Abstract

This study presents an experimental investigation into the seismic performance of seismically deficient reinforced concrete (RC) bridge columns retrofitted with passive and active confinement systems. Four single-cantilever RC columns, representing 1/3-scale bridge piers, were constructed with poor transverse reinforcement detailing to simulate seismic deficiency. One column was left un-strengthened for baseline comparison, while the remaining three were retrofitted using: (1) a CFRP jacket, (2) welded Fe-SMA plates, and (3) bolted Fe-SMA plates. All columns were subjected to quasi-static lateral cyclic push-only loading reaching extreme drift levels exceeding 16% and high loading rates up to 6 mm/s. The study specifically explores the confinement effectiveness of CFRP and thermally activated Fe-SMA plates, comparing their contributions to lateral strength, ductility, energy dissipation, failure mode, and damage suppression. The results show that while the as-built column failed at 3.65% drift due to brittle flexural-shear failure, all retrofitted columns demonstrated significantly enhanced ductility, drift capacity, and post-peak behaviour. The CFRP and Fe-SMA jackets effectively delayed damage initiation, minimized core degradation, and improved energy dissipation. The bolted Fe-SMA system exhibited the highest and full restoration of lateral strength, while the welded system achieved the greatest increase in cumulative energy dissipation of around 40%. This research highlights the practical advantages and seismic effectiveness of Fe-SMA and CFRP confinement systems under extreme drift levels. However, future work should explore full-scale column applications, refine anchorage techniques for improved composite interaction, and investigate long-term durability under cyclic environmental conditions.

1. Introduction

Over the past few decades, numerous reinforced concrete (RC) bridges have suffered severe damage or collapse during major seismic events. Among the various types of structural failures, the loss of RC bridge columns is particularly critical because of its direct impact on the safety, stability, and functionality of the entire bridge system. Many of these vulnerable columns were built before the introduction of modern seismic design provisions in the early 1970s and thus lack the necessary detailing to ensure ductile performance under earthquake loading. Design shortcomings, such as widely spaced transverse reinforcement and insufficient lap splice lengths [1,2], have rendered these columns incapable of forming ductile plastic hinges, leading to brittle shear failures during past earthquakes.

To address this vulnerability, significant research has focused on enhancing the ductility and energy dissipation capacity of RC columns, particularly at their plastic hinge zones. According to capacity design principles, ensuring a flexural rather than a shear failure mechanism is paramount, and this can be achieved through effective confinement of the concrete core in the hinge regions. Confinement can be applied to RC columns through either passive or active means. In passive confinement, the confining mechanism engages only after the concrete begins to dilate under loading—typically after some level of damage has already occurred. In contrast, active confinement applies a sustained lateral pressure to the concrete immediately upon installation, without requiring prior deformation. Notably, numerous studies [3,4,5] have demonstrated that active confinement effectively enhances the ultimate strength, deformation capacity, and ductility of concrete columns. For instance, Gholampour et al. [5] reported that the axial strength and strain capacity of concrete confined with active NiTi-SMA spirals increased by 38% and 333%, respectively. This superior performance is attributed to the fact that active confinement engages before any damage develops in the concrete, allowing the material to fully benefit from the induced triaxial stress state and to improve its mechanical behaviour before cracking or failure initiates.

Early strengthening methods, such as steel or concrete jacketing, provided some success in providing external confinement; however, their passive nature, high cost, long installation time, and labour-intensive nature made them impractical for widespread application. Furthermore, their heavyweight nature increases the structural weight, thereby increasing the seismic demand on the structure. While a few studies, such as those by Saatcioglu and Yalcin [6], have explored the use of prestressed steel jackets to achieve an active confinement mechanism, this method often requires complex mechanical hardware and extended application time to achieve adequate prestressing levels for low confinement pressures. Such challenges raise substantial concerns regarding the feasibility and practicality of implementing active confinement systems using conventional materials.

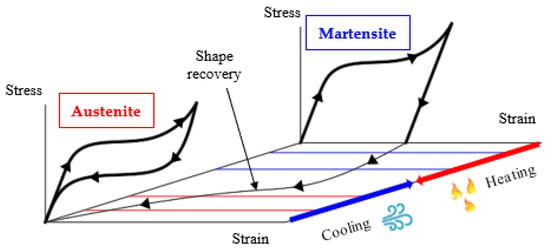

This limitation led to the rise of more advanced materials such as Fibre-Reinforced Polymers (FRP) and Shape Memory Alloys (SMA). These materials offer significant advantages in terms of strength, durability, and ease of installation. In particular, SMAs are a distinct class of metallic materials known for their ability to return to their undeformed shape due to their unique thermo-mechanical characteristics, specifically superelasticity (SE) and the shape memory effect (SME) [7,8,9]. The behaviour of SMAs is primarily governed by temperature, which influences changes in their internal crystallographic structure [7]. In their superelastic form, as shown in Figure 1, SMAs exhibit an austenitic () phase that allows them to undergo large strains and recover their original shape upon unloading. Conversely, SMAs in the martensitic () phase tend to retain permanent deformations once the load is removed [9]. To eliminate these residual strains, the material must be heated above its austenite finish temperature (), triggering a phase transformation from martensite to austenite, thereby representing the basis of the SME [8]. At temperatures above , the SMA behaves in a fully elastic manner, as illustrated in Figure 1. Notably, the transformation to the austenitic phase begins at the austenite start temperature ().

Figure 1.

Thermo-mechanical behaviour of SMA in their austenitic and martensitic phase.

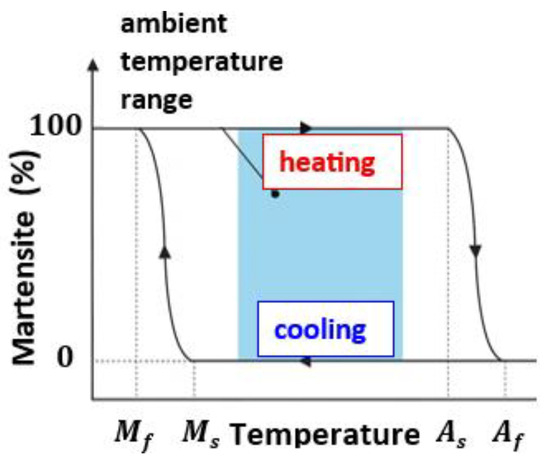

However, if the SMA is mechanically restrained during this heating process, it generates substantial internal stresses known as recovery stresses [10]. As detailed in Figure 2, once the temperature drops below the martensite finish temperature (), the material reverts to the martensitic phase and loses the recovery stresses it developed earlier [8]. Similarly, the reverse transformation begins at the martensite start temperature (). It is noteworthy to mention that when is lower than the ambient temperature, similar to what is presented in Figure 2, the SMA remains in its austenitic state, effectively retaining the recovery stresses achieved during heating. This highlights the importance of selecting SMAs with a wide thermal hysteresis range (–) to ensure that recovery stresses are maintained even after cooling back to room temperature [7].

Figure 2.

Phase transformation of SMA against the ambient temperature range.

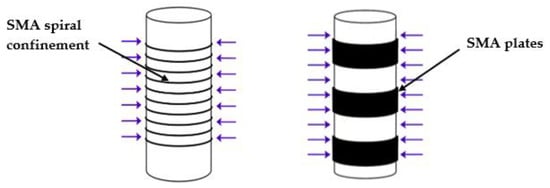

Correspondingly, the substantial recovery stresses generated by SMAs make them highly suitable for applying active confinement in RC columns without the need for extensive mechanical prestressing hardware. This technique was first introduced in 2008 by the pioneering study of Andrawes and Shin [11], who employed thermally prestressed NiTiNb (Nickel-Titanium-Niobium) Shape Memory Alloy (SMA) spirals to provide active confinement around the critical plastic hinge region of RC columns [7], as represented in Figure 3. In the study by Shin and Andrawes [7], NiTiNb-SMA spirals were heated above their austenite finish temperature () to produce active confinement pressure through recovery stresses. As reported, the active NiTiNb-SMA spirals not only minimized column damage but also led to a 186% increase in the column’s flexural ductility and 371% increase in its energy dissipation capacity. Since then, SMA has stood out as the only material capable of offering both passive and active confinement without the need for complex hardware. When unactivated, SMA functions as a passive confining material; however, once heated to trigger its austenitic phase transformation, it generates recovery stresses that produce an active confinement effect. This unique property allows SMA to deliver active confinement more efficiently and practically than traditional prestressed systems. In a similar line of research, Jung et al. [12] evaluated the effectiveness of active confinement using NiTiNb-SMA spirals as a repair technique for damaged RC columns subjected to bidirectional shaking. The SMA spirals successfully restored lateral load capacity, reduced structural damage, and retained 90% of the induced prestress even under synchronous bidirectional excitation. In addition, the NiTiNb-SMA retrofitted columns withstood 10.5% drift without concrete crushing, demonstrating the effectiveness of spiral-active SMA confinement in mitigating damage to RC columns under severe simulated earthquake loading.

Figure 3.

Utilization of SMA spirals versus SMA plates around RC columns for confinement.

Beyond transverse confinement, SMA materials have also been explored in vertical configurations to enhance flexural behaviour and lateral strength. Notably, Al Ekkawi and El-Hacha [13] recently proposed an innovative method that employed vertically oriented, prestressed Fe-SMA plates for the flexural strengthening of seismically deficient RC columns. Their approach offered a highly effective technique for leveraging the SME in a flexural application—a configuration rarely studied in RC column strengthening. The results demonstrated that the Fe-SMA system improved lateral strength and energy dissipation by 35.32% and 72.60%, respectively, and successfully prevented concrete core crushing even at drift levels exceeding 8%.

Several researchers have investigated the use of FRP jackets for improving the seismic performance of RC columns with inadequate lap-splice detailing. Ma et al. [14] and Harries et al. [15] examined the behaviour of large-scale RC columns strengthened with CFRP. In the study by Ma et al. [14], the full-scale retrofitted parking structure column with CFRP jackets sustained drift ratios of up to 9% without strength loss, achieving a displacement ductility factor of approximately 10, compared to only 3.2 for the as-built column. In addition, the retrofitting increased the estimated ultimate lateral strength from 378.6 kN (as-built) to 472 kN, representing a 24.6% enhancement and effectively preventing premature shear and lap-splice failures. Similarly, Harries et al. [15] concluded that CFRP confinement improved column ductility by 230% and lateral strength by 21%, and delayed the initiation of severe bar slip, allowing the columns to attain their nominal flexural capacity. However, once slip is initiated, the ductility benefits are diminished. Sause et al. [16] further demonstrated that applying CFRP wrapping to the plastic hinge region of RC columns resulted in a 176% increase in displacement ductility, although the associated increase in lateral load capacity was relatively modest, averaging around 3.20%. In contrast, Shaheen et al. [17] observed substantial strength gains, reporting a 20% and 46% increase in lateral strength with one and two layers of CFRP wrapping, respectively, spaced at 100 mm. They also recorded a 102% enhancement in displacement ductility, which effectively shifted the column’s failure mode from brittle shear to ductile flexure. Meanwhile, He et al. [18] presented compelling evidence for CFRP’s effectiveness in restoring torsional capacity in damaged RC columns. Their study showed that uniform CFRP jacketing along the entire column height successfully restored 118% of the column’s original torsional strength and 106% of its ductility.

Although passive FRP confinement is widely recognized as an effective method for enhancing the seismic performance of RC columns, ongoing research efforts have continued to explore its potential for use in active confinement systems. This sustained interest, even after passive confinement proved effective in addressing seismic deficiencies, is largely attributed to studies by Rechart et al. [19,20], which demonstrated that active confinement can offer superior benefits.

In this context, Nesheli and Meguro [21] proposed a novel approach for manually prestressing CFRP and aramid FRP (AFRP) belts after their installation around RC columns using a simple mechanical wrench. Their results showed that the non-retrofitted columns exhibited brittle shear failure, losing more than 50% of their lateral strength at a drift of only 4.5%. By contrast, damaged columns retrofitted with prestressed carbon or aramid FRP belts restored their lateral strength and maintained shear capacity up to 5% drift, with only about 7% strength loss. Building on this, Zhou et al. [22] carried out a comprehensive experimental study involving 25 circular RC columns retrofitted with lateral prestressed CFRP strips. Their findings revealed that prestressed CFRP strips delayed the formation of inclined cracks and shifted the failure mode from brittle shear to more ductile bending or bending-shear behaviour. Enhancements in load capacity, ductility, and energy dissipation were observed, rising by up to 52%, 147%, and 831%, respectively. Although high axial load ratios influenced the seismic response, the use of prestressed CFRP confining strips consistently improved column performance. Zhou et al. [22] further recommended limiting the prestress level to 25% of the CFRP’s ultimate tensile strength and found that surface grinding combined with epoxy bonding yielded optimal performance for this system. More recently, Wang et al. [23] implemented a method similar to that of Nesheli and Meguro [21], using a prestressed confining CFRP sheet to strengthen RC columns. It was reported that square RC columns strengthened with multi-layer prestressed CFRP fabric showed significant improvements in seismic performance. Compared to un-strengthened columns, the ultimate horizontal load capacity increased by up to 41%, the ultimate displacement increased by 80%, and the displacement ductility improved by 81%. Furthermore, fully wrapped specimens maintained stable hysteresis and exhibited delayed stiffness degradation under a high axial compression ratio (0.7).

While active confinement using FRP and steel materials has shown promise in enhancing the seismic performance of RC elements, both share a common limitation: achieving sufficient active confinement pressure with FRP typically requires complex mechanical systems and substantial hardware. Moreover, the use of prestressed FRP systems necessitates careful design considerations to prevent issues such as creep rupture. Consequently, researchers have increasingly turned their attention to innovative alternatives, focusing on active confinement using smart materials such as SMA, which can simplify its implementation in RC columns.

2. Research Gaps for SMA Active Jacketing—Research Novelty and Plan

The effectiveness of SMA-based active confinement in enhancing the seismic performance of deficient RC columns has been well established. However, most previous studies have focused on SMA spiral confinement using relatively thin wires, typically 1–2 mm in diameter [7,12,24,25,26]. Such an SMA confinement method requires meticulous spacing and precise alignment along the column height to ensure uniform confinement, thereby making their installation labour-intensive and less practical. In addition, these studies have primarily evaluated the lateral cyclic behaviour of columns subjected to drift levels ranging from 5% to 14%, with very few studies extending beyond these drift limits.

To address these limitations, the present study pioneers the use of flat Fe-SMA plates (1.5 mm × 120 mm) as active confining jackets; a method that departs from the traditional SMA spiral configuration. In this study, these flat Fe-SMA plates are used on RC columns to provide high confinement pressures around their plastic hinge regions, while remaining in line with the ductility and drift requirements of CSA S6-19 [27]. The SMA plate confinement approach is shown on the right in Figure 3. This proposed SMA plate confinement method significantly simplifies installation by eliminating the need for continuous spiral winding, thereby offering a more practical and scalable solution for retrofitting applications. Furthermore, the Fe-SMA plates used in this study are either welded along their overlapped length or mechanically anchored to the column’s concrete core using wedge anchors. Therefore, this study, which introduces the first experimental application of Fe-SMA plates as confinement jackets, also experimentally investigates a comparative evaluation of their anchorage/utilization on RC columns.

The second source of novelty arises from the testing configuration. As mentioned earlier, most previous studies have tested RC columns under considerably lower displacement demands−typically around 15 mm, 30 mm, and 45 mm [25], 50 mm [23,28], 150 mm [16], and 200 mm [14], with only a few studies [7,15] exceeding 200 mm. Similarly, cyclic loading rates in past studies have generally ranged from 0.02 mm/s [29] to 0.25 mm/s [7]. Correspondingly, the strengthened columns prepared in this study are subjected to extreme loading conditions, which represent another source of novelty. Specifically, the columns are subjected to severe lateral cyclic loading with drift levels exceeding 16% (corresponding to 237 mm of lateral displacement) and a high loading rate of 2 to 6 mm/sec. These parameters represent a substantial change from conventional lateral cyclic testing protocols and more accurately replicate the severe seismic demands observed in real bridge piers during strong earthquakes.

Accordingly, the main research gaps addressed in this study are as follows:

- Lack of research on the use of SMA plates, as opposed to spirals, for active confinement applications.

- Absence of comparative evaluation of different anchorage methods for SMA plates (welded vs. bolted).

- Limited experimental data on strengthened RC columns tested under extreme drift demands (>14% drift) and high loading rates.

- Limited understanding of how SMA and CFRP confinement systems perform in preventing damage and preserving column integrity at very high drift levels and shaking frequency.

To achieve these objectives and address the aforementioned research gaps, four single-cantilever RC columns, representing one-third scale models of RC bridge piers, were constructed and tested. The first served as an un-strengthened control column. The second was strengthened with a CFRP jacket to provide passive confinement, while the third and fourth were confined with welded and mechanically bolted Fe-SMA plates, respectively. The Fe-SMA plates were thermally activated to induce recovery stresses, thereby providing active confinement.

All specimens were subjected to quasi-static lateral cyclic loading with a maximum displacement amplitude of 237 mm. Their seismic performance was evaluated comparatively in terms of lateral strength, displacement ductility, energy dissipation capacity, stiffness degradation, failure mode, and damage progression. Strain measurements were also recorded on the confining jackets to assess their engagement and effectiveness throughout the entire range of imposed displacements.

Furthermore, this research compares the efficiency of the popular passive CFRP jackets with that of the novel active Fe-SMA plate system under the same large drift demands. Thereby, as mentioned earlier, one column specimen was confined with CFRP. Such a comparative investigation provides further understanding of the limitations of the passive CFRP compared with the novel active Fe-SMA plate jacketing when applied to RC columns subjected to large drift demands and a faster loading frequency.

3. Experimental Program

3.1. Materials

3.1.1. Normal-Strength Concrete

The concrete mix was designed with a target specified compressive strength of 35 MPa at 28 days. The mix proportions by weight were: cement = 1.0, water = 0.45, fine aggregate = 2.3, and coarse aggregate = 2.1. Type GU Portland cement was used, along with an air-entraining admixture to introduce a 5% air content for improved workability [30]. The coarse aggregate consisted of crushed Canadian limestone with a maximum size of 14 mm, while the fine aggregate was natural Canadian river sand. Although the particle-size distributions of the coarse and fine aggregates are not presented in this study, it is noted that all concrete mix components were sourced from a local concrete supplier. Therefore, it is reasonable to assume that both aggregate gradations conform to the requirements of ASTM C33 [31].

Both the columns and their corresponding foundations were constructed using normal-strength concrete with a specified compressive strength of 35 MPa. To replicate realistic construction practices, the foundations were cast before the columns. The curing process of the RC columns involved covering their tops with plastic burlap immediately after casting. Four days after placement, the columns’ formwork was removed, and curing continued by regularly spraying the columns with water using a hose to ensure adequate moisture retention. Notably, the same curing process was followed for the RC foundations.

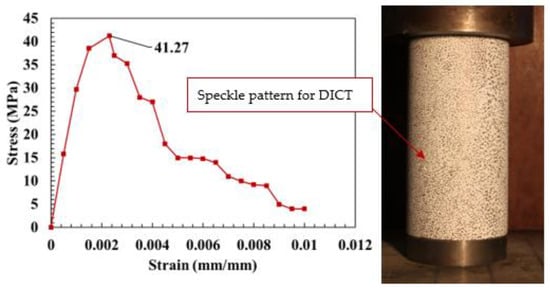

In accordance with ASTM C39/C39M [32], the average 28-day compressive strength () of the RC columns’ concrete was 44.86 MPa (4.35 MPa), determined from uniaxial compression tests on four 100 × 200 mm standard cylinders, cured in a moist room at 98% relative humidity and 21.3 °C. The stress–strain curve for one concrete cylinder, obtained through Digital Image Correlation Technique (DICT), is presented in Figure 4. At the time of testing the columns, the average measured was 42 MPa (3.95 MPa), based on ten standard cylinders cured under the same ambient laboratory humidity conditions as the columns, with relative humidity ranging between 60 and 70%, which is a typical climatic condition in Calgary, Alberta. Since the aforementioned cylinders were cured at ambient climatic conditions, their average was slightly lower than that obtained after curing at 98% humidity for 28 days.

Figure 4.

Stress–strain curve of cured normal-strength concrete cylinder under uniaxial compression after 28 days.

Furthermore, the average splitting tensile strength at 28 days, measured in accordance with ASTM C496/C496M [33], was 4.05 MPa (0.58 MPa, three cylinders), whereas the value at the age of testing the columns was 3.63 MPa (0.32 MPa, eleven cylinders). Similarly, the average value obtained at 28 days pertains to cured cylinders in a 98% humidity room. Meanwhile, the average value obtained at the time the columns were tested corresponds to an uncured cylinder, thereby explaining its lower value.

3.1.2. Reinforcing Steel

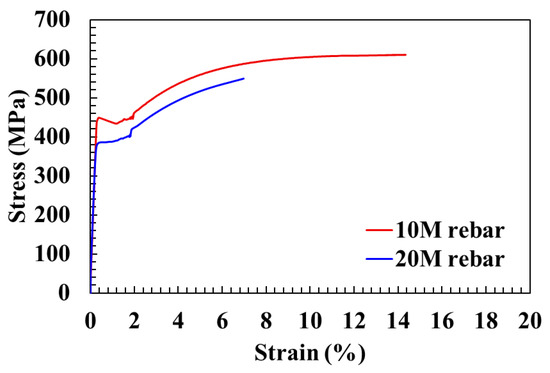

Two rebar sizes were utilized in the construction of all columns: 10M rebars (nominal diameter of 11.3 mm) for transverse (shear) reinforcement and 20M rebars (nominal diameter of 19.5 mm) for the longitudinal reinforcement. Both bar types had a specified yield strength of 400 MPa. To verify their mechanical properties, multiple steel samples (four samples for size 10 M and six for 20 M) were tested under uniaxial tension in accordance with ASTM A370 [34]. The measured recorded yield strengths were 439 MPa (34.45 MPa) for the 10 M rebars and 404.4 MPa (32.11 MPa) for the 20 M rebars. For clarity purposes, the stress–strain curves for one steel sample per size are presented in Figure 5.

Figure 5.

Stress–strain curves obtained from the uniaxial tension of one 10 M and 20 M rebar samples.

3.1.3. Fe-SMA Plates

In this study, martensitic Fe-SMA plates—supplied in a flat form with a thickness of 1.5 mm and a width of 120 mm—are employed to provide active confinement for the RC columns. A comprehensive material characterization of the same Fe-SMA alloy was previously conducted by Shahverdi et al. [9], with its key properties summarized in Table 1. The material’s phase transformation temperatures were reported by Lee et al. [35] as −64 °C (), −60 °C (), 103 °C (), and 163 °C (). During manufacturing, the Fe-SMA plates were pre-strained to 2% at ambient temperature, resulting in a residual strain of 1.25% after unloading while maintaining a martensitic crystal structure.

Table 1.

Mechanical properties of the Fe-SMA plate as characterized by Shahverdi et al. [9].

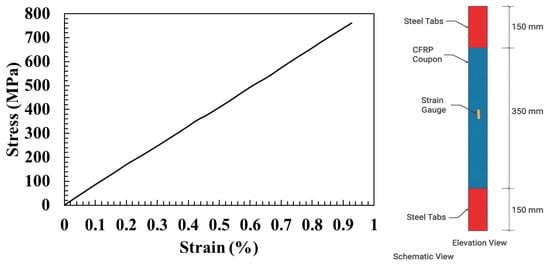

3.1.4. CFRP

The CFRP wraps employed in this research serve to provide confinement within the anticipated plastic hinge region of one of the tested RC columns. These wraps, supplied by Sika [36], were characterized in accordance with the ASTM D3039/D3039M [37] standard for tensile testing. The results indicated an average tensile strength of 710 MPa (140 MPa), an elastic modulus of 68.90 GPa (9.16 GPa), and a rupture strain of 1.29% (0.15) [38]. The stress–strain curve for one of the CFRP coupons is shown in Figure 6. Notably, the aforementioned average results and the test data shown in Figure 6 were extracted from the work of Abdelrahman and El-Hacha [25,38], who performed uniaxial tensile testing on the same CFRP batch used in this study.

Figure 6.

CFRP tensile coupon and its respective stress–strain curve (data determined from [38]).

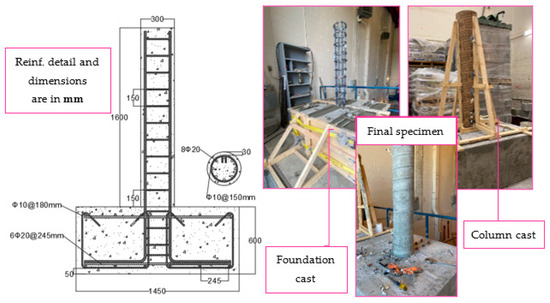

3.2. Design of Column Specimens

The experimental program involved four single-cantilever reinforced concrete (RC) columns, each constructed at a 1/3 scale to replicate bridge piers. These columns measured 300 mm in diameter and had a 1600 mm clear height, supported by 600 mm-thick RC footings. Their reinforcement design was guided by the provisions of CSA S6–19 [27]. The columns were intentionally detailed to simulate seismic deficiencies, specifically by using widely spaced transverse hoops at 150 mm spacing. This spacing significantly exceeds the code’s maximum allowable limit of 75 mm (0.25 times the column diameter), making them representative of vulnerable bridge piers that typically had such poor reinforcement design.

Each column was reinforced with eight 20M longitudinal rebars arranged along the perimeter and enclosed with a 30 mm concrete cover. The reinforcement layout and casting process are illustrated in Figure 7. The resulting transverse and longitudinal reinforcement ratios were 1.16% and 3.40%, respectively.

Figure 7.

Reinforcement detail and cast of the RC columns.

It is noteworthy that, although the test specimens were scaled down, their reinforcement detailing was deliberately chosen to trigger critical failure modes often observed in deficient bridge piers—such as stirrup opening, core concrete crushing, and shear-induced damage. These behaviours have been widely documented and reported by Priestley et al. [39]. Finally, while acknowledging that using a 1/3 scale introduces limitations, the authors emphasize the importance of future research to validate the performance and applicability of these strengthening strategies on full-scale bridge columns with larger diameters and heights.

3.3. Column Testing Matrix

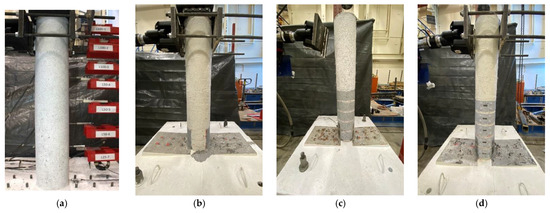

This study investigates four RC columns, all designed to represent seismically deficient conditions resulting from the use of widely spaced transverse reinforcement. It is essential to note that, although the columns are initially deficient, the applied strengthening interventions are designed to rectify these deficiencies—this being the primary objective of the study. The first column (RC) was left un-strengthened to serve as a baseline for comparison. The second column, designated as RC-CC, was strengthened using a CFRP confining jacket. The third column, RC-CSW, was confined with Fe-SMA plates welded along their overlapping lengths. Lastly, the fourth column, RC-CSB, was confined with Fe-SMA plates mechanically anchored to the column’s concrete core using anchor wedges. For RC-CSW and RC-CSB columns, the Fe-SMA plates are then thermally activated to provide active confinement around the RC columns. The testing matrix is presented in Figure 8. It is worth noting that the RC-CC, RC-CSW, and RC-CSB columns were previously tested by the authors under lateral cyclic loading, with the addition of vertical Fe-SMA plates, to assess their potential to enhance the columns’ flexural performance and lateral resistance. The studies can be found in Al Ekkawi and El-Hacha [13,40]. However, those tests were limited to a relatively low drift level of 8%, during which the columns exhibited minimal signs of damage—no significant concrete cracking, cover spalling, or core crushing was observed. The structural response was primarily limited to the yielding of the longitudinal reinforcement, while the overall columns remained undamaged. Based on these findings, the authors of this study decided to remove the vertical Fe-SMA plates (i.e., the flexural strengthening component) and focus solely on the confining jackets—CFRP and Fe-SMA plates—to isolate and examine their effectiveness. This decision enabled a deeper investigation into how these confinement systems perform under more demanding, less conventional testing conditions, including very high drift levels and elevated loading rates, and into their role in preserving the structural integrity of the columns. A close-up image of the confined columns, taken before being painted white for crack detection purposes, is presented in Figure 9.

Figure 8.

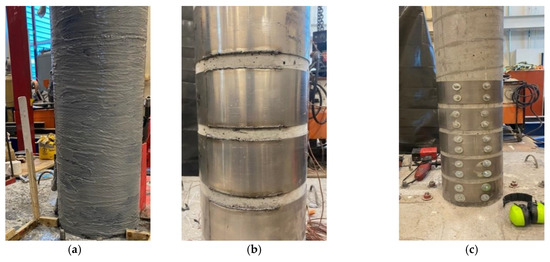

Testing matrix (Refer to Section 3.3 for abbreviations). (a) As-built column; (b) RC-CC column; (c) RC-CSW column; (d) RC-CSB column.

Figure 9.

Close-up image of the confined columns. (a) RC-CC column; (b) RC-CSW column; (c) RC-CSB column.

3.4. Strengthening Procedure

3.4.1. Analytical Estimation of the Columns’ Plastic Hinge Length

The CFRP sheets and Fe-SMA plates, which were used as confining jackets, were applied along the columns’ plastic hinge length (). The latter was initially estimated using analytical expressions derived from well-established research on reinforced concrete behaviour. These key studies, along with their corresponding equations, are summarized in Table 2. Based on these formulations, the calculated values for the tested columns ranged from 0.48 to 0.96 . This difference in between the studies is due to differences in column dimensions, reinforcement details, types of loading, material strengths, and many other factors.

In contrast, the CSA S6-19 [27] specifies a critical plastic hinge length of 2 = 600 mm, as shown in Table 2. This discrepancy created the need for a rational choice on which value to adopt for design and retrofit applications. To remain consistent with code requirements and to ensure simplicity, this study adopted the conservative CSA S6-19 [27] 2 . This choice satisfies CSA provisions while providing a standardized, robust basis for applying strengthening systems to the columns’ plastic hinge zones.

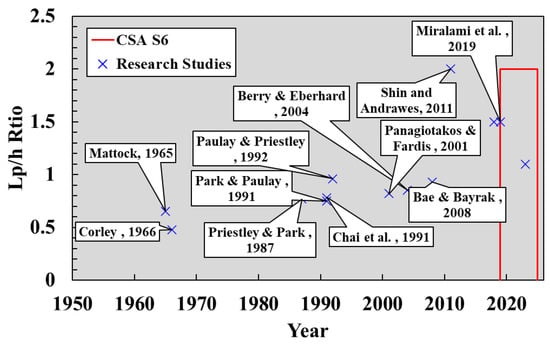

A review of historical -to-depth ratios, illustrated in Figure 10, shows that most empirical estimates cluster between 0.7 and 1.0 , accounting for strain penetration and seismic demand. By comparison, CSA S6-19 [27] prescribes a conservative 2 , thereby prioritizing safety by overestimating the column’s retrofit needs. Meanwhile, ACI 318 [41] does not explicitly define , but its provisions are often interpreted to support values ranging from 0.8 to 2 , which aligns reasonably with the empirical trends shown in Figure 10.

Figure 10.

Historical background on values [1,7,27,28,42,43,44,45,46,47,48,49].

Table 2.

Theoretical estimation of the columns’ plastic hinge length ().

Table 2.

Theoretical estimation of the columns’ plastic hinge length ().

| Study | Equations | ) (mm) | |

|---|---|---|---|

| Priestley and Park 1987 [42] | 231 (0.77) | (1) | |

| Paulay and Priestley 1992 [43] | 287.49 (0.96 ) | (2) | |

| Chai et al. 1991 [1] | 234.70 (0.78 ) | (3) | |

| Mattock 1965 [44] | 195.73 (0.65 ) | (4) | |

| Corley 1966 [45] | 142.54 (0.48 ) | (5) | |

| CSA S6-19 [27] | Greater of | 600 (2 ) | (6) |

| Park and Paulay 1991 [46] | 300 (1 ) | (7) |

Although the adopted = 2 exceeds the estimates provided by conventional models; this assumption is neither unique nor unprecedented. Previous research on retrofitted RC columns has often used similar values, with ranging from 1.5 to 2 [7,28]. Notably, selecting such a large value provides a conservative margin, which is advantageous in seismic retrofit applications where uncertainty in seismic demand and in members’ seismic capacity is high.

Additionally, CSA S6–19 [27] standard stipulates that confinement must extend beyond the critical plastic hinge region by a distance equal to the plastic hinge length itself (600 mm). Accordingly, the confined columns were provided with supplementary confinement in the extended region using CFRP jackets, thereby ensuring full compliance with the standard.

3.4.2. Strengthening of the RC-CC Column

The RC-CC column was confined using a CFRP jacket applied over a 600 mm segment corresponding to the column’s potential plastic hinge region, as outlined in Section 3.4.1. To meet the ductility provisions of CSA S6-19 [27] (refer to Equations (8) and (9)), two layers of CFRP were employed, resulting in a confinement pressure of 4.05 MPa, calculated using Equation (10). A 50 mm clearance was maintained between the base of the column and the CFRP jacket to prevent the jacket from contributing to the column’s flexural resistance. The CFRP overlap length was set to 300 mm, which is equal to the diameter of the column. It is noteworthy that neither CSA S6:19 [27] nor ACI 440.2 [50] provides explicit guidance on the minimum overlap length for FRP-confined columns. Recent experimental work, such as that of Moretti et al. [51], has suggested an overlap length of approximately 0.8 D. In contrast, CSA S806:12 [52] prescribes a minimum overlap length of 100 mm. To prevent premature CFRP debonding during testing, the overlap length in this study was conservatively set to 1.0D. This choice not only exceeds the requirement of CSA S806:12 [52] but also provides a margin above the value recommended in the literature.

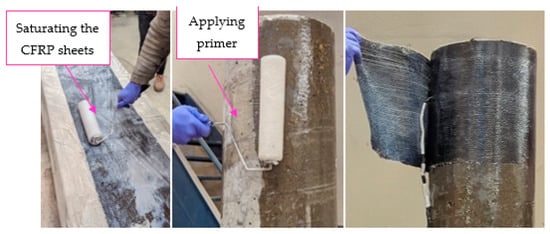

The upper 600 mm portion of the RC-CC column was also wrapped with two CFRP layers as secondary confinement, as elaborated in Section 3.4.1. As a result, a consistent confinement pressure of 4.05 MPa was maintained over the full height of the RC-CC column. The installation process of the CFRP jacket is presented in Figure 11.

Figure 11.

Installation procedure of the CFRP sheets.

3.4.3. Strengthening of the RC-CSW and RC-CSB Columns

The RC-CSW column features laterally oriented Fe-SMA plates designed to deliver active confinement once thermally activated. These plates are fabricated by cutting and bending them to shape, as shown in Figure 12a, then tightly secured to the column using hose clamps to eliminate any air gaps and ensure full contact with the surface (Figure 12b). The lateral Fe-SMA confinement is applied only to the lower 600 mm of the column, thereby targeting its critical . The plates are overlapped and MIG-welded along a length equal to twice their width (2), which corresponds to 240 mm, as shown in Figure 12b. Given that the ultimate strength of the Fe-SMA plate is 176 kN (see Table 1), the weld configuration was designed using Equation (11). The two longitudinal welds, each 240 mm long, provided a total weld strength of 110 kN. Therefore, a transverse weld was added to the Fe-SMA to increase the weld resistance beyond 176 kN.

Figure 12.

Steps for using the welded-and-bolted Fe-SMA plates around the RC columns. (a) Pre-installation procedure of the confining Fe-SMA plates (welded or bolted); (b) installation of the welded Fe-SMA confining plates; (c) installation layout of the bolted Fe-SMA confining plates.

Notably, although the welding temperature exceeded the of the Fe-SMA material, the welding was performed locally at the overlap region of the Fe-SMA confining plates. The welds were applied as tack welds rather than continuously, since continuous welding could lead to localized melting or degradation of the Fe-SMA. Consequently, the heat effect propagated only a few millimetres into the plate and thereby is not expected to alter the overall microstructure of the Fe-SMA from martensitic to austenitic. Furthermore, recent studies [53,54] have demonstrated that welding Fe-SMA to structural steel is feasible and does not induce significant microstructural changes, confirming the suitability of this technique for prestressed applications. However, Hong et al. [54] emphasized that post-weld heat treatment is essential to restore the original mechanical properties of the welded Fe-SMA.

The RC-CSB column is also confined along its lower 600 mm using Fe-SMA plates that are mechanically anchored to the concrete core with bolts. Each plate is secured using four wedge anchors embedded 90 mm into the column, following the layout illustrated in Figure 5. To prevent prestress losses—which may result from anchor loosening caused by cracking near the connection points—the overlapping region of the plates, measuring 240 mm, is also welded, as shown in Figure 12b.

3.4.4. Confinement Pressure Delivered by the Fe-SMA Confining Plates

The confining Fe-SMA plates used in the RC-CSW and RC-CSB columns are also spaced to achieve a target confinement pressure of 4.05 MPa, similar to the one achieved by the CFRP jacket in the RC-CC column. To calculate the equivalent confinement pressure for the Fe-SMA plates, Equations (12)–(15) are employed, leading to a clear spacing of 30 mm between adjacent Fe-SMA plates, as illustrated in Figure 12.

These equations were originally proposed by Mander et al. [55] for estimating the confinement pressure provided by internal transverse reinforcement in RC columns. Due to the comparable stress–strain responses and yielding characteristics between steel and Fe-SMA materials [9], several studies [3,7] have employed these equations to approximate the confinement pressure generated by SMA or other ductile jacket systems.

To prevent dislocation and interference of the Fe-SMA plates with the base of the column, a 50 mm gap is maintained between the lowest Fe-SMA plate and the footing. This gap also mirrors the detailing typically used in CFRP-confined column systems, as described earlier in Section 3.4.2.

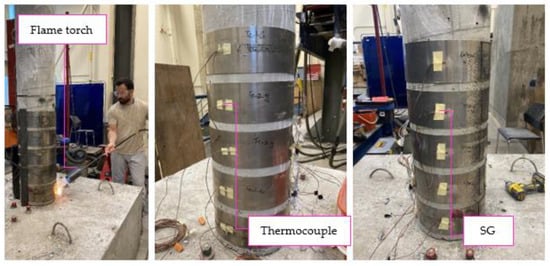

3.4.5. Activation of the Confining Fe-SMA Plates

As illustrated in Figure 13, the confining Fe-SMA plates in the RC-CSW and RC-CSB columns were thermally activated using a flame torch to induce an active confinement around the columns. To monitor the temperature during activation, a thermocouple was attached to each plate. Additionally, strain gauges were installed on every Fe-SMA plate to track strain development during heating, as any measured strain may indicate potential prestress losses [56,57]. The peak temperatures reached by each plate in both columns during activation are summarized in Table 3. Notably, the plate numbering starts at the bottom of the column, with plate #1 being the one closest to the RC foundation.

Figure 13.

Heat activation and instrumentation of the confining Fe-SMA plates.

Table 3.

Maximum temperature and estimated effective recovery stress reached by each Fe-SMA confining plate.

Although of the Fe-SMA plates is 163 °C [35], as seen in Table 3, the plates were intentionally heated to higher temperatures to counteract the rapid cooling that occurs once the flame torch is removed. This method ensured that the temperature of the Fe-SMA confining plates remained above 163 °C for several minutes, providing sufficient time for the full martensite-to-austenite transformation. Moreover, research by Shahverdi et al. [9] demonstrated that exposing Fe-SMA to higher activation temperatures can increase recovery stresses, thereby improving its overall prestressing capability. Notably, there is no strict heating protocol that must be followed to trigger the austenitic transformation in Fe-SMA plates. The critical requirement is to ensure that the plates reach a temperature at or slightly above and are maintained at that level for several minutes. This assures that the Fe-SMA plates have fully transformed into the austenitic phase. However, a heating approach and heat monitoring are recommended over flame torches and thermocouples, as explained in Section 8.

According to Table 3, the Fe-SMA plates reached an average peak temperature of 420.27 °C. On average, the plates remained above the austenitic finish temperature ( = 163 °C) for approximately 10.23 min. Sustaining these elevated temperatures for this duration ensures a full crystallographic transformation from martensite to austenite, effectively triggering the SME of the Fe-SMA plates.

The recovery stress of the Fe-SMA plates was estimated to be approximately 450 MPa, based on the relationship between activation temperature and recovery stress established by Shahverdi et al. [9]. To assess any prestress losses in the Fe-SMA plates, the strain data recorded during thermal activation were carefully analyzed. Using the observed strain patterns from the SGs along with the analytical approach developed by Al Ekkawi and El-Hacha [13,40]—which reliably calculates the recovery stress in the Fe-SMA plates from measured strain—the analysis revealed that the confining Fe-SMA plates developed an average effective recovery stress () of 398.94 MPa. The specific values for each plate are provided in Table 3. Importantly, these results are consistent with those reported in previous research [9,58], confirming both the effectiveness of the Fe-SMA plates’ prestressing response and the reliability of the strain-based calculation method employed in this study.

3.5. Test Setup and Loading Regime

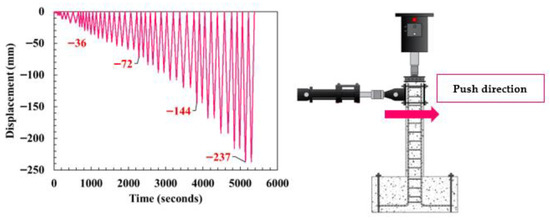

All columns were subjected to a quasi-static lateral cyclic push-only loading, applied at their tops using a 250 kN displacement-controlled hydraulic actuator. The effective height of the columns—measured from the base to the centre of the actuator—was 1425 mm. The test began with a displacement amplitude of 2 mm, applied at a constant loading rate of 0.25 mm/s. The displacement was then incremented by 6 mm per step, with the same loading rate maintained up to 18 mm. Beyond this point, the displacement increment remained at 6 mm, but the loading rate was increased to 0.75 mm/s, continuing until a displacement of 60 mm was reached. From 60 mm to 120 mm, the displacement increment was increased to 12 mm, with the loading rate raised to 1.25 mm/s. For displacements between 120 mm and 215 mm, the increment and rate were further increased to 24 mm and 2 mm/s, respectively. Notably, two full loading cycles were applied at each target displacement level throughout these stages.

Finally, once the maximum stroke capacity of the actuator (237 mm) was reached, the columns were subjected to repeated cycling at elevated rates of 3 mm/s and 6 mm/s until failure occurred. The loading regime is demonstrated in Figure 14.

Figure 14.

Test setup and loading regime applied to the tested columns.

A constant axial load, equivalent to 5% of the columns’ gross concrete compressive strength, is applied at the top of each column to simulate the effect of dead loads. The 5% intensity was specifically selected to align with the CSA A23.3-19 [59] guidelines for RC columns dominated by flexural behaviour. Notably, a stiff steel roller system is added between the vertical actuator and the columns to allow their smooth lateral displacement without considerable friction. The test setup is shown in Figure 14.

The rationale for applying push-pull lateral cyclic loading to the as-built control column was to capture its full seismic response and enable direct comparison with results from other strengthened columns in a companion study by Al Ekkawi and El-Hacha [13,40]. In contrast, for the strengthened columns in the present study, a push-only lateral cyclic loading protocol was necessary due to the actuator’s stroke limitation of 237 mm. To investigate the performance of the jacketing systems under extreme drift demands, it was essential to utilize the full stroke length, which could be achieved only under push-only loading.

It is important to note that this difference in loading protocol does not compromise the validity of the results. The as-built column was inherently deficient, exhibiting severe cracking and loss of ductility at low drift levels. Thus, whether tested under push–pull or push-only cycles, the control specimen would reach failure at essentially the same drift and ductility levels. Therefore, while the loading histories differ slightly, all columns were subjected to a lateral cyclic loading, and the comparison of their seismic performance remains both valid and meaningful.

4. Results and Discussion

4.1. Hysteretic Response

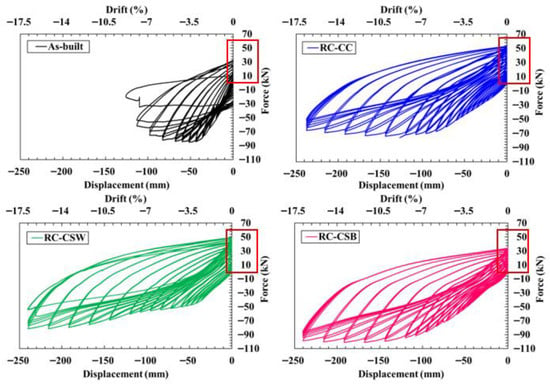

The hysteretic responses of the four tested columns are illustrated in Figure 15. The as-built column, which lacked any form of confinement, demonstrated a limited lateral load capacity accompanied by a steep post-peak strength degradation. After reaching its nominal lateral capacity at approximately 3.65% drift, the column experienced a rapid and significant degradation in strength. Noteworthy, this column was subjected to a lower drift range, between +8.84% and –8.84%, yet it still failed prematurely at a substantially lower drift level than the confined columns. Furthermore, the narrow hysteresis loops observed reflect the column’s limited energy dissipation capacity and brittle behaviour. This poor seismic performance is primarily attributed to the crushing of the concrete core and the severe buckling of the longitudinal reinforcement, both consequences of inadequate confinement in the plastic hinge region.

Figure 15.

Hysteretic response of the tested columns.

In contrast, all confined columns demonstrated significant enhancements in lateral strength, ductility, and deformation capacity. Their hysteresis loops were noticeably wider and more stable, indicating their superior energy dissipation and a more ductile seismic response. These improvements can be attributed to the effectiveness of the confinement systems, specifically the passive confinement provided by the two-layer CFRP jacket and the active confinement delivered by the welded and bolted Fe-SMA plates. Each confinement approach successfully mitigated brittle shear failure and enabled the column to withstand much higher drift levels—substantially exceeding those of the unconfined as-built column. This improved performance is primarily due to the ability of the CFRP and Fe-SMA jackets to delay damage initiation, limit crack propagation, and prevent concrete cover spalling by providing effective lateral confinement in the critical plastic hinge region.

It is worth noting that all confined columns exhibited noticeable residual displacements, as highlighted by the red boxes in Figure 15. This behaviour is attributed to the prior testing history of the specimens. Each column had been previously subjected to a limited drift range of 8.84%, as described in Section 7, which resulted in the yielding of their longitudinal reinforcement. Despite this prior loading, all columns remained structurally intact along their full height, exhibiting no visible damage. Therefore, this preserved condition enabled the authors to conduct a subsequent experimental investigation, which is the focus of the current study. However, it is evident that the as-built column exhibits significant residual deformation despite being subjected to a comparatively lower drift demand. This clearly reflects the severe cumulative damage sustained by the column, leading to its premature loss of structural integrity at low drift levels.

4.2. Restoration of Lateral Strength

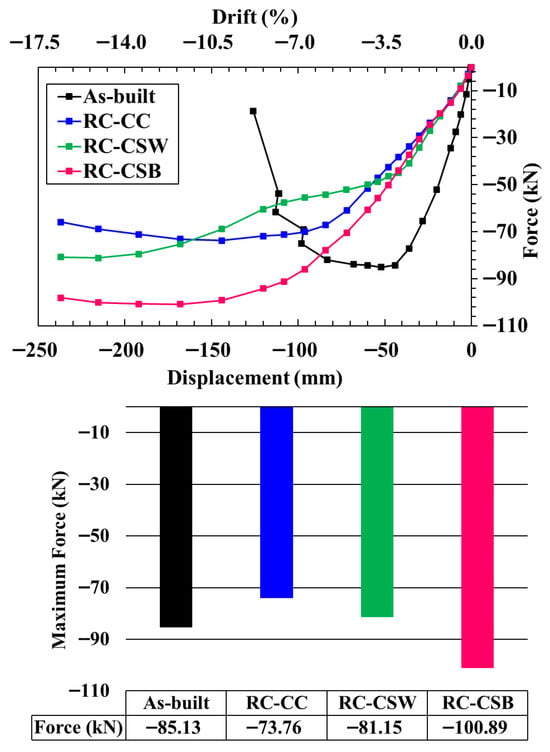

The increase in the columns’ lateral strength with increasing drift levels is shown in Figure 16. The as-built column achieved a lateral strength of −85.13 kN. In addition, the column experienced a rapid and severe post-peak strength degradation immediately after reaching its nominal capacity at a drift of 3.65%. This abrupt decline in strength is attributed to the accumulation of significant structural damage, including concrete crushing and reinforcement buckling, within its plastic hinge region.

Figure 16.

Increase in the columns’ lateral strength with the increase in the drift levels.

In contrast, although the confined columns (RC-CC, RC-CSW, and RC-CSB) recorded peak lateral strengths that were marginally lower or higher than those of the as-built column, they displayed superior post-peak behaviour and seismic resilience. Among them, the RC-CSB column demonstrated the highest lateral strength of −100.89 kN (18.51% higher than the as-built column), underscoring the effectiveness of active bolted Fe-SMA plate confinement.

It is important to note that the confined columns had been previously tested over a drift range of ±8.84%, resulting in some initial stiffness loss. This is clearly reflected in Figure 16, where the as-built column exhibits the highest initial stiffness, whereas the confined columns show lower stiffness. Nevertheless, two key observations emerge from the results:

- 1.

- Despite prior testing, the CFRP and Fe-SMA confining jackets successfully restored 86.64% to 118.51% of the columns’ lateral strength, demonstrating their effectiveness in restoring structural capacity.

- 2.

- More importantly, all confined columns witnessed a significantly enhanced post-peak seismic response. This included increased deformation capacity, reduced strength degradation even at extreme drift levels exceeding 16%, and enhanced energy dissipation.

The restoration of lateral strength observed in this study has important implications for seismic resilience. As shown earlier, the as-built column rapidly lost its lateral capacity at low drift levels, underscoring its vulnerability and the implications that seismic detailing can have for the column’s structural integrity during earthquakes. In contrast, all confined columns, despite prior cyclic loading and damage, retained significant lateral strength and demonstrated remarkable resilience during subsequent testing under higher drift demands. Notably, the confined specimens sustained higher lateral forces at extreme drift levels and, in some cases, even exceeded the original strength of the unconfined column.

This highlights the effectiveness of CFRP sheets and Fe-SMA plate confining jackets in preserving the lateral resistance of deficient RC columns. More importantly, confinement provides a form of strength reserve, enabling columns to continue resisting seismic demands even after initial strength degradation. Under mild to moderate earthquakes, confined columns may lose some capacity, but sufficient reserve strength and energy dissipation remain available for subsequent events. This reserve is particularly valuable in the context of aftershocks or multiple seismic events, where maintaining residual strength and integrity is critical.

Furthermore, the confined columns demonstrated that CFRP jackets and Fe-SMA plates can effectively restore and preserve the load-carrying capacity of deficient RC columns. The CFRP jacket provided reliable passive confinement, allowing the columns to recover most of their nominal strength while significantly enhancing ductility. On the other hand, the Fe-SMA plates, especially the bolted configuration, not only restored the lost capacity but also enabled the column to surpass the lateral strength of the as-built column. This superior performance can be attributed to the active confinement provided by the Fe-SMA plates, as well as the enhanced composite interaction between the bolted Fe-SMA plates and the concrete core. In contrast, the welded Fe-SMA plates (RC-CSW) were only surface-mounted and lacked mechanical interlock with the concrete, which limited their confining effectiveness.

The restoration of lateral strength is thus an important key indicator of seismic resilience, as it ensures that retrofitted columns can continue to resist lateral demands during aftershocks or future seismic events. This underscores the high importance of CFRP and Fe-SMA confinement systems in extending the service life of deficient RC columns and ensuring the safety of bridge structures under seismic loading. Specifically, the Fe-SMA confinement system with bolted anchorage is the most effective approach for strengthening and for restorative measures, especially due to its ability to restore and sustain the seismic resilience of RC columns. Thereby, the latter remain serviceable under repeated or extreme seismic demands, making this outcome a central consideration for cost-effective and rapid retrofit strategies.

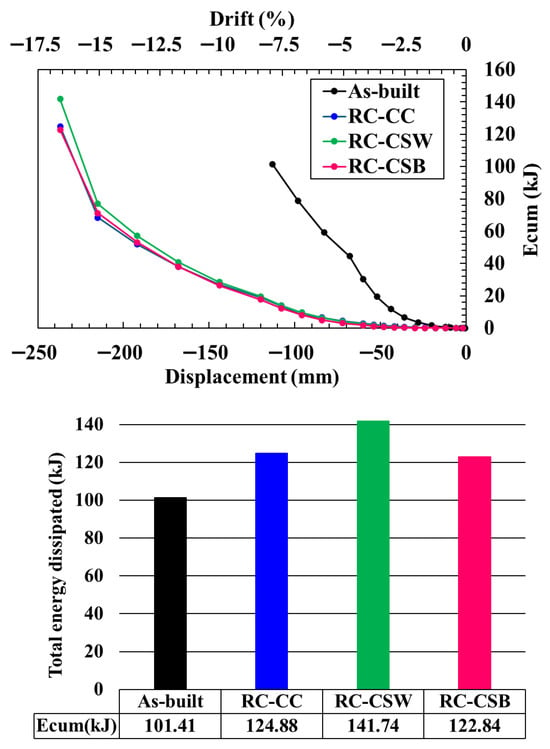

4.3. Energy Dissipation Capacity ()

The ability of the columns to dissipate the applied lateral load in terms of displacement and damage suppression represents the columns’ energy dissipation capacity. The latter is calculated by summing the areas enclosed in each cycle for all cycles before failure [60], thereby named the cumulative dissipated energy (). The curve demonstrating the evolution of the columns’ energy dissipation with increasing drift levels is shown in Figure 17. The total cumulative energy dissipated by each column is also shown in the bar graph of Figure 17. The as-built column initially demonstrated a consistent, strong energy-dissipation trend, particularly after yielding at approximately 2.49% drift. During this phase, energy dissipation increased nearly linearly with rising drift levels. However, this trend was interrupted when the column failed at a drift of 7.93%, capping its cumulative energy dissipation at 101.41 kJ. This early termination is attributed to the severe damage accumulation that occurred following the attainment of its nominal lateral strength at a 3.65% drift. Beyond this point, the column experienced rapid deterioration, including excessive concrete cracking, core crushing, and longitudinal bar buckling.

Figure 17.

Increase in the columns’ energy dissipation with the increase in the drift levels.

In contrast, all confined columns exhibited a steady and sustained increase in cumulative energy dissipation, particularly as drift levels exceeded 7%, at which point the trend began to exhibit an exponential rise. Despite prior testing up to ±8.84% drift, all confined columns maintained robust performance and reached drift levels exceeding 16% without significant loss of capacity. At 16.6% drift, the RC-CC, RC-CSW, and RC-CSB columns achieved total dissipated energies of 124.88 kJ, 141.74 kJ, and 122.84 kJ, representing increases of 23.15%, 39.76%, and 21.13%, respectively, over the as-built column.

These results highlight the effectiveness of the CFRP and Fe-SMA confining jackets in enhancing seismic resilience. The confinement systems successfully mitigated damage accumulation in the columns’ plastic hinge zones, thereby allowing them to sustain larger deformations and dissipate greater amounts of energy under extreme lateral cyclic loading.

Notably, Figure 17 reveals a key distinction in the energy dissipation behaviour between the as-built and the confined columns. To match the maximum value recorded by the as-built column, the confined specimens had to be pushed to drift levels exceeding 14%. In contrast, the as-built column reached the same level of energy dissipation at just 7.93% drift−essentially half the deformation. Furthermore, the initial slope of the curve for the as-built column is noticeably steeper, indicating a higher rate of energy dissipation in the early stages of loading than in the confined columns.

These differences are primarily attributed to the reduced stiffness of the confined columns, as evidenced in Figure 16. Since the confined specimens had already undergone prior testing and yielding, their residual stiffness decreased, thereby leading to lower lateral force resistance and, consequently, reduced energy dissipation per cycle during the early stages of loading. However, the most significant observation lies in the sustained energy dissipation behaviour of the confined columns. Despite their prior testing history and reduced initial stiffness, all confined specimens demonstrated a gradual, consistent increase in up to drift levels exceeding 16%. This trend strongly suggests that the confinement systems−whether CFRP or Fe-SMA plates−successfully mitigated damage progression and preserved the structural integrity of the plastic hinge zones throughout the majority of the test.

Beyond 16% drift, the curves for the confined columns began to rise more steeply. This accelerated increase reflects the onset of more substantial damage, as the columns likely began experiencing higher levels of cracking, crushing, and strain on the reinforcement. Nevertheless, the fact that the confined columns were able to withstand such extreme drift levels while maintaining a steadily increasing energy absorption capacity is a testament to the effectiveness of the applied confinement systems in enhancing the columns’ seismic resilience.

4.4. Displacement Ductility ()

The displacement ductility factor () is a key metric used to evaluate a column’s ability to sustain inelastic deformations without experiencing substantial strength degradation. As previously discussed in Section 7, the confined columns had already undergone an earlier testing phase in which they had yielded. Since is defined as the ratio of ultimate displacement () to yield displacement (), using a new yield displacement derived from the curves in Figure 16 would be misleading. This is because a significant portion of the columns’ stiffness had already been lost during the first round of testing.

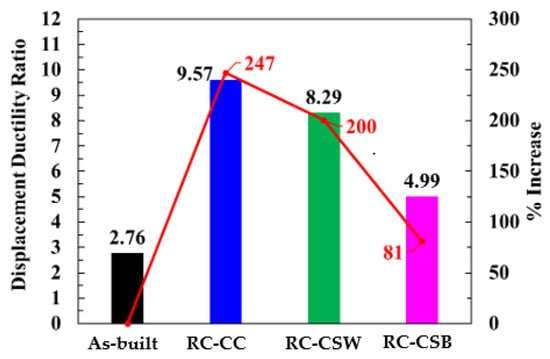

Given this prior damage, it is expected that the confined columns would exhibit a delayed yielding response during the current test presented in this paper, resulting in a higher apparent yield displacement. This occurs because the loss of the columns’ stiffness is delayed, resulting in the columns transitioning from linear to nonlinear behaviour at a larger deformation. As a consequence, calculating ductility using this new, elevated yield point would artificially lower the ductility factor and misleadingly suggest that the confined columns performed similarly to the unconfined as-built column—an interpretation that clearly contradicts the actual behavioural trends observed in Figure 16. The displacement ductility factor () for all tested columns is summarized in Table 4 and visualized in Figure 18.

Table 4.

Displacement ductility factor recorded by the tested columns.

Figure 18.

Displacement ductility ratio of the tested columns.

As anticipated from the hysteretic response in Figure 16, the as-built column exhibited the lowest of 2.76, falling significantly short of the minimum ductility requirement of 4.0 specified by the CSA S6-19 [27] standard for ductile RC columns. This result clearly reflects the limited deformation capacity and brittle behaviour of the as-built column’s plastic hinge region, which suffered extensive damage, leading to rapid post-peak strength degradation.

In contrast, all confined columns showed a substantial increase in , affirming the effectiveness of the applied confinement systems. Specifically, the RC-CC and RC-CSW columns achieved values of 9.57 and 8.29, respectively—well above the CSA threshold—corresponding to increases of 247% and 200% compared to the as-built column. These notable improvements highlight the ability of both the CFRP jacket and the welded Fe-SMA plates to provide robust confinement in the plastic hinge zone. This confinement delayed the onset and propagation of damage, preserved the columns’ concrete integrity, and substantially enhanced their displacement capacity and ductility.

Among the confined specimens, the RC-CSB column recorded the lowest , with a value of 4.99, representing an 81% improvement over the as-built column. Although this increase is modest relative to the other confined columns, it still exceeds the CSA’s minimum requirement. The comparatively lower ductility of the RC-CSB column is attributed to its higher apparent yield drift (3.33%), which is attributed to stress concentrations induced by the anchor bolts securing the bolted Fe-SMA plates during its first testing phase. These localized stress concentrations triggered premature cracking in the concrete core, thereby slowing the development of lateral strength during the early testing cycles. Consequently, the yield point occurred at a higher displacement, thereby increasing the denominator in the calculation and lowering the ductility factor. However, this reduction in should not overshadow the effectiveness of the bolted Fe-SMA plates. As seen in Figure 16, the RC-CSB column demonstrated a lateral strength development trajectory comparable to that of the other confined columns. Once initial cracks formed and stress concentrations were relieved, especially at higher drift levels, the confinement provided by the bolted plates effectively pevented further damage and maintained the structural integrity of the concrete core. This allowed the RC-CSB column to achieve ultimate displacement and strength similar to those of the other columns. Thus, even with the noted initial delay in yielding, the bolted Fe-SMA confinement system still contributed significantly to enhancing the column’s ductility. An 81% improvement in remains a meaningful advancement, particularly considering the residual damage from prior testing.

5. Strain Response and Confinement Engagement of the Jackets

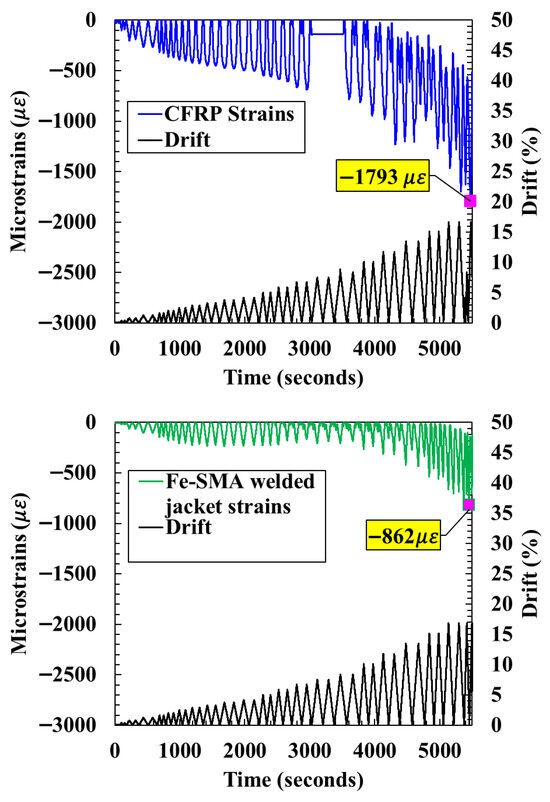

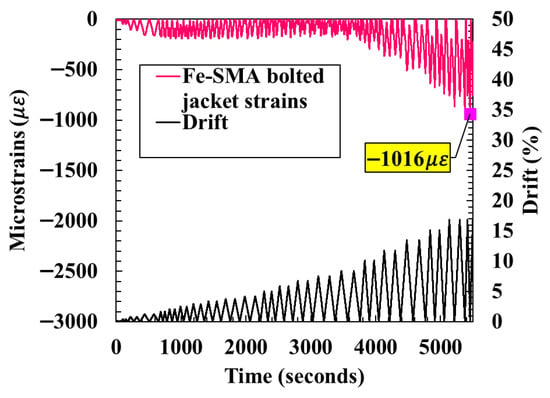

The strain histories recorded from the three confining jackets throughout the entire lateral cyclic test are shown in Figure 19. The SG installed on the CFRP jacket was positioned approximately 50 mm above the foundation level, while the SGs for the Fe-SMA jackets were mounted on the first Fe-SMA plate in each of the actively confined columns.

Figure 19.

Strain histories recorded by the three confining jackets during the lateral cyclic test.

As anticipated, the lateral tensile strains in all jackets increased progressively with the applied drift. The strain growth was most pronounced in the CFRP jacket, which reached a peak tensile strain of −1793 (0.17%) at a maximum drift level of 16.63%. Notably, this value remains substantially below the rupture strain of the CFRP material, reported to be approximately −12,900 (1.29%) as described in Section 3.1.4. This behaviour is typical in laterally loaded RC columns, where lateral deformation leads to localized concrete crushing and slight volumetric dilation in the plastic hinge region at both sides of the column. As a result, this dilation is passively resisted by the confining jacket, particularly in the case of CFRP.

The continuous increase in strain with drift level confirms the effective engagement of the CFRP jacket in providing lateral confinement. Moreover, given that the column was wrapped in accordance with the ductility requirements outlined in CSA S6-19 [27] standard, the absence of CFRP rupture aligns with expectations. As a result, the jacket performed as designed, engaging effectively without exceeding its rupture capacity, thereby ensuring sustained confinement throughout the test.

For both the welded and bolted Fe-SMA confining jackets, a steady increase in lateral tensile strain was observed as the drift level progressed throughout the test, especially after 10% drift. However, the magnitude of strain recorded in these jackets was substantially lower than that observed in the CFRP jacket. At a drift of 16.63%, the welded and bolted Fe-SMA jackets registered maximum tensile strains of −862 (0.0862%) and −1016 (0.101%), respectively. These values are approximately 108% and 76% lower than the peak strain recorded in the CFRP jacket.

The lower strain levels in the Fe-SMA plates are primarily due to the absence of composite interaction between the plates and the concrete surface. Unlike the CFRP jacket—which is fully bonded to the column surface and thus behaves compositely with the underlying concrete during dilation—the Fe-SMA plates are secured externally. As a result, the ability of the Fe-SMA plates to effectively follow the column’s volumetric expansion during damage progression. This limitation is further evidenced by the strain history of both the welded and bolted Fe-SMA plates, which showed minimal strain development and a plateau-like behaviour up to drift levels of approximately 8–10%. During this early phase, despite ongoing damage and concrete dilation, the Fe-SMA plates showed little engagement, confirming their limited mechanical interaction with the column. This unresponsiveness reinforces the conclusion that the absence of a robust bond or composite mechanism reduces confinement efficiency and increases strain in the Fe-SMA plates, especially during the initial stages of the columns’ inelastic deformation. After a 10% drift, the increase in strains became significant and linear, suggesting an increased confining responsiveness of the Fe-SMA plates as the columns experienced higher drift demands and more damage levels.

One might question why previous studies [3,7,38] employing SMA wires reported higher strain values despite the lack of bonding. The answer lies in the fundamental difference in axial stiffness between SMA wires and plates. SMA wires, being much thinner and more flexible, can better respond to the lateral dilation of the concrete core, thereby accumulating more strain under the same confinement conditions. In contrast, SMA plates, with their significantly higher stiffness, offer greater resistance to deformation, which can limit their strain response unless substantial dilation occurs.

Even with that said, the relatively low strain values recorded in the Fe-SMA plates should not be misinterpreted and conclusively judged as a lack of effectiveness. On the contrary, the strain data demonstrate that even with minimal strain engagement, the Fe-SMA jackets made a meaningful contribution to the columns’ seismic performance. Their ability to suppress concrete damage and enhance post-peak behaviour validates their role as efficient confinement devices. Furthermore, considering that the yield strain of the Fe-SMA material is approximately 7000 (0.7%) as noted in Section 3.1.3 (yield stress divided by the austenitic modulus of elasticity; Table 1), the measured strains are well below this threshold, indicating that the Fe-SMA plates remained fully within the elastic range throughout the test. Given this high yield, it is likely that the Fe-SMA plates would remain elastic even with improved composite interaction. As a result, this highlights the unique advantage of Fe-SMA plates: their potential to function as durable, high-performance confining systems that remain elastic and effective under extreme lateral cyclic demands, making them excellent candidates for supplemental energy dissipation and long-term seismic devices.

Notably, “effective confinement” does not refer exclusively to the magnitude of strain recorded in the jackets, but rather to the overall structural performance achieved as a result of jacket engagement. For CFRP, effectiveness is evidenced by the continuous increase in strain with drift level and the absence of rupture, demonstrating that the jacket remained engaged throughout the test and successfully contained the column’s volumetric dilation. For the Fe-SMA plates, effectiveness is established differently: although the recorded strains were relatively low, the plates nevertheless provided sufficient confinement to suppress concrete crushing, delay severe spalling, and improve the post-peak response of the columns. In other words, low strain values in the plates do not imply a lack of confinement but instead reflect their higher axial stiffness.

In addition, it is important to note that higher recorded strains in the Fe-SMA plates would not necessarily translate to improved confinement performance. Once the plates yield (around 7000 ), their ability to provide sustained confinement would diminish. Thus, “effective confinement” in this context is defined not by maximizing jacket strain but by the ability of the confining system to (i) engage under increasing drift demands, (ii) limit damage progression in the plastic hinge region, and (iii) enhance ductility, energy dissipation, and residual capacity. From this perspective, the Fe-SMA jackets were effective despite their low strain levels, and their elastic behaviour further underscores their suitability as durable seismic strengthening devices.

6. Failure Mode and Damage

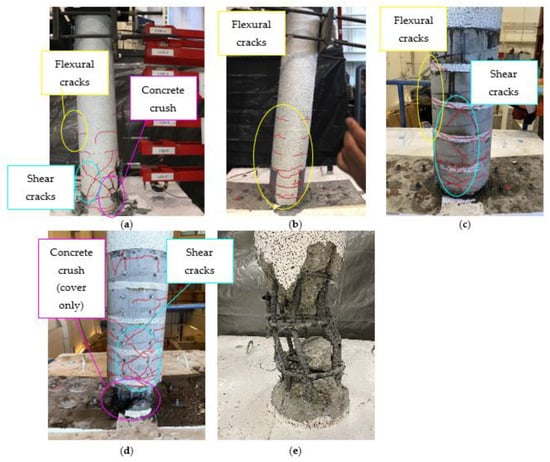

As demonstrated in Figure 20a, the as-built column exhibited a combination of flexural and shear cracks during the lateral cyclic test, clearly indicating a flexural-shear failure mode.

Figure 20.

Columns’ crack pattern and damage level. (a) As-built column; (b) RC-CC; (c) RC-CSW; (d) RC-CSB; (e) As-built column (post failure).

Initial flexural cracks appeared near the column base at approximately 2.53% drift, spaced around 150 mm, and progressively propagated upward as drift levels increased. Subsequently, diagonal shear cracks developed at the mid-height of the plastic hinge zone around 5.82% drift, intensifying and widening with continued loading. Upon completing the test and removing surface debris, Figure 20e shows that severe concrete crushing was observed in the lower third of the column—within the plastic hinge region—where the concrete core was entirely crushed, accompanied by significant buckling of the longitudinal reinforcement. This pattern of damage reflects a complete loss of the column’s structural integrity and confirms the brittle failure in the absence of confinement.

As seen in Figure 20b, the RC-CC column exhibited a well-distributed pattern of horizontal flexural cracks along its height, indicating a predominantly flexural behaviour with no signs of significant shear cracking. The absence of visible concrete crushing or major spalling confirms the effectiveness of the CFRP jacket in confining the column’s critical plastic hinge zone. This effective confinement suppressed the progression of severe damage, resulting in a controlled, ductile flexural response under lateral cyclic loading.

In the case of the RC-CSW column (Figure 20c), a combination of flexural and diagonal shear cracks was observed, suggesting a mixed flexural-shear failure mode. However, compared to the as-built column, the diagonal cracks were less pronounced, narrower, and more widely spaced, while the concrete cover and core remained largely intact. These observations highlight the effectiveness of the welded Fe-SMA plates in providing adequate confinement, thereby delaying and suppressing severe concrete deterioration and improving overall column damage control.

Similarly, Figure 20d shows that the RC-CSB column experienced both flexural and shear cracking. However, concrete crushing was limited to a small zone near the column base (within the lower 50 mm), with no signs of core crushing or significant spalling. This performance confirms the confinement effectiveness of the bolted Fe-SMA plates in preserving the integrity of the plastic hinge region. Although some diagonal cracks were present, they were less severe and less dense than those in the as-built column. It is also evident that the anchor bolt locations served as stress concentration points, where several diagonal cracks initiated and propagated through or around the bolt holes, occasionally linking multiple anchors. Despite localized stress concentrations, the bolted Fe-SMA plates provided robust, continuous confinement, enabling the column to maintain structural integrity under large inelastic deformations and extreme drifts.

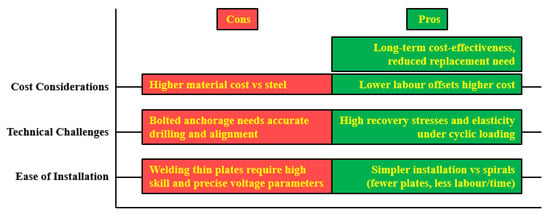

7. Comparative Evaluation of Fe-SMA Plate Jacketing and Conventional Strengthening Methods

To better evaluate the effectiveness of the Fe-SMA plate confinement method, a comparative assessment against other established confinement techniques is necessary. This comparison, summarized in Table 5, considers the key seismic performance indicators of strength, ductility, and energy dissipation capacity. With respect to strength, the Fe-SMA plate confinement system achieved an approximate 19% increase, which is greater than the improvement reported for Fe-SMA spiral winding in other studies. However, this level of enhancement is comparable to that provided by steel jacketing, which was 19% for passive steel jackets and 15% for prestressed steel jacketing. This indicates that Fe-SMA plates and steel jackets can deliver similar gains in lateral strength due to their close material characteristics and similar confinement mechanisms (the absence of adhesion and composite action with the column). In contrast, FRP jacketing methods generally provide more pronounced strength improvements, particularly when combined with prestressing.

Table 5.

Comparative enhancements for different column strengthening methods.

The superior performance of FRP systems lies in their unique confinement mechanism. Unlike steel or Fe-SMA plates, FRP jackets are continuously bonded to the column surface, thus enabling full composite action between the FRP material and the dilating concrete core. This bond ensures that the FRP stretches concurrently with column dilation, thereby mobilizing higher confinement pressures and improving overall efficiency. As a result, even passive FRP jackets are consistently ranked among the most effective confinement methods. When prestressing is introduced, the confinement efficiency is further enhanced, resulting in significant improvements in the column’s seismic performance. This underscores why prestressed FRP jacketing often ranks at the top of confinement strategies when additional column strength is targeted. However, its complex hardware is the main reason for its limited applications in the field of seismic strengthening of RC columns.

In terms of ductility enhancement, Fe-SMA plate confinement and steel jacketing outperform even prestressed FRP systems. This advantage stems from the inherently ductile behaviour and high rupture strain of Fe-SMA and steel, which allow them to remain effective in confining the column under very large drift demands. Consequently, these materials significantly enhance the column’s drift capacity and, in turn, overall ductility. Thus, when the primary objective is maximizing ductility, ductile materials with high rupture strain, such as Fe-SMA and steel, are the most effective choice.

Finally, energy dissipation is one of the most challenging parameters to quantify and compare across studies, as it necessitates the detailed numerical integration of load-displacement hysteresis curves. Nevertheless, both the literature and the present findings confirm that Fe-SMA plate confinement provides a remarkable increase in a column’s energy dissipation capacity. This stems from its ability to enhance the column’s drift capacity, preserve its structural integrity, suppress progressive damage, and maintain its lateral strength at extreme drift levels. As a result, the column exhibits stable inelastic deformations over many cycles, thereby demonstrating its outstanding ability to dissipate the energy levels imposed through displacement. While comparable improvements are occasionally observed with FRP confinement, they are less consistent because FRP’s brittle nature and low rupture strain make it prone to rupture and sudden loss of confinement, which leads to the imminent loss of the column’s structural integrity, as explicitly shown in the study of Al Ekkawi and El-Hacha [13].

8. Research Limitations: Cost Effectiveness and Challenges of Fe-SMA Plate Confinement

8.1. General Research Limitations

Despite the promising outcomes, this study identified several limitations that require adequate attention in future research. One key limitation is that the experimental scope was restricted to a specific set of column conditions. The confined columns were subjected to high drift demands after undergoing an initial phase of cyclic loading, which may have influenced their residual stiffness and strength during retesting. Although this effect was explicitly acknowledged and considered in the analysis, future studies should include tests on undamaged columns to fully isolate these influences when investigating the effectiveness of the active Fe-SMA plate confinement. However, testing pre-damaged specimens, as adopted in this study, accurately captures a more realistic seismic response of strengthened columns with reduced stiffness and ductility. Nevertheless, testing undamaged columns confined with Fe-SMA plates remains an essential first step in this novel line of research. Such experiments would help distinguish between the intrinsic effectiveness of active Fe-SMA plate confinement and the influence of prior damage, thereby strengthening the reliability of comparative assessments.

In addition, there is a need to further develop improved connection mechanisms for Fe-SMA plates to ensure better bond and stress transfer with the concrete substrate, especially to mitigate the stress concentrations observed in bolted configurations.

Furthermore, the as-built column was evaluated under push-pull loading, whereas the strengthened columns were subjected to push-only loading. While this discrepancy is unlikely to reverse the observed trends since the drift capacity of the as-built column is extremely low due to its inherent seismic deficiency, it may have introduced minor differences in the conducted quantitative comparisons.

Instrumentation used in this study presented another limitation. Strain measurements were restricted to localized regions of the jackets, limiting the ability to capture strain development across the entire column height. Future studies should employ more advanced techniques, such as distributed fibre optic sensing or digital image correlation (DIC), to provide a more comprehensive picture of strain distribution, crack propagation, and damage evolution.

Additional constraints were linked to material activation and testing conditions. In this study, the Fe-SMA plates were activated using manual flame-torch heating, a method prone to causing non-uniform temperature distribution on the Fe-SMA plates. More precise methods, such as resistive heating combined with thermal imaging, should be employed to ensure a uniform temperature distribution along the length of the Fe-SMA plates and complete austenitic transformation.