Behavior of Self-Compacting Concrete Cylinders Internally Confined with Various Types of Composite Grids

Abstract

1. Introduction

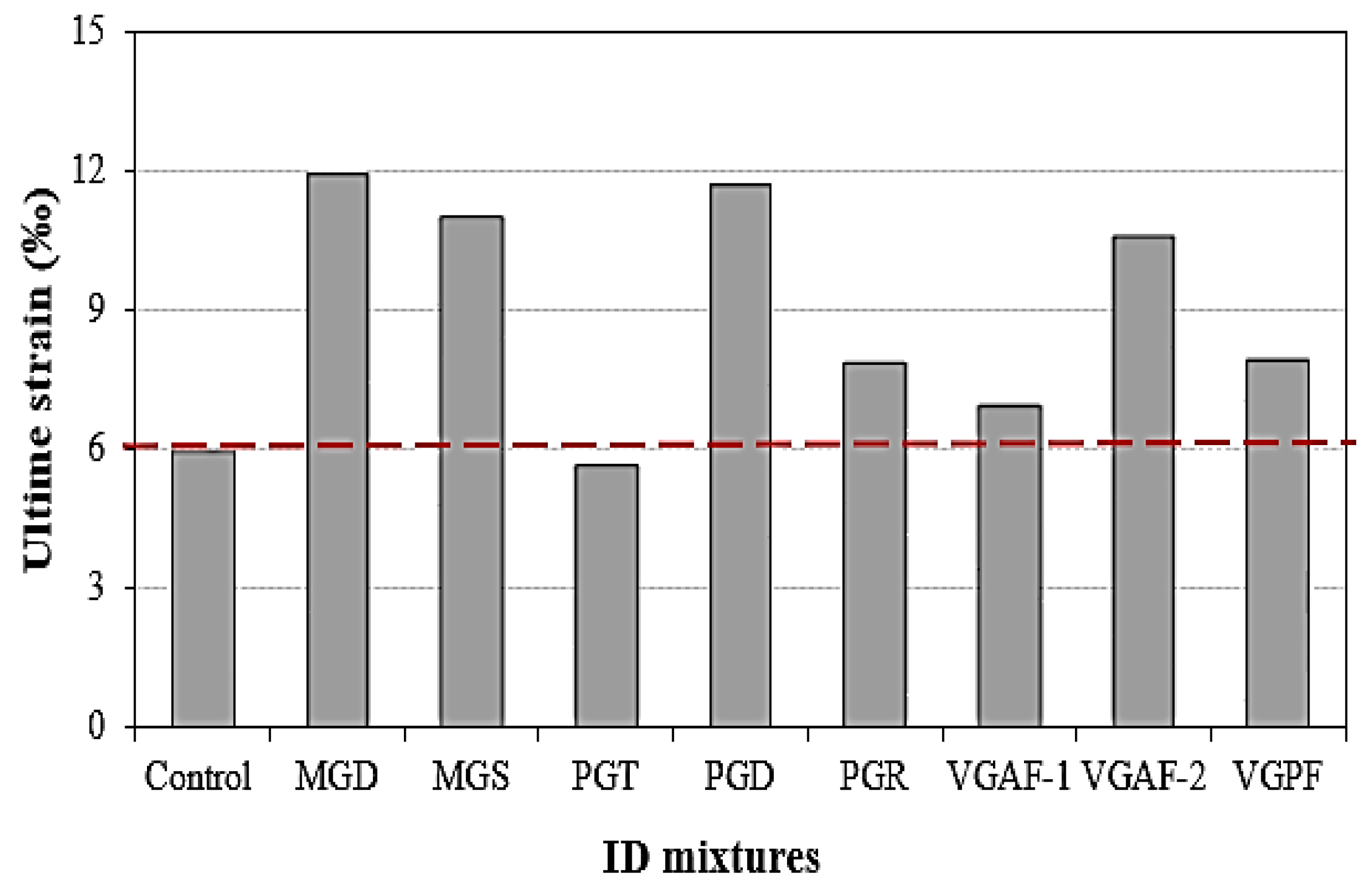

2. Materials and Methods

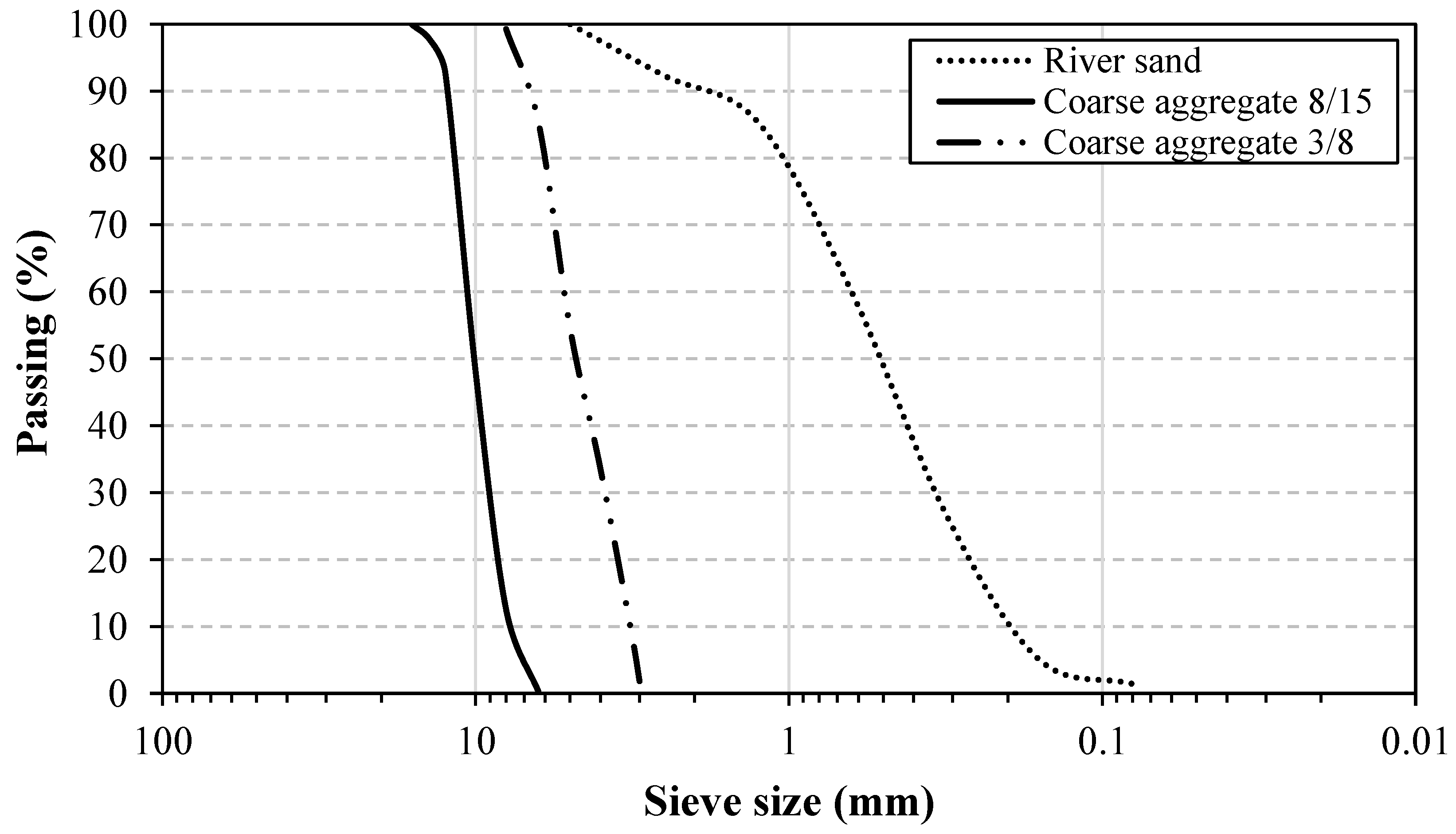

2.1. Materials

2.2. Mix Proportions of SCC

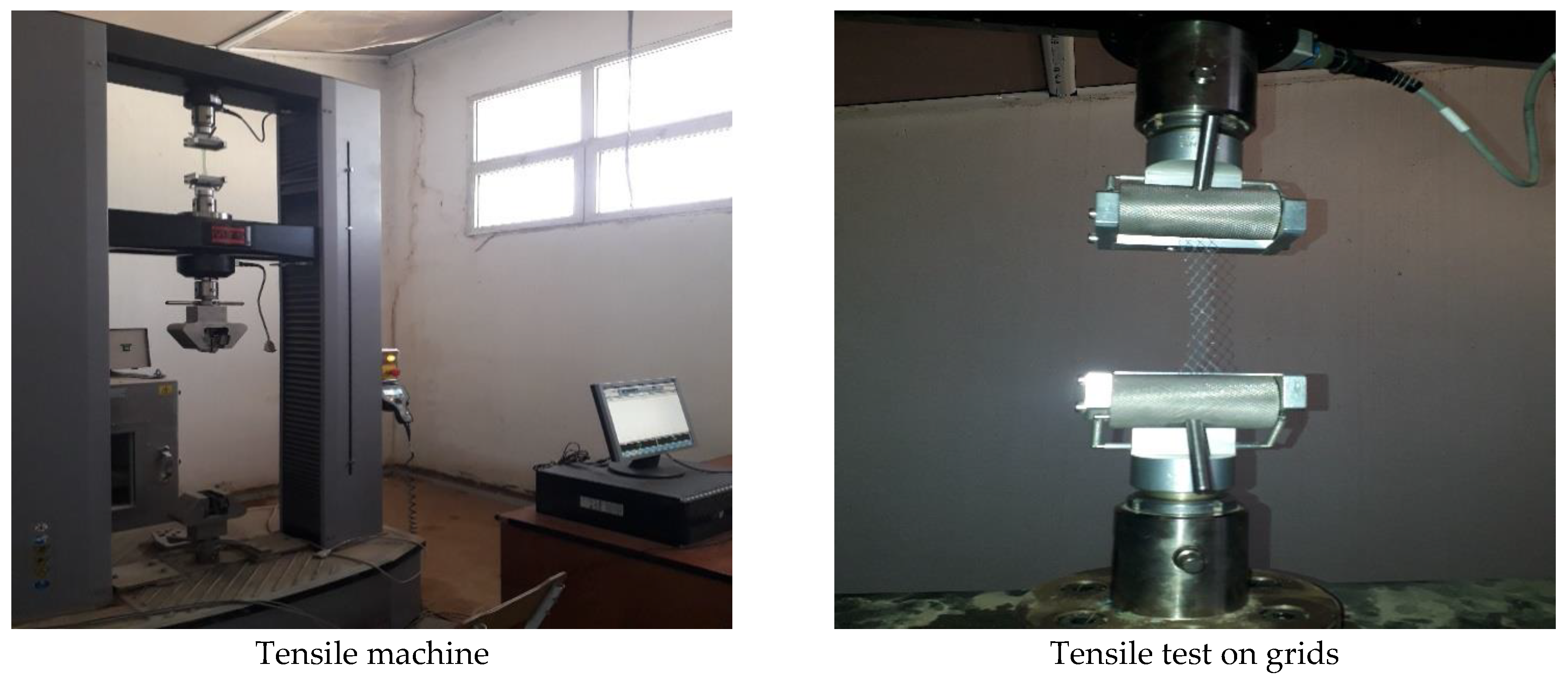

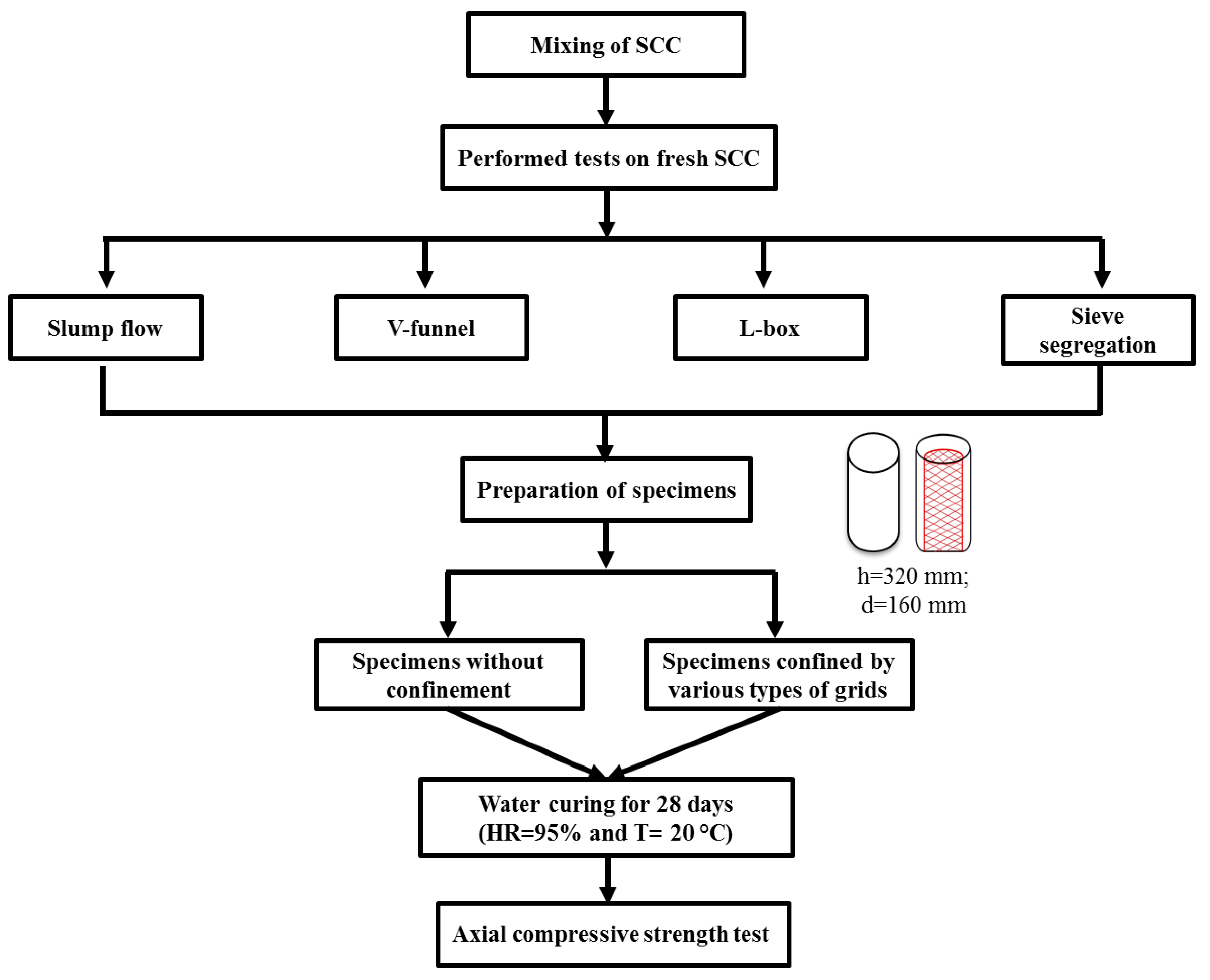

2.3. Experimental Program

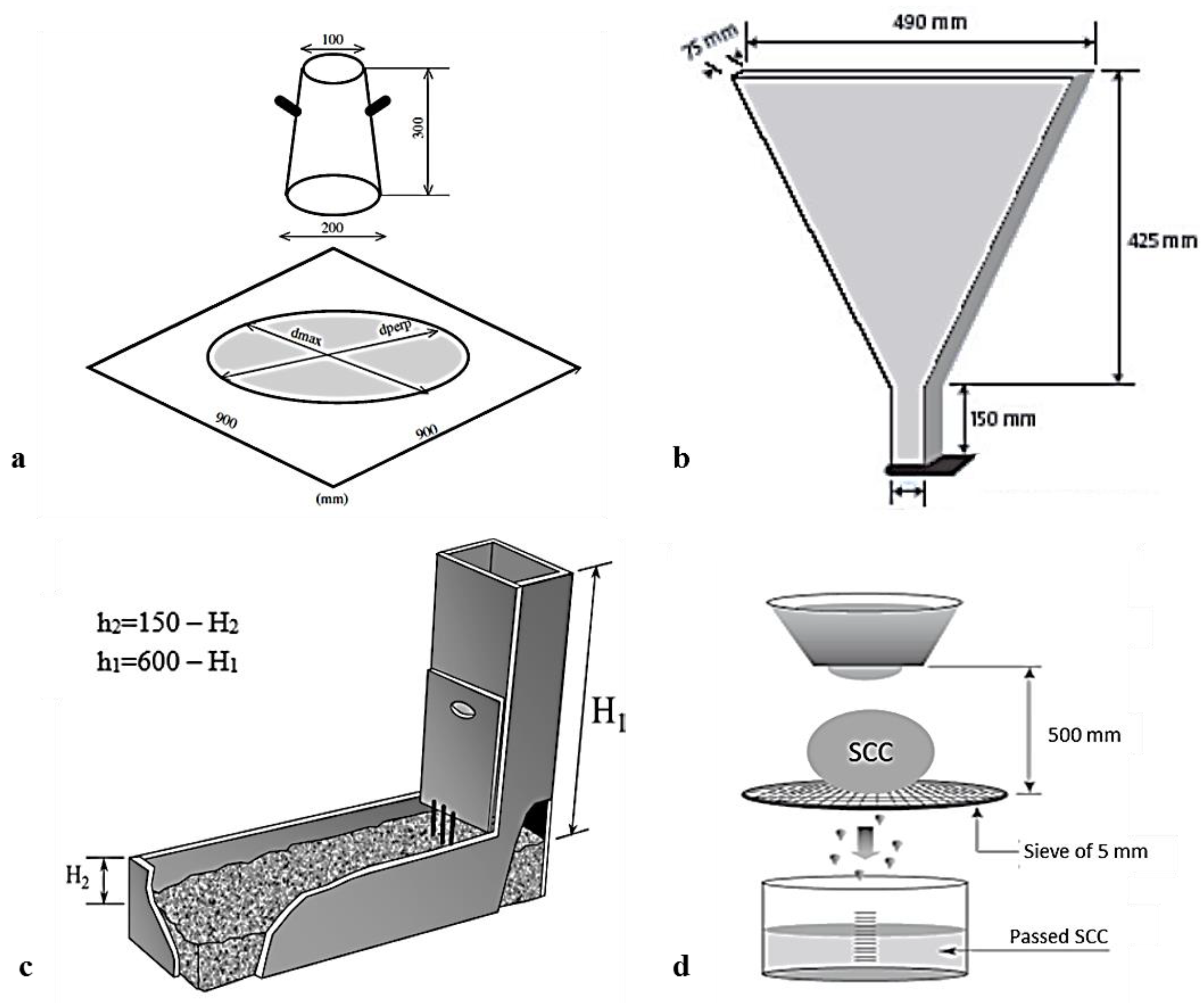

2.3.1. Tests on Fresh SCC

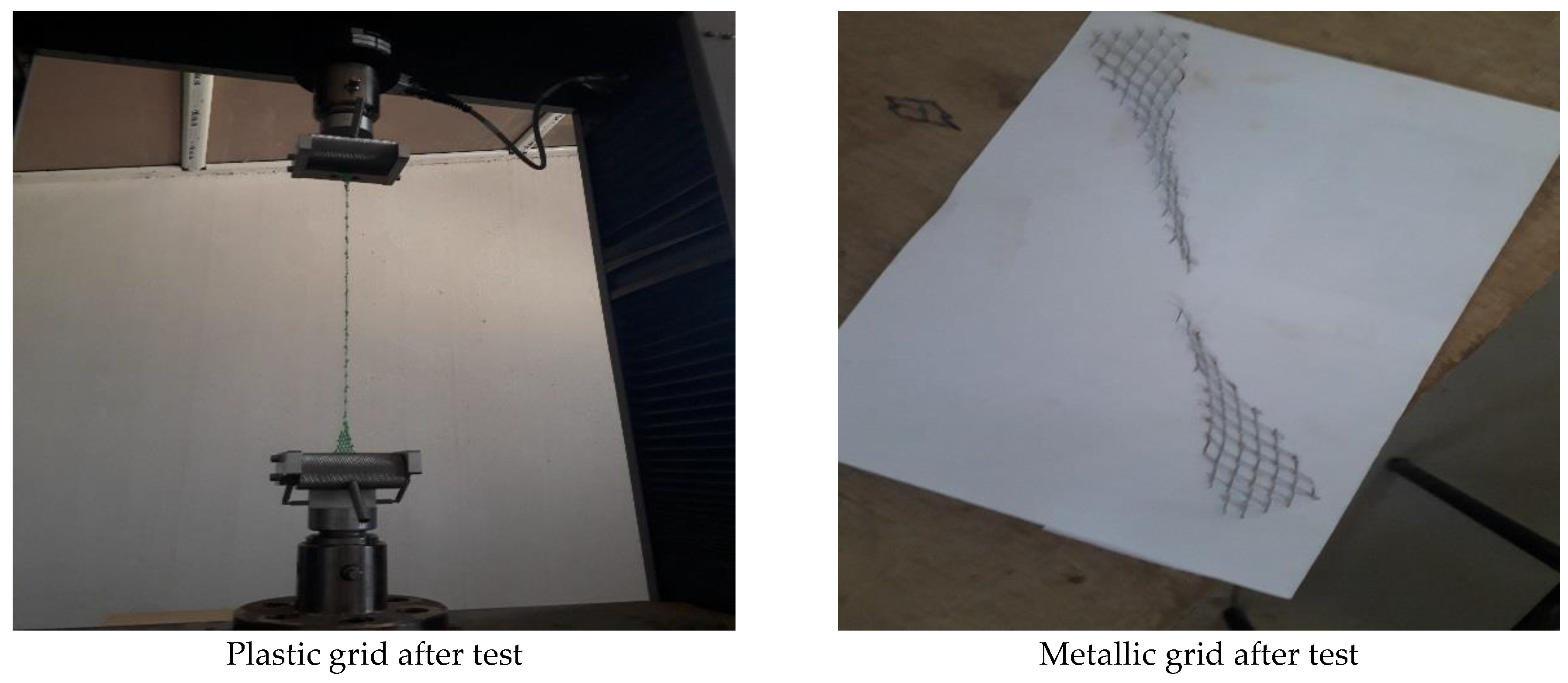

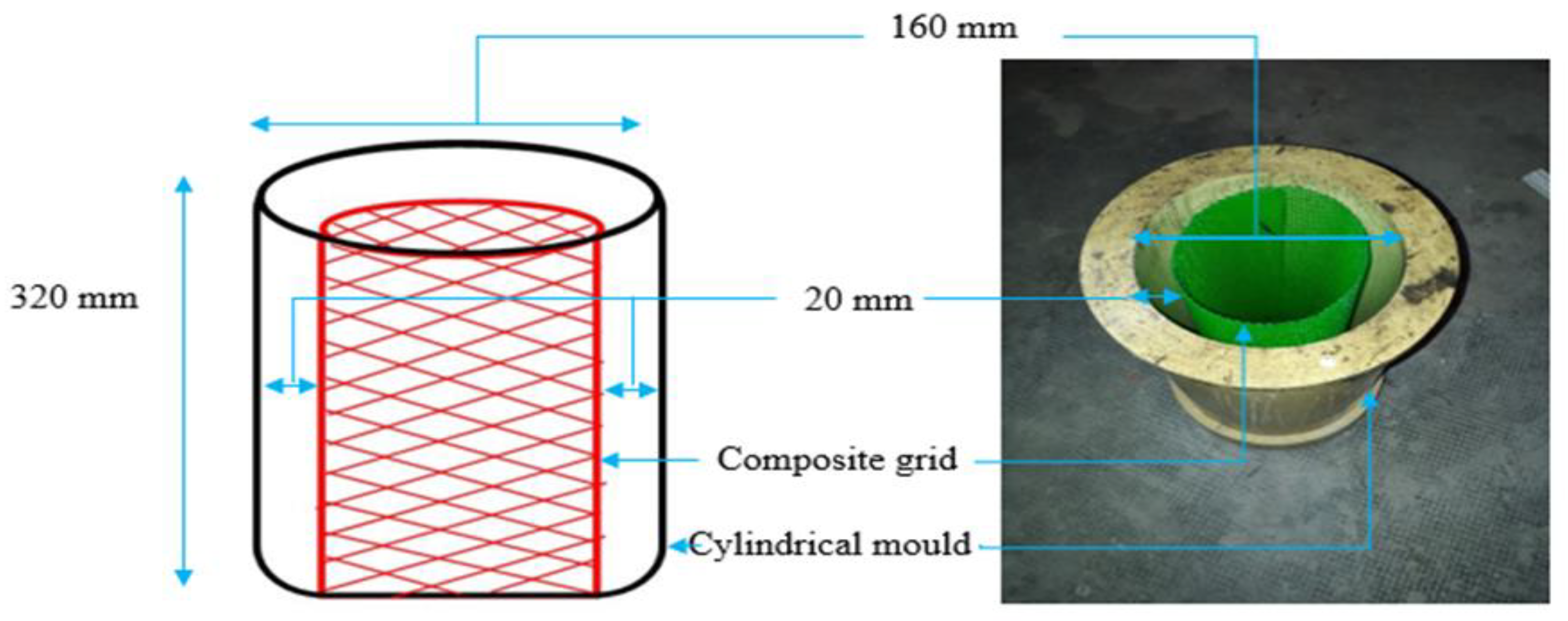

2.3.2. Method of Confinement

2.3.3. Test Setup

3. Results and Discussion

3.1. SCC Fresh Properties

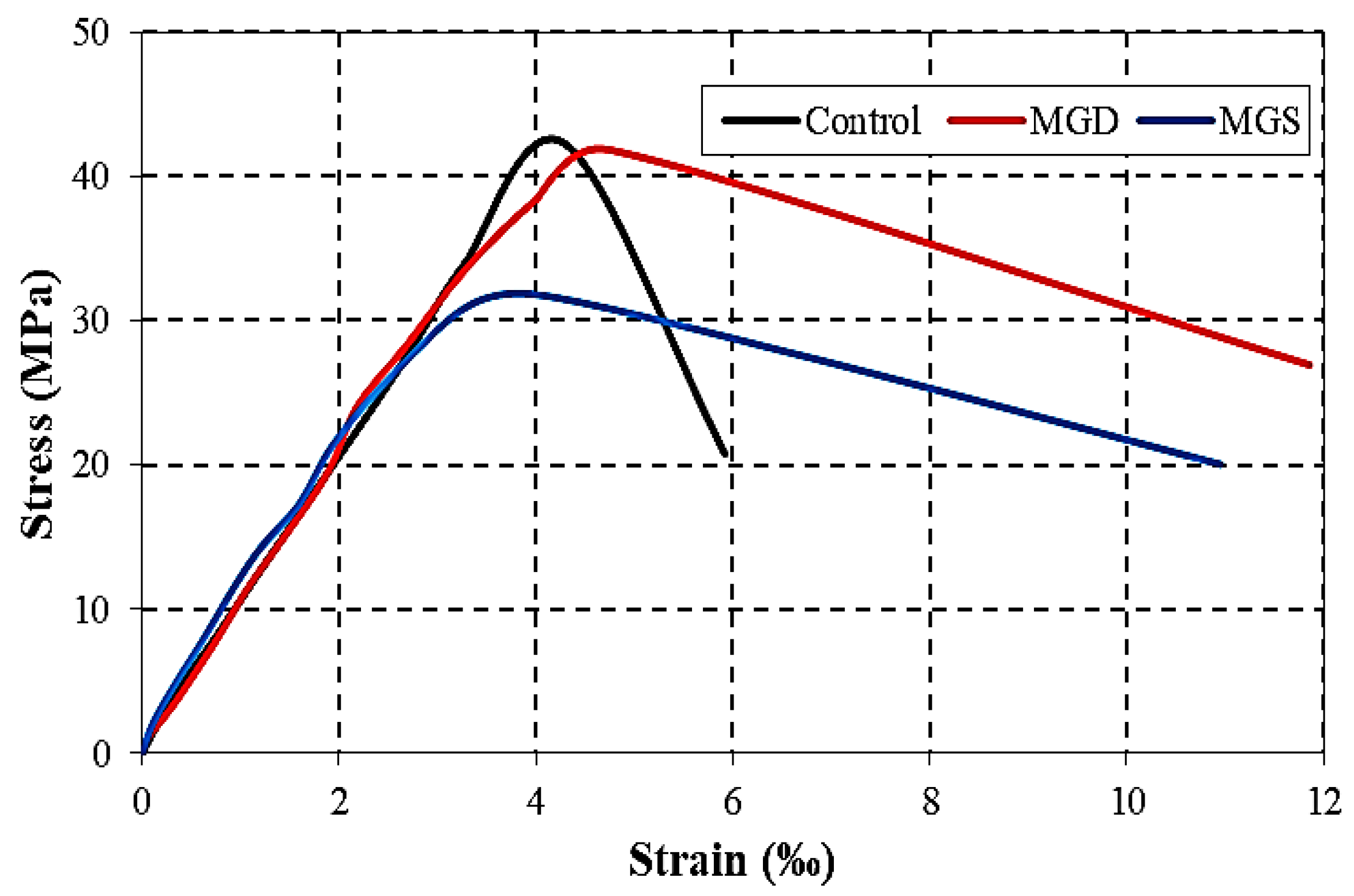

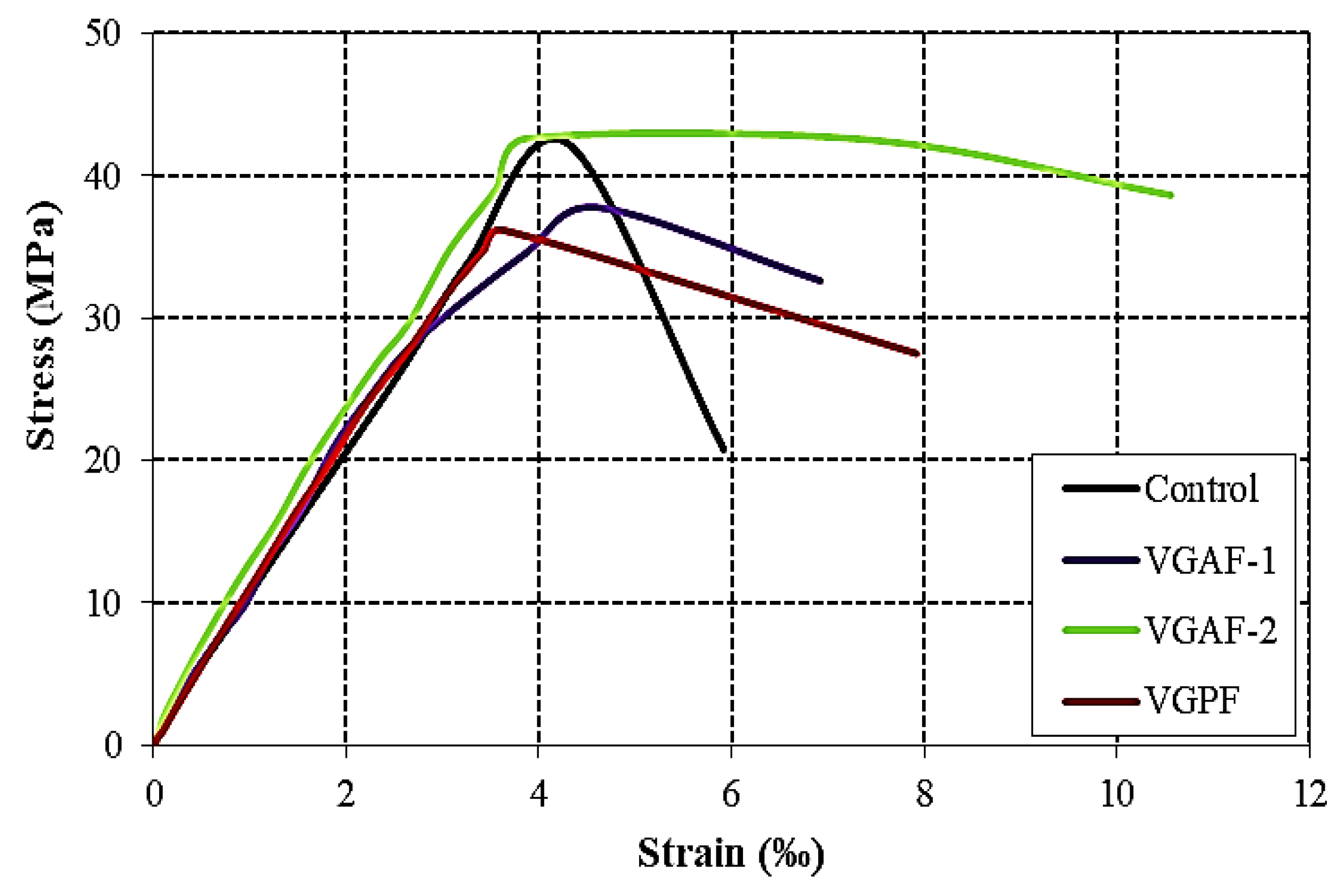

3.2. Axial Load–Strain Behavior

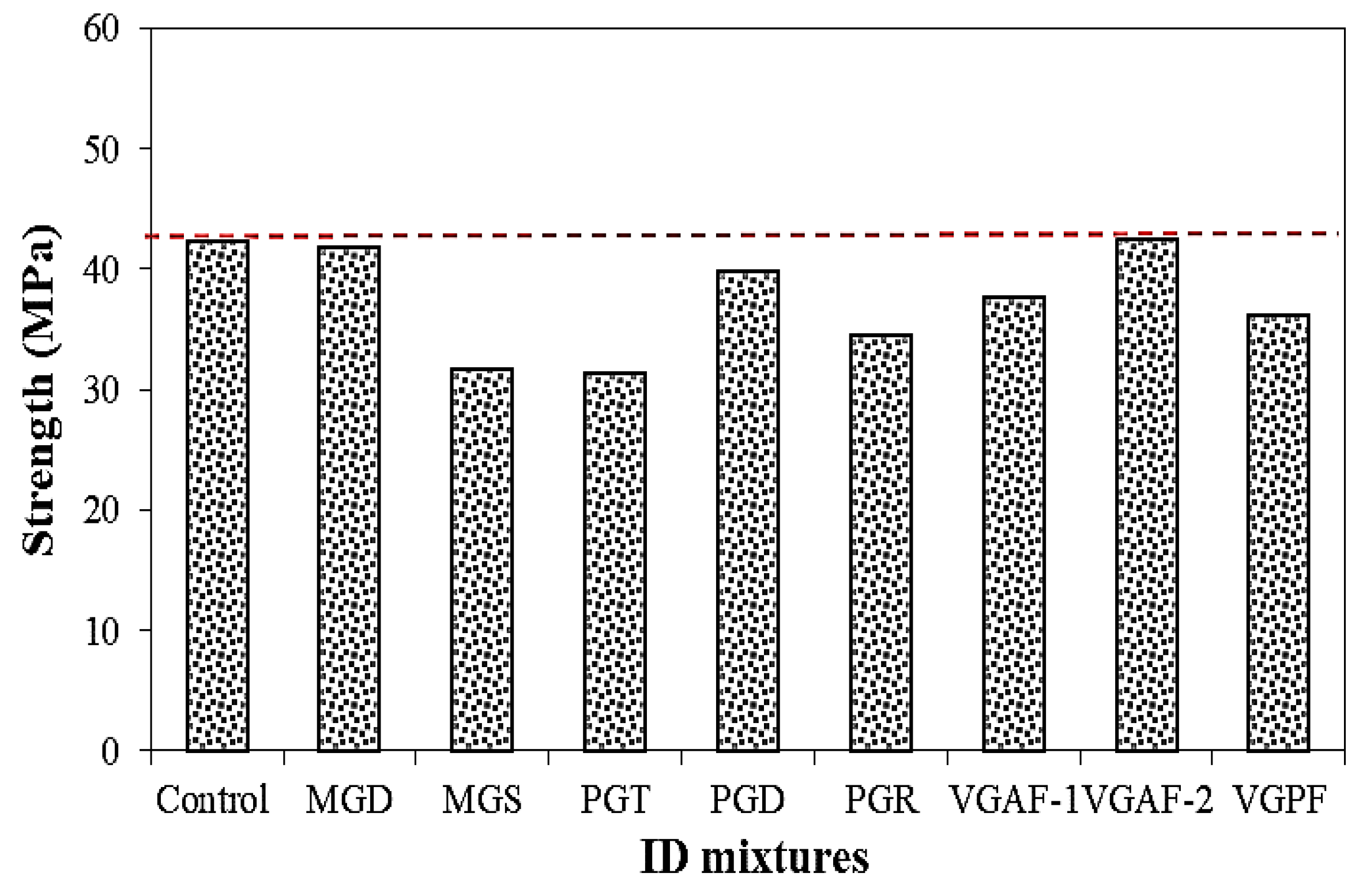

3.3. Evaluation of Mechanical Properties

3.4. Discussion

3.4.1. Strength Gain and Ductility Gain

3.4.2. Axial Stress as a Function of Axial Strain

3.4.3. Mechanical Behavior of Unconfined and Confined SCC Samples

- A first practical linear phase before micro-cracking of the concrete remains similar to unconfined SCC up to about 50% of the breaking load, so the modulus of elasticity is not very sensitive to the presence of the composite.

- A second curved phase of the ascending part, during which the concrete micro-cracks and the grid fibers are put in tension.

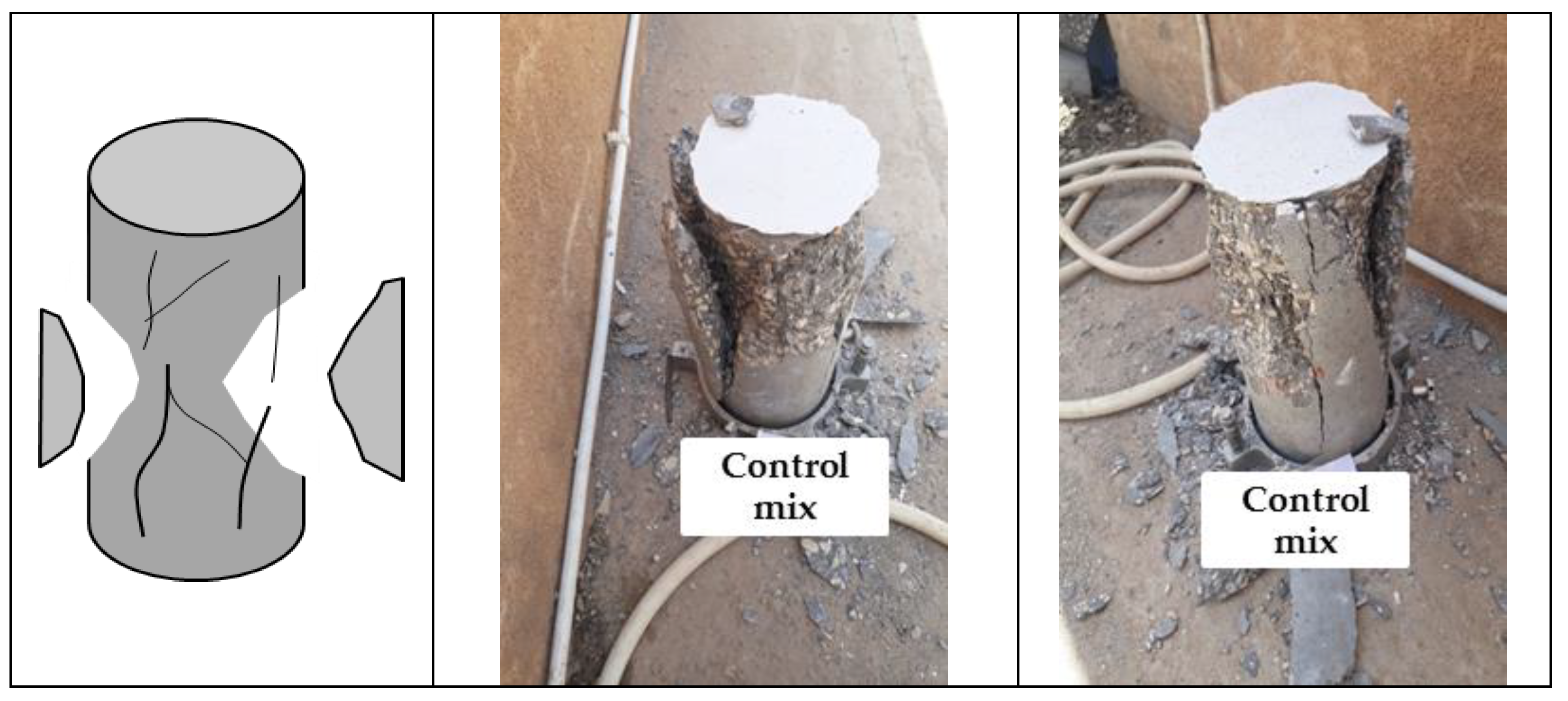

- A third descending phase, during which the force is absorbed by the fibers of the composite grids, which hold the cracked concrete until failure.

3.4.4. Influence of the Shape of the Grid Mesh on the Behavior of Confined SCC Samples

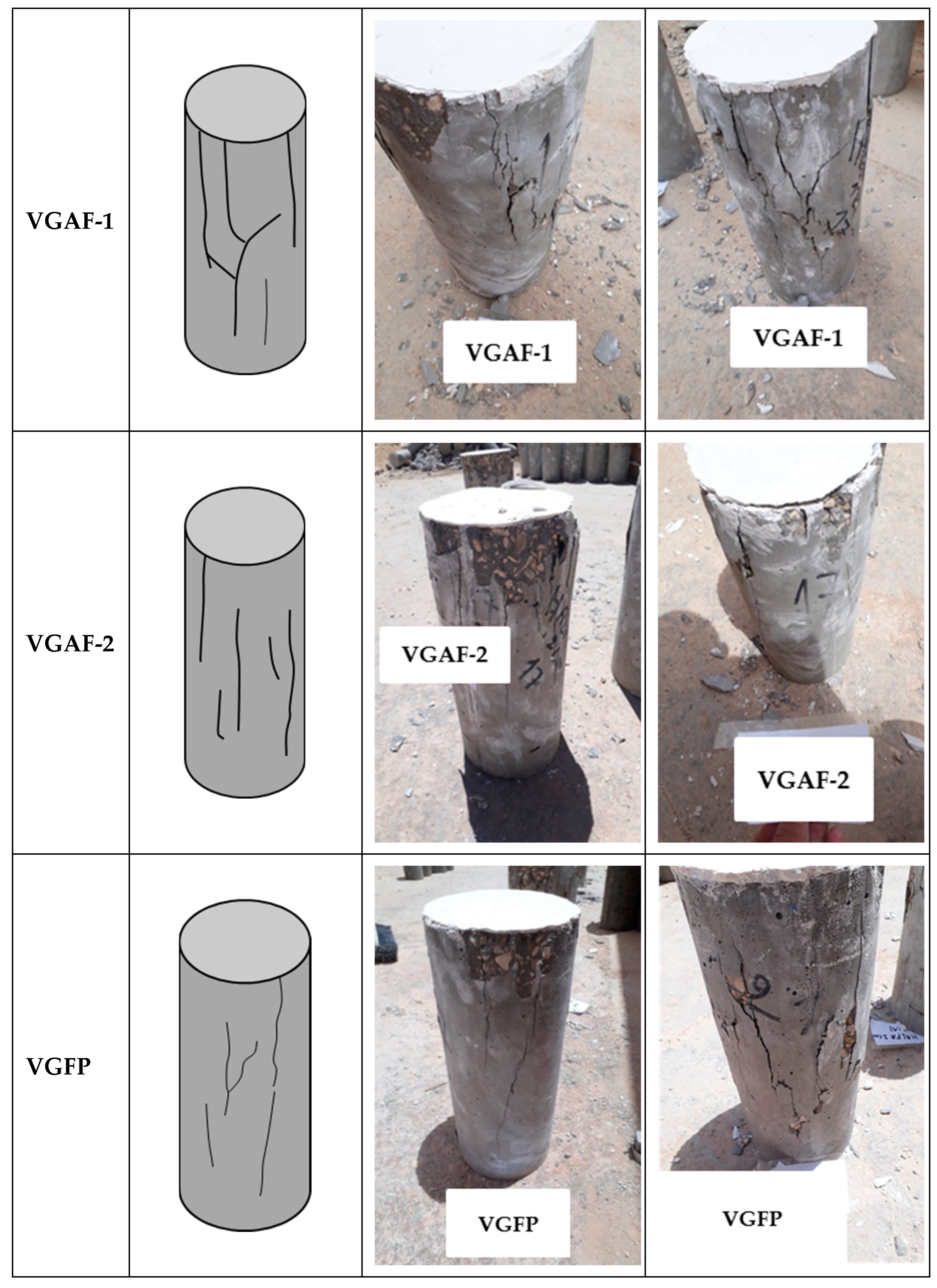

3.5. Failure Modes

3.5.1. Unconfined Concrete

3.5.2. Confined Concrete with Plastic Grids

3.5.3. Confined Concrete with Metallic Grids

3.5.4. Confined Concrete with Vegetable Grids

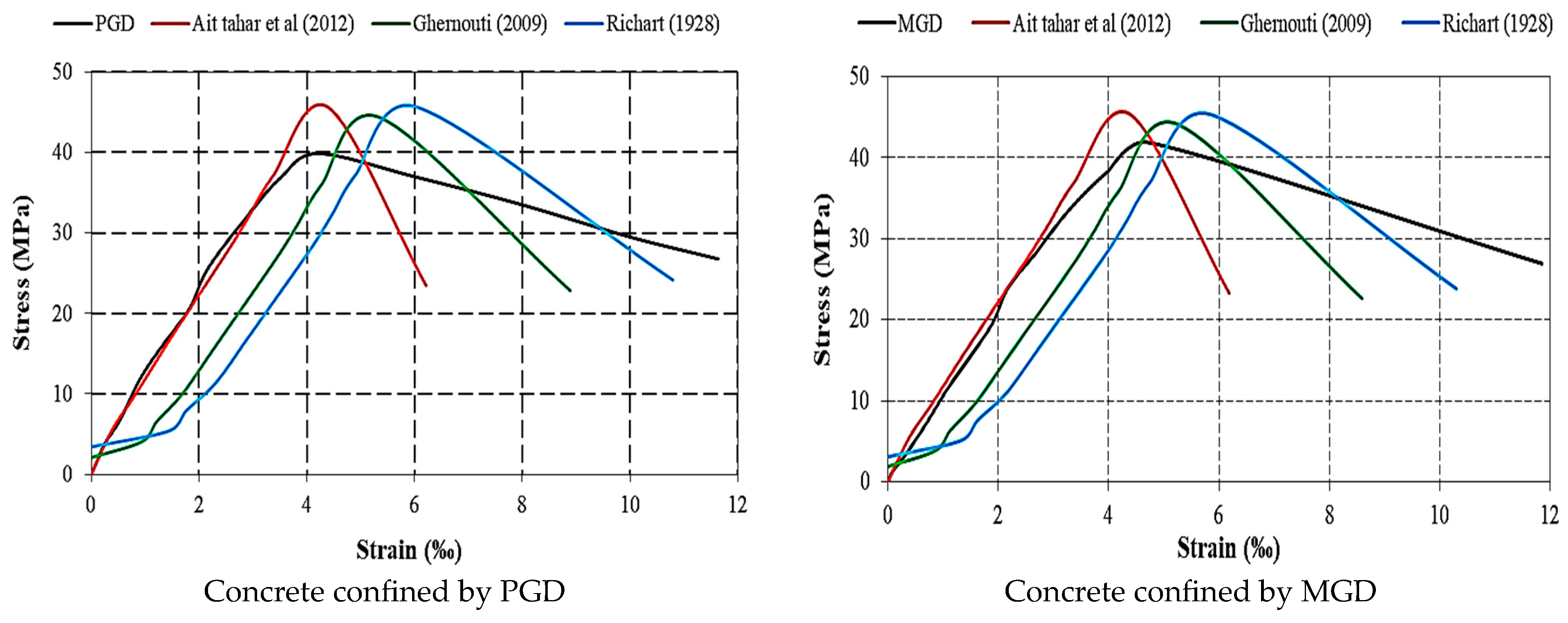

3.6. Comparison of Experimental and Analytical Confinement Models

4. Conclusions

- The ultimate compressive strength of SCC confined by different types of grids was almost closer to that of unconfined SCC. The only exception was SCC reinforced with alfa fiber grids (VGAF-2), where the resistance was slightly higher (42.57 vs. 42.25 MPa). It is therefore possible to improve the bearing capacity of SCC by incorporating grids of alfa fibers with a size of 20 × 20 mm (VGAF-2).

- Using reinforcement grids with different types and geometries resulted in SCC with better ductility than the reference SCC mixture. For example, in SCC confined by PGD and PGR, there was an improvement in ductility, of about 96.45% and 32.77%, respectively. The specimens confined by MGD and MGS presented a significant increase in ductility, of about 100.33% and 85.13%, respectively. For SCC confined by vegetable grids (VGAF-1, VGAF-2, and VGPF), there was an improvement in the ductility, of approximately 16.89%, 78.37%, and 33.78%, respectively.

- Mechanical behavior is largely influenced by the properties of the grid and the mesh shape. From the perspective of bearing capacity and ductility, the best performances occurred in SCC confined by a diamond grid shape.

- The grid thickness, an often-overlooked parameter, exerts a pronounced influence on the effectiveness of the strengthening regimen. The high thickness of the grid influences the concrete–grid interface area and the concrete cover, which leads to poor adhesion, resulting in lowering mechanical performance.

- Vegetable grids of alfa fibers with a large mesh (20 × 20 mm) offered better adhesion between concrete and grid than mesh with smaller sizes (10 × 10 mm), thus resulting in superior strength and ductility.

- The rigidity was not affected by the type of grid materials because the modulus of elasticity of all types confined SCC studied was almost the same as that of unconfined SCC, with the exception of PGD confined SCC, which developed a superior elasticity modulus (13.74 GPa) compared to unconfined SCC (10.15 GPa).

- Among the models that were selected, it was found that the Richart et al. [47] model provides good agreement between the experimental and analytical results in terms of the overall behavior.

- The technique of lateral confinement may be used in the rehabilitation, strengthening, and reinforcement of weaker concrete structural members subjected to excessive axial loads, like columns, to enhance the mechanical properties of concrete and prevent sudden failure and therefore improve the service life of building structures. These innovative materials have found new applications in the rehabilitation, strengthening, and confinement of reinforced concrete members.

5. Recommendations for Future Research

- More research on the effect of grid mesh size on the mechanical behavior of SCC should be conducted.

- Investigation regarding the adhesion between cement matrix and grids should be conducted using SEM.

- Investigation of the economic feasibility of using various types of grids in SCC should be carried out.

- The effect of eccentric and cyclic load on the mechanical properties of concrete should also be examined.

- To better understand the mechanical behavior of cylinders confined using the proposed technique, it is necessary to test columns on a real scale.

- Future work should validate the results obtained using the finite elements method.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Kheetan, M.J.; Al-Tarawneh, M.; Ghaffar, S.H.; Chougan, M.; Jweihan, Y.S.; Rahman, M.M. Resistance of hydrophobic concrete with different moisture contents to advanced freeze–thaw cycles. Struct. Concr. 2020, 22, E1050–E1061. [Google Scholar] [CrossRef]

- Ghernouti, Y.; Rabehi, B.; Benhamna, A.; Mostefa, A.H. Strengthening of concrete beams by CFRP: Experimental study and finite element analysis. J. Build. Mater. Struct. 2014, 1, 47–57. [Google Scholar] [CrossRef]

- Ghernouti, Y. Design and Mechanical Analysis of Confinement of Cylindrical Concrete Elements with Mixed Reinforcements. Ph.D. Thesis, University of Boumerdes, Boumerdes, Algeria, 2009; p. 177. (In French). [Google Scholar]

- Li, W.; Li, W.; Lu, Y.; Hu, B.; Zhou, Y.; Wu, H.; Wang, P.; Ke, L.; Yu, J. Axial compressive behavior and failure mechanism of CFRP partially confined ultra-high performance concrete (UHPC). Constr. Build. Mater. 2024, 426, 136104. [Google Scholar] [CrossRef]

- Ancheeswari, M.; Jegan, J. Improvement on axial compressive strength of concrete cylinders using BFRP composites. J. Struct. Eng. 2018, 44, 545–551. [Google Scholar]

- Bouamra, Y.; Tahar, K.A. Mechanical performance of a confined reinforced concrete beam. Procedia Struct. Integr. 2017, 5, 155–162. [Google Scholar] [CrossRef]

- Daou, A.; Chehab, G.; Saad, G.; Hamad, B. Experimental and numerical investigations of reinforced concrete columns confined internally with biaxial geogrids. Constr. Build. Mater. 2020, 263, 120115. [Google Scholar] [CrossRef]

- Bastami, M.; Mousavi, A.E.; Abbasnejadfard, M. Evaluation of mechanical characteristics of high-strength reinforced concrete columns with hexagonal chicken wire mesh under cyclic loading. Int. J. Concr. Struct. Mater. 2022, 16, 1–14. [Google Scholar] [CrossRef]

- Donnini, J.; Spagnuolo, S.; Corinaldesi, V. A comparison between the use of FRP, FRCM and HPM for concrete confinement. Compos. Part B Eng. 2019, 160, 586–594. [Google Scholar] [CrossRef]

- Miyauchi, K.; Inoue, S.; Kuroda, T.; Kobayashi, A. Strengthening effects with carbon fiber sheet for concrete column. Proc. Jpn. Concr. Inst. 1999, 21, 1453–1458. (In Japanese) [Google Scholar]

- Ali Ahmed, C.; Ait Tahar, K. Behavior of concrete cylinder confined with helical composites Strips. Procedia Eng. 2015, 114, 157–164. [Google Scholar] [CrossRef]

- Chin, C.-L.; Ma, C.-K.; Tan, J.-Y.; Ong, C.-B.; Awang, A.Z.; Omar, W. Review on development of external steel-confined concrete. Constr. Build. Mater. 2019, 211, 919–931. [Google Scholar] [CrossRef]

- Desprez, C.; Mazars, J.; Kotronis, P.; Paultre, P.; Roy, N.; B-Trudeau, M. Cyclic model of concrete confined by TFC For circular reinforced concrete columns. In Proceedings of the 19th French Congress of Mechanics, Marseille, France, 24–28 August 2009. (In French). [Google Scholar]

- Xavier, R.; Mukilan, K. Experimental and numerical investigation of geosynthetic reinforced concrete structure. Int. J. Civ. Eng. 2024, 11, 145–152. [Google Scholar]

- Hadi, M.N.S.; Pham, T.M.; Lei, X. New method of strengthening reinforced concrete square columns by circularizing and wrapping with fiber-reinforced polymer or steel straps. J. Compos. Constr. 2013, 17, 229–238. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Zhao, H. Experimental study of high-strength concrete columns confined with different types of mesh under eccentric and concentric loads. J. Mater. Civ. Eng. 2011, 23, 823–832. [Google Scholar] [CrossRef]

- Saafi, M. Design and fabrication of FRP grids for aerospace and civil engineering applications. J. Aerosp. Eng. 2000, 13, 144–149. [Google Scholar] [CrossRef]

- Michael, A.P.; Hamilton, H.R., III; Ansley, M.H. Concrete confinement using carbon fibre reinforced polymer grid. ACI Spec. Publ. 2005, 230, 991–1010. [Google Scholar]

- Wu, G.; Wu, Z.S.; Luo, Y.B.; Jiang, J.B. Aseismic performance of circular concrete columns confined with FRP grids. J. Archit. Civil. Eng. 2007, 24, 39–44. (In Chinese) [Google Scholar]

- Choi, E.; Kim, J.-W.; Rhee, I.; Kang, J.-W. Behavior and modeling of confined concrete cylinders in axial compression using FRP rings. Compos. Part B Eng. 2014, 58, 175–184. [Google Scholar] [CrossRef]

- Heo, Y.-S.; Sanjayan, J.G.; Han, C.-G.; Han, M.-C. Construction application of Fibre/Mesh method for protecting concrete columns in fire. Constr. Build. Mater. 2011, 25, 2928–2938. [Google Scholar] [CrossRef]

- Lignola, G.P.; Prota, A.; Manfredi, G.; Cosenza, E. Nonlinear modeling of RC hollow piers confined with CFRP. Compos Struct. 2009, 88, 56–64. [Google Scholar] [CrossRef]

- Dai, J.-G.; Bai, Y.-L.; Teng, J.G. Behavior and modeling of concrete confined with FRP composites of large deformability. J. Compos. Constr. 2011, 15, 963–973. [Google Scholar] [CrossRef]

- Peled, A. Confinement of damaged and nondamaged structural concrete with FRP and TRC sleeves. J. Compos. Constr. 2007, 11, 514–522. [Google Scholar] [CrossRef]

- Rousakis, T.C. Hybrid confinement of concrete by fiber-reinforced polymer sheets and fiber ropes under cyclic axial compressive loading. J. Compos. Constr. 2013, 17, 732–743. [Google Scholar] [CrossRef]

- Rousakis, T.C. Elastic fiber ropes of ultrahigh-extension capacity in strengthening of concrete through confinement. J. Mater. Civ. Eng. 2014, 26, 34–44. [Google Scholar] [CrossRef]

- Paramasivam, P.; Ong, K.; Lim, C. Ferrocement laminates for strengthening RC T-beams. Cem. Concr. Compos. 1994, 16, 143–152. [Google Scholar] [CrossRef]

- Nassif, H.H.; Najm, H. Experimental and analytical investigation of ferrocement–concrete composite beams. Cem. Concr. Compos. 2004, 26, 787–796. [Google Scholar] [CrossRef]

- Abdullah, T.K. Shear strengthening of reinforced concrete columns using ferrocement jacket. Struct. J. 2001, 98, 696–704. [Google Scholar]

- Kumar, P.R.; Oshima, T.; Mikami, S.H.; Yamazaki, T. Studies on RC and ferrocement jacketed columns subjected to simulated seismic loading. Asian J. Civ. Eng. (Build. Hous.) 2007, 8, 215–225. [Google Scholar]

- Bansal, P.P.; Kumar, M.; Kaushik, S.K. Effect of wire mesh orientation on strength of beams retrofitted using Ferrocement jackets. Int. J. Eng. 2008, 2, 8–19. [Google Scholar]

- Makki, R.F. Response of reinforced concrete beams retrofitted by ferrocement. Int. J. Sci. Technol. Res. 2014, 3, 27–34. [Google Scholar]

- Bentayeb, F.; Tahar, K.A.; Chateauneuf, A. New technique for reinforcement of concrete columns confined by embedded composite grid. Constr. Build. Mater. 2008, 22, 1624–1633. [Google Scholar] [CrossRef]

- Ait tahar, K.; Bahar, R. Influence of the dimensions of the mesh of the fiber grid reinforcement of composite materials. Key Eng. Mater. 2013, 550, 9–16. [Google Scholar] [CrossRef]

- Boukhelkhal, A.; Azzouz, L.; Belaïdi, A.S.E.; Benabed, B. Effects of marble powder as a partial replacement of cement on some engineering properties of self-compacting concrete. J. Adhes. Sci. Technol. 2016, 30, 2405–2419. [Google Scholar] [CrossRef]

- Boukhelkhal, A.; Azzouz, L.; Benabed, B.; Belaïdi, A.S.E. Strength and durability of low-impact environmental self-compacting concrete incorporating waste marble powder. J. Build. Mater. Struct. 2017, 4, 31–41. [Google Scholar] [CrossRef]

- EFNARC. Specification and Guidelines for Self-Compacting Concrete; European Federation of Producers and Applicators of Specialist Products for Structures, EFNARC: Norfolk, VA, USA, 2005; p. 32. [Google Scholar]

- NF EN 12390; Testing Hardened Concrete Part 3: Compressive Strength of Test Specimens. AFNOR: Paris, France, 2019.

- Baron, J. Resistance to Crack Propagation: Hydraulic Concrete; ENPC: Paris, France, 1982. [Google Scholar]

- Gorisse, F. Concrete Testing and Control; Edition Eyrolles: Paris, France, 1978. (In French) [Google Scholar]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Pearson Education Inc.: London, UK, 2003. [Google Scholar]

- Thermou, G.E.; Katakalos, K.; Manos, G. Concrete confinement with steel-reinforced grout jackets. Mater. Struct. 2014, 48, 1355–1376. [Google Scholar] [CrossRef]

- Binici, B. An analytical model for stress–strain behavior of confined concrete. Eng. Struct. 2005, 27, 1040–1051. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Marwan, N.Y.; Maria, Q.F.; Ayman, S.M. Stress-strain model for concrete confined by FRP composites. Composites Part B Eng. 2007, 38, 614–628. [Google Scholar]

- Harajli, M.H. Axial stress–strain relationship for FRP confined circular and rectangular concrete columns. Cem. Concr. Compos. 2006, 28, 938–948. [Google Scholar] [CrossRef]

- Richart, F.; Brandtzaeg, A.; Brown, R.L. A Study of the Failure of Concrete Under Combined Compressive Stresses; University of Illinois, Engineering Experimental Station: Urbana, IL, USA, 1928; Bulletin N° 185, 104. [Google Scholar]

- Ghernouti, Y.; Ait Tahar, K. Multiple confinements of concrete columns by various embedded composite grids. J. Reinf. Plast. Compos. 2009, 28, 1495–1507. [Google Scholar] [CrossRef]

- Tahar, K.A.; Taouche, F.; Bouamra, Y. Parametric Analysis of the models of confinement of the concrete column. Key Eng. Mater. 2012, 498, 1–14. [Google Scholar] [CrossRef]

- Fardis, M.N.; Khalili, H.H. FRP-encased concrete as a structural material. Mag. Concr. Res. 1982, 34, 191–202. [Google Scholar] [CrossRef]

- Karbhari, V.; Eckel, D.; Tunis, G. Strengthening of Concrete Column Stubs through Resin Infused Composite Wraps. J. Thermoplast. Compos. Mater. 1993, 6, 92–107. [Google Scholar] [CrossRef]

- Saafi, M.; Toutanji, A.H.; Li, Z. Behaviour of Concrete Columns Confined with Fibre Reinforced Polymer Tubes. ACI Mater. J. 1999, 96, 500–509. [Google Scholar]

| Chemical Composition | Physical Properties | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Element (%) | SiO2 | CaO | MgO | Al2O3 | Fe2O3 | SO3 | K2O | TiO2 | Na2O | P2O5 | Loss Ignition | Specific Density | Fineness (cm2/g) |

| Cement | 20.14 | 63.47 | 2.12 | 3.71 | 4.74 | 2.67 | 0.47 | 0.21 | 0.69 | 0.06 | 1.72 | 3.1 | 3300 |

| MP | 0.42 | 56.01 | 0.12 | 0.13 | 0.06 | 0.01 | 0.01 | 0.01 | 0.43 | 0.03 | 42.78 | 2.7 | 3600 |

| Aggregate | Sand 0/5 | Gravel 3/8 | Gravel 8/15 |

|---|---|---|---|

| Absorption coefficient (%) | 1.16 | 4.85 | 3.48 |

| Specific density | 2.47 | 2.5 | 2.5 |

| Bulk density | 1.51 | 1.29 | 1.24 |

| Property coefficient (%) | 90.28 | - | - |

| Fineness modulus | 1.85 | - | - |

| Grid Properties | Photos |

|---|---|

| Plastic grids of triangular mesh (PGT) Dimensions of mesh: 5 × 5 × 5 mm Thickness: 5 mm Weight: 3037.26 g/m2 Number of meshes: 44,627 mesh/m2 Breaking load: 20 N Strain at rupture: 1.24 mm/mm Modulus of elasticity: 2 MPa |  |

| Plastic grids of diamond mesh (PGD) Dimensions of mesh: 3 × 3 mm Thickness: 2 mm Weight: 331.5 g/m2 Number of meshes: 35,420 mesh/m2 Breaking load: 50 N Modulus of elasticity: 10 MPa |  |

| Plastic grids of rectangular mesh (PGR) Dimensions of mesh: 3 × 2 mm Thickness: 0.5 mm Weight: 331.5 g/m2 Number of meshes: 131,794 mesh/m2 Breaking load: 8 N Strain at rupture: 0.875 mm/mm Modulus of elasticity: 86 MPa |  |

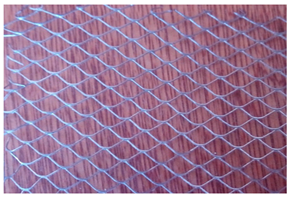

| Metallic grids of diamond mesh (MGD) Dimensions of mesh: 5 × 5 mm Thickness: 1 mm Weight: 407.5 g/m2 Number of meshes: 16,000 mesh/m2 Breaking load: 90 N Strain at rupture: 0.123 mm/mm Modulus of elasticity: 71 MPa |  |

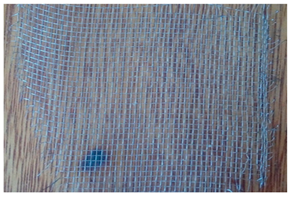

| Metallic grids of square mesh (MGS) Dimensions of mesh: 1.5 × 1.5 mm Thickness: 0.5 mm Weight: 355.5 g/m2 Number of meshes: 376,584 mesh/m2 Breaking load: 100 N Strain at rupture: 0.384 mm/mm Modulus of elasticity: 47 MPa |  |

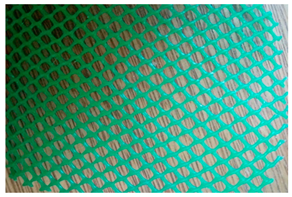

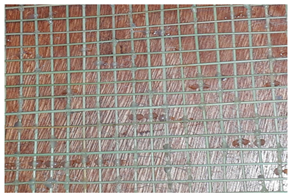

| Vegetable grids of alfa fibers (VGAF-1) Square mesh Dimensions of mesh: 10 × 10 mm Thickness: 3 mm Weight: 248 g/m2 Number (mesh): 9801 mesh/m2 |  |

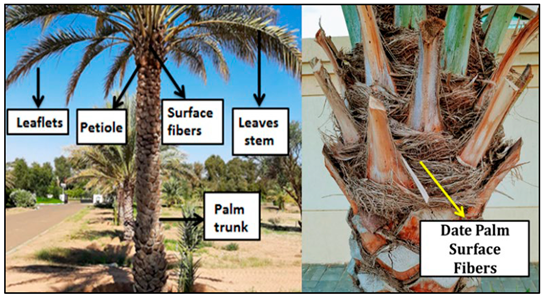

| Vegetable grids of alfa fibers (VGAF-2) Square mesh Dimensions of mesh: 20 × 20 mm Thickness: 3 mm Weight: 124 g/m2 Number (mesh): 2451 mesh/m2 |  Illustration of alfa fibers (Stipa Tenacissima) |

| |

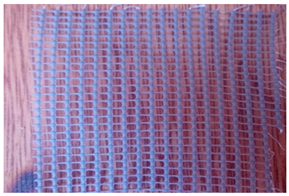

| Vegetable grids of date palm fibers (VGPF) Tissue mesh Thickness: 4 mm Weight: 347.13 g/m2 Breaking load: 72 N Strain at rupture: 0.024 mm/mm Modulus of elasticity: 67 MPa |  |

Illustration of date palm fibers | |

| Materials | Weight (kg) | Test on Fresh SCC | Result | Class (EFNARC) [37] | Limit Values |

|---|---|---|---|---|---|

| OPC | 412.54 | Slump flow diameter (mm) | 760 | SFR3 | 760–850 |

| Marble powder | 39.92 | V-funnel flow time (s) | 9 | VS2/VF2 | 9–25 |

| Sand 0/5 | 803.20 | L-box blocking ratio (%) | 83 | PA2 | >80 |

| Gravel 8/15 | 534.08 | Segregation index (%) | 10 | SR2 | <15 |

| Gravel 3/8 | 263.25 | ||||

| Water | 220.39 | ||||

| Superplasticizer | 4.07 | ||||

| Water/binder (w/b) | 0.4 |

| Strength Gain (%) | Ductility Gain (%) | Modulus of Elasticity E (GPa) | ||

|---|---|---|---|---|

| Unconfined concrete | --- | --- | 10.14 | |

| Confined concrete | ||||

| Plastic grids | PGT | −25.96 | −4.89 | 10.79 |

| PGD | −5.63 | 96.45 | 13.74 | |

| PGR | −18.41 | 32.77 | 10.32 | |

| Metal grids | MGD | −0.92 | 100.33 | 11.20 |

| MGS | −24.85 | 85.13 | 10.74 | |

| Vegetable grids | VGAF-1 (Alfa) | −10.67 | 16.89 | 9.82 |

| VGAF-2 (Alfa) | 0.75 | 78.37 | 11.64 | |

| VGPF (palm) | −14.31 | 33.78 | 11.27 | |

| Reference | Concrete Strength | Concrete Strain |

|---|---|---|

| Richart et al. [47] | ||

| Ghernouti [48] | = 2.5 | |

| Ait tahar et al. [49] | ||

| Fardis and Khalili [50] | ||

| Karbahari and Eckel [51] | ||

| Saafi et al. [52] |

| Parameters of Model | Experimental Value | Ait tahar et al. [49] | Ghernouti [48] | Richart et al. [47] |

|---|---|---|---|---|

| K | / | / | 2.5 | 4.1 |

| (MPa) | 42.25 | / | / | / |

| Analytical value | ||||

| PGD | ||||

| (MPa) | 39.87 | 45.57 | 44.33 | 45.66 |

| (‰) | 4.19 | 4.41 | 5.36 | 6.04 |

| (MPa) | 26.78 | 23.48 | 22.84 | 24.17 |

| (‰) | 11.63 | 6.21 | 8.89 | 10.79 |

| MGD | ||||

| (MPa) | 41.86 | 45.33 | 44.12 | 45.32 |

| (‰) | 4.75 | 4.39 | 5.25 | 5.86 |

| (MPa) | 26.93 | 23.28 | 22.63 | 23.83 |

| (‰) | 11.86 | 6.18 | 8.59 | 10.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boukhelkhal, A.; Benabed, B.; Abousnina, R.; Vimonsatit, V. Behavior of Self-Compacting Concrete Cylinders Internally Confined with Various Types of Composite Grids. Buildings 2025, 15, 1286. https://doi.org/10.3390/buildings15081286

Boukhelkhal A, Benabed B, Abousnina R, Vimonsatit V. Behavior of Self-Compacting Concrete Cylinders Internally Confined with Various Types of Composite Grids. Buildings. 2025; 15(8):1286. https://doi.org/10.3390/buildings15081286

Chicago/Turabian StyleBoukhelkhal, Aboubakeur, Benchaa Benabed, Rajab Abousnina, and Vanissorn Vimonsatit. 2025. "Behavior of Self-Compacting Concrete Cylinders Internally Confined with Various Types of Composite Grids" Buildings 15, no. 8: 1286. https://doi.org/10.3390/buildings15081286

APA StyleBoukhelkhal, A., Benabed, B., Abousnina, R., & Vimonsatit, V. (2025). Behavior of Self-Compacting Concrete Cylinders Internally Confined with Various Types of Composite Grids. Buildings, 15(8), 1286. https://doi.org/10.3390/buildings15081286