Investigation into the Impacts of Cover-and-Cut Top-Down Metro Station Construction on Adjacent Buildings: A Case Study

Abstract

1. Introduction

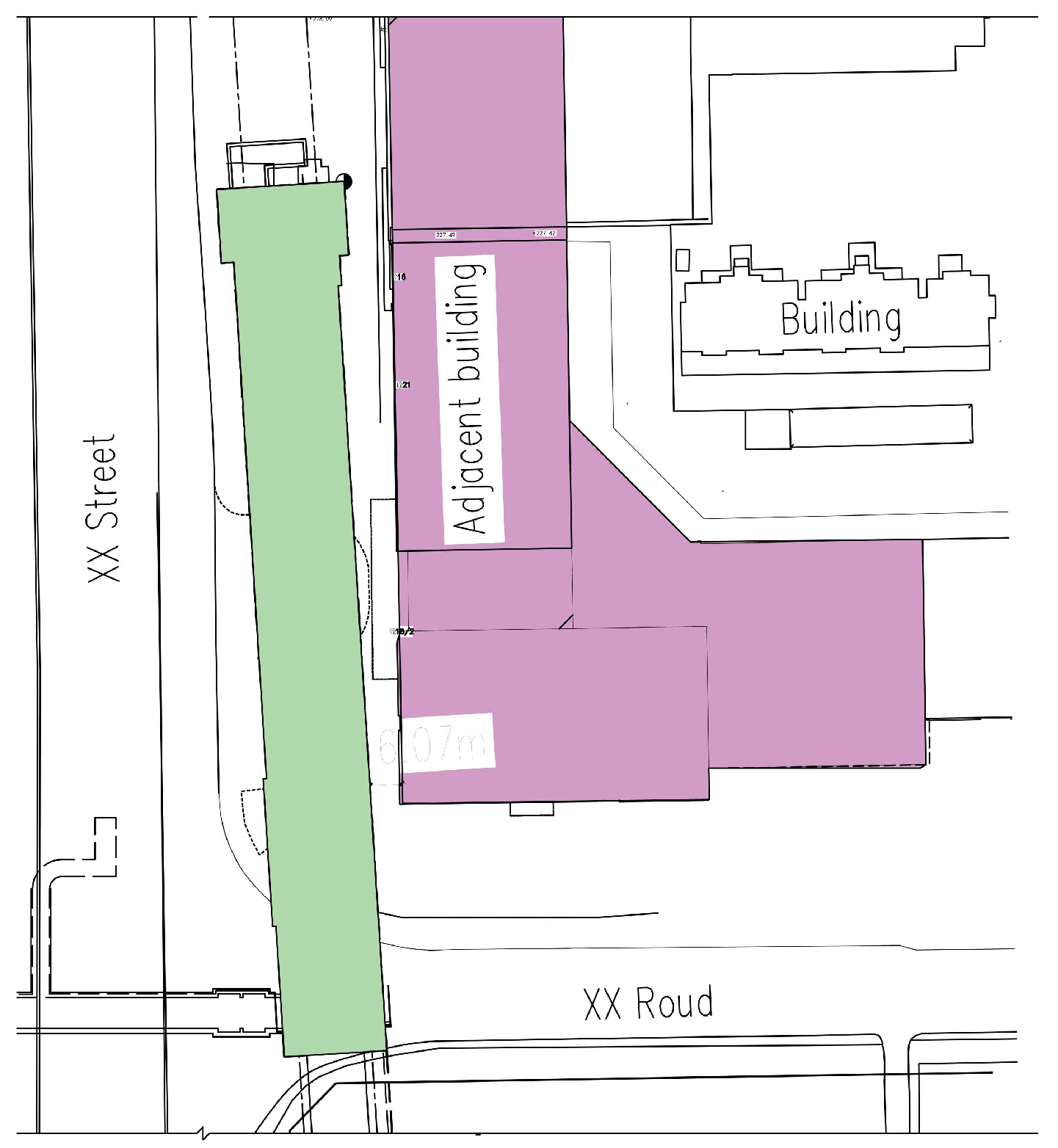

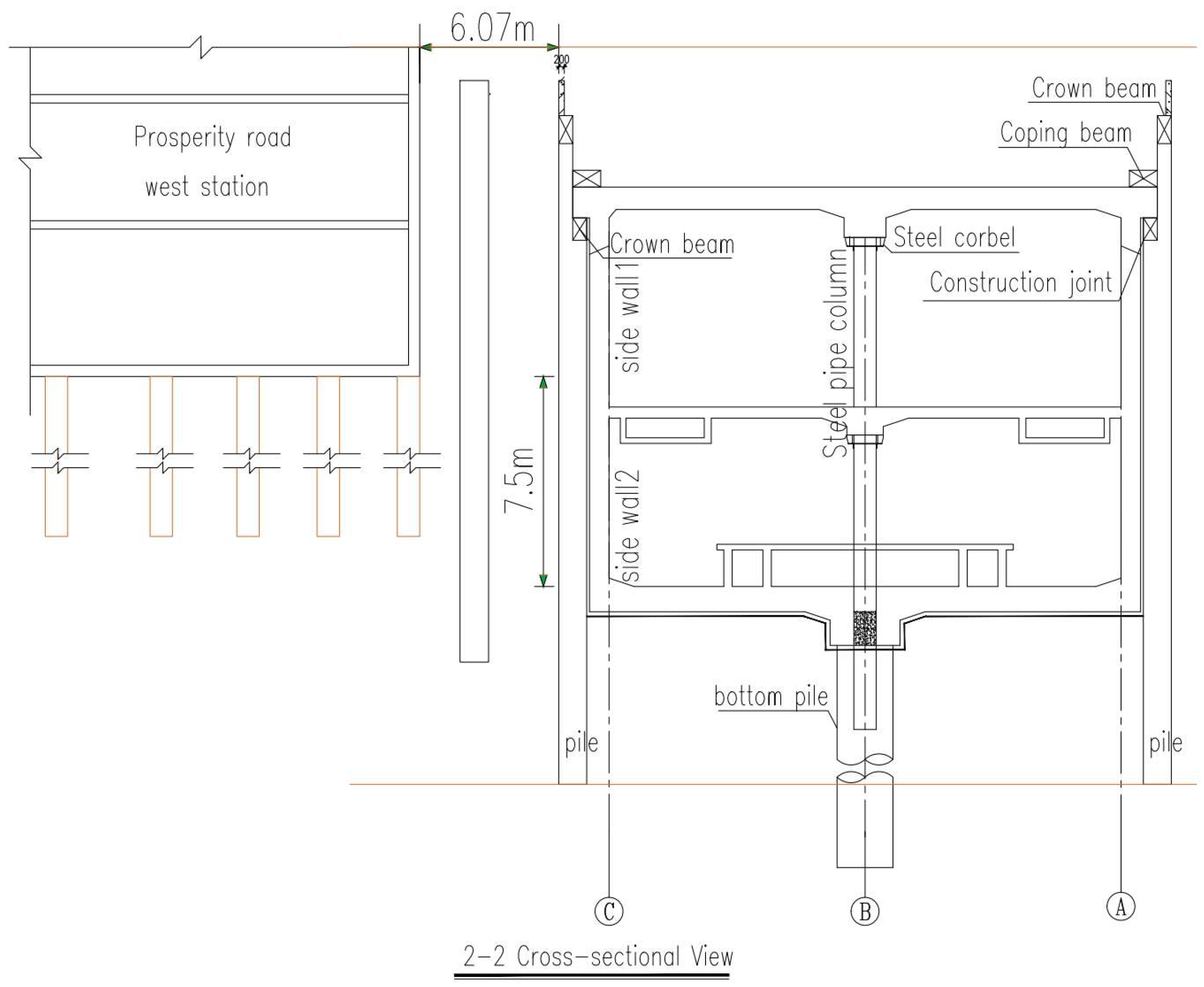

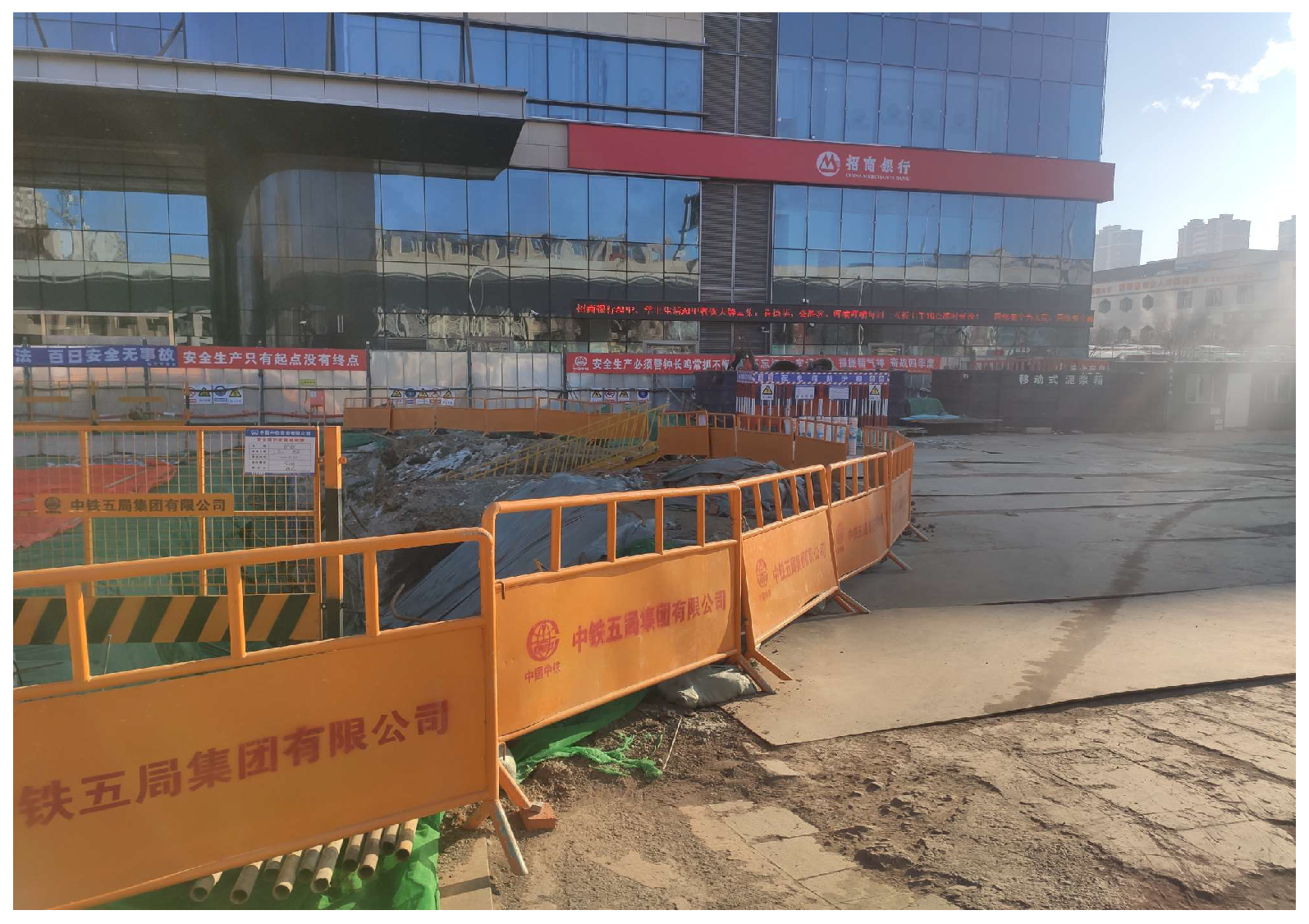

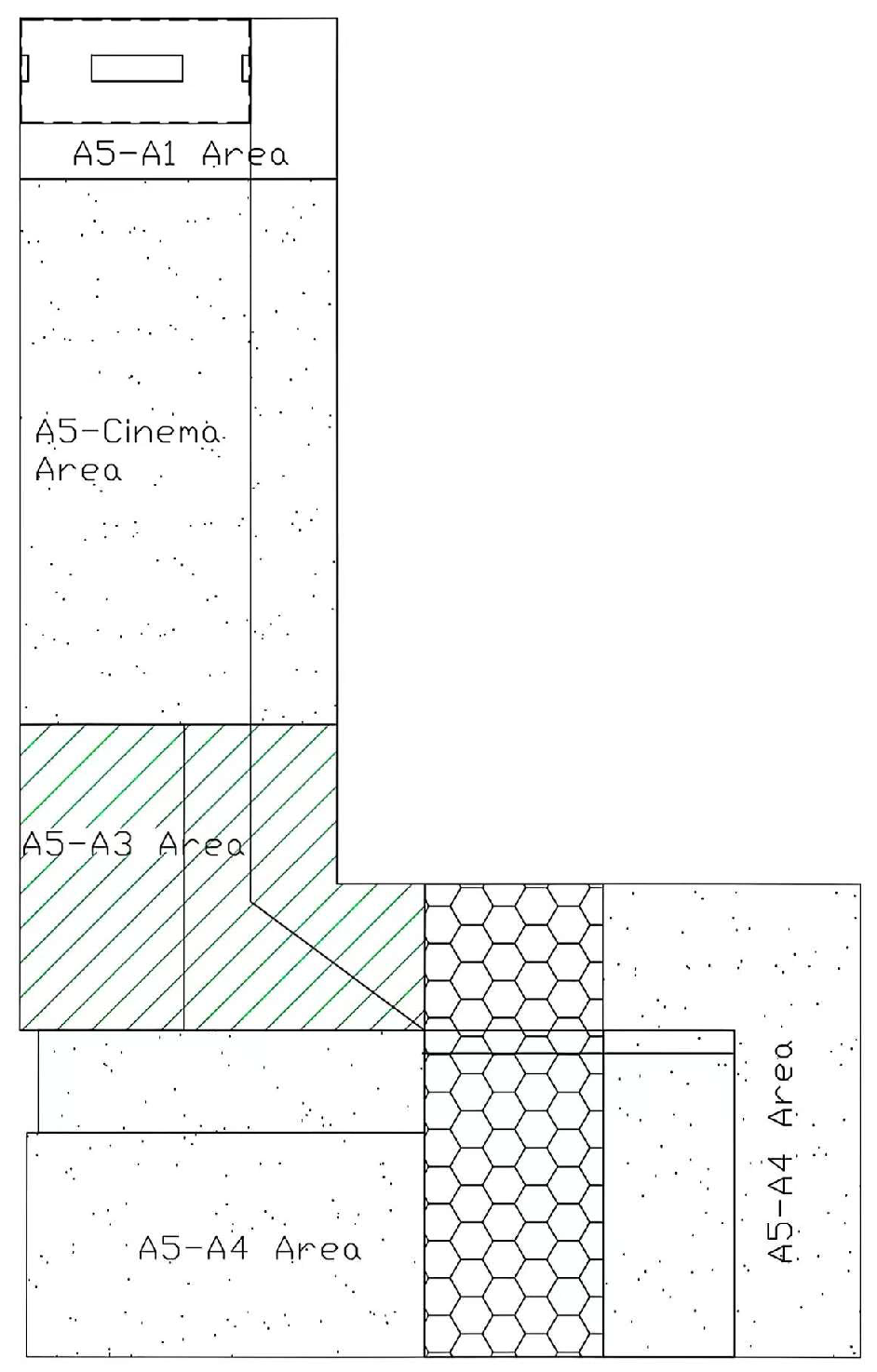

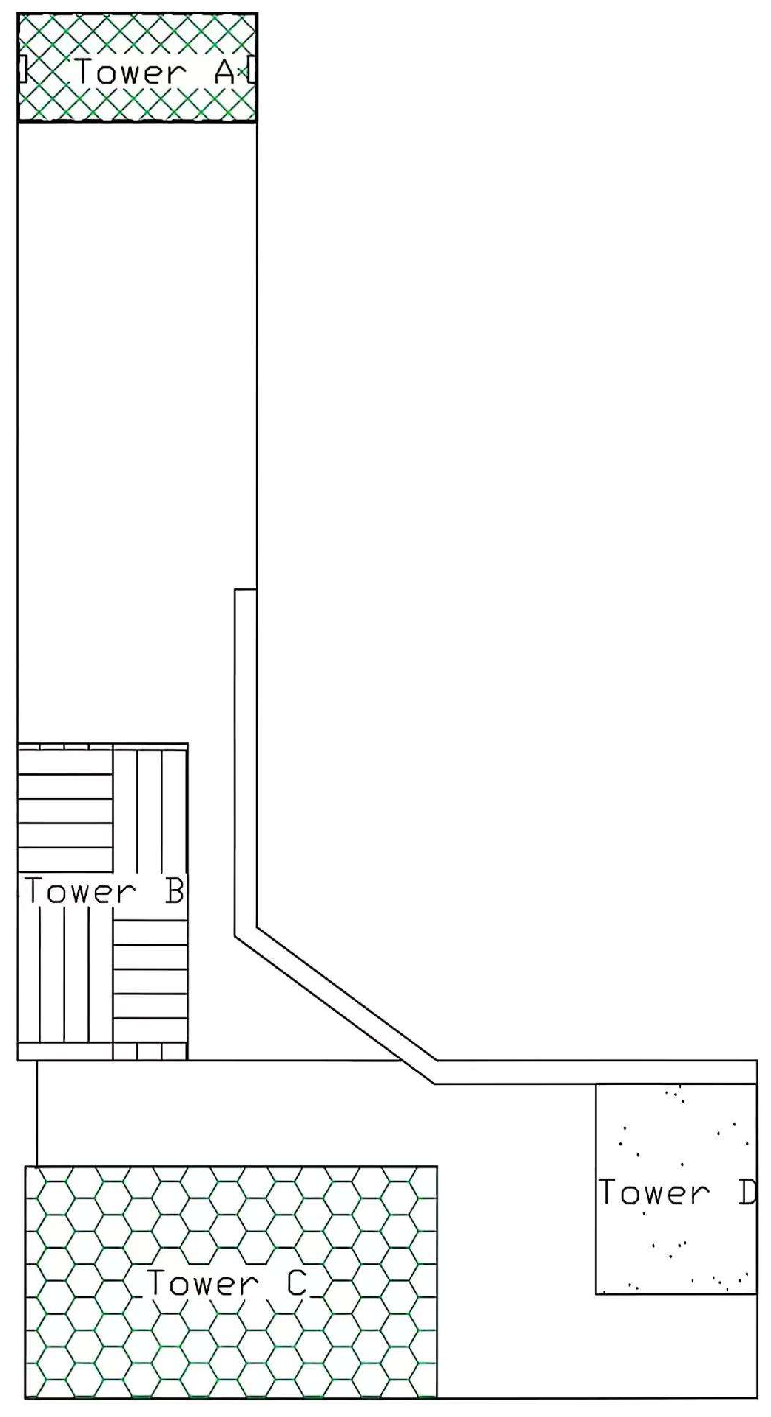

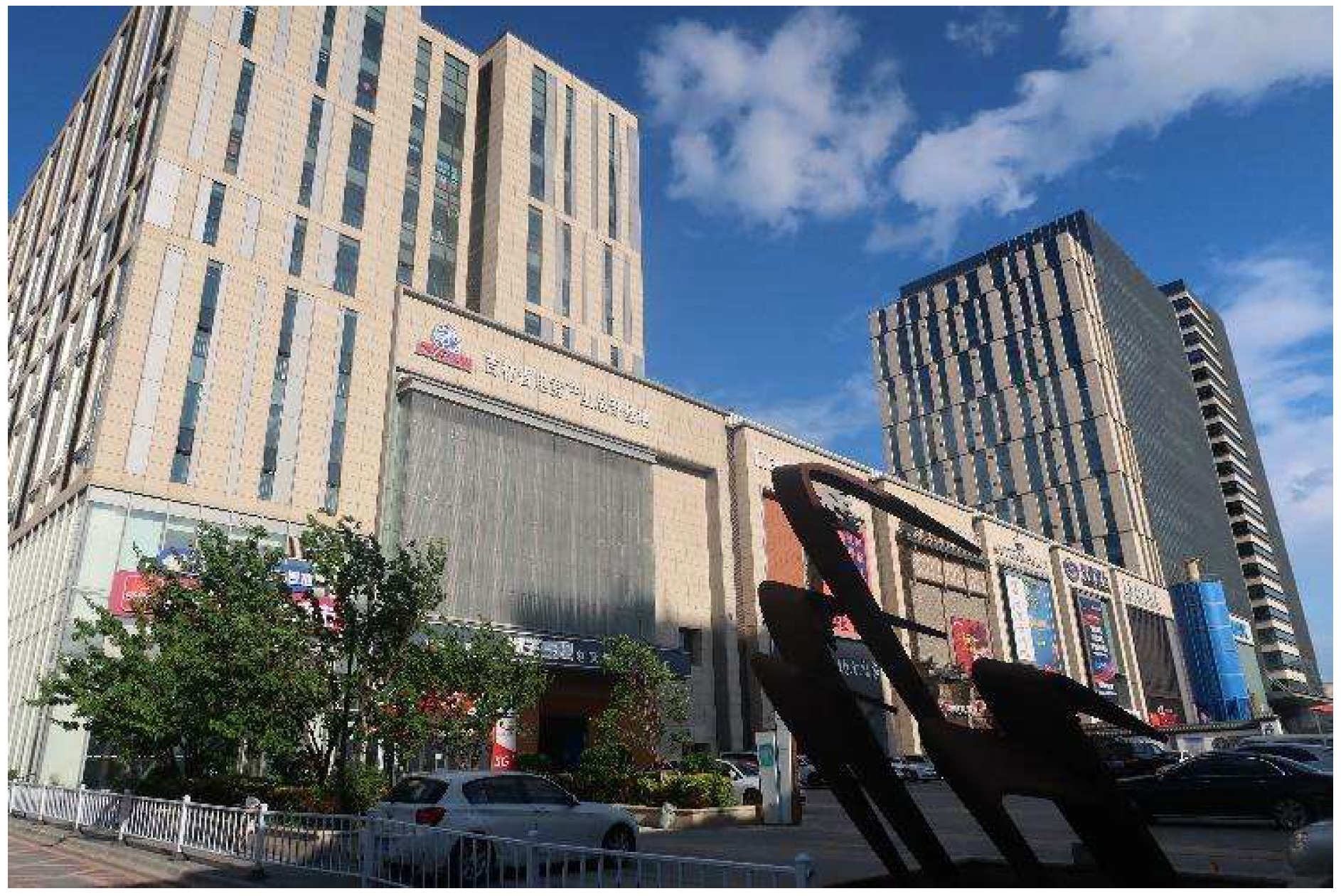

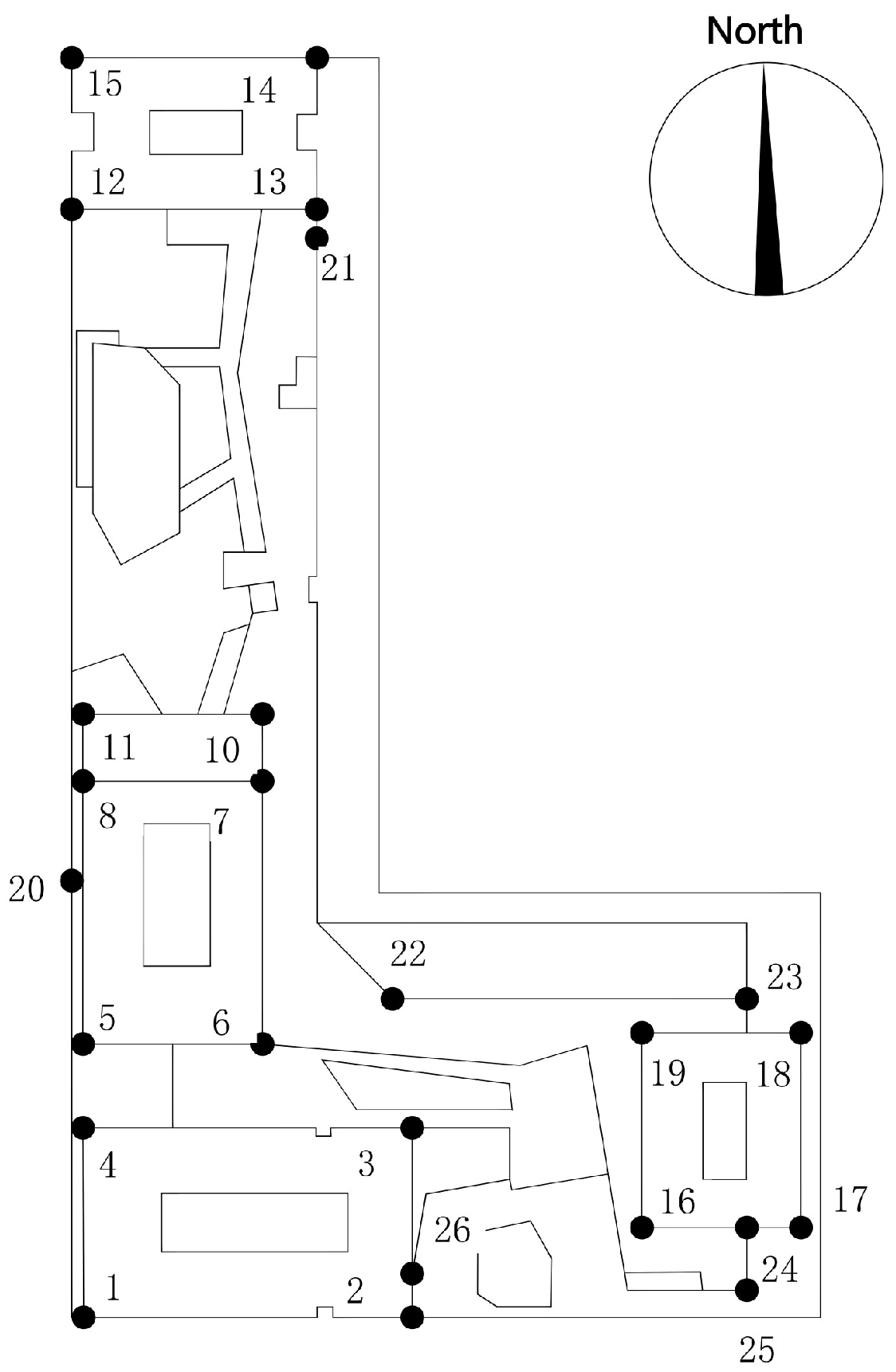

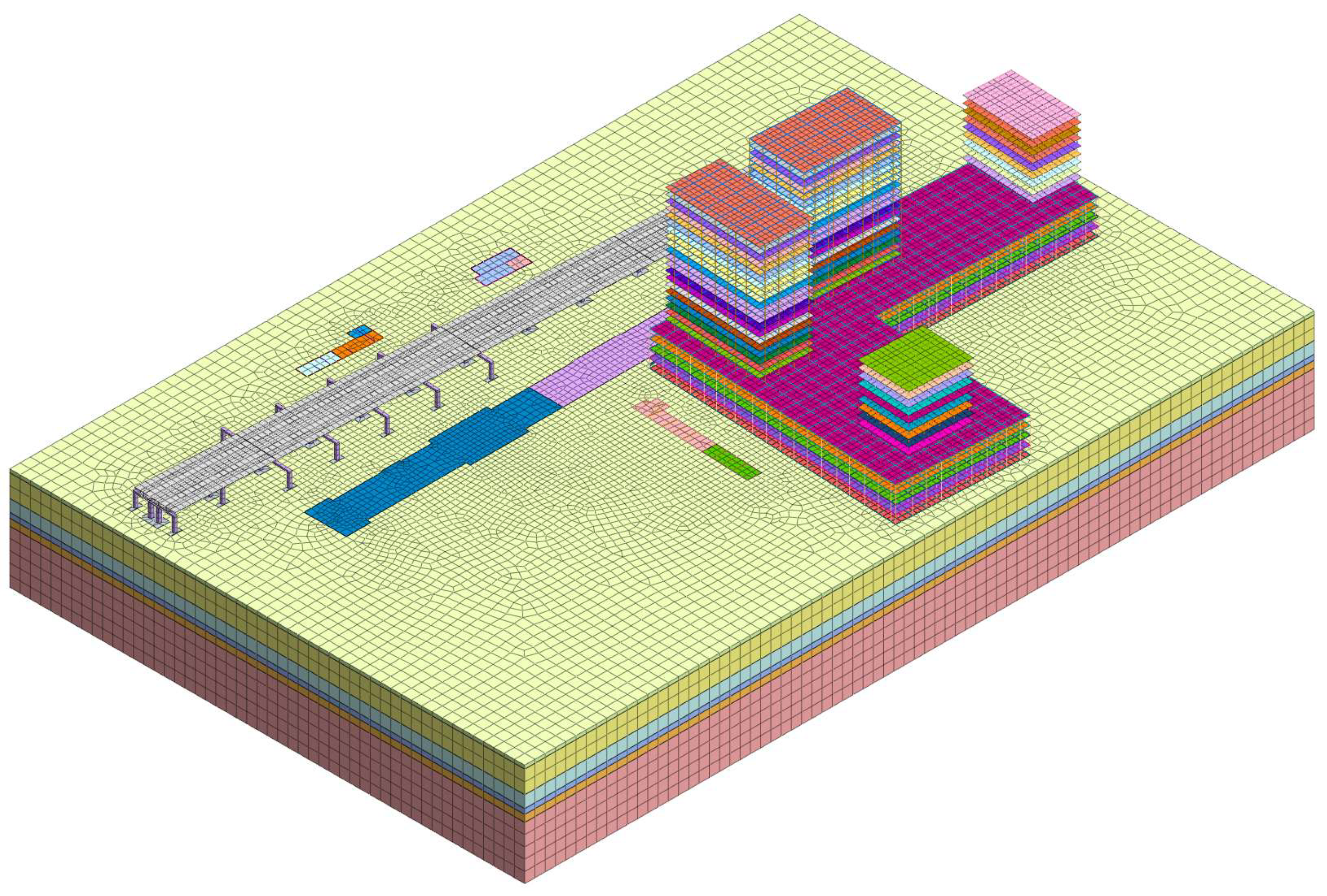

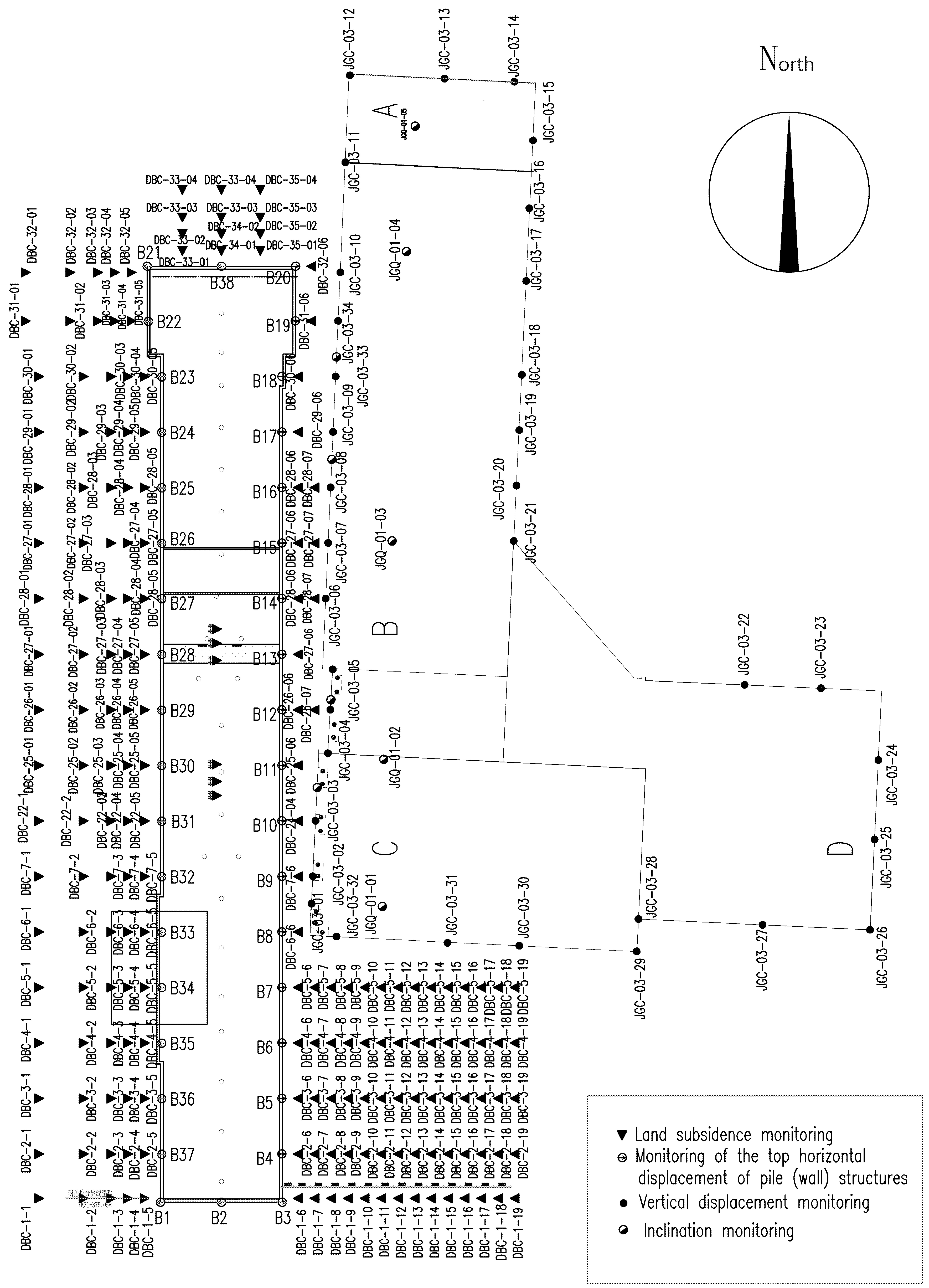

2. Construction Environment

3. Structural Overview of Existing Adjacent Building

4. Engineering Geology and Hydrogeology Overview

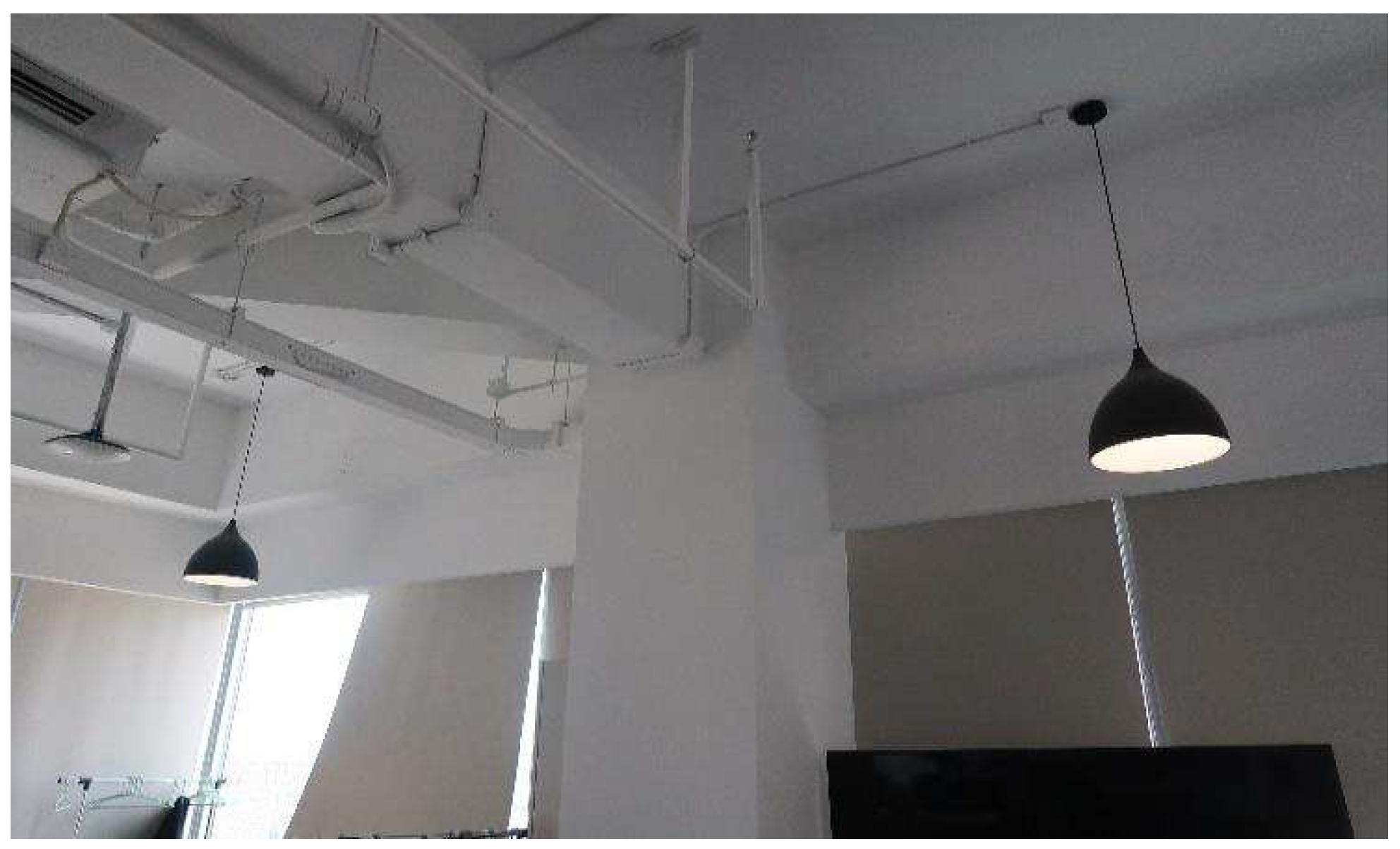

5. Inspection and Analysis of the Structural Status of Existing Adjacent Building

- (1)

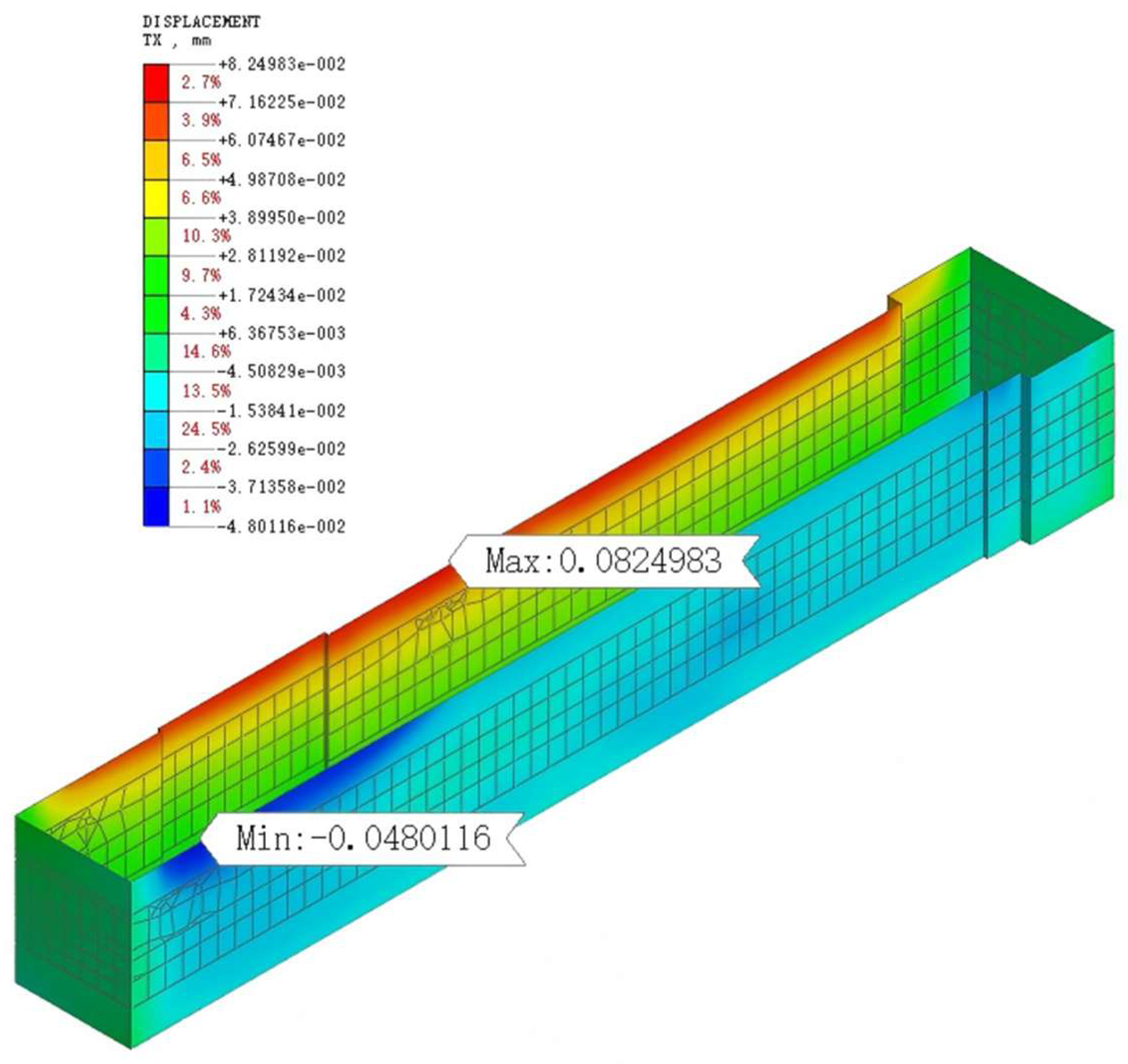

- Detection of Concrete Compressive Strength of Structural Members

- (2)

- Detection of Section Dimensions of Structural Components

- (3)

- Detection of Rebar Arrangement in Structural Components

- (4)

- Inspection of Structural Appearance Quality

- (5)

- Detection of Lateral Horizontal Displacement at Structural Apex

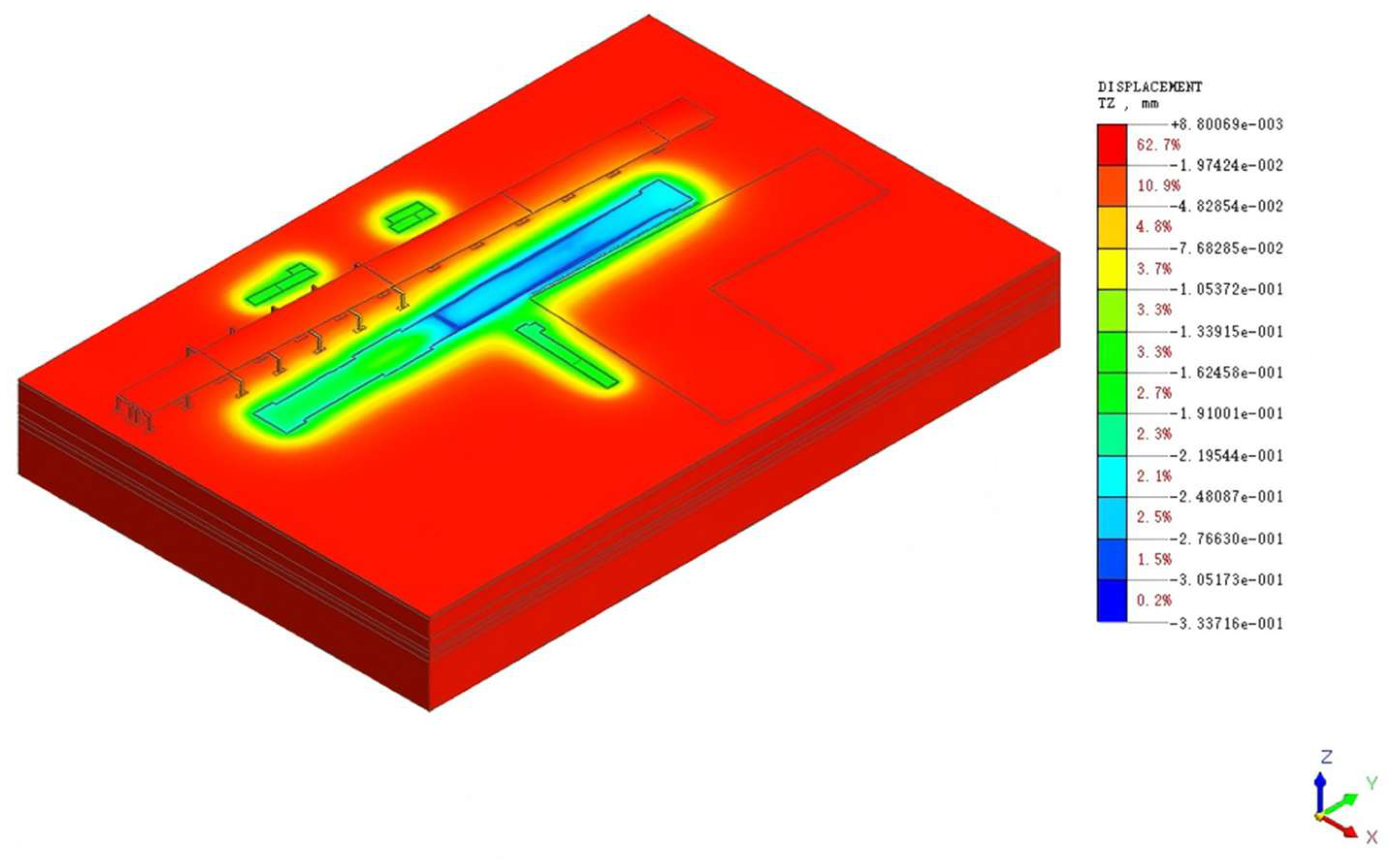

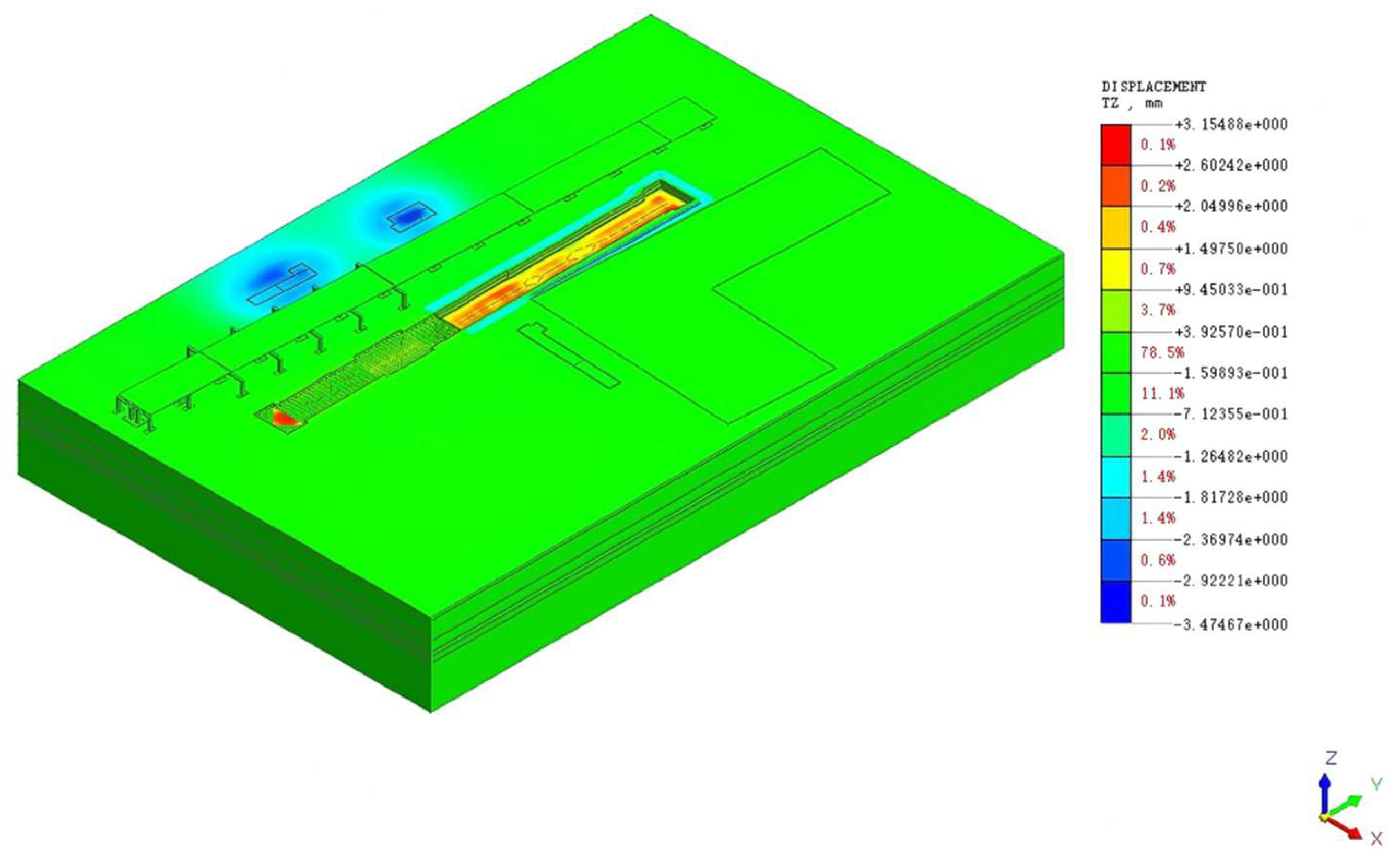

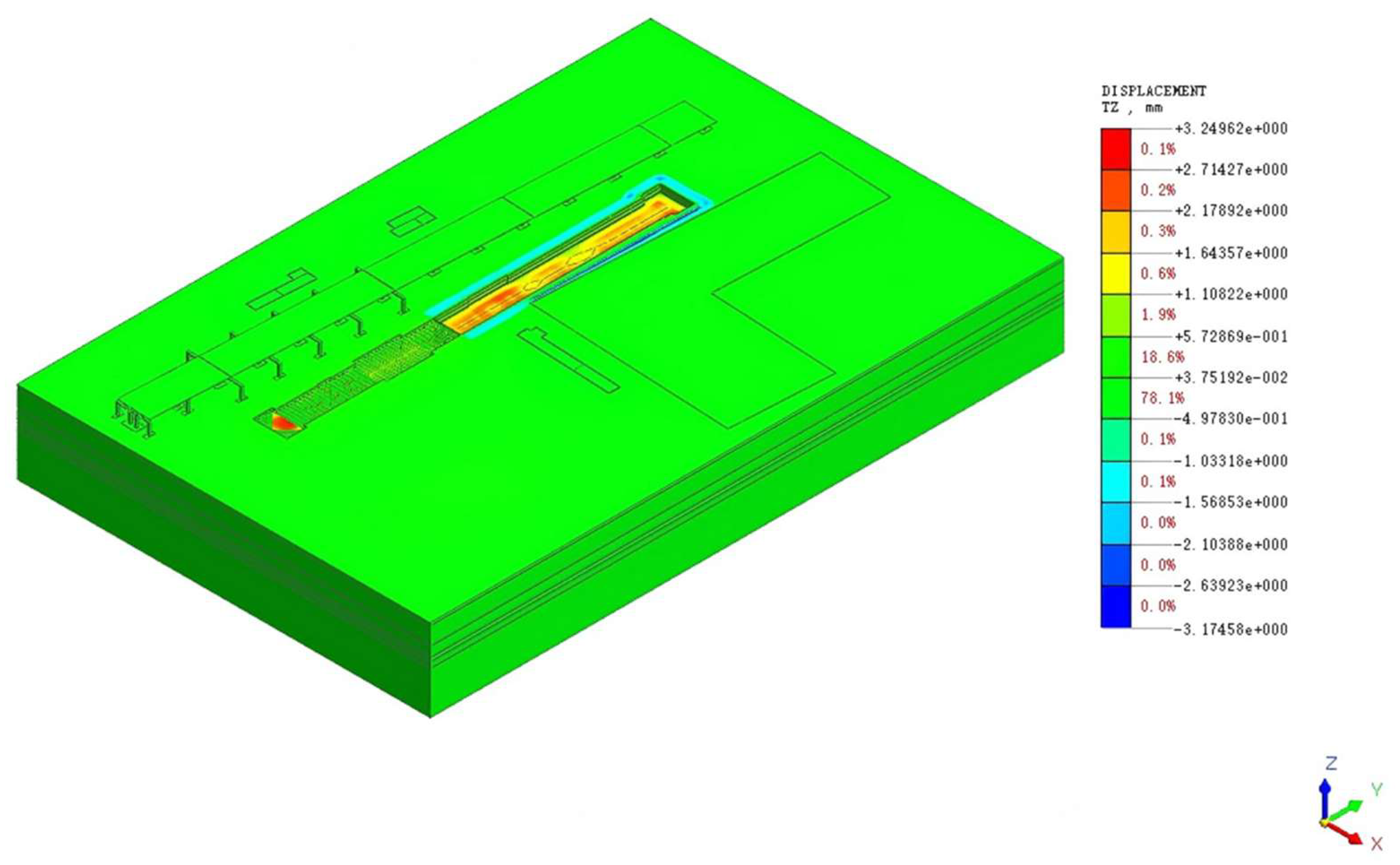

6. Excavation

7. Analysis of Effects of Metro Construction on Existing Structures

8. Study and Analysis of Horizontal Displacement Patterns of Retaining Piles Under Various Working Conditions

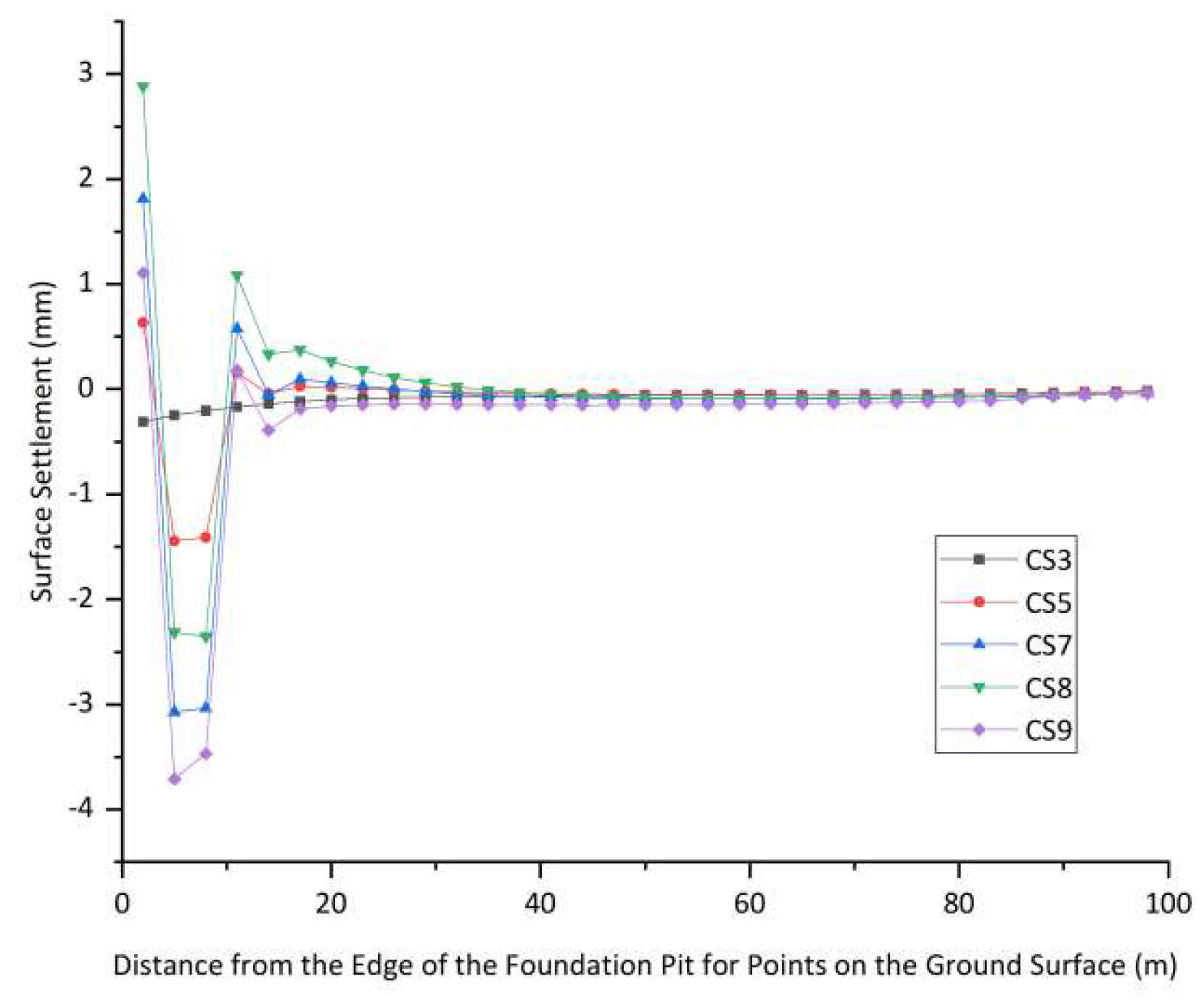

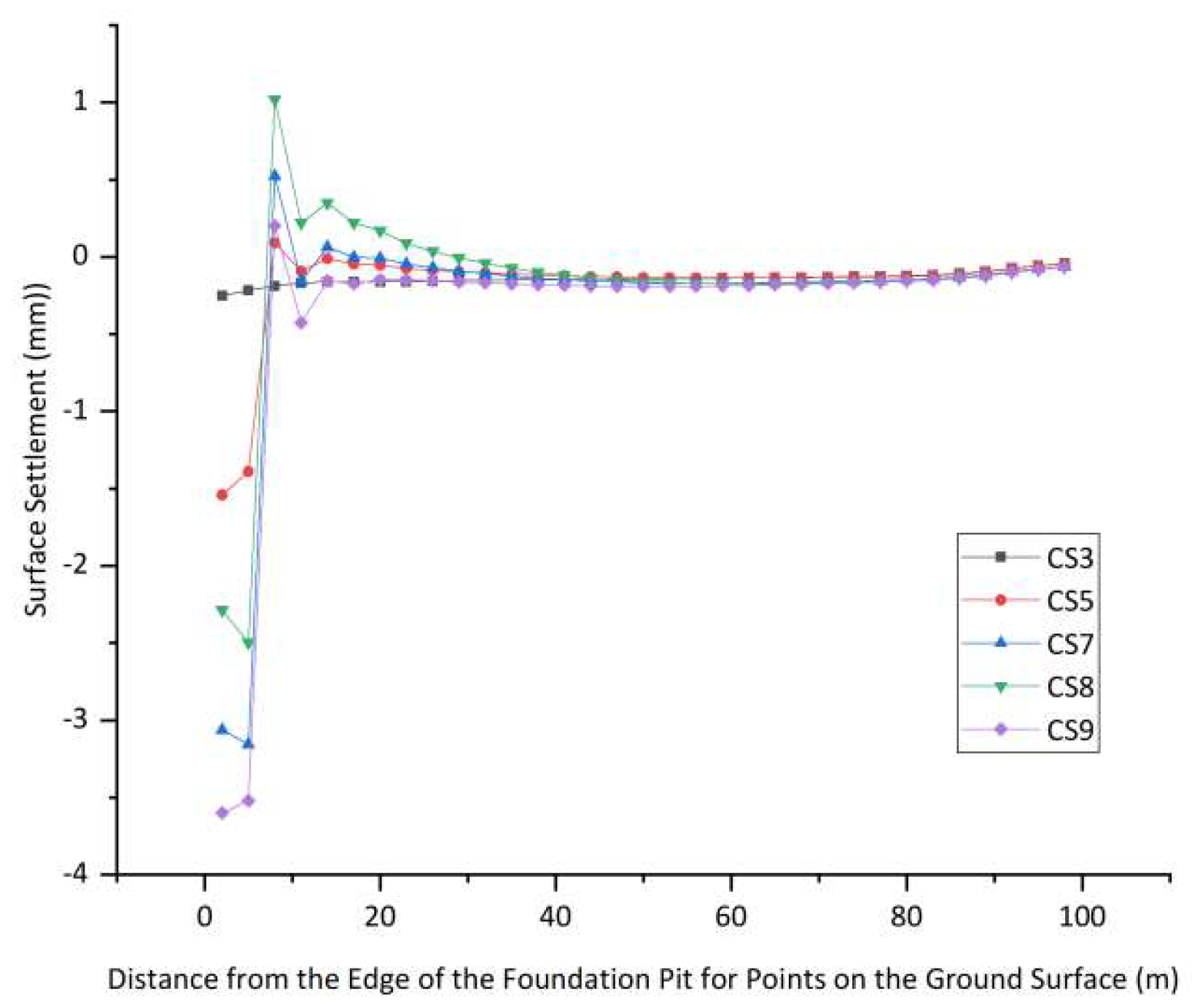

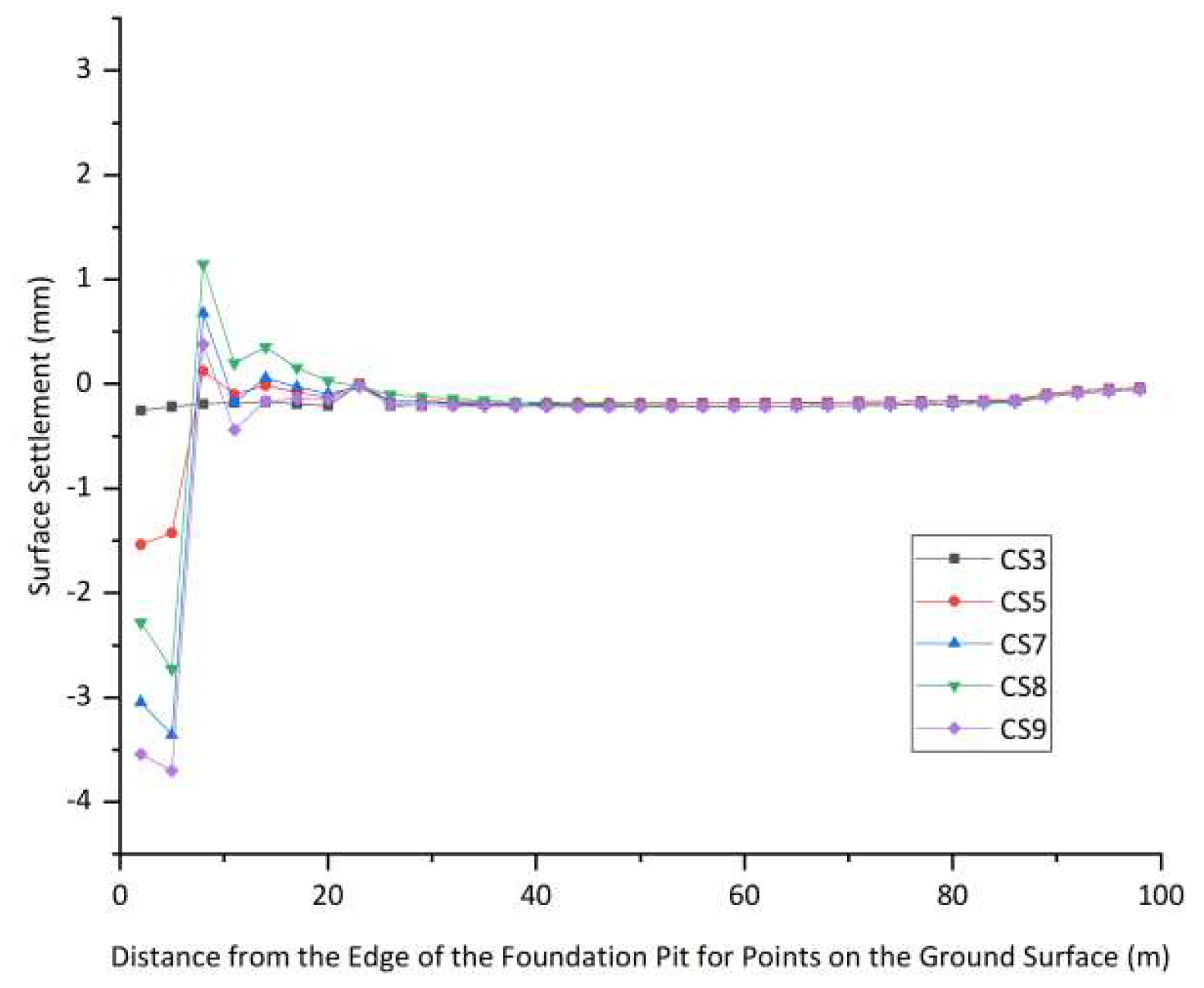

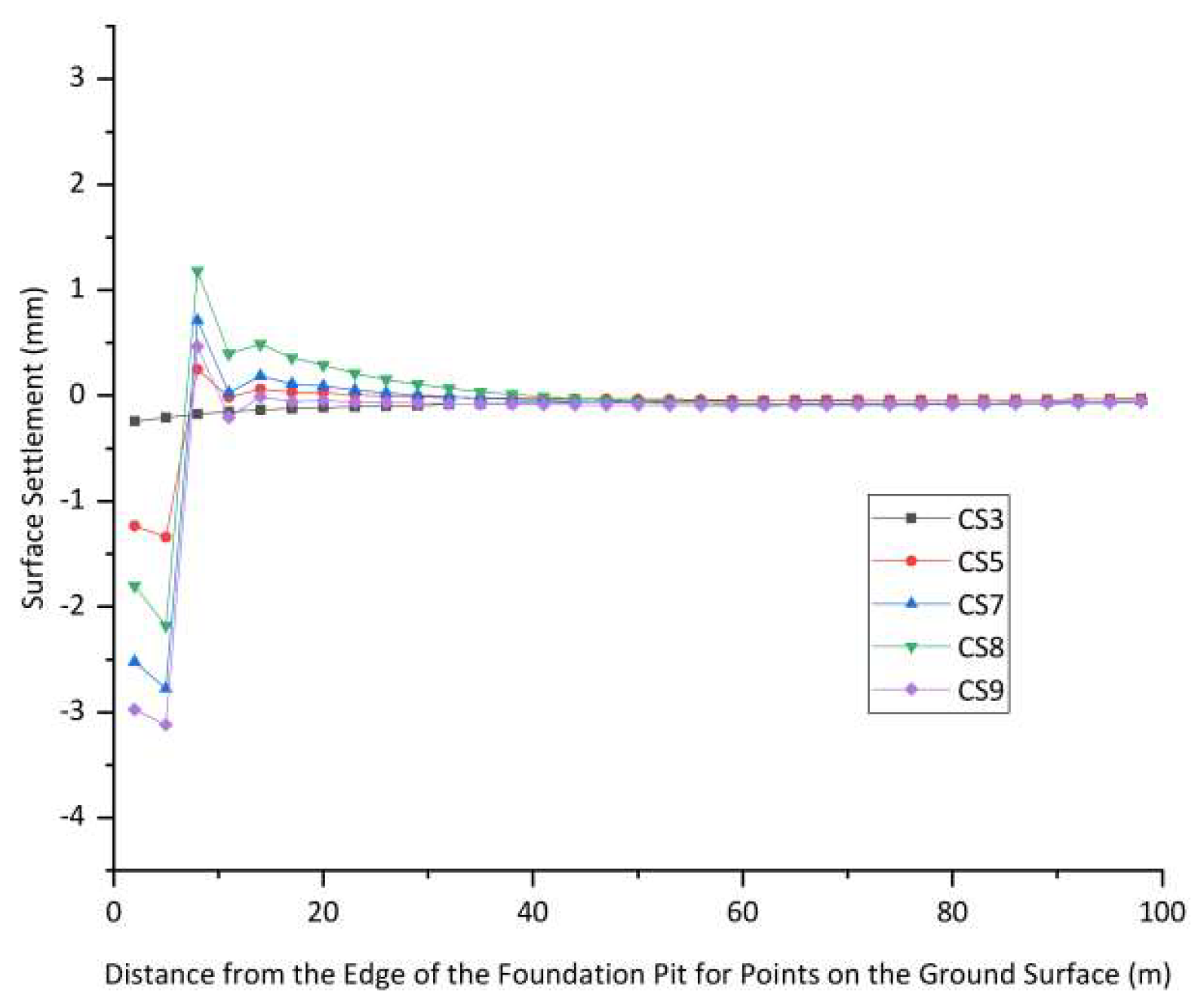

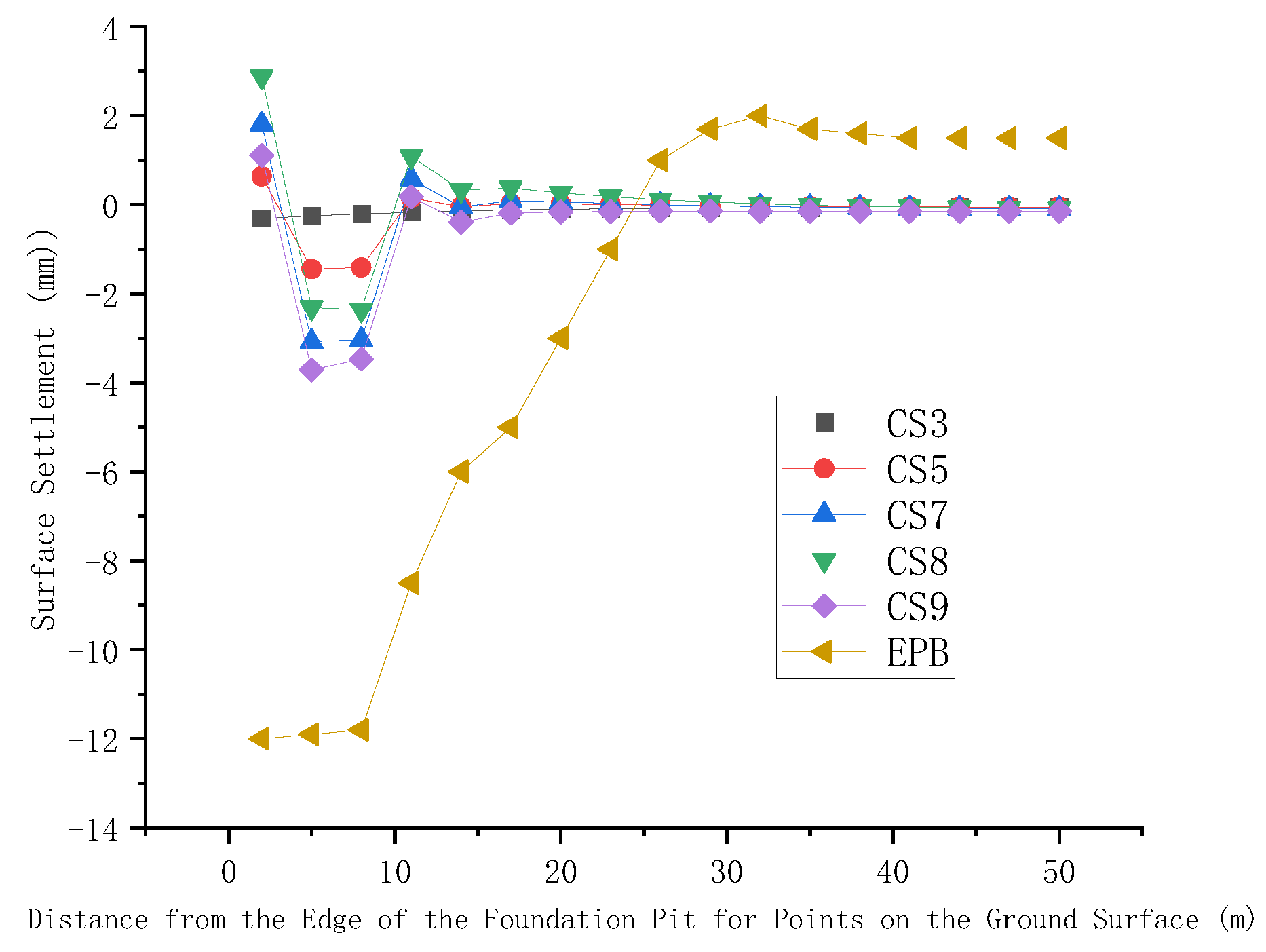

9. Study on Settlement Patterns of Surrounding Soil

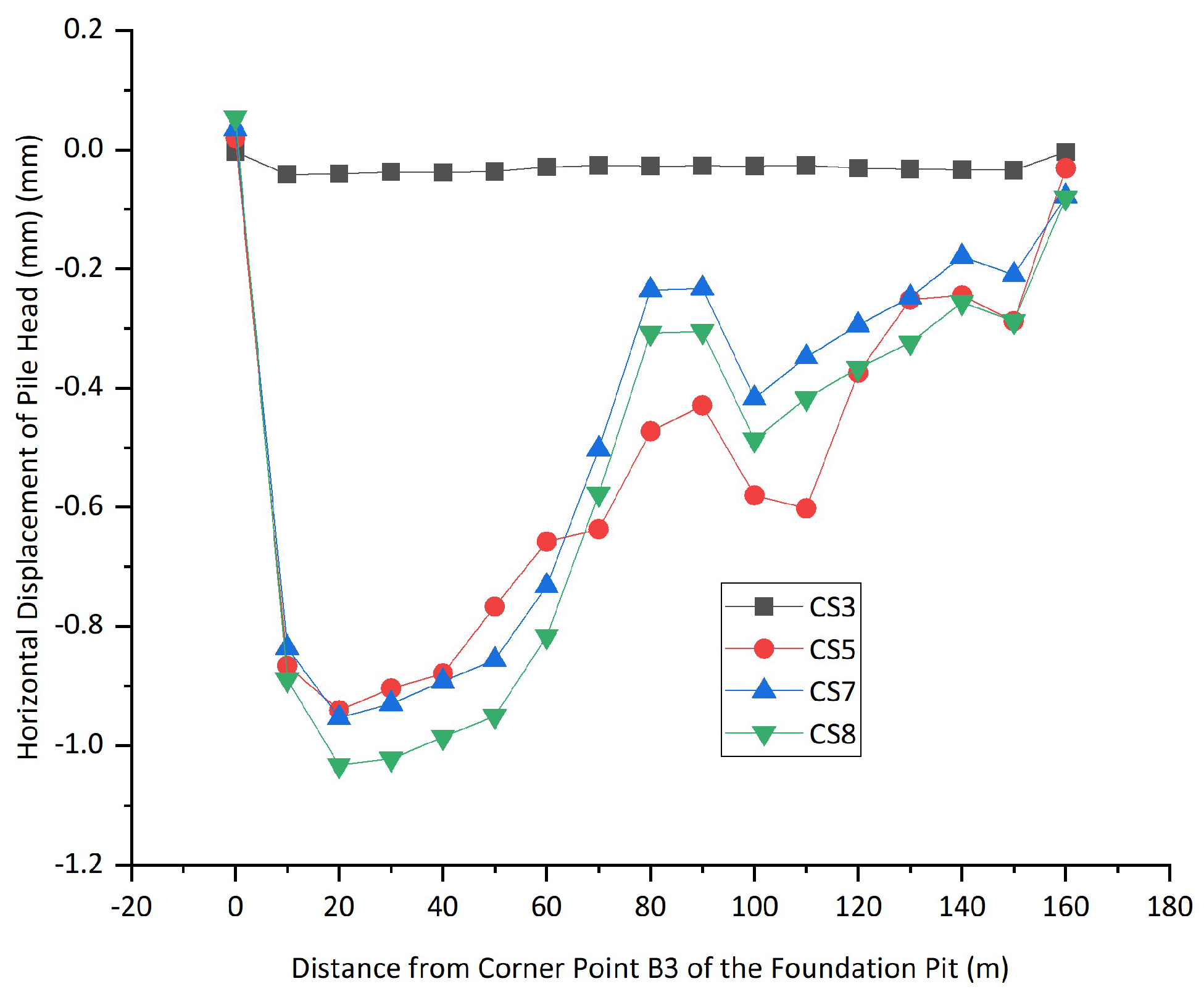

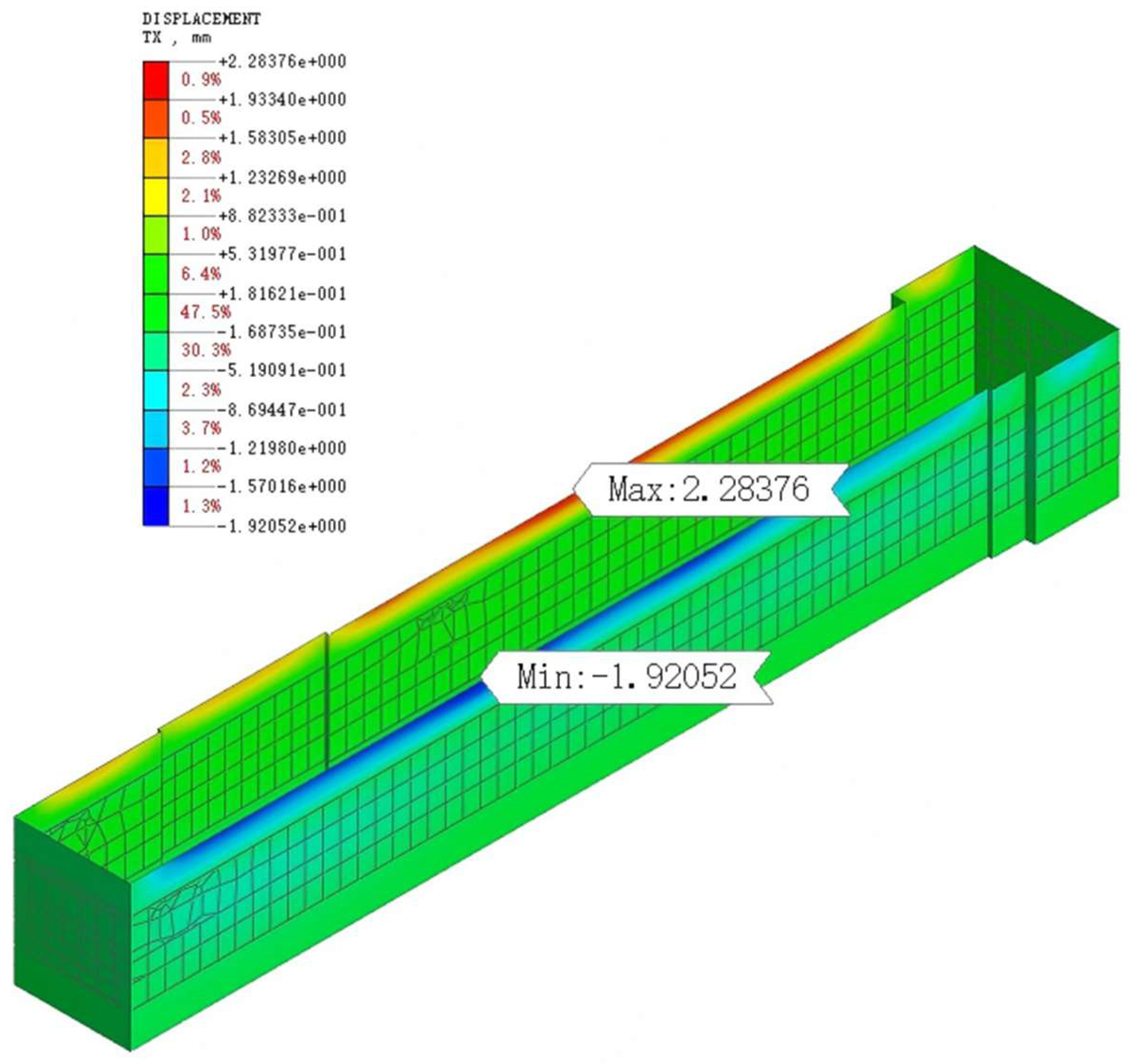

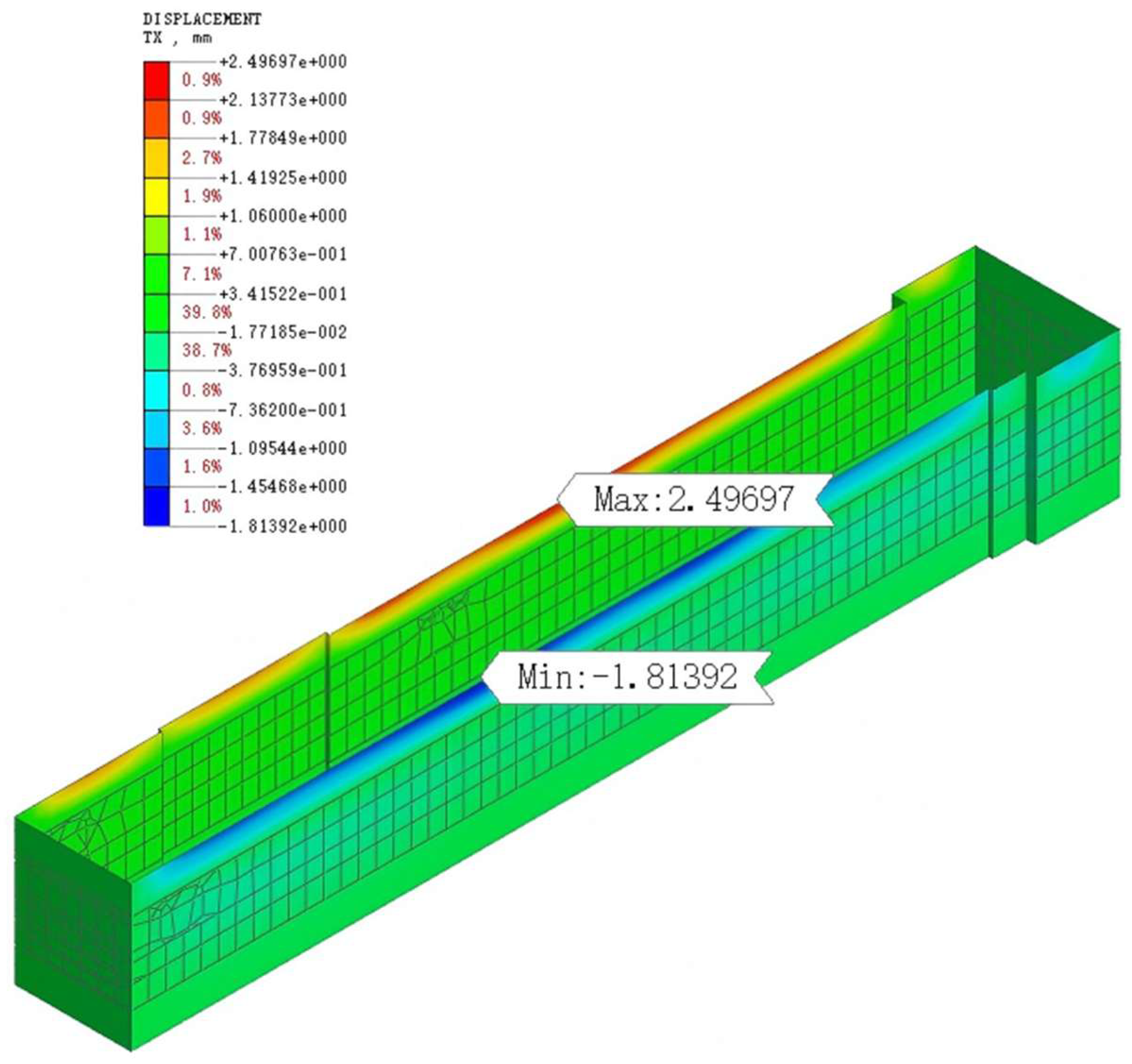

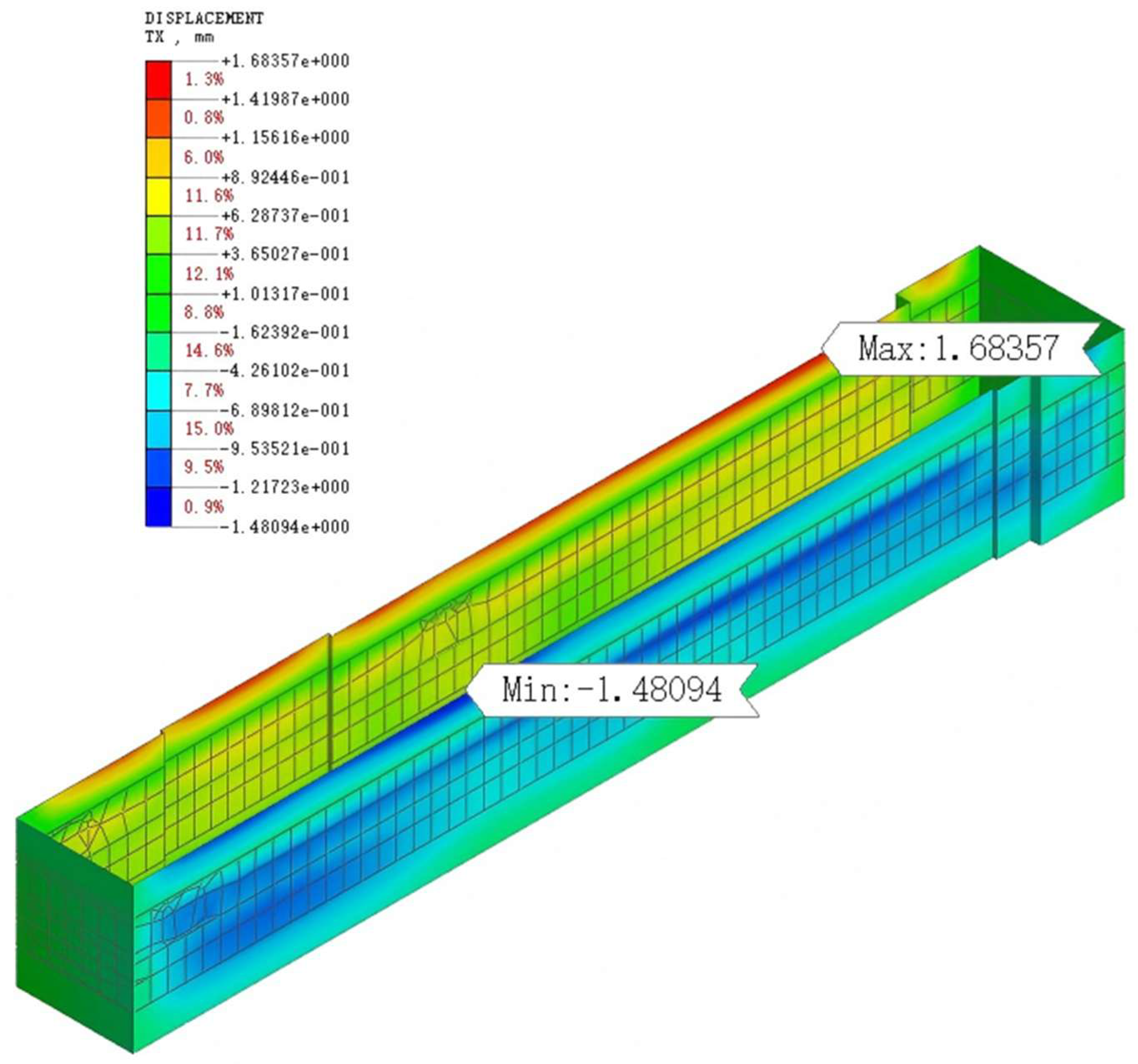

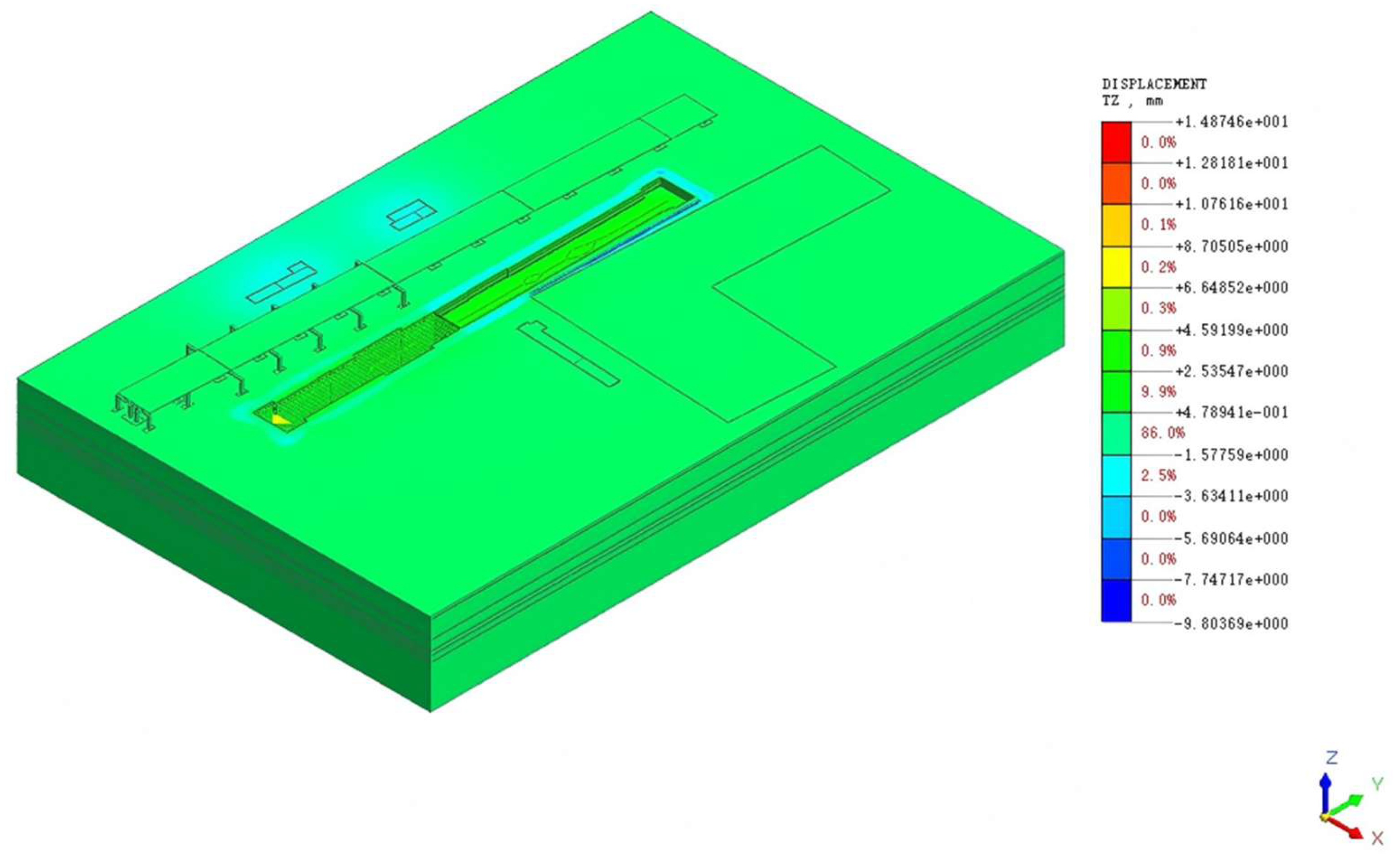

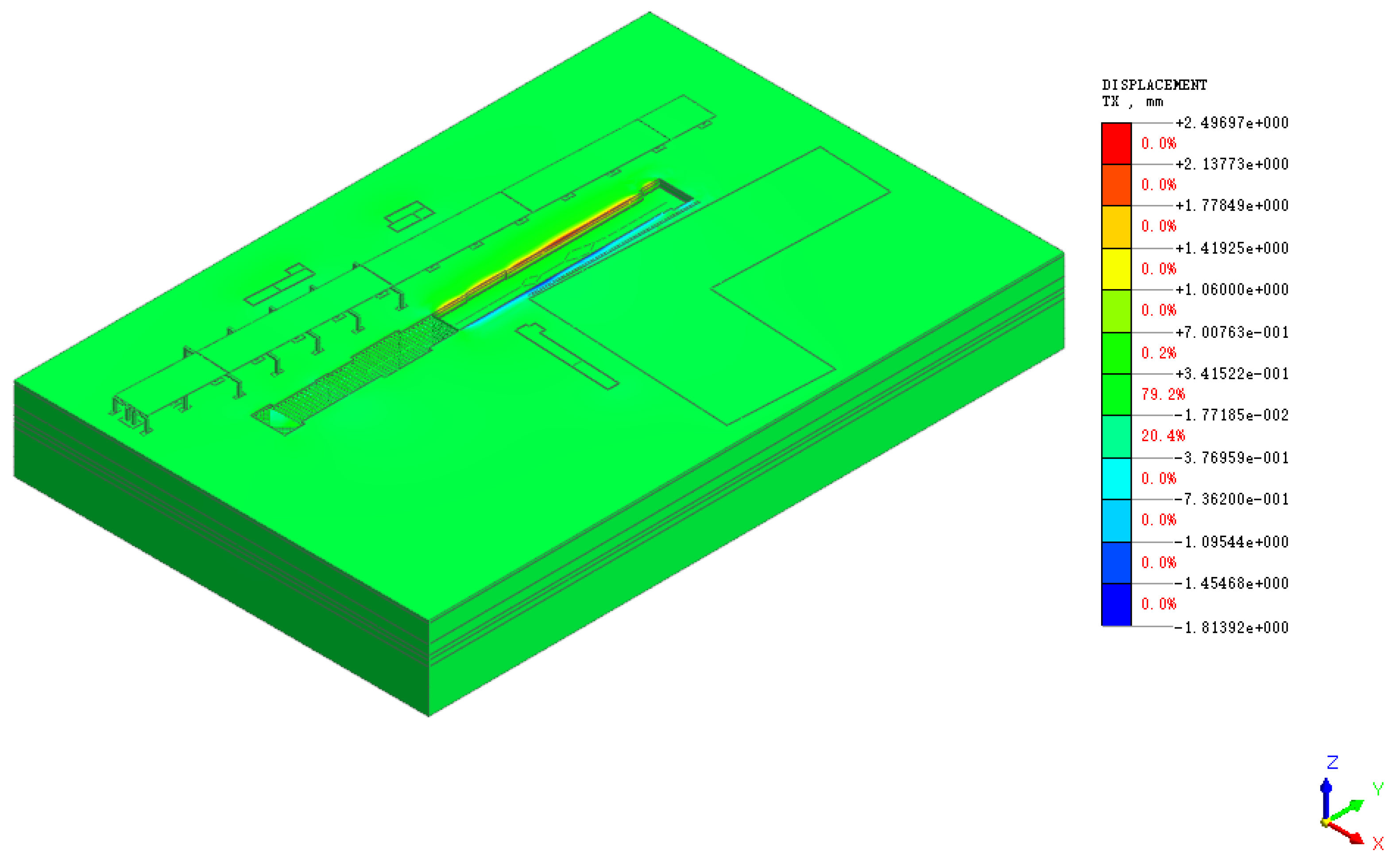

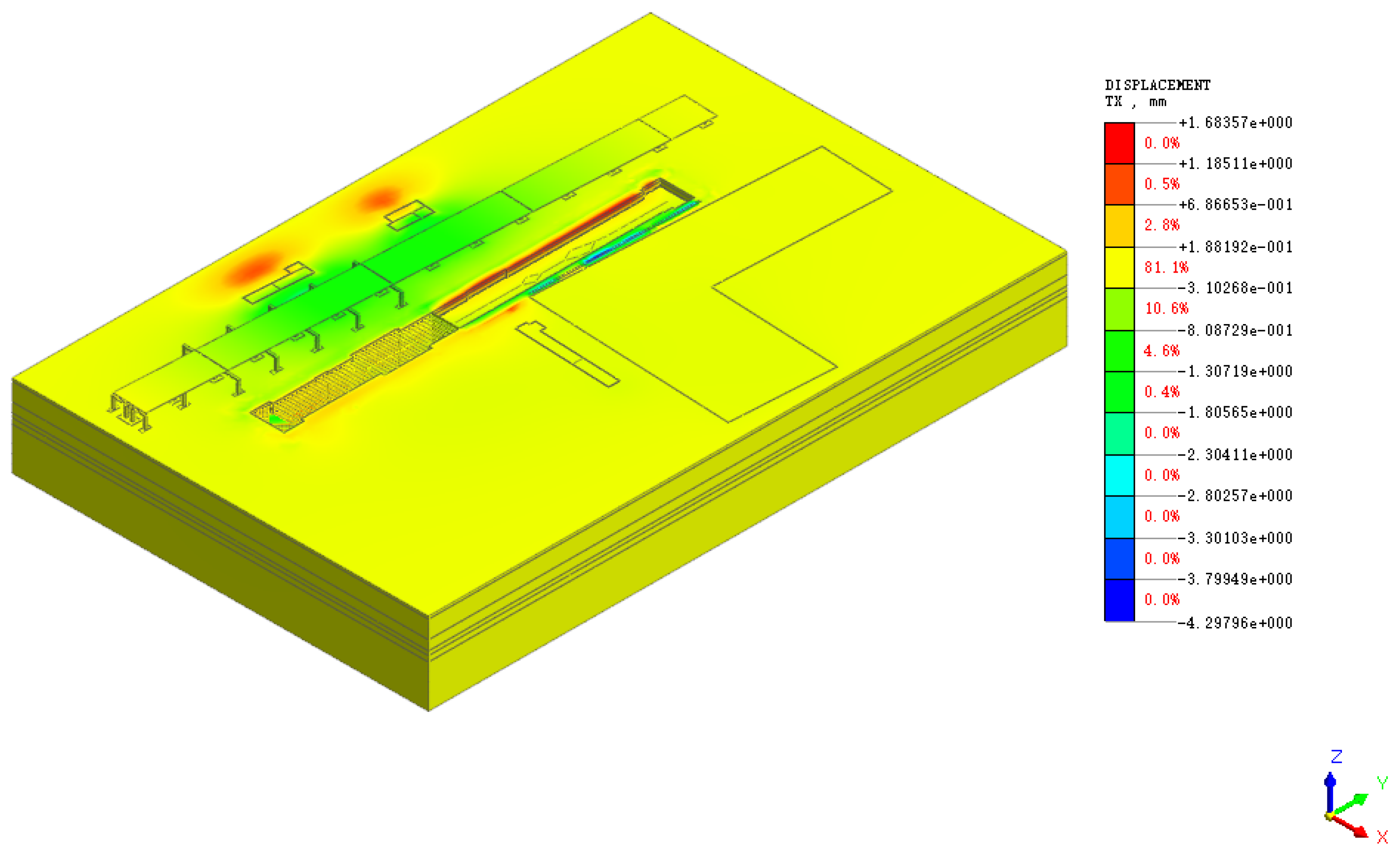

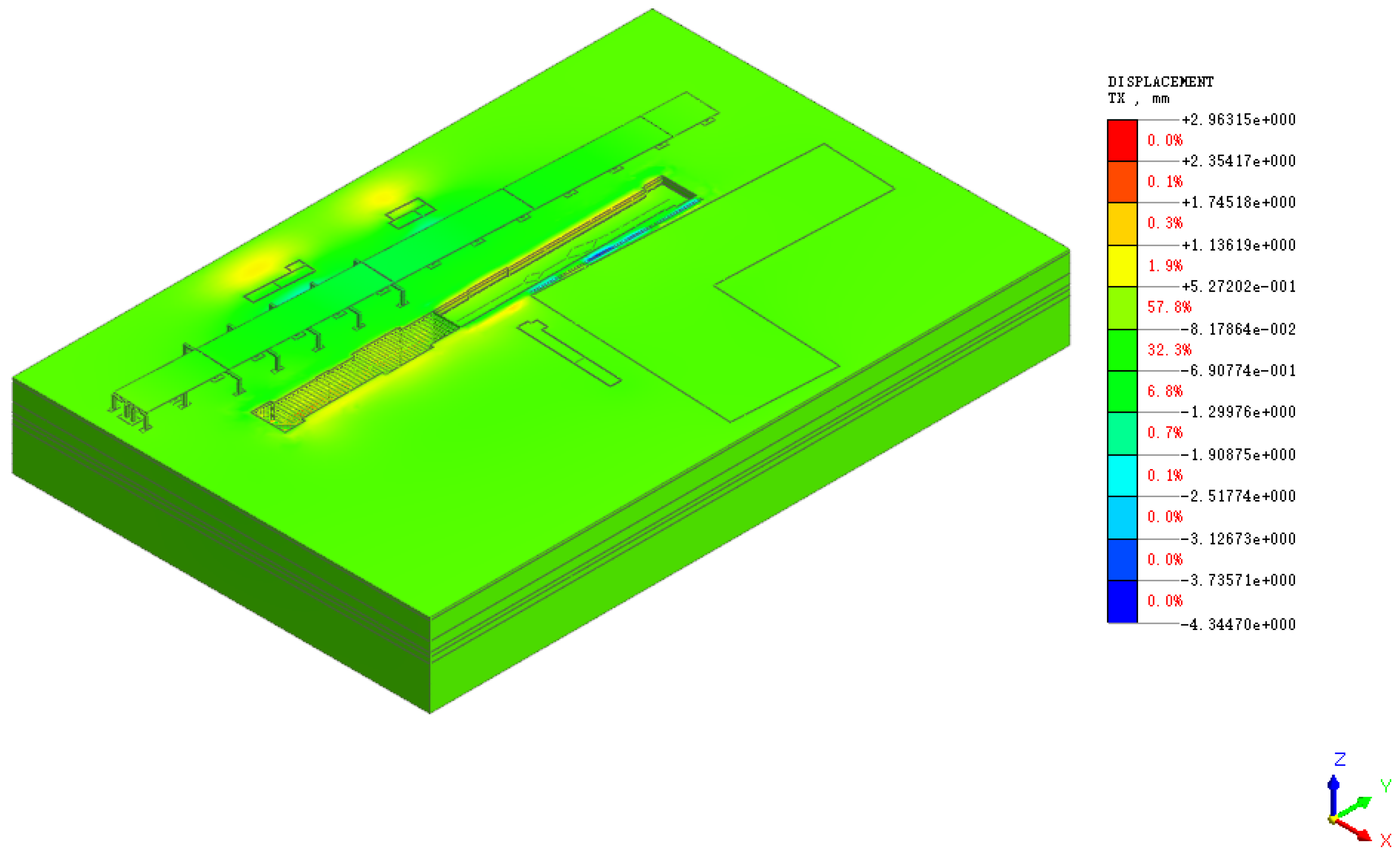

10. Study on the Patterns of Horizontal Displacement in the Surrounding Soil

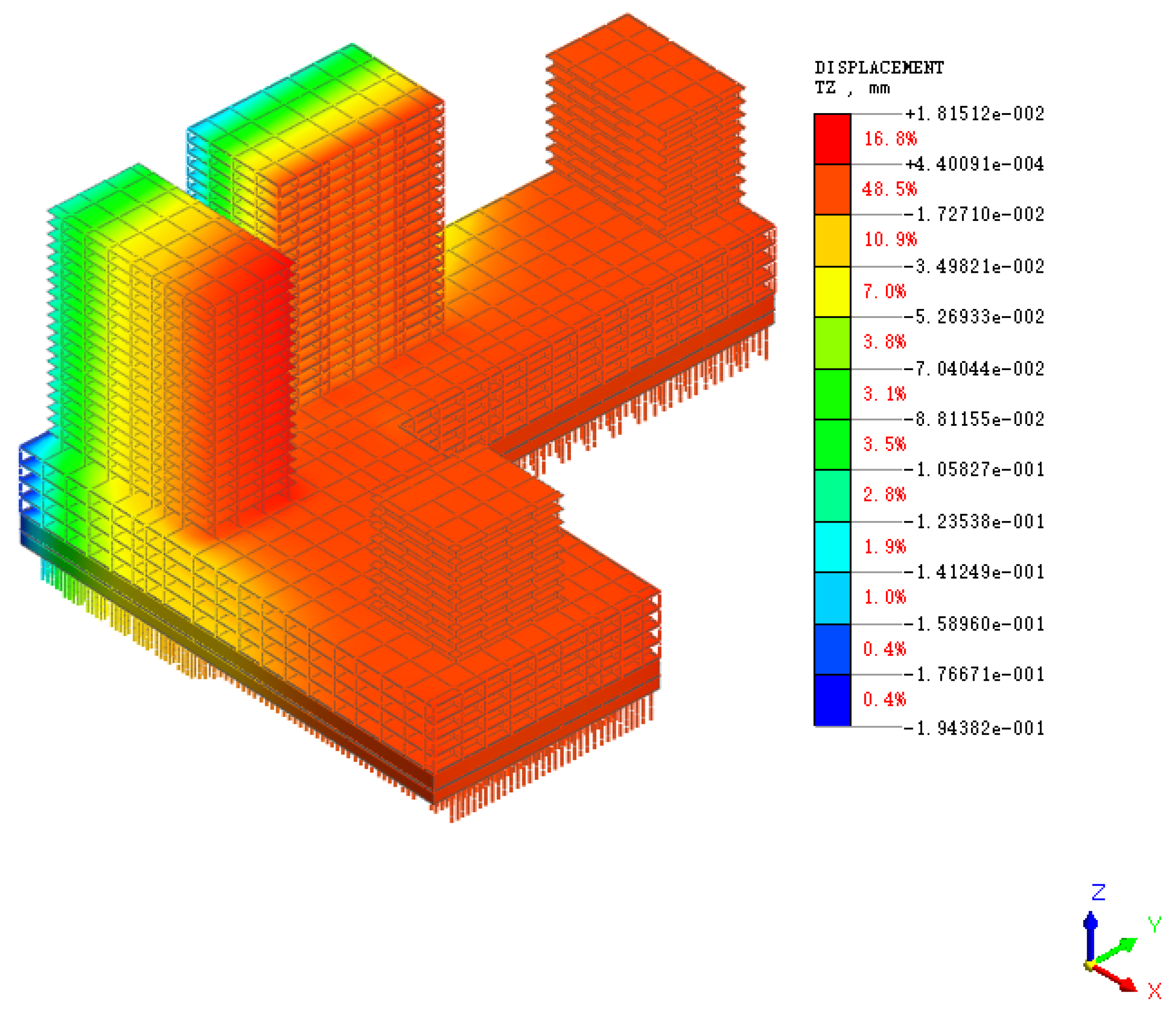

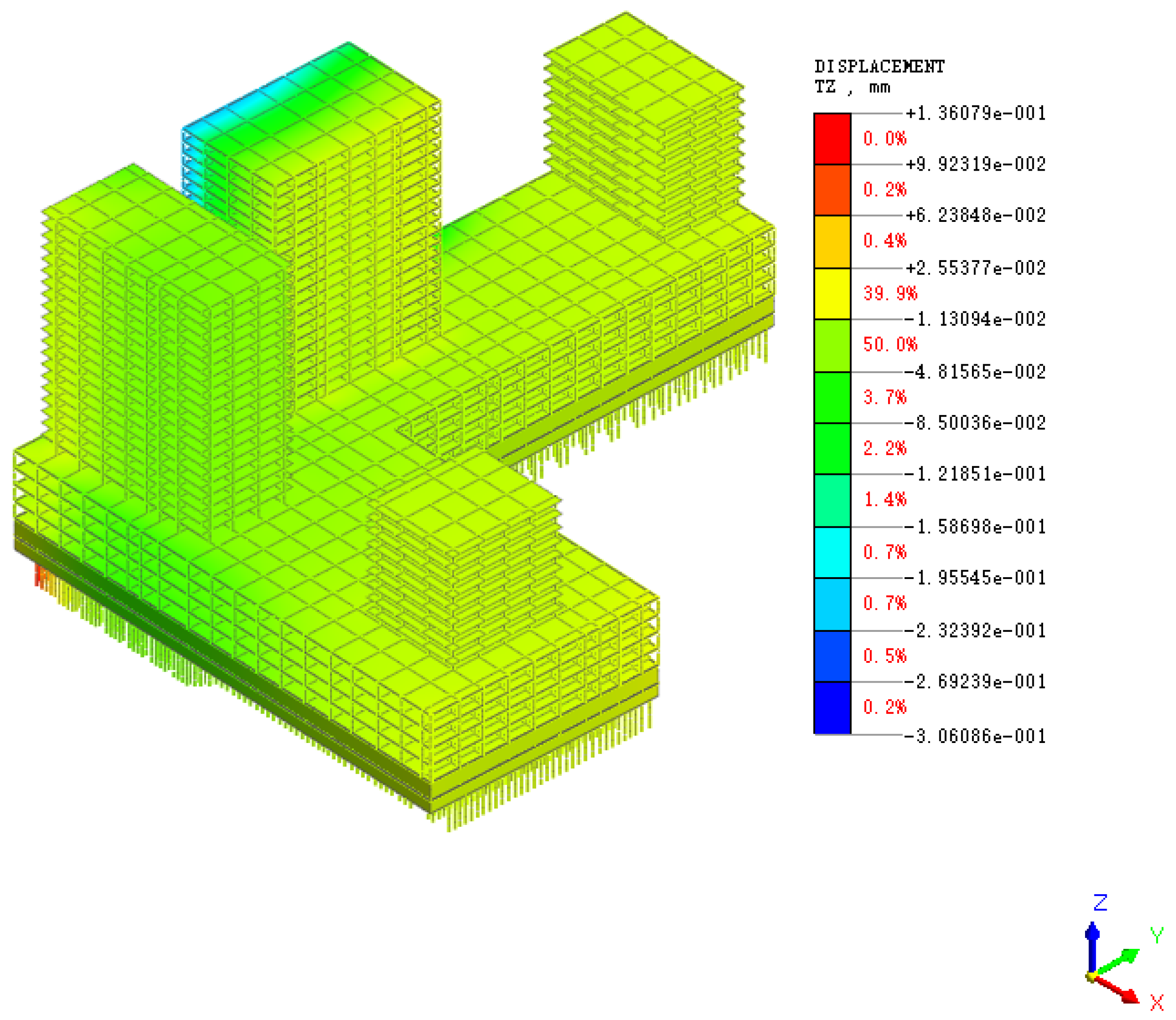

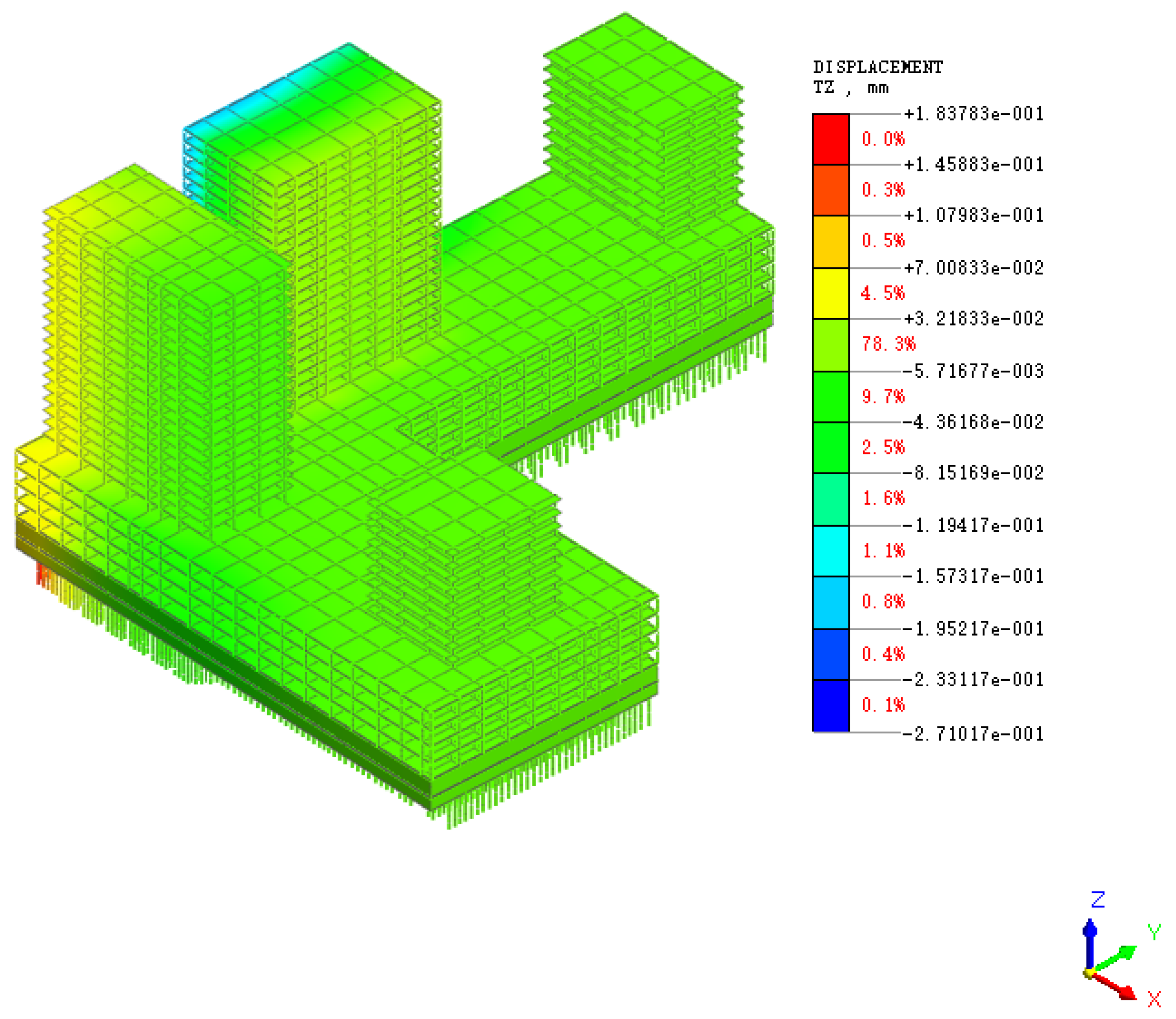

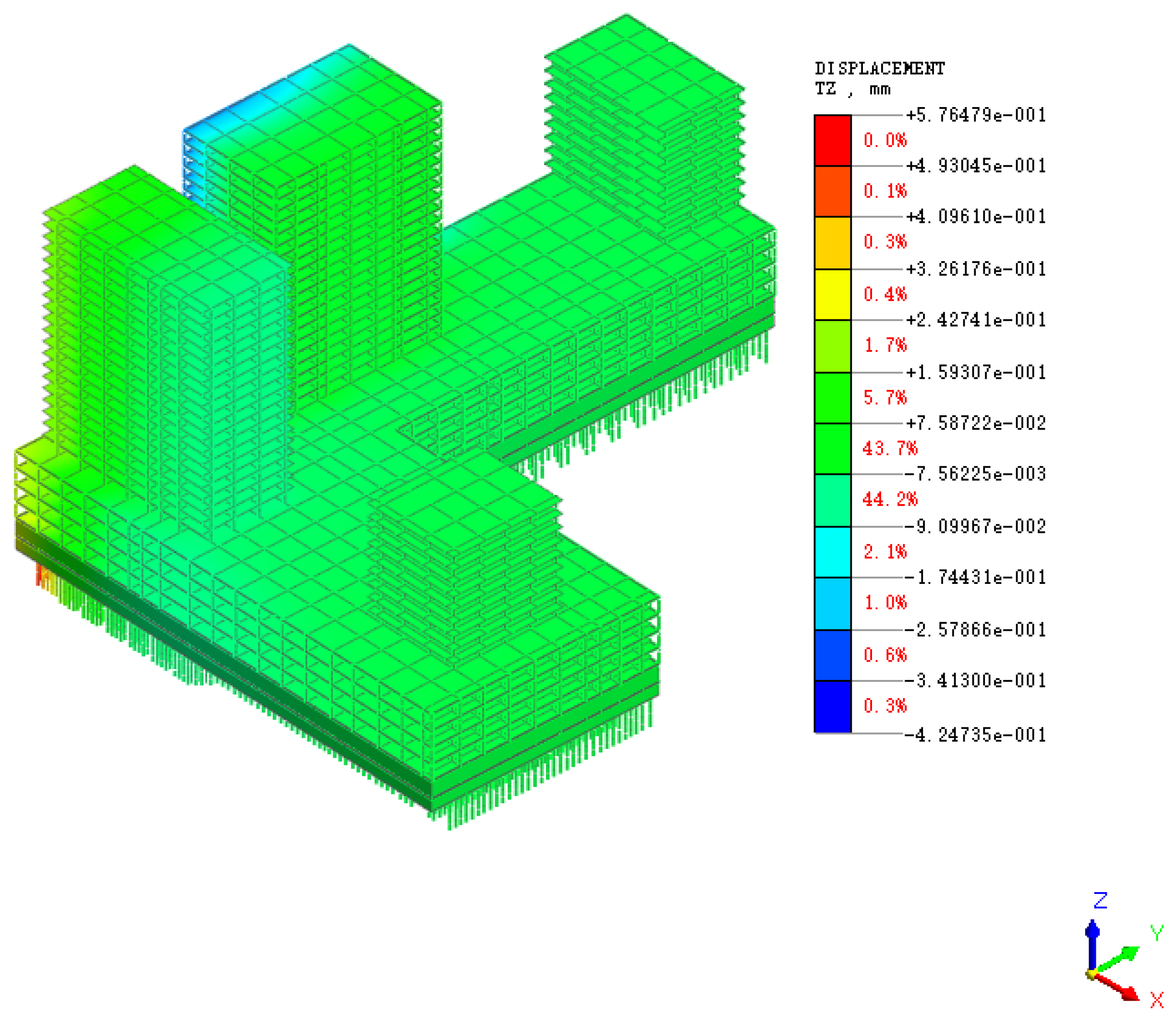

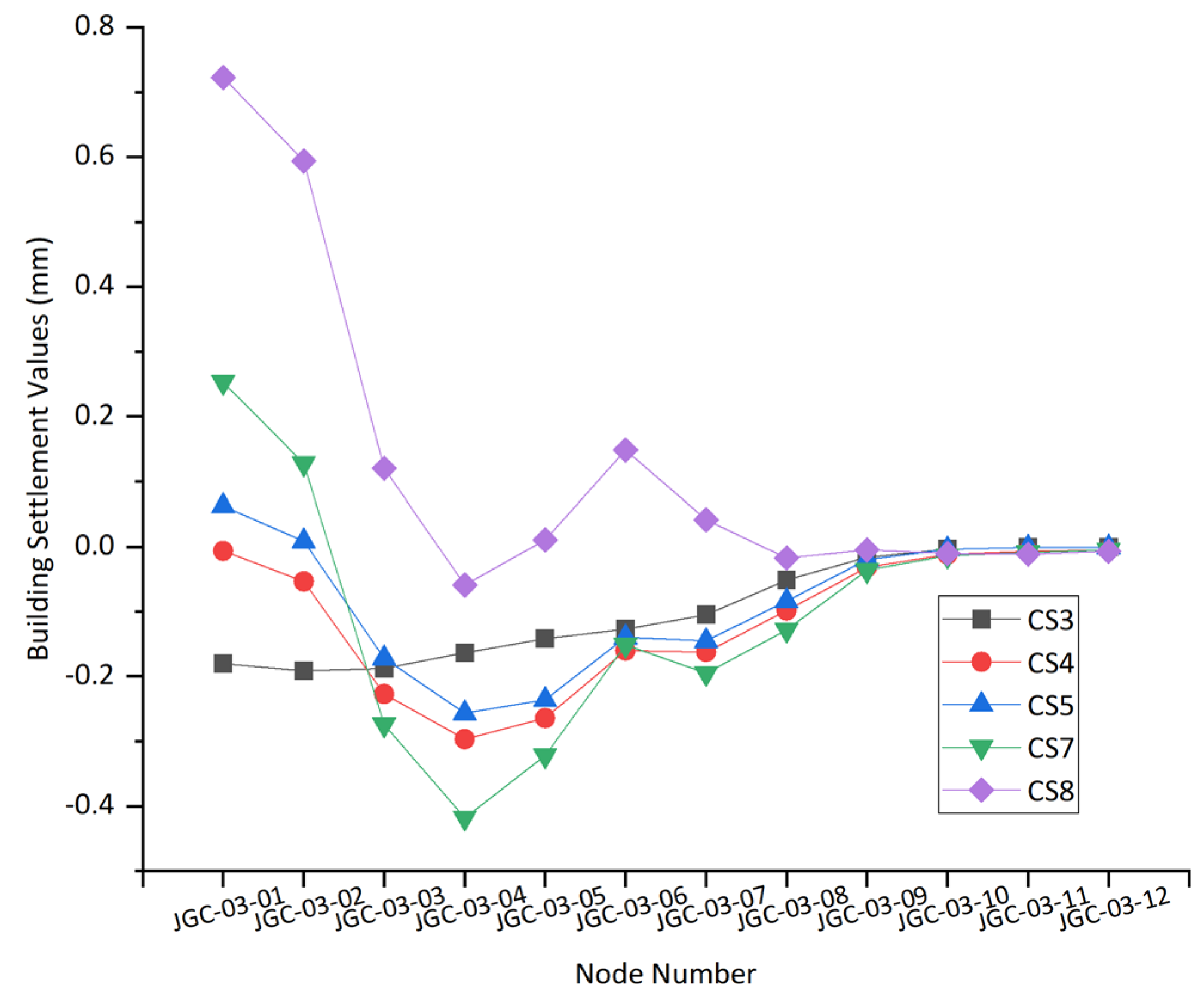

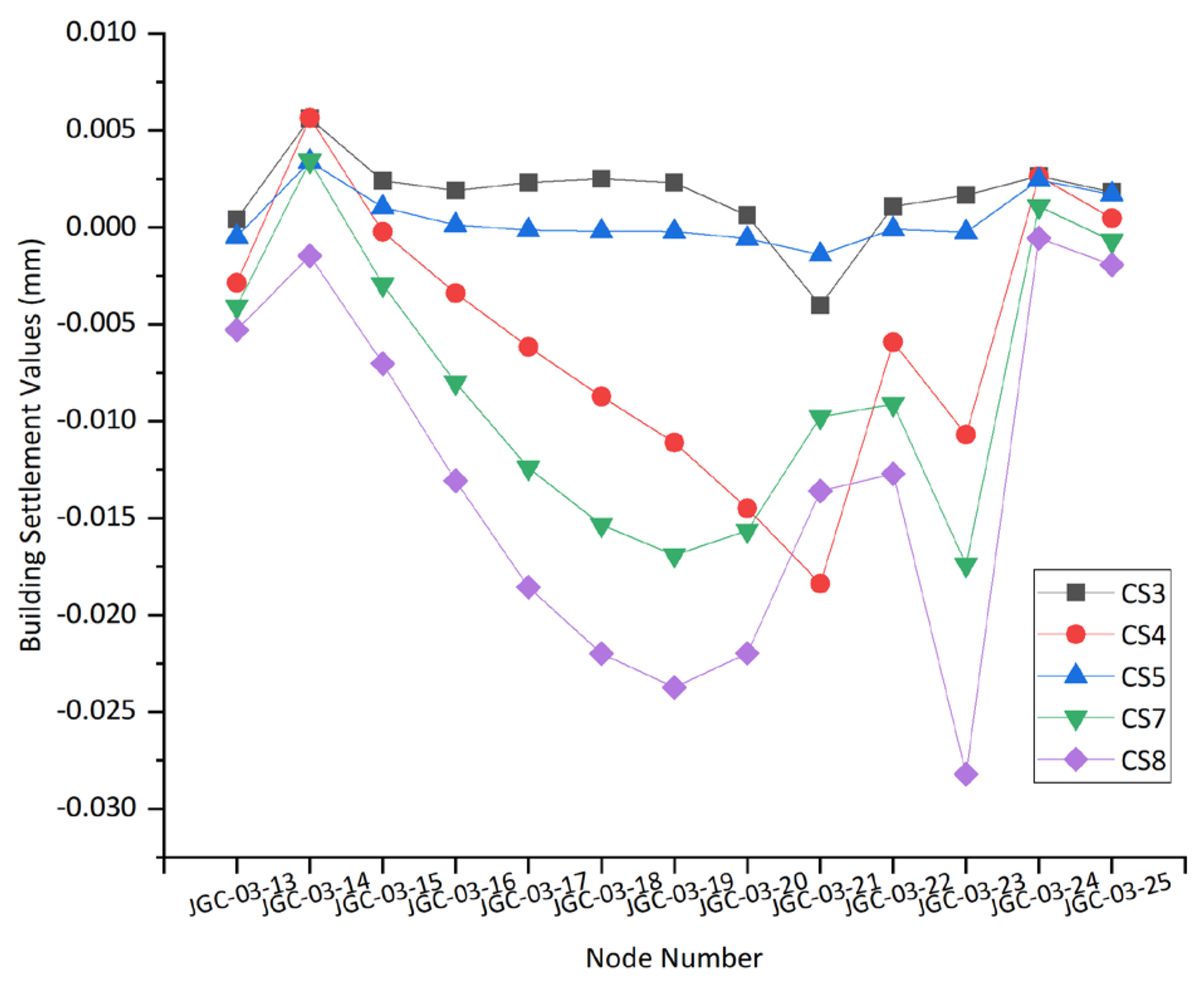

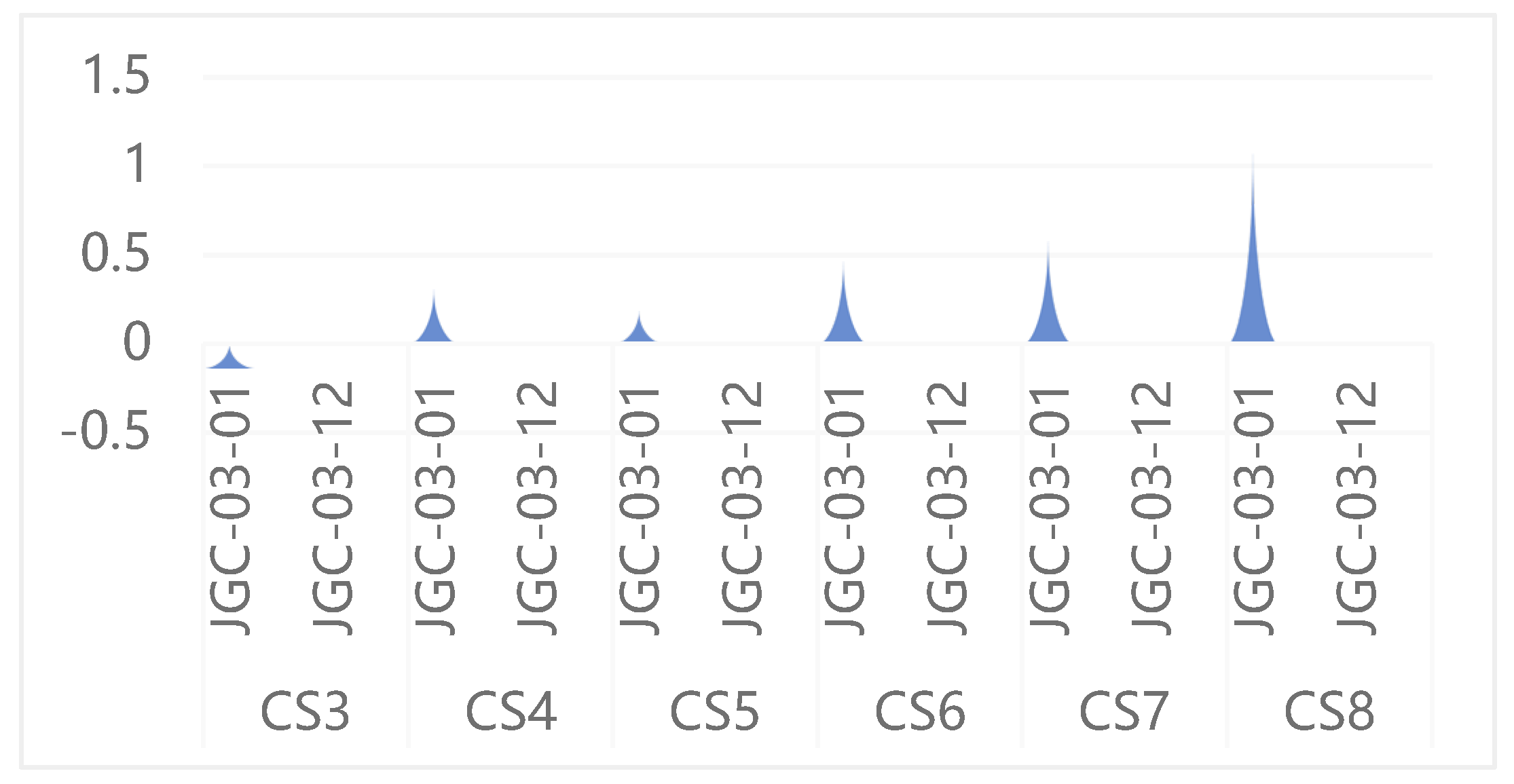

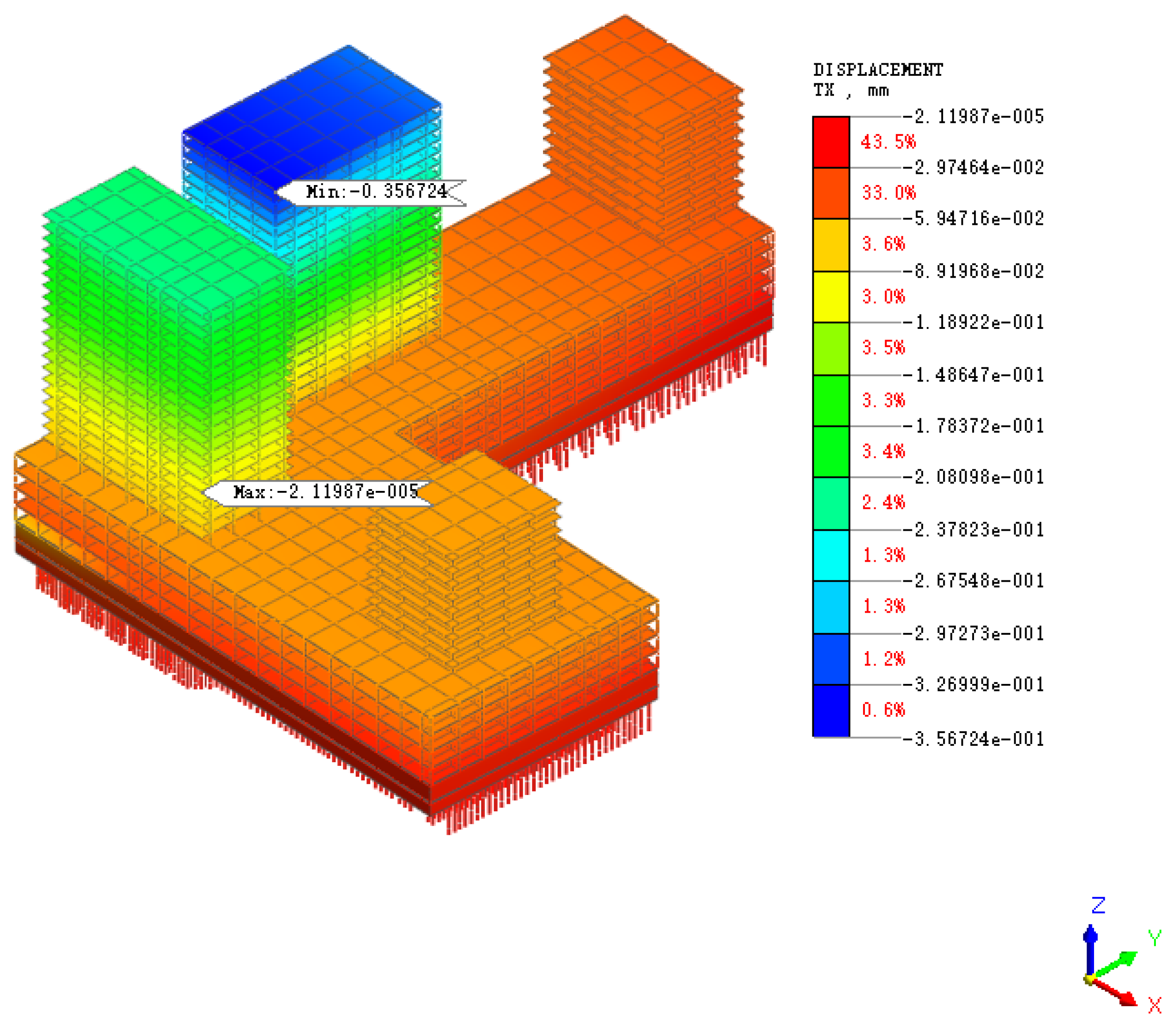

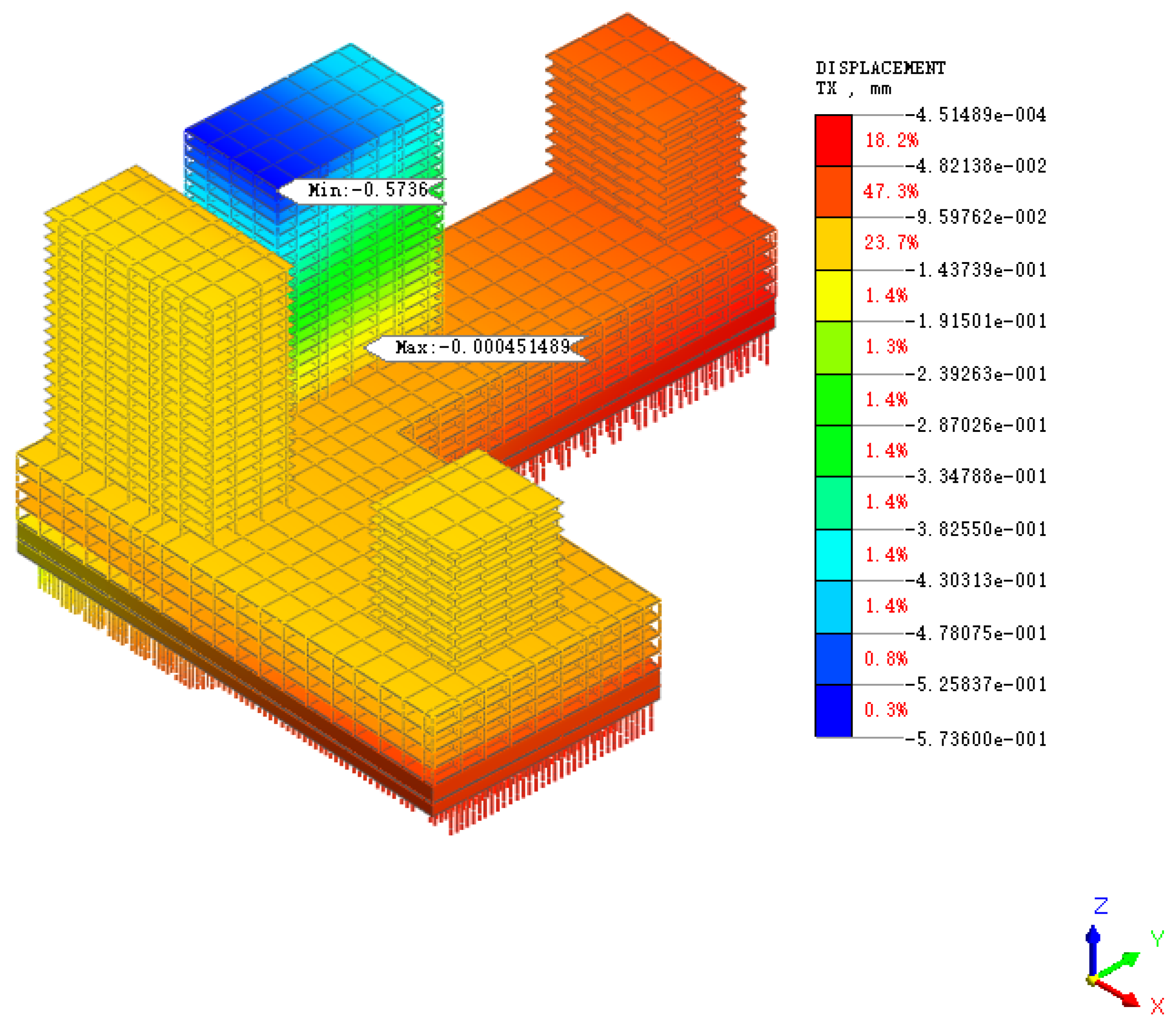

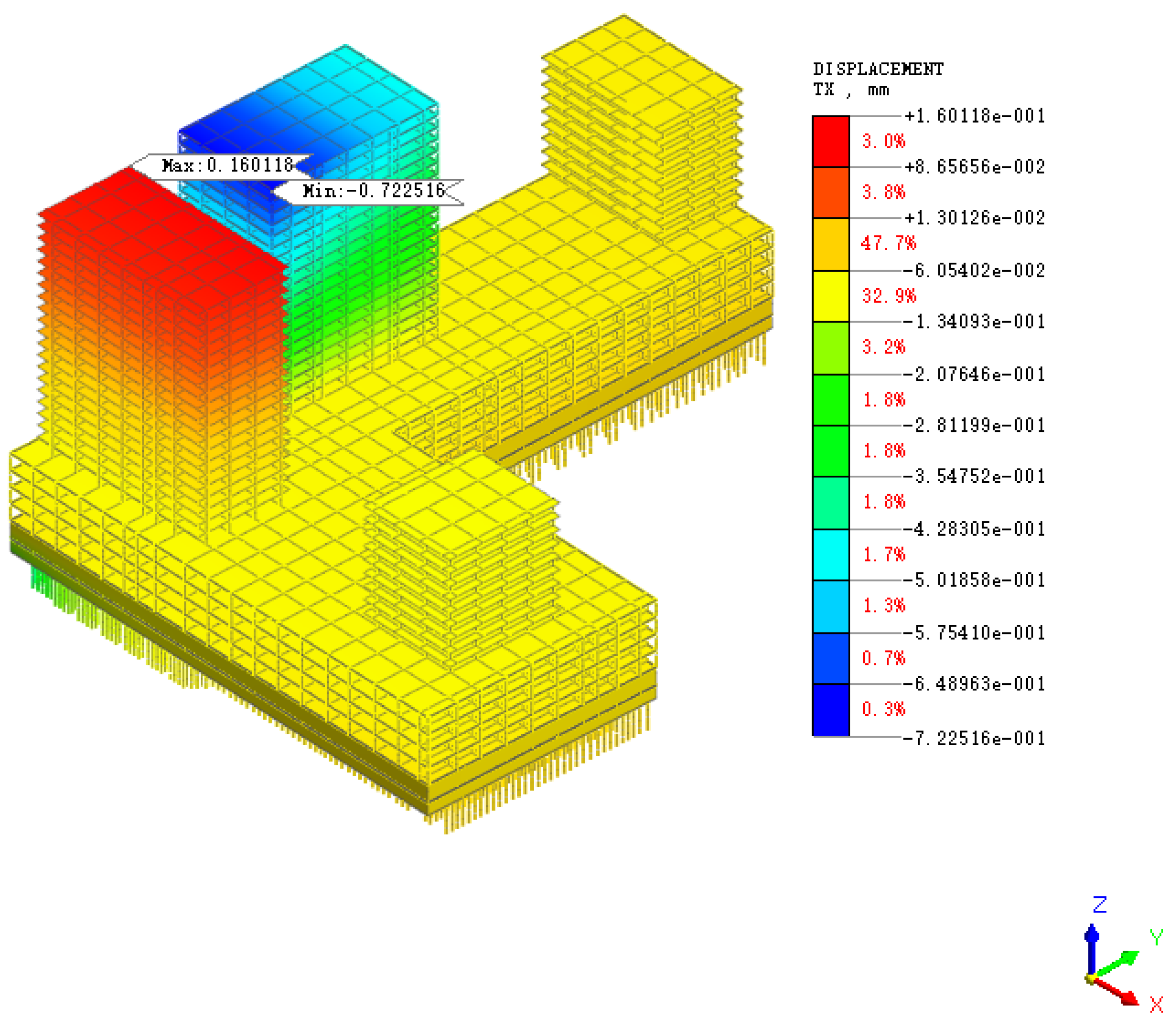

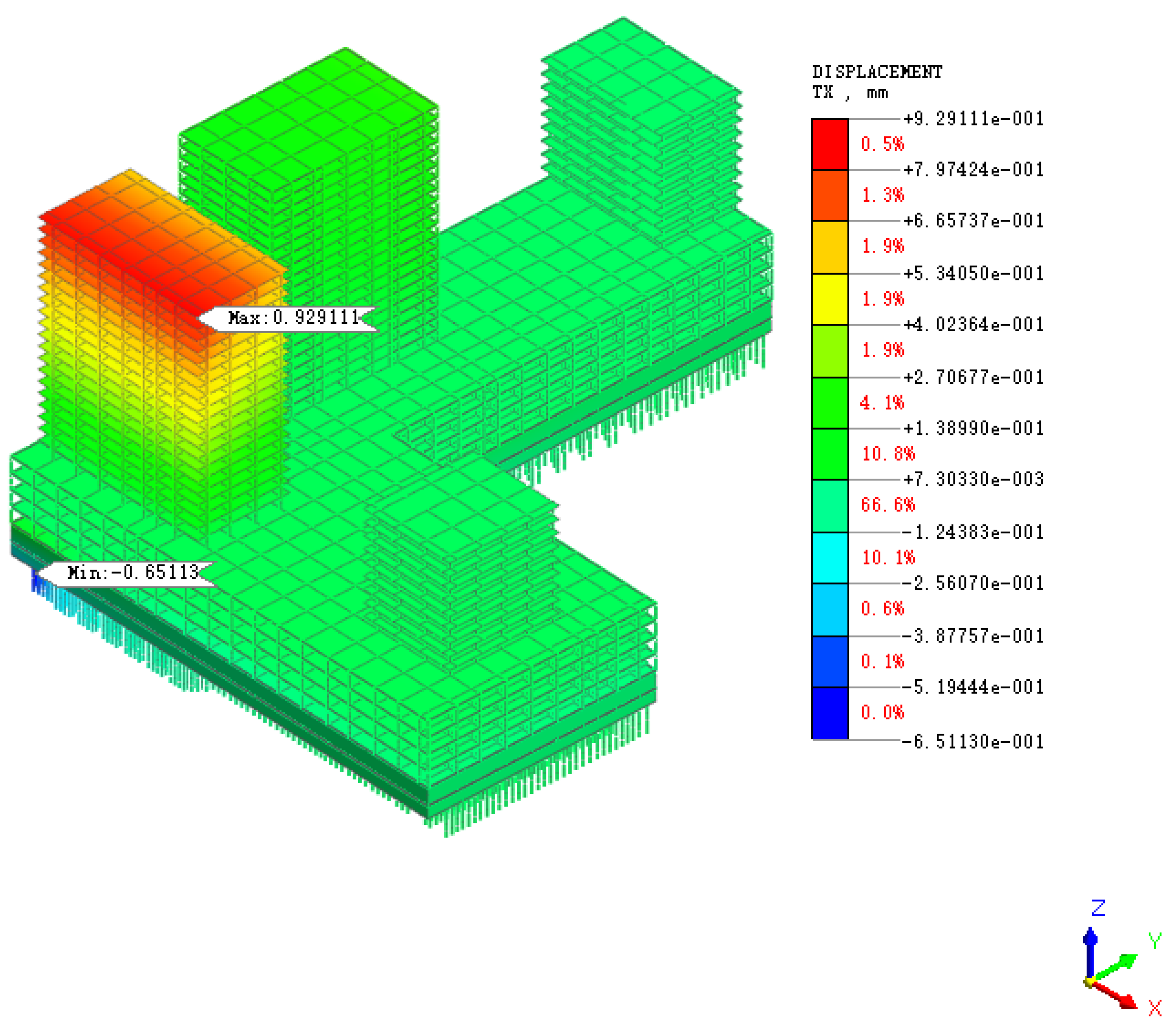

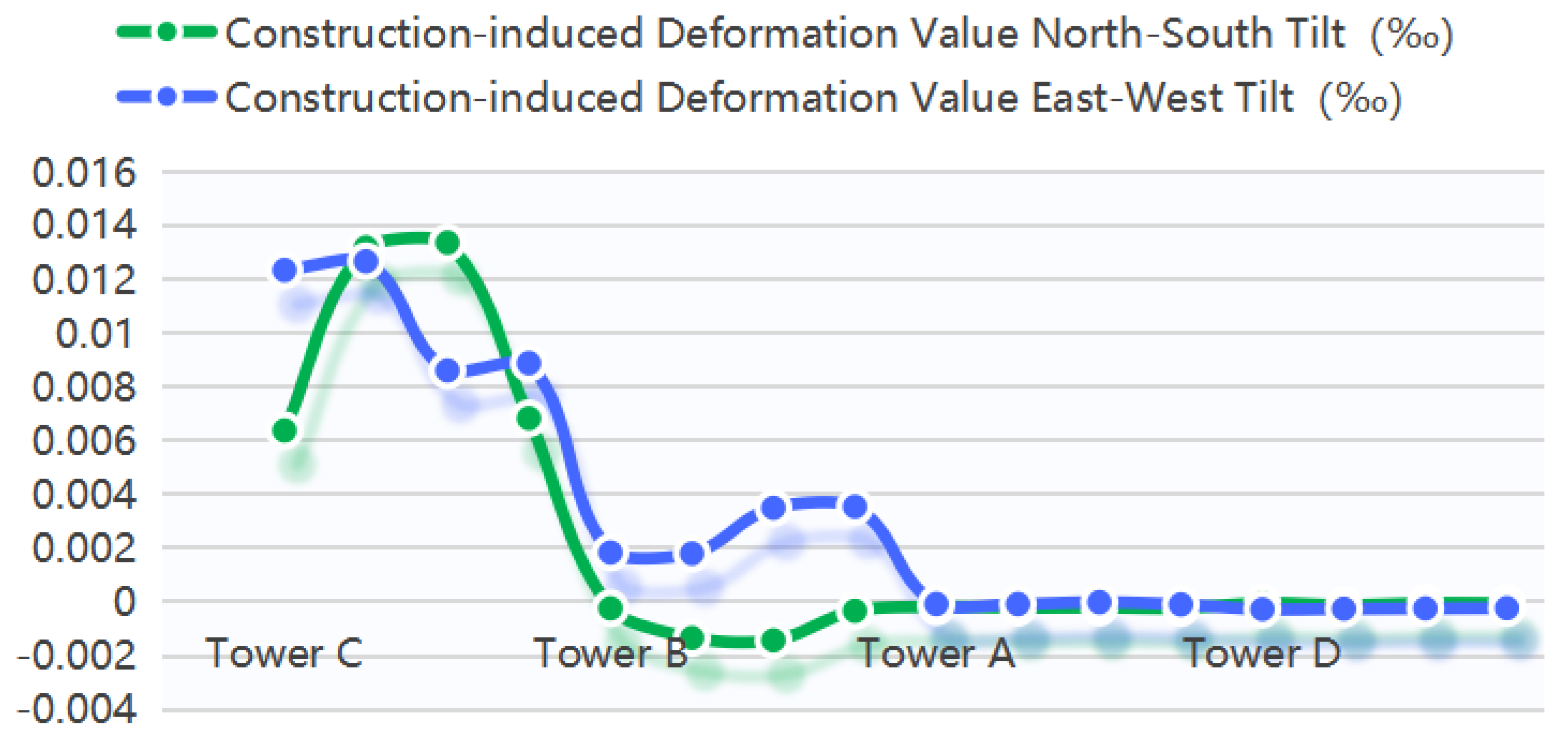

11. Study on the Impact of Each Construction Process on Adjacent Buildings

12. Results

- The horizontal displacement of the support structure gradually increases with soil excavation under each construction condition, with the displacement direction all toward the inner side of the foundation pit. The overall horizontal displacement is small [25], and the displacement curve shows a “stepped” pattern. Along the excavation depth direction, it generally exhibits a trend of first increasing, then decreasing, and then increasing again, with the maximum horizontal displacement occurring at CS8;

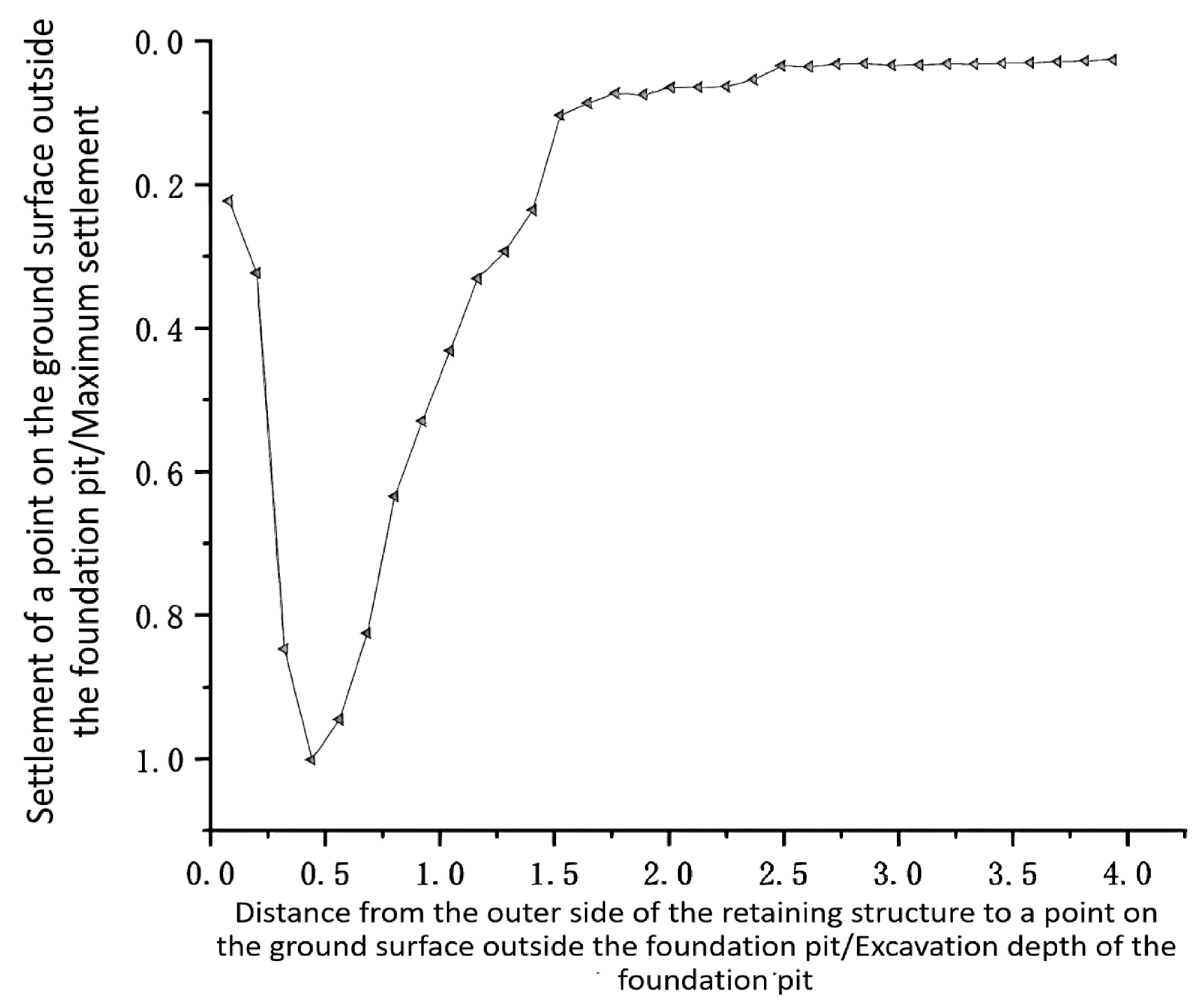

- The ground surface settlement curve is roughly “V-shaped” in distribution, with a steeper slope within the range of 0.34 He, followed by a gradual decrease, and the area beyond 1.73 He is almost unaffected by excavation, which is highly consistent with the influence range of ground surface settlement;

- The overall horizontal displacement of the ground surface increases with the increase in excavation depth, with a higher deformation rate during dewatering, followed by a decrease in deformation rate. The horizontal displacement of the ground surface perpendicular to the foundation pit is generally consistent with that along the foundation pit direction, but the horizontal displacement perpendicular to the foundation pit is greater than that along the foundation pit direction;

- With the progression of construction sequences, the settlement curve of adjacent buildings exhibits a parabola-like form with initial uplift followed by subsidence. The settlement magnitude of buildings decreases with increasing distance from the foundation pit, and the main influence zone of building settlement coincides with that of ground surface settlement;

- The cover-and-cut top-down method has minimal impact on the tilt rate of adjacent buildings, with all values within the allowable limits. The tilt rates comply with the relevant provisions in the Code for Design of Building Foundation (GB50007-2011) [23], which stipulates that the overall tilt rate of multi-story and high-rise buildings shall not exceed 2.5‰.

- 1.

- Dynamically adjust the stiffness of supporting systems and depth-dependent displacement characteristics. In the pre-bottom slab stage, strengthen the stiffness of the middle section of retaining structures to suppress the initial displacement growth. In the post-bottom slab stage, reduce redundant stiffness in the lower section of retaining structures (where displacement tends to decrease) to balance structural safety and construction economy.

- 2.

- Based on the predicted deformation values of the existing structures and considering a certain safety margin, the control indicators for the existing structures are determined by integrating the following factors: the predicted values from three-dimensional finite element calculation and simulation; the deformation control requirements for buildings specified in the technical standard for monitoring measurement of urban rail transit engineering (DB22/T 5020-2019) [19] and the Code for Design of Building Foundations (GB 50007-2011) [23]; the allowable deformation values corresponding to the ultimate limit state (ULS) and serviceability limit state (SLS); a certain safety factor incorporated based on the predicted deformation values; and experience from other similar projects. The suggested control values are presented in Table 5.

- 3.

- Divide the construction area into three zones based on the settlement influence scope and implement targeted measures. In the core influence zone (≤0.34 He), the hydraulic gradient is controlled to reduce soil consolidation settlement and constrain lateral soil displacement. In the transition zone (0.34 He–1.73 He), conventional supports are combined with waterproof curtains, and deformation monitoring data are linked to dewatering intensity. In the unaffected zone (>1.73 He), protection measures are simplified to optimize construction efficiency.

- 4.

- Based on the quantified influence scope, a zoned synergistic mechanism that integrates real-time monitoring data with design parameters is established.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ralph, B.P. Deep excavation and tunneling in soft ground. In Proceedings of the 7th International Conference on Soil Mechanics and Foundation Engineering, State-of-the-Art-Volume, Mexico City, Mexico, 25–29 August 1969; pp. 225–290. [Google Scholar]

- Ou, C.-Y. Building response and ground movements induced by a deepexcavation. Geotechnique 2000, 50, 209–220. [Google Scholar] [CrossRef]

- Finno, R.J. Response of Building Adjacent to Stiff Excavation Support System in Soft Clay. J. Perform. Constr. Facil. 2001, 16, 10–20. [Google Scholar] [CrossRef]

- Son, M.; Cording, E.J. Responses of Buildings with Different Structural Types to Excavation-Induced Ground Settlements. J. Geotech. Geoenvironmental Eng. 2011, 137, 323–333. [Google Scholar] [CrossRef]

- Mair, R.J.; Bracegirdle, A. Subsurface settlement profiles above tunnels in clays. Gkotechnique 1993, 43, 315–320. [Google Scholar] [CrossRef]

- Bryson, L.S.; Kotheimer, M.J. Cracking in Walls of a Building Adjacent to a Deep Excavation. J. Perform. Constr. Facil. 2011, 25, 491–503. [Google Scholar] [CrossRef]

- Konnov, N.N.A. Settlement prediction for protected buildings nearby deep. In Proceedings of the Materials Science and Engineering, Moscow, Russia, 25–27 April 2018; Volume 365. [Google Scholar]

- Tan, Y.; Huang, R.; Kang, Z.; Bin, W. Covered Semi-Top-Down Excavation of Subway Station Surrounded by Closely Spaced Buildings in Downtown Shanghai: Building Response. J. Perform. Constr. Facil. 2016, 30, 04016040. [Google Scholar] [CrossRef]

- JGJ/T 23-2011; Technical Specification for Inspecting of Concrete Compressive Strength by Rebound Method. China Architecture & Building Press: Beijing, China, 2011.

- GB/T 50344-2019; Technical Standard for Inspection of Building Structure. China Architecture & Building Press: Beijing, China, 2019.

- JGJ/T 152-2019; Technical Standard for Test of Reinforcing Steel Bar in Concrete. China Architecture & Building Press: Beijing, China, 2019.

- GB 50018-2021; General Code for Engineering Survey. China Architecture & Building Press: Beijing, China, 2021.

- GB 50292-2015; Standard Forappraisal of Reliability of Civil Buildings. China Architecture & Building Press: Beijing, China, 2015.

- Finno, R.J.; Voss Jr, F.T.; Rossow, E.; Blackburn, J.T. Evaluating Damage Potential in Buildings Affected by Excavations. J. Geotech. Geoenvironmental Eng. 2005, 131, 1199–1210. [Google Scholar] [CrossRef]

- Whittle, A.J.; Corral, G.; Jen, L.C.; Rawnsley, R.P. Prediction and Performance of Deep Excavations for Courthouse Station, Boston. J. Geotech. Geoenvironmental Eng. 2015, 141, 04014123. [Google Scholar] [CrossRef]

- Ahmad, M.; Ray, R. Modelling of the Torsional Simple Shear Test with Randomized Tresca Model Properties in Midas GTS NX. Geotech. Geol. Eng. 2023, 41, 1937–1946. [Google Scholar] [CrossRef]

- Dong Heping, D.J.; Xiaolei, W. Numerical analysis of secant pile supporting deep foundation pit based on ABAQUS. J. Lanzhou Univ. Technol. 2024, 50, 121–128. [Google Scholar]

- Abbo, A.J.; Lyamin, A.V.; Sloan, S.W.; Hambleton, J.P. A C2 continuous approximation to the Mohr–Coulomb yield surface. Int. J. Solids Struct. 2011, 48, 3001–3010. [Google Scholar] [CrossRef]

- DB22/T 5020-2019; Technical Standard for Monitoring Measurement of Urban Rail Transit Engineering. Jilin Provincial Department of Housing and Urban Rural Development: Jilin, China, 2019.

- Wang, Y. Supporting Design and Numerical Simulation Analysis of A Deep Foundation Pit with Combined Method in Changchun. Master’s Thesis, Changchun Institute of Technology, Changchun, China, 2023. [Google Scholar]

- He, W.; Kong, X.; Tang, L.; Chen, W.; Hu, W.; Chen, G. A Preliminary Study on Mitigation Techniques for 3D Deformation of Adjacent Buildings Induced by Tunnelling in Water-Rich Strata: A Case. Symmetry 2024, 16, 1339. [Google Scholar] [CrossRef]

- DG/TJ 08-61-2018; Technical Code for Excavation Engineering. Tongji University Press: Shanghai, China, 2018.

- GB 50007-2011; Code for Design of Building Foundations. China Architecture & Building Press: Beijing, China, 2011.

- Wang, H.T. Numerical Simulation Technology and Engineering Applications of MIDAS GTS NX, 2nd ed.; Dalian University of Technology Press: Dalian, China, 2020. [Google Scholar]

- JGJ 120-2012; Technical Specification for Retaining and Protection of Building Foundation Excavations. China Architecture & Building Press: Beijing, China, 2012.

| Soil Layer Name | Soil Layer Thickness (m) | Average Water Content (%) | Natural Density (g/cm3) | Specific Gravity | Void Ratio | Compression Modulus (MPa) | Internal Friction Angle (°) | Cohesion |

|---|---|---|---|---|---|---|---|---|

| Miscellaneous Fill Layer ①1 | 0.70~3.0 | |||||||

| Silty Clay Layer ②2 | 9.50~16.60 | 26.4 | 1.97 | 2.72 | 0.751 | 6.02 | 14 | 27 |

| Silty Clay Layer ②3 | 0.80~9.00 | 24.5 | 1.99 | 2.74 | 0.712 | 9.88 | 14 | 31 |

| Clay Layer ②5 | 1.10~4.00 | 24.6 | 1.99 | 2.74 | 0.718 | 13.97 | 14 | 33 |

| Soil Layer Name | ϒ (kN/m3) | Liquid Limit (%) | Plastic Limit (%) | Liquidity Index | Plasticity Index | Ψ (°) | Es | |

| Silty Clay Layer ②2 | 18.9 | 33.3 | 19.2 | 0.74 | 14.3 | 18 | 4.04 | |

| Silty Clay Layer ②3 | 18.7 | 33.2 | 19.1 | 0.94 | 13.9 | 19 | 2.89 | |

| Clay Layer ②5 | 19.5 | 37.5 | 22.2 | 0.15 | 18.4 | 20 | 14.35 | |

| Hydrogeological Unit | Groundwater Classification | Stable Water Level | Observation Time | Aquifer | |

|---|---|---|---|---|---|

| Burial Depth (m) | Elevation (m) | ||||

| I | Unconfined Groundwater (Two) | 2.00~3.50 | 224.28~229.53 | 2020.5~2020.8 | Clayey Soil, Weathered Rock |

| Time of Water Level Measurement | Maximum Groundwater Level Conditions |

|---|---|

| 1956 | Burial Depth of 1 to 3 Meters Below Ground Surface |

| recent 3–5 years | Burial Depth of 2 to 5 Meters Below Ground Surface |

| current investigation | maximum water level elevation: 229.53 m |

| Simulated Construction Stage Description | |

|---|---|

| CS1 | Generate the initial stress field, construct the building structure, and eliminate the initial displacement field |

| CS2 | Reset displacement |

| CS3 | Construction of retaining structure |

| CS4 | Dewatering construction |

| CS5 | Excavation of the cover excavation section to the roof level and construction of the roof slab |

| CS6 | Backfilling |

| CS7 | Excavation of the cover excavation section to the middle plate level and construction of the middle plate |

| CS8 | Excavation of the cover excavation section to the middle plate level and construction of the bottom plate |

| CS9 | Water level restoration |

| Existing Structures | Item | Suggested Control Values |

|---|---|---|

| Adjacent buildings | vertical displacement | 5.0 mm |

| overall inclination | 0.20% | |

| deformation rate | 1 mm/d | |

| Ground surface settlement | 20.0 mm | |

| Ground surface horizontal displacement | 20.0 mm | |

| Horizontal displacement of retaining piles | 18.0 mm | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhao, D.; Shi, X.; Gao, X.; Zhang, Y.; Wang, S. Investigation into the Impacts of Cover-and-Cut Top-Down Metro Station Construction on Adjacent Buildings: A Case Study. Buildings 2025, 15, 4149. https://doi.org/10.3390/buildings15224149

Zhang X, Zhao D, Shi X, Gao X, Zhang Y, Wang S. Investigation into the Impacts of Cover-and-Cut Top-Down Metro Station Construction on Adjacent Buildings: A Case Study. Buildings. 2025; 15(22):4149. https://doi.org/10.3390/buildings15224149

Chicago/Turabian StyleZhang, Xiaojiao, Dajun Zhao, Xin Shi, Xikun Gao, Yi Zhang, and Shengda Wang. 2025. "Investigation into the Impacts of Cover-and-Cut Top-Down Metro Station Construction on Adjacent Buildings: A Case Study" Buildings 15, no. 22: 4149. https://doi.org/10.3390/buildings15224149

APA StyleZhang, X., Zhao, D., Shi, X., Gao, X., Zhang, Y., & Wang, S. (2025). Investigation into the Impacts of Cover-and-Cut Top-Down Metro Station Construction on Adjacent Buildings: A Case Study. Buildings, 15(22), 4149. https://doi.org/10.3390/buildings15224149