Research on the Flexural Performance of Shield Tunnel Segments Strengthened with Fabric-Reinforced Cementitious Matrix Composite Panels

Abstract

1. Introduction

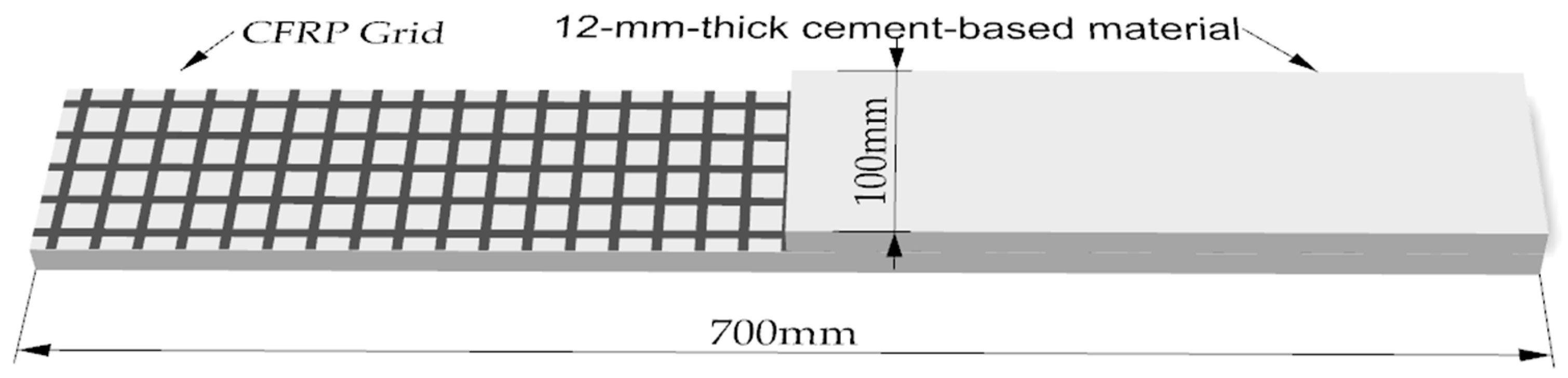

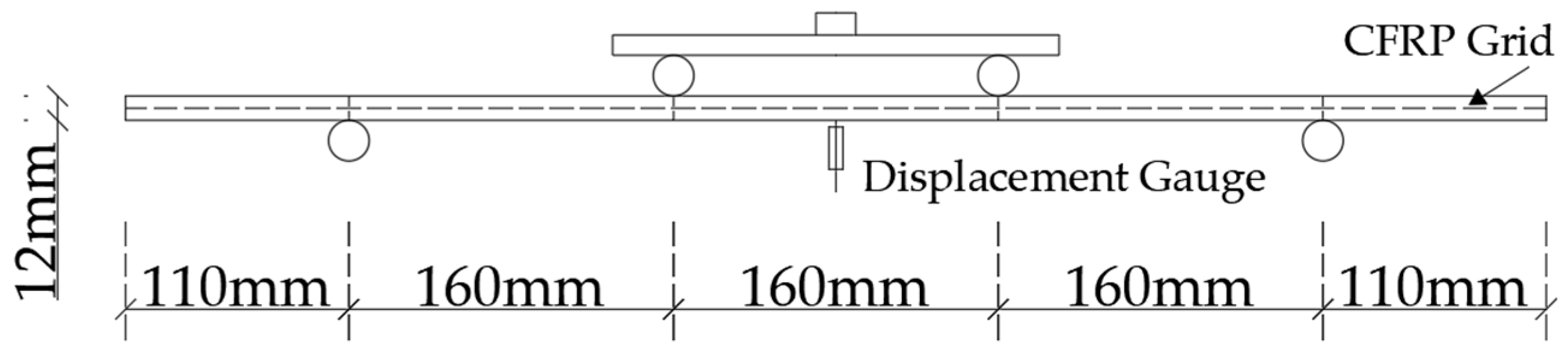

2. Experimental Study on the Flexural Behavior of FRCM Composite Panels

2.1. Specimen Preparation and Material Characterization

2.2. Experimental Apparatus and Loading Configuration

2.3. Analysis of Experimental Results

2.3.1. Failure Mechanisms of Specimens

- Initial Elastic Stage: During this phase, the specimen adheres to Hooke’s law, with the bending stress–strain curve displaying a linear relationship. No surface cracks are observed.

- Post-Crack Strengthening Stage: The first crack initiates at the specimen’s base. As the load increases, additional cracks form within the pure bending zone, accompanied by progressively pronounced bending deformation. An initial fine crack widens and evolves into a dominant crack. Audible fiber fracture or pull-out events within the matrix occur during this phase.

- Post-Peak Softening Stage: After reaching the ultimate load, the dominant crack rapidly propagates through the specimen’s cross-section, culminating in structural failure.

2.3.2. Stress–Strain Curve

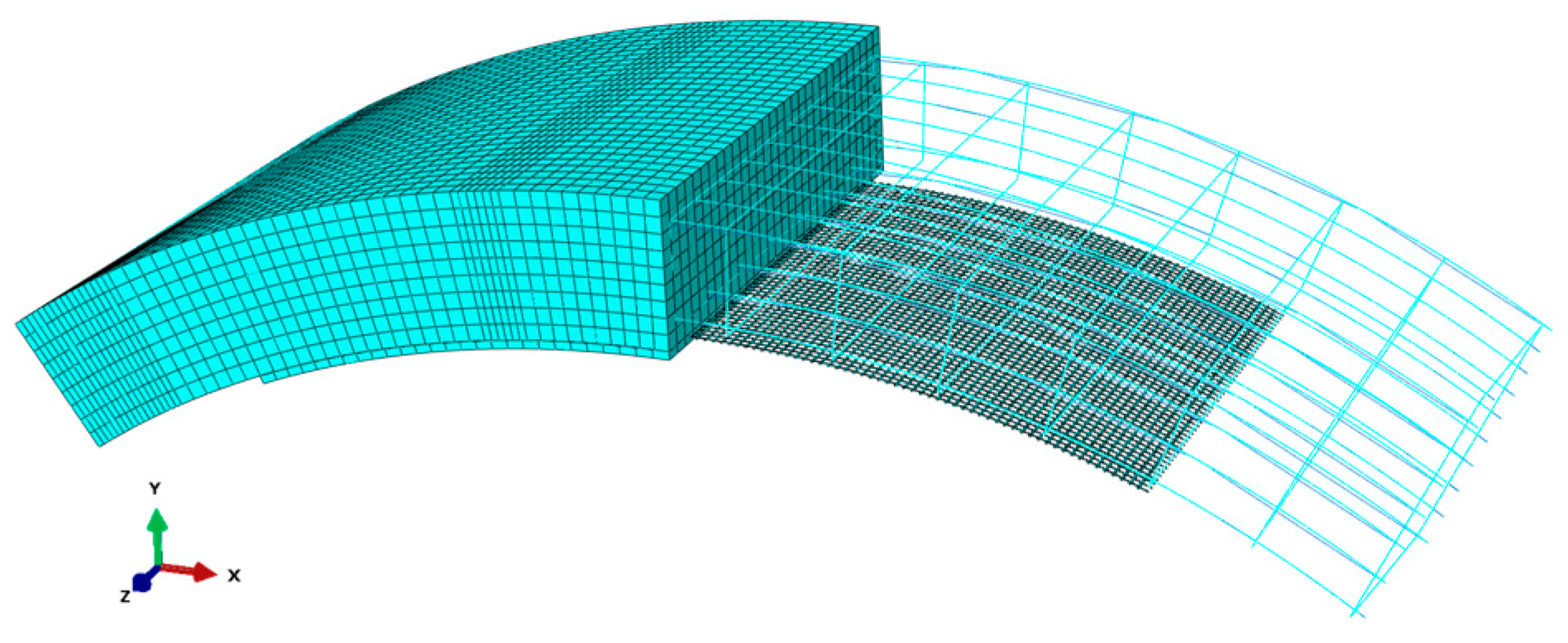

3. Finite Element Modeling and Validation of FRCM-Strengthened Tunnel Segments

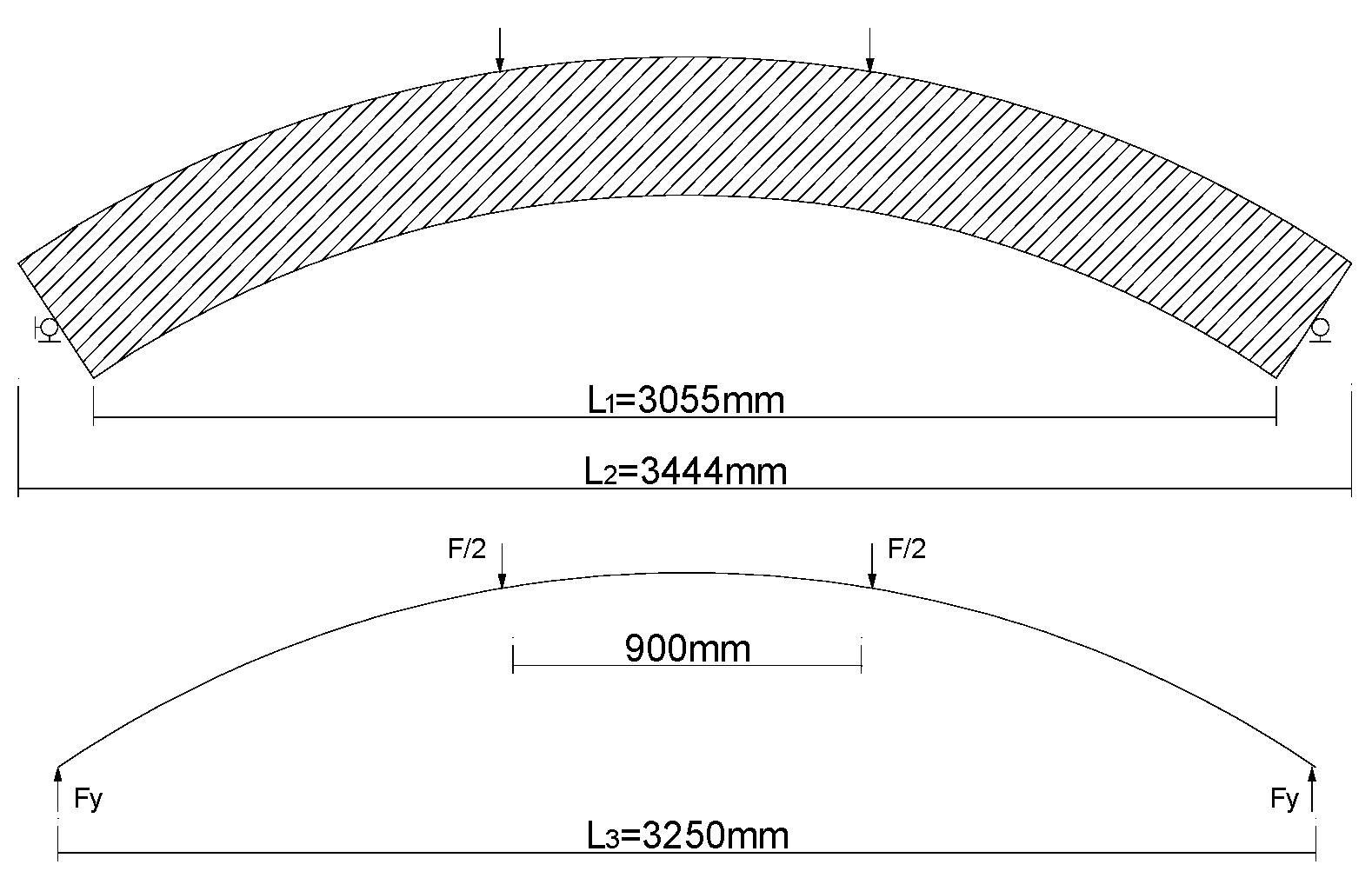

3.1. Model Configuration Overview

3.2. Material Characterization

3.3. Load Application and Boundary Conditions

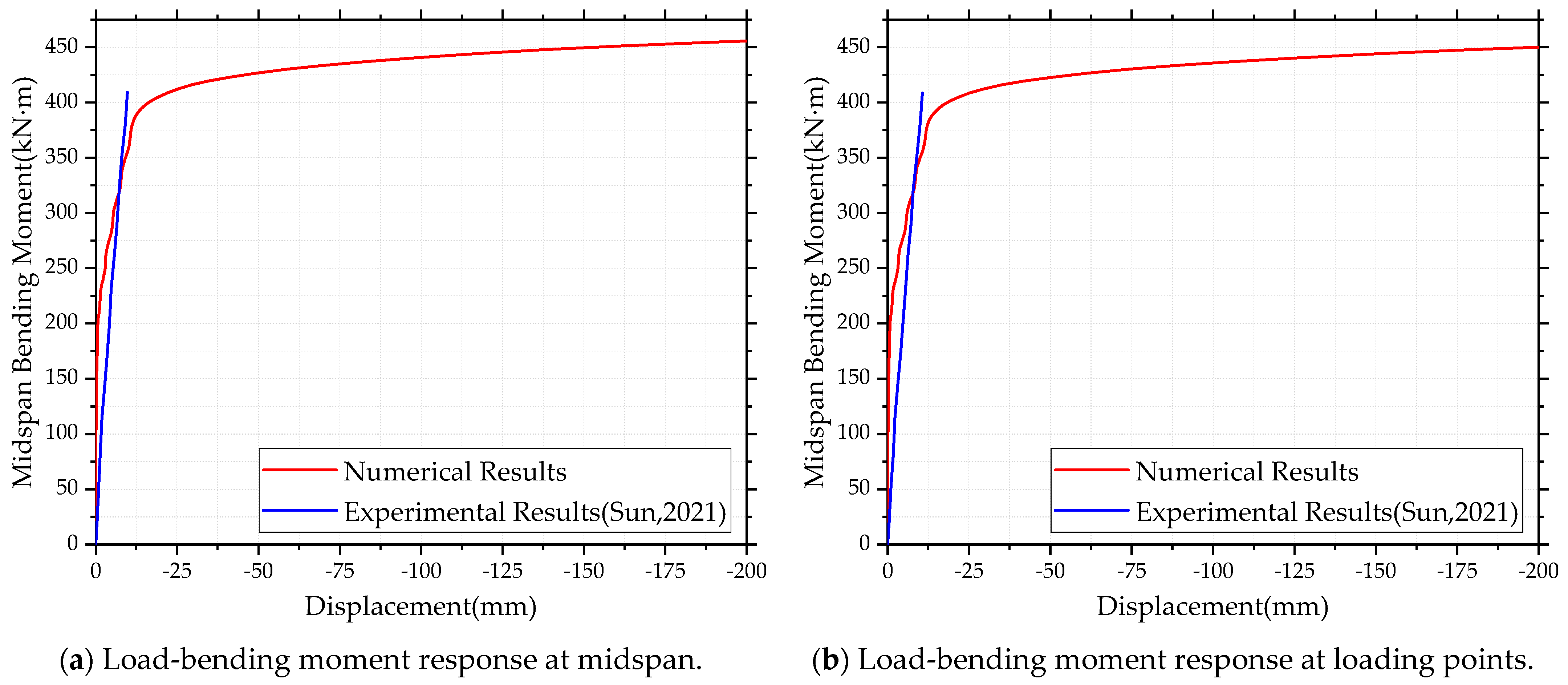

3.4. Model Validation

4. Performance Evaluation of FRCM-Strengthened Tunnel Segments

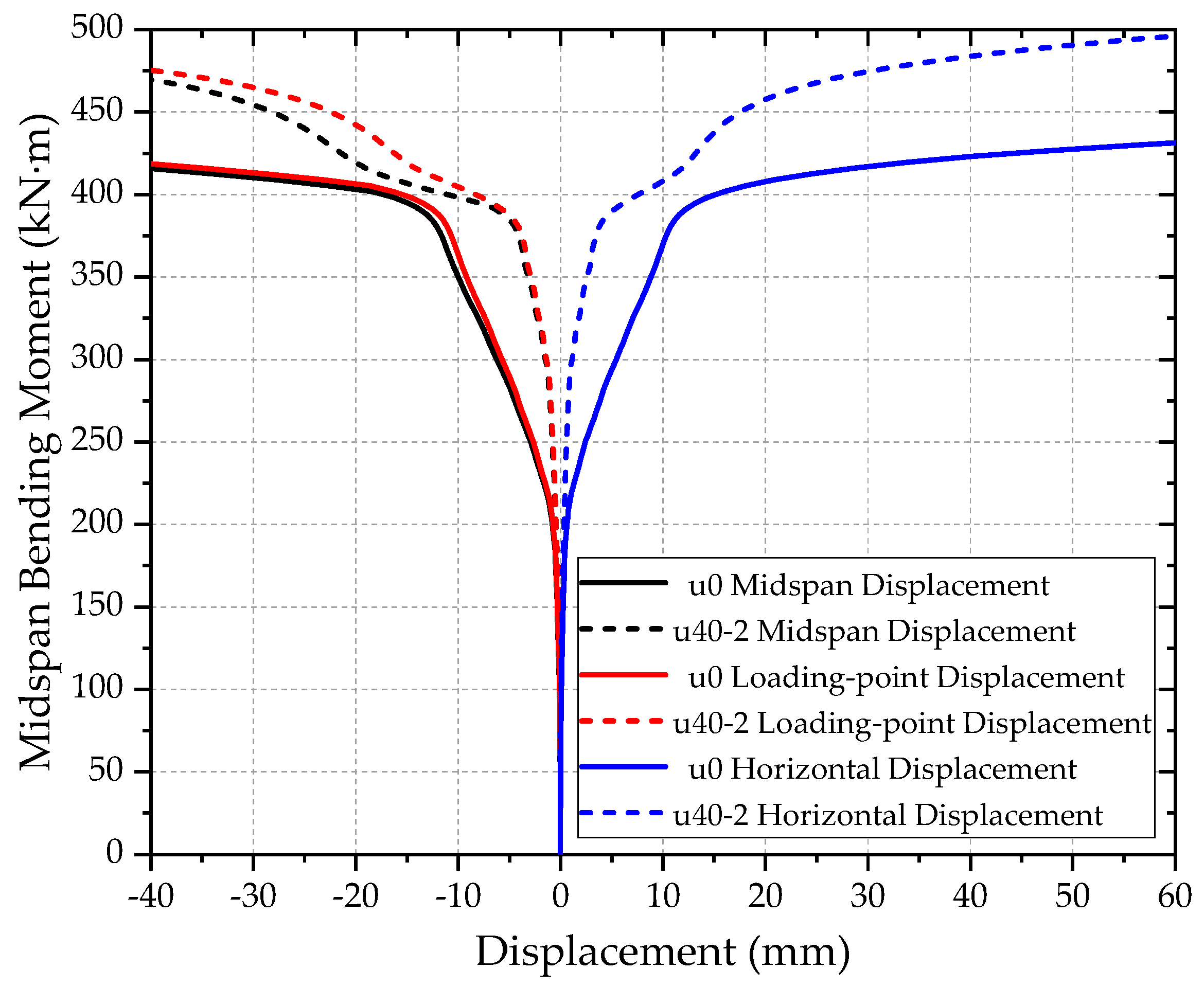

4.1. Deformation Behavior of Strengthened Segments

4.2. Influence of FRCM Strengthening on Reinforcement Stresses

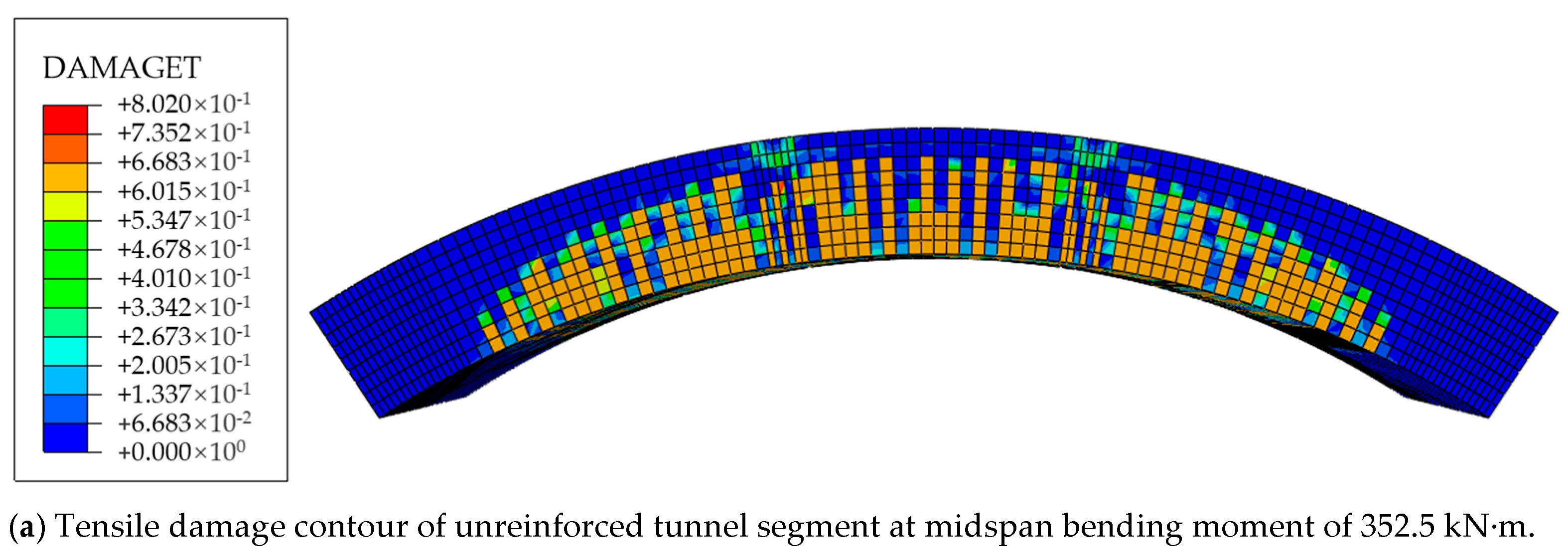

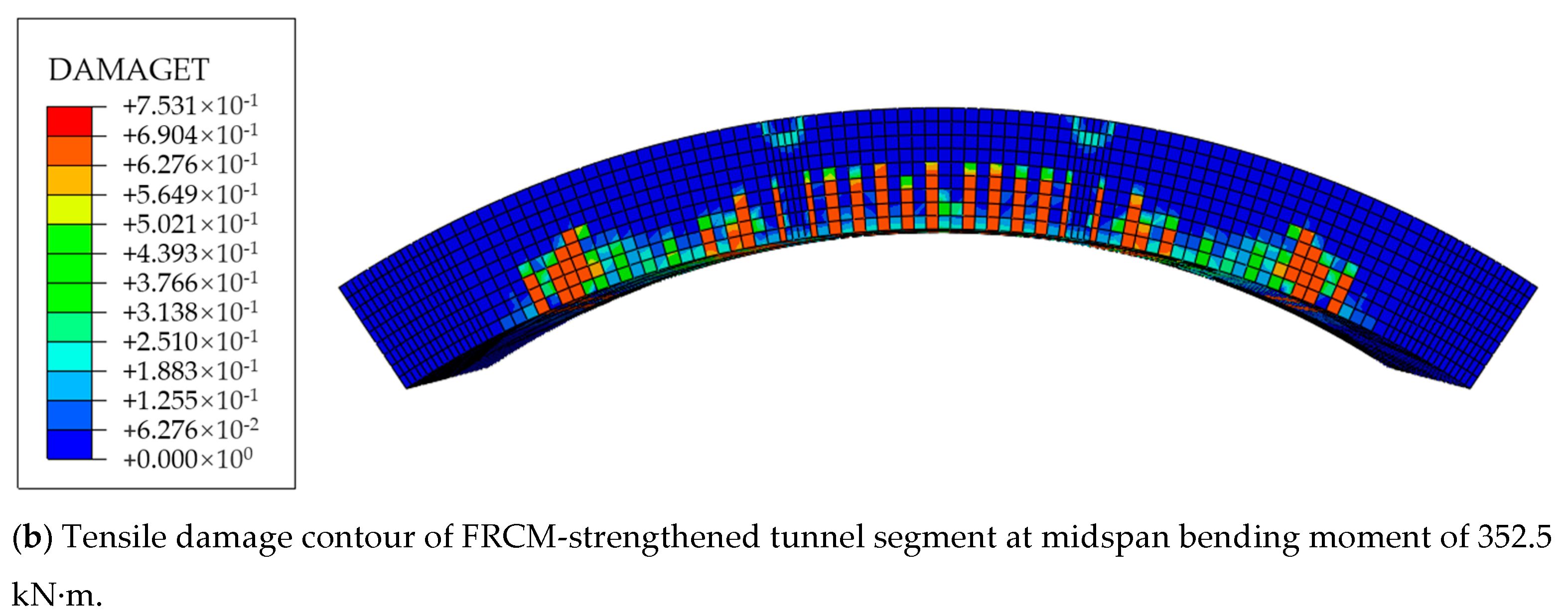

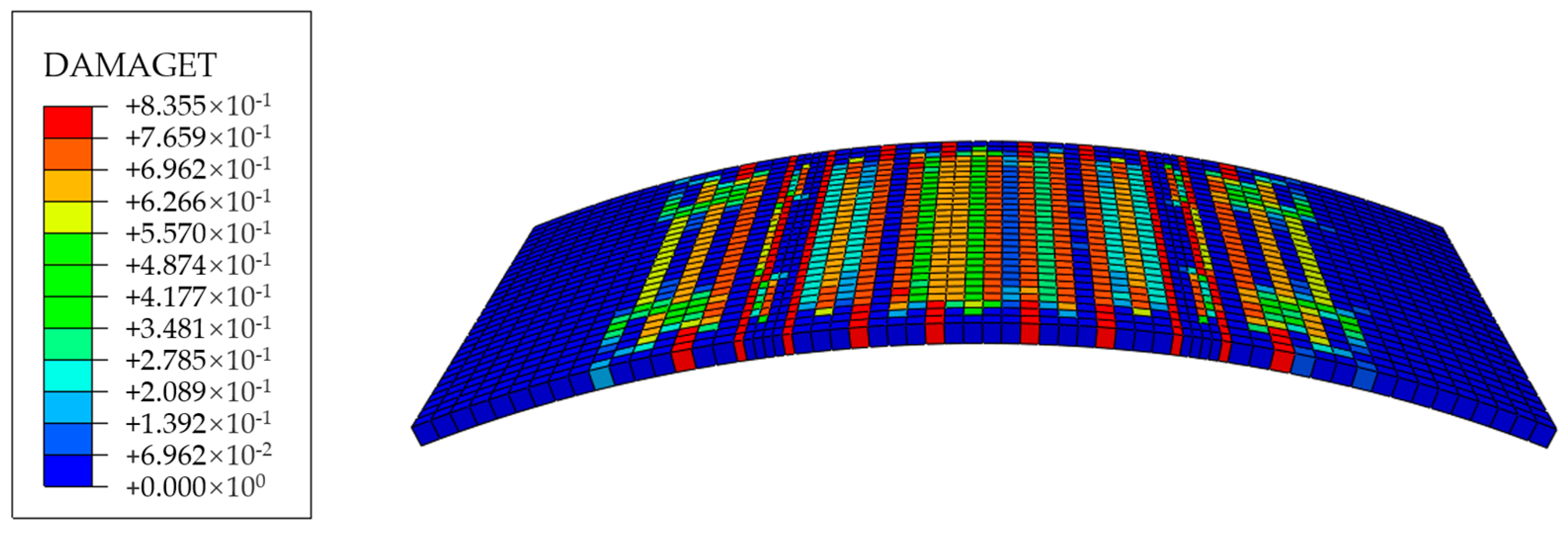

4.3. Influence of Strengthening on Segment Damage

5. Parametric Study on FRCM-Strengthened Segments

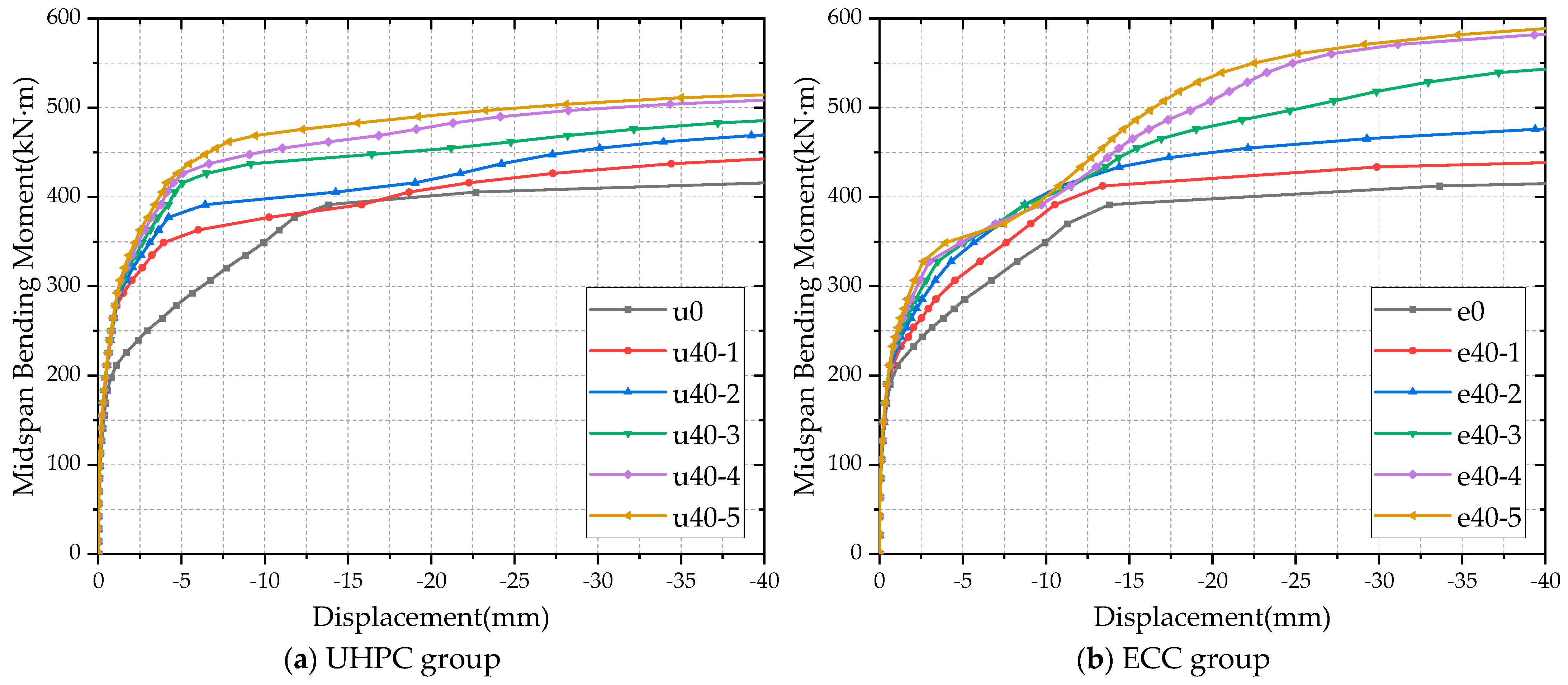

5.1. Influence of CFRP Grid Layers on Strengthening Efficacy

- For low midspan bending moments, the midspan displacement for segments with FRCM composite plates is essentially the same for varying grid layers. Nevertheless, the unreinforced segments’ midspan displacement becomes steeply higher than that when the bending moment reaches 204.4 kN·m. Segments strengthened with UHPC-based FRCM composite plates show no significant displacement increase until the bending moment reaches 296 kN·m, while those with ECC-based materials experience marked displacement growth after 225.6 kN·m. This disparity indicates that UHPC-based FRCM plates provide superior control of early-stage segment deformation compared to ECC-based systems.

- The strengthening effectiveness of FRCM composite plates increases progressively upon the inclusion of additional grid layers. Ultimate bending moment comparisons of test conditions at a midspan displacement of 15 mm between the grid layer-reinforced UHPC group (reinforced with one to five grid layers) and unreinforced segments showed increases in bending moment of 0.92%, 9.16%, 15.59%, 21.11%, and 25.59%, respectively. Also, ECC group specimens having 1–5 grid layers showed increases of 6.43%, 12.85%, 22.21%, 27.54%, and 30.61%, respectively. The analysis of changes in reinforcement efficacy shows a nonlinear relationship: reinforcement efficacy initially rises but diminishes beyond three grid layers, with the most significant improvement occurring between two and three layers.

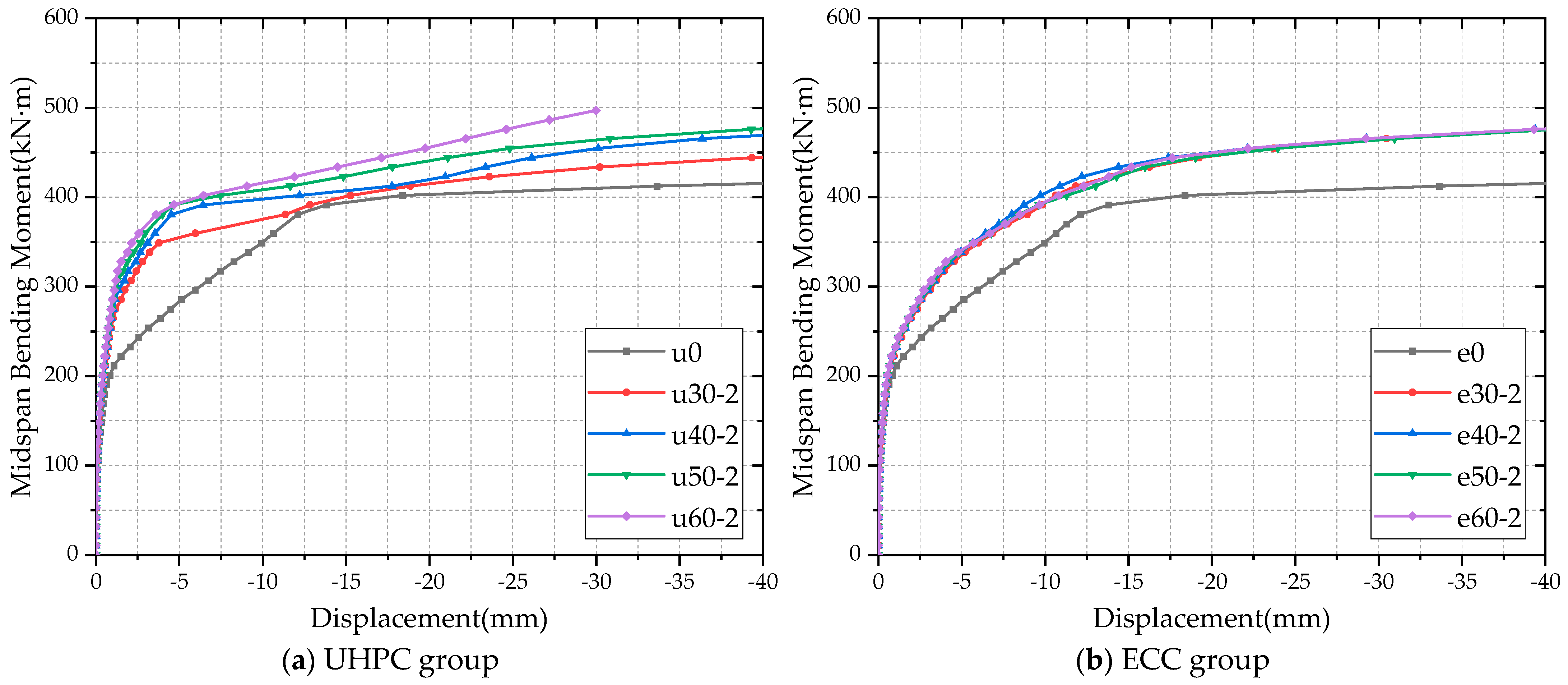

5.2. Influence of Cementitious Matrix Thickness on Reinforcement Effectiveness

- The UHPC group demonstrated a similar trend in reinforcement performance between specimens strengthened with varying cementitious matrix thicknesses and those with different textile grid layers. Specifically, the flexural strengthening efficiency exhibited a progressive improvement with increasing cementitious matrix thickness. Comparisons of the moment capacity at a midspan displacement of 15 mm revealed that FRCM-strengthened specimens with matrix thicknesses of 30 mm, 40 mm, 50 mm, and 60 mm achieved enhancements of 4.58%, 9.16%, 10.10%, and 14.52%, respectively, relative to the unreinforced specimen.

- The midspan displacement–moment curves of the ECC-group strengthened specimens exhibited minimal variation across different cementitious matrix thicknesses, indicating that increasing the matrix thickness without augmenting the textile grid layers provides negligible improvement in strengthening effectiveness when ECC serves as the cementitious matrix in FRCM composites.

5.3. The Influence of Cement-Based Types on Reinforcement Effect

- FRCM composite panels utilizing a UHPC matrix demonstrated superior reinforcement performance at a single textile grid layer configuration. However, when the grid layer count increased, ECC-based FRCM exhibited enhanced strengthening effectiveness compared to its UHPC counterparts. This observation suggests that multi-layered textile configurations disrupt the load-transfer continuity of short fibers within UHPC matrices, while ECC, owing to its inherent ductility and strain-hardening characteristics, maintains synergistic load-sharing compatibility with the textile reinforcement.

- When used as a reinforcement layer for UHPC-based FRCM, cementitious materials offer higher early strength and enhanced reinforcement efficacy under low-load conditions. However, under significant segment deformation, segments reinforced with ECC-based FRCM demonstrate a significantly higher load-bearing capacity compared to those reinforced with UHPC-based FRCM. Therefore, the selection of reinforcement materials should be optimized based on the deformation severity observed in tunnel engineering applications. For scenarios involving minor deformation magnitudes, UHPC-based FRCM systems are recommended, whereas ECC-based FRCM systems demonstrate superior suitability under high-deformation conditions due to their enhanced strain-hardening and multi-cracking capabilities.

6. Conclusions

- FRCM composite plates exhibit excellent flexural performance. The stress response of FRCM specimens during four-point bending tests can be categorized into three distinct stages: Initial Elastic, Post-Crack Strengthening, and Post-Peak Softening. ECC-based FRCM specimens demonstrated a multi-crack failure mode, whereas those with a UHPC matrix exhibited fewer, more concentrated cracks. The cement type exhibited minimal influence on the flexural strength of FRCM specimens.

- FRCM composite plates effectively reduce segment deformation, reduce reinforcement stress on shield segments, inhibit tension crack propagation, and improve the ultimate flexural capacity. These results show the great reinforcement of FRCM composite plates.

- FRCM composite-strengthened segments strengthened by a UHPC cementitious matrix had increasing effectiveness of reinforcement with increasing textile layers and matrix thickness, while the ECC matrix-strengthened segments did so only with increasing textile layers, without significant variation with matrix thickness.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FRP | Fiber-reinforced polymer |

| ECC | Engineered cementitious composite |

| UHPC | Ultra-high performance concrete |

| FRCM | Fabric-Reinforced Cementitious Matrix |

| TRC | Textile-reinforced concrete |

References

- Xu, S.; Ma, E.; Lai, J.; Yang, Y.; Liu, H.; Yang, C.; Hu, Q. Diseases failures characteristics and countermeasures of expressway tunnel of water-rich strata: A case study. Eng. Fail. Anal. 2022, 134, 106056. [Google Scholar] [CrossRef]

- Lou, P.; Huang, W.; Huang, X. Analysis of shield tunnels undercrossing an existing building and tunnel reinforcement measures. Appl. Sci. 2023, 13, 5729. [Google Scholar] [CrossRef]

- Zhai, W.; Chapman, D.; Zhang, D.; Huang, H. Experimental study on the effectiveness of strengthening over-deformed segmental tunnel lining by steel plates. Tunn. Undergr. Space Technol. 2020, 104, 103530. [Google Scholar] [CrossRef]

- Gang, W.; Qin, W.; Tianbao, X.; Tao, X.; Zhiguo, Z. Study on the coupling mechanism and reinforcement effect of a shield tunnel reinforced by channel steel under side pit excavation. Tunn. Undergr. Space Technol. 2024, 153, 106055. [Google Scholar] [CrossRef]

- Wei, G.; Wang, Q.; Zhou, X.; Feng, F.; Wang, X.; Zhang, L.; Liang, L. Experiments and numerical simulation of the reinforcement effect of channel-steel-reinforced shield tunnel segments under unloading conditions. Eur. J. Environ. Civ. Eng. 2023, 27, 4142–4164. [Google Scholar] [CrossRef]

- Liu, D.; Feng, X.; Duan, K.; Zuo, J.; Chen, G.; Li, M.; Chang, Y.; Xia, Z. A novel concrete-filled flange steel tubular composite supports for tunnels: A numerical perspective. Case Stud. Constr. Mater. 2024, 21, e03384. [Google Scholar] [CrossRef]

- Li, W.; Gang, W.; Dong, Z.; Wang, S. Experimental study on a pre-damaged scaled tunnel model strengthened with CFRP grids. J. Southeast Univ. 2017, 33, 196–202. [Google Scholar] [CrossRef]

- Ding, W.; Guo, Y.; Li, S.; Li, X.; Zhang, Q. Experimental research on the mechanical behavior of segmental joints of shield tunnel reinforced with a new stainless steel corrugated plate. Case Stud. Constr. Mater. 2023, 18, e02170. [Google Scholar] [CrossRef]

- Zhou, J.; Lin, W.; Guo, S.; Zeng, J.; Bai, Y. Behavior of FRP-confined FRP spiral reinforced concrete square columns (FCFRCs) under axial compression. J. Build. Eng. 2022, 45, 103452. [Google Scholar] [CrossRef]

- Papanicolaou, C.G.; Triantafillou, T.C.; Papathanasiou, M.; Karlos, K. Textile reinforced mortar (TRM) versus FRP as strengthening material of URM walls: Out-of-plane cyclic loading. Mater. Struct. 2008, 41, 143–157. [Google Scholar] [CrossRef]

- Raoof, S.M.; Koutas, L.N.; Bournas, D.A. Textile-reinforced mortar (TRM) versus fibre-reinforced polymers (FRP) in flexural strengthening of RC beams. Constr. Build. Mater. 2017, 151, 279–291. [Google Scholar] [CrossRef]

- Soranakom, C.; Mobasher, B. Geometrical and mechanical aspects of fabric bonding and pullout in cement composites. Mater. Struct. 2009, 42, 765–777. [Google Scholar] [CrossRef]

- Ahmad, S.; Rasul, M.; Adekunle, S.K.; Al-Dulaijan, S.U.; Maslehuddin, M.; Ali, S.I. Mechanical properties of steel fiber-reinforced UHPC mixtures exposed to elevated temperature: Effects of exposure duration and fiber content. Compos. Pt. B—Eng. 2019, 168, 291–301. [Google Scholar] [CrossRef]

- Lu, C.; Li, V.C.; Leung, C.K. Flaw characterization and correlation with cracking strength in Engineered Cementitious Composites (ECC). Cem. Concr. Res. 2018, 107, 64–74. [Google Scholar] [CrossRef]

- Keskin, S.B.; Keskin, O.K.; Anil, O.; Şahmaran, M.; Alyousif, A.; Lachemi, M.; Amleh, L.; Ashour, A.F. Self-healing capability of large-scale engineered cementitious composites beams. Compos. Pt. B—Eng. 2016, 101, 1–13. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, W.; Brigham, J.C. Flexural behaviour of reinforced concrete beams strengthened with a composite reinforcement layer: BFRP grid and ECC. Constr. Build. Mater. 2016, 115, 424–437. [Google Scholar] [CrossRef]

- Yang, X.; Gao, W.; Dai, J.; Lu, Z.; Yu, K. Flexural strengthening of RC beams with CFRP grid-reinforced ECC matrix. Compos. Struct. 2018, 189, 9–26. [Google Scholar] [CrossRef]

- AL-Gemeel, A.N.; Zhuge, Y. Experimental investigation of textile reinforced engineered cementitious composite (ECC) for square concrete column confinement. Constr. Build. Mater. 2018, 174, 594–602. [Google Scholar] [CrossRef]

- Al-Gemeel, A.N.; Zhuge, Y. Using textile reinforced engineered cementitious composite for concrete columns confinement. Compos. Struct. 2019, 210, 695–706. [Google Scholar] [CrossRef]

- Chen, H.; Jiang, Y.; Chen, D.; Zhang, X.; Yan, P.; Wang, B.; Lin, Q. Strengthening effect of the CFRP method on fire-damaged segments. Tunn. Undergr. Space Technol. 2024, 154, 105871. [Google Scholar] [CrossRef]

- Gao, B.; Chen, R.; Wu, H.; Chen, T.; Zhang, Y. Enhancement mechanism of UHPC secondary lining on the mechanical performance at joints of shield tunnels: Full-scale experiment and simulation. Tunn. Undergr. Space Technol. 2025, 157, 106282. [Google Scholar] [CrossRef]

- Liu, D.; Shang, Q.; Li, M.; Zuo, J.; Gao, Y.; Xu, F. Cracking behaviour of tunnel lining under bias pressure strengthened using FRP Grid-PCM method. Tunn. Undergr. Space Technol. 2022, 123, 104436. [Google Scholar] [CrossRef]

- JC/T 2461-2018; Standard test method for the mechanical properties of ductile fiber reinforced cementitious composites. China Architecture & Building Press: Beijing, China, 2018.

- T/CBMF 37-2018; Basic Properties and Test Methods of Ultra-High Performance Concrete. China Building Materials Federation, China Concrete and Cement Products Association: Beijing, China, 2018.

- GB/T 36262-2018; Fiber Reinforced Polymer Composite Grids for Civil Engineering. China Architecture & Building Press: Beijing, China, 2018.

- GB/T 50152-2012; Standard for Test Method of Concrete Structures. China Architecture & Building Press: Beijing, China, 2012.

- DSS (Dassault Systèmes Simulia Corp). ABAQUS Analysis User’s Manual 6.14-2; DSS: Providence, RI, USA, 2014. [Google Scholar]

- Sun, Q. Mechanical Performance Test and Numerical Simulation of Shield Tunnel Segments Reinforced with Internal Adhesive Steel Plates. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2021. [Google Scholar]

- CJJT164-2011; Standard for Quality Inspection of Shield Tunnel Segment. China Architecture & Building Press: Beijing, China, 2011.

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010.

| Cementitious Matrix Type | Specimen ID | Specimen Quantity |

|---|---|---|

| ECC | FE | 3 |

| UHPC | FU | 3 |

| Cementitious Matrix Type | Admixtures | Water | Water-Reducing Admixtures | Short Reinforcing Fibers |

|---|---|---|---|---|

| ECC | 1 | 0.3 | / | 0.01 |

| UHPC | 1 | 0.086 | 0.01 | 0.06 |

| Material Type | Ultimate Tensile Strength (MPa) | Ultimate Tensile Strain (%) | Compressive Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|

| ECC | 3.41 | 6.28 | 33.6 | 1.75 |

| UHPC | 7.28 | 1.31 | 121.04 | 5.89 |

| CFRP | 1345.44 | 3.50 | / | 588.79 |

| Case No. | Cementitious Matrix Type | Matrix Thickness (mm) | CFRP Grid Layers | Case No. | Cementitious Matrix Type | Matrix Thickness (mm) | CFRP Grid Layers |

|---|---|---|---|---|---|---|---|

| u0/ | / | / | / | e0 | / | / | / |

| u30-2 | UHPC | 30 | 2 | e30-2 | ECC | 30 | 2 |

| u40-1 | 40 | 1 | e40-1 | 40 | 1 | ||

| u40-2 | 40 | 2 | e40-2 | 40 | 2 | ||

| u40-3 | 40 | 3 | e40-3 | 40 | 3 | ||

| u40-4 | 40 | 4 | e40-4 | 40 | 4 | ||

| u40-5 | 40 | 5 | e40-5 | 40 | 5 | ||

| u40-6 | 40 | 6 | e40-6 | 40 | 6 | ||

| u50-2 | 50 | 2 | e50-2 | 50 | 2 | ||

| u60-2 | 60 | 2 | e60-2 | 60 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, C.; Yang, K.; Duan, Y.; Li, J.; Wang, J.; Lu, W. Research on the Flexural Performance of Shield Tunnel Segments Strengthened with Fabric-Reinforced Cementitious Matrix Composite Panels. Buildings 2025, 15, 1355. https://doi.org/10.3390/buildings15081355

Guo C, Yang K, Duan Y, Li J, Wang J, Lu W. Research on the Flexural Performance of Shield Tunnel Segments Strengthened with Fabric-Reinforced Cementitious Matrix Composite Panels. Buildings. 2025; 15(8):1355. https://doi.org/10.3390/buildings15081355

Chicago/Turabian StyleGuo, Caixia, Kaiwen Yang, Yichen Duan, Jiulin Li, Jianlin Wang, and Weidong Lu. 2025. "Research on the Flexural Performance of Shield Tunnel Segments Strengthened with Fabric-Reinforced Cementitious Matrix Composite Panels" Buildings 15, no. 8: 1355. https://doi.org/10.3390/buildings15081355

APA StyleGuo, C., Yang, K., Duan, Y., Li, J., Wang, J., & Lu, W. (2025). Research on the Flexural Performance of Shield Tunnel Segments Strengthened with Fabric-Reinforced Cementitious Matrix Composite Panels. Buildings, 15(8), 1355. https://doi.org/10.3390/buildings15081355