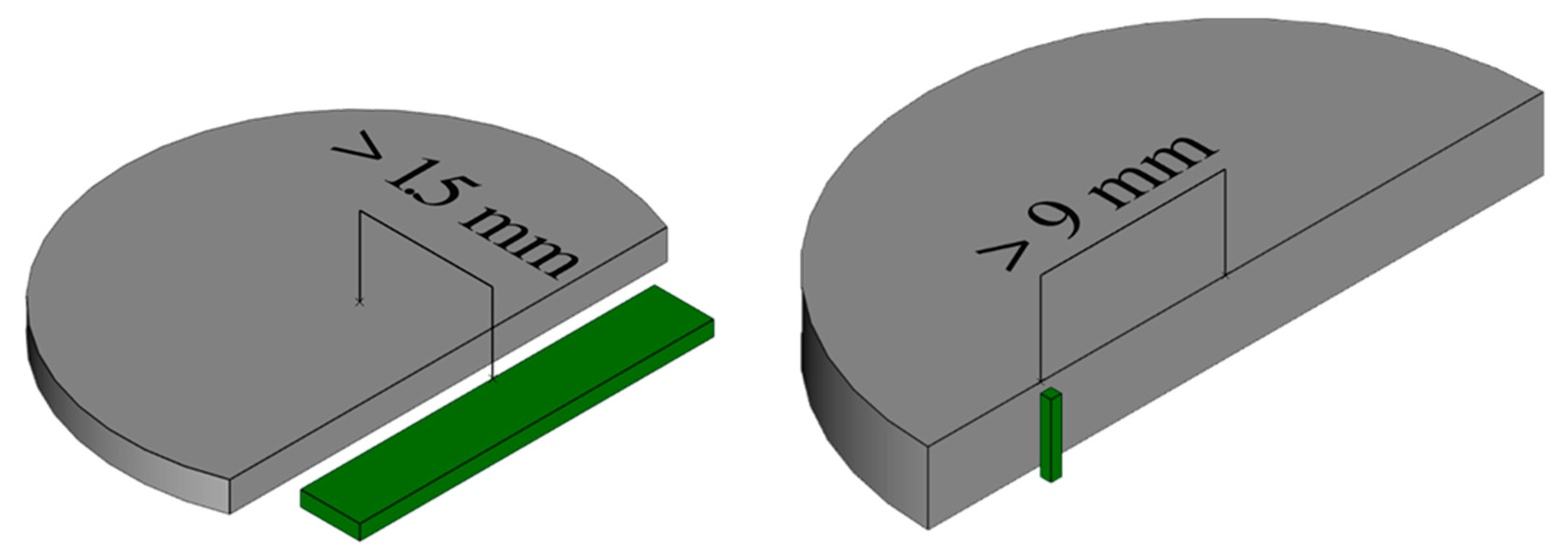

2. Materials and Methods

3. Results

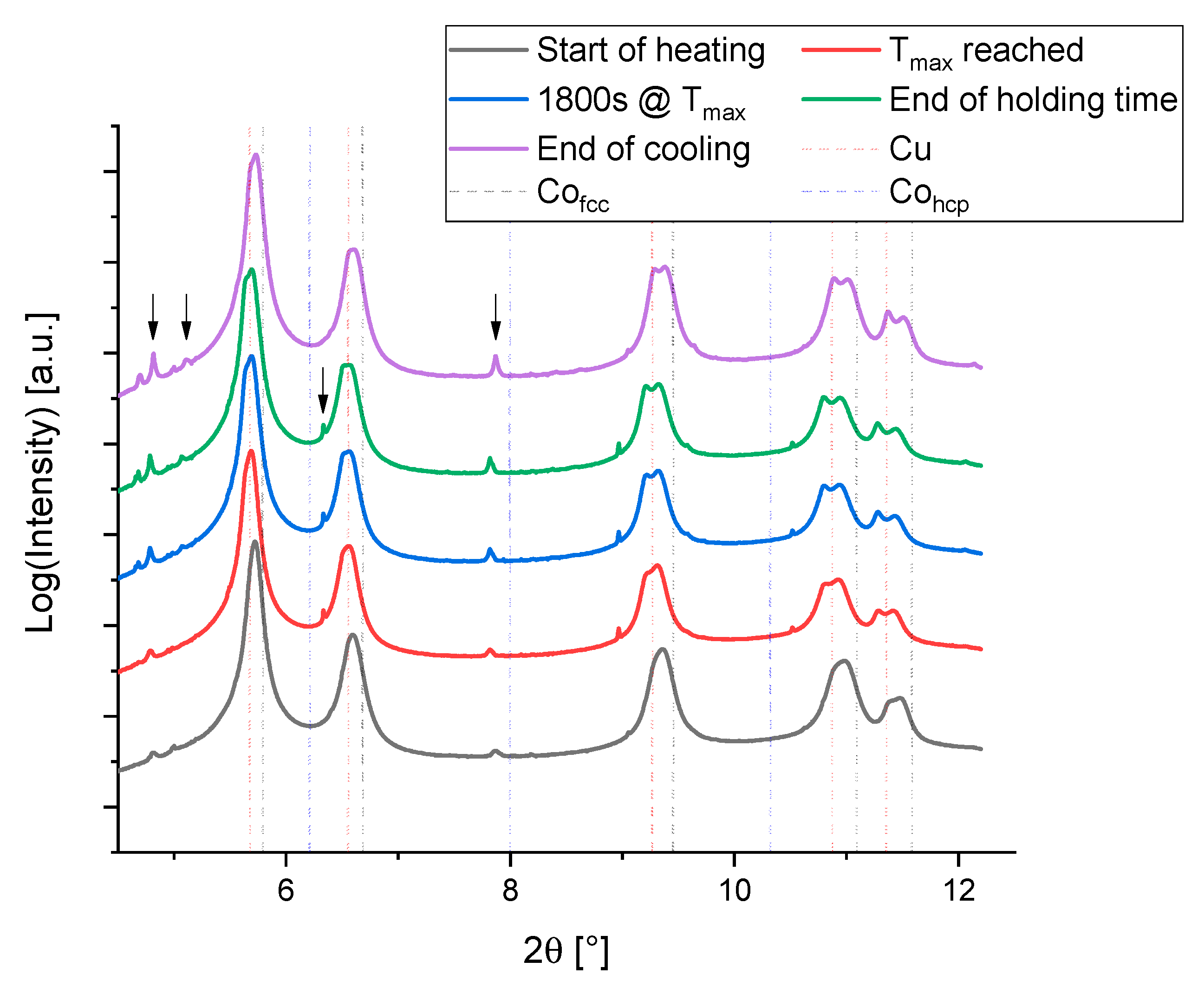

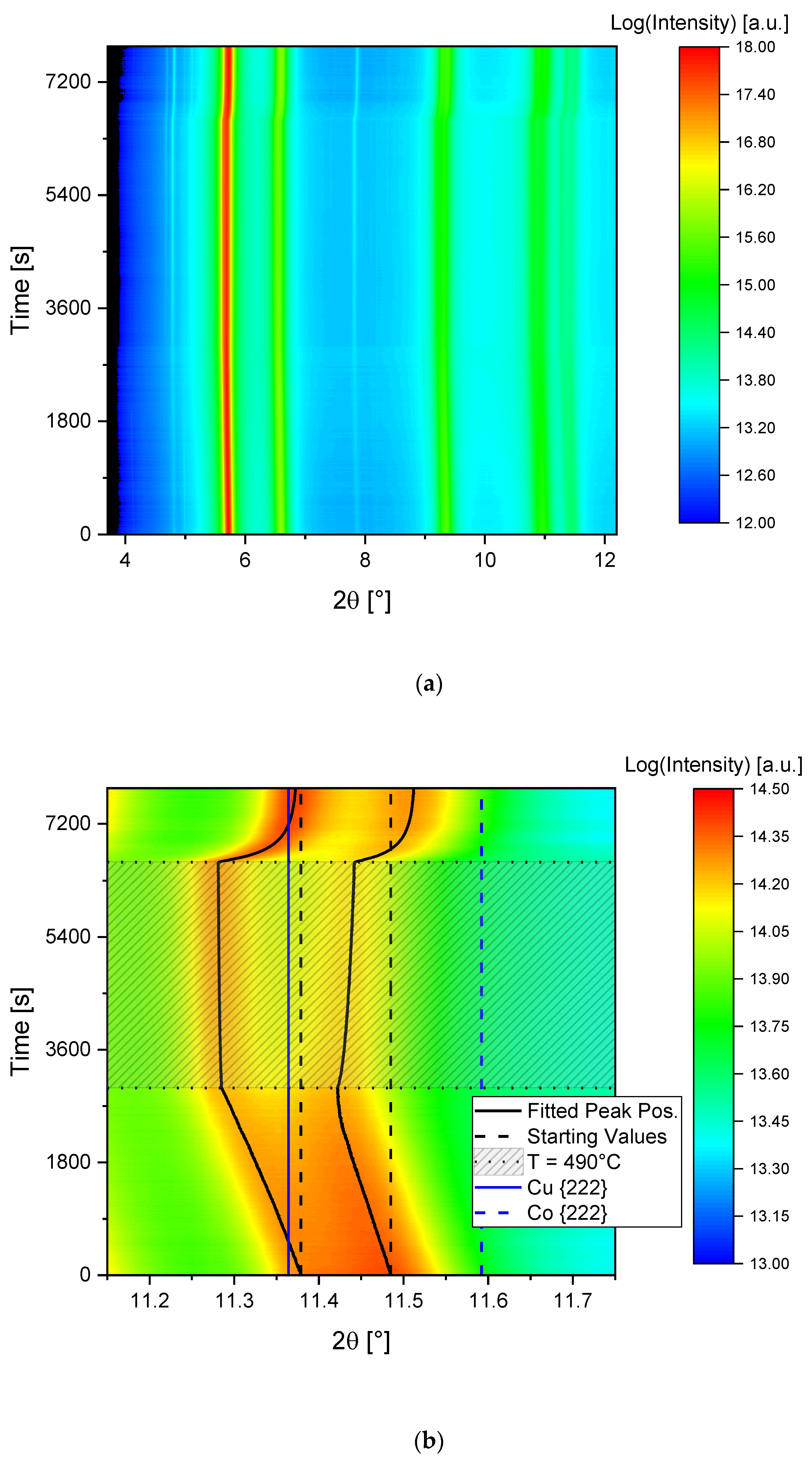

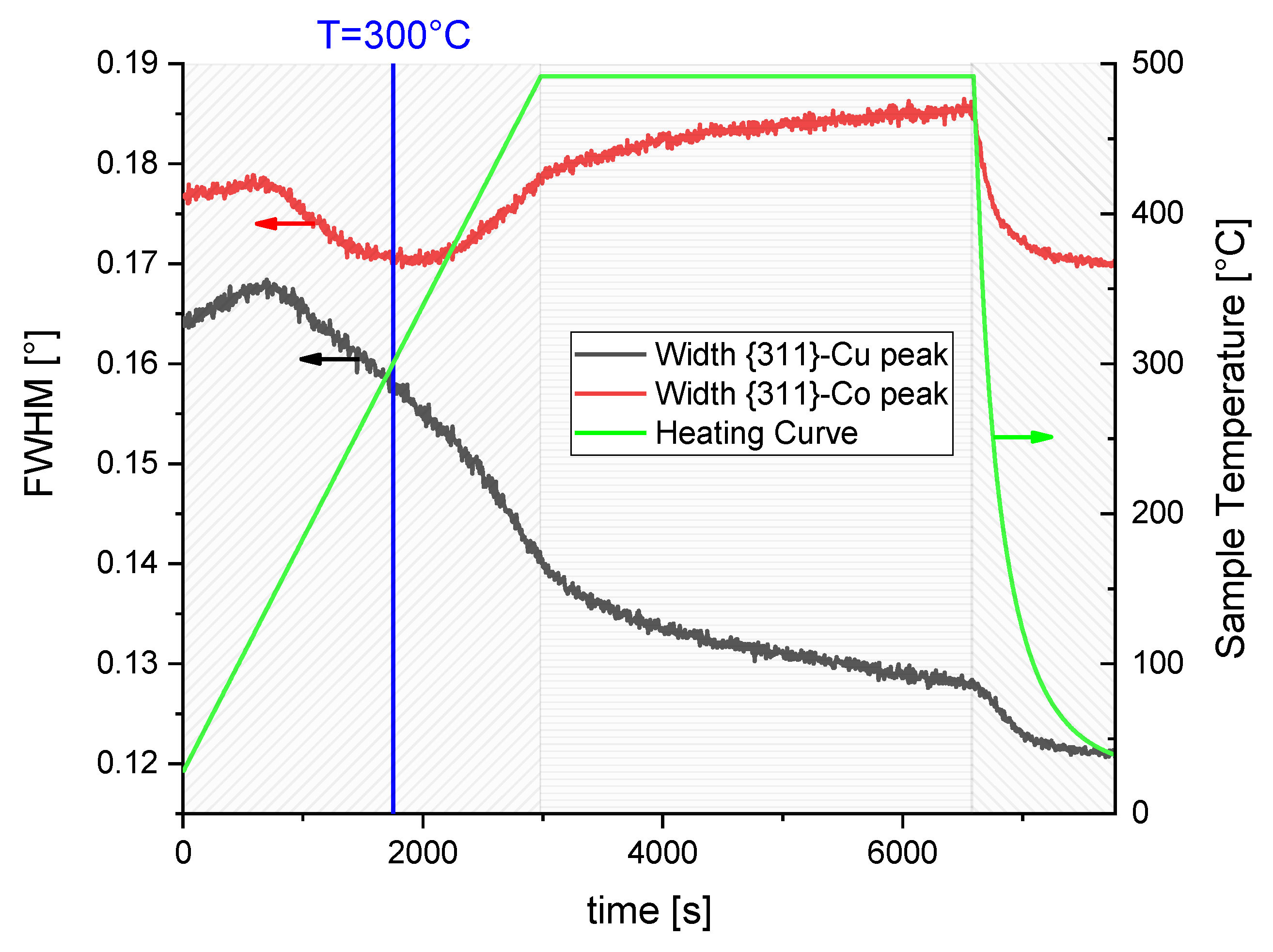

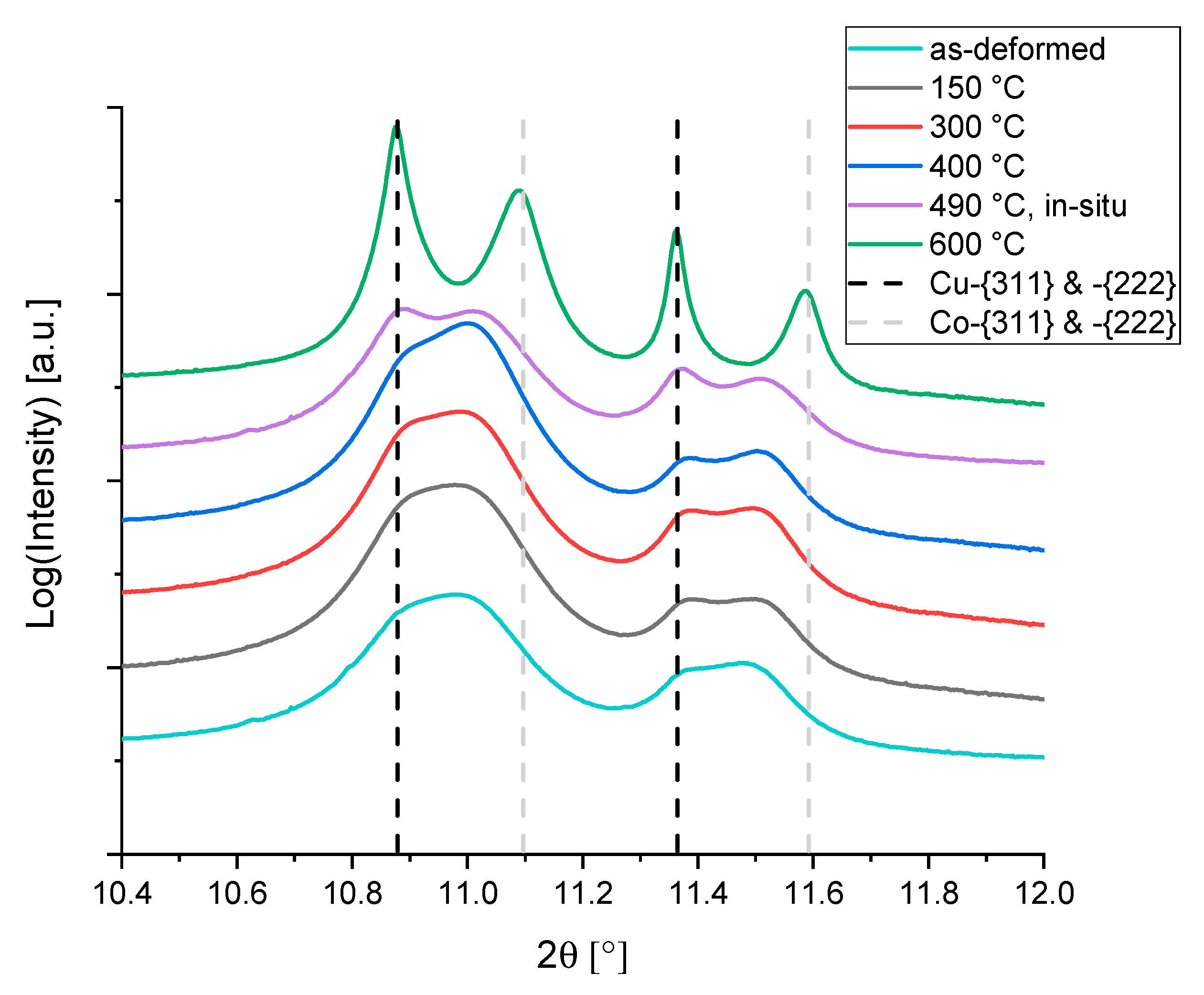

3.1. In-Situ HEXRD Measurement

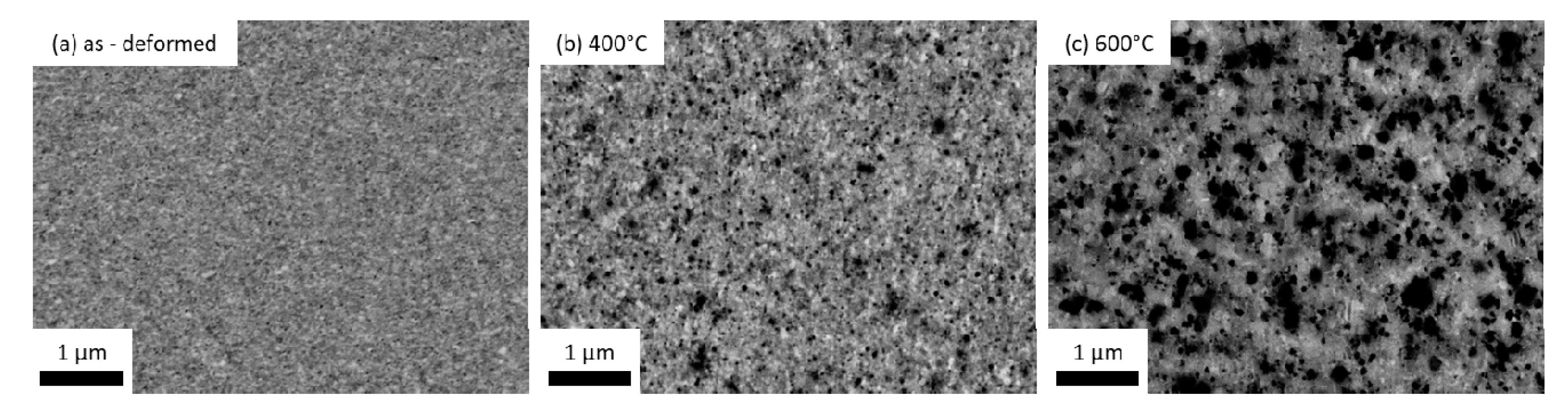

3.2. Ex-Situ Annealing Treatments

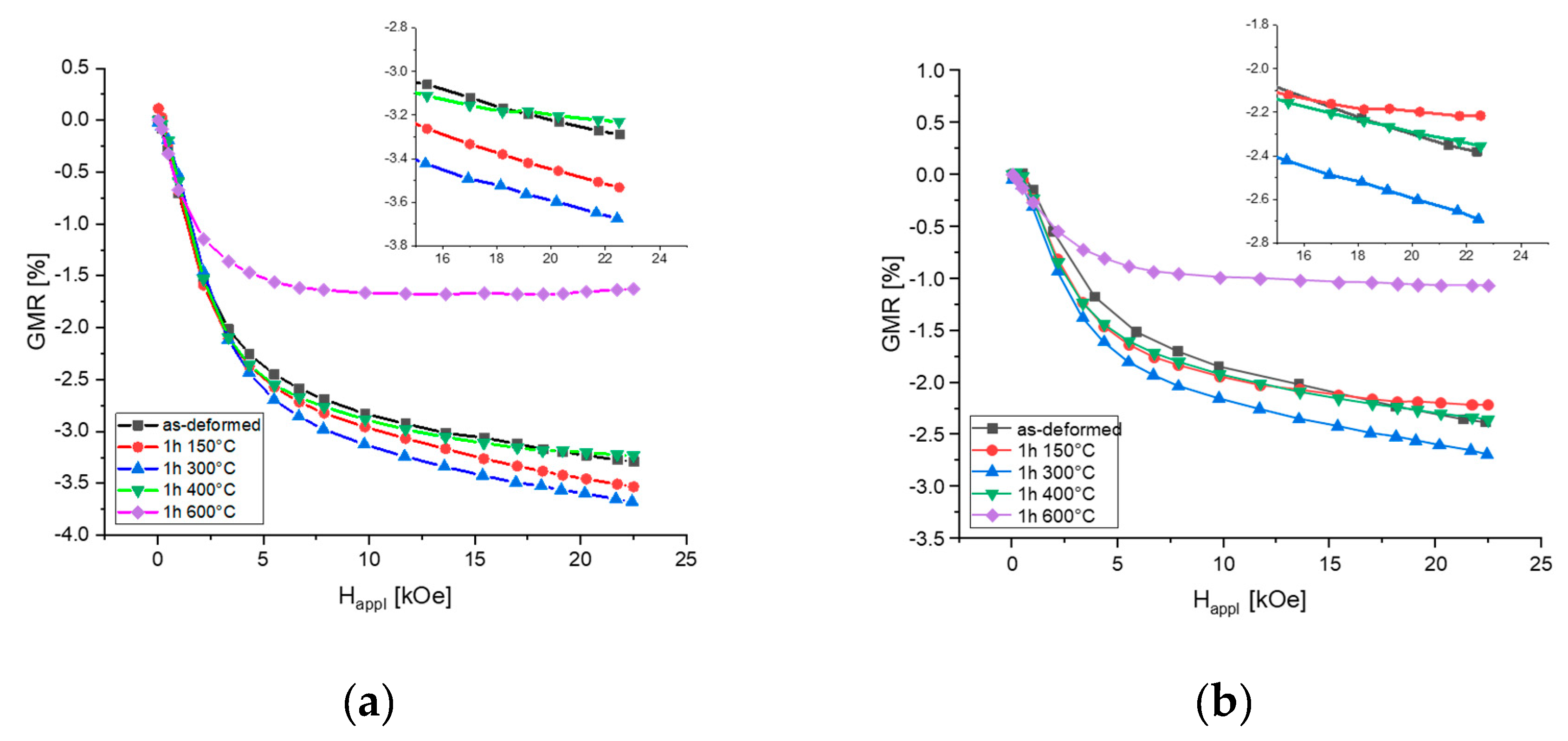

3.3. Medium Ferromagnetic Content: Magnetoresistance Measurements

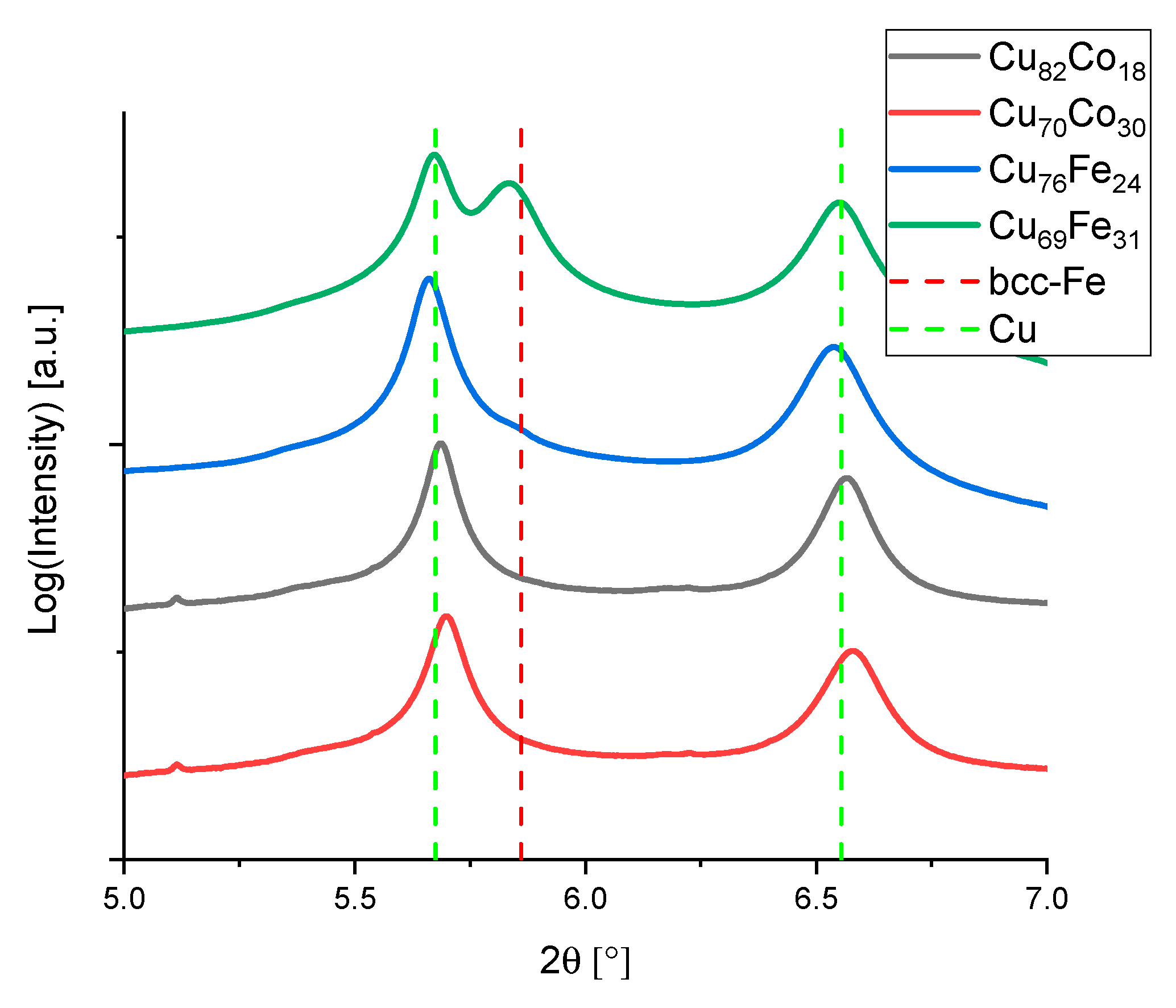

3.4. Improving the Magnetoresistive Effect

4. Discussion

4.1. Is the Change in Resistance a Magnetic Effect?

4.2. Where Does the Change in GMR Come From?

4.3. What Is the Optimum Composition and Thermal Treatment after RT HPT?

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thomson, W. XIX. On the electro-dynamic qualities of metals:—Effects of magnetization on the electric conductivity of nickel and of iron. Proc. R. Soc. London, Ser. A 1857, 8, 546–550. [Google Scholar] [CrossRef]

- Binasch, G.; Grünberg, P.; Saurenbach, F.; Zinn, W. Enhanced magnetoresistance in layered magnetic structures with antiferromagnetic interlayer exchange. Phys. Rev. B 1989, 39, 4828–4830. [Google Scholar] [CrossRef] [PubMed]

- Baibich, M.N.; Broto, J.M.; Fert, A.; Van Dau, F.N.; Petroff, F.; Etienne, P.; Creuzet, G.; Friederich, A.; Chazelas, J. Giant Magnetoresistance of (001)Fe/(001)Cr Magnetic Superlattices. Phys. Rev. Lett. 1988, 61, 2472–2475. [Google Scholar] [CrossRef] [PubMed]

- Berkowitz, A.E.; Mitchell, J.R.; Carey, M.J.; Young, A.P.; Zhang, S.; Spada, F.E.; Parker, F.T.; Hutten, A.; Thomas, G. Giant magnetoresistance in heterogeneous Cu-Co alloys. Phys. Rev. Lett. 1992, 68, 3745. [Google Scholar] [CrossRef]

- Xiao, J.Q.; Jiang, J.S.; Chien, C.L. Giant magnetoresistance in nonmultilayer magnetic systems. Phys. Rev. Lett. 1992, 68, 3749. [Google Scholar] [CrossRef]

- Wecker, J.; von Helmolt, R.; Schultz, L.; Samwer, K. Giant magnetoresistance in melt spun Cu-Co alloys. Appl. Phys. Lett. 1993, 62, 1985–1987. [Google Scholar] [CrossRef]

- Coey, J.M.D.; Fagan, A.J.; Skomski, R.; Gregg, J.; Ounadjela, K.; Thompson, S.M. Magnetoresistance in nanostructured Co-Ag prepared by mechanical-alloying. IEEE Trans. Magn. 1994, 30, 666–668. [Google Scholar] [CrossRef]

- Bernardi, J.; Hütten, A.; Thomas, G. GMR behavior of nanostructured heterogeneous M-Co (M= Cu, Ag, Au) alloys. Nanostruct. Mater. 1996, 7, 205–220. [Google Scholar] [CrossRef]

- Suehiro, K.; Nishimura, S.; Horita, Z.; Mitani, S.; Takanashi, K.; Fujimori, H. High-pressure torsion for production of magnetoresistance in Cu–Co alloy. J. Mater. Sci. 2008, 43, 7349–7353. [Google Scholar] [CrossRef]

- Nishihata, S.; Suehiro, K.; Arita, M.; Masuda, M.; Horita, Z. High-Pressure Torsion for Giant Magnetoresistance and Better Magnetic Properties. Adv. Eng. Mater. 2010, 12, 793–797. [Google Scholar] [CrossRef]

- Wurster, S.; Weissitsch, L.; Stückler, M.; Knoll, P.; Krenn, H.; Pippan, R.; Bachmaier, A. Tuneable Magneto-Resistance by Severe Plastic Deformation. Metals 2019, 9, 1188. [Google Scholar] [CrossRef]

- Hütten, A.; Müller, K.-H. Giant magnetoresistance in bulk materials. Sens. Actuators, A 1997, 59, 236–242. [Google Scholar] [CrossRef]

- Wang, J.-Q.; Xiao, G. Transition-metal granular solids: Microstructure, magnetic properties, and giant magnetoresistance. Phys. Rev. B 1994, 49, 3982–3996. [Google Scholar] [CrossRef] [PubMed]

- Nishizawa, T.; Ishida, K. The Co−Cu (Cobalt-Copper) system. Bull. Alloy Phase Diagr. 1984, 5, 161–165. [Google Scholar] [CrossRef]

- von Goldbeck, O.K. Iron—Copper Fe—Cu. In IRON—Binary Phase Diagrams; Springer: Berlin, Heidelberg, 1982; pp. 35–37. [Google Scholar]

- Stückler, M.; Krenn, H.; Weissitsch, L.; Wurster, S.; Pippan, R.; Bachmaier, A. Intermixing of Fe and Cu on the Atomic Scale by High-Pressure Torsion as Revealed by Dc- and Ac-Squid Susceptometry. Acta Mater. 2020, 196, 210–219. [Google Scholar] [CrossRef]

- Bridgman, P.W. Effects of High Shearing Stress Combined with High Hydrostatic Pressure. Phys. Rev. 1935, 48, 825–847. [Google Scholar] [CrossRef]

- Valiev, R.; Islamgaliev, R.; Alexandrov, I. Bulk nanostructured materials from severe plastic deformation. Prog. Mater Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Pippan, R.; Scheriau, S.; Taylor, A.; Hafok, M.; Hohenwarter, A.; Bachmaier, A. Saturation of Fragmentation during Severe Plastic Deformation. Annu. Rev. Mater. Res. 2010, 40, 319–343. [Google Scholar] [CrossRef]

- Kormout, K.S.; Pippan, R.; Bachmaier, A. Deformation-Induced Supersaturation in Immiscible Material Systems during High-Pressure Torsion. Adv. Eng. Mater. 2017, 19. [Google Scholar] [CrossRef]

- Stückler, M.; Krenn, H.; Pippan, R.; Weissitsch, L.; Wurster, S.; Bachmaier, A. Magnetic Binary Supersaturated Solid Solutions Processed by Severe Plastic Deformation. Nanomaterials 2019, 9, 6. [Google Scholar] [CrossRef]

- Stückler, M.; Weissitsch, L.; Wurster, S.; Felfer, P.; Krenn, H.; Pippan, R.; Bachmaier, A. Magnetic dilution by severe plastic deformation. AIP Adv. 2020, 10, 015210. [Google Scholar] [CrossRef]

- Hegedüs, Z.; Müller, T.; Hektor, J.; Larsson, E.; Bäcker, T.; Haas, S.; Conceiçao, A.; Gutschmidt, S.; Lienert, U. Imaging modalities at the Swedish Materials Science beamline at PETRA III. IOP Conf. Ser. Mater. Sci. Eng. 2019, 580, 012032. [Google Scholar] [CrossRef]

- Ashiotis, G.; Deschildre, A.; Nawaz, Z.; Wright, J.P.; Karkoulis, D.; Picca, F.E.; Kieffer, J. The fast azimuthal integration Python library: pyFAI. J. Appl. Cryst. 2015, 48, 510–519. [Google Scholar] [CrossRef] [PubMed]

- Bachmaier, A.; Pfaff, M.; Stolpe, M.; Aboulfadl, H.; Motz, C. Phase separation of a supersaturated nanocrystalline Cu–Co alloy and its influence on thermal stability. Acta Mater. 2015, 96, 269–283. [Google Scholar] [CrossRef]

- Bachmaier, A.; Rathmayr, G.B.; Schmauch, J.; Schell, N.; Stark, A.; de Jonge, N.; Pippan, R. High strength nanocrystalline Cu–Co alloys with high tensile ductility. J. Mater. Res. 2018, 1–11. [Google Scholar] [CrossRef]

- Predel, B. Co-Cu (Cobalt-Copper). In Ca-Cd–Co-Zr; Springer: Berlin/Heidelberg, Germany, 1993; pp. 1–5. [Google Scholar]

- Chiarotti, G. Electronic and Vibrational Properties; 1.6 Crystal structures and bulk lattice parameters of materials quoted in the volume; Springer: Berlin/Heidelberg, Germany, 1994; Volume 24b, pp. 21–26. ISBN 978-3-540-56070-8. [Google Scholar]

- Owen, E.A.; Jones, D.M. Effect of Grain Size on the Crystal Structure of Cobalt. Proc. Phys. Soc. B 1954, 67, 456–466. [Google Scholar] [CrossRef]

- Vegard, L. Die Konstitution der Mischkristalle und die Raumfüllung der Atome. Z. Phys. 1921, 5, 17–26. [Google Scholar] [CrossRef]

- Kormout, K.S.; Ghosh, P.; Bachmaier, A.; Hohenwarter, A.; Pippan, R. Effect of processing temperature on the microstructural characteristics of Cu-Ag nanocomposites: From supersaturation to complete phase decomposition. Acta Mater. 2018, 154, 33–44. [Google Scholar] [CrossRef]

- Bachmaier, A.; Schmauch, J.; Aboulfadl, H.; Verch, A.; Motz, C. On the process of co-deformation and phase dissolution in a hard-soft immiscible Cu Co alloy system during high-pressure torsion deformation. Acta Mater. 2016, 115, 333–346. [Google Scholar] [CrossRef]

- Villars, P.; Cenzual, K. α-Co (Co rt) Crystal Structure: Datasheet from “PAULING FILE Multinaries Edition—2012”. In SpringerMaterials; Springer: Berlin/Heidelberg, Germany; Material Phases Data System (MPDS): Vitznau, Switzerland; National Institute for Materials Science (NIMS): Tsukuba, Japan, 2012; Available online: https://materials.springer.com/isp/crystallographic/docs/sd_0531743 (accessed on 17 June 2020).

- Bachmaier, A.; Katzensteiner, A.; Wurster, S.; Aristizabal, K.; Suarez, S.; Pippan, R. Thermal stabilization of metal matrix nanocomposites by nanocarbon reinforcements. Scr. Mater. 2020, 186, 202–207. [Google Scholar] [CrossRef]

- Villars, P.; Cenzual, K. Fe Crystal Structure: Datasheet from “PAULING FILE Multinaries Edition—2012”. In SpringerMaterials; Springer: Berlin/Heidelberg, Germany; Material Phases Data System (MPDS): Vitznau, Switzerland; National Institute for Materials Science (NIMS): Tsukuba, Japan, 2012; Available online: https://materials.springer.com/isp/crystallographic/docs/sd_1324321 (accessed on 17 June 2020).

- Stückler, M.; Teichert, C.; Matkovic, A.; Krenn, H.; Weissitsch, L.; Wurster, S.; Pippan, R.; Bachmaier, A. On the magnetic nanostructure of a Co-Cu alloy processed by high-pressure torsion. J. Sci. Adv. Mat. Dev. 2020. submitted. [Google Scholar]

- Miranda, M.G.M.; Estévez-Rams, E.; Martínez, G.; Baibich, M.N. Phase separation in Cu 90 Co 10 high-magnetoresistance materials. Phys. Rev. B 2003, 68, 014434. [Google Scholar] [CrossRef]

- Hohenwarter, A.; Pippan, R. Sample Size and Strain-Rate-Sensitivity Effects on the Homogeneity of High-Pressure Torsion Deformed Disks. Metall. Mater. Trans. A 2019, 50, 601–608. [Google Scholar] [CrossRef]

| Composition [at%] | HPT—Tool and Sample Diameter [mm] | No. of Rotations |

|---|---|---|

| Cu82Co18 | 8 | 100 |

| Cu70Co30 | 8 | 100 |

| Cu55Co45 | 30 | 250 |

| Cu76Fe24 | 8 | 100 |

| Cu69Fe31 | 8 | 100 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wurster, S.; Stückler, M.; Weissitsch, L.; Müller, T.; Bachmaier, A. Microstructural Changes Influencing the Magnetoresistive Behavior of Bulk Nanocrystalline Materials. Appl. Sci. 2020, 10, 5094. https://doi.org/10.3390/app10155094

Wurster S, Stückler M, Weissitsch L, Müller T, Bachmaier A. Microstructural Changes Influencing the Magnetoresistive Behavior of Bulk Nanocrystalline Materials. Applied Sciences. 2020; 10(15):5094. https://doi.org/10.3390/app10155094

Chicago/Turabian StyleWurster, Stefan, Martin Stückler, Lukas Weissitsch, Timo Müller, and Andrea Bachmaier. 2020. "Microstructural Changes Influencing the Magnetoresistive Behavior of Bulk Nanocrystalline Materials" Applied Sciences 10, no. 15: 5094. https://doi.org/10.3390/app10155094

APA StyleWurster, S., Stückler, M., Weissitsch, L., Müller, T., & Bachmaier, A. (2020). Microstructural Changes Influencing the Magnetoresistive Behavior of Bulk Nanocrystalline Materials. Applied Sciences, 10(15), 5094. https://doi.org/10.3390/app10155094