1. Introduction

Noise pollution onboard ships is increasingly recognized as a significant occupational and environmental concern, with implications that extend from regulatory compliance to human performance and well-being at sea [

1,

2]. The maritime industry generates a complex acoustic environment, with noise originating primarily from engines, ventilation systems, machinery, and propulsion mechanisms [

3]. These noise sources affect not only the structural soundscape of vessels but also the physical and psychological health of seafarers [

4], potentially leading to increased fatigue, reduced sleep quality, impaired communication, and long-term auditory and non-auditory health consequences [

5,

6].

Although existing research has addressed noise exposure in commercial vessels, particularly in relation to standards set by the International Maritime Organization (IMO) and European Union directives [

7], most studies have focused on specific vessel types or failed to consider differences in design and operational characteristics [

8]. High-speed craft (HSCs), for example, have received limited attention despite their increasing importance in regional and short-sea shipping [

9]. These vessels typically have lightweight aluminium hulls and are fitted with high-performance propulsion systems that introduce distinct acoustic dynamics. Their reduced structural mass can lead to increased transmission of structure-borne sound, which could compromise the acoustic insulation of accommodation and work areas [

10,

11].

While both types of vessels fall under the broader category of Ro-Pax ships, which are designed to carry passengers and vehicles, there are significant differences in their design, construction materials, and propulsion systems. For clarity, this study refers to the steel-hulled vessel as a ‘conventional ferry’ and to the aluminium catamaran as an ‘HSC’.

In contrast, conventional roll-on/roll-off passenger ferries (Ro-Pax) are typically built with denser steel hulls and older propulsion systems, which, although noisier at the source, tend to offer better natural sound dampening [

12,

13]. Despite these fundamental structural and functional differences, both vessel types are subject to the same regulatory thresholds, such as those outlined in IMO Resolution A.468(XII) and the 2000 High-Speed Craft Code. These uniform standards do not fully account for variations in sound propagation behaviour, material acoustics, or the lived experience of crew members onboard [

14].

Although Ro-Pax ferries and HSCs are both designed for short-distance maritime transport and operate in similar coastal and regional environments [

15], such as the Strait of Gibraltar, the comparative effects of their differing acoustic environments on crew well-being remain underexplored. Moreover, few studies integrate both objective noise measurements and subjective assessments of fatigue and workload, particularly in real operational conditions [

16]. This lack of comparative, interdisciplinary research creates a critical knowledge gap regarding how vessel design and construction influence noise exposure and its occupational impacts.

To address this gap, the present study provides a comparative case analysis of two vessels: a conventional Ro-Pax ferry and a high-speed craft. Both vessels operate on similar routes and in similar environmental conditions in the Strait of Gibraltar. The investigation combines objective noise level measurements across key onboard zones with subjective fatigue data collected via psychometric tools. Specifically, the study aims to:

Evaluate differences in the acoustic profiles of conventional ferries and HSC vessels.

Assess the implications of noise exposure for seafarer fatigue and rest quality.

Recommend vessel-specific strategies for noise mitigation and regulatory adaptation.

This approach contributes to a more nuanced understanding of maritime noise exposure and its human effects, with the ultimate goal of informing the design of vessels, regulatory policies, and occupational health strategies that are tailored to the type of vessel.

2. Regulatory Framework for Onboard Noise

This study uses IMO Resolution A.468(XII) as the main regulatory reference for assessing onboard noise exposure, since this resolution applies to the two vessels examined: a conventional Ro-Pax ferry built in 1993, and a high-speed craft (HSC) built in 2003. Although the HSC is subject to a specialised code (the HSC Code), it adheres to most A.468(XII) standards, with only minor adjustments applied to certain operational and accommodation spaces. Understanding these similarities and differences is essential for meaningful comparative analysis.

2.1. IMO Resolution A.468(XII)

In 1981, the IMO adopted Resolution A.468(XII) [

17], known as the Code on Noise Levels Onboard Ships. This code sets out recommended noise limits to protect crew from excessive noise exposure, including thresholds such as 90 dB(A) for manned engine rooms, 75 dB(A) for engine control rooms, and 60 dB(A) for cabins and hospitals. Hearing protection was recommended in areas exceeding 85 dB(A) (

Table 1). These limits are expressed as equivalent continuous A-weighted sound pressure levels (LAeq) measured under representative operating conditions. In occupational health practice, and consistent with European Directive 2003/10/EC, these LAeq values are typically normalised to an 8 h reference period (LEX,8h), corresponding to a standard work shift. Therefore, the thresholds in

Table 1 should be interpreted as average values over such an exposure period rather than instantaneous peaks.

This code applies to ships built before 2014, making it the relevant baseline for the Ro-Pax ferry constructed in 1993. While A.468(XII) was initially a non-binding recommendation, it was incorporated into national maritime regulations by many IMO member states, including Spain, thus giving it practical enforceability.

Although the High-Speed Craft (HSC) Code is a specialized IMO instrument that governs the HSCs, its acoustic provisions largely mirror those of Resolution A.468(XII), with only minor adjustments (see

Section 2.2). Therefore, for the purpose of direct comparison between the two vessels, A.468(XII) is retained as the common reference framework across all areas, except where HSC-specific thresholds apply.

In 2012, the IMO adopted Resolution MSC.337(91) [

18], a more stringent revision of A.468(XII) applicable to ships of 1600 GT and above built on or after 1 July 2014. Although neither vessel in this study meets these criteria, the updated code is relevant as it reflects the IMO’s increasing concern regarding the effects of shipboard noise on crew health and performance. For this reason, MSC.337(91) is discussed as a forward-looking benchmark. Its stricter limits (e.g., 85 dB(A) for manned machinery spaces, 70 dB(A) for workshops, and 55 dB(A) for cabins and hospitals) highlight the regulatory trend towards improved noise protection standards, underscoring the potential gap between the acoustic environments of older vessels and the expectations set by current regulations.

2.2. High-Speed Craft Code

The International Code of Safety for High-Speed Craft (HSC Code) was adopted by the IMO in 1994 to address the specific design, safety, and operational characteristics of high-speed vessels, including structural constraints and vibration levels. The 2000 revision of the HSC Code [

19], which applies to the high-speed craft examined in this study (built in 2003), includes targeted provisions on acoustic conditions.

In contrast to Resolution A.468(XII), which serves as the general standard for conventional ships, the HSC Code recommends the following:

A maximum of 75 dB(A) in crew accommodation and public areas;

A limit of 65 dB(A) in operational areas, such as the bridge, to preserve speech intelligibility and situational awareness.

These limits are less stringent than those established by A.468(XII) in certain areas—particularly accommodation zones, where A.468(XII) recommends 60–65 dB(A). The relaxed thresholds reflect the practical challenges of achieving lower noise levels in high-speed vessels, often built with lighter materials and subject to greater structural vibration and propulsion noise.

Despite these deviations, the HSC Code remains closely aligned with A.468(XII) in scope and intent. For the purposes of this study’s comparative analysis, A.468(XII) is applied as the principal reference framework, with the HSC Code’s adjusted values noted where relevant.

2.3. European and National Regulations

The European Directive 2003/10/EC was introduced to protect workers from the adverse health effects of excessive noise exposure [

20]. Unlike IMO codes, which focus on design thresholds, the Directive establishes operational exposure limits based on an 8 h time-weighted average (LEX,8h). The lower action value is set at 80 dB(A), the upper action value at 85 dB(A), and the maximum limit at 87 dB(A) after accounting for hearing protection.

The directive has been transposed into national legislation across EU Member States, including Spain’s Royal Decree 286/2006 [

21], and applies to all maritime workers, regardless of their vessel’s year of construction.

Even though the Ro-Pax ferry (built in 1993) and the HSC (built in 2003) predate the directive, their crews are still subject to these occupational limits. The EU framework, therefore, offers a useful lens through which to interpret health risks in high-exposure areas such as engine compartments. It also reinforces the importance of preventive measures such as hearing protection, crew rotation, regular exposure monitoring, and medical surveillance. In this way, EU and national regulations complement IMO design codes by addressing the cumulative and long-term effects of noise in the maritime work environment.

3. Materials and Methods

The present study employs a mixed-methods approach to assess and compare noise exposure and its occupational impact on crew members aboard two types of vessels: a conventional ferry and an HSC.

Both vessels operate under similar conditions in the Strait of Gibraltar and are subject to international and European maritime noise regulations. The methodology integrates objective acoustic measurements with subjective psychometric assessments, thereby providing a comprehensive understanding of onboard acoustic environments and their impact on seafarer fatigue and well-being.

3.1. Case Study Vessels

The conventional ferry under analysis was constructed in 1993 and has a gross tonnage of 10,971 GT. The HSC, built in 2003, is a catamaran with a gross tonnage of 6662 GT (

Table 2). Both ships operate short-haul passenger and vehicle services across the Strait of Gibraltar. The vessels differ significantly in terms of construction materials, propulsion systems, and hull design, providing a robust basis for comparative analysis.

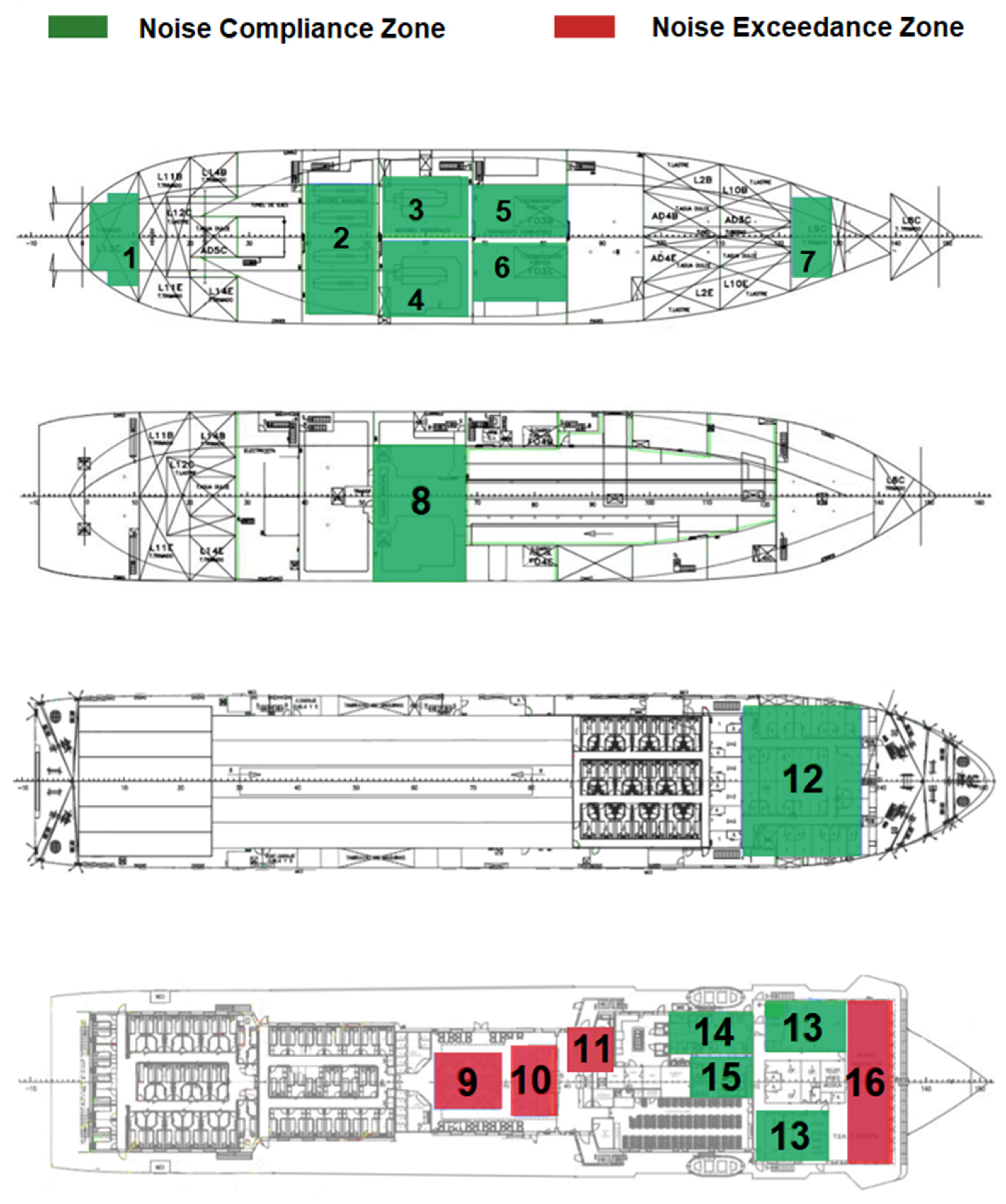

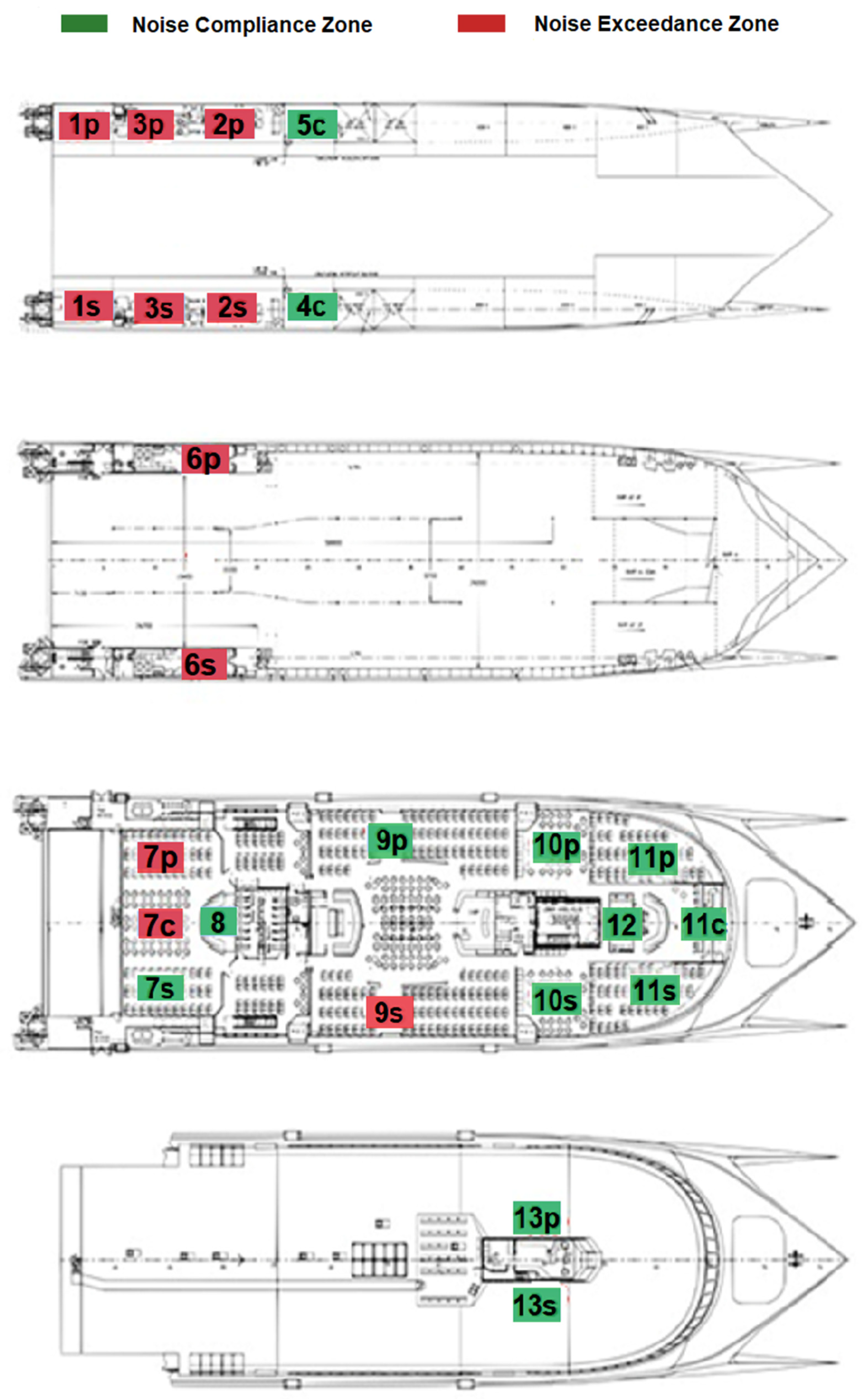

To facilitate interpretation of the acoustic data, the general layouts of both vessels are presented in

Figure 1 and

Figure 2. These schematics display the numbered locations where noise measurements were conducted, including key operational zones such as the engine rooms, navigation bridges, accommodation areas, and crew messrooms. The corresponding sound pressure levels recorded at each of these locations are provided in

Table 3 and

Table 4.

While

Figure 1 and

Figure 2 provide schematic layouts of measurement points, the representative numerical values are detailed in

Table 3 and

Table 4 and were used to calculate daily exposure levels (LEX,8h). Comprehensive noise mapping analyses for high-speed craft, including validated numerical sound maps, are available in a previous study by the authors [

9].

3.2. Objective Acoustic Measurements

Sound pressure levels were measured using a PCE-999 Class 2 integrating sound level meter that complies with IEC 61672-1 standards. The device was calibrated before measurements using a PCE SC 41 Class 2 acoustic calibrator (94 dB, 1 kHz), following the manufacturer’s instructions.

All measurements were conducted under normal operating conditions during commercial sea passages to ensure representative results. For the conventional Ro-Pax ferry, normal operation corresponded to navigation at 16 knots with a gross tonnage of approximately 10,971 tons, the main engines running at 750 r.p.m., turbochargers at 28,000 r.p.m., three generators in service during manoeuvring and two during cruising, air-conditioning systems operating, and a load of 646 passengers together with 3 trailers, 2 platforms, 1 truck, and 177 cars. For the high-speed craft, normal operation was defined as navigation at 40 knots (36 knots at the time of measurement) with a gross tonnage of approximately 6662 tons, powered by four main engines (7080 kW each, 980 r.p.m.) driving water jets, and supported by four auxiliary engines (240 kW each; two in operation during manoeuvring and navigation, one in port). The vessel operated with air-conditioning systems in passenger lounges and the bridge, as well as garage ventilation fans and auxiliary machinery, while carrying up to 900 passengers and 220 vehicles (288 linear meters).

The methodology adhered to the applicable regulatory framework for each vessel. For the conventional ferry, the procedures outlined in IMO Resolution A.468(XII) were followed. For the HSC, the approach was based on the acoustic-related provisions of the IMO High-Speed Craft Code 2000, which focuses on noise control in accommodation and navigation spaces.

Measurement zones included the following:

Machinery spaces (e.g., engine room, purifier rooms);

Accommodation areas (e.g., officers’ and ratings’ cabins, messrooms);

Navigation spaces (e.g., wheelhouse).

These zones were selected based on their relevance to occupational exposure and compliance with acoustic regulatory criteria.

Figure 3 shows the locations of the onboard spaces where acoustic measurements were taken, including cabins, engine compartments, and bridge areas on both types of vessel [

22].

All readings were taken at 1.6 m above the deck, using the “slow” time weighting and A-frequency weighting. Zones were sampled with a minimum distance of 2 m between points. For each location, continuous readings were recorded over a minimum 5 min period to calculate equivalent continuous sound levels (LAeq).

While the measurement zones included accommodation spaces such as cabins for the conventional ferry, this was not the case for the high-speed craft (HSC). This reflects a fundamental operational difference: HSC crew members follow a day-schedule system and sleep ashore between voyages. As a result, cabins are not used as overnight rest areas, and noise measurements in these spaces were not applicable or collected for the HSC.

3.2.1. Exposure Time and Dosimetry

While sound pressure levels (LAeq) provide essential information on the acoustic environment of shipboard spaces, occupational risk assessment requires a calculation level for a working day (LEX,8h), which depends on the duration of time spent in each area.

Raw noise measurements were collected in key operational and accommodation spaces on both vessels. For the conventional ferry, these measurements are presented in

Table 3, and for the HSC, they are summarized in

Table 4. These measurements provided the reference acoustic levels for each compartment, which were then combined with crew work schedules and station assignments to derive representative LAeq values for use in the dosimetry calculations.

Locked LAeq values were derived from the logarithmic (energy-based) averaging of the measured sound levels at each location, consistent with ISO 9612:2025. For practical presentation, these energy-based averages were converted back to dB(A) and rounded to the nearest integer. The resulting mappings of duty roster locations to representative LAeq values are provided in

Table 5 for the HSC (derived from

Table 4) and in

Table 6 for the conventional ferry (derived from

Table 3). These locked values were then used to calculate individual crew exposures according to Equation (1):

where

LEX,8h = daily noise exposure level normalized to 8 h, in dB(A);

ti = time spent at location i, in minutes;

Li = sound pressure level (LAeq) at location i, in dB(A);

i = index over all locations visited during the shift;

T = total reference period in minutes (8 h = 480 min).

For the engine crew, scenarios with and without hearing protection were estimated using the available earmuffs (IMO 30 dB; Peltor II NRR 27 dB; Peltor III NRR 30 dB). To approximate real-world conditions, the nominal attenuation was conservatively derated by 50% (≈13–15 dB effective reduction). This effective attenuation was then incorporated into the LEX,8h calculation using the standard logarithmic summation, rather than by simply subtracting a fixed value.

3.2.2. Participant Demographics and Professional Background

A total of 36 crew members participated in the subjective assessments across the two vessels: 22 from the conventional ferry and 14 from the HSC.

Table 7 presents an overview of the demographic and professional characteristics of both groups, including age, gender, maritime experience, and working patterns.

The HSC group was older and more experienced on average, with a mean age of 47.9 years (SD ± 2.9) and 22.4 years (SD ± 6.1) of total maritime experience. The majority were male (71.4%). Regarding shipboard roles, 21.4% were deck officers, 14.3% engine officers, 14.3% engine ratings, and 14.3% deck ratings. The remaining crew worked in hotel services (7.1%) and as passenger assistants (28.6%).

The ferry crew had a younger and more diverse experience profile, with a mean age of 42.4 years (SD ± 10.0) and an average of 10.2 years (SD ± 9.1) of maritime experience. Males accounted for 81.8% of respondents. By role, 27.3% were deck officers, 27.3% engine officers, 18.2% deck ratings, 13.6% engine ratings, 4.5% hotel staff, and 9.1% passenger assistants.

The marked contrast in age, role tenure, working hours, and sleep duration reflects distinct operational and organizational characteristics between vessel types. These factors are likely to influence the subjective experience of fatigue and workload and are considered in the interpretation of subsequent psychometric data.

3.3. Subjective Fatigue and Workload Assessments

To complement the objective noise measurements, a structured, survey-based protocol was implemented on both the conventional ferry and the HSC. This aimed to evaluate crew members’ subjective perceptions of fatigue, workload, and rest quality in regular operational conditions. Three validated psychometric tools, each adapted to the Spanish language, were used:

The NASA Task Load Index (NASA-TLX) [

23]: This multidimensional rating scale evaluates perceived workload across six dimensions: mental demand, physical demand, temporal demand, performance, effort, and frustration. It is widely used in transportation and human factors research.

The Swedish Occupational Fatigue Inventory–Spanish Modified (SOFI-SM) [

24,

25]: This validated Spanish short form is adapted from the original Swedish version and is designed to assess acute work-related fatigue. It covers key aspects such as lack of energy, physical discomfort, lack of motivation, and sleepiness. It is particularly suitable for operational maritime contexts.

The Reduced Morningness–Eveningness Questionnaire (rMEQ) [

26]: This tool classifies individuals according to their circadian typology (morning or evening), which can affect alertness, fatigue, and the ability to adapt to shift work. The version used was the validated Spanish adaptation.

The questionnaires were distributed digitally in Spanish, the working language on both vessels, and were completed voluntarily by crew members outside their working hours. All participants were informed of the purpose of the study and provided written informed consent. The survey protocol was approved by the Research Ethics Committee of the University of Oviedo (approval code: 37_RRI_2023).

A total of 36 valid crew responses were gathered across the two study vessels, comprising 14 from the HSC and 22 from the conventional ferry. These figures represent response rates of 87.5% for the HSC (14 out of 16 crew members) and 64.7% for the conventional ferry (22 out of 34). This high level of participation supports the reliability of the subjective data on fatigue, workload, and rest quality, and reflects a broad representation across departments, ranks, and shift patterns. The collected data contribute to the comparative assessment of how vessel-specific acoustic environments may influence seafarer well-being under operational conditions in the Strait of Gibraltar.

3.4. Data Analysis

The acoustic data were analysed by comparing the recorded sound pressure levels with the regulatory thresholds defined in IMO Resolution A.468(XII) and the 2000 High-Speed Craft (HSC) Code. These thresholds also apply to European Directive 2003/10/EC concerning occupational noise risks. For vessels built before 2014, such as the Ro-Pax ferry and the HSC examined in this study, Resolution A.468(XII) remains the applicable IMO framework. Additional criteria from the 2000 HSC Code were applied to evaluate noise levels in public and operational areas of the high-speed craft, with a particular focus on acoustic comfort and communication effectiveness.

To evaluate occupational exposure risks, daily equivalent noise levels (LEX,8h) were calculated for multiple crew departments and compared with the action and limit values specified in Directive 2003/10/EC (80 dB(A), 85 dB(A), and 87 dB(A)). These values are enforced in Spain through Royal Decree 286/2006, which governs noise exposure aboard Spanish-flagged vessels.

Subjective workload and fatigue were analysed using descriptive statistics (mean ± standard deviation) and multivariate regression models to examine associations with noise exposure across departments and vessels. Comparative assessments considered differences in compartmental noise levels, frequency of regulatory exceedances, and reported workload (NASA-TLX) and fatigue (SOFI-SM). Individual circadian typology (rMEQ) was described to contextualize vulnerability to fatigue and workload under operational schedules.

These combined methods provide an integrated assessment of how vessel design and regulatory context influence onboard acoustic conditions and their impact on seafarer health. Although this study does not aim to make statistical generalisations due to the modest sample size and the operational constraints of data collection at sea, the results provide valuable insights into real-world exposure scenarios and inform recommendations for ship-specific noise management.

4. Results

This section presents the findings from the comparative analysis of a conventional ferry and an HSC operating in the Strait of Gibraltar. The results are organized into objective acoustic measurements and subjective assessments of fatigue and workload, with a focus on occupational health implications for seafarers.

4.1. Objective Acoustic Environment

Equivalent continuous noise levels (LAeq) were recorded in key operational and accommodation areas on both vessels. The raw measurements are reported in

Table 3 and

Table 4, while the mapped values used for dosimetry calculations are presented in

Table 5 and

Table 6. The results revealed clear differences in acoustic exposure between the conventional ferry and the HSC, particularly in the engine and accommodation compartments.

Noise limits for comparison were taken from IMO Resolution A.468(XII), applicable to all ship types unless superseded. Additional thresholds from the HSC Code 2000 were considered for the HSC, applying only to accommodation and public spaces, not machinery compartments. Crew exposures over an eight-hour period were evaluated against the occupational exposure limits set out in European Directive 2003/10/EC, transposed into Spanish law via Royal Decree 286/2006.

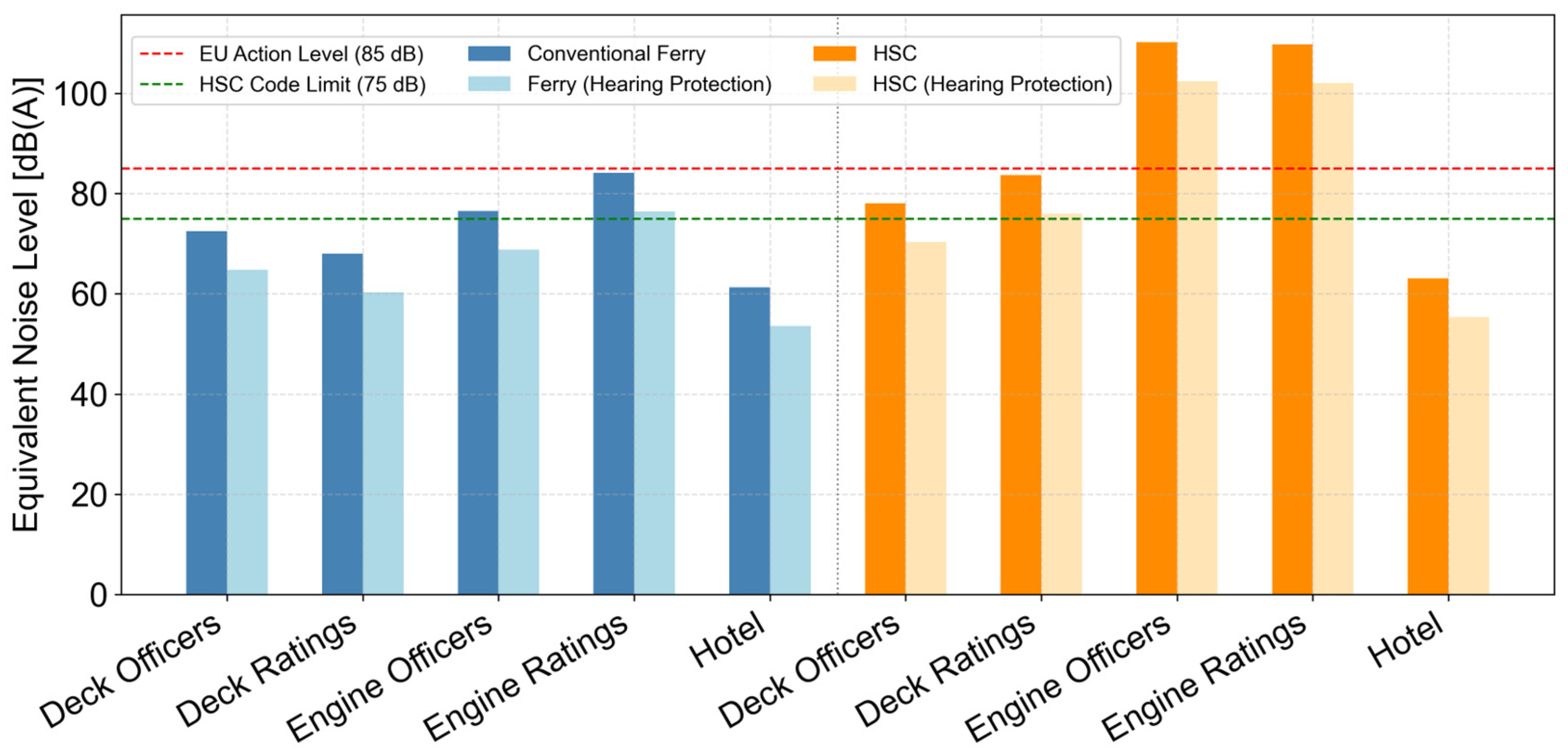

For the HSC, levels exceeding 110 dB(A) were consistently recorded in the engine spaces, breaching the maximum allowable values for manned and unmanned compartments as set out in Resolution A.468(XII). Several accommodation areas, including lounges and bars, also recorded noise levels above the IMO threshold of 65 dB(A) and approaching or surpassing the 75 dB(A) limit suggested by the HSC Code 2000. These elevated levels are likely attributable to the aluminium hull, which provides less acoustic insulation than the ferry’s denser steel structure.

For the conventional ferry, most operational and accommodation spaces complied with IMO limits. Certain passenger service areas, such as the bar (77 dB(A)), exceeded the 65 dB(A) guideline, and machinery spaces reached 97–98 dB(A). Overall, acoustic conditions aboard the ferry were more favourable than on the HSC, particularly in rest and accommodation areas.

Although the recorded levels aboard both vessels remain broadly within regulatory limits, the HSC bridge noise approached the threshold specified in the HSC Code. Prolonged exposure at these levels may result in cognitive fatigue and impaired performance among navigation officers, even under technically compliant conditions.

4.2. Individual Crew Noise Exposure Assessment (LEX,8h)

To ensure that comparisons between acoustic measurements and survey data (fatigue and workload) were meaningful, individual crew exposures were calculated using full dosimetry. Crew work schedules and station assignments were mapped to representative LAeq values for each space visited during their shifts. Working day equivalent noise exposures (LEX,8h) were then calculated for each crew member using the standard formula, incorporating both the sound pressure levels and the time spent in each location. For engine personnel, scenarios with and without hearing protection were also considered. This procedure allows LEX,8h values to reflect true individual exposure across all compartments, providing a valid basis for comparison with subjective workload and fatigue data.

Using the crew work schedules and the acoustic reference values presented in

Table 5 and

Table 6, individual LEX,8h values were calculated for each crew member. For the HSC, results are summarized in

Table 8.

Deck department officers and ratings recorded LEX,8h values between 71 and 84 dB(A), spanning levels below the lower exposure action value (80 dB(A)) and approaching the upper exposure action value (85 dB(A)) defined in EU Directive 2003/10/EC. Hearing protection is not mandatory below 80 dB(A), but must be made available between 80 and 85 dB(A).

Engine department officers and ratings reached LEX,8h ≈ 110 dB(A) unprotected, which far exceeds the exposure limit value of 87 dB(A) established by the Directive. Even with earmuffs providing −27 to −30 dB attenuation, effective exposures remained between 95 and 100 dB(A). In this case, the law requires not only the mandatory use of hearing protectors, but also technical and organizational measures to reduce noise at the source, since protective equipment alone cannot ensure compliance.

Hotel and service personnel experienced LEX,8h values of 61–73 dB(A), consistently below the lower exposure action value (80 dB(A)), meaning no hearing protection is required under the directive.

Similarly, daily noise exposure levels for ferry crew were calculated using the mappings in

Table 6, with results summarized in

Table 9.

Crew members aboard the conventional ferry were subject to substantially lower noise exposures compared with those recorded on the HSC. None of the groups exceeded the EU Directive 2003/10/EC maximum exposure limit of 87 dB(A). However, engine ratings approached the upper action value of 85 dB(A), indicating potential need for routine hearing protection and monitoring. By contrast, all deck officers, deck ratings, and hotel/service staff remained consistently below both lower and upper action thresholds. These results suggest that, while risk is not negligible in engine spaces, the overall acoustic environment aboard the ferry is less hazardous than that of high-speed craft.

Figure 4 shows how noise exposure varies for the crew on both vessels, presenting the calculated daily equivalent noise exposure levels (LEX,8h) for each department. The LEX,8h represents the time-weighted average exposure over an eight-hour navigation period and was calculated by combining short-term LAeq measurements (5 min intervals) in each compartment with crew duty rosters, accounting for the time spent in different areas. For engine officers and ratings, the only groups reported to regularly use hearing protection during shifts, the values are shown both with and without the effects of attenuation from such equipment. For all other crew categories, both protected and unprotected exposure values are presented for comparison purposes, even though hearing protection was not used as noise levels remained below regulatory thresholds.

These differences emphasise the important role of vessel design and insulation in shaping acoustic exposure onboard. A detailed breakdown of daily equivalent noise exposure levels (LEX,8h) by crew department and vessel type is provided in

Appendix A (

Table A1).

4.3. Subjective Workload and Fatigue Perceptions

This section examines the subjective experience of workload and fatigue among the crew of Ro-Pax ferries and HSCs, as measured by validated psychometric tools administered onboard. The analysis focuses on three tools: the NASA Task Load Index (NASA-TLX), the Swedish Occupational Fatigue Inventory–Spanish Modified (SOFI-SM), and the Reduced Morningness–Eveningness Questionnaire (rMEQ). The NASA-TLX assesses perceived workload; the SOFI-SM, fatigue symptoms; and the rMEQ, chronotype alignment. Together, these tools provide insight into the psychosocial implications of noise exposure onboard ships.

4.3.1. NASA-TLX: Mental Workload Scores

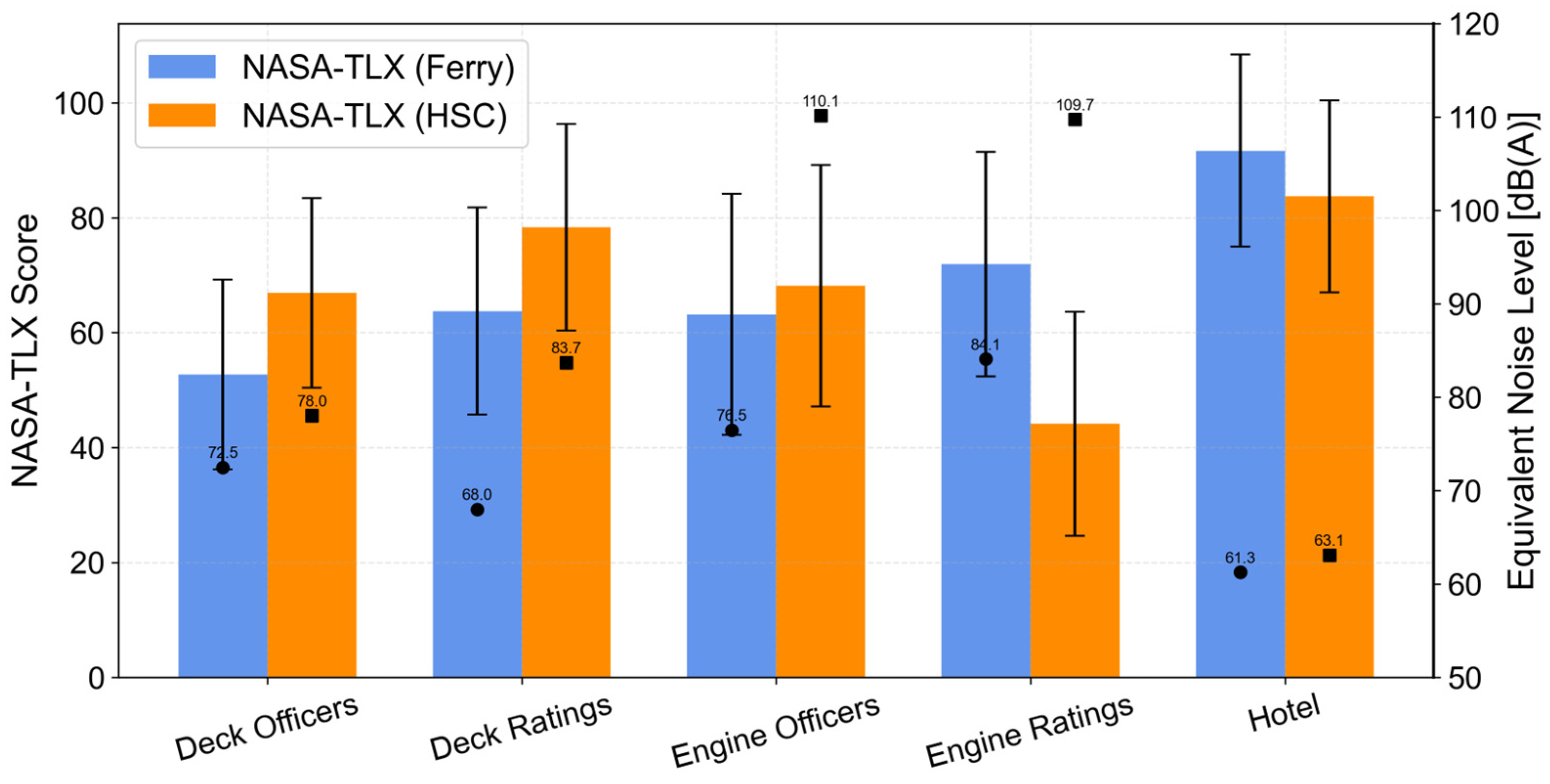

To evaluate their perceived workload, crew members completed the NASA-TLX (Task Load Index) questionnaire, comprising six dimensions: mental demand, physical demand, temporal demand, performance, effort, and frustration. Overall perceived workload was assessed using composite total scores.

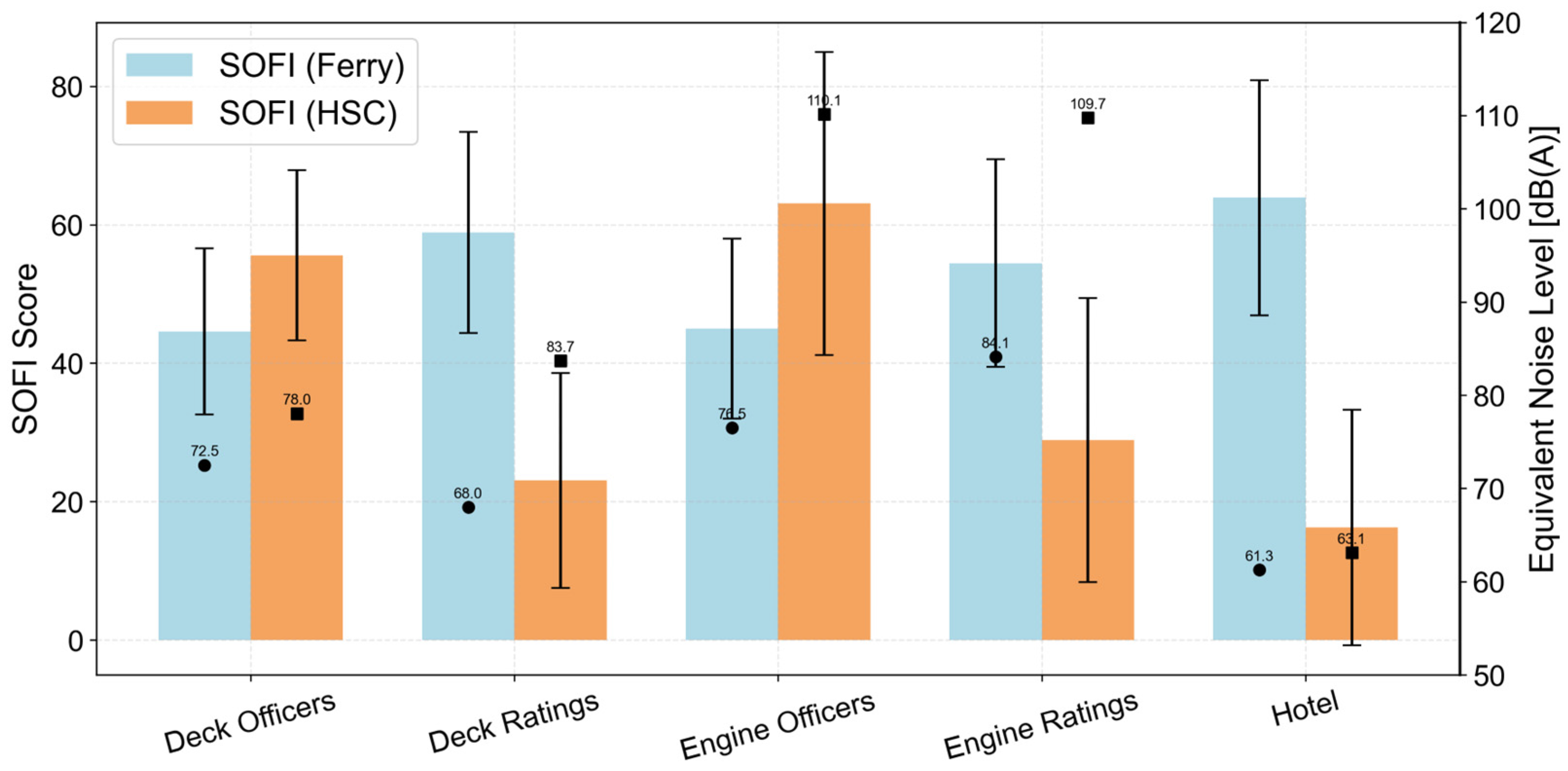

Figure 5 shows the average NASA-TLX scores for each crew group, comparing the conventional ferry with the HSC. Overlaid on the chart are the equivalent continuous noise levels (LEX,8h) experienced by each group during navigation. The term LEX,8h refers to the equivalent continuous noise level averaged over an 8 h period, providing a standardized measure of noise exposure. Noise levels are indicated by black markers for both the HSC and conventional ferry.

Deck ratings and hotel staff aboard the HSC reported the highest workload scores, with NASA-TLX totals reaching 78.3 ± 18.0 and 83.8 ± 16.7, respectively. These results align with the elevated noise exposure experienced by these groups, particularly in the bridge (78 dB(A)) and accommodation spaces. Conversely, engine officers on the ferry reported the lowest workload values (63.2 ± 21.0), despite working in areas with relatively high noise levels (84 dB(A)).

The multivariate regression analysis revealed a significant negative correlation between LEX,8h and NASA for the HSC (estimate = −0.735, SE = 0.207, t = −3.546, p = 0.005). The model intercept was 129.955 (p < 0.001), with a strong model fit (R = 0.750, R2 = 0.562). In contrast, for the ferry crew, NASA was not a significant predictor of LEX,8h (estimate = −0.00680, SE = 0.0753, t = −0.0903, p = 0.929). The ferry model showed low fit (R = 0.194, R2 = 0.038), indicating that noise exposure was not strongly associated with perceived workload for this group.

Certain groups deviated from this trend, suggesting that factors beyond noise also contribute to workload perception. For example, hotel crew on the ferry experienced the highest perceived workload (91.7 ± 16.7), despite relatively low acoustic exposure (61 dB(A)). This likely reflects additional stressors such as irregular shift patterns, physically demanding service, and passenger interactions.

These results emphasise the importance of vessel design and working conditions in moderating physical and cognitive workloads at sea.

4.3.2. SOFI-SM: Fatigue Scores

In addition to workload, subjective fatigue was assessed using the Swedish Occupational Fatigue Inventory–Spanish Modified (SOFI-SM), which measures fatigue across five dimensions: lack of energy, physical discomfort, lack of motivation, sleepiness, and irritability. The SOFI scores were averaged for each crew group and vessel type.

Figure 6 shows the SOFI scores for the conventional ferry and the HSC, alongside their respective equivalent noise exposure levels (LEX,8h). The results reveal a nuanced relationship between perceived fatigue and noise exposure that varies by department.

Among the HSC crew, engine officers exhibited the highest fatigue scores (63.1 ± 18.5), closely matching their extreme noise exposure level of 110 dB(A). In contrast, deck personnel aboard the HSC reported relatively low SOFI scores (23.1 ± 9.5), despite being exposed to elevated noise. On the ferry, hotel crew showed the highest fatigue levels despite their comparatively low noise exposure, while engine ratings reported high fatigue with moderate exposure (84 dB(A)). These patterns suggest that task demands, service intensity, and organizational context contribute significantly to perceived fatigue.

The multivariate regression analysis confirmed that SOFI was not a significant predictor of LEX,8h for either vessel (HSC: estimate = 0.105, SE = 0.158, t = 0.661, p = 0.522; ferry: estimate = 0.06436, SE = 0.0886, t = 0.7264, p = 0.476). These results indicate that noise exposure alone does not consistently explain fatigue perception, which appears more closely tied to work organization and non-acoustic stressors.

On the conventional ferry, hotel crew showed the highest fatigue levels despite their comparatively low noise exposure. This discrepancy highlights the impact of non-acoustic factors such as emotionally demanding passenger interactions, irregular shift patterns, and high service intensity. Engine ratings also reported elevated fatigue (54.4 ± 12.2), despite moderate noise exposure (84 dB(A)).

Preliminary analyses further indicated no significant associations between fatigue or workload and individual characteristics (age, gender, position, years of experience; all p > 0.05), suggesting that demographic variables did not bias the observed patterns.

4.3.3. Reduced Morningness–Eveningness Questionnaire (rMEQ)

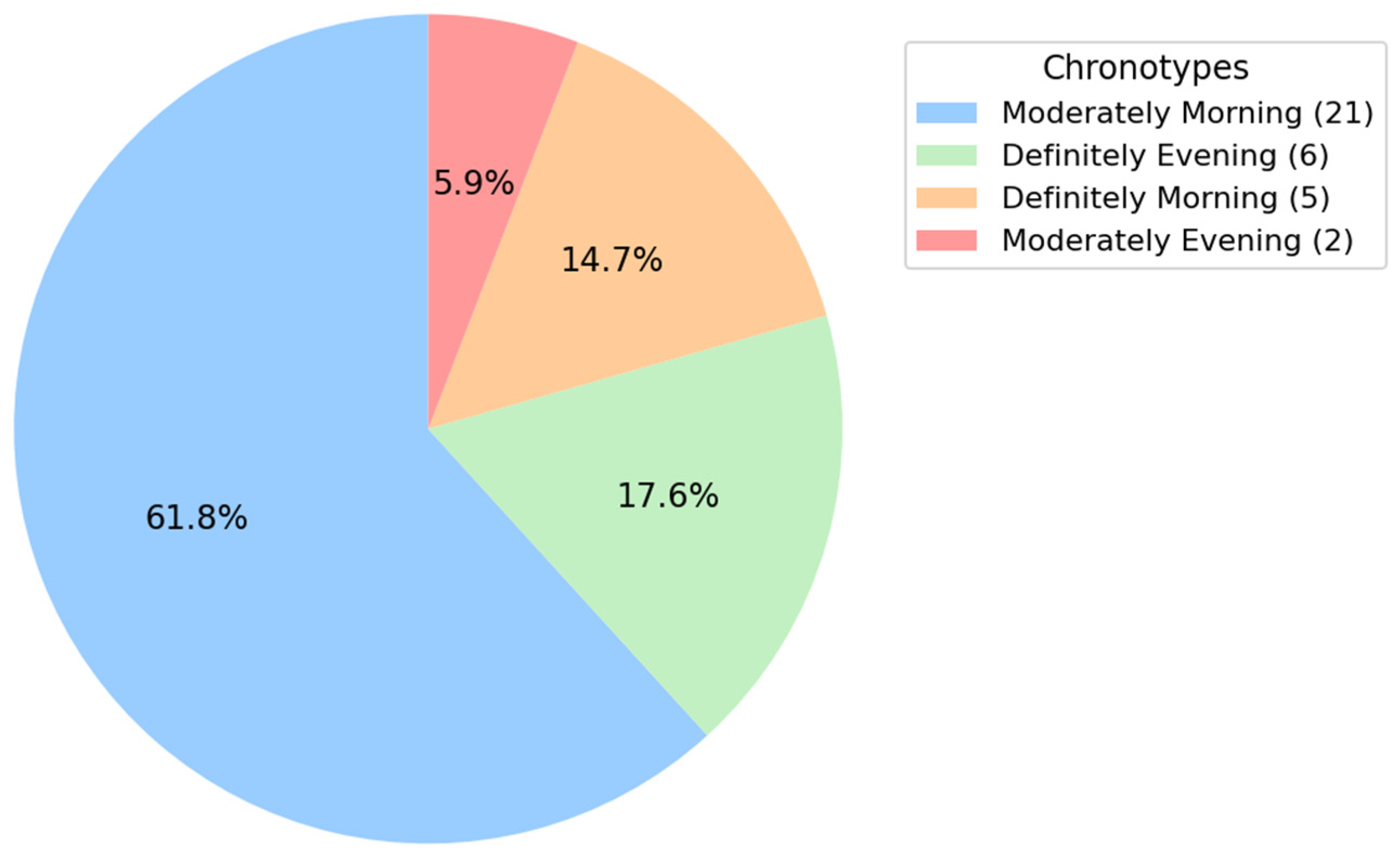

The Reduced Morningness–Eveningness Questionnaire (rMEQ) was used to assess individual circadian typologies, which may influence vulnerability to fatigue and perceived workload, particularly under rotating or night shift conditions. Participants were classified into one of four chronotype groups based on their rMEQ scores: definitely morning, moderately morning, moderately evening, or definitely evening.

Across the combined sample of 36 participants described in

Section 3.2.2, two responses were excluded due to missing data, resulting in 34 valid entries. The majority of respondents exhibited a morning-oriented chronotype, with 61.8% classified as moderately morning and 14.7% as definitely morning. A smaller proportion reported an evening orientation, with 5.9% classified as moderately evening and 17.6% as definitely evening (

Figure 7).

A Spearman’s rank-order correlation was conducted to explore the relationship between circadian typology (rMEQ) and both subjective fatigue (SOFI-SSM) and perceived workload (NASA-TLX). Results revealed a moderate, statistically significant positive correlation between eveningness and fatigue (ρ = 0.506, p = 0.003), suggesting that individuals with more evening-oriented chronotypes reported higher fatigue levels. However, given that the sample was predominantly composed of morning-type individuals, these findings should be interpreted with caution. No significant association was found between chronotype and perceived workload (ρ = −0.184, p = 0.312).

These results suggest that nearly 90% of the crew display a morning preference, which may influence their adaptability to night work and extended duty periods. This distribution aligns with prior studies showing that morning chronotypes are more prevalent among maritime professionals, possibly due to selection effects or the nature of operational schedules [

27].

5. Discussion

This study provides a comparative assessment of onboard noise exposure and its occupational implications across two vessel types: a conventional steel-hulled Ro-Pax ferry and a high-speed aluminium catamaran (HSC). The findings contribute to broader discussions in environmental acoustics and occupational health by demonstrating how vessel design, operational conditions, and structural materials affect not only measured sound levels but also perceived workload and fatigue.

Consistent with previous research [

9], the highest recorded noise levels occurred in machinery spaces, particularly aboard the HSC, where values consistently exceeded 110 dB(A). These levels breach the thresholds outlined in IMO Resolution A.468(XII) and exceed the exposure action values defined in the European Directive 2003/10/EC, even after accounting for the attenuation provided by hearing protection. While these regulations are not always explicitly harmonized, their combined application illustrates a critical distinction: IMO standards address design-based noise limitations by area, whereas EU legislation focuses on actual exposure and risk prevention.

The HSC’s bridge also exhibited elevated acoustic readings, approaching the 65 dB(A) threshold for operational spaces set by the HSC Code 2000. Such levels, although compliant, could still impair cognitive performance over long shifts. This supports calls in both psychoacoustics and acoustic ecology for more nuanced interpretations of noise impact, not only as a physiological stressor but also as a factor affecting mental workload and decision-making accuracy.

The structural differences between vessels proved significant. The HSC’s lightweight aluminium hull, while optimal for speed, transmitted more structure-borne and airborne noise into accommodation and public zones than the steel-hulled ferry. These results align with principles in architectural and underwater acoustics, which emphasize material density and damping characteristics as critical to acoustic insulation.

Subjective data further underscored the occupational impact of these acoustic environments. Multivariate regression analyses showed that for the HSC, higher NASA scores were significantly associated with lower LEX,8h, while SOFI was not significant. For the ferry, neither NASA nor SOFI predicted LEX,8h. Together with the descriptive patterns, these results confirm that workload and fatigue are not determined by noise exposure alone but are shaped by broader operational and organizational conditions.

Notably, engine crews aboard the HSC reported high perceived demands and fatigue, while some unexpected patterns emerged, such as ferry hotel personnel reporting elevated fatigue despite low acoustic exposure. These observations illustrate how noise interacts with psychosocial and organizational factors, reinforcing the importance of an interdisciplinary approach that includes ergonomics and chronobiology.

In addition to environmental conditions, individual characteristics also influenced fatigue perceptions. The crew’s inclination toward morningness, as measured by the reduced Morningness–Eveningness Questionnaire (rMEQ), aligns with previous research indicating a higher prevalence of early chronotypes among maritime professionals. This tendency may reflect occupational structures that favour morning-oriented routines. Chronotype distribution has meaningful implications for fatigue and sleep patterns, particularly during night shifts, as morning types generally exhibit lower adaptability to nocturnal work schedules [

28,

29].

This study focused on two vessels constructed before the implementation of newer design standards, which still represent a substantial portion of the active maritime fleet. Measurements were carried out with a Class 2 sound level meter compliant with IEC 61672, which limited detailed spectral analysis and prevented the use of speech intelligibility indices such as SIL or PSIL. Future research should extend this framework to vessels built under updated standards (e.g., IMO Resolution MSC.337(91)) and employ Class 1 instruments with spectral analysis to better capture low-frequency contributions and communication effectiveness.

Overall, this study highlights the limitations of applying uniform noise standards across structurally and operationally distinct vessels. It supports the need for vessel-specific acoustic management strategies and for bridging gaps between design regulations and occupational health frameworks. More broadly, the findings contribute to the emerging field of maritime soundscape research, offering practical insights into how structural, operational, and human variables intersect in shaping the acoustic experience at sea.

6. Conclusions

This study highlights the significant differences in onboard noise exposure between a conventional Ro-Pax ferry and a high-speed craft (HSC). It emphasises the influence of vessel design, materials, and operational characteristics on the acoustic environment and crew well-being. While both types of vessels comply with the structural requirements of IMO Resolution A.468(XII) and the 2000 HSC Code, noise levels on the HSC often exceed the exposure limits established by EU Directive 2003/10/EC, particularly in the engine and accommodation areas.

Subjective assessments using NASA-TLX and SOFI-SM revealed differences between vessel types. Multivariate regression analysis demonstrated that for the HSC, NASA was significantly associated with LEX,8h, whereas SOFI was not. In contrast, for the ferry, neither NASA nor SOFI predicted LEX,8h. These findings reinforce that additional organizational, task-related, and individual factors strongly influence perceived workload and fatigue beyond noise exposure itself.

These findings highlight the importance of ship-specific mitigation strategies, including improved insulation in high-noise areas and the integration of noise mapping into safety management systems, as well as the implementation of more adaptive work schedules that consider individual circadian rhythms. Furthermore, aligning voluntary comfort notations with World Health Organization (WHO) recommendations for rest environments could improve long-term health outcomes. Ultimately, both regulatory frameworks, the IMO for design compliance and the EU for occupational health protection, are indispensable and must be applied in parallel to address structural and operational risks. Only through this dual approach can the maritime industry develop effective, evidence-based strategies to protect the acoustic health and performance of seafarers.