Risk Classification of Large Deformation in Soft-Rock Tunnels Using an Improved Matter–Element Extension Model with Asymmetric Proximity

Abstract

1. Introduction

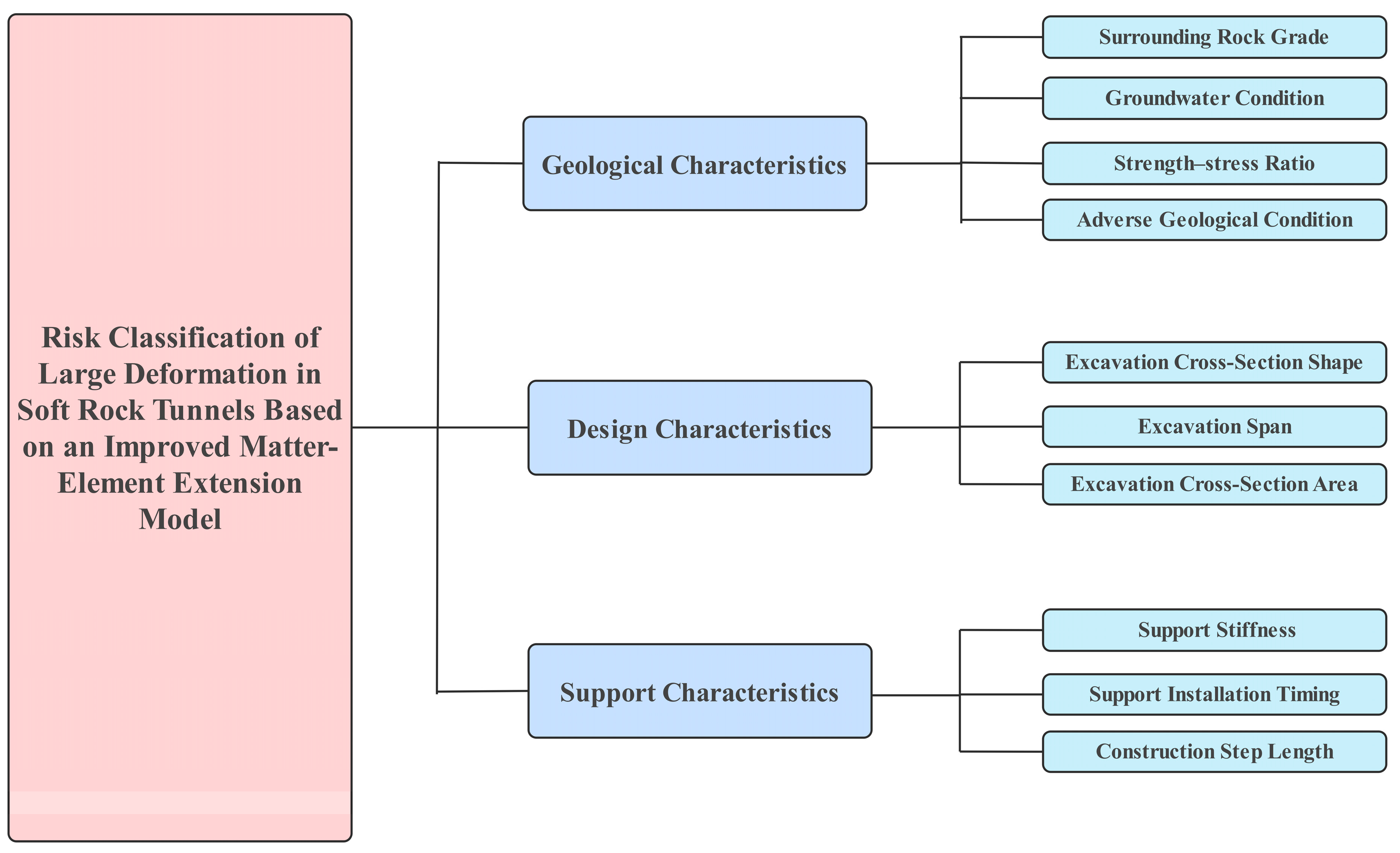

2. Establishment of the Evaluation System

2.1. Construction of the Indicator System

2.1.1. Geological Characteristics

2.1.2. Design Characteristics

2.1.3. Support Characteristics

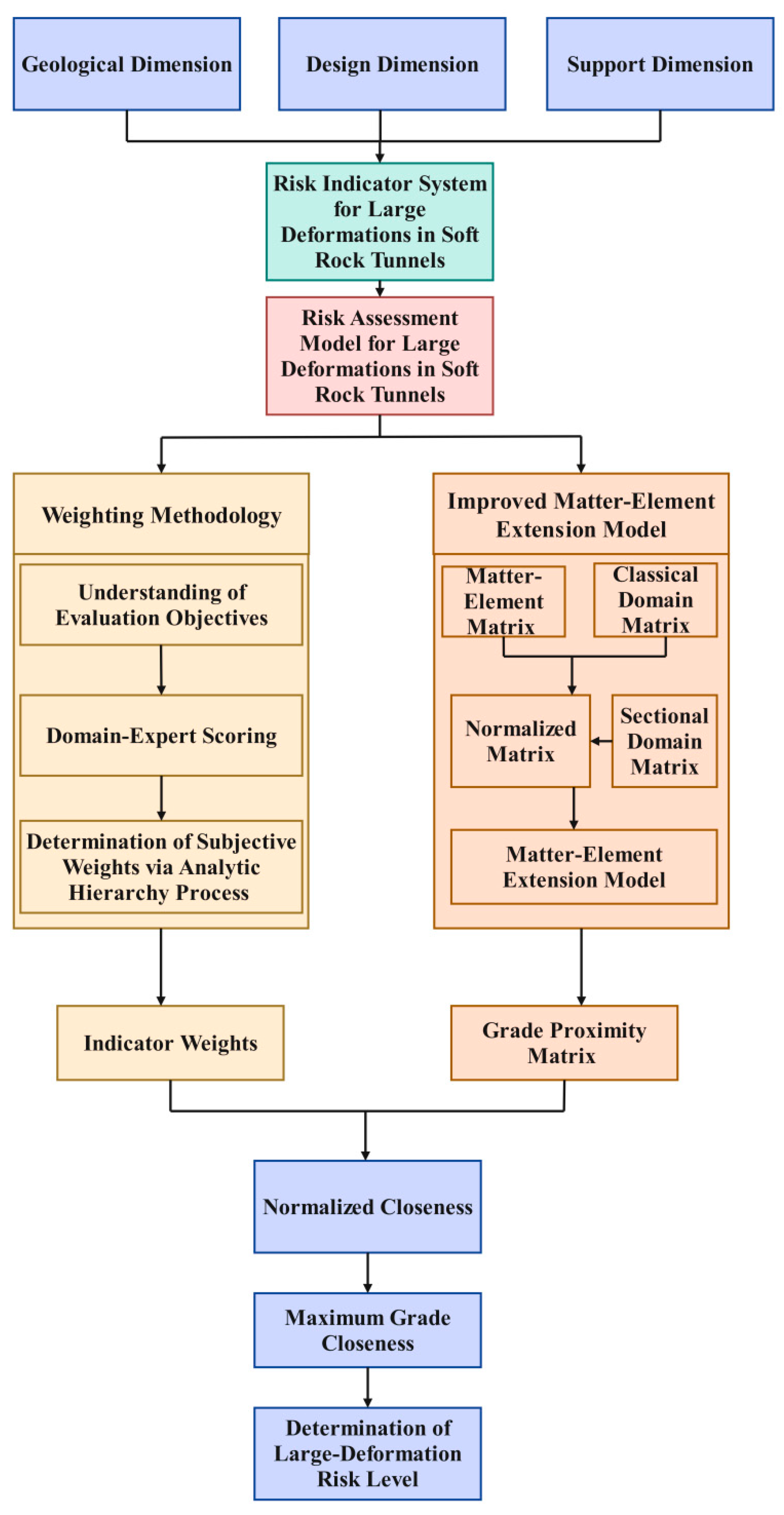

2.2. Classification of Evaluation Indicator

2.3. Evaluation Method

2.3.1. Calculation of Indicator Weights

- ●

- Hierarchical Structure Division

- ●

- Expert Scoring and Priority Relationship Judgment Matrix

- (1)

- Questionnaire Design and Expert Selection

- (2)

- Relative Importance Scale

- (3)

- Construction of the Judgment Matrix

- (4)

- Weight Calculation and Consistency Test

2.3.2. Improved Matter–Element Extension Model

- ●

- Construction of Matter–Element Matrices

- ●

- Normalization Processing

- ●

- Proximity Calculation

- ●

- Evaluation Grade Determination

3. Example Applications

3.1. Risk Assessment of Large Deformations in Soft-Rock Tunnels

3.2. Determination of Indicator Weights

3.3. Construction of the Matter–Element Matrix

3.4. Determination of Risk Levels

3.4.1. Normalization of Proximity Intervals

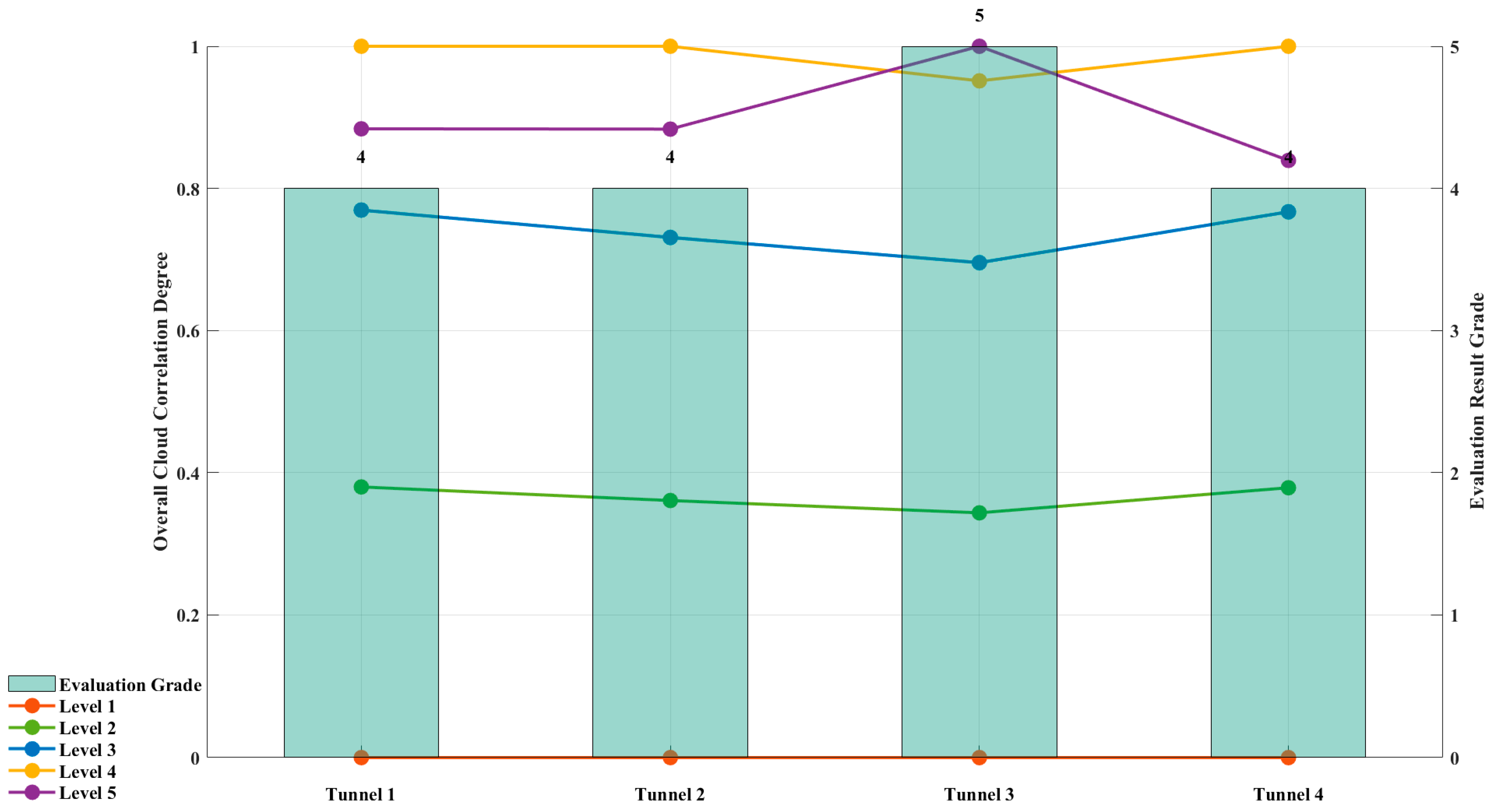

3.4.2. Comprehensive Assessment and Level Determination

4. Model Results

4.1. Evaluation Accuracy and Recognition Precision

4.2. Continuity and Sensitivity

4.3. Multi-Indicator Fusion Capability

5. Comparison Between the Improved Matter–Element Model and the Traditional N1 Method

5.1. Overview of the Traditional N1 Method

5.2. Classification Clarity and Boundary Sample Discrimination Capability

- (1)

- Fine Grained Classification

- (2)

- Boundary Sample Robustness

5.3. Stability and Consistency Assessment

- (1)

- Stability Analysis

- (2)

- Consistency Verification

5.4. Evaluation Accuracy and Engineering Applicability

5.4.1. Evaluation Accuracy

5.4.2. Engineering Applicability

5.5. Methodological Innovations and Prospects for Deployment

5.5.1. Asymmetric Proximity

5.5.2. Hierarchical Fuzzy Boundary Correction

6. Conclusions

- (1)

- Ten key evaluation indicators were identified across three dimensions—geological characteristics, design characteristics, and support characteristics—including surrounding rock grade, groundwater conditions, strength–stress ratio, adverse geological conditions, excavation cross-section shape, excavation span, excavation cross-section area, support stiffness, support installation timing, and construction step length. These indicators underpin a comprehensive, hierarchical framework for assessing large deformations in soft-rock tunnels, thereby supplying rigorously quantified inputs for subsequent risk grading.

- (2)

- The matter–element extension model was innovatively enhanced by incorporating asymmetric proximity in place of the traditional maximum membership principle. Min–max normalization applied to the proximity intervals of each risk class produces smooth, continuous mappings at class boundaries, thereby mitigating information loss and abrupt transitions, and enabling the model to distinguish tunnel risk levels with greater precision.

- (3)

- Comparative experiments with the classical N1 method further confirmed the improved model’s superior evaluation accuracy, classification discriminability, and interference resistance. Field measurements closely matched on-site monitoring, and the model effectively captured transient exceedance and subtle variations. Moreover, its straightforward and efficient normalization process facilitates rapid field deployment, demonstrating strong potential for engineering-scale application. However, the method depends on expert-derived weights and overlooks construction dynamics. This limitation will be explored in greater depth in future research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yu, W.; Wang, B.; Liu, J.; Chen, L.; Zi, X. Mechanical properties of partially bonded rock anchors in squeezing large-deformation soft rock tunnels. Tunn. Undergr. Space Technol. 2024, 147, 105699. [Google Scholar] [CrossRef]

- Deng, H.-S.; Fu, H.-L.; Shi, Y.; Zhao, Y.-Y.; Hou, W.-Z. Countermeasures against large deformation of deep-buried soft rock tunnels in areas with high geostress: A case study. Tunn. Undergr. Space Technol. 2022, 119, 104238. [Google Scholar] [CrossRef]

- Guo, E.; Zhang, W.; Lai, J.; Hu, H.; Xue, F.; Su, X. Enhancement of Cement-Based Materials: Mechanisms, Impacts, and Applications of Carbon Nanotubes in Microstructural Modification. Buildings 2025, 15, 1234. [Google Scholar] [CrossRef]

- Guo, E.; Hu, H.; Lai, J.; Zhang, W.; He, S.; Cui, G.; Wang, K.; Wang, L. Deformation analysis of high-speed railway CFG pile composite subgrade during shield tunnel underpassing. Structures 2025, 78, 109193. [Google Scholar] [CrossRef]

- Qiu, J.; Cui, G.; Lai, J.; Zhao, K.; Tang, K.; Qiang, L.; Jia, D. Influence of Fissure-Induced Linear Infiltration on the Evolution Characteristics of the Loess Tunnel Seepage Field. Tunn. Undergr. Space Technol. 2025, 162, 106640. [Google Scholar] [CrossRef]

- Zhang, Z.-K.; Lai, J.-X.; Song, Z.-P.; Xie, Y.-L.; Qiu, J.-L.; Cheng, Y.; Zhang, L. Investigating fracture response characteristics and fractal evolution laws of pre-holed hard rock using infrared radiation: Implications for construction of underground works. Tunn. Undergr. Space Technol. 2025, 161, 106594. [Google Scholar] [CrossRef]

- Wei, F.; Lai, J.; Su, X. Investigation of power-law fluid infiltration grout characteristics on the basis of fractal theory. Buildings 2025, 15, 987. [Google Scholar] [CrossRef]

- Lei, J.; Fang, H.; Zhu, Y.; Chen, Z.; Wang, X.; Xue, B.; Yang, M.; Wang, N. GPR detection localization of underground structures based on deep learning and reverse time migration. NDT E Int. 2024, 143, 103043. [Google Scholar] [CrossRef]

- Wei, W.; Gong, J.; Deng, J.; Xu, W. Effects of Air Vent Size and Location Design on Air Supply Efficiency in Flood Discharge Tunnel Operations. J. Hydraul. Eng. 2023, 149, 4023050. [Google Scholar] [CrossRef]

- Liang, J.; Liu, W.; Yin, X.; Li, W.; Yang, Z.; Yang, J. Experimental study on the performance of shield tunnel tail grout in ground. Undergr. Space 2025, 20, 277–292. [Google Scholar] [CrossRef]

- Yin, Q.; Xin, T.; Zhenggang, H.; Minghua, H.; Hui, C. Measurement and Analysis of Deformation of Underlying Tunnel Induced by Foundation Pit Excavation. Adv. Civ. Eng. 2023, 2023, 8897139. [Google Scholar] [CrossRef]

- Liu, G.; Zhong, Z.; Ye, T.; Meng, J.; Zhao, S.; Liu, J.; Luo, S. Impact failure and disaster processes associated with rockfalls based on three-dimensional discontinuous deformation analysis. Earth Surf. Process. Landforms 2024, 49, 3344–3366. [Google Scholar] [CrossRef]

- Li, Z.-Q.; Nie, L.; Xue, Y.; Li, W.; Fan, K. Model Testing on the Processes, Characteristics, and Mechanism of Water Inrush Induced by Karst Caves Ahead and Alongside a Tunnel. Rock Mech. Rock Eng. 2025, 58, 5363–5380. [Google Scholar] [CrossRef]

- Li, X.; Meng, S.; Sun, W.; Yuan, M.; Liu, X.; Nan, Y.; Sun, Y.; Sun, D.; Tao, J.; Li, J.; et al. Research on the risk assessment of the green construction of hydraulic tunnels based a on combination weighting-cloud model. Evol. Intell. 2025, 18, 57. [Google Scholar] [CrossRef]

- Bai, C.; Xue, Y.; Qiu, D.; Yang, W.; Su, M.; Ma, X. Real-time updated risk assessment model for the large deformation of the soft rock tunnel. Tunn. Undergr. Space Technol. 2021, 21, 04020234. [Google Scholar] [CrossRef]

- Bai, C.; Xue, Y.; Qiu, D.; Su, M.; Ma, X.; Liu, H. Analysis of factors affecting the deformation of soft rock tunnels by data envelopment analysis and a risk assessment model. Tunn. Undergr. Space Technol. 2021, 116, 104111. [Google Scholar] [CrossRef]

- Zhang, X.; Minghao, W.; Feng, D.; Jingchun, W. Risk classification assessment and early warning of large deformation of soft rock in tunnels based on CNN-LSTM model. Sci. Rep. 2024, 14, 29944. [Google Scholar] [CrossRef] [PubMed]

- He, L.P.; Xu, Y.D.; Hu, Q.J.; Cai, Q.J. Assessment of Large Deformation Risk in Soft-Rock Tunnels Based on Game-Theory–Cloud Model. Mod. Tunn. Technol. 2021, 58, 85–94. [Google Scholar] [CrossRef]

- Sun, Y.; Xu, N.; Xiao, P.; Sun, Z.; Li, H.; Liu, J.; Li, B. Characterizing large deformation of soft rock tunnel using microseismic monitoring and numerical simulation. J. Rock Mech. Geotech. Eng. 2025, 17, 309–322. [Google Scholar] [CrossRef]

- Deng, P.; Liu, Q.; Liu, B.; Lu, H. Failure mechanism and deformation prediction of soft rock tunnels based on a combined finite–discrete element numerical method. Comput. Geotech. 2023, 161, 105622. [Google Scholar] [CrossRef]

- GB/T 50266-2013; Standard for Test Methods of Engineering Rock Mass. China Planning Press: Beijing, China, 2013.

- GB/T 50218-2014; Standard for Engineering Classification of Rock Mass. China Planning Press: Beijing, China, 2014.

- Hyun, K.-C.; Min, S.; Choi, H.; Park, J.; Lee, I.-M. Risk analysis using fault-tree analysis (FTA) and analytic hierarchy process (AHP) applicable to shield TBM tunnels. Tunn. Undergr. Space Technol. 2015, 49, 121–129. [Google Scholar] [CrossRef]

- Nezarat, H.; Sereshki, F.; Ataei, M. Ranking of geological risks in mechanized tunneling by using Fuzzy Analytical Hierarchy Process (FAHP). Tunn. Undergr. Space Technol. 2015, 50, 358–364. [Google Scholar] [CrossRef]

- Kim, J.; Kim, C.; Park, J.; Lee, I.-M.; Min, S. Probabilistic tunnel collapse risk evaluation model using analytical hierarchy process (AHP) and Delphi survey technique. Tunn. Undergr. Space Technol. 2021, 120, 104262. [Google Scholar] [CrossRef]

- Niu, C.-C.; Wang, Q.; Chen, J.-P.; Wang, K.; Zhang, W.; Zhou, F.-J. Debris-flow hazard assessment based on stepwise discriminant analysis and extension theory. Q. J. Eng. Geol. Hydrogeol. 2014, 47, 211–222. [Google Scholar] [CrossRef]

- Zhang, S.; Pan, Q.; Gong, D. Construction and implementation of matter-element matching model for soil heavy metal pollution evaluation. Sustain. Energy Grids Netw. 2022, 109, 695–700. [Google Scholar]

- Luo, Z.; Zhao, J.; Qi, S.; Feng, X. Evaluation of soil pollution by potential toxic elements in cultivated land in the Poyang Lake region based on an improved matter–element extension model. Forests 2022, 13, 1445. [Google Scholar] [CrossRef]

- Li, H.; Bai, X.; Zhai, X.; Zhao, J.; Zhu, X.; Li, C.; Liu, K.; Wang, Q. Research on extension evaluation method of mudslide hazard based on Analytic Hierarchy Process–criteria importance through intercriteria correlation combination assignment of game theory ideas. Water 2023, 15, 2961. [Google Scholar] [CrossRef]

- Caixia, T.; Zhongfu, T.; Jianbin, W.; Huiwen, Q.; Xiangyu, Z.; Zhenbo, X. Benefit analysis and evaluation of virtual power plants considering electric vehicles. EDP Sci. 2021, 248, 02024. [Google Scholar]

- Chen, C.; Ma, B. Risk evaluation of tailings dam-break based on the extension matter-element model. EDP Sci. 2021, 253, 01056. [Google Scholar]

- Liang, G.; Niu, D.; Liang, Y. Core competitiveness evaluation of clean energy incubators based on matter-element extension combined with TOPSIS and KPCA-NSGA-II-LSSVM. Sustainability 2020, 12, 9570. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, X.; Zou, Y.; Zhang, C.; Liu, S. Debris flow risk mapping based on GIS and Extenics. Nat. Hazards Earth Syst. Sci. 2018, 1–15. [Google Scholar]

- Wang, Z.C.; Zhao, B.T.; Xie, S.H.; Fan, H.B.; Wang, R.Q.; Qiu, J.L. Hydro-environmental evolution and mechanical response of support structures in loess-oilfield tunnels during water injection well leakage. Tunn. Undergr. Space Technol. 2025, 166, 106971. [Google Scholar] [CrossRef]

| Level | Description | Mitigation Measures |

|---|---|---|

| I (Very Low) | The surrounding rock remains in an elastic deformation or strain-hardening stage, without noticeable cracking or spalling; all design and support parameters are within safe limits. | Routine inspections and instrument based monitoring should be carried out at scheduled intervals. |

| II (Low) | Localized minor cracks or slight spalling have developed; overall stability remains adequate. | Monitoring frequency should be increased; localized grouting should be applied to reinforce cracks; excavation intervals may be shortened to better control deformation. |

| III (Medium) | A distinct soft zone has formed in the surrounding rock, with plastic spalling and small-scale block detachment; the support structure’s load capacity is approaching its warning threshold. | Support should be installed promptly and grouting should be performed; excavation intervals should be further shortened to ensure deformation remains controllable |

| IV (High) | The surrounding rock has exhibited extensive plastic deformation; the support capacity has reached its limit, significantly increasing safety hazards. | High-stiffness prestressed anchor cables and closely spaced steel ribs shall be adopted immediately as reinforcement measures |

| V (Very High) | The surrounding rock has lost its self-supporting capacity, resulting in local or full collapse; the support system has clearly failed, posing a significant safety risk. | Temporary supports (e.g., large support ribs or precast pipe sheds) should be installed urgently, and a full-face relining should be conducted. |

| Primary Indicator | Secondary Indicator | I | II | III | IV | V |

|---|---|---|---|---|---|---|

| Geological Factor | Surrounding rock grade | I | II | III | IV | V |

| Groundwater condition | Capillary water | Pore water | Fracture water | Karst water | Confined water | |

| Strength–stress ratio | >10 | 7–10 | 4–7 | 2–4 | <2 | |

| Adverse geological condition | Non-hazardous | Weak hazard | Low hazard | Moderate hazard | High hazard | |

| Excavation gross section shape | Circular (or near-circular) | Elliptical | Semicircular arch with flat floor | Horseshoe-shaped | Rectangular (or right-angle box section) | |

| Excavation span (m) | [0,6] | [6,9] | [9,12] | [12,15] | [15,50] | |

| Excavation cross section area (m2) | [0,30] | [30,50] | [50,80] | [80,120] | [120,300] | |

| Support stiffness | Very high | High | Moderate | Low | Very low | |

| Support installation timing | Very appropriate | Appropriate | Moderately appropriate | Inappropriate | Very inappropriate | |

| Construction step length | Very appropriate | Appropriate | Moderately appropriate | Inappropriate | Very inappropriate |

| Indicator | Surrounding-Rock Grade | Groundwater Condition | Strength–Stress Ratio | Adverse Geological Condition | Excavation Cross Section Shape | Excavation Span | Excavation Cross-Section Area | Support Stiffness | Support Installation Timing | Construction Step Length |

|---|---|---|---|---|---|---|---|---|---|---|

| Fixed weight | 0.12 | 0.12 | 0.12 | 0.12 | 0.07 | 0.11 | 0.04 | 0.16 | 0.10 | 0.05 |

| Risk Level | Tunnel 1 (Xinchengzi Tunnel) | Tunnel 2 (Xinlian Tunnel) | Tunnel 3 (Muzhailing Tunnel) | Tunnel 4 (Gonghe Tunnel) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Proximity | Normalized Value | Risk Assessment Level | Proximity | Normalized Value | Risk Assessment Level | Proximity | Normalized Value | Risk Assessment Level | Proximity | Normalized Value | Risk Assessment Level | |

| I | 0.5904 | 0.0000 | IV | 0.5909 | 0.0000 | IV | 0.5569 | 0.0000 | V | 0.6089 | 0.0000 | V |

| II | 0.7385 | 0.3799 | 0.7390 | 0.3608 | 0.7050 | 0.3435 | 0.7570 | 0.3788 | ||||

| III | 0.8903 | 0.7694 | 0.8908 | 0.7309 | 0.8567 | 0.6954 | 0.9087 | 0.7670 | ||||

| IV | 0.9802 | 1.0000 | 1.0014 | 1.0000 | 0.9670 | 0.9513 | 0.9999 | 1.0000 | ||||

| V | 0.9349 | 0.8838 | 0.9534 | 0.8834 | 0.9880 | 1.0000 | 0.9370 | 0.8393 | ||||

| Level | I | II | III | IV | V |

|---|---|---|---|---|---|

| Range | [0,0.2) | [0.2,0.4) | [0.4,0.6) | [0.6,0.8) | [0.8,1] |

| Tunnel | Tunnel 1 | Tunnel 2 | Tunnel 3 | Tunnel 4 |

|---|---|---|---|---|

| NL | 0.5674 | 0.701 | 0.719 | 0.689 |

| N1 | III | IV | IV | IV |

| RL | IV | IV | V | IV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Xie, Y.; Qiu, J.; Lai, J.; Sun, H. Risk Classification of Large Deformation in Soft-Rock Tunnels Using an Improved Matter–Element Extension Model with Asymmetric Proximity. Buildings 2025, 15, 3943. https://doi.org/10.3390/buildings15213943

Ma S, Xie Y, Qiu J, Lai J, Sun H. Risk Classification of Large Deformation in Soft-Rock Tunnels Using an Improved Matter–Element Extension Model with Asymmetric Proximity. Buildings. 2025; 15(21):3943. https://doi.org/10.3390/buildings15213943

Chicago/Turabian StyleMa, Shuangqing, Yongli Xie, Junling Qiu, Jinxing Lai, and Hao Sun. 2025. "Risk Classification of Large Deformation in Soft-Rock Tunnels Using an Improved Matter–Element Extension Model with Asymmetric Proximity" Buildings 15, no. 21: 3943. https://doi.org/10.3390/buildings15213943

APA StyleMa, S., Xie, Y., Qiu, J., Lai, J., & Sun, H. (2025). Risk Classification of Large Deformation in Soft-Rock Tunnels Using an Improved Matter–Element Extension Model with Asymmetric Proximity. Buildings, 15(21), 3943. https://doi.org/10.3390/buildings15213943