Visual and Non-Destructive Testing of ASR Affected Piers from Montreal’s Champlain Bridge

Abstract

1. Introduction

1.1. Background

1.2. Scope of Work

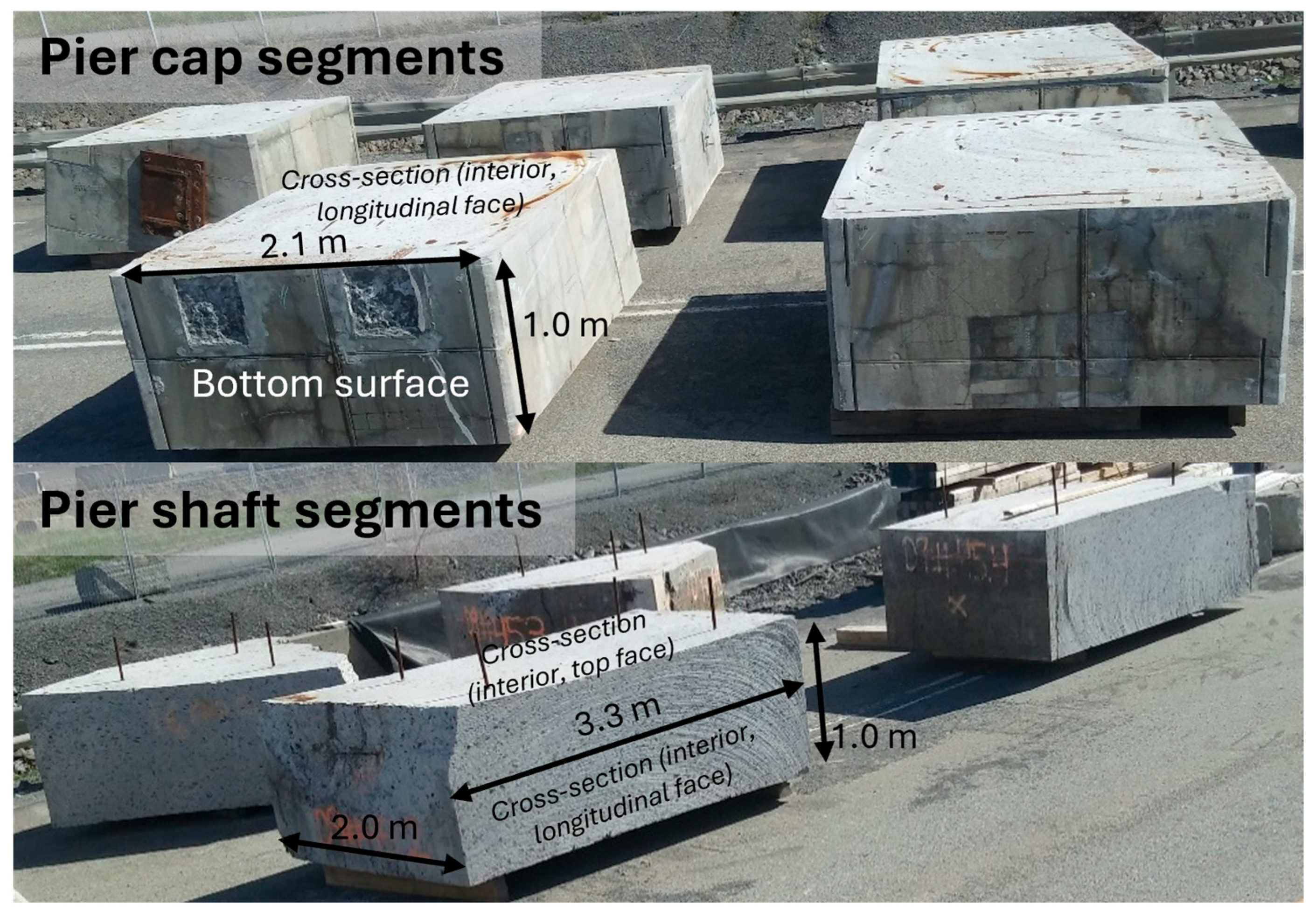

2. Materials and Methods

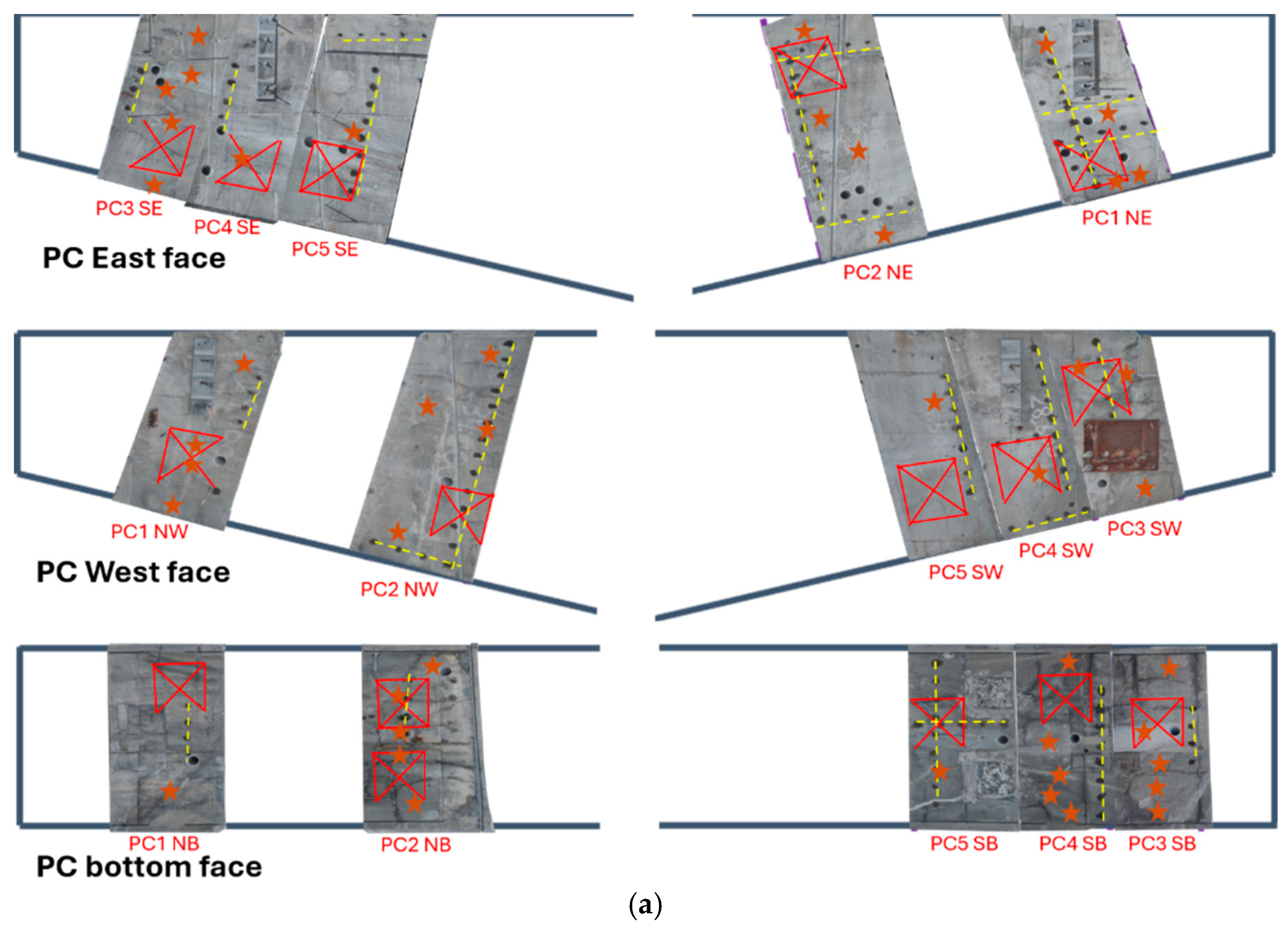

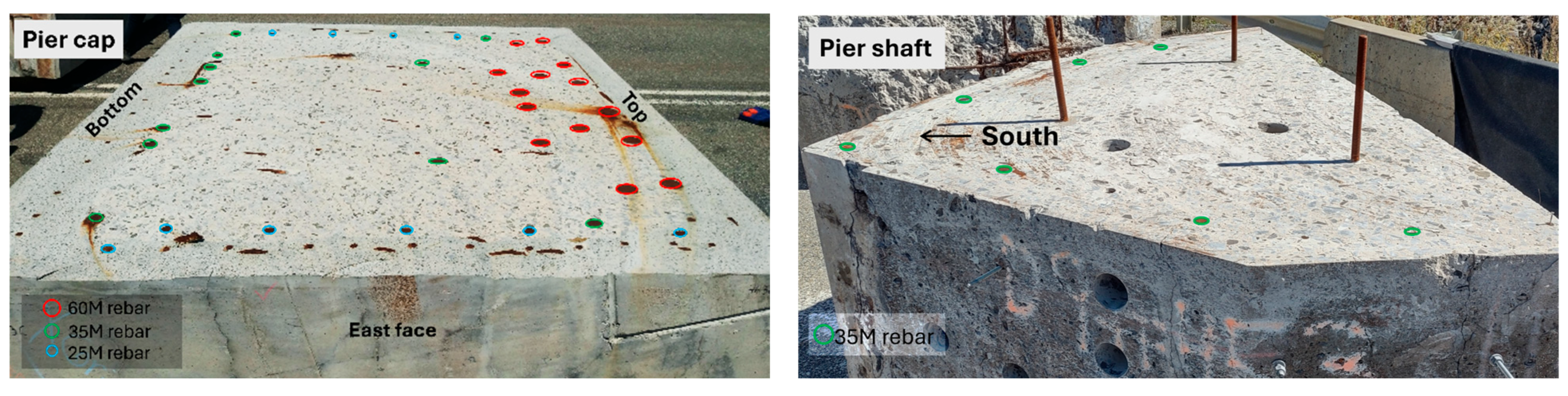

2.1. Visual Inspection

2.2. Non-Destructive Testing

3. Results

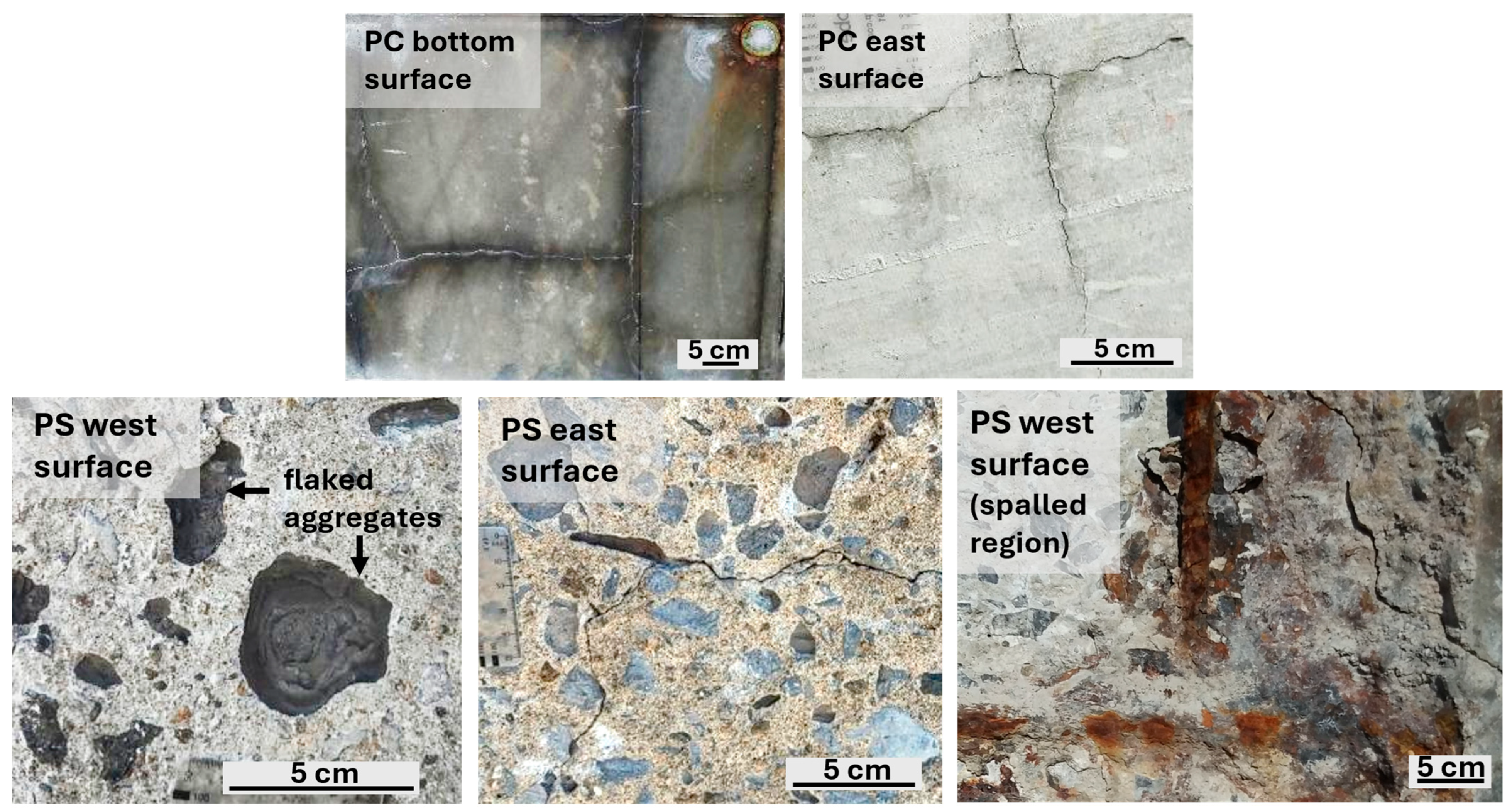

3.1. Visual Inspection (Qualitative)

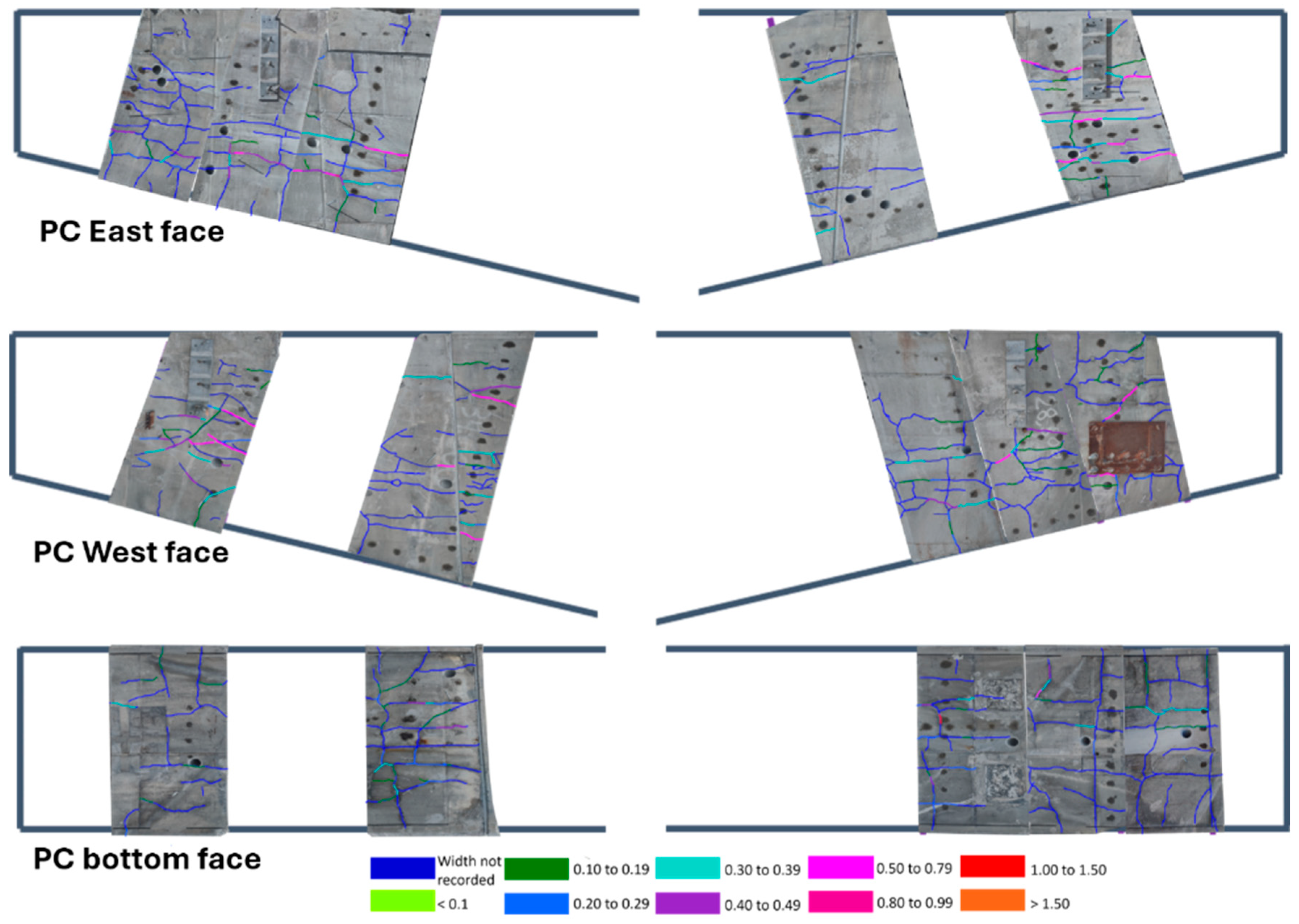

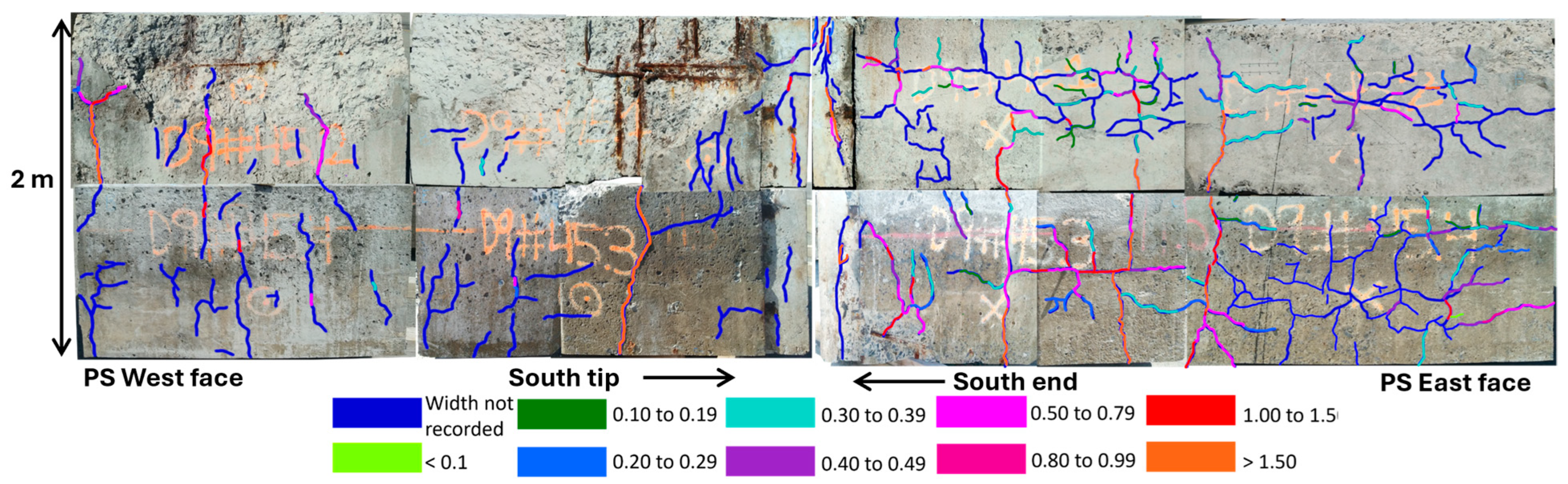

3.1.1. Crack Patterns on Members

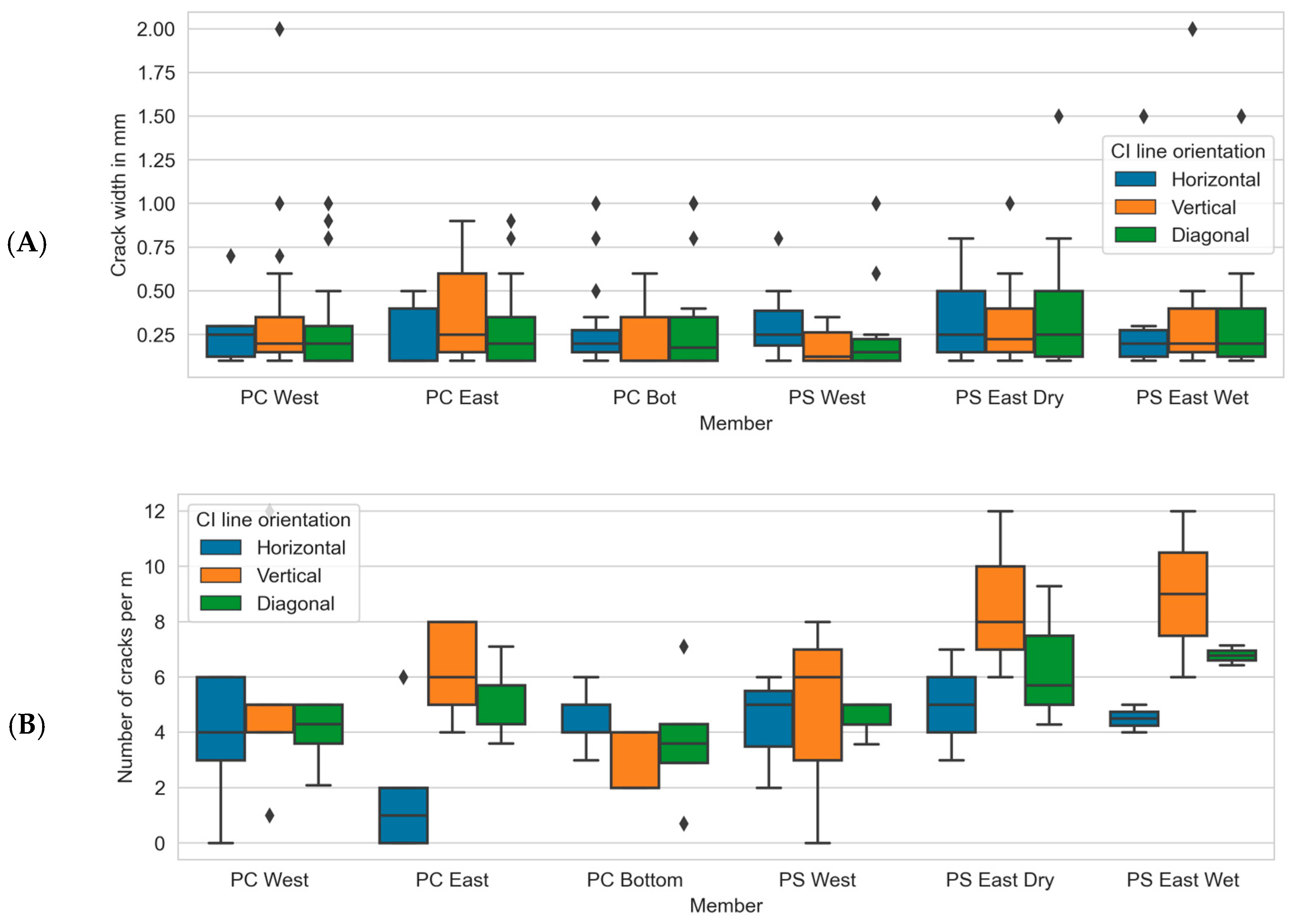

3.1.2. Cracking Index (CI)

3.2. Non-Destructive Testing

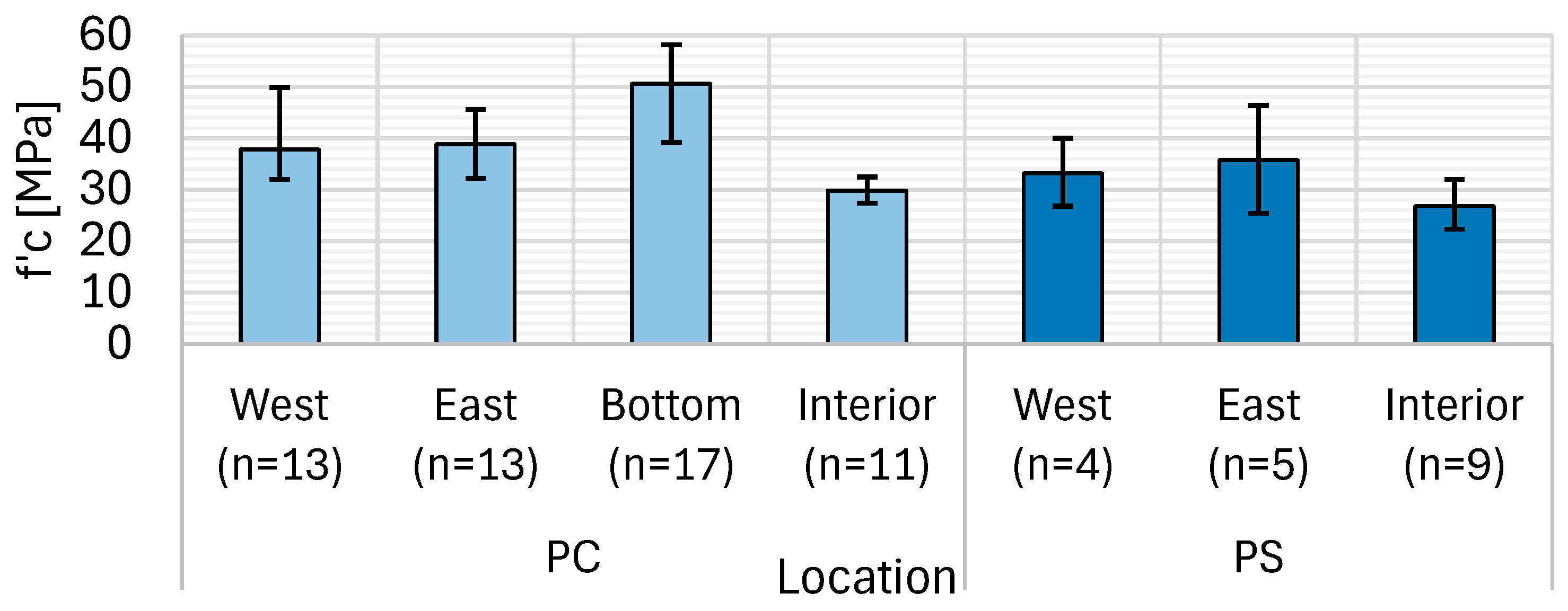

3.2.1. Rebound Hammer

3.2.2. Ultrasonic Pulse Velocity (UPV)

3.2.3. Surface Electrical Resistivity

4. Discussion

4.1. Directional Cracking Identified in Visual Assessment

4.1.1. Observed Cracking

4.1.2. The CI and Individual Crack Widths

4.2. Assessment of Surface and Internal Damage

4.2.1. Observed Cracking

4.2.2. Non-Destructive Testing

4.2.3. Impact of PC Encapsulation Repair

5. Conclusions

5.1. Visual Assessment

- ‘Map cracking’ patterns were noted in areas with moderate reinforcement regions of both members. Reduced cracking was visible in high reinforcement regions of the PC as well as the semi-submerged region of the PS.

- Anisotropy was identified with crack widths varying by direction. In the PC and on the east face of the PS, vertical cracks (i.e., intersecting the horizontal CI lines) were both thinner and less frequent compared to horizontal cracks. In the context of an internal swelling reaction such as ASR, these differences in crack widths suggest expansion is occurring preferentially in one direction (i.e., vertically) compared to another.

- The CI indicating the highest damage was obtained on the PS east face. The CI corresponding to this location exhibited wider and more frequent cracks intersecting the CI, with cracks primarily oriented horizontally.

- Although the PC was encapsulated in repair concrete 15 years before decommissioning of the structure, average crack widths were similar to average crack widths recorded on the PS. This suggests that assessment of reinforced concrete members using crack width measurements can provide insight into increasing deterioration within the member.

- The presence of ASR in the members was not clearly indicated by inspection of exterior surfaces, while internal surfaces exposed during decommissioning of the members included clear indicators of ASR gel in aggregates and paste.

5.2. Non-Destructive Testing

- The rebound hammer estimated an average concrete strength between 33 and 39 MPa in east, west and interior locations of the PS and PC. The average compressive strength on the PC bottom surfaces was estimated at 50 MPa. In the PC, the rebound hammer did not identify significant differences in compressive strength on the exterior (repair concrete) surfaces compared to the interior (original) concrete.

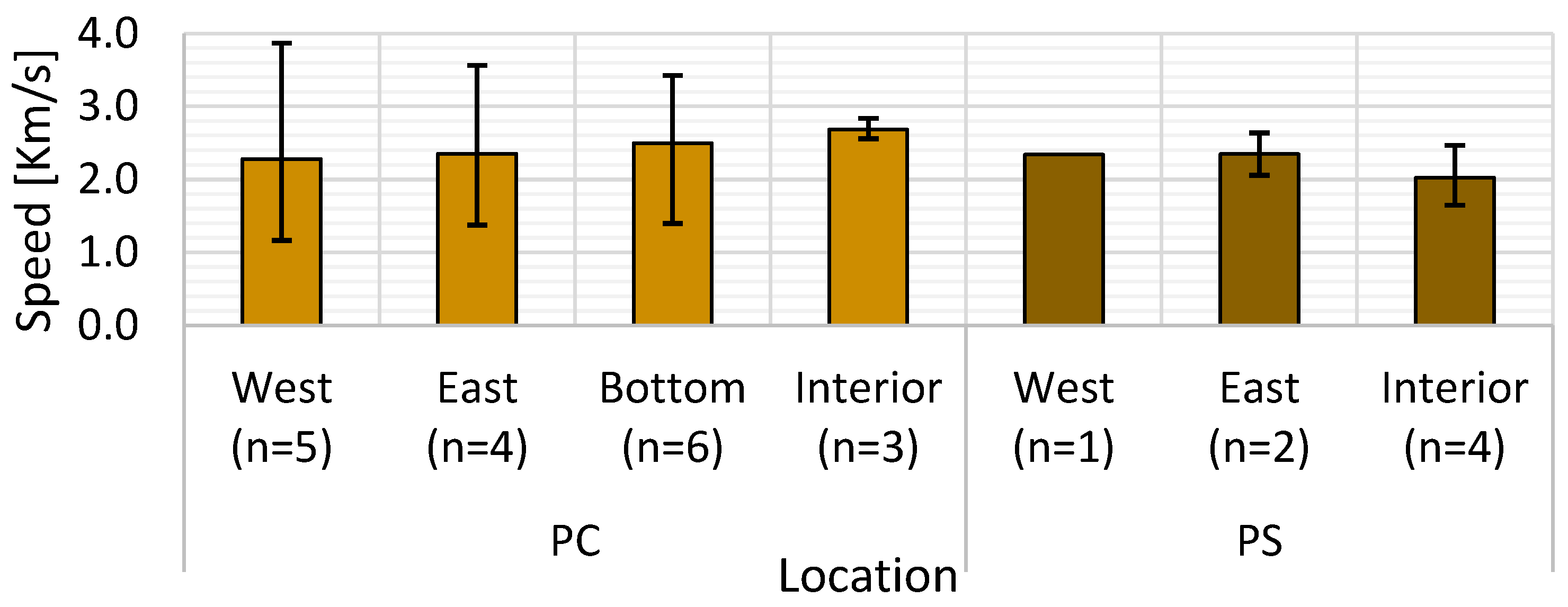

- Ultrasonic pulse velocity results were less than 3.0 km/s, indicating the need for further investigation (e.g., extraction of cores for laboratory analysis), which agrees with the extent of cracking observed during the visual inspection.

- Electrical surface resistivity measurements clearly distinguished between the PC repair concrete (low permeability to chloride ingress) and the internal concrete (higher permeability); however, there was high variation when used solely on the repair concrete. The electrical surface resistivity was comparable for the PC interior concrete and PS external and internal concrete.

- The application of the investigated non-destructive tests was limited in areas with wide crack widths, such as the east face of the PS, emphasizing the need for complementary semi-quantitative and quantitative visual assessments (i.e., crack width measurements and CI) in the evaluation of reinforced concrete damage.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Breugel, K. Societal Burden and Engineering Challenges of Ageing Infrastructure. Procedia Eng. 2017, 171, 53–63. [Google Scholar] [CrossRef]

- Sanchez, L.F.M.; Fournier, B.; Jolin, M.; Mitchell, D.; Bastien, J. Overall assessment of Alkali-Aggregate Reaction (AAR) in concretes presenting different strengths and incorporating a wide range of reactive aggregate types and natures. Cem. Concr. Res. 2017, 93, 17–31. [Google Scholar] [CrossRef]

- Trejo, D.; Mazarei, V.; Ideker, J.H.; Isgor, O.B. Influence of alkali-silica reaction reactivity on corrosion in reinforced concrete. ACI Mater. J. 2017, 114, 723–731. [Google Scholar] [CrossRef]

- Fournier, B.; Bérubé, M.-A. Alkali-Aggregate reaction in concrete: A review of basic concepts and engineering implications. Can. J. Civ. Eng. 2000, 27, 167–191. [Google Scholar] [CrossRef]

- RILEM Guide to Diagnosis and Appraisal of AAR Damage to Concrete in Structures; Springer: Dordrecht, The Netherlands, 2013.

- Rivard, P.; Saint-Pierre, F. Assessing alkali-silica reaction damage to concrete with non-destructive methods: From the lab to the field. Constr. Build. Mater. 2009, 23, 902–909. [Google Scholar] [CrossRef]

- RILEM technical committee 259-ISR. Diagnosis & Prognosis of AAR Affected Structures; Springer Nature: Cham, Switzerland, 2021. [Google Scholar]

- Fournier, B.; Bérubé, M.-A.; Folliard, K.J.; Thomas, M. Report on the Diagnosis, Prognosis, and Mitigation of Alkali-Silica Reaction (ASR) in Transportation Structures; United States Federal Highway Administration, Office of Pavement Technology: Washington, DC, USA, 2010.

- Barbosa, R.A.; Hansen, S.G.; Hansen, K.K.; Hoang, L.C.; Grelk, B. Influence of alkali-silica reaction and crack orientation on the uniaxial compressive strength of concrete cores from slab bridges. Constr. Build. Mater. 2018, 176, 440–451. [Google Scholar] [CrossRef]

- Kanjee, J.P.; Ballim, Y.; Otieno, M. A visual condition assessment of a reinforced concrete railway bridge subject to alkali silica reaction (ASR) deterioration in Johannesburg. MRS Adv. 2023, 8, 570–576. [Google Scholar] [CrossRef]

- Ahmed, H.; Zahedi, A.; Sanchez, L.F.M.; Fecteau, P.L. Condition assessment of ASR-affected reinforced concrete columns after nearly 20 years in service. Constr. Build Mater. 2022, 347, 128570. [Google Scholar] [CrossRef]

- Sanchez, L.F.M.; Fournier, B.; Mitchell, D.; Bastien, J. Condition assessment of an ASR-affected overpass after nearly 50 years in service. Constr. Build. Mater. 2020, 236, 117554. [Google Scholar] [CrossRef]

- Godart, B.; Fasseu, P.; Michel, M. Diagnosis and monitoring of concrete bridges damaged by AAR in Northern France. In Proceedings of the Ninth International Conference on Alkali-Aggregate Reaction in Concrete, London, UK, 27–31 July 1992; pp. 368–375. [Google Scholar]

- Nguyen, A.; Gharehbaghi, V.; Le, N.T.; Sterling, L.; Chaudhry, U.I.; Crawford, S. ASR crack identification in bridges using deep learning and texture analysis. Structures 2023, 50, 494–507. [Google Scholar] [CrossRef]

- ASTM C597; Standard Test Method for Pulse Velocity Through Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- Carlin, G.P.; Mirza, M.S.; Gaudreault, M. Rehabilitation Measures for Champlain Bridge, Montreal, Canada. Can. J. Civ. Eng. 1996, 23, 1326–1340. [Google Scholar] [CrossRef]

- Bérubé, M.-A.; Frenette, J. Évaluation de la Réactivité Alcaline dans le Béton des Piles 12, 18 et 20 W du Pont Champlain; Labratoire de Matériaux de Quebec Inc.: Quebec City, Canada, 1994. [Google Scholar]

- Noël, M.; Sanchez, L.; Tawil, D. Structural implications of internal swelling reactions in concrete: Review and research needs. Mag. Concr. Res. 2018, 70, 1052–1063. [Google Scholar] [CrossRef]

- Diao, B.; Sun, Y.; Cheng, S.; Ye, Y. Effects of Mixed Corrosion, Freeze-Thaw Cycles, and Persistent Loads on Behavior of Reinforced Concrete Beams. J. Cold Reg. Eng. 2011, 25, 37–52. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Zhang, P.; Ma, Y.; Zhao, T.; Wang, H.; Zhang, Z. Water absorption and chloride diffusivity of concrete under the coupling effect of uniaxial compressive load and freeze-thaw cycles. Constr. Build. Mater. 2019, 209, 566–576. [Google Scholar] [CrossRef]

- Panesar, D.K.; Ching, G. Implications of coupled degradation mechanisms of cement based materials exposed to cold climates. Int. J. Mech. Sci. 2018, 144, 865–876. [Google Scholar] [CrossRef]

- Sanchez, L.F.M.; Drimalas, T.; Fournier, B.; Mitchell, D.; Bastien, J. Comprehensive damage assessment in concrete affected by different internal swelling reaction (ISR) mechanisms. Cem. Concr. Res. 2018, 107, 284–303. [Google Scholar] [CrossRef]

- Antolik, A.; Jóźwiak-Niedźwiedzka, D. ASR induced by chloride- and formate-based deicers in concrete with non-reactive aggregates. Constr. Build Mater. 2023, 400, 132811. [Google Scholar] [CrossRef]

- Bérubé, M.A.; Smaoui, N.; Bissonnette, B.; Fournier, B. Outil D’Evaluation et de Gestion des Ouvrages D’art Affectes de Reactions Alcalis-Silice (RAS); Ministere des Transports du Quebec: Quebec City, Canada, 2005.

- Rogers, C. Alkali-aggregate reactivity in Canada. Cem. Concr. Compos. 1993, 15, 13–19. [Google Scholar] [CrossRef]

- Bérubé, M.-A.; Durand, B.; Vézina, D.; Fournier, B. Alkali-aggregate reactivity in Québec (Canada). Can. J. Civ. Eng. 2000, 27, 226–245. [Google Scholar] [CrossRef]

- Gautam, B.P.; Panesar, D.K.; Sheikh, S.A.; Vecchio, F.J. Effect of multiaxial stresses on alkali-silica reaction damage of concrete. ACI Mater. J. 2017, 114, 595–604. [Google Scholar] [CrossRef]

- Fan, S.; Hanson, J.M. Length Expansion and Cracking of Plain and Reinforced Concrete Prisms Due to Alkali-Silica Reaction. ACI Mater. J. 1998, 95, 480–485. [Google Scholar] [CrossRef]

- Fan, S.; Hanson, J.M. Effect of Alkali Silica Reaction Expansion and Cracking on Structural Behavior of Reinforced Concrete Beams. ACI Mater. J. 1999, 95, 488–495. [Google Scholar]

- Zahedi, A.; Sanchez, L.F.M.; Noël, M. Appraisal of visual inspection techniques to understand and describe ASR-induced development under distinct confinement conditions. Constr. Build Mater. 2022, 323, 126549. [Google Scholar] [CrossRef]

- Zahedi, A.; Trottier, C.; Sanchez, L.F.; Noël, M. Condition assessment of alkali-silica reaction affected concrete under various confinement conditions incorporating fine and coarse reactive aggregates. Cem. Concr. Res. 2022, 153, 106694. [Google Scholar] [CrossRef]

- Groupe Counseil Genivar (2003) Champlain Bridge, Rehabilitation of Piers, Pier Caps, Bearings and Beams (2004) Phases of Demolition.

- Leroux Beaudoin Hurens & Associes Inc. (2005) Pont Champlain, réfection de piles, chevêtres, appuis et poutres (2004) CONTRAT No: 60494.

- Kristufek, L.; Zahedi, A.; Tawil, D.; Sanchez, L.; Martín-Pérez, B.; Noël, M. Preliminary evaluation of Pier cap from an ASR affected bridge in Central Canada. MATEC Web Conf. 2022, 364, 03005. [Google Scholar] [CrossRef]

- Kristufek, L.; Sanchez, L.; Martin-Perez, B.; Noël, M. Condition Assessment of Concrete Pier Shaft Segment from Bridge in Central Canada. In Proceedings of the CSCE 2023 Conference, Moncton, NB, Canada, 24–27 May 2023. [Google Scholar]

- Institution of Structural Engineers (ISE). Structural Effects of Alkali-Silica Reaction—Technical Guidance Appraisal of Existing Structures; Institution of Structural Engineers: London, UK, 1992. [Google Scholar]

- ASTM C 805/C805M-18; Standard Test Method for Rebound Number of Hardened Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- IS 13311-1 (Part 1); Method of Non-Destructive Testing of Concrete, Part 1: Ultrasonic Pulse Velocity [CED 2: Cement and Concrete]. 1–7 Bureau of Indian Standards: New Delhi, India, 1992.

- AASHTO T 358-15; Standard Method of Test for Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- Report on Nondestructive Test Methods for Evaluation of Concrete in Structures; ACI 228. American Concrete Institute: Farmington Hills, MI, USA, 2013. [CrossRef]

- Rosenqvist, M.; Pham, L.W.; Terzic, A.; Fridh, K.; Hassanzadeh, M. Effects of interactions between leaching, frost action and abrasion on the surface deterioration of concrete. Constr. Build. Mater. 2017, 149, 849–860. [Google Scholar] [CrossRef]

- ACI Committee 222. Protection of Metals in Concrete Against Corrosion Reported by ACI Committee 222; American Concrete Institute: Farmington Hills, MI, USA, 2001; ACI 1–41. [Google Scholar]

- Lacombe, P.; Beauprd, D.; Pouliot, N. Rheology and bonding characteristics of self-leveling concrete as a repair material. Mater. Struct. 1999, 32, 593–600. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kristufek, L.; Sanchez, L.F.M.; Martín-Pérez, B.; Noël, M. Visual and Non-Destructive Testing of ASR Affected Piers from Montreal’s Champlain Bridge. Buildings 2025, 15, 3262. https://doi.org/10.3390/buildings15183262

Kristufek L, Sanchez LFM, Martín-Pérez B, Noël M. Visual and Non-Destructive Testing of ASR Affected Piers from Montreal’s Champlain Bridge. Buildings. 2025; 15(18):3262. https://doi.org/10.3390/buildings15183262

Chicago/Turabian StyleKristufek, Leah, Leandro F. M. Sanchez, Beatriz Martín-Pérez, and Martin Noël. 2025. "Visual and Non-Destructive Testing of ASR Affected Piers from Montreal’s Champlain Bridge" Buildings 15, no. 18: 3262. https://doi.org/10.3390/buildings15183262

APA StyleKristufek, L., Sanchez, L. F. M., Martín-Pérez, B., & Noël, M. (2025). Visual and Non-Destructive Testing of ASR Affected Piers from Montreal’s Champlain Bridge. Buildings, 15(18), 3262. https://doi.org/10.3390/buildings15183262