Degradation Law of Dynamic Mechanical Properties of Coral Concrete Under Marine Environment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Specimens Preparation

2.3. Laboratory Modeling Methods for Different Marine Environments

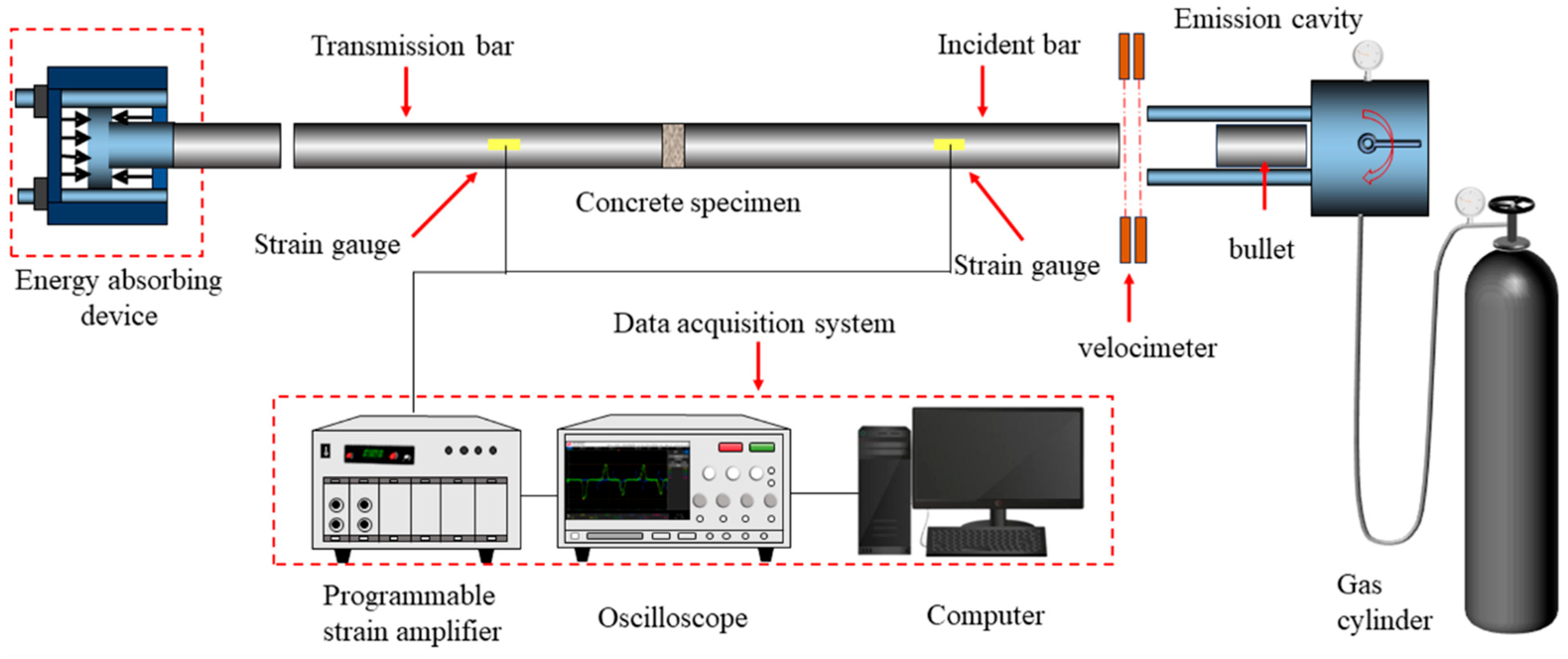

2.4. Impact Test Program

3. Results and Discussion

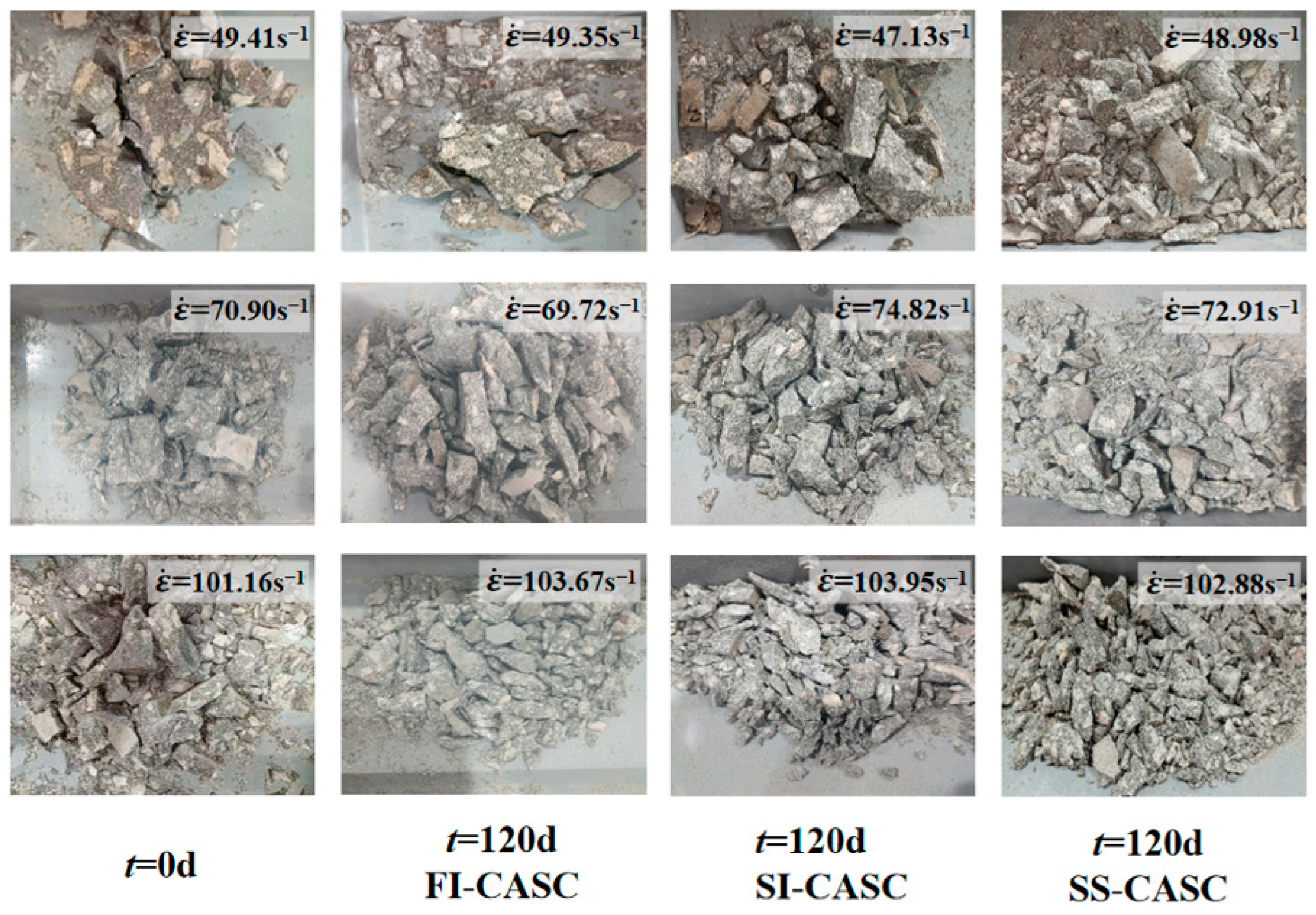

3.1. Impact Damage Patterns

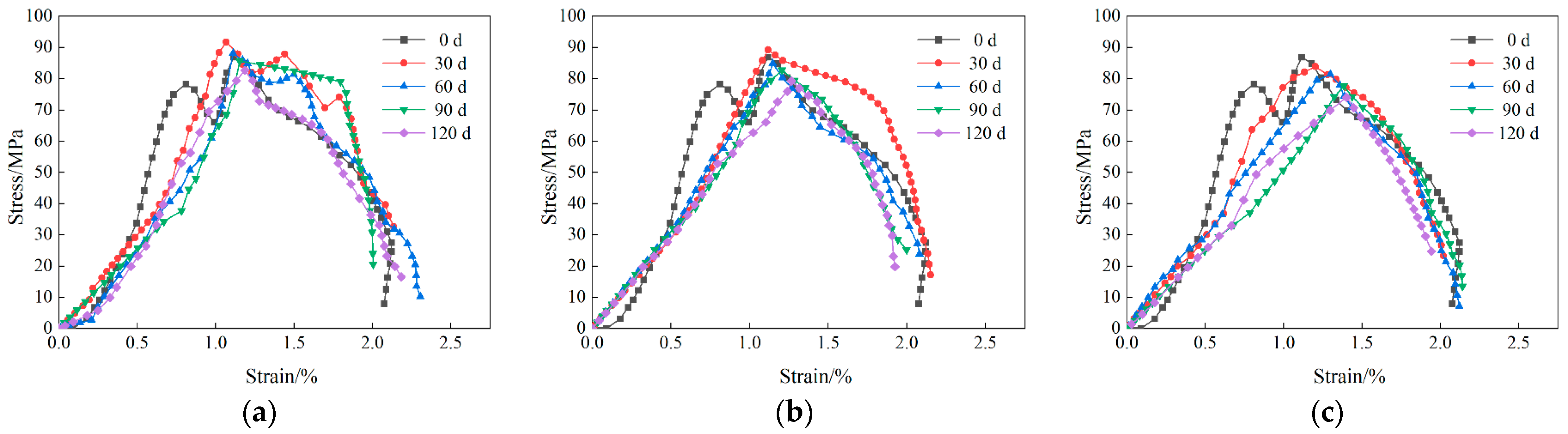

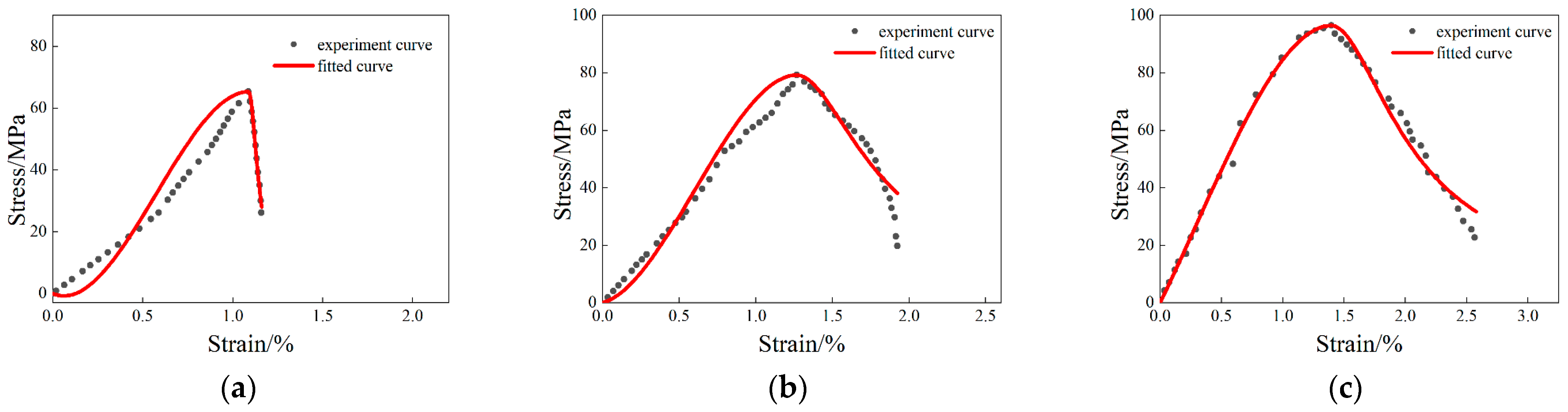

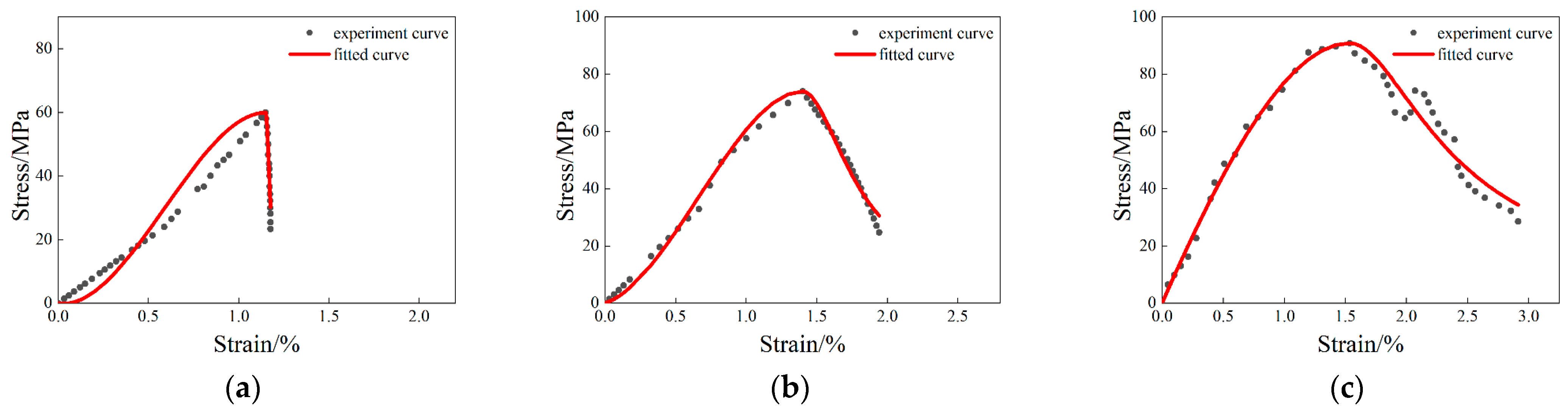

3.2. Stress–Strain Curve

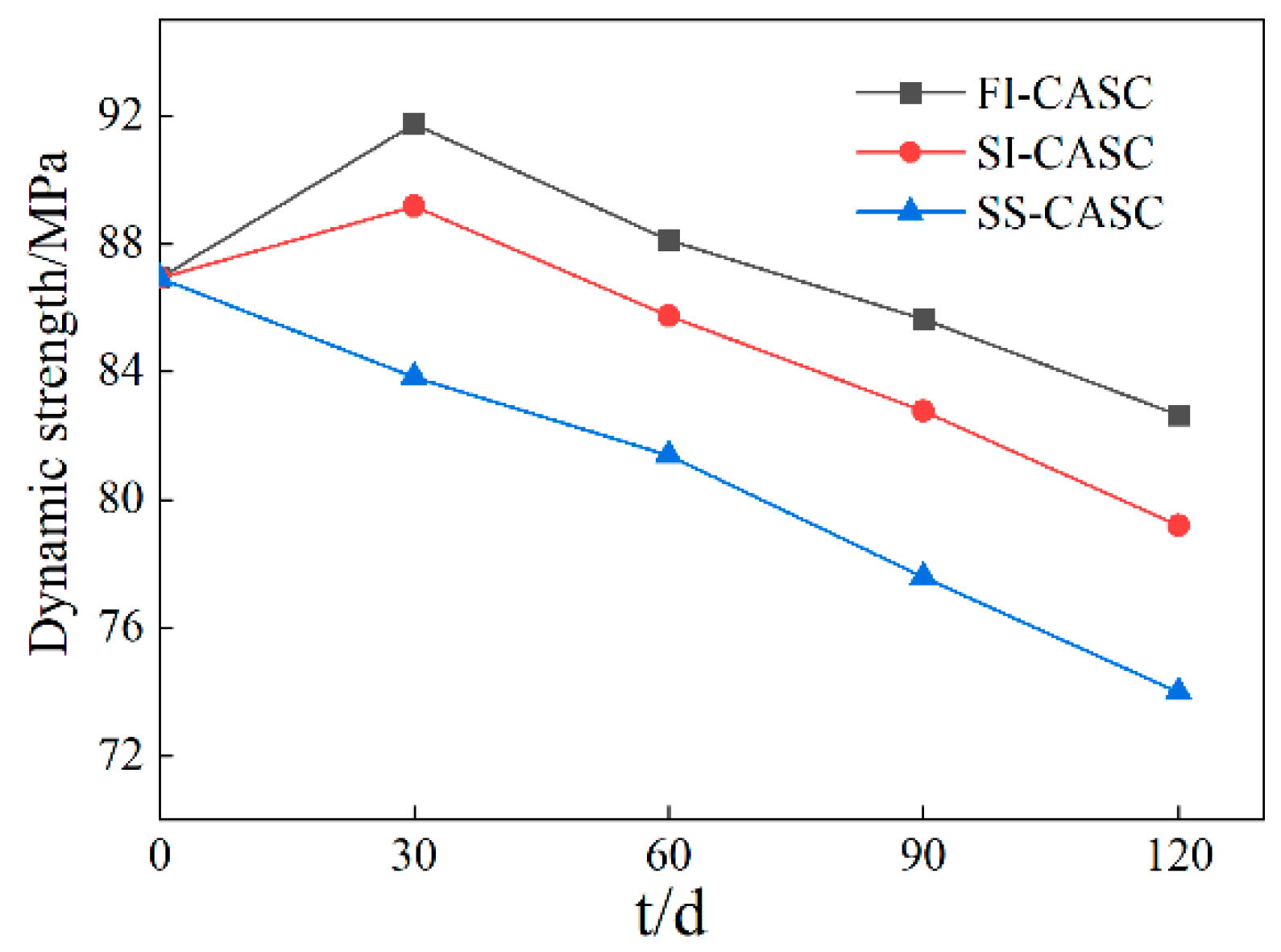

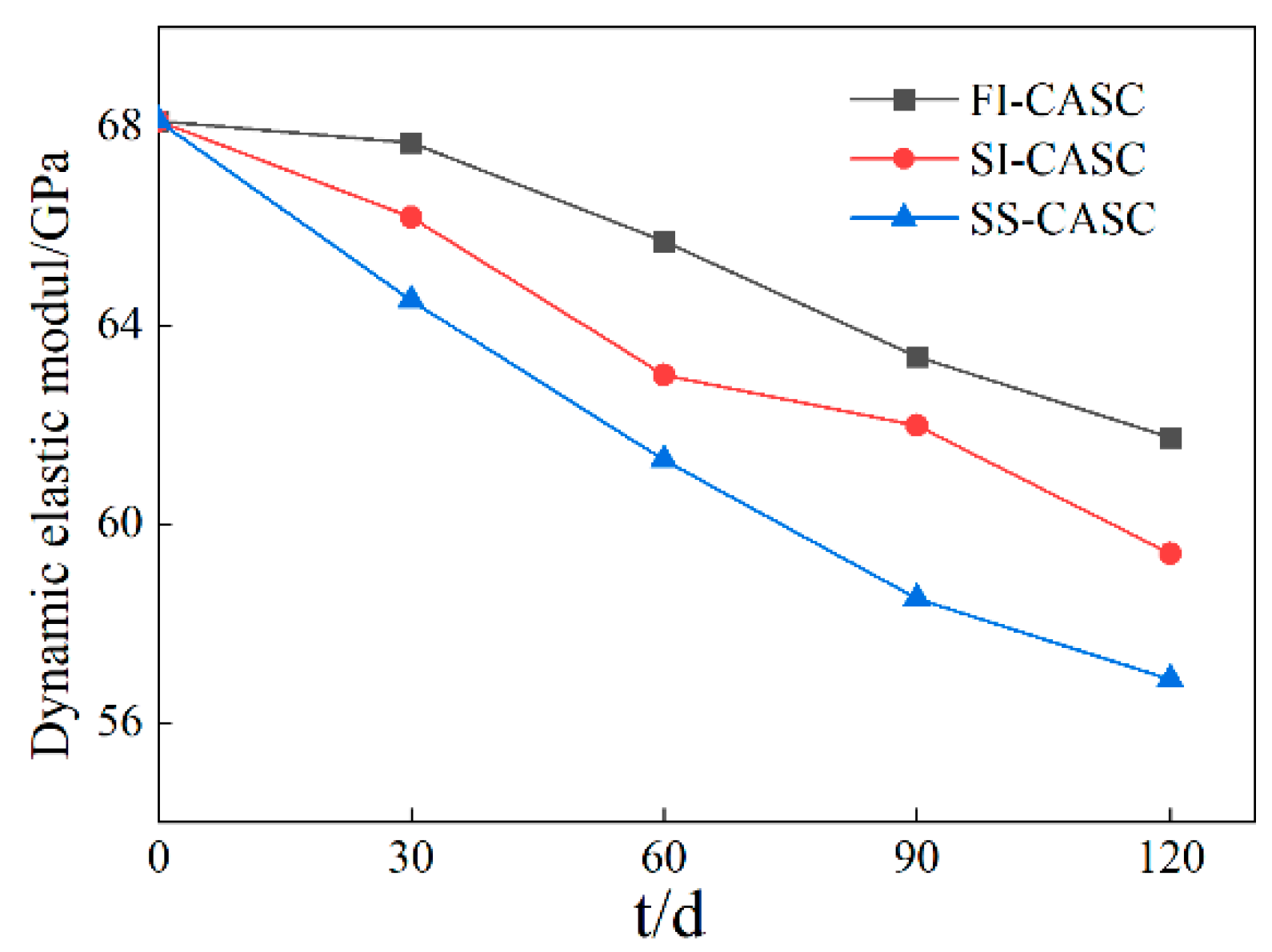

3.3. Dynamic Strength and Modulus of Elasticity

3.4. Strain-Rate Effects

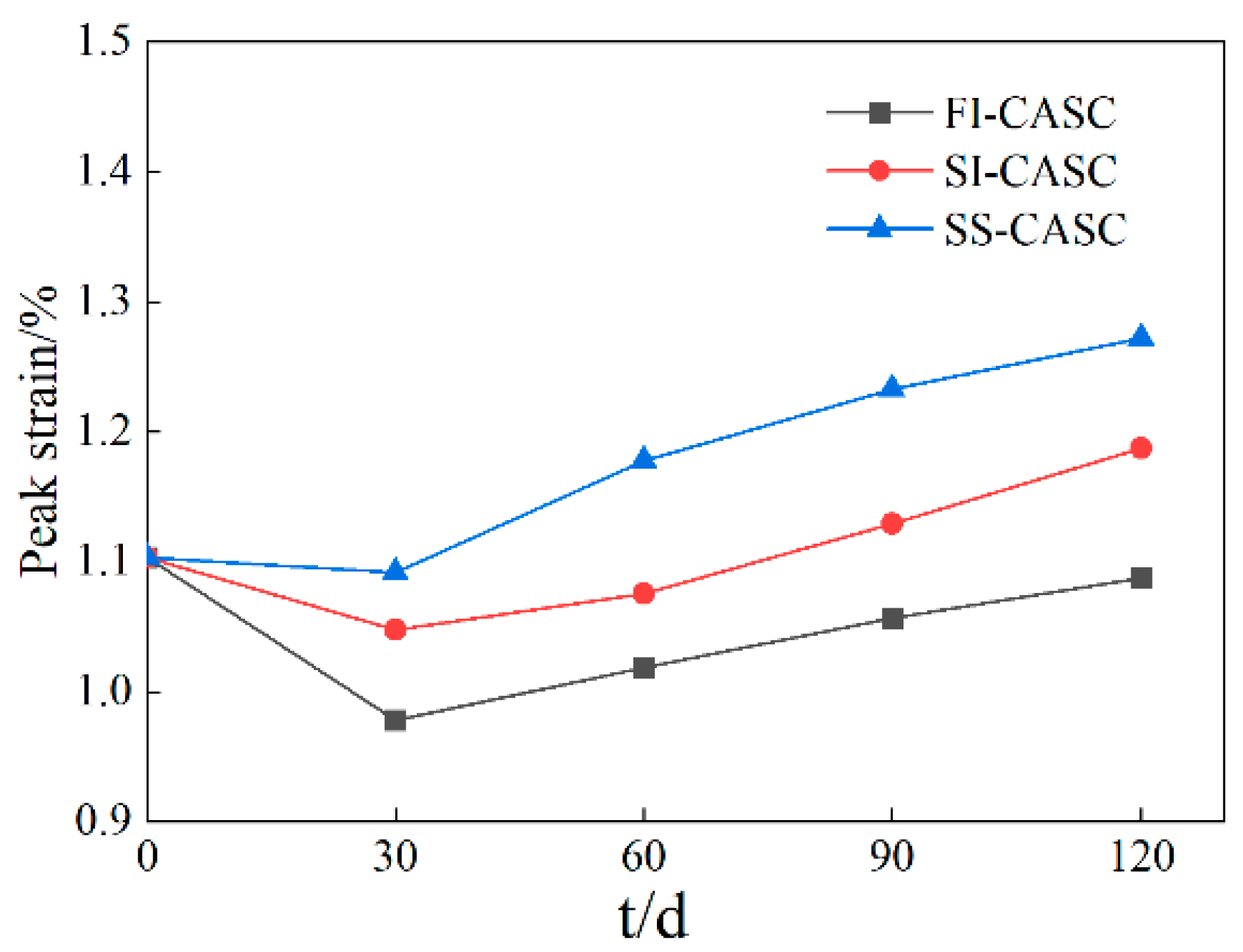

3.5. Peak Strain

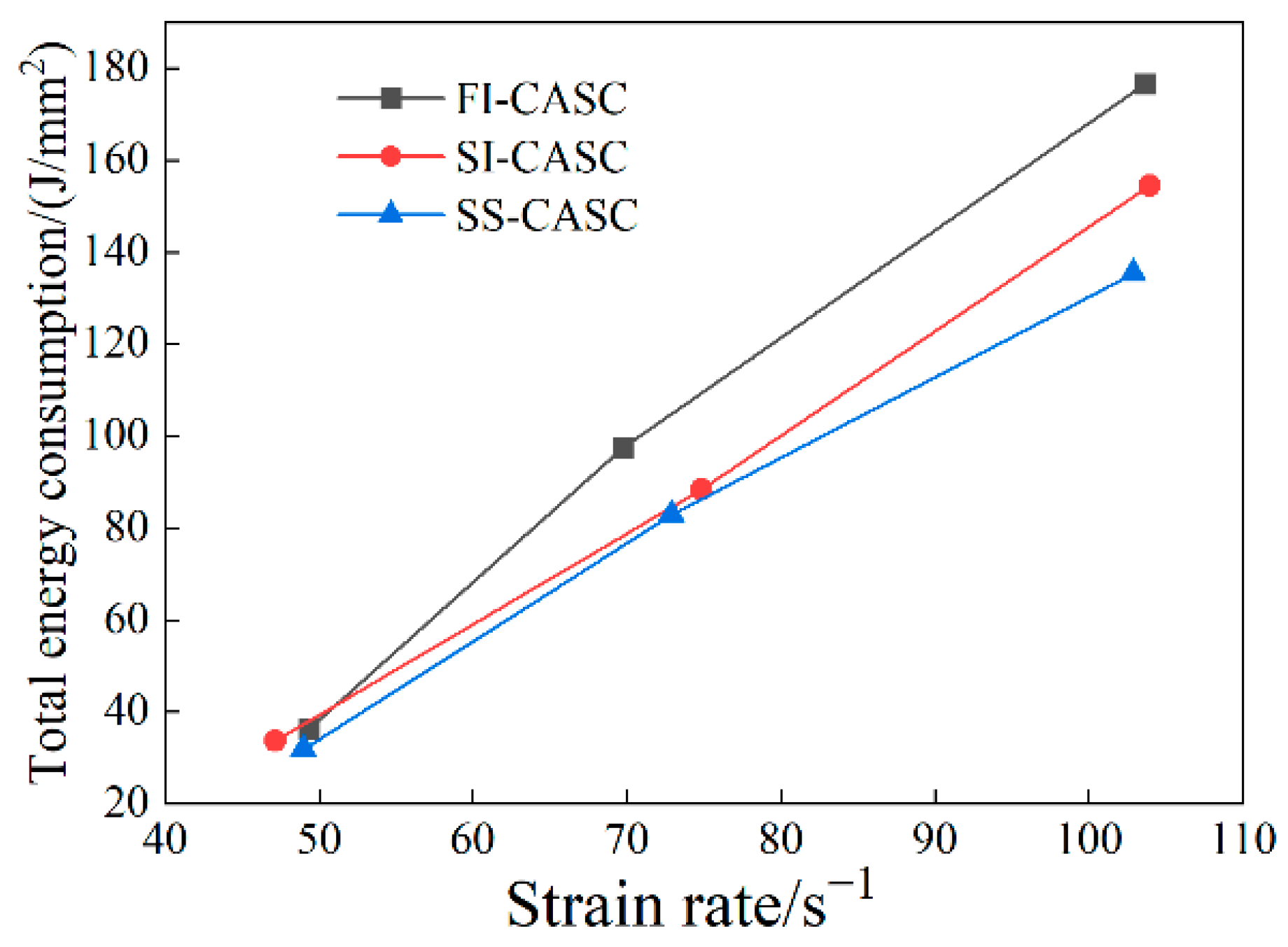

3.6. Analysis of Total Energy Consumption

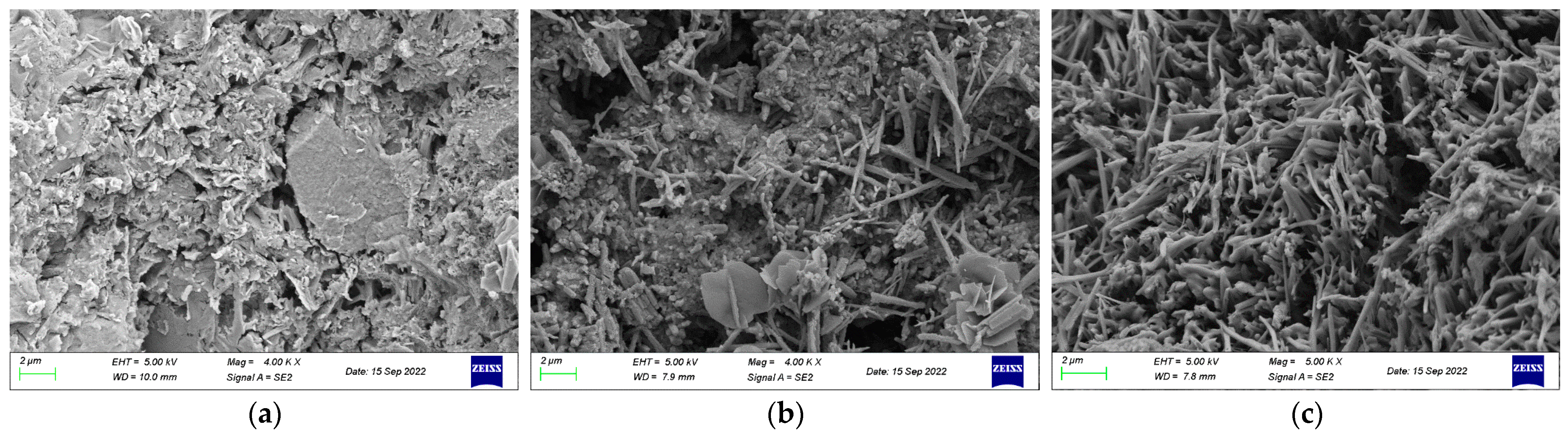

3.7. Micro-Analysis

4. Dynamic Model

- Capable of capturing all geometric characteristics of the experimental curve, this model offers accurate fitting over a wide range of strains. Its broad applicability enables a superior representation of concrete’s stress performance.

- There is only one parameter for each of the ascending and descending segments, and the parameters are independent of each other, so the formula is simple.

- Parameters a and b have definite physical significance and can reflect the deformation modulus, deformation properties, etc., of concrete.

5. Conclusions

- (1)

- The dynamic strength, dynamic modulus of elasticity, and total energy consumption of CASC specimens under the three corrosion conditions decreased substantially with the corrosion time during the 120 d corrosion cycle, and the degree in decrease was largest in the salt-spray zone, followed by the semi-immersion zone, and smallest in the full-immersion zone. However, due to the pore-filling effect of CASC caused by corrosion products, the dynamic strength and total energy consumption of the specimens located in the full-immersion zone appeared to be elevated at 30 d of corrosion, whereas those located in the salt-spray zone showed monotonically decreasing dynamic strength and total energy consumption. Combining the trends of dynamic strength of CASC in the full-immersion and semi-immersion zones, it can be surmised that a similar critical point exists in the early stage of corrosion for the specimens with CASC located in the salt-spray zone, after which the effect of corrosion products on CASC is dominated by destruction. It is noteworthy that the dynamic elastic moduli of both SI-CASC and FI-CASC demonstrate a continuous decline, contrasting with the trend in dynamic strength. This behavior is attributed to the formation of fine micro-cracks and pores from corrosion-product expansion. While these defects have an insignificant effect on dynamic strength, they substantially reduce the dynamic elastic modulus.

- (2)

- The DIF under the three corrosion conditions increases with the increase in corrosion time and strain rate, and the size was largest in the salt-spray zone, followed by the semi-immersion zone, and smallest in the full-immersion zone. When the corrosion time is the same, with the increase in strain rate, the dynamic strength of CASC in all three conditions shows a stronger strain-rate effect than that of ordinary concrete, which is mainly due to the fact that under stronger impact loading, CASC specimens produce a large number of cracks in a short time in order to obtain the shortest energy release path, and due to the low strength of coral aggregate itself, the cracks can directly pass through the coral aggregate to dissipate the energy, thus making the dynamic strength increase.

- (3)

- The stress–strain curves of CASC with a corrosion time of 120 d at different strain rates were fitted using the Guo model, which was a good fit, with the correlation coefficients of the ascending segments being greater than 0.9, and the correlation parameters of the coefficients of the descending segments being greater than 0.85, except for a few data. Its effectiveness was verified, and insights were provided for the application of CASC in engineering.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Caras, T.; Pasternak, Z. Long-term environmental impact of coral mining at the Wakatobi marine park, Indonesia. Ocean Coast. Manag. 2009, 52, 539–544. [Google Scholar] [CrossRef]

- Rasmusson, I.S. Concrete at Advance Bases. J. Am. Concr. Inst. 1946, 17, 541–551. [Google Scholar]

- Cao, Y.; Bao, J.; Zhang, P.; Sun, Y.; Cui, Y. A state-of-the-art review on the durability of seawater coral aggregate concrete exposed to marine environment. J. Build. Eng. 2022, 60, 105199. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, Z.; Zhang, Y.; Fang, Q.; Yu, H.; Jiang, C. Mesoscopic characteristics and macroscopic mechanical properties of coral aggregates. Constr. Build. Mater. 2021, 309, 125125. [Google Scholar] [CrossRef]

- Lyu, B.; Wang, A.; Zhang, Z.; Liu, K.; Xu, H.; Shi, L.; Sun, D. Coral aggregate concrete: Numerical description of physical, chemical and morphological properties of coral aggregate. Cem. Concr. Compos. 2019, 100, 25–34. [Google Scholar] [CrossRef]

- Shi, Z.; Shui, Z.; Li, Q.; Geng, H. Combined effect of metakaolin and sea water on performance and microstructures of concrete. Constr. Build. Mater. 2015, 74, 57–64. [Google Scholar] [CrossRef]

- Zhang, X.; Zuo, J.; Wang, Z.; Cai, Y.; Zhou, Y. The evolution of the microstructure and mechanical properties of coral aggregate mortar under uniaxial compression using ultrasonic analysis. Constr. Build. Mater. 2021, 300, 124000. [Google Scholar] [CrossRef]

- Su, W.; Liu, J.; Liu, L.; Chen, Z.; Shi, C. Progresses of high-performance coral aggregate concrete (HPCAC): A review. Cem. Concr. Compos. 2023, 140, 105059. [Google Scholar] [CrossRef]

- Ma, L.; Li, Z.; Wang, M.; Wei, H.; Fan, P. Effects of size and loading rate on the mechanical properties of single coral particles. Powder Technol. 2019, 342, 961–971. [Google Scholar] [CrossRef]

- Huang, Y.; Li, X.; Lu, Y.; Wang, H.; Wang, Q.; Sun, H.; Li, D. Effect of mix component on the mechanical properties of coral concrete under axial compression. Constr. Build. Mater. 2019, 223, 736–754. [Google Scholar] [CrossRef]

- Ma, L.; Li, Z.; Liu, J.; Duan, L.; Wu, J. Mechanical properties of coral concrete subjected to uniaxial dynamic compression. Constr. Build. Mater. 2019, 199, 244–255. [Google Scholar] [CrossRef]

- Wu, W.; Wang, R.; Zhu, C.; Meng, Q. The effect of fly ash and silica fume on mechanical properties and durability of coral aggregate concrete. Constr. Build. Mater. 2018, 185, 69–78. [Google Scholar] [CrossRef]

- Chen, X.; Yu, H.; Ma, H.; Xu, Y.; Gao, Y.; Mei, Q.; Dou, X.; Da, B. Analysis of service life and reliability of C50CASC structures in the splash zone of the South China Sea. Constr. Build. Mater. 2024, 441, 137524. [Google Scholar] [CrossRef]

- Hosseinzadehfard, E.; Mobaraki, B. Investigating concrete durability: The impact of natural pozzolan as a partial substitute for microsilica in concrete mixtures. Constr. Build. Mater. 2024, 419, 135491. [Google Scholar] [CrossRef]

- Hosseinzadehfard, E.; Mobaraki, B. Corrosion performance and strain behavior of reinforced concrete: Effect of natural pozzolan as partial substitute for microsilica in concrete mixtures. Structures 2025, 79, 109397. [Google Scholar] [CrossRef]

- Alexander, A.E.; Shashikala, A.P. Studies on the mechanical and durability performance of textile reinforced geopolymer concrete beams. Mater. Today Commun. 2023, 35, 105837. [Google Scholar] [CrossRef]

- Gaylarde, C.C.; Ortega-Morales, B.O. Biodeterioration and Chemical Corrosion of Concrete in the Marine Environment: Too Complex for Prediction. Microorganisms 2023, 11, 2438. [Google Scholar] [CrossRef]

- Noushini, A.; Castel, A.; Aldred, J.; Rawal, A. Chloride diffusion resistance and chloride binding capacity of fly ash-based geopolymer concrete. Cem. Concr. Compos. 2020, 105, 103290. [Google Scholar] [CrossRef]

- Homayoonmehr, R.; Ramezanianpour, A.A.; Mirdarsoltany, M. Influence of metakaolin on fresh properties, mechanical properties and corrosion resistance of concrete and its sustainability issues: A review. J. Build. Eng. 2021, 44, 103011. [Google Scholar] [CrossRef]

- Kim, S.; Kim, Y.; Usman, M.; Park, C.; Hanif, A. Durability of slag waste incorporated steel fiber-reinforced concrete in marine environment. J. Build. Eng. 2021, 33, 101641. [Google Scholar] [CrossRef]

- Aziz, M.A.; Aleem, S.A.; Heikal, M.; Didamony, H. Hydration and durability of sulphate-resisting and slag cement blends in Caron’s Lake water. Cem. Concr. Res. 2005, 35, 1592–1600. [Google Scholar] [CrossRef]

- Li, F.; Yuan, Y.; Li, C.-Q. Corrosion propagation of prestressing steel strands in concrete subject to chloride attack. Constr. Build. Mater. 2011, 25, 3878–3885. [Google Scholar] [CrossRef]

- Da, B.; Yu, H.; Ma, H.; Tan, Y.; Mi, R.; Dou, X. Chloride diffusion study of coral concrete in a marine environment. Constr. Build. Mater. 2016, 123, 47–58. [Google Scholar] [CrossRef]

- Liu, W.; Du, H.; Li, Y.; Yi, P.; Luo, Y.; Tang, L.; Xing, F. Effects of chloride content on early hydration performance of cement pastes. Mater. Today Commun. 2023, 35, 106257. [Google Scholar] [CrossRef]

- Geng, J.; Easterbrook, D.; Li, L.; Mo, L. The stability of bound chlorides in cement paste with sulfate attack. Cem. Concr. Res. 2015, 68, 211–222. [Google Scholar] [CrossRef]

- Yu, H.; Da, B.; Ma, H.; Dou, X.; Wu, Z. Service life prediction of coral aggregate concrete structure under island reef environment. Constr. Build. Mater. 2020, 246, 118390. [Google Scholar] [CrossRef]

- Huang, D.; Niu, D.; Su, L.; Liu, Y.; Guo, B.; Xia, Q.; Peng, G. Diffusion behavior of chloride in coral aggregate concrete in marine salt-spray environment. Constr. Build. Mater. 2022, 316, 125878. [Google Scholar] [CrossRef]

- Wang, G.; Wu, Q.; Zhou, H.; Peng, C.; Chen, W. Diffusion of chloride ion in coral aggregate seawater concrete under marine environment. Constr. Build. Mater. 2021, 284, 122821. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H. Durability of seawater coral aggregate concrete under seawater immersion and dry-wet cycles. J. Build. Eng. 2023, 66, 105894. [Google Scholar] [CrossRef]

- Zhang, B.; Peng, H.; Xiong, T.; Zhu, H. Towards enhancing the durability of seawater coral aggregate concrete under drying-wetting cycles with slag-based geopolymers. J. Sustain. Cem. Based Mater. 2024, 13, 389–401. [Google Scholar] [CrossRef]

- Qin, Q.; Meng, Q.; Mei, Q.; Wu, K.; Wang, C.; Zhang, J. Dynamic response characteristics of coral reef sand concrete under impact loading. J. Build. Eng. 2023, 66, 105847. [Google Scholar] [CrossRef]

- Ma, H.; Yue, C.; Yu, H.; Mei, Q.; Chen, L.; Zhang, J.; Zhang, Y.; Jiang, X. Experimental study and numerical simulation of impact compression mechanical properties of high strength coral aggregate seawater concrete. Int. J. Impact Eng. 2020, 137, 103466. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P.; Han, Y.; Hao, R.; Liu, W. Dynamic compressive properties of seawater coral aggregate concrete (SCAC) reinforced with mono or hybrid fibers. Constr. Build. Mater. 2022, 340, 127801. [Google Scholar] [CrossRef]

- Fu, Q.; Xu, W.; He, J.; Su, L.; Song, H.; Niu, D. Dynamic strength criteria for basalt fibre-reinforced coral aggregate concrete. Compos. Commun. 2021, 28, 100983. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, D.; Zhang, S.; Fan, X. Dynamic behavior of carbon nanotubes and basalt fiber reinforced coral sand cement mortar at high strain rates. Constr. Build. Mater. 2022, 340, 127396. [Google Scholar] [CrossRef]

- Guo, J.; Yu, H.; Ma, H.; Wu, Z. Damage and deterioration characteristics of basic magnesium sulfate cement-coral aggregate concrete exposed to elevated temperature. Eng. Fail. Anal. 2022, 137, 106275. [Google Scholar] [CrossRef]

- Chen, B.; Yu, H.; Zhang, J.; Ma, H. Evolution law of crack propagation and crack mode in coral aggregate concrete under compression: Experimental study and 3D mesoscopic analysis. Theor. Appl. Fract. Mech. 2022, 122, 103663. [Google Scholar] [CrossRef]

- JGJ 12-2006; Technical Specification for Lightweight Aggregate Concrete Structures. National Standards of the Republic of China: Beijing, China, 2006.

- JGJ 55-2011; Specification for Mix Proportion Design of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2011.

- T/CECS 694-2020; Technical Specification for Coral Aggregate Concrete. China Academy of Building Research: Beijing, China, 2020.

- GB/T 50082; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of PRC: Beijing, China, 2009.

- Yu, P.; Qin, K.; Chen, Z.; Ren, Z.; Zhang, J. Degradation Behavior of Coral Concrete Exposed to Different Marine Environments. 2026. Available online: https://dl.astm.org/jte/article-abstract/doi/10.1520/JTE20240546/30299/Degradation-Behavior-of-Coral-Concrete-Exposed-to?redirectedFrom=fulltext (accessed on 21 October 2025).

- Gray, G.T., III. Classic Split-Hopkinson Pressure Bar Testing. In Mechanical Testing and Evaluation; Kuhn, H., Medlin, D., Eds.; ASM International: Almere, The Netherlands, 2000; pp. 462–476. ISBN 978-1-62708-176-4. [Google Scholar]

- Huang, D.; Niu, D.; Su, L.; Pan, D.; Liu, Y. Durability of coral aggregate concrete under coupling action of sulfate, chloride and drying-wetting cycles. Case Stud. Constr. Mater. 2022, 16, e01003. [Google Scholar] [CrossRef]

- Yu, P.; Qiu, H.; He, S.; Qin, Y.; Zhou, Y. Pore structure and prediction of mechanical properties by ANN of concrete mixed MK and SF under hydrochloric acid corrosion. Constr. Build. Mater. 2023, 409, 133665. [Google Scholar] [CrossRef]

| Chemical Component | CaO | SiO2 | Al2O3 | Fe2O3 | SO3 | MgO | Other |

|---|---|---|---|---|---|---|---|

| Mass fraction (%) | 65.24 | 21.12 | 5.34 | 4.63 | 1.58 | 1.25 | 0.84 |

| Fine Modulus | Apparent Density (g × cm−3) | Stacking Density (g × cm−3) | Moisture Content (%) | Dust Content (%) |

|---|---|---|---|---|

| 3.0 | 2.800 | 1.298 | 2.9% | 0.5% |

| Apparent Density (g × cm−3) | Bulk Density (g × cm−3) | Water Content (%) | Dust Content (%) | Press Strength (MPa) | Particle Gradation (mm) |

|---|---|---|---|---|---|

| 1.841 | 0.915 | 2.6 | 2.9 | 3.1 | 5~20 |

| Cement (kg × m−3) | Coral (kg × m−3) | Coral Sand (kg × m−3) | Seawater Consumption (kg × m−3) | Water Reducer (kg × m−3) | Water-Binder Ratio | The Sand Coarse Aggregate Ratio |

|---|---|---|---|---|---|---|

| 708 | 531 | 614 | 248 | 12 | 0.35 | 0.54 |

| t/d | σd/MPa | ||

|---|---|---|---|

| FI-CASC | SI-CASC | SS-CASC | |

| 0 | 86.94 | 86.94 | 86.94 |

| 30 | 91.75 | 89.17 | 83.84 |

| 60 | 88.13 | 85.74 | 81.39 |

| 90 | 85.65 | 83.78 | 77.58 |

| 120 | 82.66 | 79.19 | 73.99 |

| ID | /s−1 | Rising Phase | Descending Phase | ||

|---|---|---|---|---|---|

| a | b | ||||

| FI-CASC | 49.35 | 0.511 | 0.9845 | 2515.139 | 0.7606 |

| 69.72 | −0.616 | 0.9850 | 4.939 | 0.8970 | |

| 103.67 | 1.691 | 0.9903 | 2.927 | 0.8687 | |

| SI-CASC | 47.13 | −0.420 | 0.9166 | 309.885 | 0.9694 |

| 74.82 | 0.244 | 0.9670 | 6.089 | 0.8770 | |

| 103.95 | 1.259 | 0.9960 | 5.270 | 0.9600 | |

| SS-CASC | 48.98 | −0.167 | 0.9363 | 1715.156 | 0.9539 |

| 72.91 | 0.308 | 0.9899 | 13.208 | 0.9730 | |

| 102.88 | 1.642 | 0.996 | 3.881 | 0.8797 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, Y.; Luo, Y.; Zhang, J.; He, S.; Luo, Y.; Yu, P. Degradation Law of Dynamic Mechanical Properties of Coral Concrete Under Marine Environment. Buildings 2025, 15, 4288. https://doi.org/10.3390/buildings15234288

Zhong Y, Luo Y, Zhang J, He S, Luo Y, Yu P. Degradation Law of Dynamic Mechanical Properties of Coral Concrete Under Marine Environment. Buildings. 2025; 15(23):4288. https://doi.org/10.3390/buildings15234288

Chicago/Turabian StyleZhong, Yi, Yansong Luo, Jiafeng Zhang, Sheng He, Yuejing Luo, and Peng Yu. 2025. "Degradation Law of Dynamic Mechanical Properties of Coral Concrete Under Marine Environment" Buildings 15, no. 23: 4288. https://doi.org/10.3390/buildings15234288

APA StyleZhong, Y., Luo, Y., Zhang, J., He, S., Luo, Y., & Yu, P. (2025). Degradation Law of Dynamic Mechanical Properties of Coral Concrete Under Marine Environment. Buildings, 15(23), 4288. https://doi.org/10.3390/buildings15234288