Cost-Effectiveness of Reinforced Recycled Aggregate Concrete Structures with Fly Ash and Basalt Fibres Under Corrosion: A Life Cycle Cost Analysis

Abstract

1. Introduction

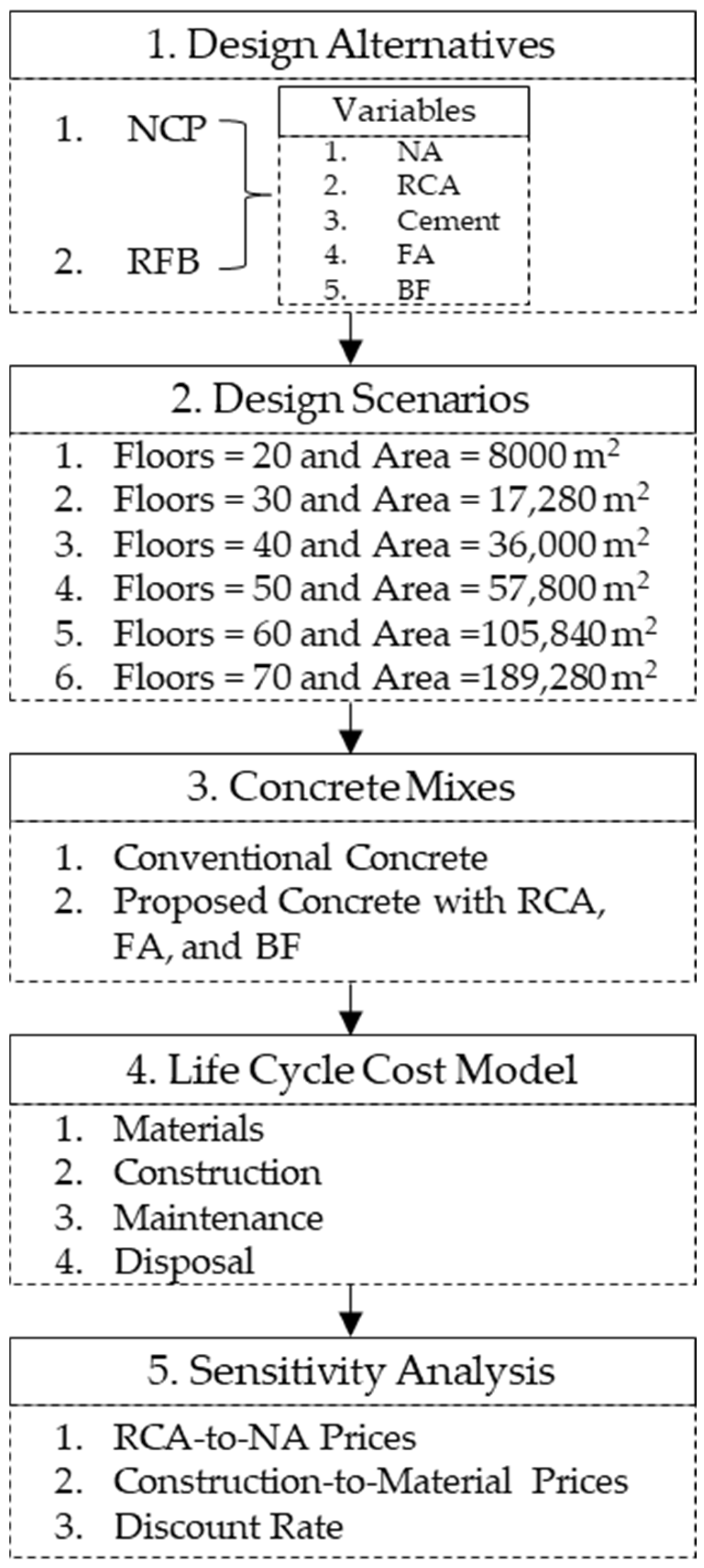

2. Materials and Methods

2.1. Design Alternatives

2.2. Design Scenarios

2.3. Concrete Mixes

- 1.

- RCA were characterised by high cracks and pores, which increased their water absorption, and, in turn, decreased the fresh slump of RAC [50]. To address this deficiency, both types of aggregates (NA and RCA) were planned to be immersed in water for 24 h to achieve a saturated surface dry condition. This ensures the uniformity of the water absorption of both aggregate types and reduces the loss of slump of RAC [51].

- 2.

- The use of 100% RCA and 20% FA was expected to reduce the compressive strength of concrete by 10% to 30% [4,51]. Nonetheless, Du et al. [52] and Zhang et al. [53] reported that the compressive strength of RAC was improved by about 23% and 61%, respectively, when 0.2% volume fractions of BF were added to RAC. Therefore, incorporating BF into RAC with FA mixes could offset the compressive strength loss due to RCA and FA.

- 3.

- The replacement of 20% of OPC with FA could improve the slump of fibre-reinforced concrete. Therefore, no additional superplasticisers would be needed to compensate for the slump loss due to the inclusion of BF.

- 4.

- The RCA were planned to be incorporated using the volume replacement method to ensure an equal volume of the concrete mixes of both alternatives. Accordingly, the difference in density between NA and RCA was considered in calculating the quantity of RCA for alternative RFB.

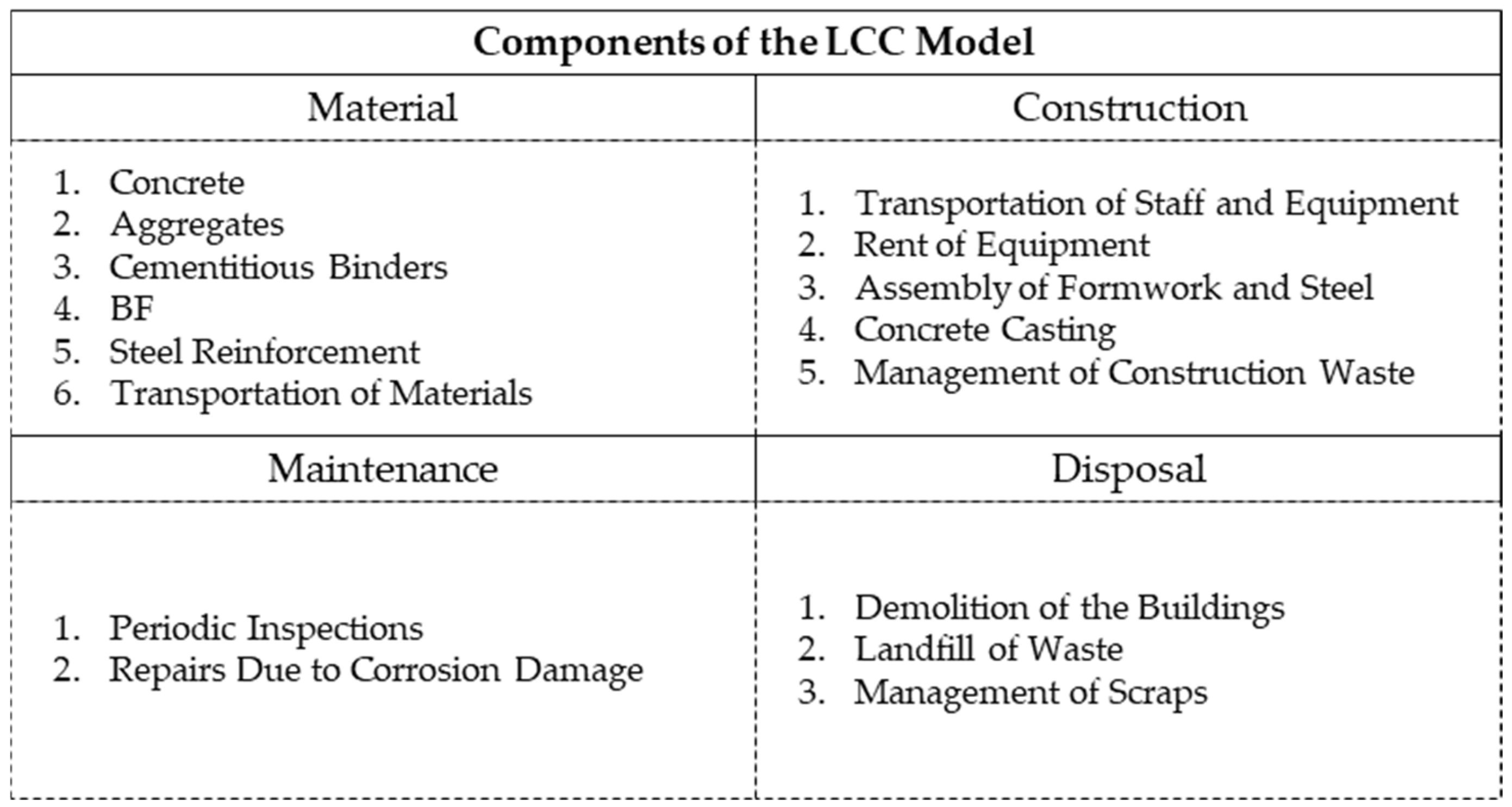

2.4. Life Cycle Cost Model

2.4.1. Materials

- 1.

- The price of concrete includes the costs for aggregates, sand, cement, and water.

- 2.

- The price of the steel bars includes the costs of bending activities.

- 3.

- The strength of the steel bars is assumed to be 420 MPa.

- 4.

- The type of cement used is Type I.

| Item | Cost | Reference |

|---|---|---|

| Concrete | 207 USD/m3 | * RSMeans [56] |

| Steel Bars | 1.31 USD/kg | RSMeans [56] |

| NA | 18.81 USD/tonne | Davis and McGinnis [57] |

| RCA | 14.09 USD/tonne | Davis and McGinnis [57] |

| Cement | 125.70 USD/tonne | Shwekat and Wu [58] |

| FA | 66.14 USD/tonne | Shwekat and Wu [58] |

| BF | 8.70 USD/kg | Local Supplier |

| Demolition | 158.03 USD/m3 of concrete | RSMeans [56] |

| Landfill | 0.12 USD/kg | RSMeans [56] |

| Resell of Steel Scrap | 0.249 USD/kg | RSMeans [56] |

2.4.2. Construction

2.4.3. Maintenance

2.4.4. Disposal

2.5. Calculations of the Life Cycle Cost

3. Results and Discussion

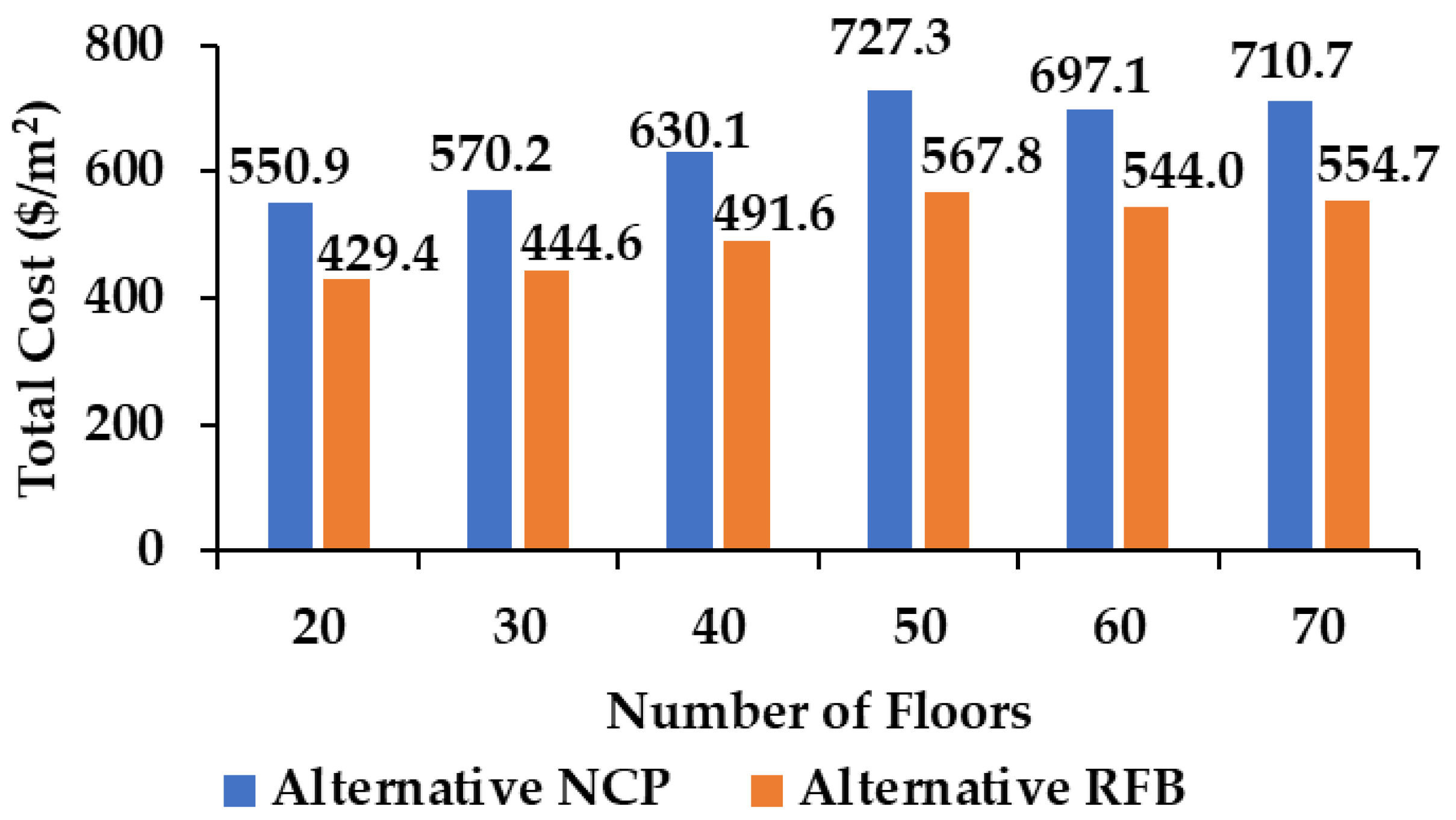

3.1. Effect of Concrete Mix and Number of Floors

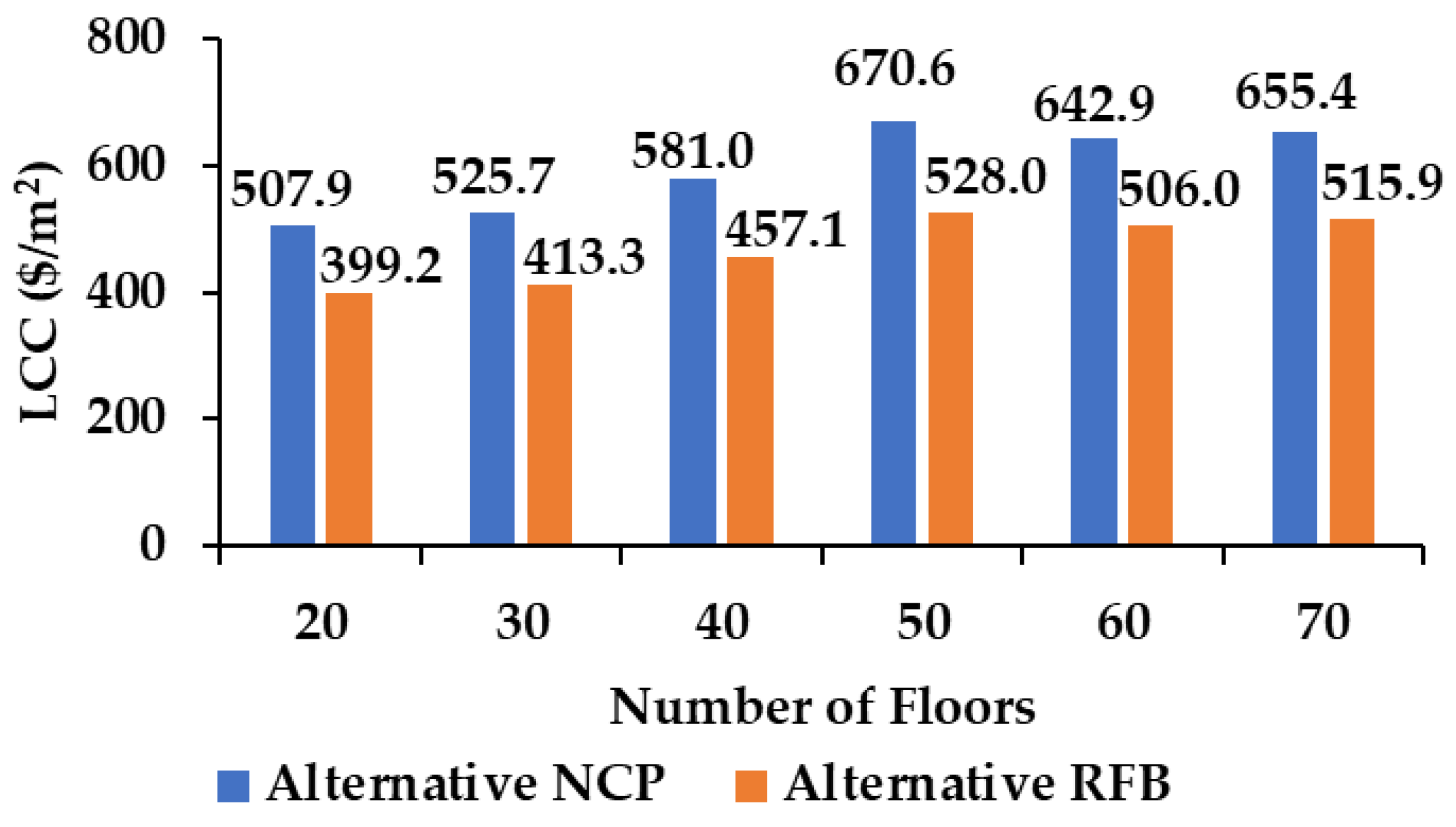

3.2. LCCA

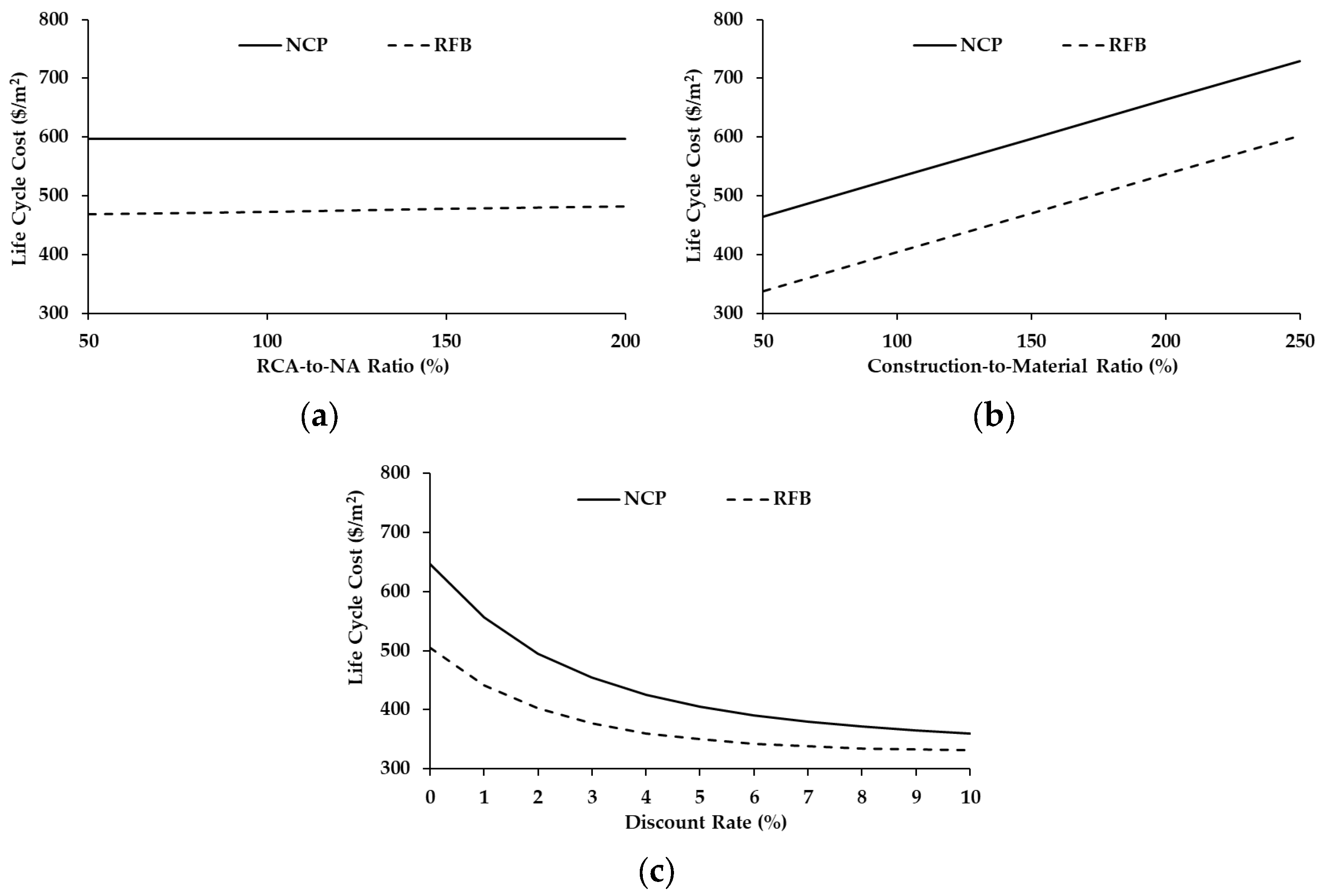

3.3. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| NA | Natural aggregates |

| RCA | Recycled concrete aggregates |

| RAC | Recycled aggregate concrete |

| FA | Fly ash |

| RC | Reinforced concrete |

| BF | Basalt fibres |

| LCCA | Life cycle cost analysis |

| LCC | Life cycle cost |

References

- Aprianti, S.E. A Huge Number of Artificial Waste Material Can Be Supplementary Cementitious Material (SCM) for Concrete Production—A Review Part II. J. Clean. Prod. 2017, 142, 4178–4194. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Abotaleb, I.S.; ElMenshawy, M. Life Cycle Cost Analysis of Lightweight Green Concrete Utilizing Recycled Plastic Aggregates. J. Build. Eng. 2021, 40, 102670. [Google Scholar] [CrossRef]

- Paldyna, J.; Krasnodebska-Ostrega, B.; Kregielewska, K.; Kowalska, J.; Jedynak, L.; Golimowski, J.; Grobelski, T.; Farbiszewska-Kiczma, J.; Farbiszewska, T. The Assessment of Environmental Pollution Caused by Mining and Metallurgy Wastes from Highly Polluted Post-Industrial Regions in Southern Poland. Environ. Earth Sci. 2013, 68, 439–450. [Google Scholar] [CrossRef][Green Version]

- Ali, B.; Qureshi, L.A.; Shah, S.H.A.; Rehman, S.U.; Hussain, I.; Iqbal, M. A Step towards Durable, Ductile and Sustainable Concrete: Simultaneous Incorporation of Recycled Aggregates, Glass Fiber and Fly Ash. Constr. Build. Mater. 2020, 251, 118980. [Google Scholar] [CrossRef]

- Huda, S.B.; Shahria Alam, M. Mechanical and Freeze-Thaw Durability Properties of Recycled Aggregate Concrete Made with Recycled Coarse Aggregate. J. Mater. Civ. Eng. 2015, 27, 04015003. [Google Scholar] [CrossRef]

- Wang, Y.; Hughes, P.; Niu, H.; Fan, Y. A New Method to Improve the Properties of Recycled Aggregate Concrete: Composite Addition of Basalt Fiber and Nano-Silica. J. Clean. Prod. 2019, 236, 117602. [Google Scholar] [CrossRef]

- Khan, S.A.; Jassim, M.; Ilcan, H.; Sahin, O.; Bayer, İ.R.; Sahmaran, M.; Koc, M. 3D Printing of Circular Materials: Comparative Environmental Analysis of Materials and Construction Techniques. Case Stud. Constr. Mater. 2023, 18, e02059. [Google Scholar] [CrossRef]

- Lv, H.; Xiong, Z.; Li, H.; Liu, J.; Xu, G.; Chen, H. Investigating the Mechanical Properties and Water Permeability of Recycled Pervious Concrete Using Three Typical Gradation Schemes. Buildings 2025, 15, 358. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of Incorporation of High Volume of Recycled Concrete Aggregates and Fly Ash on the Strength and Global Warming Potential of Concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Nawaz, M.; Aslam, H.M.U. Combined Influence of Fly Ash and Recycled Coarse Aggregates on Strength and Economic Performance of Concrete. Civ. Eng. J. 2019, 5, 832–844. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.; Agrela, F. Comparisons of Natural and Recycled Aggregate Concretes Prepared with the Addition of Different Mineral Admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Dilbas, H.; Şimşek, M.; Çakır, Ö. An Investigation on Mechanical and Physical Properties of Recycled Aggregate Concrete (RAC) with and without Silica Fume. Constr. Build. Mater. 2014, 61, 50–59. [Google Scholar] [CrossRef]

- Jaglan, A.; Singh, R.R. Recycled Aggregate Concrete Incorporating GGBS and Polypropylene Fibers Using RSM and Machine Learning Techniques. Buildings 2024, 15, 66. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water Absorption and Electrical Resistivity of Concrete with Recycled Concrete Aggregates and Fly Ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Faraj, R.H.; Sherwani, A.F.H.; Daraei, A. Mechanical, Fracture and Durability Properties of Self-Compacting High Strength Concrete Containing Recycled Polypropylene Plastic Particles. J. Build. Eng. 2019, 25, 100808. [Google Scholar] [CrossRef]

- Hefni, Y.; El Zaher, Y.A.; Wahab, M.A. Influence of Activation of Fly Ash on the Mechanical Properties of Concrete. Constr. Build. Mater. 2018, 172, 728–734. [Google Scholar] [CrossRef]

- Jiménez, C.; Barra, M.; Josa, A.; Valls, S. LCA of Recycled and Conventional Concretes Designed Using the Equivalent Mortar Volume and Classic Methods. Constr. Build. Mater. 2015, 84, 245–252. [Google Scholar] [CrossRef]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental Evaluation of Green Concretes versus Conventional Concrete by Means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef]

- Sabău, M.; Bompa, D.V.; Silva, L.F.O. Comparative Carbon Emission Assessments of Recycled and Natural Aggregate Concrete: Environmental Influence of Cement Content. Geosci. Front. 2021, 12, 101235. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Influence of Recycled Aggregates and High Contents of Fly Ash on Concrete Fresh Properties. Cem. Concr. Compos. 2017, 84, 198–213. [Google Scholar] [CrossRef]

- Nawaz, M.A.; Qureshi, L.A.; Ali, B.; Raza, A. Mechanical, Durability and Economic Performance of Concrete Incorporating Fly Ash and Recycled Aggregates. SN Appl. Sci. 2020, 2, 162. [Google Scholar] [CrossRef]

- Abushanab, A.; Alnahhal, W. Life Cycle Cost Analysis of Sustainable Reinforced Concrete Buildings with Treated Wastewater, Recycled Concrete Aggregates, and Fly Ash. Results Eng. 2023, 20, 101565. [Google Scholar] [CrossRef]

- Abd El Fattah, A.; Al-Duais, I.; Riding, K.; Thomas, M. Field Evaluation of Corrosion Mitigation on Reinforced Concrete in Marine Exposure Conditions. Constr. Build. Mater. 2018, 165, 663–674. [Google Scholar] [CrossRef]

- Abushanab, A.; Alnahhal, W. Bond Strength of Corroded Reinforced Recycled Aggregate Concrete with Treated Wastewater and Fly Ash. J. Build. Eng. 2023, 79, 107778. [Google Scholar] [CrossRef]

- Ali, B.; Raza, S.S.; Kurda, R.; Alyousef, R. Synergistic Effects of Fly Ash and Hooked Steel Fibers on Strength and Durability Properties of High Strength Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 168, 105444. [Google Scholar] [CrossRef]

- Qureshi, L.A.; Ali, B.; Ali, A. Combined Effects of Supplementary Cementitious Materials (Silica Fume, GGBS, Fly Ash and Rice Husk Ash) and Steel Fiber on the Hardened Properties of Recycled Aggregate Concrete. Constr. Build. Mater. 2020, 263, 120636. [Google Scholar] [CrossRef]

- Dong, C.; Zhang, Q.; Chen, C.; Jiang, T.; Guo, Z.; Liu, Y.; Lin, S. Fresh and Hardened Properties of Recycled Plastic Fiber Reinforced Self-Compacting Concrete Made with Recycled Concrete Aggregate and Fly Ash, Slag, Silica Fume. J. Build. Eng. 2022, 62, 105384. [Google Scholar] [CrossRef]

- El-Hassan, H.; Hussein, A.; Medljy, J.; El-Maaddawy, T. Performance of Steel Fiber-Reinforced Alkali-Activated Slag-Fly Ash Blended Concrete Incorporating Recycled Concrete Aggregates and Dune Sand. Buildings 2021, 11, 327. [Google Scholar] [CrossRef]

- Sohail, M.G.; Alnahhal, W.; Taha, A.; Abdelaal, K. Sustainable Alternative Aggregates: Characterization and Influence on Mechanical Behavior of Basalt Fiber Reinforced Concrete. Constr. Build. Mater. 2020, 255, 119365. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the Mechanical Properties of Recycled Concrete Aggregate Using Chopped Basalt Fibers and Acid Treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Dong, J.F.; Wang, Q.Y.; Guan, Z.W. Material Properties of Basalt Fibre Reinforced Concrete Made with Recycled Earthquake Waste. Constr. Build. Mater. 2017, 130, 241–251. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; He, Y.; Huang, G.; Li, J.; Niu, Z.; Gao, B. A Review on Durability of Basalt Fiber Reinforced Concrete. Compos. Sci. Technol. 2022, 225, 109519. [Google Scholar] [CrossRef]

- ISO 15686-5: 2017; Buildings and Constructed Assets–Service-Life Planning–Part 5: Life-Cycle Costing. International Organization for Standardization: Geneva, Switzerland, 2017.

- Tam, V.W.Y.; Tam, C.M. Economic Comparison of Recycling Over-Ordered Fresh Concrete: A Case Study Approach. Resour. Conserv. Recycl. 2007, 52, 208–218. [Google Scholar] [CrossRef]

- Makul, N. Cost-Benefit Analysis of the Production of Ready-Mixed High-Performance Concrete Made with Recycled Concrete Aggregate: A Case Study in Thailand. Heliyon 2020, 6, e04135. [Google Scholar] [CrossRef]

- Ohemeng, E.A.; Ekolu, S.O. Comparative Analysis on Costs and Benefits of Producing Natural and Recycled Concrete Aggregates: A South African Case Study. Case Stud. Constr. Mater. 2020, 13, e00450. [Google Scholar] [CrossRef]

- Panesar, D.K.; Kanraj, D.; Abualrous, Y. Effect of Transportation of Fly Ash: Life Cycle Assessment and Life Cycle Cost Analysis of Concrete. Cem. Concr. Compos. 2019, 99, 214–224. [Google Scholar] [CrossRef]

- Shin, B.; Kim, S. CO2 Emission and Construction Cost Reduction Effect in Cases of Recycled Aggregate Utilized for Nonstructural Building Materials in South Korea. J. Clean. Prod. 2022, 360, 131962. [Google Scholar] [CrossRef]

- Jamora, J.B.; Gudia, S.E.L.; Go, A.W.; Giduquio, M.B.; Loretero, M.E. Potential CO2 Reduction and Cost Evaluation in Use and Transport of Coal Ash as Cement Replacement: A Case in the Philippines. Waste Manag. 2020, 103, 137–145. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. CONCRETop Method: Optimization of Concrete with Various Incorporation Ratios of Fly Ash and Recycled Aggregates in Terms of Quality Performance and Life-Cycle Cost and Environmental Impacts. J. Clean. Prod. 2019, 226, 642–657. [Google Scholar] [CrossRef]

- Reiner, M.; Rens, K. High-Volume Fly Ash Concrete: Analysis and Application. Pract. Period. Struct. Des. Constr. 2006, 11, 58–64. [Google Scholar] [CrossRef]

- Yang, W.; Huang, Y.; Li, C.; Tang, Z.; Quan, W.; Xiong, X.; He, J.; Wu, W. Damage Prediction and Long-Term Cost Performance Analysis of Glass Fiber Recycled Concrete under Freeze-Thaw Cycles. Case Stud. Constr. Mater. 2024, 21, e03795. [Google Scholar] [CrossRef]

- Younis, A.; Ebead, U.; Judd, S. Life Cycle Cost Analysis of Structural Concrete Using Seawater, Recycled Concrete Aggregate, and GFRP Reinforcement. Constr. Build. Mater. 2018, 175, 152–160. [Google Scholar] [CrossRef]

- Asadi, A.; Baaij, F.; Mainka, H.; Rademacher, M.; Thompson, J.; Kalaitzidou, K. Basalt Fibers as a Sustainable and Cost-Effective Alternative to Glass Fibers in Sheet Molding Compound (SMC). Compos. Part B Eng. 2017, 123, 210–218. [Google Scholar] [CrossRef]

- Lu, L. Optimal Replacement Ratio of Recycled Concrete Aggregate Balancing Mechanical Performance with Sustainability: A Review. Buildings 2024, 14, 2204. [Google Scholar] [CrossRef]

- Yang, W.; Liu, L.; Wu, W.; Zhang, K.; Xiong, X.; Li, C.; Huang, Y.; Zhang, X.; Zhou, H. A Review of the Mechanical Properties and Durability of Basalt Fiber Recycled Concrete. Constr. Build. Mater. 2024, 412, 134882. [Google Scholar] [CrossRef]

- Bekdaş, G.; Nigdeli, S.M.; Yang, X.-S. Optimum Reinforced Concrete Design by Harmony Search Algorithm; Yang, X.-S., Bekdaş, G., Nigdeli, S.M., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 165–180. ISBN 978-3-319-26245-1. [Google Scholar]

- Foraboschi, P.; Mercanzin, M.; Trabucco, D. Sustainable Structural Design of Tall Buildings Based on Embodied Energy. Energy Build. 2014, 68, 254–269. [Google Scholar] [CrossRef]

- EN 1991-1-4; Eurocode 1: Actions on Structures–Part 1-4: General Actions—Wind Actions. European Standards: Brussels, Belgium, 1991.

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled Aggregate from C&D Waste & Its Use in Concrete—A Breakthrough towards Sustainability in Construction Sector: A Review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Abushanab, A.; Alnahhal, W. Performance of Sustainable Concrete Incorporating Treated Domestic Wastewater, RCA, and Fly Ash. Constr. Build. Mater. 2022, 329, 127118. [Google Scholar] [CrossRef]

- Du, X.; Li, Y.; Si, Z.; Huang, L.; Chen, X. Effects of Basalt Fiber and Polyvinyl Alcohol Fiber on the Properties of Recycled Aggregate Concrete and Optimization of Fiber Contents. Constr. Build. Mater. 2022, 340, 127646. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhuo, J.; Zhang, P.; Ma, M. Mechanical Properties and Meso-Microscopic Mechanism of Basalt Fiber-Reinforced Recycled Aggregate Concrete. J. Clean. Prod. 2022, 370, 133555. [Google Scholar] [CrossRef]

- Coinnews Media Group LLC U.S. Inflation Calculator: Current Inflation Rates from 2000 to 2023. Available online: https://www.usinflationcalculator.com/inflation/current-inflation-rates/ (accessed on 27 January 2025).

- Paranhos, R.S.; Cazacliu, B.G.; Sampaio, C.H.; Petter, C.O.; Neto, R.O.; Huchet, F. A Sorting Method to Value Recycled Concrete. J. Clean. Prod. 2016, 112, 2249–2258. [Google Scholar] [CrossRef]

- RSMeans Construction and Cost Estimating Data. Available online: https://www.rsmeans.com/ (accessed on 25 January 2025).

- Davis, M.; McGinnis, M.; Kurama, Y.C. Use of Recycled Concrete Aggregates for Improved Sustainability of Reinforced Concrete Building Structures–Economic Considerations. In Proceedings of the 2015 ASEE Gulf-Southwest Annual Conference, San Antonio, TX, USA, 14–17 June 2015. [Google Scholar]

- Shwekat, K.; Wu, H.-C. Benefit-Cost Analysis Model of Using Class F Fly Ash-Based Green Cement in Masonry Units. J. Clean. Prod. 2018, 198, 443–451. [Google Scholar] [CrossRef]

- Val, D.V.; Stewart, M.G. Life-Cycle Cost Analysis of Reinforced Concrete Structures in Marine Environments. Struct. Saf. 2003, 25, 343–362. [Google Scholar] [CrossRef]

- Mistry, M.; Koffler, C.; Wong, S. LCA and LCC of the World’s Longest Pier: A Case Study on Nickel-Containing Stainless Steel Rebar. Int. J. Life Cycle Assess. 2016, 21, 1637–1644. [Google Scholar] [CrossRef]

- Ehlen, M.A.; Thomas, M.D.A.; Bentz, E.C. Life-365 Service Life Prediction ModelTM Version 2.2.3.1. Concr. Int. 2022, 31. [Google Scholar]

- Stambaugh, N.D.; Bergman, T.L.; Srubar, W. V Numerical Service-Life Modeling of Chloride-Induced Corrosion in Recycled-Aggregate Concrete. Constr. Build. Mater. 2018, 161, 236–245. [Google Scholar] [CrossRef]

- Park, K.-B.; Lee, H.-S.; Wang, X.-Y. Prediction of Time-Dependent Chloride Diffusion Coefficients for Slag-Blended Concrete. Adv. Mater. Sci. Eng. 2017, 2017, 1901459. [Google Scholar] [CrossRef]

- Zahid, C.Z.B.; Rezwan, M.M.; Redwan-Ul-Islam; Mohammed, T.U. Service Life Optimization and Life Cycle Assessment of Concrete Using SCMs as Partial Replacement of Cement. J. Phys. Conf. Ser. 2023, 2521, 012008. [Google Scholar] [CrossRef]

- Cabrera, J.G. Deterioration of Concrete Due to Reinforcement Steel Corrosion. Cem. Concr. Compos. 1996, 18, 47–59. [Google Scholar] [CrossRef]

- Xuan, Y.; Yue, Q. Forecast of Steel Demand and the Availability of Depreciated Steel Scrap in China. Resour. Conserv. Recycl. 2016, 109, 1–12. [Google Scholar] [CrossRef]

- Omura, A.; Todorova, N.; Li, B.; Chung, R. Steel Scrap and Equity Market in Japan. Resour. Policy 2016, 47, 115–124. [Google Scholar] [CrossRef]

- Broadbent, C. Steel’s Recyclability: Demonstrating the Benefits of Recycling Steel to Achieve a Circular Economy. Int. J. Life Cycle Assess. 2016, 21, 1658–1665. [Google Scholar] [CrossRef]

- Office of Management and Budget Circular A-94 Appendix C: Discount Rates for Cost-Effectiveness, Lease Purchase, and Related Analyses. Available online: https://www.federalregister.gov/documents/2022/05/24/2022-11085/discount-rates-for-cost-effectiveness-analysis-of-federal-programs (accessed on 10 January 2025).

- Infrastructure Australia. Overview Assessment Framework; Infrastructure Australia: Sydney, Australia, 2021; ISBN 9781925352498. [Google Scholar]

- Martínez-Lage, I.; Vázquez-Burgo, P.; Velay-Lizancos, M. Sustainability Evaluation of Concretes with Mixed Recycled Aggregate Based on Holistic Approach: Technical, Economic and Environmental Analysis. Waste Manag. 2020, 104, 9–19. [Google Scholar] [CrossRef] [PubMed]

| Design Alternative | Aggregate Used | FA | BF * |

|---|---|---|---|

| NCP | NA | 0% | 0% |

| RFB | RCA | 20% | 0.2% |

| Scenario No. | No. of Floors | Area (m2) | Concrete (m3) | Steel (kg) |

|---|---|---|---|---|

| 1 | 20 | 8000 | 2185 | 341,547 |

| 2 | 30 | 17,280 | 4883 | 764,123 |

| 3 | 40 | 36,000 | 11,222 | 1,764,518 |

| 4 | 50 | 57,800 | 20,772 | 3,275,740 |

| 5 | 60 | 105,840 | 36,371 | 5,772,557 |

| 6 | 70 | 189,280 | 66,345 | 10,515,272 |

| Design Scenario | Year | Total (USD/m2) | |||||

|---|---|---|---|---|---|---|---|

| 0 | 10 | 20 | 30 | 40 | 50 | ||

| NCP-20 | 281.2 | 39.4 | 39.4 | 39.4 | 39.4 | 112.3 | 551.1 |

| NCP-30 | 291.1 | 40.7 | 40.7 | 40.7 | 40.7 | 116.1 | 570.0 |

| NCP-40 | 321.8 | 45.1 | 45.1 | 45.1 | 45.1 | 128.1 | 630.1 |

| NCP-50 | 371.6 | 52.0 | 52.0 | 52.0 | 52.0 | 147.6 | 727.3 |

| NCP-60 | 356.5 | 49.9 | 49.9 | 49.9 | 49.9 | 141.1 | 697.1 |

| NCP-70 | 363.3 | 50.9 | 50.9 | 50.9 | 50.9 | 143.9 | 710.7 |

| RFB-20 | 278.0 | 0.0 | 0.0 | 39.2 | 0.0 | 112.3 | 429.4 |

| RFB-30 | 287.8 | 0.0 | 0.0 | 40.6 | 0.0 | 116.1 | 444.6 |

| RFB-40 | 318.6 | 0.0 | 0.0 | 44.9 | 0.0 | 128.1 | 491.6 |

| RFB-50 | 368.4 | 0.0 | 0.0 | 51.9 | 0.0 | 147.6 | 567.8 |

| RFB-60 | 353.2 | 0.0 | 0.0 | 49.7 | 0.0 | 141.1 | 544.0 |

| RFB-70 | 360.1 | 0.0 | 0.0 | 50.7 | 0.0 | 143.9 | 554.7 |

| Design Scenario | Cost (USD/m2) | LCC (USD/m2) | LCC Saving (%) | |||

|---|---|---|---|---|---|---|

| Material | Construction | Maintenance | Disposal | |||

| NCP-20 | 112.5 | 168.7 | 139.2 | 87.5 | 507.9 | - |

| NCP-30 | 116.4 | 174.6 | 144.1 | 90.5 | 525.7 | - |

| NCP-40 | 128.7 | 193.1 | 159.3 | 99.8 | 581.0 | - |

| NCP-50 | 148.6 | 223.0 | 184.0 | 115.0 | 670.6 | - |

| NCP-60 | 142.6 | 213.9 | 176.5 | 109.9 | 642.9 | - |

| NCP-70 | 145.3 | 218.0 | 179.9 | 112.1 | 655.4 | - |

| RFB-20 | 109.3 | 168.7 | 33.8 | 87.5 | 399.2 | 21.4 |

| RFB-30 | 113.2 | 174.6 | 34.9 | 90.5 | 413.3 | 21.4 |

| RFB-40 | 125.5 | 193.1 | 38.7 | 99.8 | 457.1 | 21.3 |

| RFB-50 | 145.4 | 223.0 | 44.7 | 115.0 | 528.0 | 21.3 |

| RFB-60 | 139.4 | 213.9 | 42.8 | 109.9 | 506.0 | 21.3 |

| RFB-70 | 142.1 | 218.0 | 43.7 | 112.1 | 515.9 | 21.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abushanab, A.; Vimonsatit, V. Cost-Effectiveness of Reinforced Recycled Aggregate Concrete Structures with Fly Ash and Basalt Fibres Under Corrosion: A Life Cycle Cost Analysis. Buildings 2025, 15, 1167. https://doi.org/10.3390/buildings15071167

Abushanab A, Vimonsatit V. Cost-Effectiveness of Reinforced Recycled Aggregate Concrete Structures with Fly Ash and Basalt Fibres Under Corrosion: A Life Cycle Cost Analysis. Buildings. 2025; 15(7):1167. https://doi.org/10.3390/buildings15071167

Chicago/Turabian StyleAbushanab, Abdelrahman, and Vanissorn Vimonsatit. 2025. "Cost-Effectiveness of Reinforced Recycled Aggregate Concrete Structures with Fly Ash and Basalt Fibres Under Corrosion: A Life Cycle Cost Analysis" Buildings 15, no. 7: 1167. https://doi.org/10.3390/buildings15071167

APA StyleAbushanab, A., & Vimonsatit, V. (2025). Cost-Effectiveness of Reinforced Recycled Aggregate Concrete Structures with Fly Ash and Basalt Fibres Under Corrosion: A Life Cycle Cost Analysis. Buildings, 15(7), 1167. https://doi.org/10.3390/buildings15071167