Tensile Strength of RA Concrete Containing Supplementary Cementitious Materials and Polypropylene Fibers Utilizing Machine Learning with GUI

Abstract

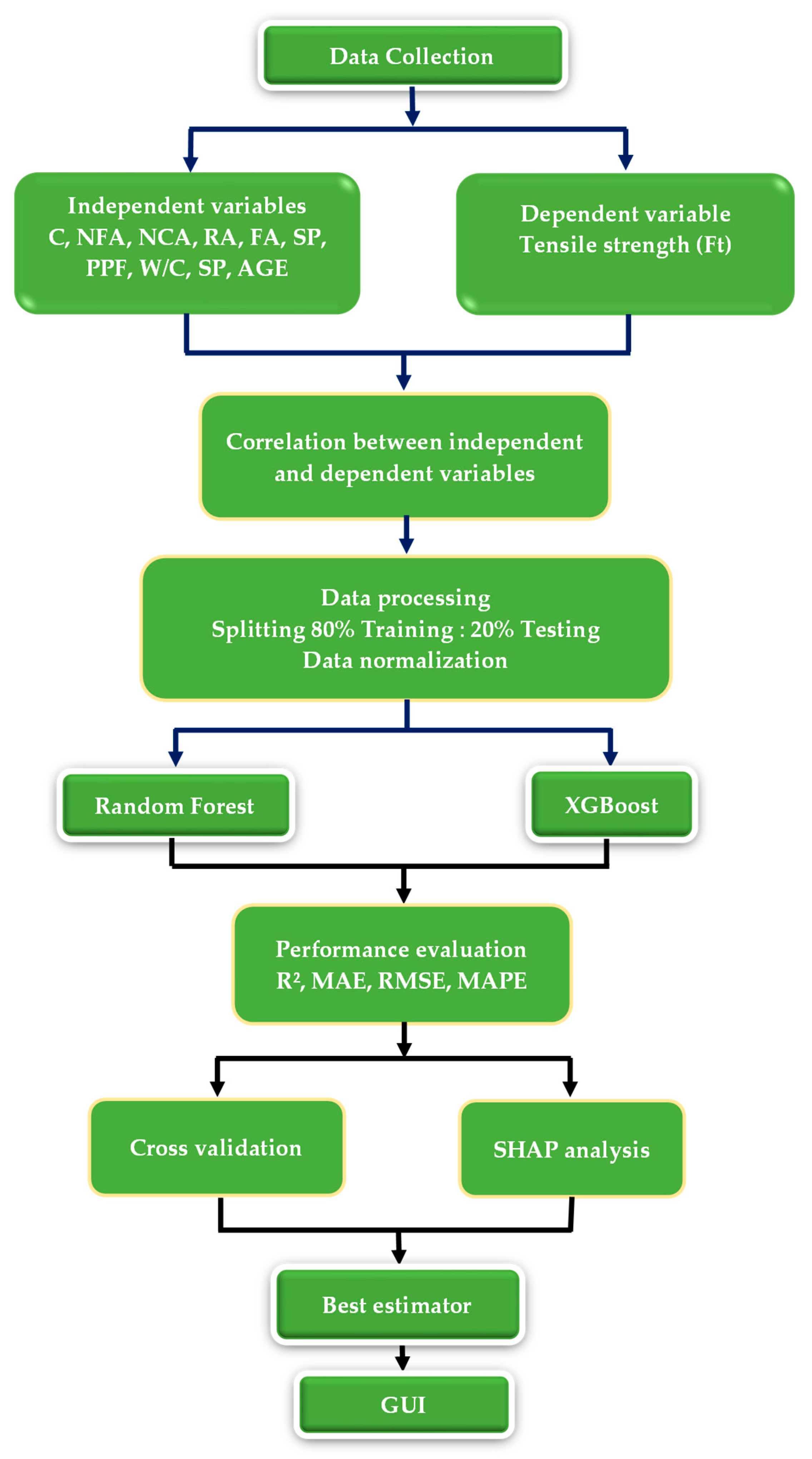

1. Introduction

- 1.

- To assemble and organize a thorough, high-caliber database from the literature pertaining to RA-SCM-PPF concrete.

- 2.

- To systematically train and evaluate the performance of proposed machine learning algorithms: Random Forest and XGBoost.

- 3.

- To utilize SHapley Additive exPlanations (SHAP) for both global and local interpretability, thereby clarifying the non-linear effects and interactions of mix design parameters.

- 4.

- To provide a Graphical User Interface (GUI) tool that incorporates the ideal model for practical application by researchers and engineers.

2. Materials and Methods

2.1. Data Collection

2.2. Data Statistics

2.2.1. Correlation Between Independent and Dependent Variables

2.2.2. Multicollinearity Check

2.3. Data Processing

2.3.1. Data Splitting

2.3.2. Data Scaling

2.4. Machine Learning (ML) Approach

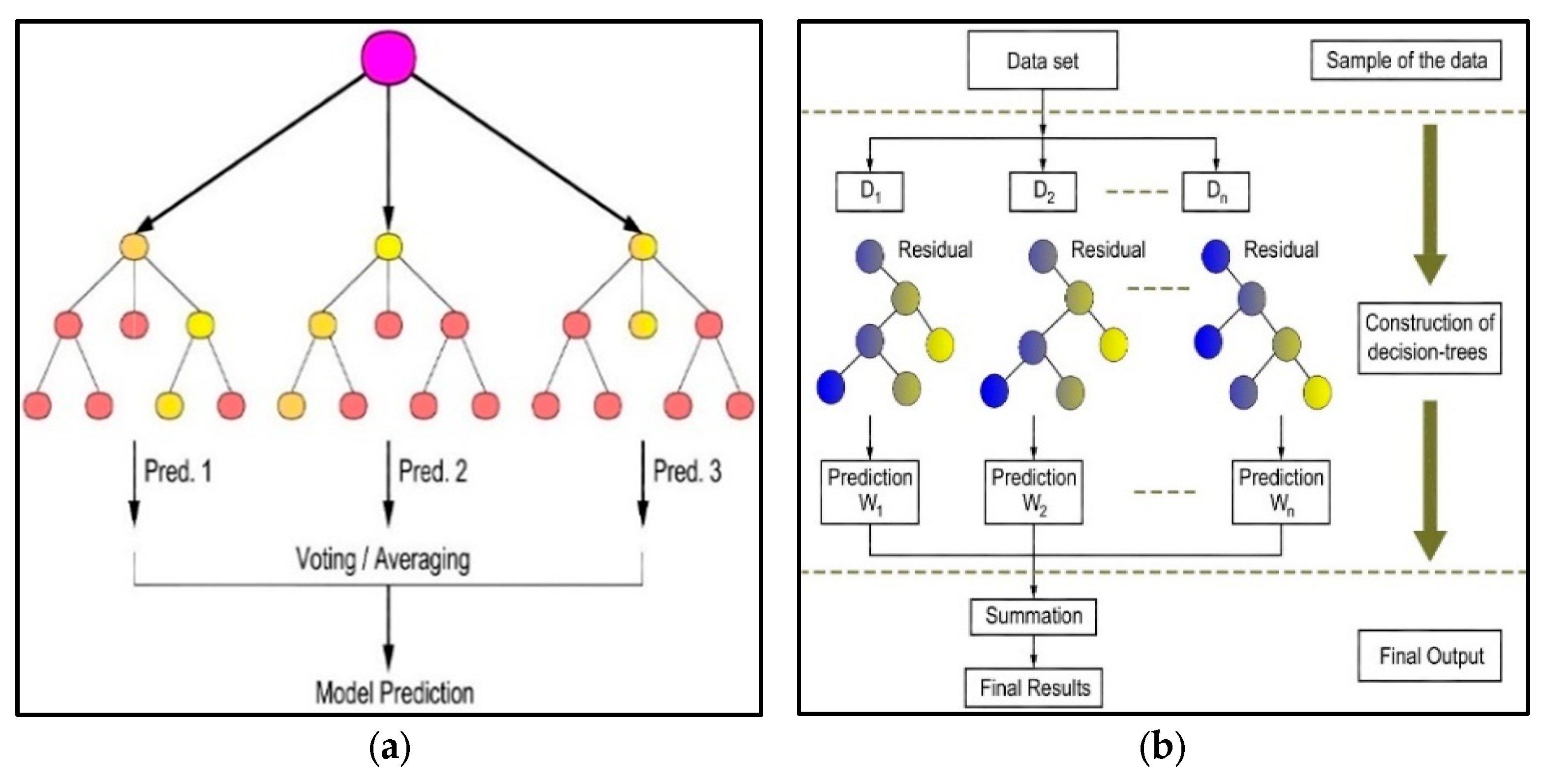

2.4.1. Random Forest (RF)

2.4.2. Extreme Gradient Boosting (XGBoost)

2.5. Model Efficiencies

2.6. PSO Hyperparameter Optimization

3. Results and Discussion

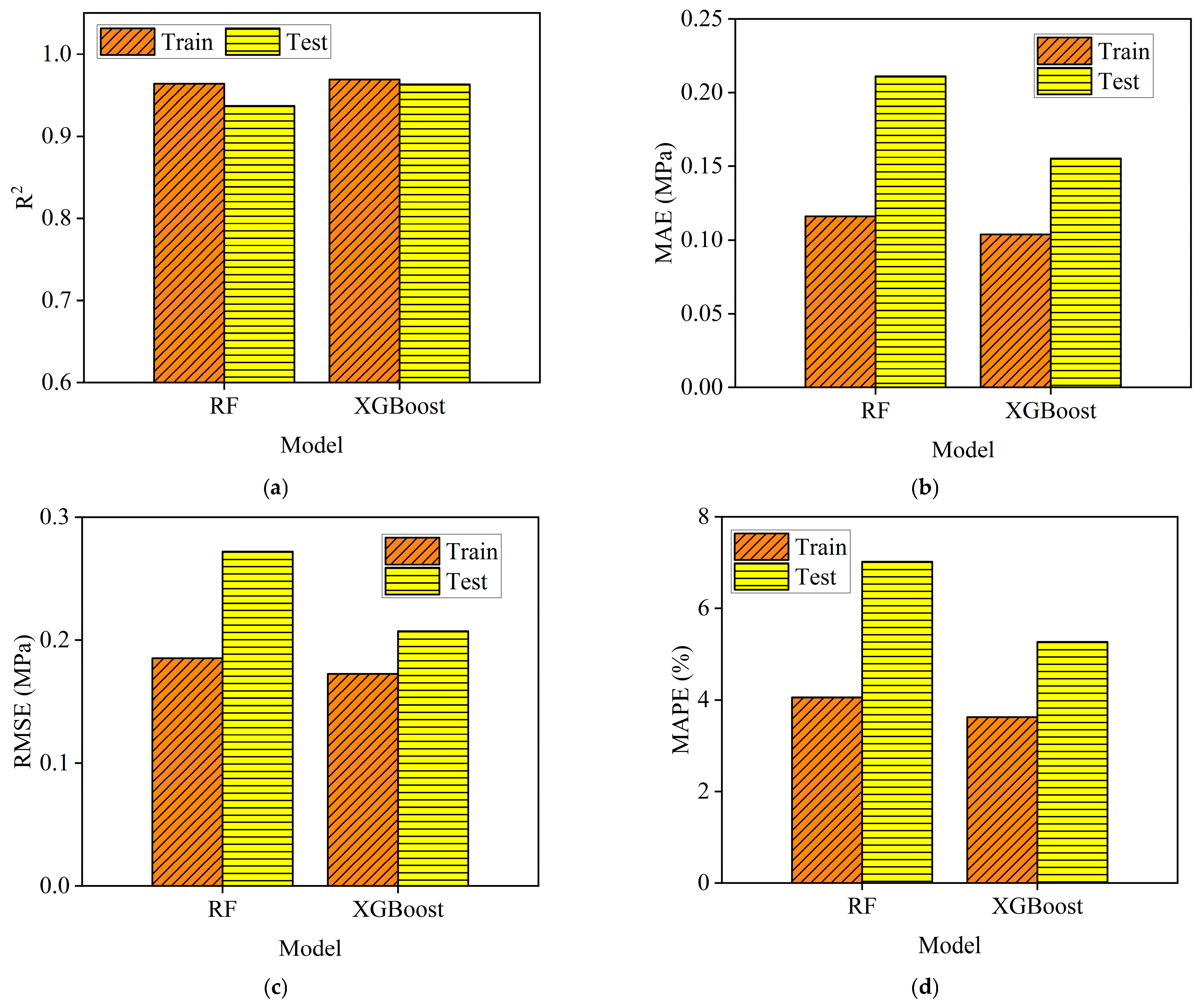

3.1. Performance of ML Models

3.1.1. XGBoost Regression

3.1.2. Random Forest (RF) Regression

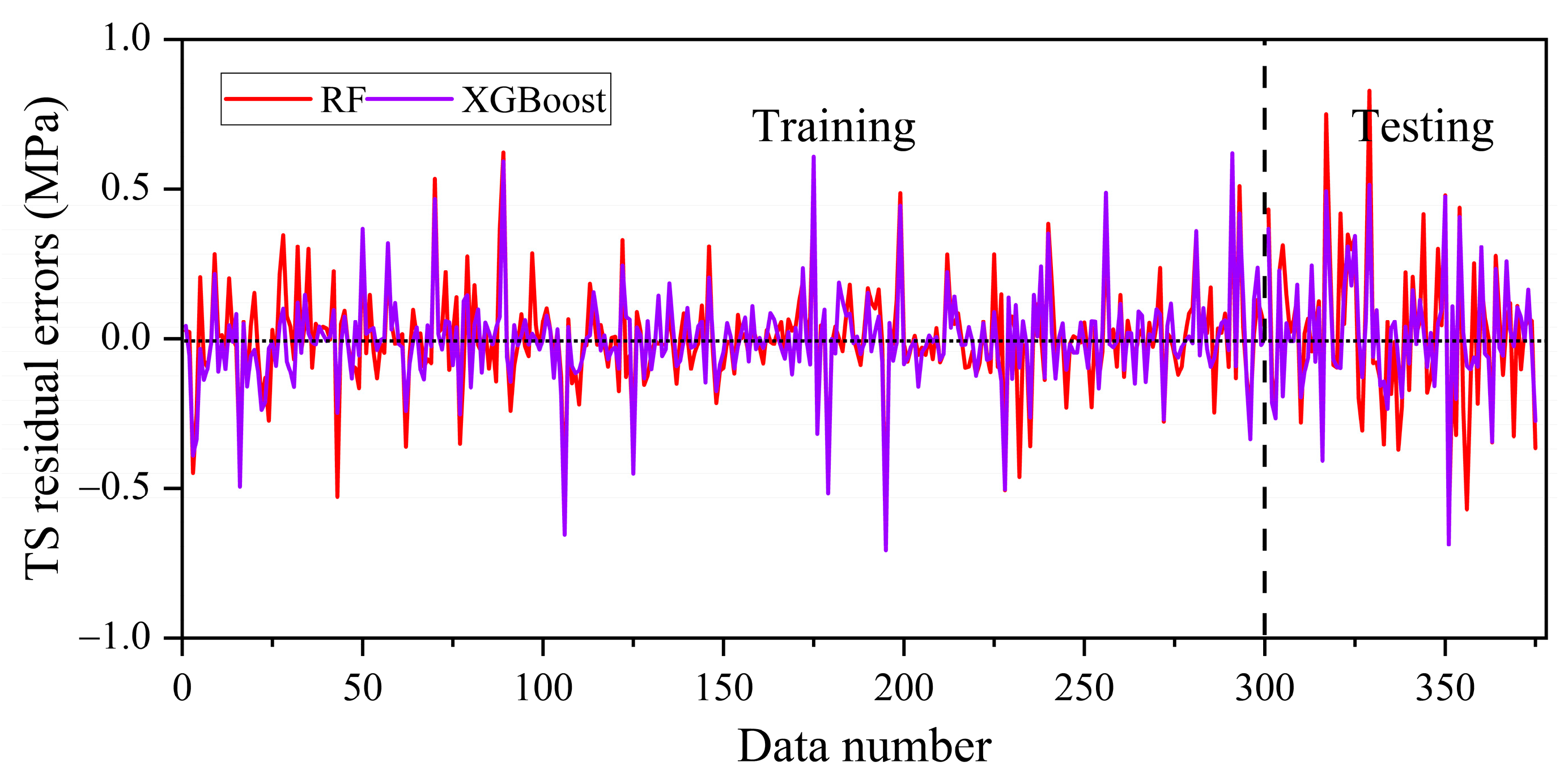

3.1.3. Residual Errors

3.1.4. Comparison Between the Developed Models

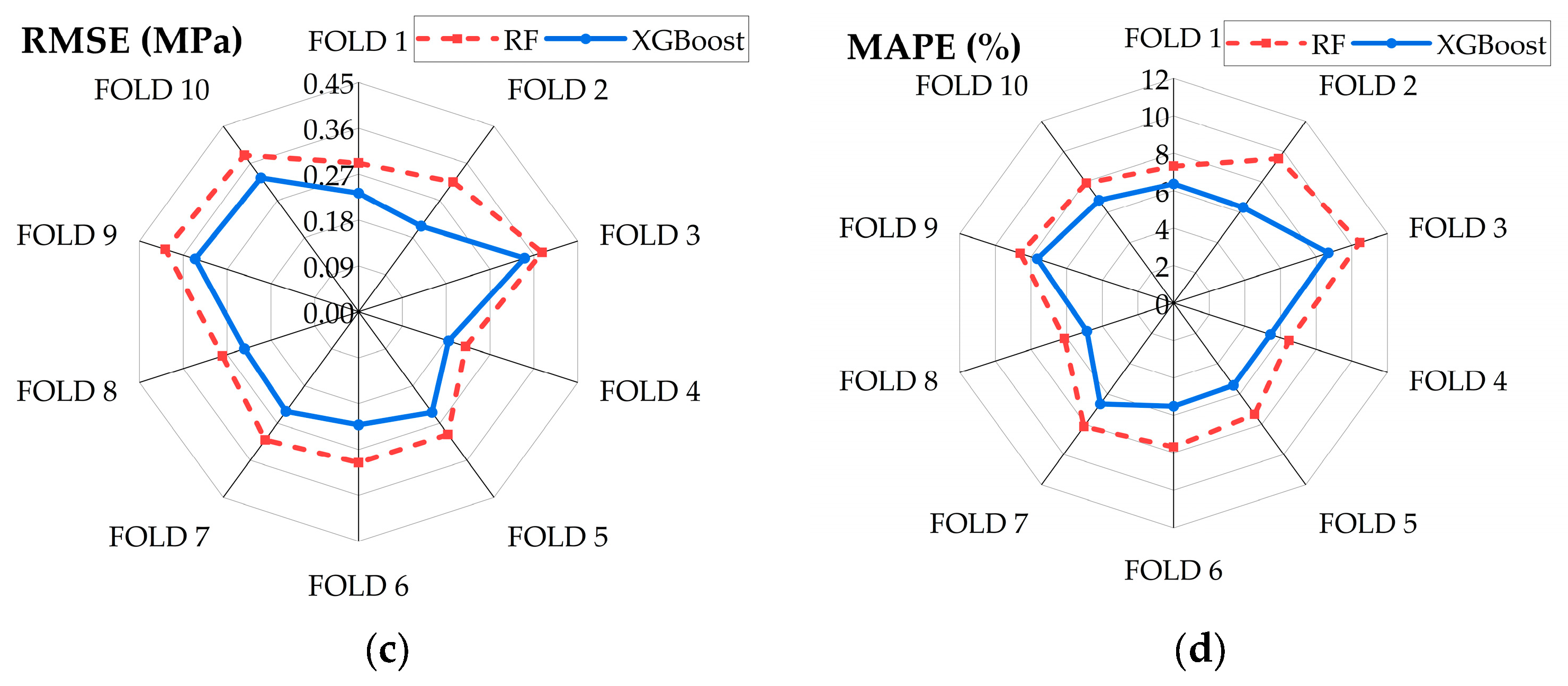

3.2. Cross-Validation

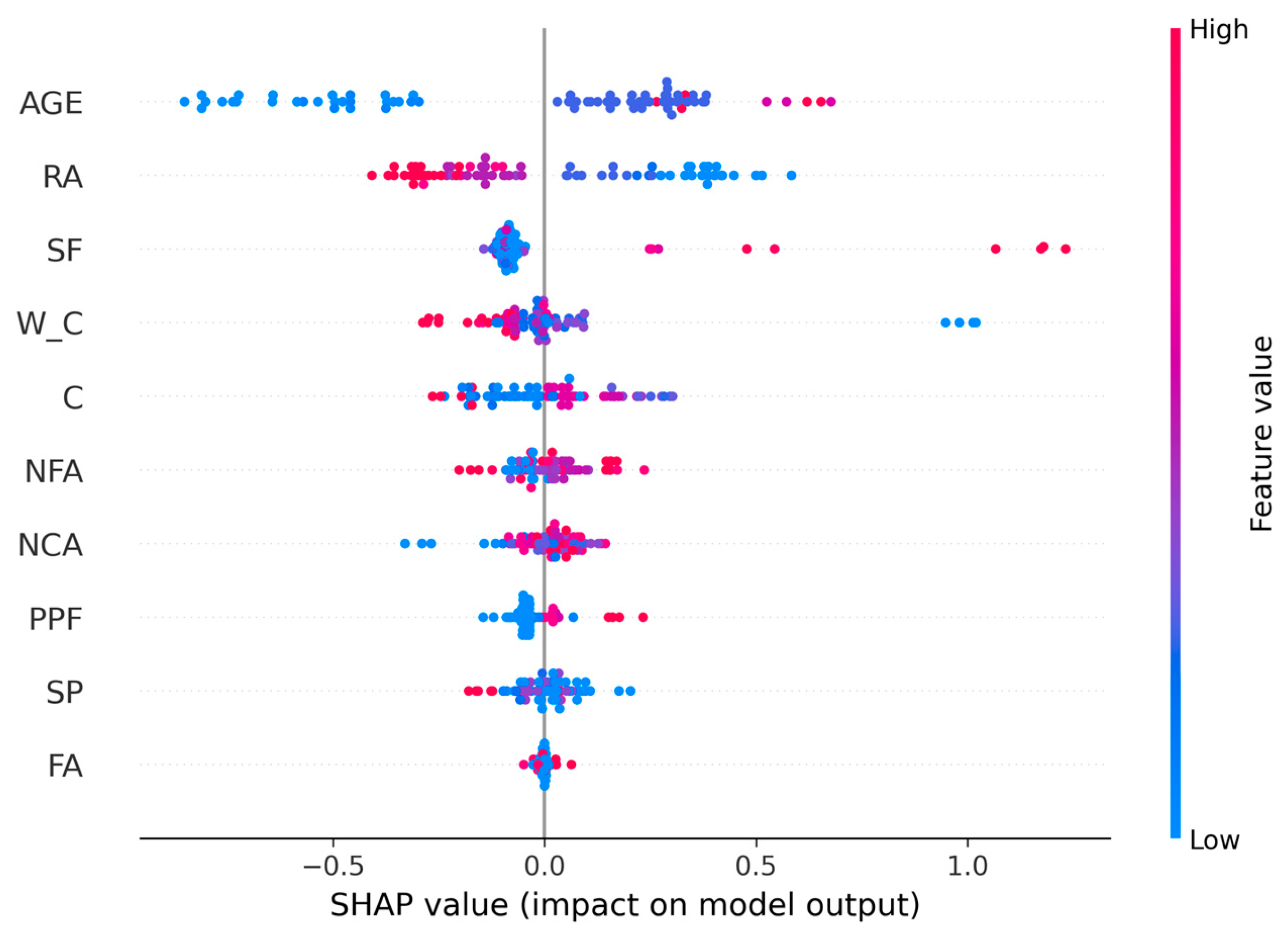

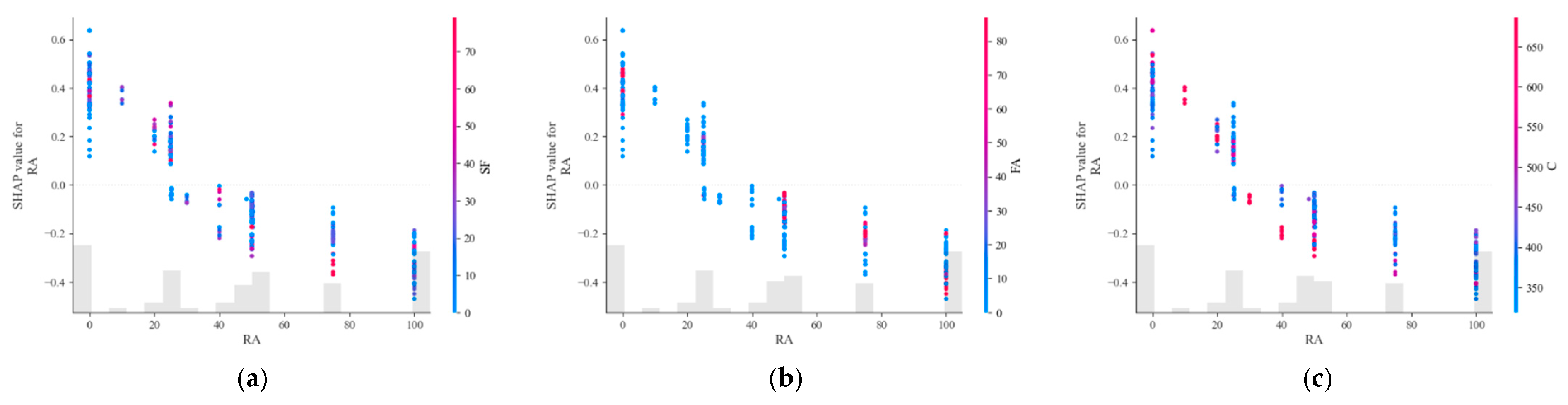

3.3. SHAP Analysis for the Developed Models

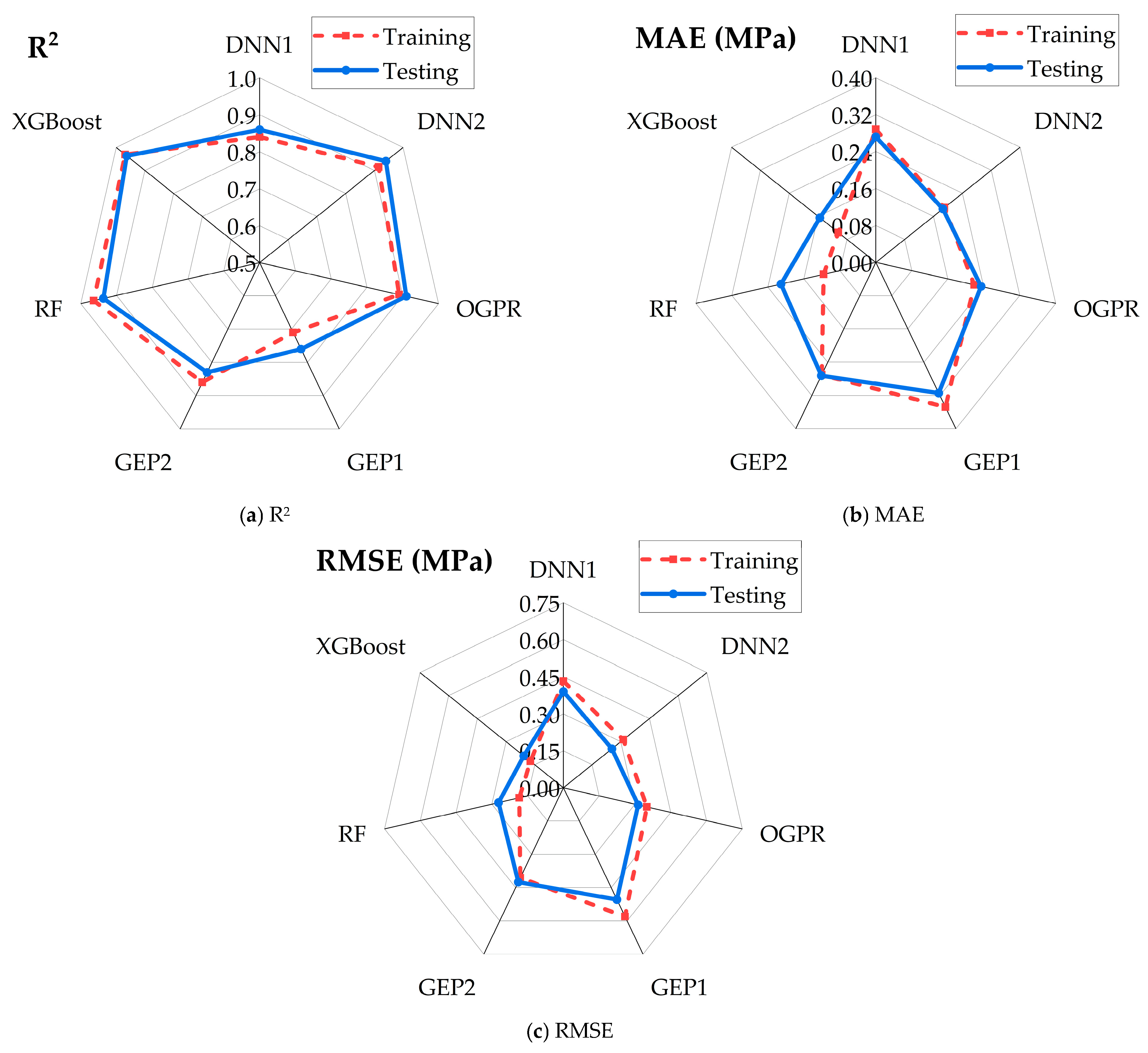

3.4. Comparison of Proposed TS Models with Previous Models

3.5. Graphical User Interface (GUI)

Verification of the Prediction GUI

4. Conclusions

- The tensile strength (Ft) has a robust positive relationship with SF, followed by AGE and SP, while displaying a significant negative correlation with the W/C and RA.

- The XGBoost model utilizing the PSO optimizer surpassed the RF model with the PSO optimizer in terms of resilience and accuracy during 10-fold cross-validation, having R2 values of 0.9689 and 0.9632 for the training and testing datasets, respectively.

- The XGBoost model findings indicated that the RMSE, MAE, and MAPE values for Ft were 0.207 MPa, 0.155 MPa, and 5.26%, respectively, illustrating that the XGB prediction model displayed enhanced overall performance characterized by a higher R2 and reduced error values.

- The SHAP analysis indicated that the curing period, SP, C, NFA, NCA, PPF, SF, and FA exert a favorable influence on tensile strength. Conversely, W/C and RA adversely impact Ft. The effects of aging and RA are the most pronounced compared to other factors.

- SHAP-based interpretability identifies the fundamental shortcomings of RA-based mixtures and recommends a definitive material synergy—integrating SCMs, fibers, and a low water–cement ratio with proper curing—to develop RAC with consistently improved tensile strength.

- XGBoost outperformed previously established prediction models for Ft, including DNN, OGPR, and GEP.

- An intuitive GUI has been created to efficiently predict the Ft of RA concrete incorporating SCMs and PPF, utilizing essential input parameters, hence reducing the necessity for resource-demanding practical trials.

5. Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RA | Recycled aggregate |

| RCA | Recycled concrete aggregate |

| PPF | Polypropylene fiber |

| FA | Fly ash |

| SF | Silica fume |

| Ft | Tensile strength |

| ML | Machine learning |

| RF | Random forest |

| XGBoost | Extreme gradient boosting |

| SHAP | SHapley additive explanations |

| GUI | Graphical user interface |

| SCMs | Supplementary cementitious materials |

| CV | Cross-validation |

| C | Cement |

| NFA | Natural fine aggregate |

| NCA | Natural coarse aggregate |

| W/C | Water/binder ratio |

| SP | Superplasticizer |

| AGE | Curing period |

| R | Correlation coefficient |

| R2 | Coefficient of determination |

| MAE | Mean absolute error |

| RMSE | Root mean squared error |

| MAPE | Mean absolute percentage error |

References

- Fanijo, E.O.; Kolawole, J.T.; Babafemi, A.J.; Liu, J. A Comprehensive Review on the Use of Recycled Concrete Aggregate for Pavement Construction: Properties, Performance, and Sustainability. Clean. Mater. 2023, 9, 100199. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water Absorption and Electrical Resistivity of Concrete with Recycled Concrete Aggregates and Fly Ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of Incorporation of High Volume of Recycled Concrete Aggregates and Fly Ash on the Strength and Global Warming Potential of Concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Junior, G.A.F.; Leite, J.C.T.; Mendez, G.d.P.; Haddad, A.N.; Silva, J.A.F.; da Costa, B.B.F. A Review of the Characteristics of Recycled Aggregates and the Mechanical Properties of Concrete Produced by Replacing Natural Coarse Aggregates with Recycled Ones—Fostering Resilient and Sustainable Infrastructures. Infrastructures 2025, 10, 213. [Google Scholar] [CrossRef]

- Cantero, B.; Seara-Paz, S.; Cuenca, E.; Ferrara, L.; González-Fonteboa, B. Self-Healing Mechanisms in Concrete Cured in CO2-Saturated Environments: Synergistic Effects of Biomass Forest Ash and Metakaolin. Cem. Concr. Compos. 2025, 163, 106160. [Google Scholar] [CrossRef]

- Matar, P.; Assaad, J.J. Concurrent Effects of Recycled Aggregates and Polypropylene Fibers on Workability and Key Strength Properties of Self-Consolidating Concrete. Constr. Build. Mater. 2019, 199, 492–500. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Cao, K.; Sun, L. Review on the Durability of Polypropylene Fibre-Reinforced Concrete. Adv. Civ. Eng. 2021, 2021, 1–13. [Google Scholar] [CrossRef]

- Dahish, H.A.; Alkharisi, M.K. Predicting the Properties of Polypropylene Fiber Recycled Aggregate Concrete Using Response Surface Methodology and Machine Learning. Buildings 2025, 15, 3709. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising Cement and Concrete Production: Strategies, Challenges and Pathways for Sustainable Development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Akbar, D.; Shabbir, F.; Raza, A.; Kahla, N. Ben Synergistic Enhancement of Recycled Aggregate Concrete Using Hybrid Natural-Synthetic Fiber Reinforcement and Silica Fume. Results Eng. 2025, 27, 106291. [Google Scholar] [CrossRef]

- Katar, I.; Ibrahim, Y.; Abdul Malik, M.; Khahro, S.H. Mechanical Properties of Concrete with Recycled Concrete Aggregate and Fly Ash. Recycling 2021, 6, 23. [Google Scholar] [CrossRef]

- Karthik, C.H.; Nagaraju, A. An Experimental Study on Recycled Aggregate Concrete With Partial Replacement of Cement With Flyash and Alccofine. IOP Conf. Ser. Earth Environ. Sci. 2023, 1130, 012012. [Google Scholar] [CrossRef]

- Velumani, S.K.; Venkatraman, S. Assessing the Impact of Fly Ash and Recycled Concrete Aggregates on Fibre-Reinforced Self-Compacting Concrete Strength and Durability. Processes 2024, 12, 1602. [Google Scholar] [CrossRef]

- Fan, M.; Li, Y.; Shen, J.; Jin, K.; Shi, J. Multi-Objective Optimization Design of Recycled Aggregate Concrete Mixture Proportions Based on Machine Learning and NSGA-II Algorithm. Adv. Eng. Softw. 2024, 192, 103631. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, R.; Lu, Y.; Huang, J. Prediction of Compressive Strength of Geopolymer Concrete Landscape Design: Application of the Novel Hybrid RF–GWO–XGBoost Algorithm. Buildings 2024, 14, 591. [Google Scholar] [CrossRef]

- Al Adnan, M.; Babur, M.; Farooq, F.; Shahid, M.; Ahmed, Z.; Das, P. Prediction of Splitting Tensile Strength of Fiber-Reinforced Recycled Aggregate Concrete Utilizing Machine Learning Models with SHAP Analysis. Hybrid Adv. 2025, 11, 100507. [Google Scholar] [CrossRef]

- Guo, L.; Li, Z.; Tian, Q.; Guo, L.; Wang, Q. Prediction of CSG Splitting Tensile Strength Based on XGBoost-RF Model. Mater. Today Commun. 2023, 34, 105350. [Google Scholar] [CrossRef]

- Alarfaj, M.; Qureshi, H.J.; Shahab, M.Z.; Javed, M.F.; Arifuzzaman, M.; Gamil, Y. Machine Learning Based Prediction Models for Spilt Tensile Strength of Fiber Reinforced Recycled Aggregate Concrete. Case Stud. Constr. Mater. 2024, 20, e02836. [Google Scholar] [CrossRef]

- Paruthi, S.; Verma, R.; Sharma, N.; Khan, A.H.; Hasan, M.A. Ensemble Machine Learning Models for Predicting Strength of Concrete with Foundry Sand and Coal Bottom Ash as Fine Aggregate Replacements. Sci. Rep. 2025, 15, 38331. [Google Scholar] [CrossRef]

- Liu, J.; Guan, D.; Liu, X. Comparative Performance Analysis of Machine Learning Models for Compressive Strength Prediction in Concrete Mix Design. Math. Comput. Appl. 2025, 30, 128. [Google Scholar] [CrossRef]

- Alkharisi, M.K.; Dahish, H.A. The Application of Response Surface Methodology and Machine Learning for Predicting the Compressive Strength of Recycled Aggregate Concrete Containing Polypropylene Fibers and Supplementary Cementitious Materials. Sustainability 2025, 17, 2913. [Google Scholar] [CrossRef]

- Li, D.; Tang, Z.; Kang, Q.; Zhang, X.; Li, Y. Machine Learning-Based Method for Predicting Compressive Strength of Concrete. Processes 2023, 11, 390. [Google Scholar] [CrossRef]

- Hasan, M.R.; Shuvo, A.K.; Pranto, E.B.; Hasan, M.; Miah, M.M. Data-Driven Prediction of Concrete Strength by Machine Learning: Hybrid-Fiber-Reinforced Recycled Aggregate Concrete. World J. Eng. 2025. [Google Scholar] [CrossRef]

- Alharthai, M.; Ali, T.; Qureshi, M.Z.; Ahmed, H. The Enhancement of Engineering Characteristics in Recycled Aggregates Concrete Combined Effect of Fly Ash, Silica Fume and PP Fiber. Alex. Eng. J. 2024, 95, 363–375. [Google Scholar] [CrossRef]

- Ali, B.; Ahmed, H.; Ali Qureshi, L.; Kurda, R.; Hafez, H.; Mohammed, H.; Raza, A. Enhancing the Hardened Properties of Recycled Concrete (RC) through Synergistic Incorporation of Fiber Reinforcement and Silica Fume. Materials 2020, 13, 4112. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, T.W.; Ali, A.A.M.; Zidan, R.S. Properties of High Strength Polypropylene Fiber Concrete Containing Recycled Aggregate. Constr. Build. Mater. 2020, 241, 118010. [Google Scholar] [CrossRef]

- Hanumesh, B.; Harish, B.; Venkata Ramana, N. Influence of Polypropylene Fibres on Recycled Aggregate Concrete. Mater. Today Proc. 2018, 5, 1147–1155. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Li, C.; Zhao, J.; Cheng, S. Mechanical Properties of Fully Recycled Aggregate Concrete Reinforced with Steel Fiber and Polypropylene Fiber. Materials 2024, 17, 1156. [Google Scholar] [CrossRef]

- Ali, B.; Fahad, M.; Mohammed, A.S.; Ahmed, H.; Elhag, A.B.; Azab, M. Improving the Performance of Recycled Aggregate Concrete Using Nylon Waste Fibers. Case Stud. Constr. Mater. 2022, 17, e01468. [Google Scholar] [CrossRef]

- Matar, P.; Zéhil, G.-P. Effects of Polypropylene Fibers on the Physical and Mechanical Properties of Recycled Aggregate Concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2019, 34, 1327–1344. [Google Scholar] [CrossRef]

- Khoshroo, M.; Javid, A.A.S.; Bakhshandeh, N.R.; Shalchiyan, M. Investigation of the Mechanical Properties of Concrete Containing Recycled Aggregate and Scrap Crumb Rubber and Polypropylene Fibers. Prog. Rubber Plast. Recycl. Technol. 2021, 37, 167–189. [Google Scholar] [CrossRef]

- Ahmed, L.A.; Hassan, S.S.; Al-Ameer, O.A. Ultra-High Performance Reinforced by Polypropylene Fiber Concrete Made with Recycled Coarse Aggregat. Kufa J. Eng. 2017, 8, 128–141. [Google Scholar] [CrossRef]

- Nazir, S.; Mahajan, A.; Jaggi, S. An Experimental Study on Enhancing Recycled Aggregate Concrete Properties Through Silica Fume Incorporation. 2023. Available online: https://assets-eu.researchsquare.com/files/rs-2830337/v1/7fdd74a7-8649-44ab-89bc-5fd77e098ba2.pdf?c=1684510162 (accessed on 1 May 2025).

- Shahab, M.; Bashar, N. Effect of Silica Fume on Strength of Recycled Aggregate Concrete. Int. J. Res. Eng. Innov. 2024, 8, 101–107. [Google Scholar] [CrossRef]

- Ismail, A.J.; Younis, K.H.; Maruf, S.M. Recycled Aggregate Concrete Made with Silica Fume: Experimental Investigation. Civ. Eng. Archit. 2020, 8, 1136–1143. [Google Scholar] [CrossRef]

- Alamri, M.; Ali, T.; Ahmed, H.; Qureshi, M.Z.; Elmagarhe, A.; Adil Khan, M.; Ajwad, A.; Sarmad Mahmood, M. Enhancing the Engineering Characteristics of Sustainable Recycled Aggregate Concrete Using Fly Ash, Metakaolin and Silica Fume. Heliyon 2024, 10, e29014. [Google Scholar] [CrossRef]

- Nadim, F.; Hasan, R.; Rahman Sobuz, M.H.; Ashraf, J.; Sadiqul Hasan, N.M.; Dip Datta, S.; Islam, M.H.; Islam, M.A.; Awall, M.R.; Rahman, S.A.; et al. Effect of Silica Fume on the Microstructural and Mechanical Properties of Concrete Made with 100% Recycled Aggregates. Revista de la Construcción 2024, 23, 413–435. [Google Scholar] [CrossRef]

- Sun, S.; Du, Y.; Sun, S.; Yu, Q.; Li, Y. Mechanical Properties of Recycled Concrete with Polypropylene Fiber and Its Bonding Performance with Rebars. Mater. Sci. 2024, 30, 396–403. [Google Scholar] [CrossRef]

- Saravanakumar, P.; Dhinakaran, G. Strength Characteristics of High-Volume Fly Ash–Based Recycled Aggregate Concrete. J. Mater. Civ. Eng. 2013, 25, 1127–1133. [Google Scholar] [CrossRef]

- Sowmith, N.; Anjaneya Babu, P.S.S. Influence of Fly Ash on the Performance of Recycled Aggregate Concrete. Int. J. Sci. Res. (IJSR) 2016, 5, 1740–1744. [Google Scholar] [CrossRef]

- Sonkhla, P. Effect of Silica Fume and Recycled Coarse Aggregate in Concrete. Master’s Thesis, Jaypee University of Information Technology, Waknaghat, India, 2016. [Google Scholar]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; ACM: New York, NY, USA, 2016; pp. 785–794. [Google Scholar]

- Wu, J.; Ma, D.; Wang, W. Leakage Identification in Water Distribution Networks Based on XGBoost Algorithm. J. Water Resour. Plan Manag. 2022, 148, 04021107. [Google Scholar] [CrossRef]

| Parameters | C, kg/m3 | NFA, kg/m3 | NCA, kg/m3 | RA, % | FA, kg/m3 | SF, kg/m3 | PPF, % | W/C | SP, kg/m3 | AGE, day | Ft, MPa |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | 284 | 426 | 777.1 | 0 | 0 | 0 | 0 | 0.26 | 0 | 7 | 1.32 |

| Max. | 704 | 962.28 | 1278 | 100 | 114 | 79.2 | 3 | 0.66 | 7.84 | 90 | 7.4 |

| Mean | 440.06 | 654.38 | 1119.7 | 45.76 | 19.857 | 17.273 | 0.317 | 0.4411 | 1.7359 | 27.328 | 3.119 |

| Std. Deviation | 112.43 | 136.93 | 116.86 | 35.86 | 35.862 | 22.969 | 0.691 | 0.1001 | 2.3906 | 21.466 | 1.001 |

| Skewness | 0.92 | −0.16 | −0.454 | 0.248 | 1.41 | 1.31 | 2.56 | 0.19 | 1.36 | 1.76 | 1.14 |

| Kurtosis | −0.274 | −0.667 | −0.357 | −1.22 | 0.224 | 0.887 | 6.122 | −0.796 | 0.796 | 2.895 | 2.092 |

| Model | Hyperparameter | Range | Optimized Value |

|---|---|---|---|

| RF-PSO | n_estimators | [10, 500] | 166 |

| max_depth | [1, 50] | 17 | |

| min_samples_leaf | [1, 10] | 1 | |

| min_samples_split | [2, 20] | 2 | |

| max_features | [0.1, 1] | 0.57 | |

| XGBoost-PSO | n_estimators | [50, 1000] | 927 |

| learning_rate | [0.01, 0.3] | 0.1519 | |

| max_depth | [3, 15] | 3 | |

| colsample_bytree | [0.5, 1] | 0.5414 | |

| subsample | [0.5, 1] | 0.5601 | |

| reg_lambda | [0, 10] | 0.3669 | |

| reg_alpha | [0, 10] | 0.4076 |

| C, kg/m3 | NFA, kg/m3 | NCA, kg/m3 | RA, % | FA, kg/m3 | SF, kg/m3 | PPF, % | W/C | SP, kg/m3 | Age, Day | Tensile Strength (Ft) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Actual | RF | XGBoost | ||||||||||||

| Pred. | RE * | Pred. | RE * | |||||||||||

| 348 | 610 | 1218 | 50 | 87 | 21.75 | 3 | 0.58 | 3.2 | 14 | 3.1 | 3.05 | 1.6% | 3.12 | −0.6% |

| 348 | 610 | 1218 | 50 | 87 | 21.75 | 3 | 0.58 | 3.2 | 90 | 3.6 | 3.48 | 3.3% | 3.47 | 3.6% |

| 392 | 818 | 1132 | 50 | 0 | 43 | 0.75 | 0.31 | 7.84 | 28 | 2.81 | 2.79 | 0.7% | 2.73 | 2.8% |

| 457 | 628 | 942 | 100 | 114 | 0 | 0.13 | 0.44 | 5.48 | 28 | 3.15 | 3.11 | 1.3% | 3.17 | −0.6% |

| 528 | 640 | 960 | 50 | 0 | 79.2 | 0.9 | 0.26 | 6.86 | 7 | 4.1 | 4.25 | −3.7% | 4.05 | 1.2% |

| 528 | 640 | 960 | 50 | 0 | 79.2 | 0.9 | 0.26 | 6.86 | 28 | 5.6 | 5.55 | 0.9% | 5.6 | 0.0% |

| 315 | 655 | 1050 | 75 | 35 | 25 | 0 | 0.5 | 0.7 | 14 | 1.91 | 1.97 | −3.1% | 1.93 | −1.0% |

| 412 | 680 | 1084 | 50 | 0 | 0 | 0.09 | 0.45 | 0 | 28 | 4.19 | 4.14 | 1.2% | 4.11 | 1.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alkharisi, M.K.; Dahish, H.A. Tensile Strength of RA Concrete Containing Supplementary Cementitious Materials and Polypropylene Fibers Utilizing Machine Learning with GUI. Buildings 2025, 15, 4473. https://doi.org/10.3390/buildings15244473

Alkharisi MK, Dahish HA. Tensile Strength of RA Concrete Containing Supplementary Cementitious Materials and Polypropylene Fibers Utilizing Machine Learning with GUI. Buildings. 2025; 15(24):4473. https://doi.org/10.3390/buildings15244473

Chicago/Turabian StyleAlkharisi, Mohammed K., and Hany A. Dahish. 2025. "Tensile Strength of RA Concrete Containing Supplementary Cementitious Materials and Polypropylene Fibers Utilizing Machine Learning with GUI" Buildings 15, no. 24: 4473. https://doi.org/10.3390/buildings15244473

APA StyleAlkharisi, M. K., & Dahish, H. A. (2025). Tensile Strength of RA Concrete Containing Supplementary Cementitious Materials and Polypropylene Fibers Utilizing Machine Learning with GUI. Buildings, 15(24), 4473. https://doi.org/10.3390/buildings15244473