A Review of Recent Advances in MgO-Based Cementitious Composites for Green Construction: Mechanical and Durability Aspects

Abstract

1. Introduction

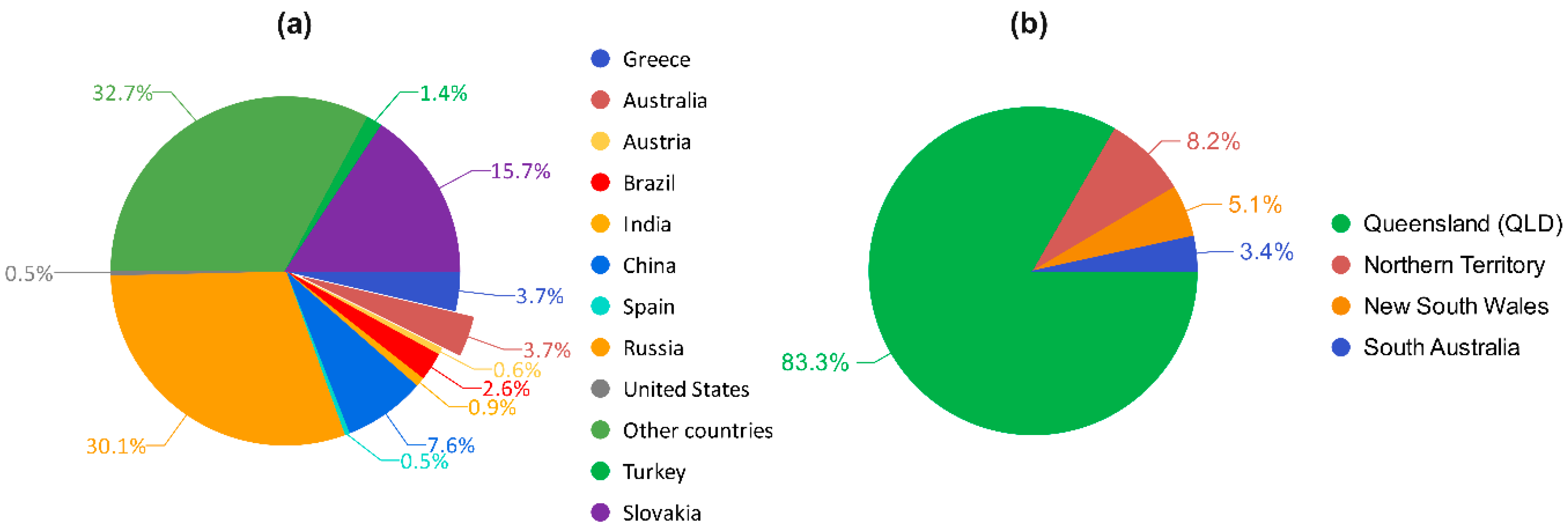

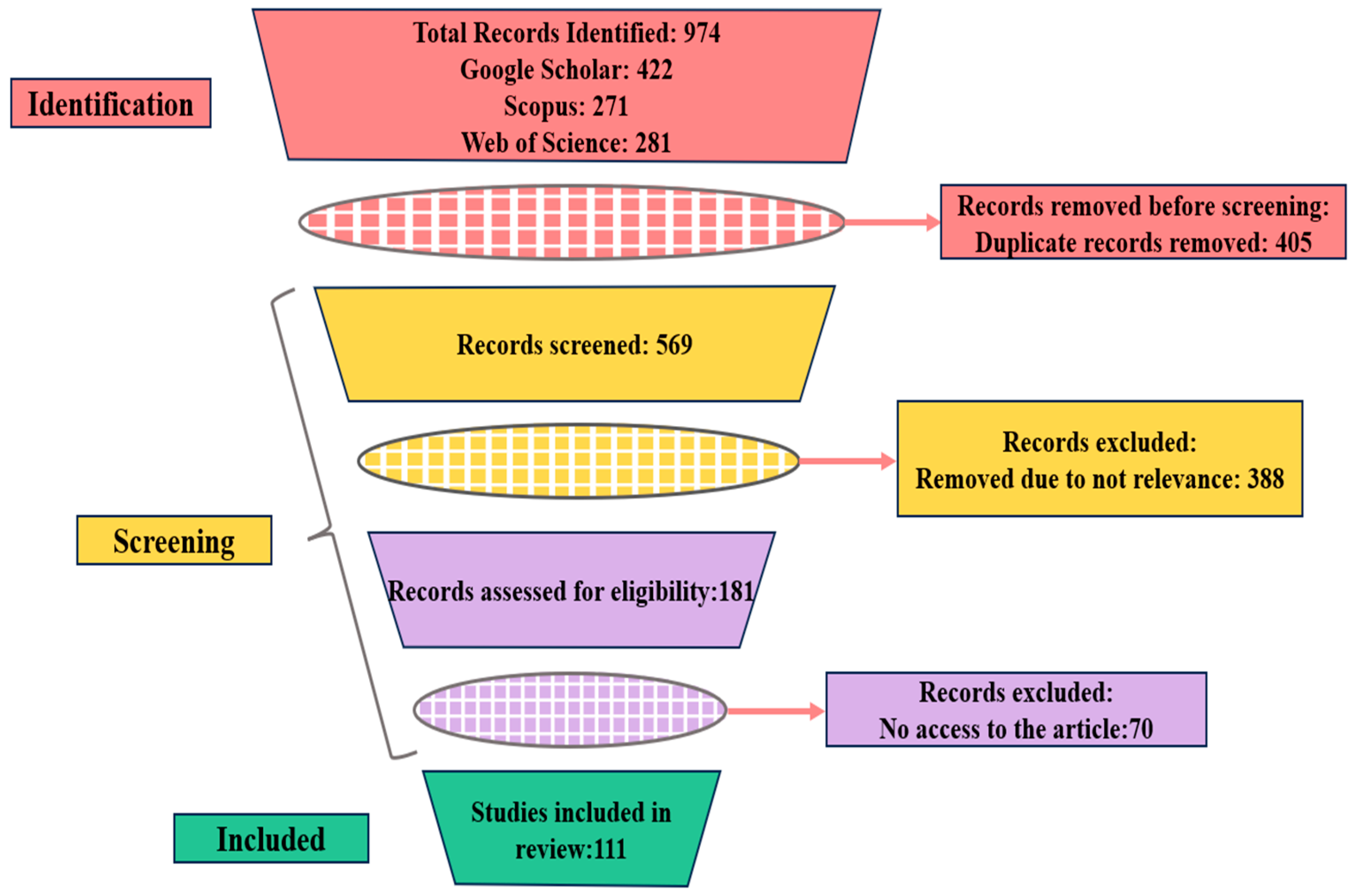

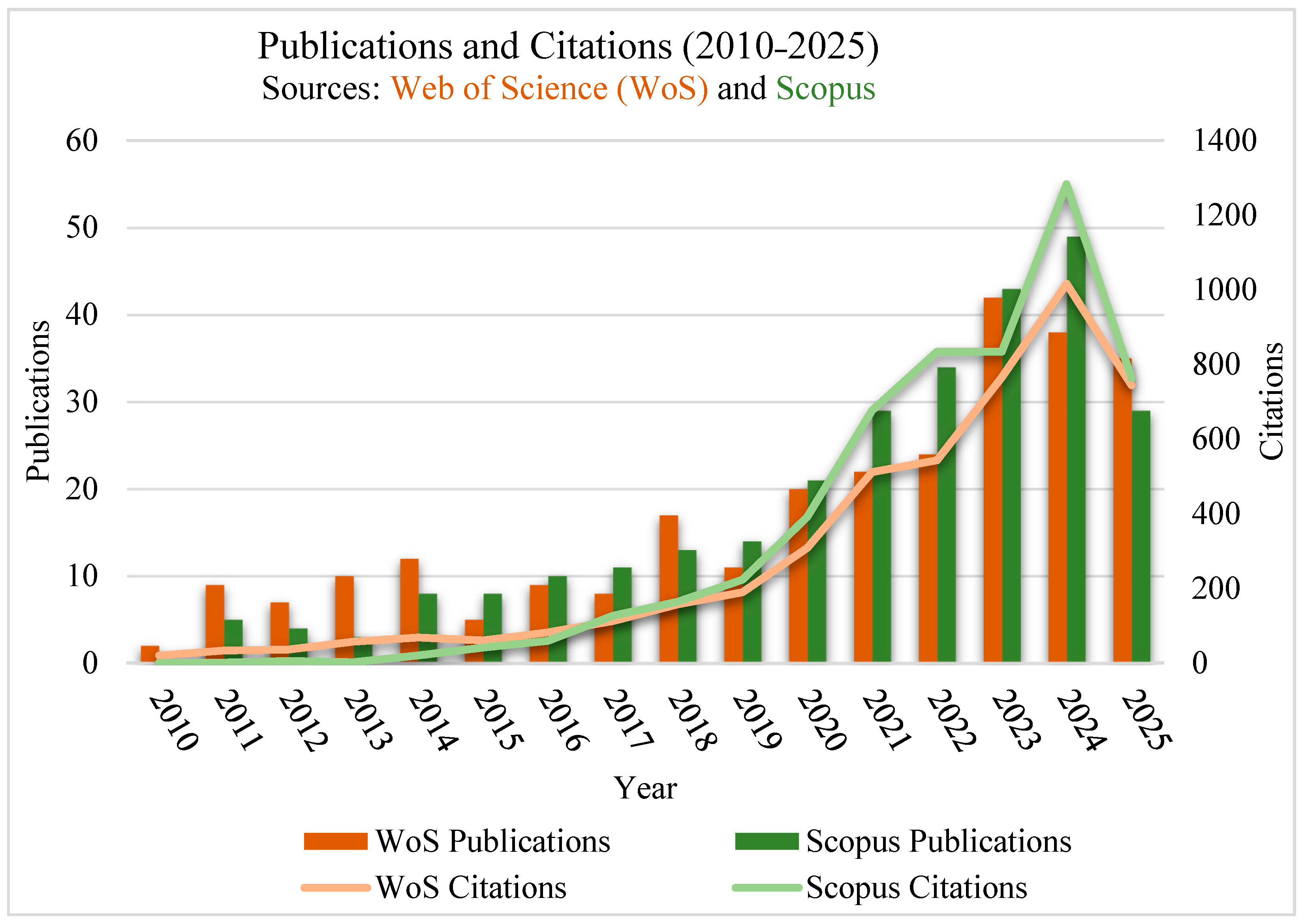

2. Methodology

3. Effect of MgO on Mechanical and Durability Properties of Cementitious Composites

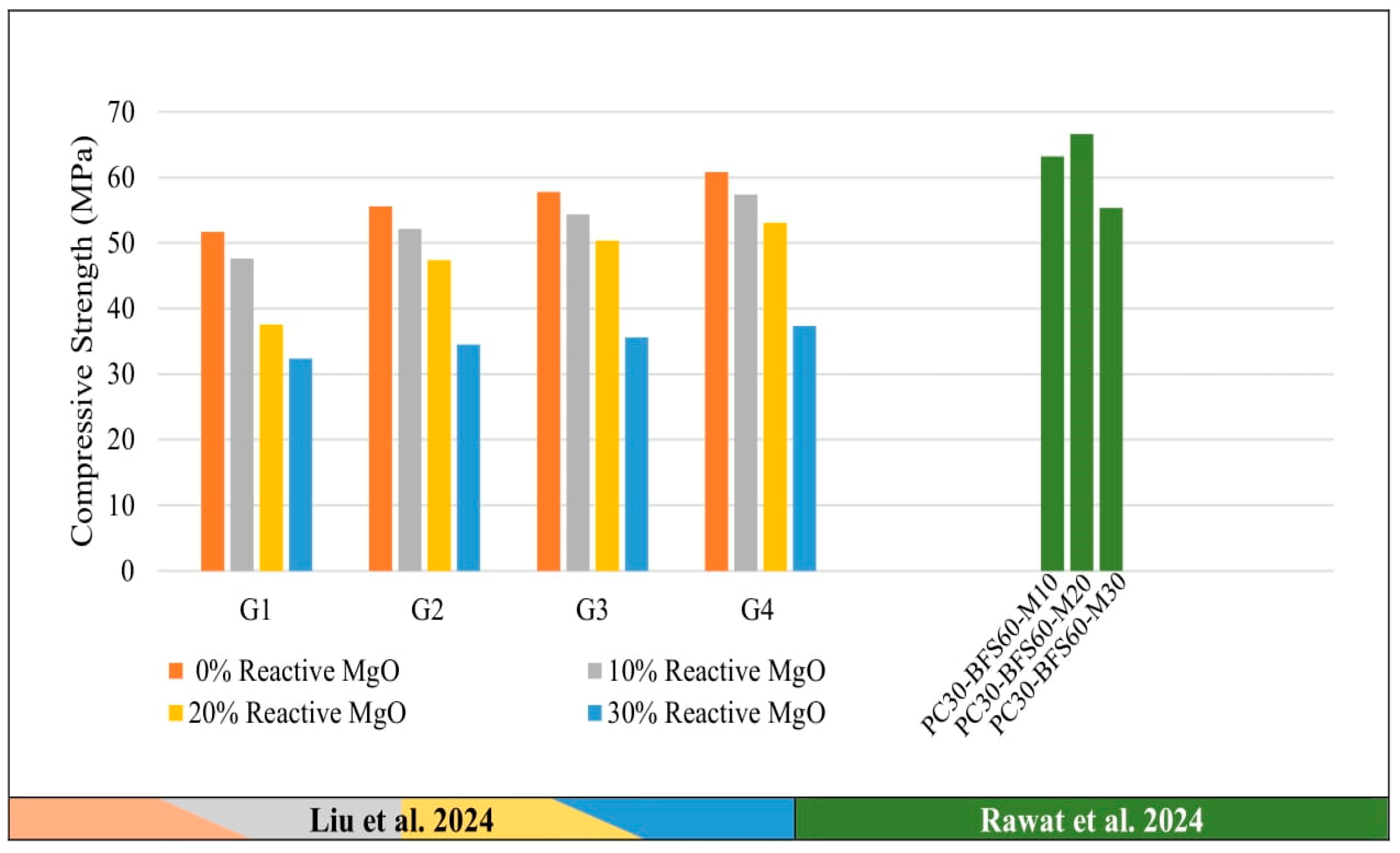

3.1. Compressive Strength

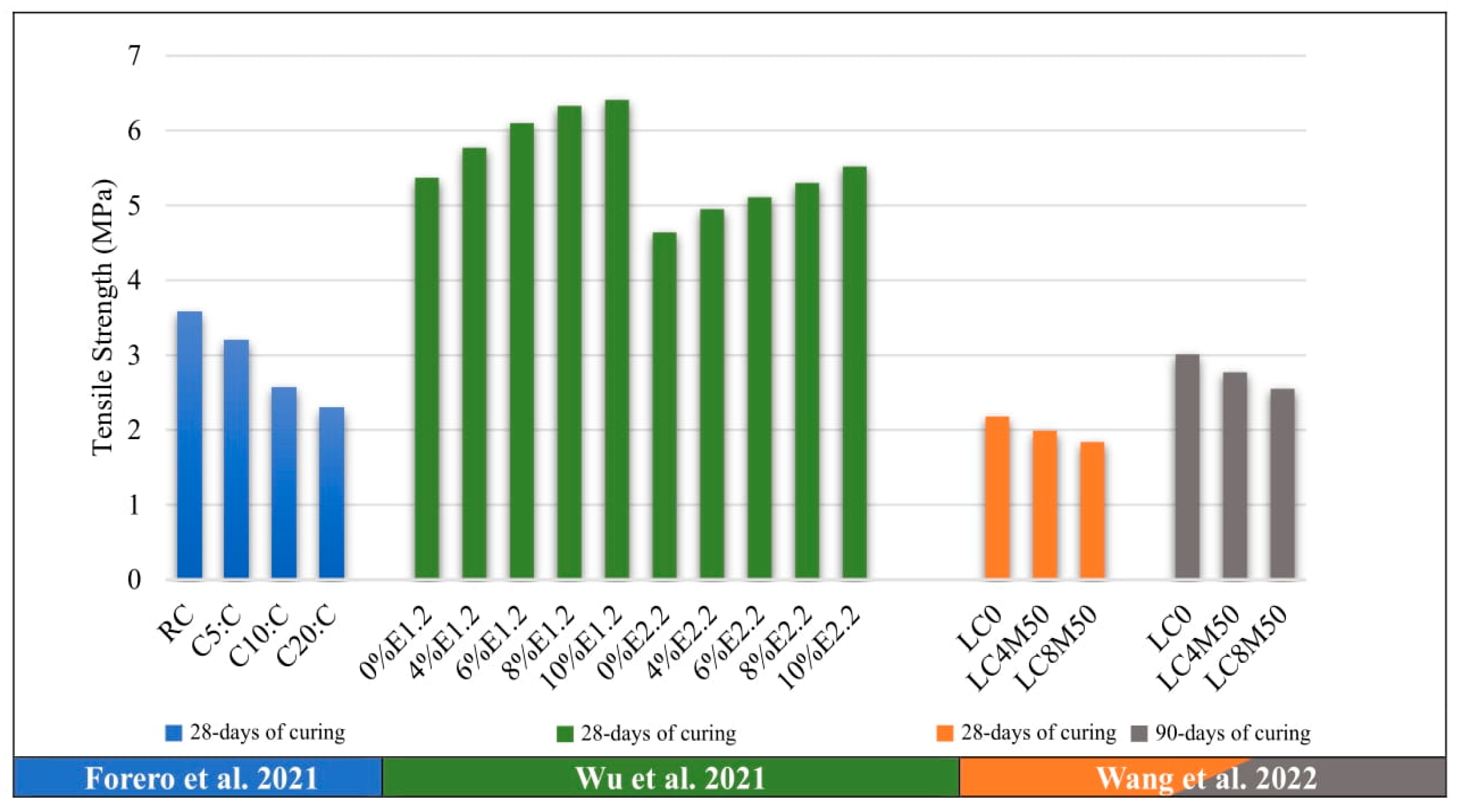

3.2. Tensile Strength

3.3. Water Absorption and Permeability

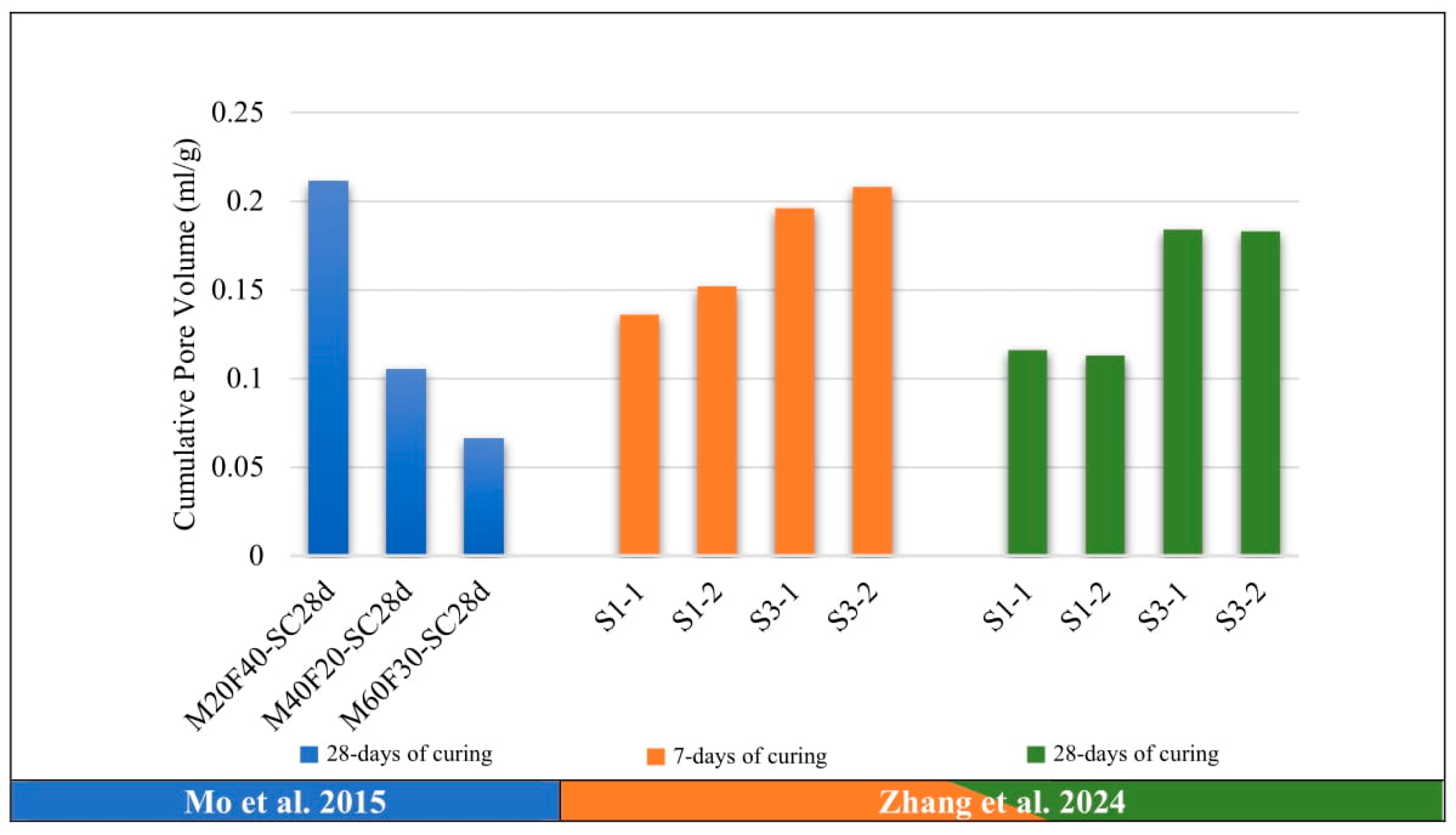

3.4. Porosity

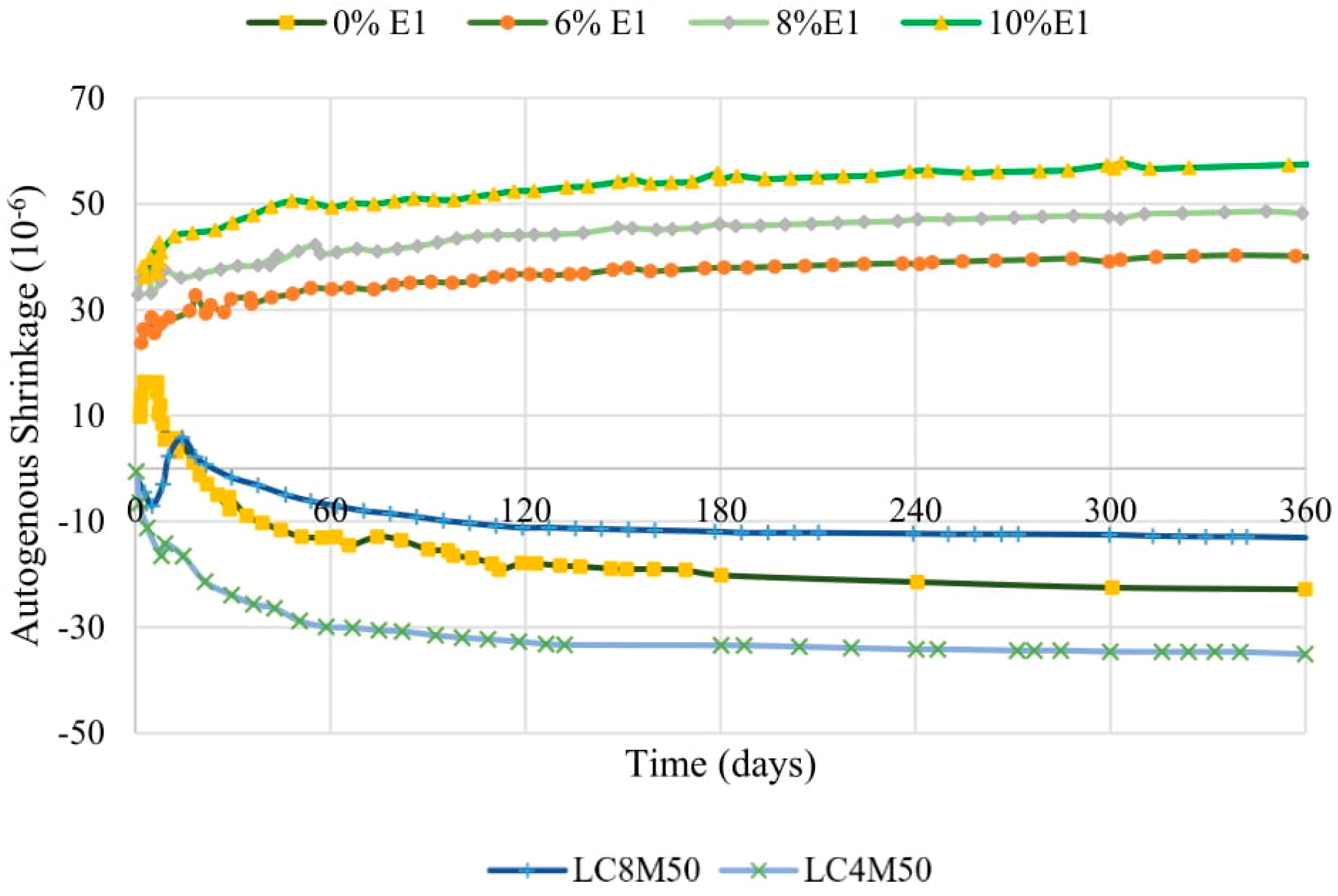

3.5. Autogenous Shrinkage

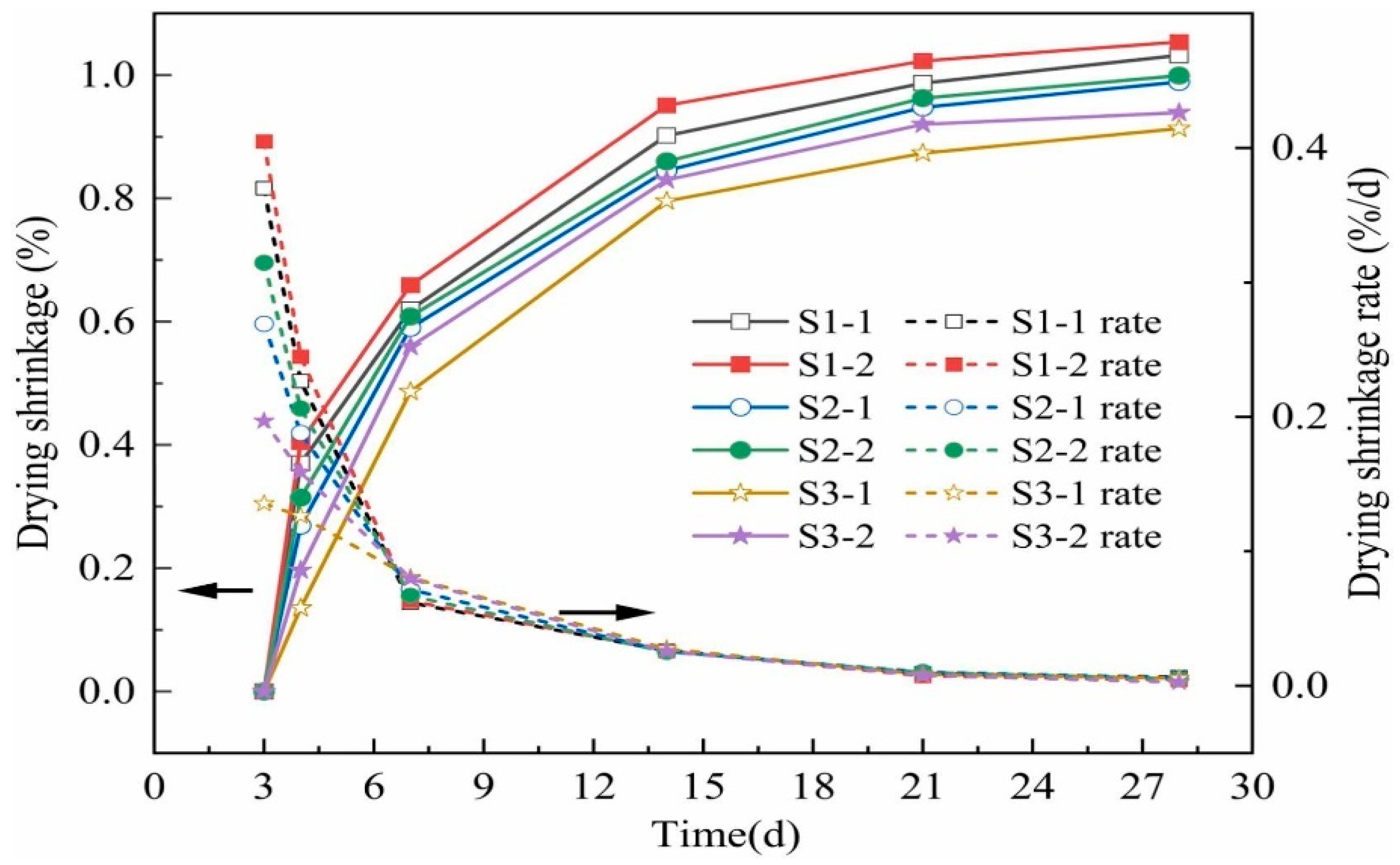

3.6. Drying Shrinkage

3.7. Carbonation

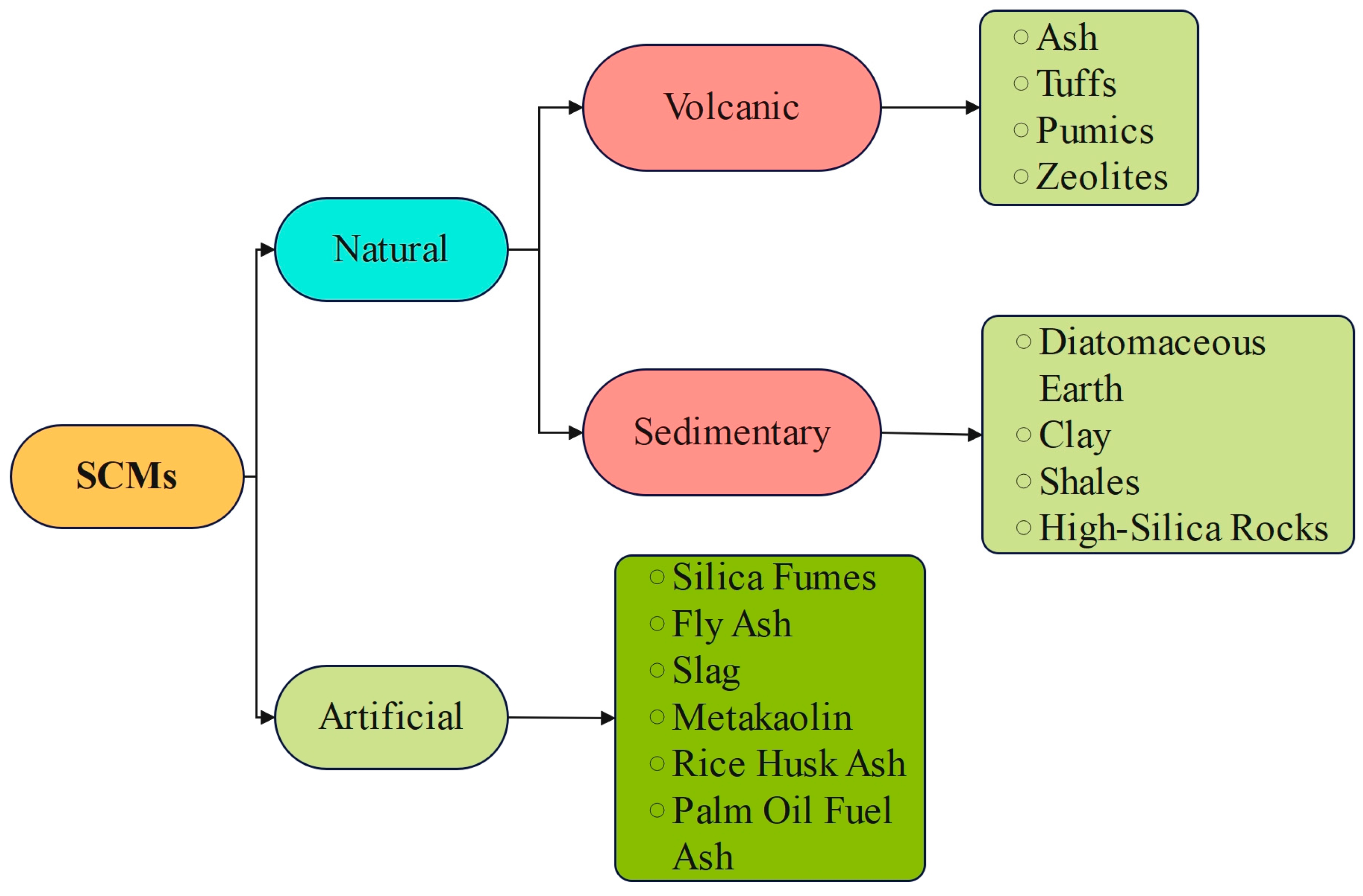

4. Effect of Supplementary Cementitious Materials (SCMs) on MgO-Based Cementitious Composites

4.1. Fly Ash (FA)

4.2. Silica Fume (SF)

4.3. Rice Husk Ash (RHA)

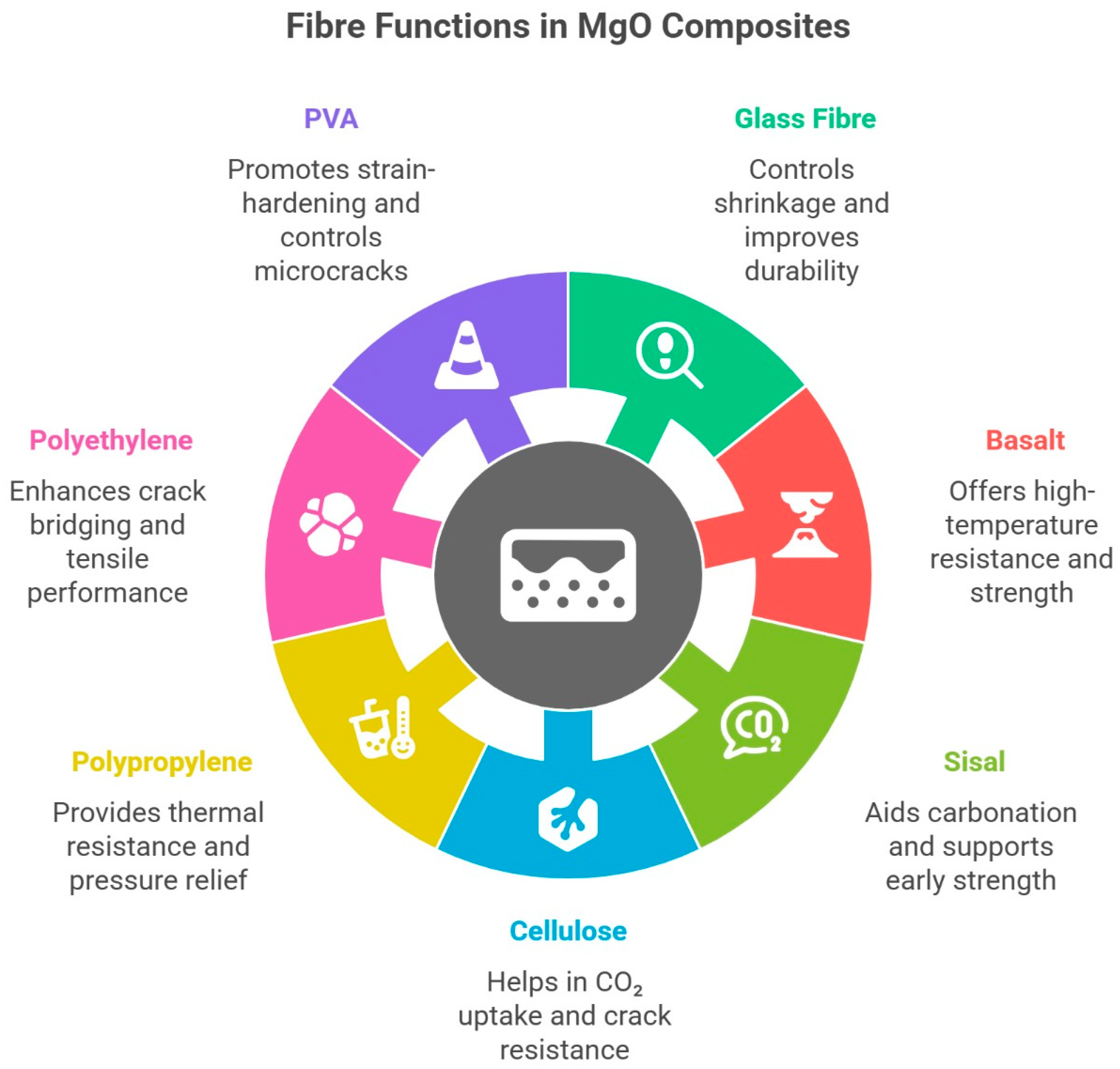

5. Effect of Fibres on MgO-Based Cementitious Composites

5.1. Natural Fibres

5.2. Synthetic and Glass Fibres

6. Conclusions

- Compressive strength in MgO-based composites depends on dosage, reactivity, and curing regime. Strength generally increases with MgO content up to ~60% under favorable conditions (e.g., high-temperature or carbonation curing). Tensile performance also improves at 4–6% dosage, enhancing ductility and strain capacity, while higher contents increase stiffness and reduce flexibility.

- Low to moderate MgO contents (around 5–20%) refine the pore structure, reduce total and harmful pore volumes, and lower water absorption and permeability by up to 33–42%. In contrast, higher MgO dosages (>10%) tend to increase porosity and water transport, lowering durability.

- Autogenous shrinkage is reduced by internal expansion from brucite formation, especially with higher MgO reactivity, which improves dimensional stability under sealed curing. Drying shrinkage is also lower with low to moderate MgO contents, as low-reactivity MgO delays deformation and stabilizes the matrix by reducing moisture loss.

- Supplementary cementitious materials such as fly ash, silica fume, and rice husk ash enhance strength, densify the pore structure, and improve chemical resistance. Their effectiveness is linked to the formation of M-S-H and M-A-S-H gels, which fill pores and strengthen the matrix.

- Synthetic fibers (PP, PE, PVA) and alkali-resistant glass fibers improve tensile strength, ductility, and crack resistance by bridging cracks and refining the pore structure. Moderate fiber contents (0.5–2% by volume) show the most reliable improvements. Excessive fiber addition, especially of glass fibers, can lead to agglomeration and higher porosity, reducing overall effectiveness. Natural fibers such as sisal and cellulose also enhance ductility and toughness, offering eco-friendly reinforcement options.

7. Future Research

- Despite promising durability results, the long-term performance of MgO-based composites under real-world conditions such as freeze–thaw cycles, sulphate attack, acid attack resistance, and chloride ingress has not been properly explored. Future studies should focus on extended exposure conditions to better evaluate performance.

- Pilot-scale projects and field applications are also needed to validate laboratory findings and demonstrate the feasibility of MgO-based composites in actual construction environments.

- The combined effects of supplementary cementitious materials (SCMs) and their interaction with fibres in MgO-based composites remain underexplored. Further studies are required to evaluate the performance of ternary and quaternary blends for high-performance construction applications.

- It is recommended that future research focus on developing performance-based design specifications for MgO-based cementitious composites. Instead of relying on fixed mix proportions, these guidelines should be centred around key target mechanical and durability properties such as compressive strength, shrinkage control, permeability, and resistance to environmental stresses. This approach would provide greater flexibility in mix design while ensuring reliable performance in real-world structural and exposure conditions.

- The application of MgO-based composites in advanced cement systems such as self-compacting concrete, ultra-high-performance concrete, self-healing concrete, and 3D-printed structures remains largely unexplored. Future research should also integrate digital tools such as artificial intelligence (AI) and machine learning (ML) for mix design optimization, durability prediction, and life-cycle assessment. Coupled with 3D printing technologies, these approaches can accelerate the development of customized, high-performance MgO-based materials.

- A comprehensive life cycle assessment (LCA) of MgO-based composites, considering raw material sourcing, energy input, emissions, and end-of-life recyclability, is necessary to validate their environmental benefits and guide their adoption in sustainable infrastructure.

- The fire performance and thermal behaviour of MgO composites also require further study. This knowledge is essential for applications in fire-sensitive zones and façade elements.

- Future studies should emphasize systematic investigations using standardized durability evaluation methods (e.g., RCM/NTBuild 492 for chloride ion diffusion, gas permeability tests, accelerated/natural carbonation, sulfate resistance, and shrinkage measurements) to ensure more reliable and verifiable results for MgO-based composites.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Adesina, A. Recent advances in the concrete industry to reduce its carbon dioxide emissions. Environ. Chall. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Rashad, A.M.; Sadek, D.M. An investigation on Portland cement replaced by high-volume GGBS pastes modified with micro-sized metakaolin subjected to elevated temperatures. Int. J. Sustain. Built Environ. 2017, 6, 91–101. [Google Scholar] [CrossRef]

- Assi, L.; Carter, K.; Deaver, E.E.; Anay, R.; Ziehl, P. Sustainable concrete: Building a greener future. J. Clean. Prod. 2018, 198, 1641–1651. [Google Scholar] [CrossRef]

- Rahimpour Golroudbary, S.; Makarava, I.; Kraslawski, A. Environmental assessment of global magnesium production. Miner. Process. Extr. Metall. Rev. 2023, 44, 389–406. [Google Scholar] [CrossRef]

- Al-Tabbaa, A. Eco-Efficient Concrete: 19. Reactive Magnesia Cement; Elsevier Inc.: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Lin, R.-S.; Liao, Y.; Fu, C.; Pan, T.-H.; Guo, R.; Wang, X.-Y. Mechanism analysis of microwave-carbonation solidification for carbide slag-based low-carbon materials. Cem. Concr. Compos. 2025, 157, 105938. [Google Scholar] [CrossRef]

- Iqra; Zahid, M. Impact of graphite nano/microplatelets on the mechanical and durability performance of concrete by incorporating mill scale waste. J. Eng. Appl. Sci. 2024, 71, 212. [Google Scholar] [CrossRef]

- Stefanidis, S.D.; Karakoulia, S.; Kalogiannis, K.G.; Iliopoulou, E.; Delimitis, A.; Yiannoulakis, H.; Zampetakis, T.; Lappas, A.; Triantafyllidis, K. Natural magnesium oxide (MgO) catalysts: A cost-effective sustainable alternative to acid zeolites for the in situ upgrading of biomass fast pyrolysis oil. Appl. Catal. B: Environ. 2016, 196, 155–173. [Google Scholar] [CrossRef]

- Pichavant, M.; Mysen, B.; Macdonald, R. Source and H2O content of high-MgO magmas in island arc settings: An experimental study of a primitive calc-alkaline basalt from St. Vincent, Lesser Antilles arc. Geochim. Cosmochim. Acta 2002, 66, 2193–2209. [Google Scholar] [CrossRef]

- Tan, Y.; Zhang, Z.; Wen, J.; Dong, J.; Wu, C.; Li, Y.; Yang, D.; Yu, H. Preparation of magnesium potassium phosphate cement using by-product MgO from Qarhan Salt Lake for low-carbon and sustainable cement production. Environ. Res. 2022, 214, 113912. [Google Scholar] [CrossRef] [PubMed]

- Oskierski, H.C.; Bailey, J.G.; Kennedy, E.M.; Jacobsen, G.; Ashley, P.M.; Dlugogorski, B.Z. Formation of weathering-derived magnesite deposits in the New England Orogen, New South Wales, Australia: Implications from mineralogy, geochemistry and genesis of the Attunga magnesite deposit. Miner. Depos. 2013, 48, 525–541. [Google Scholar] [CrossRef]

- Appiah, A.A.A.; Hunt, J.; Fathi, M.; Missen, O.P.; Hong, W.; Belousov, I.; Kameniar-Sandery, V.; Wilson, M. Geometallurgical Characterization of the Arthur River Magnesite Deposit, Northwestern Tasmania for Pathways to Production. Minerals 2025, 15, 247. [Google Scholar] [CrossRef]

- Ahmad, F.; Rawat, S.; Yang, R.C.; Zhang, L.; Zhang, Y. Fire resistance and thermal performance of hybrid fibre-reinforced magnesium oxychloride cement-based composites. Constr. Build. Mater. 2025, 472, 140867. [Google Scholar] [CrossRef]

- Ahmad, F.; Rawat, S.; Yang, R.; Zhang, L.; Fanna, D.J.; Soe, K.; Zhang, Y. Effect of metakaolin and ground granulated blast furnace slag on the performance of hybrid fibre-reinforced magnesium oxychloride cement-based composites. Int. J. Civ. Eng. 2025, 23, 853–868. [Google Scholar] [CrossRef]

- Walling, S.A.; Provis, J.L. Magnesia-based cements: A journey of 150 years, and cements for the future? Chem. Rev. 2016, 116, 4170–4204. [Google Scholar] [CrossRef]

- Harrison, A.J.W. Reactive Magnesium Oxide Cements. U.S. Patent No 7,347,896, 5 August 2008. [Google Scholar]

- Pan, Y.; Wu, C.; Huang, X. Long-term durability testing on the MgO-activated slag cured in brine. Constr. Build. Mater. 2017, 144, 271–278. [Google Scholar] [CrossRef]

- Azevedo, A.; Baltazar, L.; Faria, P.; Savastano, H. Durability assessment of MgO-based fiber cement reinforced with lignocellulosic fibers and cured in a CO2-rich atmosphere. J. Build. Eng. 2025, 104, 112327. [Google Scholar] [CrossRef]

- Sakr, K. Effects of silica fume and rice husk ash on the properties of heavy weight concrete. J. Mater. Civ. Eng. 2006, 18, 367–376. [Google Scholar] [CrossRef]

- Golewski, G.L. The role of pozzolanic activity of siliceous fly ash in the formation of the structure of sustainable cementitious composites. Sustain. Chem. 2022, 3, 520–534. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, T.; Hou, D.; Zhang, J.; Jiang, J. Insights on magnesium and sulfate ions’ adsorption on the surface of sodium alumino-silicate hydrate (NASH) gel: A molecular dynamics study. Phys. Chem. Chem. Phys. 2018, 20, 18297–18310. [Google Scholar] [CrossRef]

- Zhang, T. Development of Novel Low pH Magnesium Silicate Hydrate (MSH) Cement Systems for Encapsulation of Problematic Nuclear Wastes; Imperial College London: London, UK, 2012. [Google Scholar]

- Xu, X.; Lin, X.; Pan, X.; Ji, T.; Liang, Y.; Zhang, H. Influence of silica fume on the setting time and mechanical properties of a new magnesium phosphate cement. Constr. Build. Mater. 2020, 235, 117544. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, C. Effects of nano-silica and silica fume on properties of magnesium oxysulfate cement. J. Ceram. Soc. Jpn. 2020, 128, 164–173. [Google Scholar] [CrossRef]

- Zhang, J.; Lv, T.; Han, Q.; Zhu, Y.; Hou, D.; Dong, B. Effects of fly ash on MgO-based shrinkage-compensating cement: Microstructure and properties. Constr. Build. Mater. 2022, 339, 127648. [Google Scholar] [CrossRef]

- Vo, D.-H.; Hwang, C.-L.; Tran Thi, K.-D.; Yehualaw, M.D.; Chen, W.-C. Effect of fly ash and reactive MgO on the engineering properties and durability of high-performance concrete produced with alkali-activated slag and recycled aggregate. J. Mater. Civ. Eng. 2020, 32, 04020332. [Google Scholar] [CrossRef]

- Endale, S.A.; Taffese, W.Z.; Vo, D.-H.; Yehualaw, M.D. Rice husk ash in concrete. Sustainability 2022, 15, 137. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Murali, G.; Vatin, N.; Karelina, M.; Ozbakkaloglu, T.; Krishna, R.; Sahoo, A.K.; Das, S.K.; Mishra, J. Rice husk ash-based concrete composites: A critical review of their properties and applications. Crystals 2021, 11, 168. [Google Scholar] [CrossRef]

- Neri, A.C., Jr.; Baguhin, I.A.; Cabahug, R.R. An Investigation on the Compressive Strength of Concrete with Rice Husk Ash as Cement Replacement and Addition of Chemical Admixtures. Mindanao J. Sci. Technol. 2023, 21, 224–236. [Google Scholar] [CrossRef]

- Hosseinzadehfard, E.; Mobaraki, B. Corrosion performance and strain behavior of reinforced concrete: Effect of natural pozzolan as partial substitute for microsilica in concrete mixtures. In Structures; Eleviser: Amsterdam, The Netherlands, 2025; p. 109397. [Google Scholar]

- Gudayu, A.D.; Getahun, D.E.; Mekuriaw, D.M.; Walelign, F.T.; Ahmed, A.S. Natural fiber reinforced cementitious composites; materials, compatibility issues and future perspectives. Compos. Interfaces 2025, 32, 363–397. [Google Scholar] [CrossRef]

- Chandrathilaka, E.; Baduge, S.K.; Mendis, P.; Thilakarathna, P. Structural applications of synthetic fibre reinforced cementitious composites: A review on material properties, fire behaviour, durability and structural performance. In Structures; Eleviser: Amsterdam, The Netherlands, 2021; pp. 550–574. [Google Scholar]

- Khan, S.; Al-Deen, S.; Lee, C.K. Mechanical and durability behaviours of low carbon concrete: A systematic review. J. Build. Eng. 2025, 100, 111633. [Google Scholar] [CrossRef]

- Wei, L.; Wang, Y.; Yu, J.; Xiao, J.; Xu, S. Feasibility study of strain hardening magnesium oxychloride cement-based composites. Constr. Build. Mater. 2018, 165, 750–760. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, L.; Yu, J.; Yu, K. Mechanical properties of high ductile magnesium oxychloride cement-based composites after water soaking. Cem. Concr. Compos. 2019, 97, 248–258. [Google Scholar] [CrossRef]

- Yu, K.; Guo, Y.; Zhang, Y.; Soe, K. Magnesium oxychloride cement-based strain-hardening cementitious composite: Mechanical property and water resistance. Constr. Build. Mater. 2020, 261, 119970. [Google Scholar] [CrossRef]

- Rawat, S.; Lee, C.; Zhang, Y. Performance of fibre-reinforced cementitious composites at elevated temperatures: A review. Constr. Build. Mater. 2021, 292, 123382. [Google Scholar] [CrossRef]

- Yan, F.; Zhang, P.; Xu, F.; Tan, W. Effect of EVA polymer and PVA fiber on the mechanical properties of ultra-high performance engineered cementitious composites. Materials 2023, 16, 2414. [Google Scholar] [CrossRef]

- Noushini, A.; Samali, B.; Vessalas, K. Effect of polyvinyl alcohol (PVA) fibre on dynamic and material properties of fibre reinforced concrete. Constr. Build. Mater. 2013, 49, 374–383. [Google Scholar] [CrossRef]

- Qin, Y.; Wu, H.; Zheng, Y.; Wang, W.; Yi, Z. Microscopic Texture of Polypropylene Fiber-Reinforced Concrete with X-Ray Computed Tomography. Adv. Civ. Eng. 2019, 2019, 2386590. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Hassan, A.; ElNemr, A.; Goebel, L.; Koenke, C. Effect of hybrid polypropylene fibers on mechanical and shrinkage behavior of alkali-activated slag concrete. Constr. Build. Mater. 2024, 411, 134485. [Google Scholar] [CrossRef]

- Sun, R.-Q.; Sun, L.-B.; Chun, Y.; Xu, Q.-H.; Wu, H. Synthesizing nanocrystal-assembled mesoporous magnesium oxide using cotton fibres as exotemplate. Microporous Mesoporous Mater. 2008, 111, 314–322. [Google Scholar] [CrossRef]

- Ahmad, F.; Rawat, S.; Yang, R.C.; Zhang, L.; Guo, Y.; Fanna, D.J.; Zhang, Y. Effect of hybrid fibres on mechanical behaviour of magnesium oxychloride cement-based composites. Constr. Build. Mater. 2024, 424, 135937. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, C.; Xie, X.; Yousefi, A.M.; Zhang, G.; Li, J.; Samali, B. Compressive strength evaluation of cement-based materials in sulphate environment using optimized deep learning technology. Dev. Built Environ. 2023, 16, 100298. [Google Scholar] [CrossRef]

- Lu, J.; Feng, P.; Li, H.; Tian, Q. Deformation and cracking resistance of MgO-incorporated cementitious material: A review. Materials 2023, 16, 500. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, B.; Fan, Y.; Yu, J.; Shi, T.; Zhou, Y.; Song, Y.; Xu, G.; Xiong, C.; Zhou, X. Effects of reactive MgO on durability and microstructure of cement-based materials: Considering carbonation and pH value. Constr. Build. Mater. 2024, 426, 136216. [Google Scholar] [CrossRef]

- Rawat, S.; Vongsvivut, J.; Zhang, L.; Zhang, Y. Mechanical performance and microstructure evolution of MgO-doped high volume GGBFS-based engineered cementitious composites at room and elevated temperatures. J. Build. Eng. 2024, 98, 111437. [Google Scholar] [CrossRef]

- Jin, F.; Gu, K.; Al-Tabbaa, A. Strength and drying shrinkage of reactive MgO modified alkali-activated slag paste. Constr. Build. Mater. 2014, 51, 395–404. [Google Scholar] [CrossRef]

- Wu, H.-L.; Zhang, D.; Du, Y.-J.; Li, V.C. Durability of engineered cementitious composite exposed to acid mine drainage. Cem. Concr. Compos. 2020, 108, 103550. [Google Scholar] [CrossRef]

- Hay, R.; Celik, K. Enhancing carbonation of magnesium oxide (MgO) cement (RMC)-based composites with calcined limestone. Cement 2022, 9, 100037. [Google Scholar] [CrossRef]

- Mo, L.; Zhang, F.; Deng, M. Effects of carbonation treatment on the properties of hydrated fly ash-MgO-Portland cement blends. Constr. Build. Mater. 2015, 96, 147–154. [Google Scholar] [CrossRef]

- Li, W.-Y.; Zhang, Z.-Y.; Zhou, J.-B. Preparation of building materials from Bayer red mud with magnesium cement. Constr. Build. Mater. 2022, 323, 126507. [Google Scholar] [CrossRef]

- Forero, J.; Bravo, M.; Pacheco, J.; De Brito, J.; Evangelista, L. Fracture behaviour of concrete with reactive magnesium oxide as alternative binder. Appl. Sci. 2021, 11, 2891. [Google Scholar] [CrossRef]

- Wu, H.; Yu, J.; Du, Y.; Li, V.C. Mechanical performance of MgO-doped engineered cementitious composites (ECC). Cem. Concr. Compos. 2021, 115, 103857. [Google Scholar] [CrossRef]

- Wang, L.; Lu, X.; Liu, L.; Xiao, J.; Zhang, G.; Guo, F.; Li, L. Influence of MgO on the hydration and shrinkage behavior of low heat Portland cement-based materials via pore structural and fractal analysis. Fractal Fract. 2022, 6, 40. [Google Scholar] [CrossRef]

- Golewski, G.L. Assessing of water absorption on concrete composites containing fly ash up to 30% in regards to structures completely immersed in water. Case Stud. Constr. Mater. 2023, 19, e02337. [Google Scholar] [CrossRef]

- Wang, Q.; Banthia, N.; Sun, W.; Gu, C. Water permeability of Eco-Friendly Ductile Cementitious Composites (EDCC) under an applied compressive stress. Cem. Concr. Compos. 2020, 107, 103500. [Google Scholar] [CrossRef]

- Mavroulidou, M.; Morrison, T.; Unsworth, C.; Gunn, M. Properties of concrete made of multicomponent mixes of low-energy demanding binders. Constr. Build. Mater. 2015, 101, 1122–1141. [Google Scholar] [CrossRef]

- Moradpour, R.; Taheri-Nassaj, E.; Parhizkar, T.; Ghodsian, M. The effects of nanoscale expansive agents on the mechanical properties of non-shrink cement-based composites: The influence of nano-MgO addition. Compos. Part B Eng. 2013, 55, 193–202. [Google Scholar] [CrossRef]

- Dung, N.; Unluer, C. Improving the performance of reactive MgO cement-based concrete mixes. Constr. Build. Mater. 2016, 126, 747–758. [Google Scholar] [CrossRef]

- Di Benedetto, C.; Cappelletti, P.; Favaro, M.; Graziano, S.F.; Langella, A.; Calcaterra, D.; Colella, A. Porosity as key factor in the durability of two historical building stones: Neapolitan Yellow Tuff and Vicenza Stone. Eng. Geol. 2015, 193, 310–319. [Google Scholar] [CrossRef]

- Bharadwaj, K.; Ghantous, R.M.; Sahan, F.; Isgor, O.B.; Weiss, W.J. Predicting pore volume, compressive strength, pore connectivity, and formation factor in cementitious pastes containing fly ash. Cem. Concr. Compos. 2021, 122, 104113. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, T.; Yuan, C.; Chen, X. Influence of MgO chemical activity on the drying shrinkage of the MgO-SiO2-H2O system. Constr. Build. Mater. 2024, 453, 139108. [Google Scholar] [CrossRef]

- Tang, S.; Huang, D.; He, Z. A review of autogenous shrinkage models of concrete. J. Build. Eng. 2021, 44, 103412. [Google Scholar] [CrossRef]

- Kumarappa, D.B.; Peethamparan, S.; Ngami, M. Autogenous shrinkage of alkali activated slag mortars: Basic mechanisms and mitigation methods. Cem. Concr. Res. 2018, 109, 1–9. [Google Scholar] [CrossRef]

- Li, S.; Mo, L.; Deng, M.; Cheng, S. Mitigation on the autogenous shrinkage of ultra-high performance concrete via using MgO expansive agent. Constr. Build. Mater. 2021, 312, 125422. [Google Scholar] [CrossRef]

- Gao, P.-w.; Xu, S.-y.; Chen, X.; Li, J.; Lu, X.-l. Research on autogenous volume deformation of concrete with MgO. Constr. Build. Mater. 2013, 40, 998–1001. [Google Scholar] [CrossRef]

- Chen, X.; Yang, H.-q.; Li, W.-w. Factors analysis on autogenous volume deformation of MgO concrete and early thermal cracking evaluation. Constr. Build. Mater. 2016, 118, 276–285. [Google Scholar] [CrossRef]

- Polat, R.; Demirboğa, R.; Karagöl, F. The effect of nano-MgO on the setting time, autogenous shrinkage, microstructure and mechanical properties of high performance cement paste and mortar. Constr. Build. Mater. 2017, 156, 208–218. [Google Scholar] [CrossRef]

- Mahmood, A.; Kaish, A.A.; Gulam, N.F.B.A.; Raman, S.N.; Jamil, M.; Hamid, R. Effects of MgO-based expansive agent on the characteristics of expansive concrete. Eng. Proc. 2021, 11, 14. [Google Scholar]

- Mathew, A.; Aslani, F. Investigation of Drying Shrinkage Characteristics in Lightweight Engineered Cementitious Composites. Buildings 2024, 14, 1092. [Google Scholar] [CrossRef]

- Gao, S.; Wang, Z.; Wang, W.; Qiu, H. Effect of shrinkage-reducing admixture and expansive agent on mechanical properties and drying shrinkage of Engineered Cementitious Composite (ECC). Constr. Build. Mater. 2018, 179, 172–185. [Google Scholar] [CrossRef]

- Egan, G.; Kumar, A.; Neithalath, N.; Sant, G. Re-examining the influence of the inclusion characteristics on the drying shrinkage of cementitious composites. Constr. Build. Mater. 2017, 146, 713–722. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, C.; Ma, F.; Huang, Z. Mechanical properties and carbonation durability of engineered cementitious composites reinforced by polypropylene and hydrophilic polyvinyl alcohol fibers. Materials 2018, 11, 1147. [Google Scholar] [CrossRef]

- Choi, S.-w.; Jang, B.-s.; Kim, J.-h.; Lee, K.-m. Durability characteristics of fly ash concrete containing lightly-burnt MgO. Constr. Build. Mater. 2014, 58, 77–84. [Google Scholar] [CrossRef]

- Gonçalves, T.; Silva, R.; De Brito, J.; Fernández, J.; Esquinas, A. Mechanical and durability performance of mortars with fine recycled concrete aggregates and reactive magnesium oxide as partial cement replacement. Cem. Concr. Compos. 2020, 105, 103420. [Google Scholar] [CrossRef]

- Pu, L.; Unluer, C. Investigation of carbonation depth and its influence on the performance and microstructure of MgO cement and PC mixes. Constr. Build. Mater. 2016, 120, 349–363. [Google Scholar] [CrossRef]

- Alengaram, U.J. Effect of Non-Traditional Supplementary Cementitious Materials in Concrete. In Integrative Approaches in Urban Sustainability-Architectural Design, Technological Innovations and Social Dynamics in Global Contexts; IntechOpen: London, UK, 2023. [Google Scholar]

- Samad, S.; Shah, A. Role of binary cement including Supplementary Cementitious Material (SCM), in production of environmentally sustainable concrete: A critical review. Int. J. Sustain. Built Environ. 2017, 6, 663–674. [Google Scholar] [CrossRef]

- Skibsted, J.; Snellings, R. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar] [CrossRef]

- Nayak, D.K.; Abhilash, P.; Singh, R.; Kumar, R.; Kumar, V. Fly ash for sustainable construction: A review of fly ash concrete and its beneficial use case studies. Clean. Mater. 2022, 6, 100143. [Google Scholar] [CrossRef]

- Alterary, S.S.; Marei, N.H. Fly ash properties, characterization, and applications: A review. J. King Saud Univ.-Sci. 2021, 33, 101536. [Google Scholar] [CrossRef]

- Shah, V.; Scott, A. Hydration and microstructural characteristics of MgO in the presence of metakaolin and silica fume. Cem. Concr. Compos. 2021, 121, 104068. [Google Scholar] [CrossRef]

- Ye, Y.; Liu, Y.; Shi, T.; Hu, Z.; Zhong, L.; Wang, H.; Chen, Y. Effect of nano-magnesium oxide on the expansion performance and hydration process of cement-based materials. Materials 2021, 14, 3766. [Google Scholar] [CrossRef] [PubMed]

- Sequeira, L.; Forero, J.; Bravo, M.; Evangelista, L.; de Brito, J. Durability of concrete with partial replacement of Portland cement by incorporating reactive magnesium oxide and fly ash. Materials 2023, 16, 2670. [Google Scholar] [CrossRef] [PubMed]

- Siddique, R.; Chahal, N. Use of silicon and ferrosilicon industry by-products (silica fume) in cement paste and mortar. Resour. Conserv. Recycl. 2011, 55, 739–744. [Google Scholar] [CrossRef]

- Prem, P.R.; Ambily, P.S.; Vankudothu, B.; Bharatkumar, B.H. Sustainable production of high performance concrete. In Encyclopedia of Renewable and Sustainable Materials; Eleviser: Amsterdam, The Netherlands, 2020; pp. 527–536. [Google Scholar]

- Smarzewski, P. Influence of silica fume on mechanical and fracture properties of high performance concrete. Procedia Struct. Integr. 2019, 17, 5–12. [Google Scholar] [CrossRef]

- Li, B.; Chen, B.; Liu, N.; Jiang, Z. Understanding the positive effects of silica fume on the high-temperature resistance and water resistance of magnesium oxysulfate cement. Constr. Build. Mater. 2024, 445, 137820. [Google Scholar] [CrossRef]

- Tuxworth, J.; Ward, G. The Use of Magnesium Oxide Cement as an Ordinary Portland Cement Replacement. In Proceedings of the Concrete Institute of Australia's Biennial National Conference, Adelaide, Australia, 7–10 September 2025. [Google Scholar]

- Li, A.; Xie, H.; Qiu, Y.; Liu, L.; Lu, T.; Wang, W.; Qiu, G. Resource utilization of rice husk biomass: Preparation of MgO flake-modified biochar for simultaneous removal of heavy metals from aqueous solution and polluted soil. Environ. Pollut. 2022, 310, 119869. [Google Scholar] [CrossRef]

- Rößler, C.; Bui, D.-D.; Ludwig, H.-M. Mesoporous structure and pozzolanic reactivity of rice husk ash in cementitious system. Constr. Build. Mater. 2013, 43, 208–216. [Google Scholar] [CrossRef]

- Gomes, C.M.; Garry, A.-L.; Freitas, E.; Bertoldo, C.; Siqueira, G. Effects of Rice Husk Silica on microstructure and mechanical properties of Magnesium-oxychloride Fiber Cement (MOFC). Constr. Build. Mater. 2020, 241, 118022. [Google Scholar] [CrossRef]

- Jiang, F.; Xing, Y.; Deng, W.; Wang, Q.; Wang, J.; Mao, Z. Effect of Combined MgO Expansive Agent and Rice Husk Ash on Deformation and Strength of Post-Cast Concrete. Materials 2025, 18, 2815. [Google Scholar] [CrossRef]

- Vo, D.-H.; Hwang, C.-L.; Yehualaw, M.D.; Liao, M.-C. The influence of MgO addition on the performance of alkali-activated materials with slag−rice husk ash blending. J. Build. Eng. 2021, 33, 101605. [Google Scholar] [CrossRef]

- Abrishambaf, A.; Pimentel, M.; Nunes, S. Influence of fibre orientation on the tensile behaviour of ultra-high performance fibre reinforced cementitious composites. Cem. Concr. Res. 2017, 97, 28–40. [Google Scholar] [CrossRef]

- Makul, N. Advanced smart concrete—A review of current progress, benefits and challenges. J. Clean. Prod. 2020, 274, 122899. [Google Scholar] [CrossRef]

- Feng, H.; Li, L.; Wang, W.; Cheng, Z.; Gao, D. Mechanical properties of high ductility hybrid fibres reinforced magnesium phosphate cement-based composites. Compos. Struct. 2022, 284, 115219. [Google Scholar] [CrossRef]

- Kurpińska, M.; Pawelska-Mazur, M.; Gu, Y.; Kurpiński, F. The impact of natural fibers’ characteristics on mechanical properties of the cement composites. Sci. Rep. 2022, 12, 20565. [Google Scholar] [CrossRef]

- Wu, B.; Qiu, J. Effect of Hollow Natural Fiber (Hnf) Fraction on the Carbonation and Strength Development of Reactive Magnesium Cement (Rmc)-Based Composites. SSRN 2022, 4173908. [Google Scholar] [CrossRef]

- Bello, C.B.d.C.; Cecchi, A. Experiments on natural fibers: Durability and mechanical properties. Adv. Mater. Process. Technol. 2017, 3, 632–639. [Google Scholar] [CrossRef]

- Wu, B.; Liu, Y.; Unluer, C.; Qiu, J. Hybrid synthetic/natural fiber-reinforced strain-hardening magnesia-based composites. Constr. Build. Mater. 2024, 451, 138760. [Google Scholar] [CrossRef]

- Mármol, G.; Ribes, A.; Amigó, V.; Savastano, H., Jr. Assessment of Sisal Fiber Integrity as a reinforcing element in MgO-Based cement matrices. Waste Biomass Valorization 2020, 11, 3045–3056. [Google Scholar] [CrossRef]

- Mármol, G.; Savastano, H., Jr. Study of the degradation of non-conventional MgO-SiO2 cement reinforced with lignocellulosic fibers. Cem. Concr. Compos. 2017, 80, 258–267. [Google Scholar] [CrossRef]

- Hay, R.; Krishnan, P.; Celik, K. Influence of natural fibers on hydration and carbonation of reactive magnesium oxide cement (RMC). Constr. Build. Mater. 2024, 411, 134653. [Google Scholar] [CrossRef]

- Li, S.; Feng, Y.; Yang, J. Expansion mechanism and properties of magnesium oxide expansive hydraulic cement for engineering applications. Adv. Mater. Sci. Eng. 2021, 2021, 5542072. [Google Scholar] [CrossRef]

- Ma, H.; He, L.; Wu, C. Development of reactive mgo cement-silica fume–based strain-hardening engineered cementitious composite. J. Mater. Civ. Eng. 2023, 35, 04023354. [Google Scholar] [CrossRef]

- Rawat, S.; Zhang, L.; Zhang, Y. Fire-induced spalling in hybrid polyethylene fiber-reinforced engineered cementitious composite panels. Eng. Struct. 2025, 338, 120589. [Google Scholar] [CrossRef]

- Wu, S.; Lu, G.; Liu, Q.; Liu, P.; Yang, J. Sustainable High-Ductility Concrete with Rapid Self-Healing Characteristic by Adding Magnesium Oxide and Superabsorbent Polymer. Adv. Mater. Sci. Eng. 2020, 2020, 5395602. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, J.; Zhao, Y.; Ai, H. Study on the performance and mechanism of glass fiber-reinforced MgO-SiO2-H2O cement. Materials 2023, 16, 6668. [Google Scholar] [CrossRef]

| Reference | MgO Content (%) | Curing Age (Days) | Key Findings |

|---|---|---|---|

| [52] | 20–60 | 28 (after CO2 exposure of 3 h to 14 days) | Under 0.10 MPa CO2, cement pastes were partially or fully carbonated. Higher CO2 pressure accelerated carbonation. Mixes with higher FA and MgO showed deeper carbonation. |

| [76] | 5 | 28–180 | MgO addition (with 20% FA) did not affect carbonation in 28-day water-cured mixes. However, it reduced carbonation in 360-day cured mixes due to a filler effect, reducing porosity. |

| [78] | 5–10 | 1–14 | MgO-concrete showed 45% carbonation at 14 days vs. 22% in the OPC mix. Carbonation increased with time and depth, being higher near the surface. |

| [77] | 0–20 | 1–91 | Carbonation depth increased with MgO content. At 20% MgO, carbonation depth increased by 1.2–4.1 mm under accelerated carbonation over 28 days. |

| SCM | Optimum Replacement Level | Performance Gains | Limitations |

|---|---|---|---|

| Fly Ash (FA) | 15–30% with MgO [84,85,86] | Improves long-term compressive & flexural strength; densifies matrix; reduces water absorption and chloride ingress | Slightly lower early-age strength; performance depends on MgO reactivity |

| Silica Fume (SF) | 5–15% with MgO [48,90,91] | Increases early compressive strength and thermal resistance up to 400 °C; refines pores; reduces shrinkage, chloride, and sulphate attack | At high temperatures (>800 °C),the decomposition of silica phases reduces stability |

| Rice Husk Ash (RHA) | ~20% with MgO [94,95,96] | Enhances strength, lowers permeability, densifies microstructure, reduces water absorption | Excess (>30%) increases porosity, reduces early strength and workability |

| Refs. | Fibre Type | Typical Dosage | Effectiveness and Mechanism in MgO-Based Cementitious Composites |

|---|---|---|---|

| [103,104] | Sisal | 1–2 vol% | Improves compressive strength (~90 MPa at 28 days) and first-crack tensile strength; promotes uniform carbonation via hollow lumens; enhances matrix densification and fibre–matrix bonding. |

| [104] | Jute | ~1–2 vol% | Increases flexural strength (up to 84%) and tensile strength (40–56%) due to high aspect ratio and crack-bridging ability; improves toughness and post-cracking performance. |

| [105,106] | Cellulose | 0.25 vol% | Enhances crack resistance, internal curing, and CO2 sequestration; flexural strength improved (9.23 to 10.36 MPa after 200 ageing cycles) with stable energy absorption; maintains durability under ageing. |

| [100,101,102] | Other natural fibres (ramie, cotton, bamboo) | Varies | Provide low-density, renewable reinforcement with good tensile strength; potential to enhance toughness, though performance varies with fibre type and treatment. |

| Ref. | Name | Abbreviation | Effectiveness and Mechanism in MgO-Based Cementitious Composites |

|---|---|---|---|

| [110] | Polyvinyl Alcohol fibre | PVA | Polyvinyl alcohol fibres control crack width and enable strain-hardening in engineered cementitious composites. However, a high dosage of magnesium oxide may reduce ductility unless balanced with admixtures such as superabsorbent polymers. When optimised, these fibres improve crack resistance and promote self-healing. |

| [107] | Polypropylene fibre | PP | Polypropylene fibres improve crack resistance and impact toughness. They restrain expansion caused by magnesium oxide hydration, refine microcracks, reduce porosity, and contribute to better durability and mechanical strength. |

| [108] | Polyethylene fibre | PE | Polyethylene fibres offer high tensile strength and ductility, especially in magnesium oxide–silica fume matrices. They enhance strain capacity and energy absorption, though careful mix design is needed to ensure proper fibre dispersion. |

| [111] | Glass fibre | GF | Alkali-resistant glass fibres increase flexural strength and toughness by bridging cracks and bonding chemically with hydration products. At optimal dosages, they improve toughness significantly, but excessive content may lead to fibre agglomeration and increased porosity. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iqra; Soe, K.; Yang, R.; Zhang, Y.X. A Review of Recent Advances in MgO-Based Cementitious Composites for Green Construction: Mechanical and Durability Aspects. Buildings 2025, 15, 3513. https://doi.org/10.3390/buildings15193513

Iqra, Soe K, Yang R, Zhang YX. A Review of Recent Advances in MgO-Based Cementitious Composites for Green Construction: Mechanical and Durability Aspects. Buildings. 2025; 15(19):3513. https://doi.org/10.3390/buildings15193513

Chicago/Turabian StyleIqra, Khin Soe, Richard (Chunhui) Yang, and Y. X. Zhang. 2025. "A Review of Recent Advances in MgO-Based Cementitious Composites for Green Construction: Mechanical and Durability Aspects" Buildings 15, no. 19: 3513. https://doi.org/10.3390/buildings15193513

APA StyleIqra, Soe, K., Yang, R., & Zhang, Y. X. (2025). A Review of Recent Advances in MgO-Based Cementitious Composites for Green Construction: Mechanical and Durability Aspects. Buildings, 15(19), 3513. https://doi.org/10.3390/buildings15193513

_Yang.png)