Enhancement of Thermal–Acoustic Properties of Pinus radiata by Impregnation of Bio-Phase-Change Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Delignification of Pinus Radiata

2.3. Preparation of a Capric/Myristic Acid Mixture as PCM

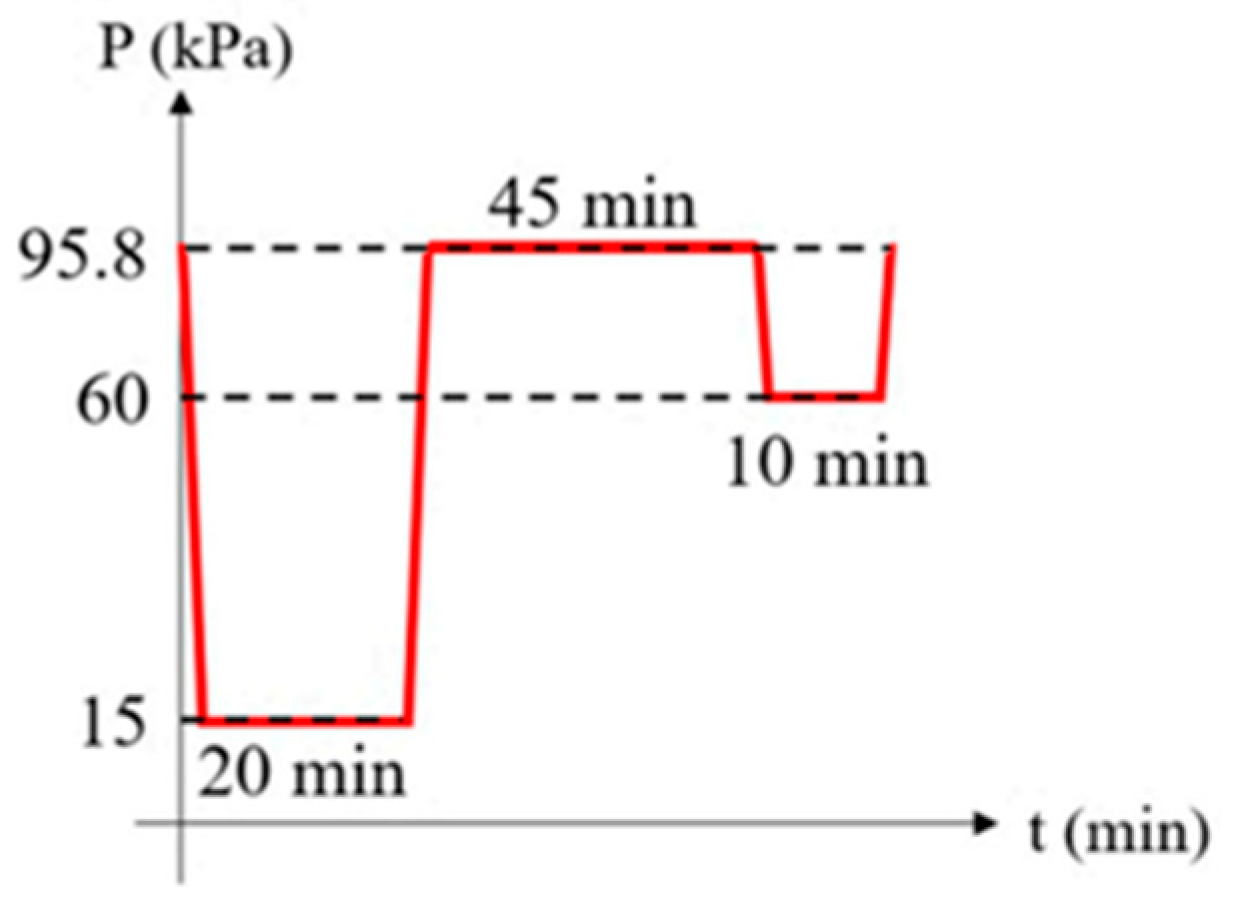

2.4. Impregnation of the Capric/Myristic Acid Mixture as a PCM in Pinus Radiata

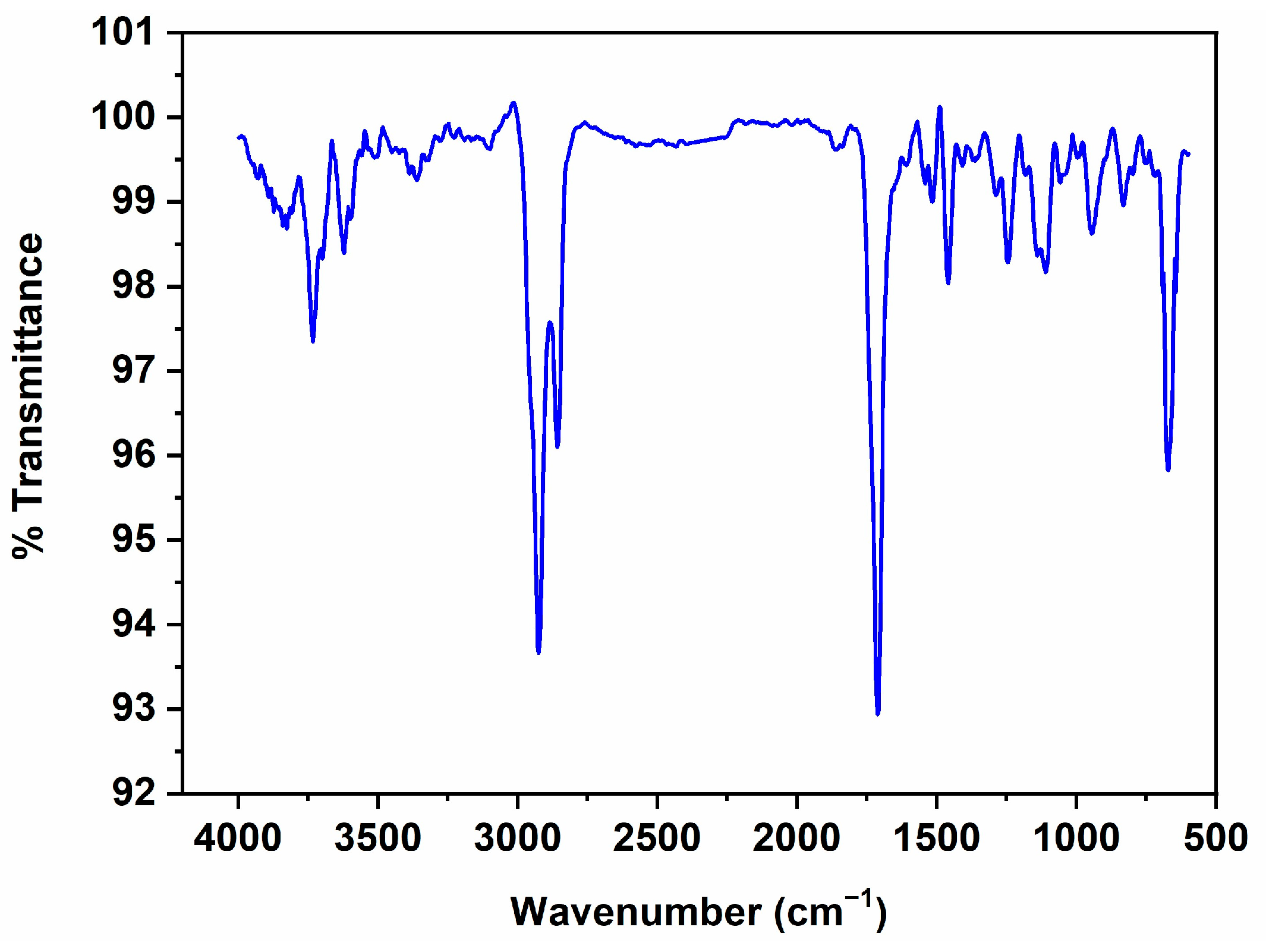

2.5. Attenuated Total Reflection Fourier Transform Infrared Characterization (ATR-FTIR)

2.6. Differential Scanning Calorimetry

2.7. Mechanical Properties: Excitation Vibration Pulse

2.8. Morphological Characterization

2.9. Thermal Analysis

2.10. Acoustic Measurements

3. Results and Discussion

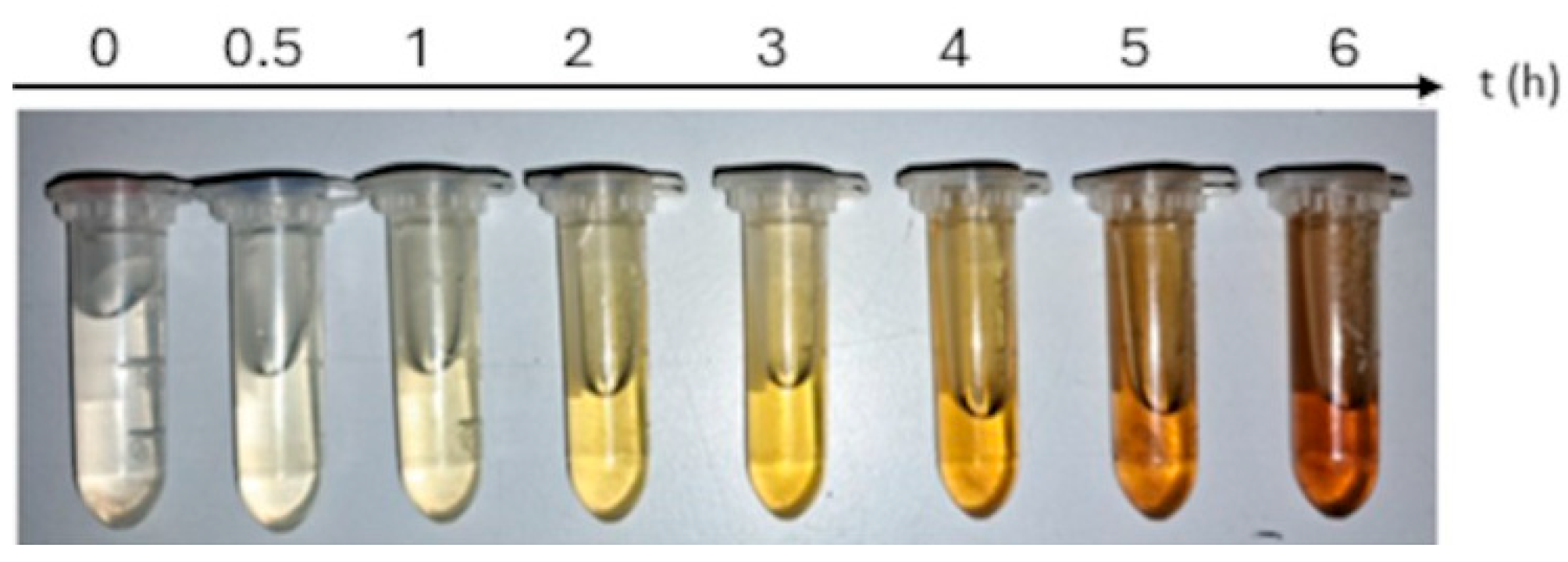

3.1. Thermo-Chemical Analysis of Capric/Myristic Acid Mixtures

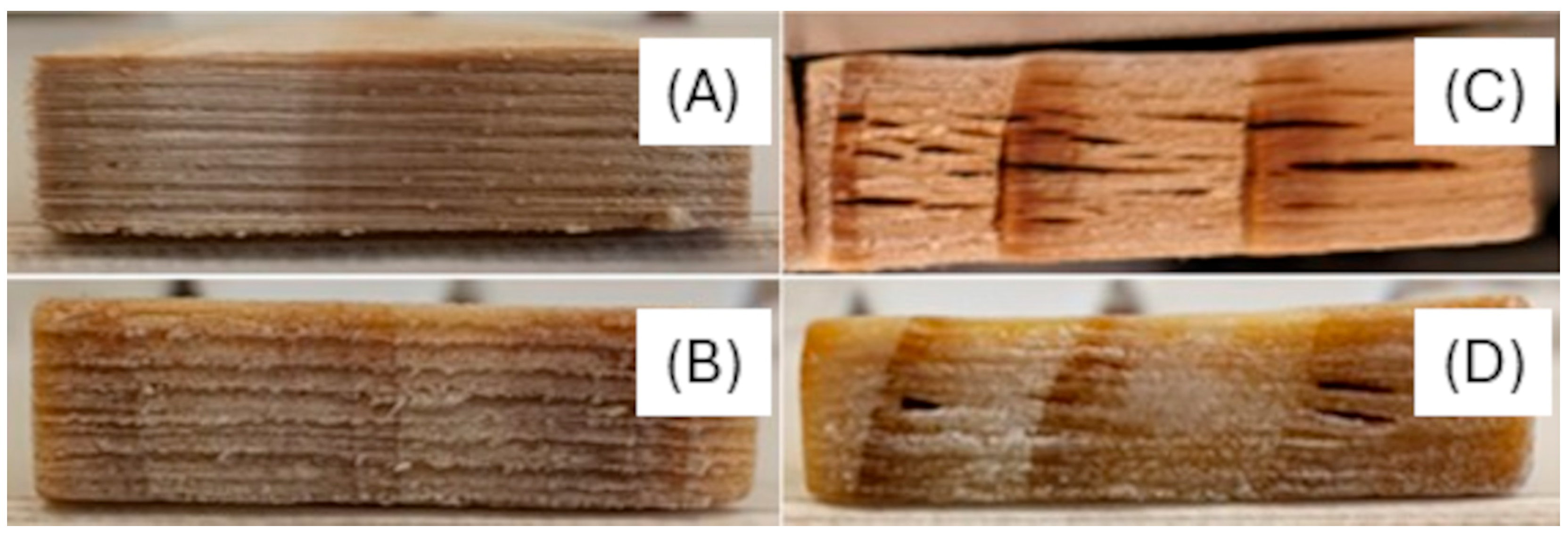

3.2. Delignification and Impregnation of Pinus Radiata Using PCM

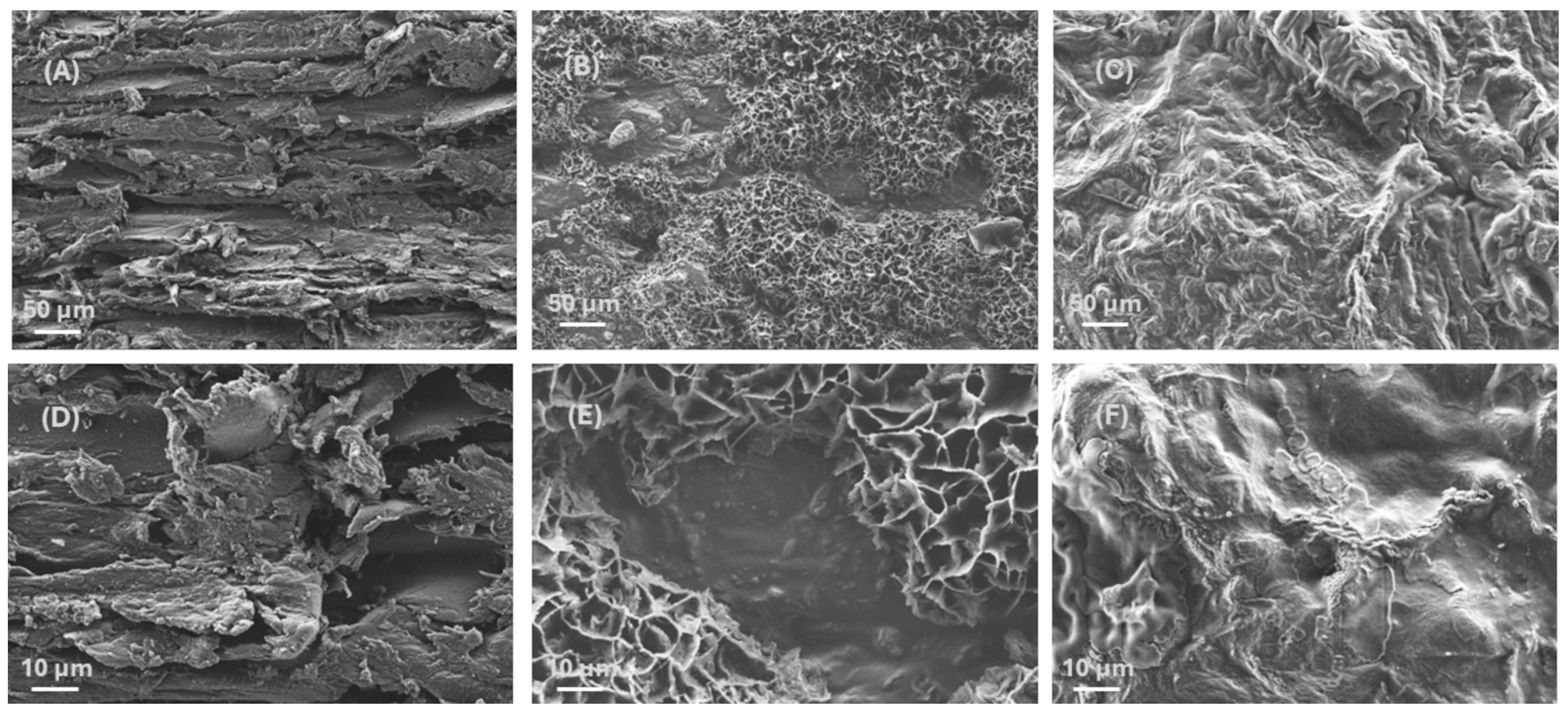

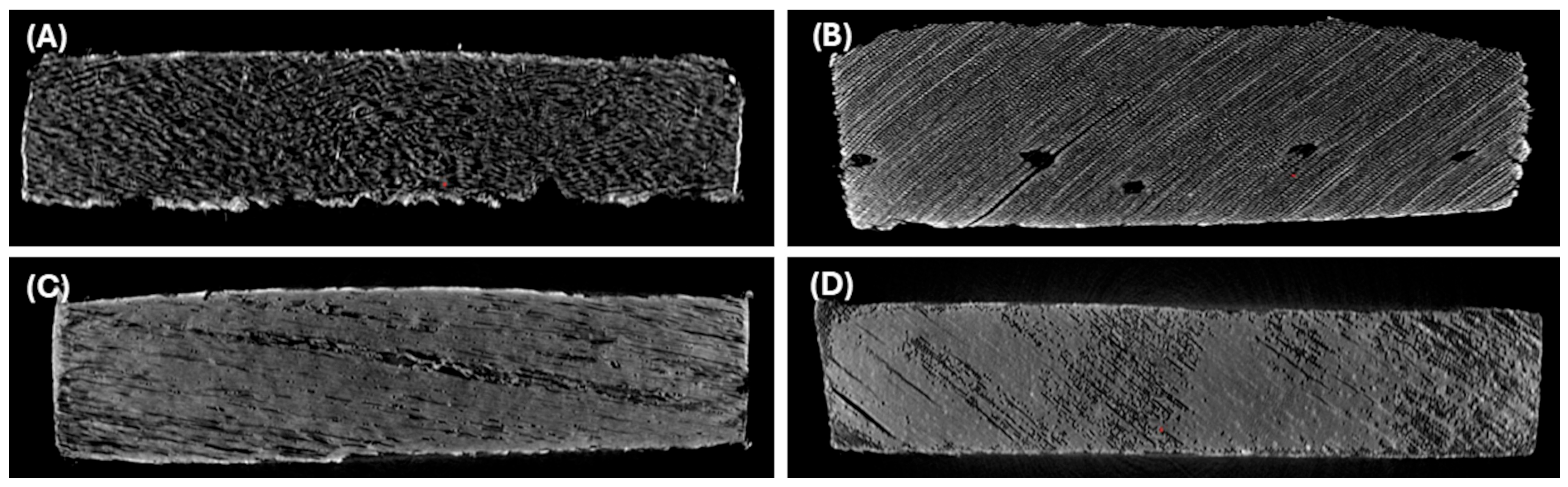

3.3. Morphological Analysis

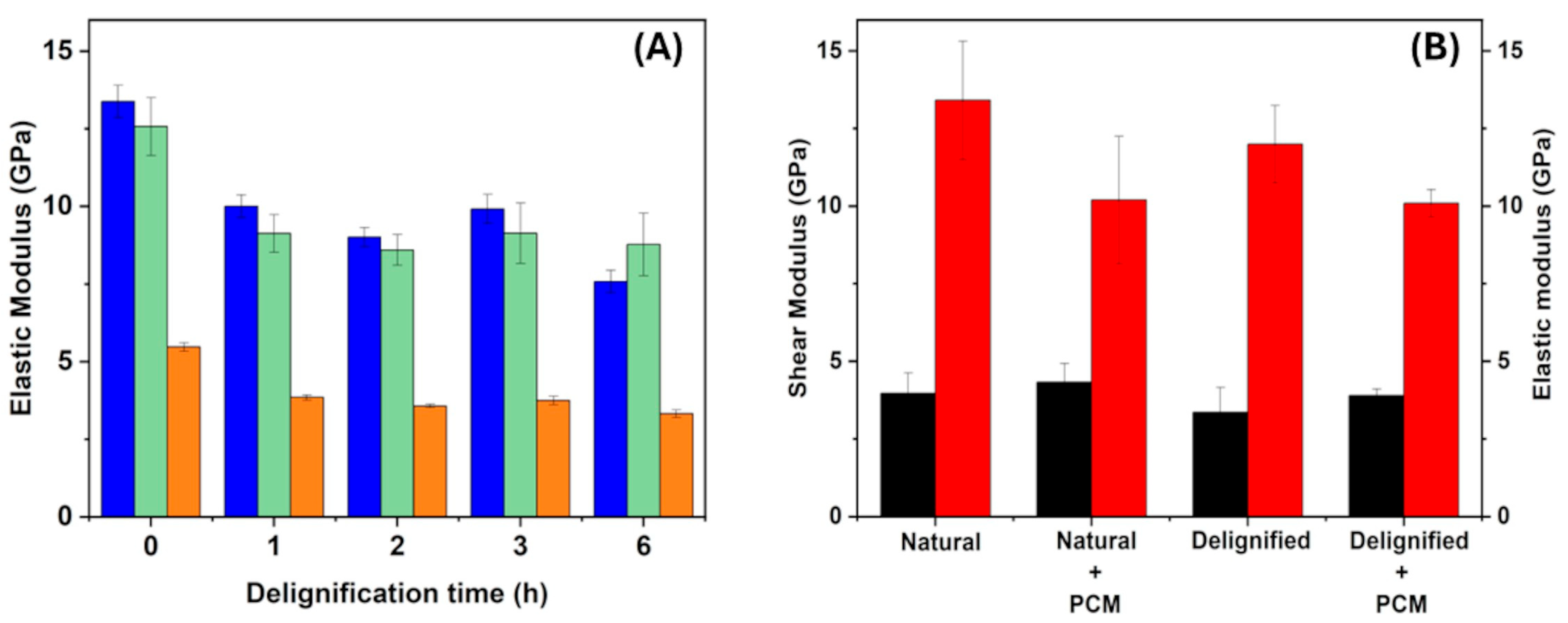

3.4. Mechanical Tests

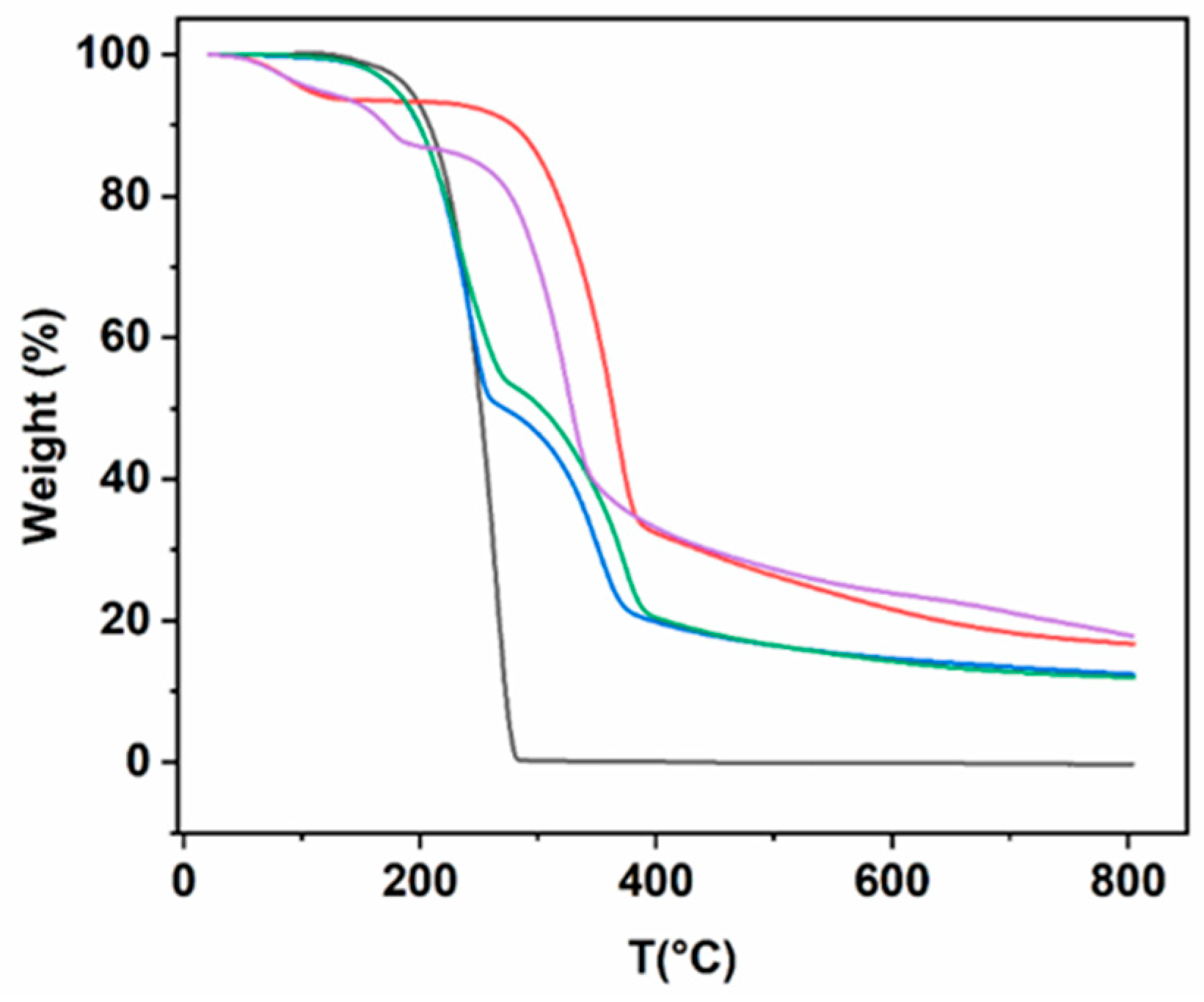

3.5. Thermal Properties

| Pinus radiata | κ (W/(mK)) | C (J/m3 K) | I (J/m2 s1/2 K) |

|---|---|---|---|

| Natural | 1.7 × 10−1 ± 7 × 10−3 | 1.5 × 105 ± 9 × 104 | 1.5 × 102 ± 6 × 101 |

| Natural + PCM | 3.5 × 10−1 ± 7 × 10−3 | 3.4 × 105 ± 6 × 104 | 3.4 × 102 ± 5 × 101 |

| Delignified + PCM | 4.2 × 10−1 ± 2 × 10−2 | 3.5 × 105 ± 7 × 104 | 3.9 × 102 ± 4 × 101 |

| Fiber cement board [50] | 1.7 × 10−1 ± 2 × 10−3 | 6.9 × 105 ± 1 × 103 | |

| Plasterboard [50] | 1.4 × 10−1 ± 1 × 10−3 | 7.7 × 105 ± 1 × 103 |

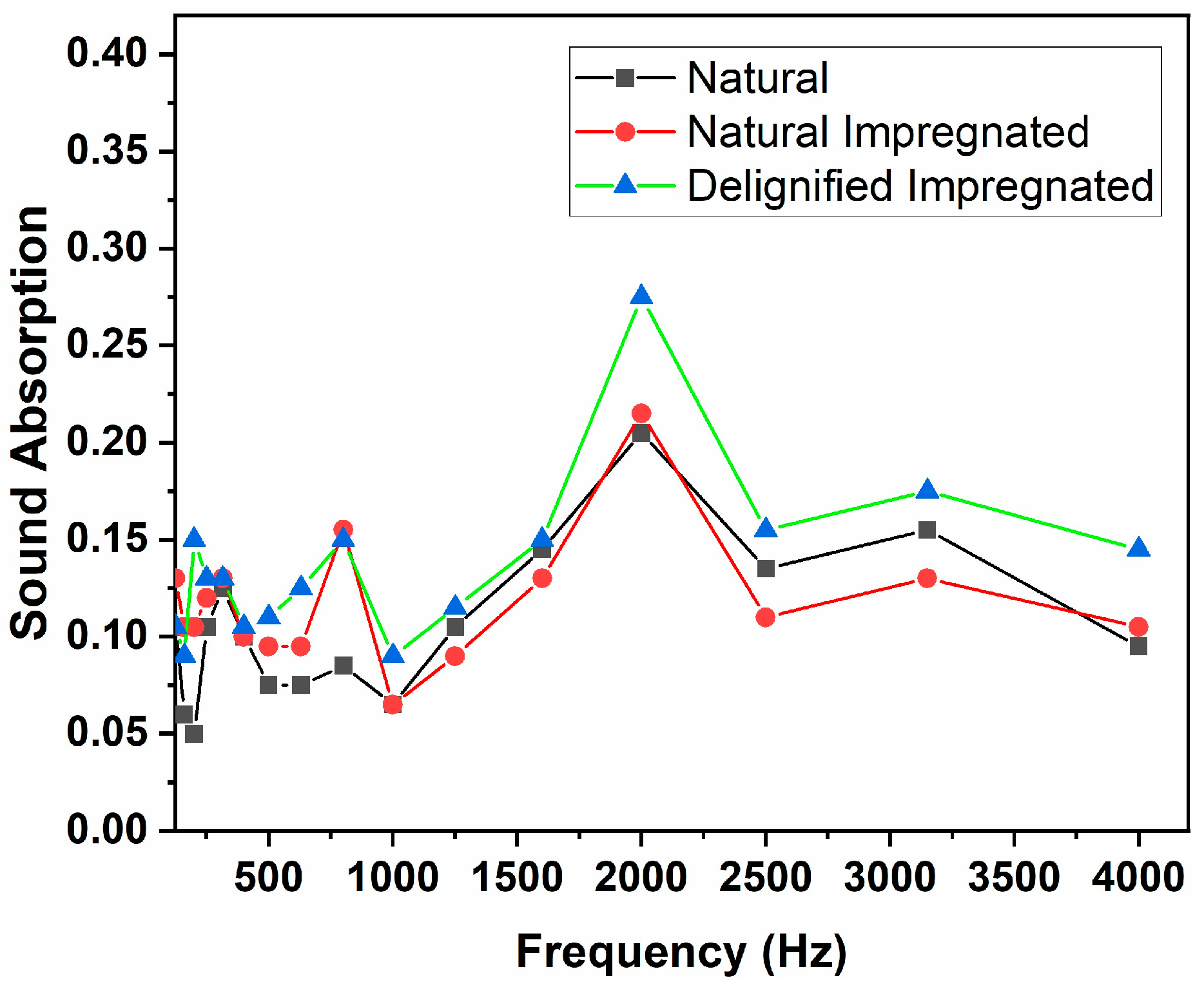

3.6. Acoustic Measurements

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PCM | Phase-change material |

| CA | Capric acid |

| LA | Lauric acid |

| MA | Myristic acid |

| PA | Palmitic acid |

| SA | Stearic acid |

| ATR-FTIR | Attenuated total reflectance–Fourier transform infrared |

| SAC | Sound absorption coefficient |

References

- Hildebrandt, J.; Hagemann, N.; Thrän, D. The Contribution of Wood-Based Construction Materials for Leveraging a Low Carbon Building Sector in Europe. Sustain. Cities Soc. 2017, 34, 405–418. [Google Scholar] [CrossRef]

- Li, B.; Chhaybi, I.; Rodrigue, D.; Berg, S.; Sandberg, D.; Huber, J.; Li, D.; Wang, X. Phase Change Materials to Improve the Energy Savings of Wood Building Envelopes in Quebec. Wood Mater. Sci. Eng. 2024, 20, 217–231. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The Role of Renewable Energy in the Global Energy Transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Duquesne, M.; Mailhé, C.; Doppiu, S.; Dauvergne, J.L.; Santos-Moreno, S.; Godin, A.; Fleury, G.; Rouault, F.; Del Barrio, E.P. Characterization of Fatty Acids as Biobased Organic Materials for Latent Heat Storage. Materials 2021, 14, 4707. [Google Scholar] [CrossRef]

- Berardi, U.; Gallardo, A.A. Properties of Concretes Enhanced with Phase Change Materials for Building Applications. Energy Build. 2019, 199, 402–414. [Google Scholar] [CrossRef]

- Sari, A. Eutectic Mixtures of Some Fatty Acids for Low Temperature Solar Heating Applications: Thermal Properties and Thermal Reliability. Appl. Therm. Eng. 2005, 25, 2100–2107. [Google Scholar] [CrossRef]

- Gunasekara, S.N.; Martin, V.; Chiu, J.N. Phase Equilibrium in the Design of Phase Change Materials for Thermal Energy Storage: State-of-the-Art. Renew. Sustain. Energy Rev. 2017, 73, 558–581. [Google Scholar] [CrossRef]

- Kenisarin, M.M. Thermophysical Properties of Some Organic Phase Change Materials for Latent Heat Storage. A Review. Solar Energy 2014, 107, 553–575. [Google Scholar] [CrossRef]

- Soodoo, N.; Poopalam, K.D.; Bouzidi, L.; Narine, S.S. Fundamental Structure-Function Relationships in Vegetable Oil Based Phase Change Materials: A Critical Review. J. Energy Storage 2022, 51, 104355. [Google Scholar] [CrossRef]

- Hassan, F.; Jamil, F.; Hussain, A.; Ali, H.M.; Janjua, M.M.; Khushnood, S.; Farhan, M.; Altaf, K.; Said, Z.; Li, C. Recent advancements in latent heat phase change materials and their applications for thermal energy storage and buildings: A state of the art review. Sustain. Energy Technol. Assess. 2022, 49, 101646. [Google Scholar] [CrossRef]

- Jiang, Z.; Palacios, A.; Zou, B.; Zhao, Y.; Deng, W.; Zhang, X.; Ding, Y. A Review on the Fabrication Methods for Structurally Stabilised Composite Phase Change Materials and Their Impacts on the Properties of Materials. Renew. Sustain. Energy Rev. 2022, 159, 112134. [Google Scholar] [CrossRef]

- Yan, Q. The Thermal Properties of Shape-Stabilized Fatty Acid Mixtures Used for Wallboard. Int. J. Sustain. Energy 2011, 30, 47–54. [Google Scholar] [CrossRef]

- Duquesne, M.; Mailhé, C.; Ruiz-Onofre, K.; Achchaq, F. Biosourced Organic Materials for Latent Heat Storage: An Economic and Eco-Friendly Alternative. Energy 2019, 188, 116067. [Google Scholar] [CrossRef]

- Chen, H.; Xuan, J.; Deng, Q.; Gao, Y. WOOD/PCM Composite with Enhanced Energy Storage Density and Anisotropic Thermal Conductivity. Prog. Nat. Sci. Mater. Int. 2022, 32, 190–195. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A Review of Structural, Thermo-Physical, Acoustical, and Environmental Properties of Wooden Materials for Building Applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Choi, J.Y.; Yun, B.Y.; Kim, Y.U.; Kang, Y.; Lee, S.C.; Kim, S. Evaluation of Thermal/Acoustic Performance to Confirm the Possibility of Coffee Waste in Building Materials in Using Bio-Based Microencapsulated PCM. Environ. Pollut. 2022, 294, 118616. [Google Scholar] [CrossRef]

- Mehrizi, A.A.; Karimi-Maleh, H.; Naddafi, M.; Karimi, F. Application of Bio-Based Phase Change Materials for Effective Heat Management. J. Energy Storage 2023, 61, 106859. [Google Scholar] [CrossRef]

- Li, D.; Zhuang, B.; Chen, Y.; Li, B.; Landry, V.; Kaboorani, A.; Wu, Z.; Wang, X.A. Incorporation Technology of Bio-Based Phase Change Materials for Building Envelope: A Review. Energy Build. 2022, 260, 111920. [Google Scholar] [CrossRef]

- Nam, J.; Yun, B.Y.; Choi, J.Y.; Kim, S. Potential of Wood as Thermal Energy Storage Materials: Different Characteristics Depending on the Hierarchical Structure and Components. Int. J. Energy Res. 2022, 46, 14926–14945. [Google Scholar] [CrossRef]

- Barreneche, C.; Vecstaudza, J.; Bajare, D.; Fernandez, A.I. PCM/Wood Composite to Store Thermal Energy in Passive Building Envelopes. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 251. [Google Scholar] [CrossRef]

- Vasco, D.A.; Salinas-Lira, C.; Barra-Reyes, I.; Elustondo, D.M. Kinematic Characterization of the Pressure-Dependent PCM Impregnation Process for Radiata Pine Wood Samples. Eur. J. Wood Wood Prod. 2018, 76, 1461–1469. [Google Scholar] [CrossRef]

- Sarı, A.; Hekimoğlu, G.; Tyagi, V.V. Low Cost and Eco-Friendly Wood Fiber-Based Composite Phase Change Material: Development, Characterization and Lab-Scale Thermoregulation Performance for Thermal Energy Storage. Energy 2020, 195, 116983. [Google Scholar] [CrossRef]

- Ma, L.; Guo, C.; Ou, R.; Sun, L.; Wang, Q.; Li, L. Preparation and Characterization of Modified Porous Wood Flour/Lauric-Myristic Acid Eutectic Mixture as a Form-Stable Phase Change Material. Energy Fuels 2018, 32, 5453–5461. [Google Scholar] [CrossRef]

- Hussain, S.I.; Kalaiselvam, S. Nanoencapsulation of Oleic Acid Phase Change Material with Ag2O Nanoparticles-Based Urea Formaldehyde Shell for Building Thermal Energy Storage. J. Therm. Anal. Calorim. 2020, 140, 133–147. [Google Scholar] [CrossRef]

- Sarı, A.; Bicer, A.; Alkan, C.; Özcan, A.N. Thermal Energy Storage Characteristics of Myristic Acid-Palmitic Eutectic Mixtures Encapsulated in PMMA Shell. Sol. Energy Mater. Sol. Cells 2019, 193, 1–6. [Google Scholar] [CrossRef]

- Ma, L.; Wang, Q.; Li, L. Delignified Wood/Capric Acid-Palmitic Acid Mixture Stable-Form Phase Change Material for Thermal Storage. Sol. Energy Mater. Sol. Cells 2019, 194, 215–221. [Google Scholar] [CrossRef]

- Kumar, A.; Jyske, T.; Petrič, M. Delignified Wood from Understanding the Hierarchically Aligned Cellulosic Structures to Creating Novel Functional Materials: A Review. Adv. Sustain. Syst. 2021, 5, 2000251. [Google Scholar] [CrossRef]

- Zhu, M.; Song, J.; Li, T.; Gong, A.; Wang, Y.; Dai, J.; Yao, Y.; Luo, W.; Henderson, D.; Hu, L. Highly Anisotropic, Highly Transparent Wood Composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef]

- Vanholme, R.; De Meester, B.; Ralph, J.; Boerjan, W. Lignin Biosynthesis and Its Integration into Metabolism. Curr. Opin. Biotechnol. 2019, 56, 230–239. [Google Scholar] [CrossRef]

- Véliz-Fadic, F.I.; Rodríguez-Grau, G.; Marín-Uribe, C.R.; García-Giraldo, J.M.; González-Palacio, L.; Araya-Letelier, G. Flexural Performance Assessment of the Effect of the Splice Length of the Jupiter Ray Type Made of Radiata Pine Using Computer-Aided Design and Computer-Assisted Manufacturing. Constr. Build. Mater. 2024, 449, 138272. [Google Scholar] [CrossRef]

- Fearon, O.; Kuitunen, S.; Ruuttunen, K.; Alopaeus, V.; Vuorinen, T. Detailed Modeling of Kraft Pulping Chemistry. Delignification. Ind. Eng. Chem. Res. 2020, 59, 12977–12985. [Google Scholar] [CrossRef]

- Han, X.; Ye, Y.; Lam, F.; Pu, J.; Jiang, F. Hydrogen-Bonding-Induced Assembly of Aligned Cellulose Nanofibers into Ultrastrong and Tough Bulk Materials. J. Mater. Chem. 2019, 7, 27023–27031. [Google Scholar] [CrossRef]

- Fuentes-Sepúlveda, R.; García-Herrera, C.; Vasco, D.A.; Salinas-Lira, C.; Ananías, R.A. Thermal Characterization of Pinus Radiata Wood Vacuum-Impregnated with Octadecane. Energies 2020, 13, 942. [Google Scholar] [CrossRef]

- Otani, L.B.; de Alcântara Segundinho, P.G.; Morales, E.A.M.; Pereira, A.H.A. Elastic Moduli Characterization of Wood and Wood Products Using the Impulse Excitation Technique. ATCP Phys. Eng. 2015, 1, 33. [Google Scholar] [CrossRef]

- Baradit, E.; Fuentealba, C.; Yáñez, M. Elastic constants of Chilean Pinus radiata using ultrasound. Maderas. Cienc. Tecnol. 2021, 23, 1–10. [Google Scholar] [CrossRef]

- ISO 22007-2:2008(E); Plastics-Determination of Thermal Conductivity and Thermal Diffusivity-Part 2:Transient Plane Heat Source (Hot Disc) Method. The International Organization for Standardization: Geneva, Switzerland, 2008.

- ASTM E1050-19; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System. ASTM International: West Conshohocken, PA, USA, 2005. [CrossRef]

- Tao, J.; Wang, P.; Qiu, X.; Pan, J. Static Flow Resistivity Measurements Based on the ISO 10534.2 Standard Impedance Tube. Build. Environ. 2015, 94, 853–858. [Google Scholar] [CrossRef]

- Mohammadi, M.; Taban, E.; Tan, W.H.; Din, N.B.C.; Putra, A.; Berardi, U. Recent Progress in Natural Fiber Reinforced Composite as Sound Absorber Material. J. Build. Eng. 2024, 84, 108514. [Google Scholar] [CrossRef]

- Steinhaus, T. Evaluation of the Thermophysical Properties of Poly(MethylMethacrylate): A Reference Material for the Development of a Flammability Test for Micro-Gravity Environments; The University of Maryland: College Park, MD, USA, 2009. [Google Scholar]

- Hung Anh, L.D.; Pásztory, Z. An Overview of Factors Influencing Thermal Conductivity of Building Insulation Materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Cao, L.; Fu, Q.; Si, Y.; Ding, B.; Yu, J. Porous Materials for Sound Absorption. Compos. Commun. 2018, 10, 25–35. [Google Scholar] [CrossRef]

- Peng, L. Sound Absorption and Insulation Functional Composites. In Advanced High Strength Natural Fibre Composites in Construction; Woodhead Publishing: Sawston, UK, 2017; pp. 333–373. [Google Scholar] [CrossRef]

- Temiz, A.; Hekimoğlu, G.; Köse Demirel, G.; Sarı, A.; Mohamad Amini, M.H. Phase Change Material Impregnated Wood for Passive Thermal Management of Timber Buildings. Int. J. Energy Res. 2020, 44, 10495–10505. [Google Scholar] [CrossRef]

- Nazari, M.; Jebrane, M.; Terziev, N. Solid Wood Impregnated with a Bio-Based Phase Change Material for Low Temperature Energy Storage in Building Application. J. Therm. Anal. Calorim. 2022, 147, 10677–10692. [Google Scholar] [CrossRef]

- Khakalo, A.; Tanaka, A.; Korpela, A.; Orelma, H. Delignification and Ionic Liquid Treatment of Wood toward Multifunctional High-Performance Structural Materials. ACS Appl. Mater. Interfaces 2020, 12, 23532–23542. [Google Scholar] [CrossRef] [PubMed]

- Nazari, M.; Jebrane, M.; Gao, J.; Terziev, N. Thermal Performance and Mold Discoloration of Thermally Modified Wood Containing Bio-Based Phase Change Material for Heat Storage. Energy Storage 2022, 4, e340. [Google Scholar] [CrossRef]

- Soret, G.M.; Vacca, P.; Tignard, J.; Hidalgo, J.P.; Maluk, C.; Aitchison, M.; Torero, J.L. Thermal Inertia as an Integrative Parameter for Building Performance. J. Build. Eng. 2021, 33, 101623. [Google Scholar] [CrossRef]

- Chen, Y.; Tshabalala, M.A.; Gao, J.; Stark, N.M.; Fan, Y.; Ibach, R.E. Thermal Behavior of Extracted and Delignified Pine Wood Flour. Thermochim. Acta 2014, 591, 40–44. [Google Scholar] [CrossRef]

- Vasco, D.A.; Muñoz-Mejías, M.; Pino-Sepúlveda, R.; Ortega-Aguilera, R.; García-Herrera, C. Thermal Simulation of a Social Dwelling in Chile: Effect of the Thermal Zone and the Temperature-Dependant Thermophysical Properties of Light Envelope Materials. Appl. Therm. Eng. 2017, 112, 771–783. [Google Scholar] [CrossRef]

- Hanif, F.; Imran, M.; Zhang, Y.; Jia, Z.; Lu, X.; Lu, R.; Tang, B. Form-Stable Phase Change Material with Wood-Based Materials as Support. Polymers 2023, 15, 942. [Google Scholar] [CrossRef]

- Chen, Y.; Tshabalala, M.A.; Stark, N.M.; Gao, J.; Fan, Y.; Ibach, R.E. Thermal Properties of Extracted and Delignified Wood Flour for Use in Wood-Plastic Composites. In Proceedings of the Advancements in Fiber-Polymer Composites: Wood Fiber, Natural Fibers and Nanocellulose, Milwaukee, WI, USA, 6–7 May 2013. [Google Scholar]

- Li, H.; Guo, X.; He, Y.; Zheng, R. A Green Steam-Modified Delignification Method to Prepare Low-Lignin Delignified Wood for Thick, Large Highly Transparent Wood Composites. J. Mater. Res. 2019, 34, 932–940. [Google Scholar] [CrossRef]

- Amares, S.; Sujatmika, E.; Hong, T.W.; Durairaj, R.; Hamid, H.S.H.B. A Review: Characteristics of Noise Absorption Material. J. Phys. Conf. Ser. 2017, 908, 012005. [Google Scholar] [CrossRef]

- Asdrubali, F. Survey on the Acoustical Properties of New Sustainable Materials for Noise Control. In Proceedings of Euronoise; Acoustical Society of Finland: Tampere, Finland, 2006; Volume 30, pp. 1–10. [Google Scholar]

- Iannace, G.; Ciaburro, G. Modelling Sound Absorption Properties for Recycled Polyethylene Terephthalate-Based Material Using Gaussian Regression. Build. Acoust. 2021, 28, 185–196. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G.; Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Acoustic Applications of a Foamed Geopolymeric-Architected Metamaterial. Appl. Sci. 2024, 14, 1207. [Google Scholar] [CrossRef]

- Lashgari, M.; Taban, E.; SheikhMozafar, M.J.; Soltan, P.; Attenborough, K.; Khavanin, A. Wood Chip Sound Absorbers: Measurements and Models. Appl. Acoust. 2024, 220, 109963. [Google Scholar] [CrossRef]

- Khrystoslavenko, O.; Astrauskas, T.; Grubliauskas, R. Sound Absorption Properties of Charcoal Made from Wood Waste. Sustainability 2023, 15, 8196. [Google Scholar] [CrossRef]

- Kolya, H.; Kang, C.W. High Acoustic Absorption Properties of Hackberry Compared to Nine Different Hardwood Species: A Novel Finding for Acoustical Engineers. Appl. Acoust. 2020, 169, 107475. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Murali, G.; Vatin, N.; Al-Fakih, A. Sound-Absorbing Acoustic Concretes: A Review. Sustainability 2021, 13, 10712. [Google Scholar] [CrossRef]

| Acid Mixture | Peak Temperature (°C) | Melting Temperature (°C) | Melting Enthalpy (J/g) |

|---|---|---|---|

| MA | 55.57 | 53.86 | 151 |

| CA | 32.95 | 31.55 | 133 |

| 82%MA-18%CA | 25.04 | 22.36 | 139 |

| 83%MA-17%CA | 25.18 | 22.09 | 146 |

| 84%MA-16%CA | 25.27 | 22.39 | 113 |

| Delignification Time (h) | Mass Variation (%) | Volume Variation (%) | Density Variation (%) |

|---|---|---|---|

| 1 | −10.98 ± 0.3 | −9.01 ± 2.1 | −2.3 ± 2.5 |

| 2 | −13.98 ± 0.7 | −15.03 ± 1.5 | +1.35 ± 1.9 |

| 3 | −14.62 ± 1.4 | −16.95 ± 1.8 | +2.83 ± 2.8 |

| 6 | −26.21 ± 0.5 | −17.53 ± 1.5 | −10.51 ± 1.6 |

| Sample | Total Porosity (%) |

|---|---|

| Natural | 62.37 ± 2.24 |

| Delignified | 71.75 ± 0.43 |

| Natural + PCM | 48.67 ± 5.31 |

| Delignified + PCM | 65.53 ± 2.37 |

| Pinus radiata Sample | Sound Absorption Coefficient at 2000 Hz | Density (kg/m3) |

|---|---|---|

| Natural | 0.205 | 3.81 × 10+2 ± 1 × 10+1 |

| Natural impregnated | 0.215 | 7.19 × 10+2 ± 5 × 100 |

| Delignified and impregnated | 0.275 | 9.18 × 10+2 ± 1 × 10+1 |

| B. pendula (30 mm thick) [59] | 0.16 | ~2.34 × 10+2 |

| P. sylvestris (30 mm thick) [59] | <0.15 | ~2.63 × 10+2 |

| Hard maple [60] | 0.259 | 4.52 × 10+2 |

| Silver poplar [60] | 0.432 | 4.76 × 10+2 |

| Plywood panel [54] | 0.1 | - |

| Fiberglass board [54] | 0.95 | - |

| Painted concrete [61] | 0.020 | - |

| Styrofoam 100 kg/m2 [61] | 0.22 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Molina, P.; Sancy, M.; Sève, G.; Córdova, D.; Erazo, I.; Sepúlveda-Vásquez, C.; Di Mambro, D.; George, K.; Urzúa-Parra, I.A.; Vasco, D.A.; et al. Enhancement of Thermal–Acoustic Properties of Pinus radiata by Impregnation of Bio-Phase-Change Materials. Buildings 2025, 15, 1320. https://doi.org/10.3390/buildings15081320

Molina P, Sancy M, Sève G, Córdova D, Erazo I, Sepúlveda-Vásquez C, Di Mambro D, George K, Urzúa-Parra IA, Vasco DA, et al. Enhancement of Thermal–Acoustic Properties of Pinus radiata by Impregnation of Bio-Phase-Change Materials. Buildings. 2025; 15(8):1320. https://doi.org/10.3390/buildings15081320

Chicago/Turabian StyleMolina, Paulo, Mamié Sancy, Gabrielle Sève, Deborah Córdova, Ignacio Erazo, Carlos Sepúlveda-Vásquez, David Di Mambro, Kesiya George, Ignacio A. Urzúa-Parra, Diego A. Vasco, and et al. 2025. "Enhancement of Thermal–Acoustic Properties of Pinus radiata by Impregnation of Bio-Phase-Change Materials" Buildings 15, no. 8: 1320. https://doi.org/10.3390/buildings15081320

APA StyleMolina, P., Sancy, M., Sève, G., Córdova, D., Erazo, I., Sepúlveda-Vásquez, C., Di Mambro, D., George, K., Urzúa-Parra, I. A., Vasco, D. A., & Rodríguez-Grau, G. (2025). Enhancement of Thermal–Acoustic Properties of Pinus radiata by Impregnation of Bio-Phase-Change Materials. Buildings, 15(8), 1320. https://doi.org/10.3390/buildings15081320