Centrifugal Model Test Study on the Influence of Subgrade Filling on Adjacent Bridge Pile Foundations

Abstract

1. Introduction

2. Materials and Methods

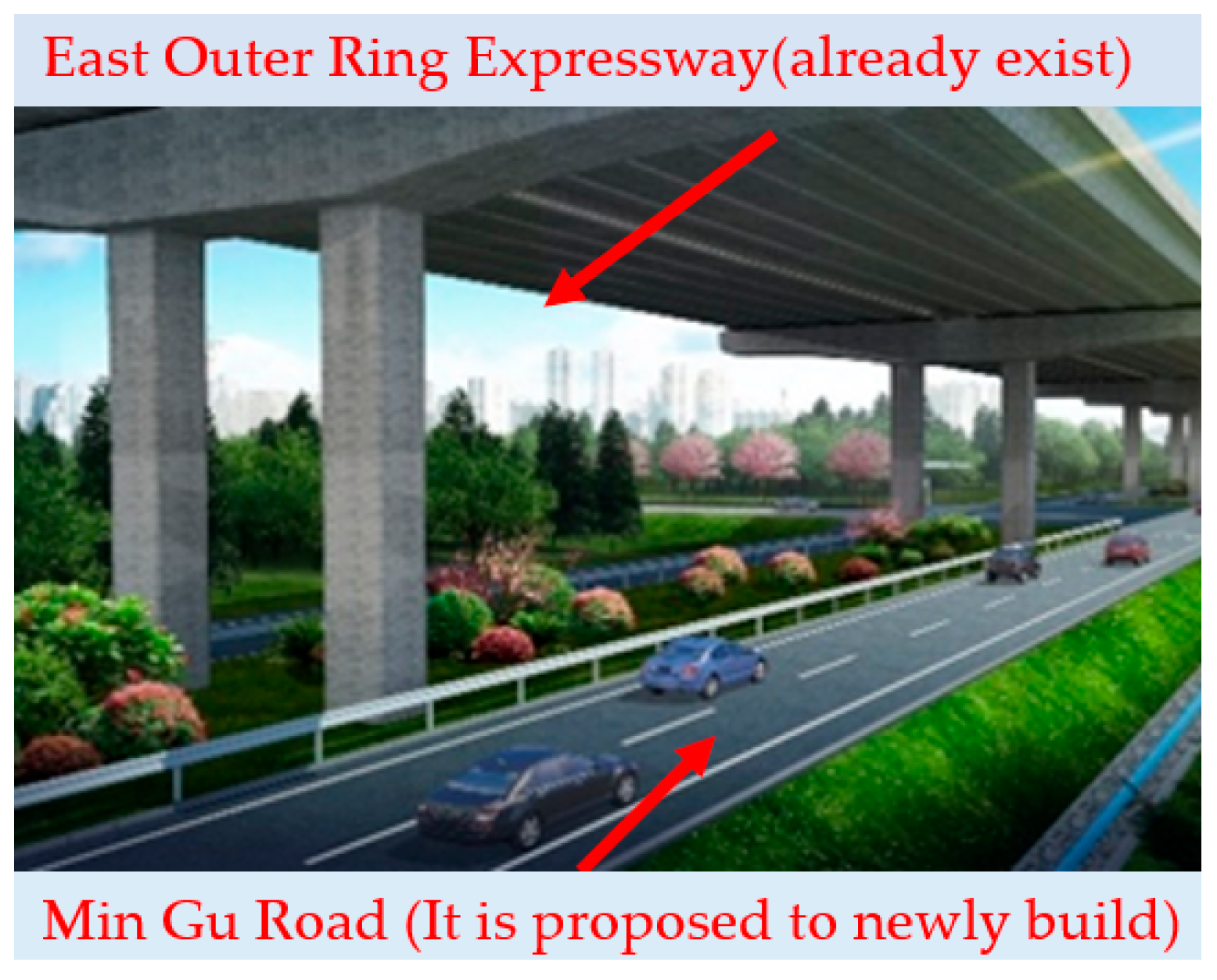

2.1. Project Overview

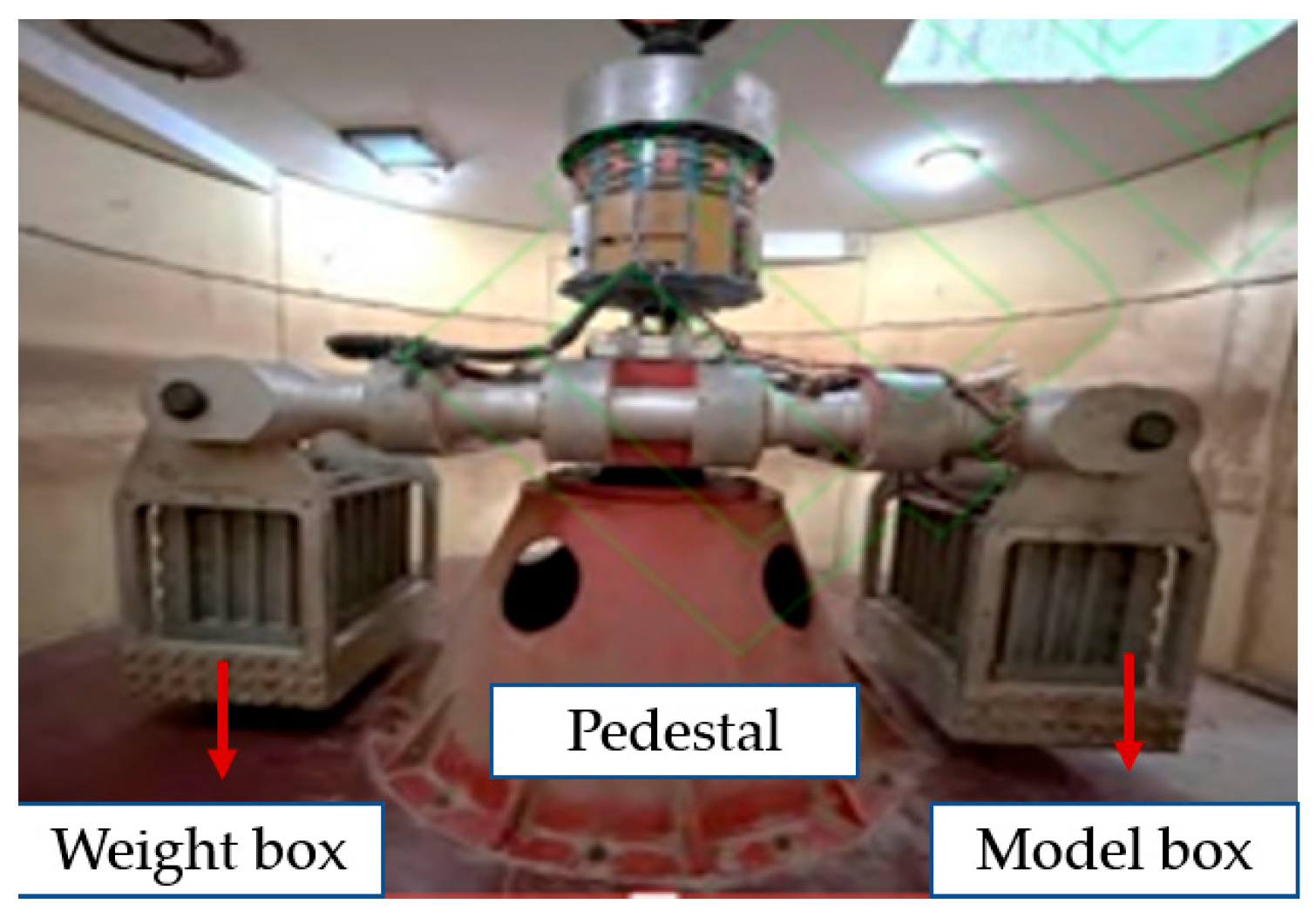

2.2. Test Equipment and Data Collection

2.3. Centrifuge Model Test Similarity Laws Tests

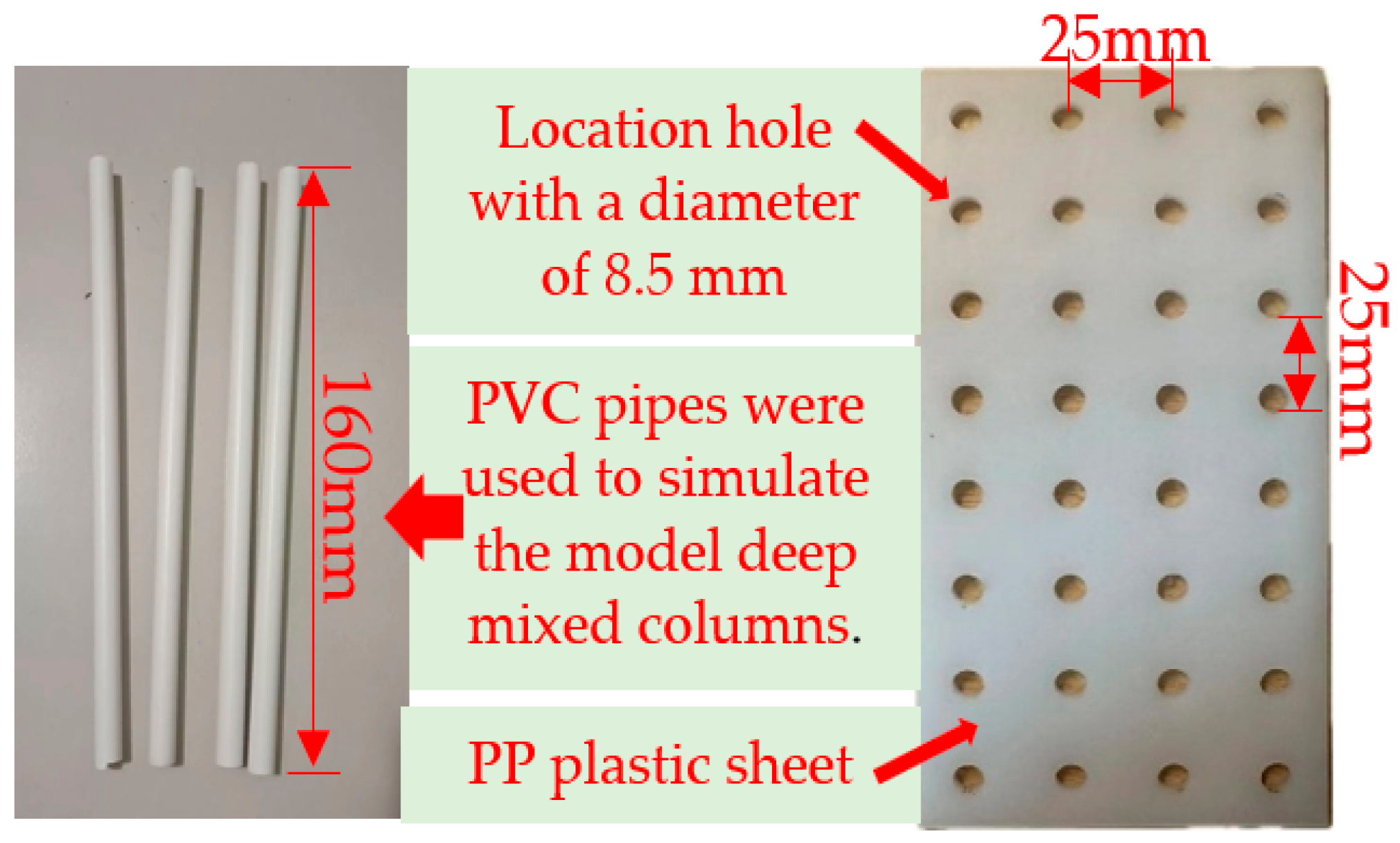

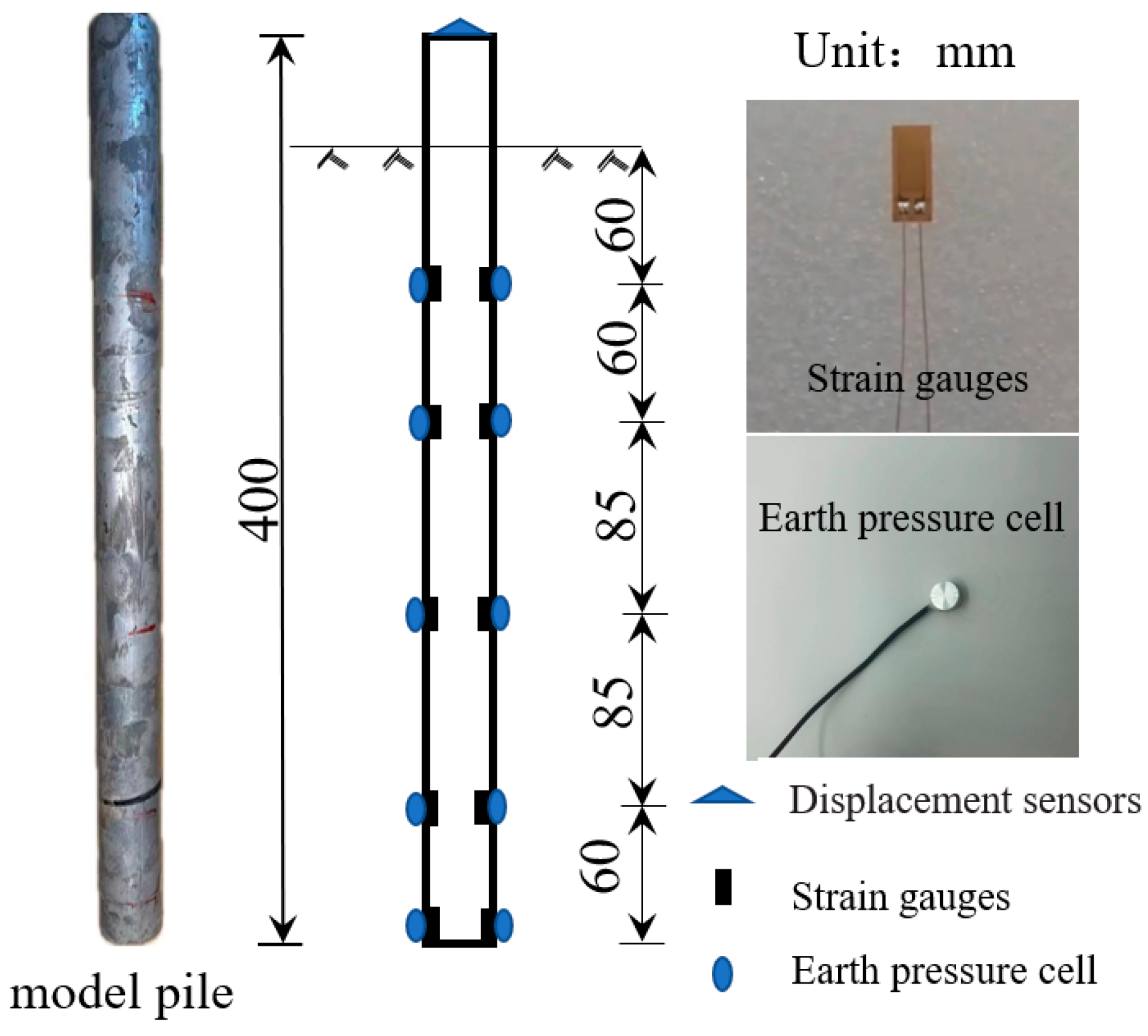

2.4. Design of the Model Pile

2.5. Model Deep Mixed Columns

2.6. Soil Sample Preparation

2.7. Experimental Protocol

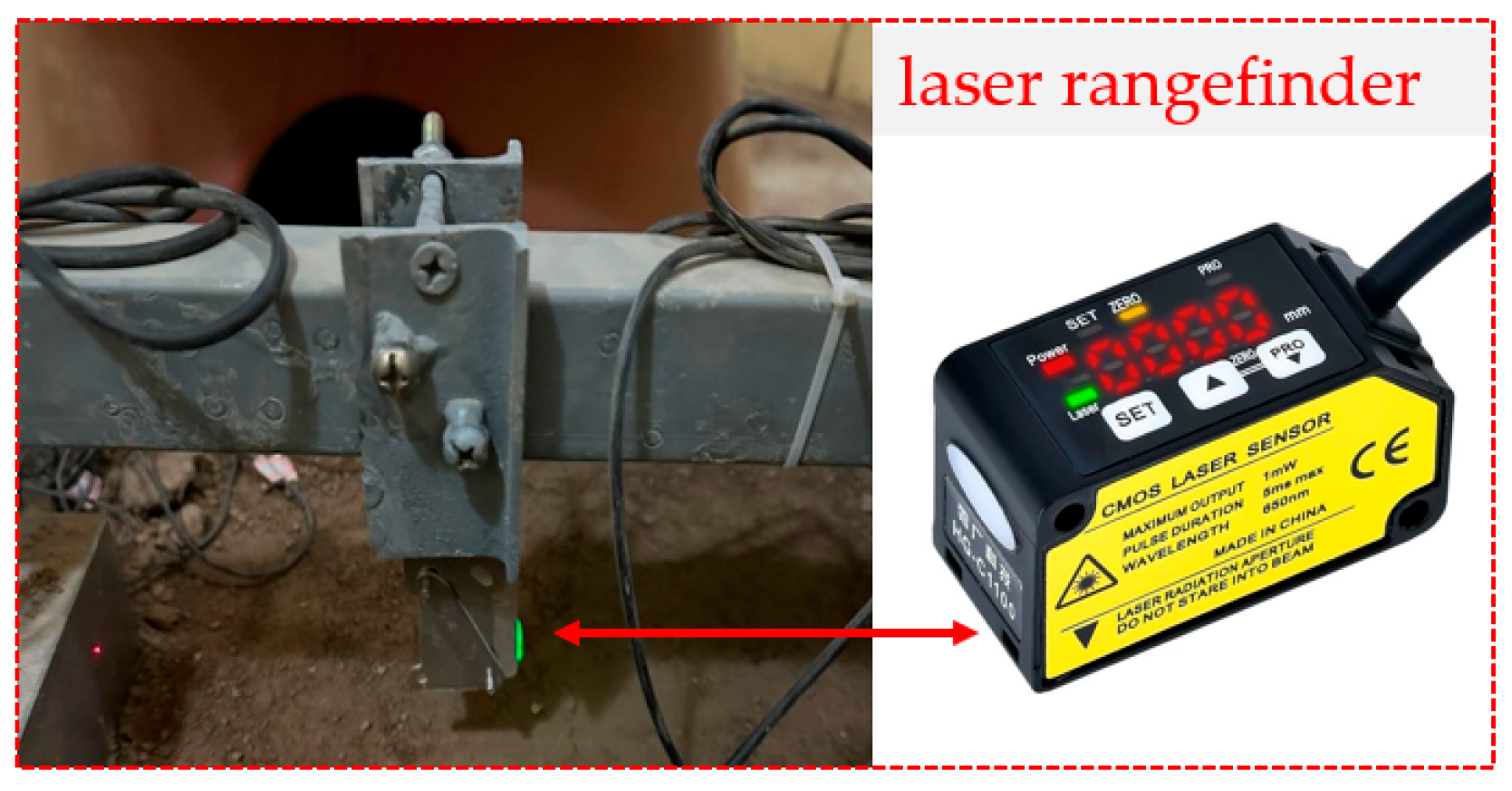

2.8. Data Collection and Processing

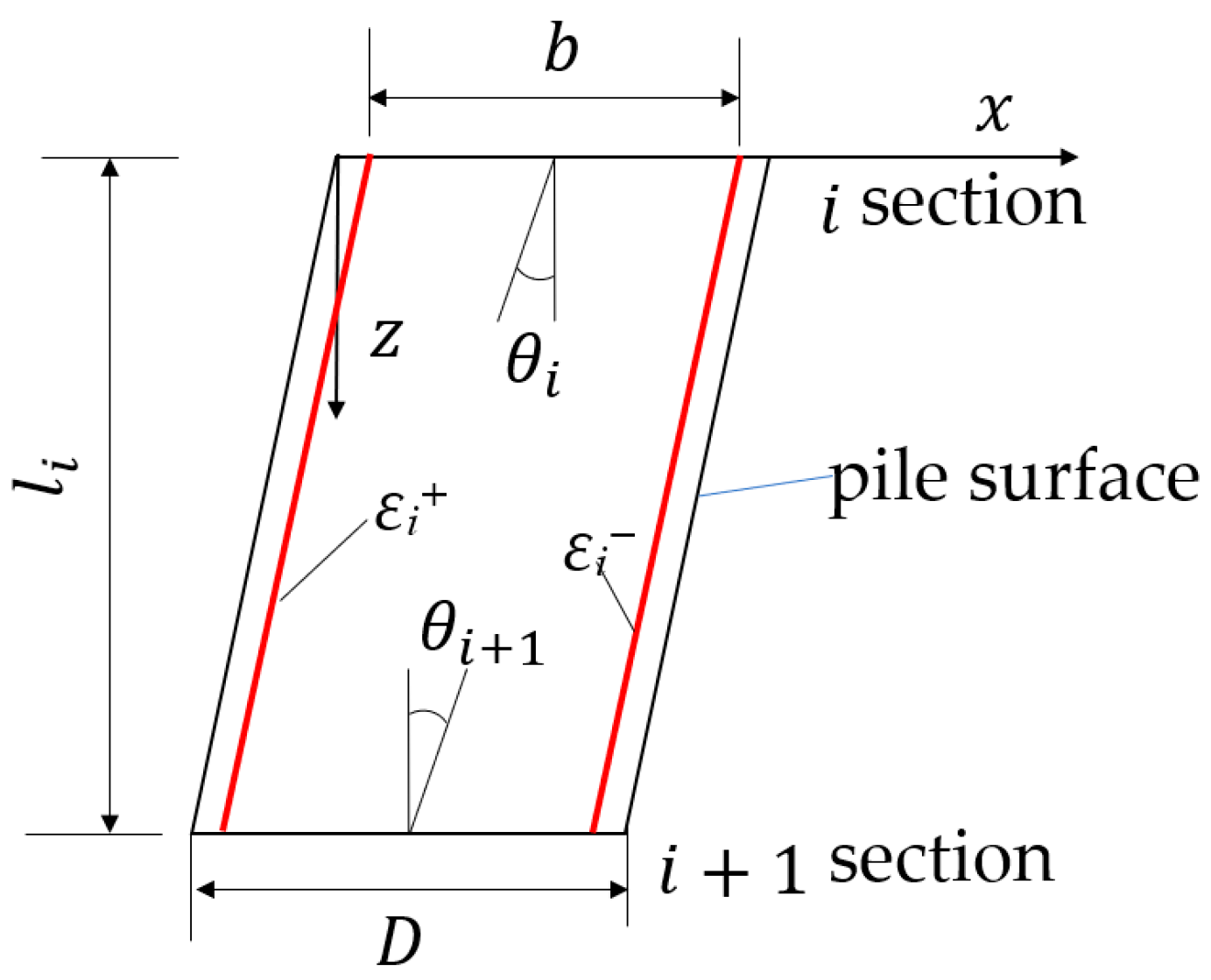

2.9. Transformation of Pile Body Displacement

3. Results

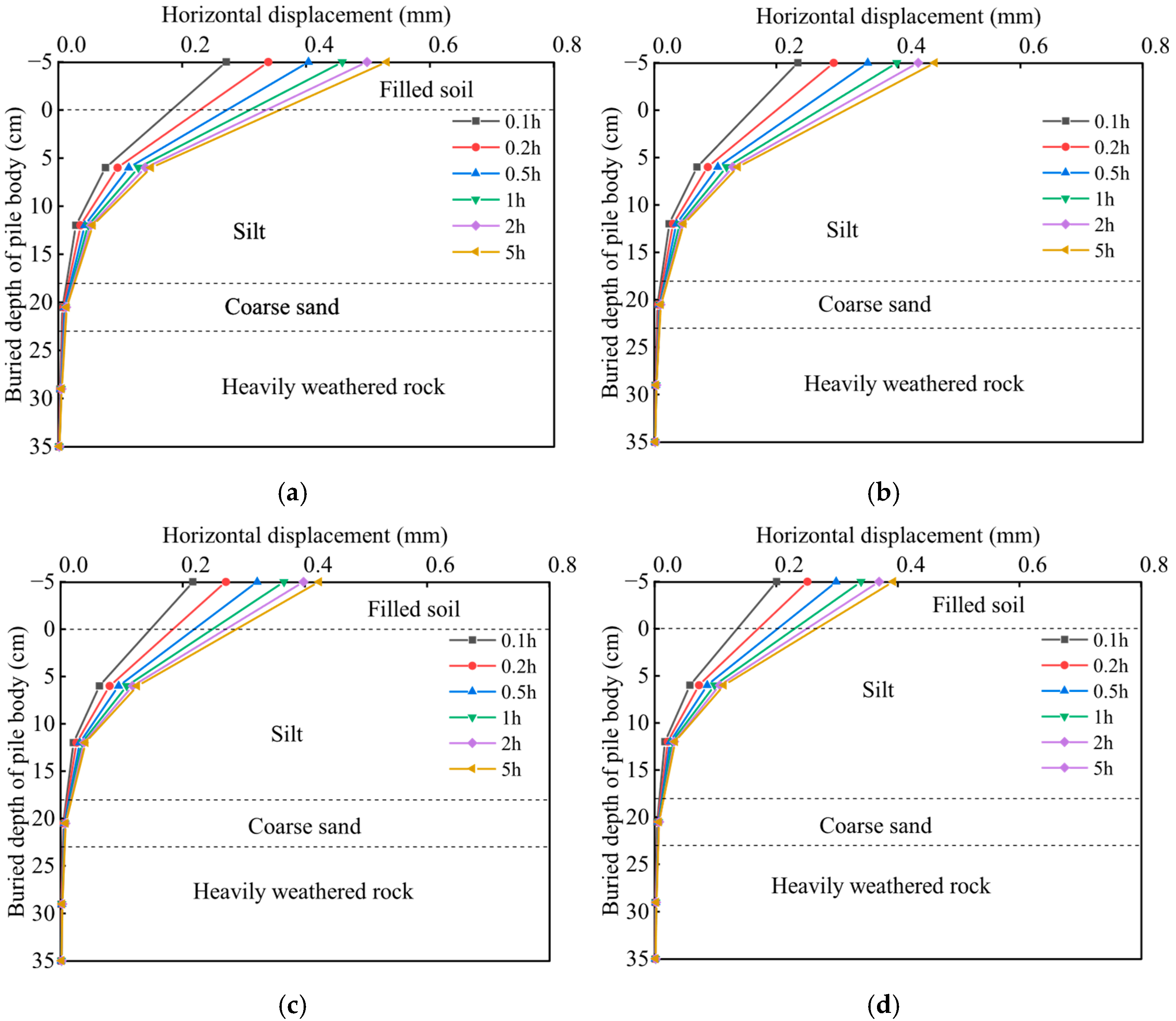

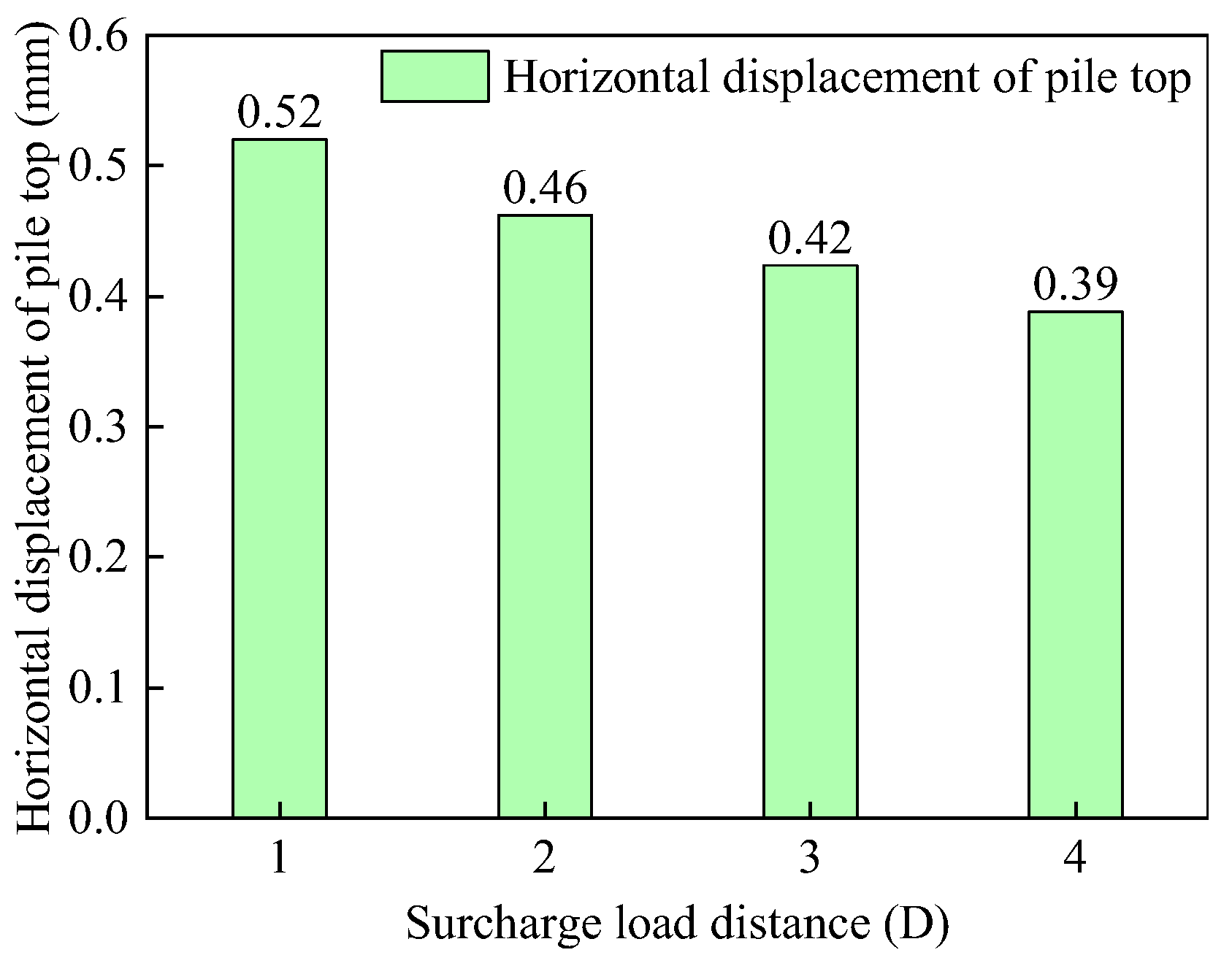

3.1. Variation in the Horizontal Displacement at the Pile Top

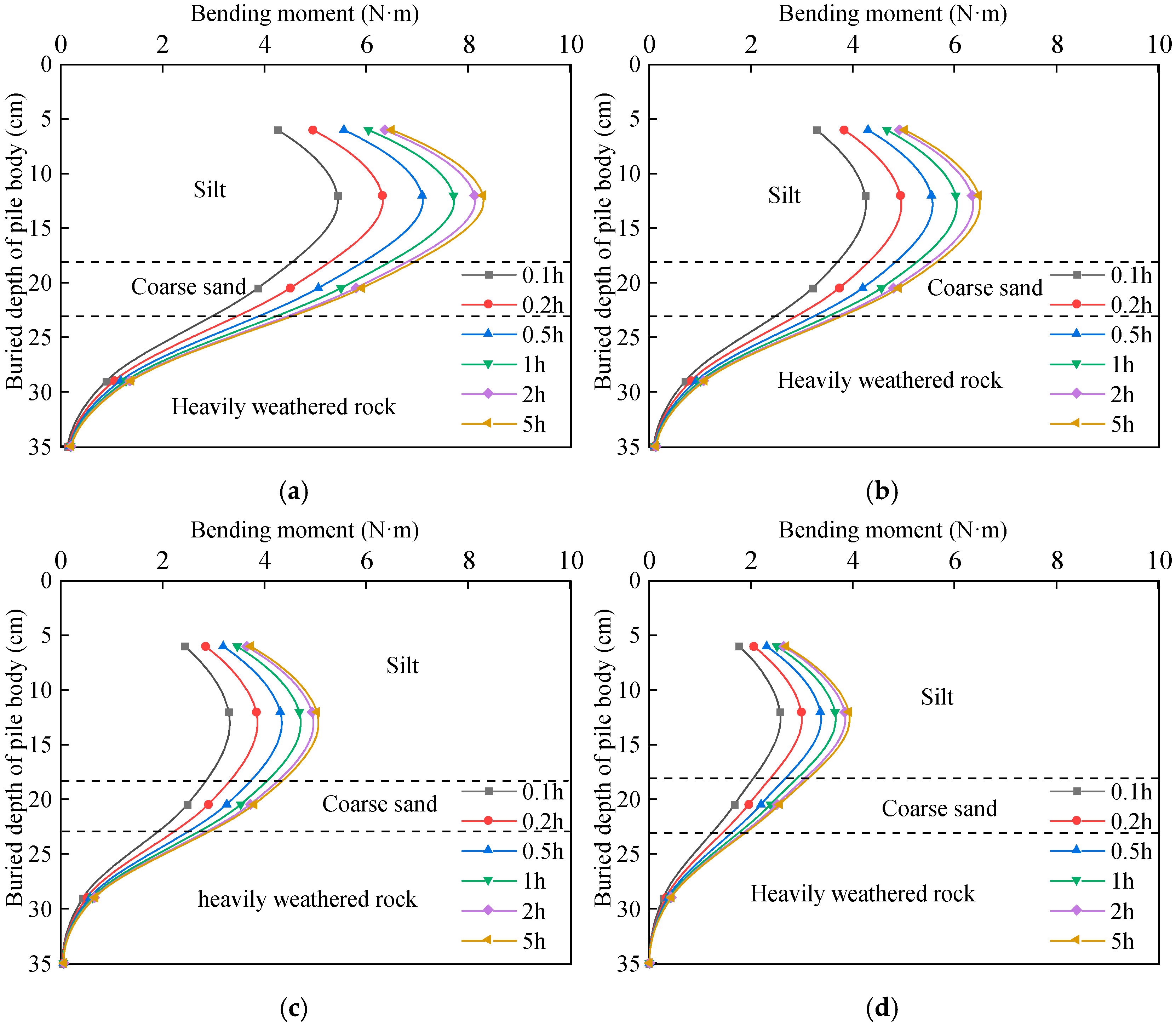

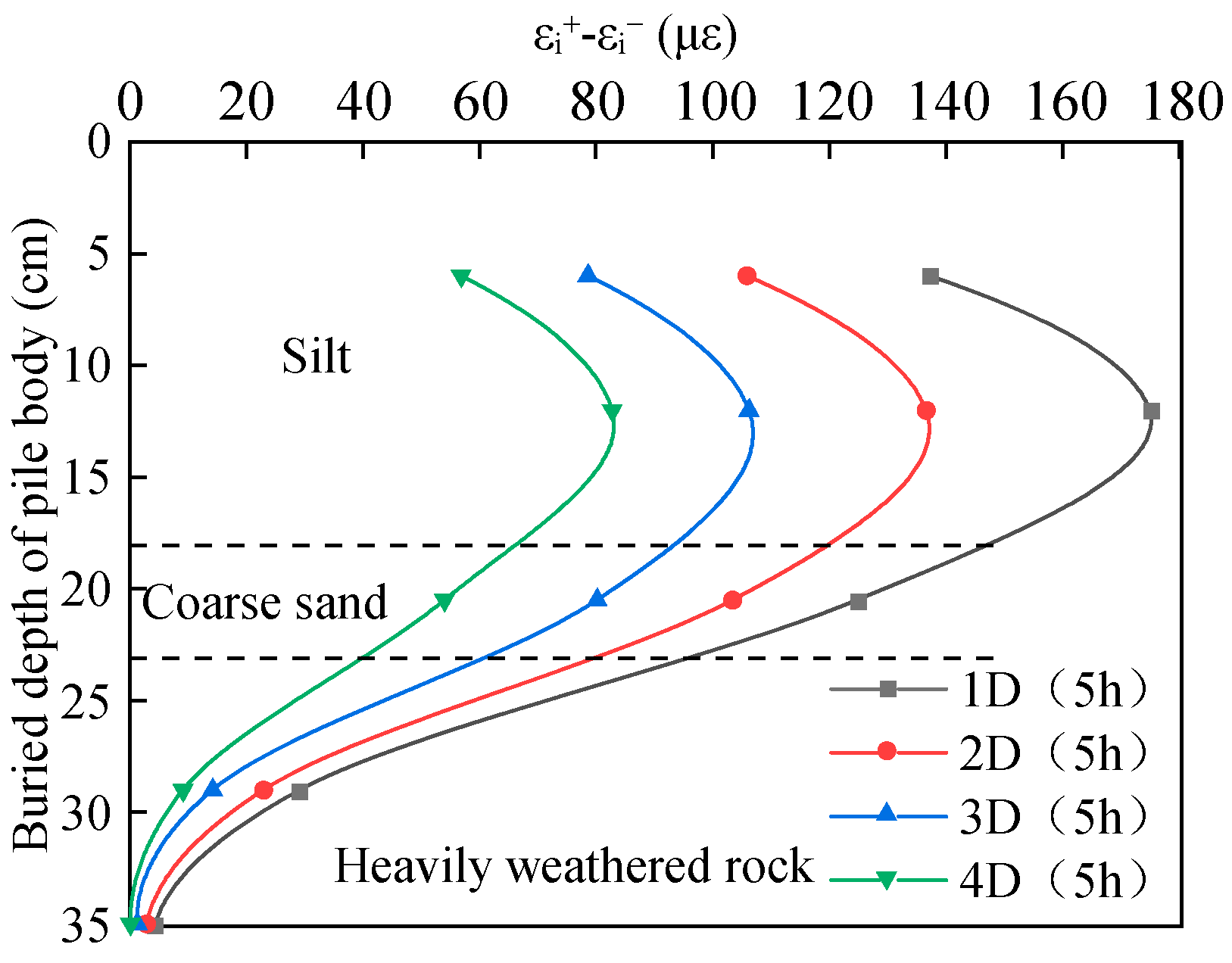

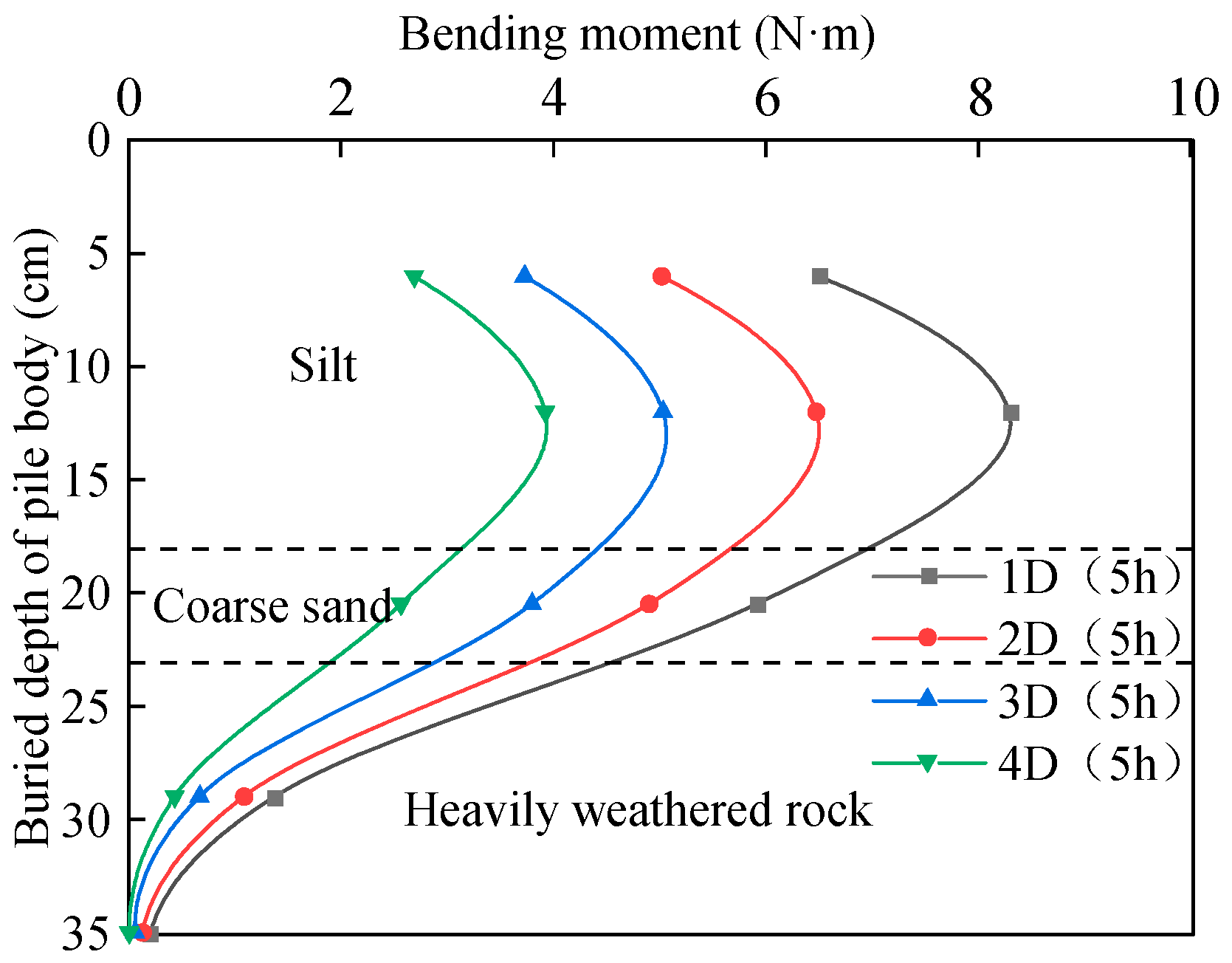

3.2. Variation in Pile Shaft Bending Moment

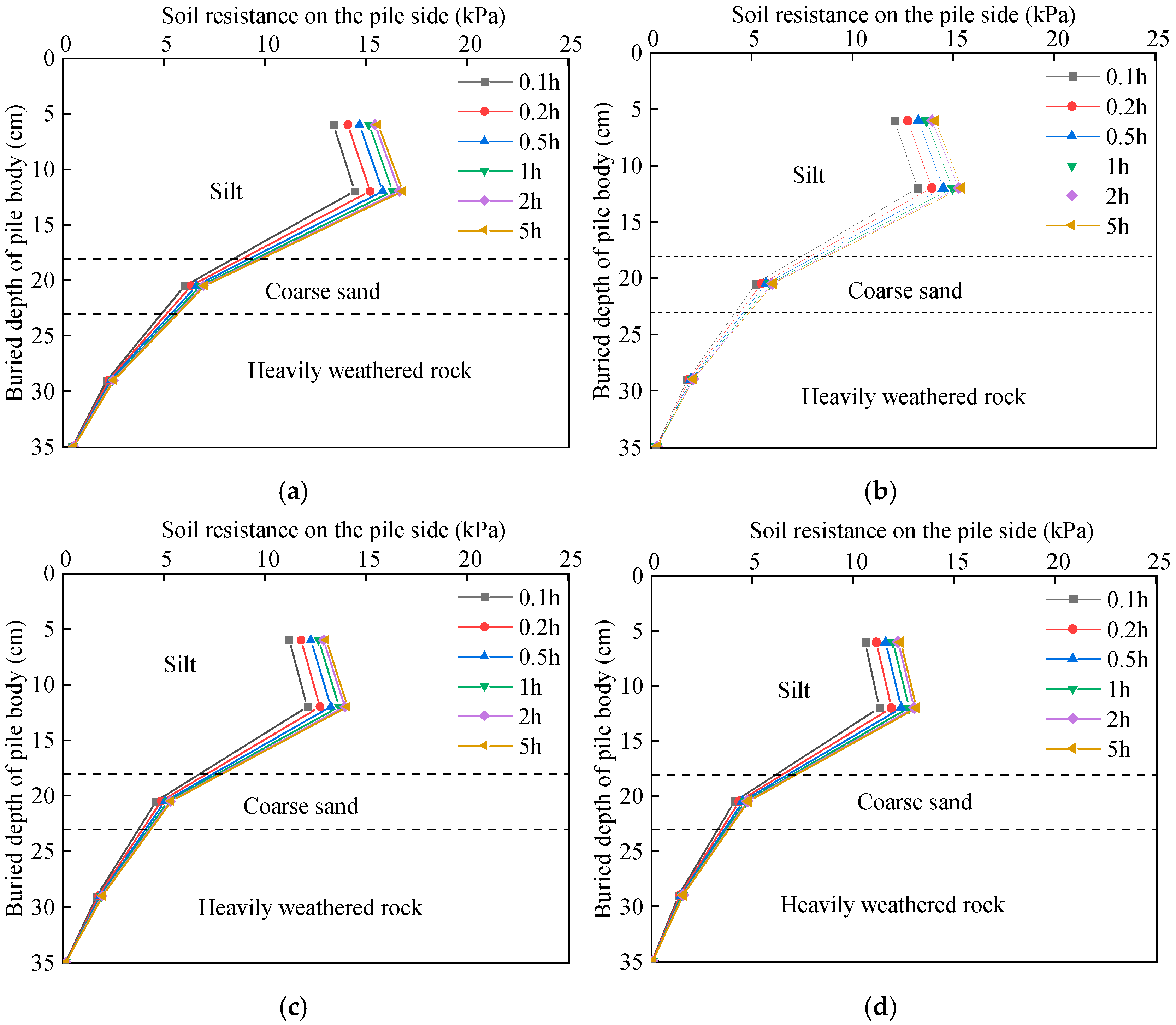

3.3. Variation in Lateral Soil Resistance of Piles

4. Discussion

5. Conclusions

- (1)

- The horizontal displacement, pile bending moment, and lateral soil resistance increase with time under sustained surcharge loading, showing pronounced time-dependent consolidation effects.

- (2)

- The horizontal displacement and bending moment both decrease with increasing surcharge distance, indicating an apparent spatial attenuation effect. The influence of surcharge loading becomes small but still measurable beyond approximately four times the diameter of the pile.

- (3)

- Along the pile depth, the bending moment exhibits a unimodal distribution with a peak in the soft upper soil layer. In contrast, lateral soil resistance follows an increase–decrease pattern, peaking in the middle layer.

- (4)

- The observed mechanical responses highlight that close surcharge loading can significantly compromise pile stability. Hence, maintaining adequate surcharge separation and improving the surrounding soil stiffness are essential for ensuring the long-term safety of bridge foundations adjacent to embankment fills.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Z. Study on the influence of adjacent surcharge loading on displacement of bridge pile foundations in soft soil. Rock Soil Mech. 2013, 34, 3594–3600. [Google Scholar]

- Yuan, B.; Chen, M.; Chen, W.; Luo, Q.; Li, H. Effect of pile-soil relative stiffness on deformation characteristics of the laterally loaded pile. Adv. Mater. Sci. Eng. 2022, 2022, 1–13. [Google Scholar] [CrossRef]

- Yuan, B.; Chen, W.; Zhao, J.; Li, L.; Liu, F.; Guo, Y.; Zhang, B. Addition of alkaline solutions and fibers for the reinforcement of kaolinite-containing granite residual soil. Appl. Clay Sci. 2022, 228, 106644. [Google Scholar] [CrossRef]

- Yuan, B.; Li, Z.; Chen, W.; Zhao, J.; Lv, J.; Song, J.; Cao, X. Influence of groundwater depth on pile-soil mechanical properties and fractal characteristics under cyclic loading. Fractal Fract. 2022, 6, 198. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, K. Influence of surcharge load on the adjacent pile foundation in coastal floodplain. Insight-Civ. Eng. 2020, 3, 17–25. [Google Scholar] [CrossRef]

- Yi, S. Parametric study of passive piles subjected to adjacent surcharge load in extensively deep soft soil. Front. Mater. 2022, 9, 1080547. [Google Scholar] [CrossRef]

- Yi, S.; Liu, J. Field investigation of steel pipe pile under lateral loading in extensively soft soil. Front. Mater. 2022, 9, 480. [Google Scholar] [CrossRef]

- Zuo, L.; Cao, S.; Zhou, S.; Wu, J. Inversion of damage inducement of wharf pile foundation under heaped load based on parametric model. SN Appl. Sci. 2022, 4, 69. [Google Scholar] [CrossRef]

- Al-abboodi, I.; Sabbagh, T.T. Numerical modeling of passively loaded pile groups. Geotech. Geol. Eng. 2019, 37, 2747–2761. [Google Scholar] [CrossRef]

- Yu, Y.H.; Yan, B. Present Situation and Development Trend of Underground Space in Megacity in China. Chin. J. Undergr. Space Eng. 2021, 17, 1–7. [Google Scholar]

- Zhang, Y.; Guo, Y.; Zhang, Q. Experimental Study on the Horizontal Bearing Performance of Pile–Soil Composite Foundation Under Coupled Action of Active and Passive Loads. Buildings 2025, 15, 3184. [Google Scholar] [CrossRef]

- Li, T.; Yang, M. Investigation of Passive Pile Groups’ Responses Induced by Combined Surcharge-Induced and Excavation-Induced Horizontal Soil Loading. Buildings 2023, 13, 2775. [Google Scholar] [CrossRef]

- Li, T.; Yang, M.; Chen, X. Lateral Deformation Response of an Adjacent Passive Pile under the Combined Action of Surcharge Loading and Foundation Excavation. Sustainability 2023, 15, 13619. [Google Scholar] [CrossRef]

- Chen, H.; Feng, Z.; Wei, X.; Li, Y. Study on the Negative Skin Friction on Bridge Pile Foundations Induced by Backfilling in Karst Areas. Buildings 2025, 15, 3672. [Google Scholar] [CrossRef]

- Cheng, F.; Li, M.; Li, Q. Multi-Method Sensitivity Analysis of Influencing Factors on the Lateral Displacement of Retaining Piles in Asymmetric Excavations in Soft Soil Areas. Symmetry 2025, 17, 1525. [Google Scholar] [CrossRef]

- Cao, F.; Ye, C.; Wu, Z.; Zhao, Z.; Sun, H. Settlement Calculation of Semi-Rigid Pile Composite Foundation on Ultra-Soft Soil under Embankment Load. Buildings 2024, 14, 1954. [Google Scholar] [CrossRef]

- Dong, Y.; Feng, Z.; Feng, K.; Wen, J.; He, J. Effect of Road Embankment Overburden with Weak Interlayer on Bridge Pile Foundation and Its Treatment Methods. Chin. J. Undergr. Space Eng. 2020, 16, 1219–1229. [Google Scholar]

- Deng, H.; Dai, G.; Gong, W.; Zhu, Z. In situ experimental study of bearing characteristics of pile foundation under different balanced surcharges. Rock Soil Mech. 2015, 36, 3063–3070. [Google Scholar]

- Feng, T.; Gao, W.; Zhang, J.; He, Y. Effect of in-situ curing of joint composite foundations on pile-loaded adjacent pile foundations. J. Cent. South Univ. (Sci. Technol.) 2024, 55, 715–729. [Google Scholar]

- Ding, R. Field test study on pile foundation subjected to adjacent surcharge in deep-soft soil strata. J. Railw. Sci. Eng. 2015, 12, 291–296. [Google Scholar]

- Liu, Z. Field tests on negative skin friction of steel pipe piles in high backfilling soils. Chin. J. Geotech. Eng. 2015, 37, 337–342. [Google Scholar]

- Yuan, G.; Li, J. Centrifugal model tests on the influences of loads of a coal storage yard on the foundation and pile-based coal shed. Chin. J. Geotech. Eng. 2024, 46 (Suppl. S1), 197–201. [Google Scholar]

- Wei, L.; Zhang, K.; He, Q.; Zhang, C. Mechanical Response Analysis for an Active–Passive Pile Adjacent to Surcharge Load. Appl. Sci. 2023, 13, 4196. [Google Scholar] [CrossRef]

- Gu, M.; Cai, X.; Fu, Q.; Li, H.; Wang, X.; Mao, B. Numerical Analysis of Passive Piles under Surcharge Load in Extensively Deep Soft Soil. Buildings 2022, 12, 1988. [Google Scholar] [CrossRef]

- Li, H.; Liu, S.; Yan, X.; Gu, W.; Tong, L. Effect of loading sequence on lateral soil-pile interaction due to excavation. Comput. Geotech. 2021, 134, 104134. [Google Scholar] [CrossRef]

| Name | Index |

|---|---|

| Maximum capacity | 60 g·t |

| Effective radius | 2.0 m |

| Degree of stability | ±0.1% F. S |

| Acceleration range | 10~200 g |

| The size of the model box | 700 × 360 × 500 mm |

| Physical Quantity | Dimension | Similarity Constant |

|---|---|---|

| Acceleration a | LT−2 | n |

| Force F | MLT−2 | 1/n2 |

| Water content w | - | 1 |

| Linear size l | L | 1/n |

| Time t (consolidation) | T−2 | 1/n2 |

| Stress σ | FL−2 | 1 |

| Density ρ | FL−4T2 | 1 |

| Name | I/m4 | E/GPa | EI/GN·m2 | n4EI/GN·m2 | Error/% |

|---|---|---|---|---|---|

| Prototype pile | 0.52 | 30 | 15.45 | - | 8.7% |

| model pile | 1.55 × 10−8 | 70 | 1.09 × 10−6 | 14.10 |

| Name | I/m4 | E/GPa | EI/GN·m2 | n4EI/GN·m2 | Error/% |

|---|---|---|---|---|---|

| Prototype deep mixed columns | 3.07 × 10−3 | 0.5 | 1.53 × 10−3 | - | 2.1% |

| Model deep mixed columns | 1.21 × 10−10 | 2 | 1.23 × 10−10 | 1.56 × 10−3 |

| Stratum | Name | Water Content | Unit Weight /kN/m3 | Compression Modulus/MPa | Friction Angle/° | Cohesion/kPa |

|---|---|---|---|---|---|---|

| Soft soil | Prototype | - | 16.6 | 2.0 | 4.5 | 5.8 |

| Coarse sand | Prototype | - | 18.8 | 5.0 | 21.0 | 2.0 |

| Heavily weathered rock | Prototype | - | 22.0 | 40.8 | 25.0 | 25.1 |

| Filled soil | Prototype | - | 20.1 | 6.2 | 16.1 | 22.0 |

| Soft soil | Model | 45.1% | 16.5 | 2.1 | 4.6 | 5.8 |

| Coarse sand | Model | 5.3% | 18.6 | 5.1 | 21.5 | 2.1 |

| Heavily weathered rock | Model | 10.7% | 21.7 | 42.1 | 25.2 | 25.3 |

| Filled soil | Model | 13.5% | 20.4 | 6.1 | 16.3 | 22.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, S.; Feng, Z.; Liu, J.; Zhang, C.; Zhang, C.; Wang, J. Centrifugal Model Test Study on the Influence of Subgrade Filling on Adjacent Bridge Pile Foundations. Buildings 2025, 15, 4162. https://doi.org/10.3390/buildings15224162

Zhou S, Feng Z, Liu J, Zhang C, Zhang C, Wang J. Centrifugal Model Test Study on the Influence of Subgrade Filling on Adjacent Bridge Pile Foundations. Buildings. 2025; 15(22):4162. https://doi.org/10.3390/buildings15224162

Chicago/Turabian StyleZhou, Shihao, Zhongju Feng, Junyong Liu, Chao Zhang, Cong Zhang, and Jikun Wang. 2025. "Centrifugal Model Test Study on the Influence of Subgrade Filling on Adjacent Bridge Pile Foundations" Buildings 15, no. 22: 4162. https://doi.org/10.3390/buildings15224162

APA StyleZhou, S., Feng, Z., Liu, J., Zhang, C., Zhang, C., & Wang, J. (2025). Centrifugal Model Test Study on the Influence of Subgrade Filling on Adjacent Bridge Pile Foundations. Buildings, 15(22), 4162. https://doi.org/10.3390/buildings15224162