1. Introduction

Fiber-reinforced polymer (FRP) composites are characterized by high strength, low weight, fatigue resistance, and corrosion resistance. In recent years, they have been widely used in engineering applications. The use of externally bonded FRP sheets to enhance the mechanical performance of reinforced concrete (RC) structures has become a common strengthening technique [

1,

2]. This involves bonding FRP plates (including sheets) to the surface of concrete at locations requiring reinforcement, primarily to resist shear and tensile forces. The bond strength at the interface between FRP and concrete plays a critical role in determining the mechanical performance of strengthened structural members [

3,

4]. While many previous studies have focused on the overall performance of reinforced components [

5,

6,

7], it is the bond behavior at the FRP–concrete interface that often determines the success and effectiveness of the reinforcement system in practical applications [

8].

Extensive research has been conducted by scholars both domestically and internationally on the bond behavior between composite materials and concrete [

9,

10]. A commonly used method involves bonding FRP composites to concrete members using epoxy resin and conducting single-shear or double-shear tests to evaluate the bond strength. Numerous models have been proposed to predict the FRP–concrete bond strength and bond–slip behavior. For instance, Tanaka [

11], Yoshizawa [

12], among others, proposed bond strength models based on the average bond stress at the interface. Subsequent studies found that the effective bond length significantly influences the interface bond strength between FRP and concrete [

13,

14,

15,

16]. Accordingly, semi-empirical models based on effective bond length have been developed. Compared with models that do not consider effective bond length, these models exhibit higher prediction accuracy. However, most of these models are based on limited experimental data and may be affected by the complex interplay of unknown variables or experimental errors, which limits their predictive accuracy for bond strength at the FRP–concrete interface.

However, these traditional analytical models are often based on limited datasets and empirical relationships, making the computational process cumbersome and time-consuming [

10,

17]. With the development of computational intelligence technologies, data-driven methods have gradually emerged as effective alternatives to these traditional models, providing more accurate predictions at lower computational costs. In the field of machine learning (ML), supervised learning techniques have been widely applied, predicting the FRP–concrete bond strength as well as solving structural engineering problems [

17,

18], particularly for predicting the FRP–concrete bond strength. Numerous studies have attempted to estimate the FRP–concrete bond strength using different ML algorithms. For instance, Aghabalaei Baghaei and Hadigheh [

18] employed Decision Trees (DTs), Support Vector Machines (SVMs), Artificial Neural Networks (ANNs), Linear Regression (LR), Ridge Regression, and Lasso to assess FRP-CBS under varying moisture conditions and sustained loading. In another study by Aghabalaei Baghaei and Hadigheh [

19], various environmental factors such as temperature and duration were considered in predicting FRP-CBS using an ANN, Multiple Linear Regression (MLR), and Adaptive Neuro-Fuzzy Inference Systems (ANFISs). Again, the ANN model demonstrated superior accuracy, with high

R2 values and low

MAE and

RMSE. Although existing ML models have shown promising predictive capabilities, they are mostly limited to a small number of environmental conditions. In addition to the aforementioned technical challenges, the application of FRP materials in cold-region tunnel engineering presents new environmental and structural considerations. In cold climates, where freeze–thaw cycles, low temperatures, and potential moisture ingress are prevalent, the durability and interfacial bonding performance of FRP–concrete systems can be significantly affected. These environmental stresses may alter the adhesive properties and degrade the integrity of the bond, potentially compromising the long-term effectiveness of the reinforcement. Therefore, it is crucial to improve the predictive accuracy of bond strength models under varying environmental conditions, especially for critical infrastructure such as tunnels in cold regions [

20,

21,

22,

23,

24].

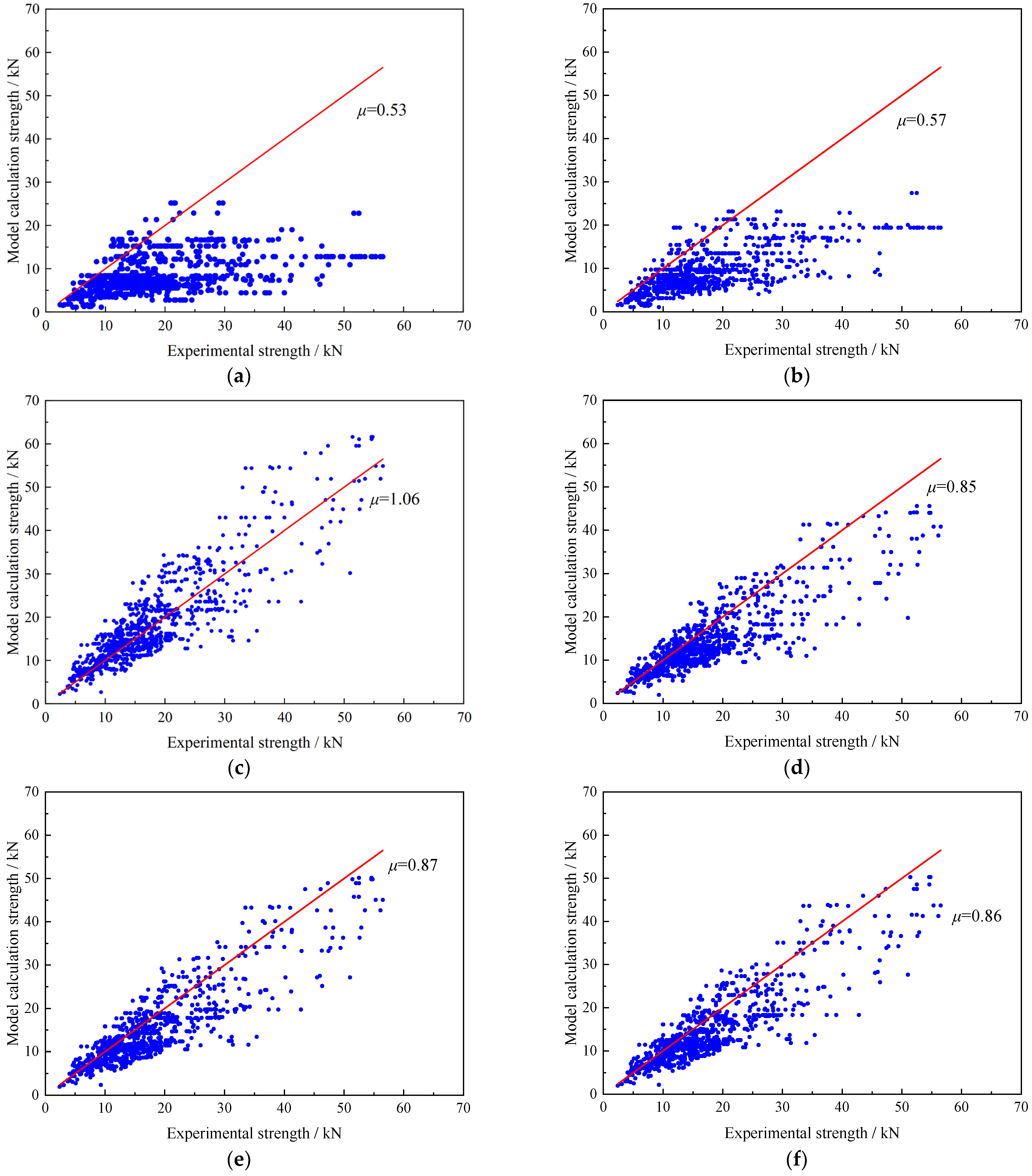

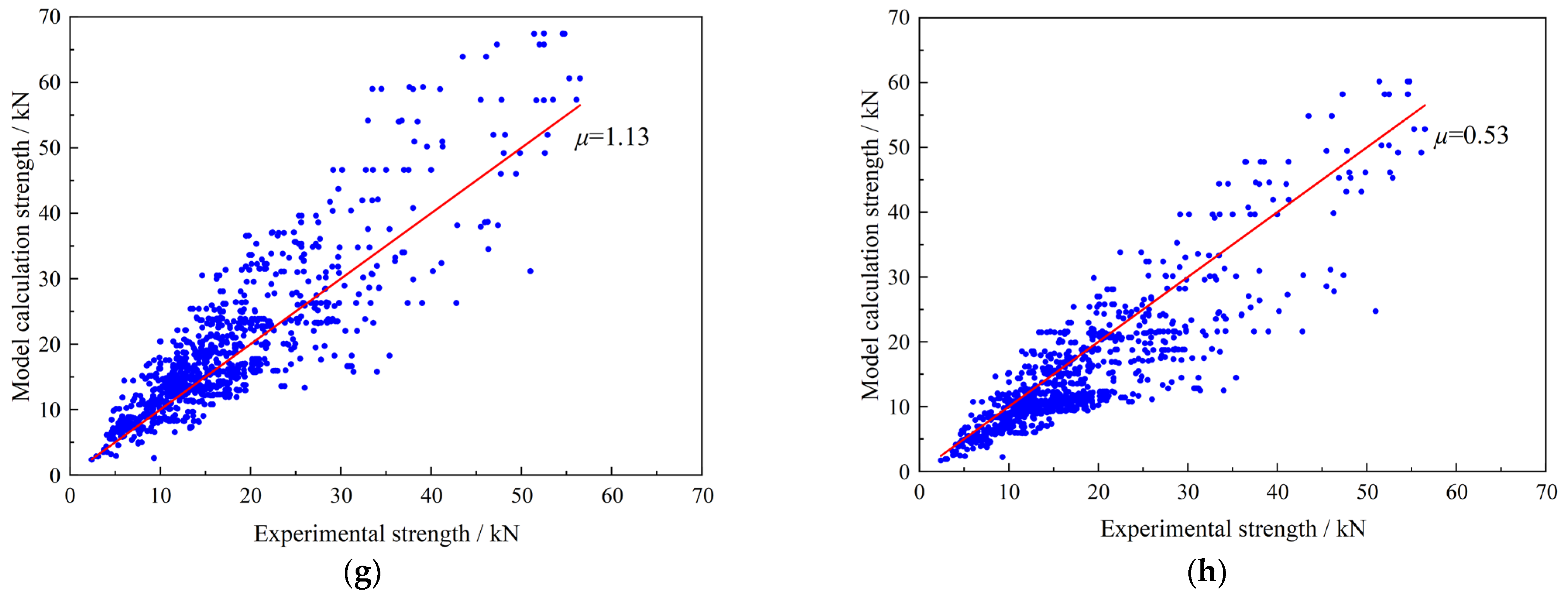

In this study, a total of 1032 FRP–concrete bond strength test data points were collected to establish a single-shear database. Eight existing bond strength models were also reviewed, and their corresponding bond strength values were computed. Given the limitations of conventional neural networks, such as slow convergence and insufficient prediction accuracy—both heavily influenced by the choice of initial weights and thresholds—a genetic algorithm (GA) was adopted to optimize the BP neural network. A GA-based BP neural network model was then developed to predict the bond strength of the collected test data. The predictions obtained from the genetic neural network model were evaluated against the computed results from the eight existing models. Both prediction accuracy and sensitivity analysis were conducted.

3. Genetic Neural Network Algorithm

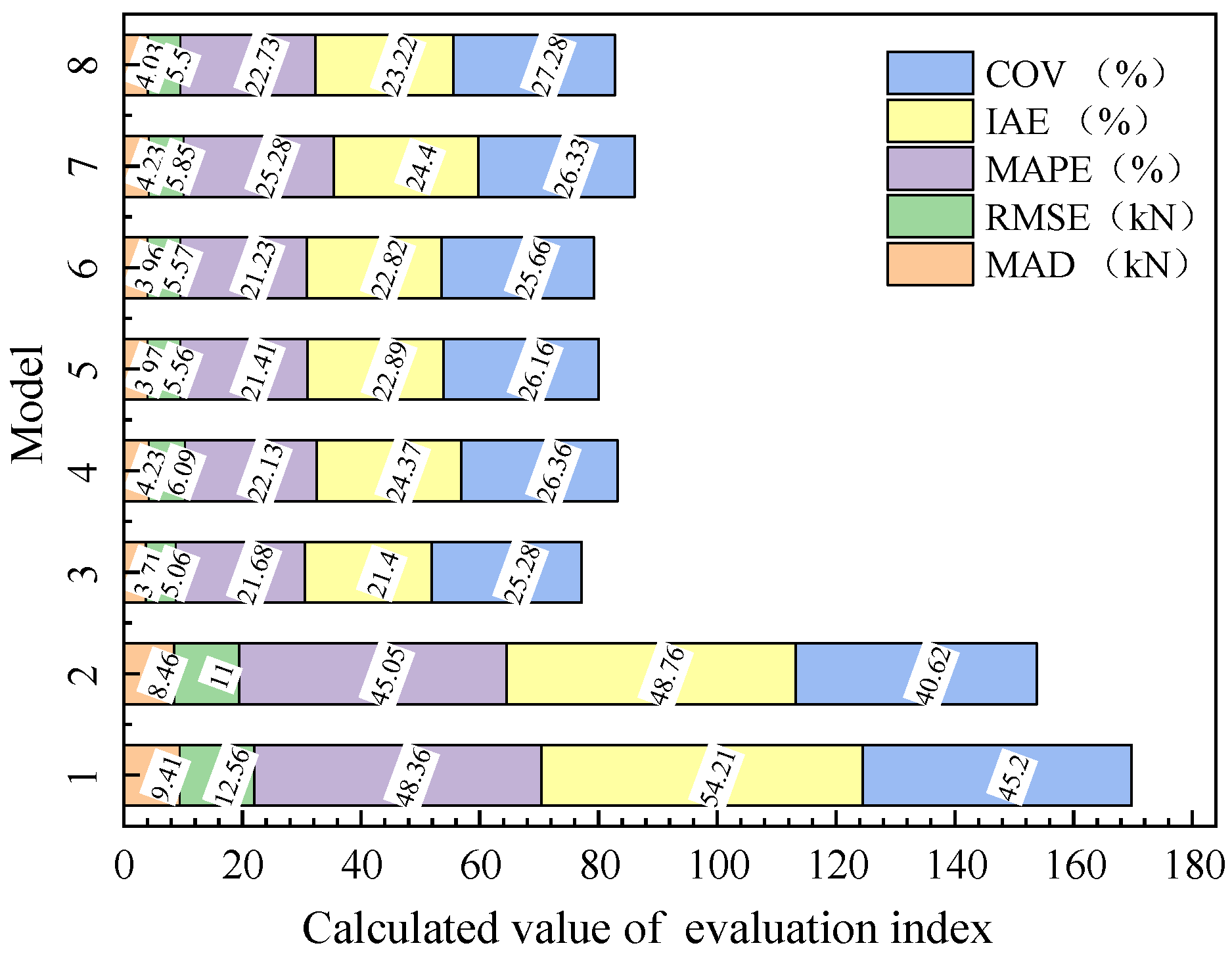

The fundamental principles of the genetic algorithm-optimized backpropagation (GA-BP) neural network are illustrated as

Figure 4. The flowchart enclosed within the black box represented the basic framework of the neural network, while the left section outlined the core procedures of the genetic algorithm. The topological structure of the neural network is presented in

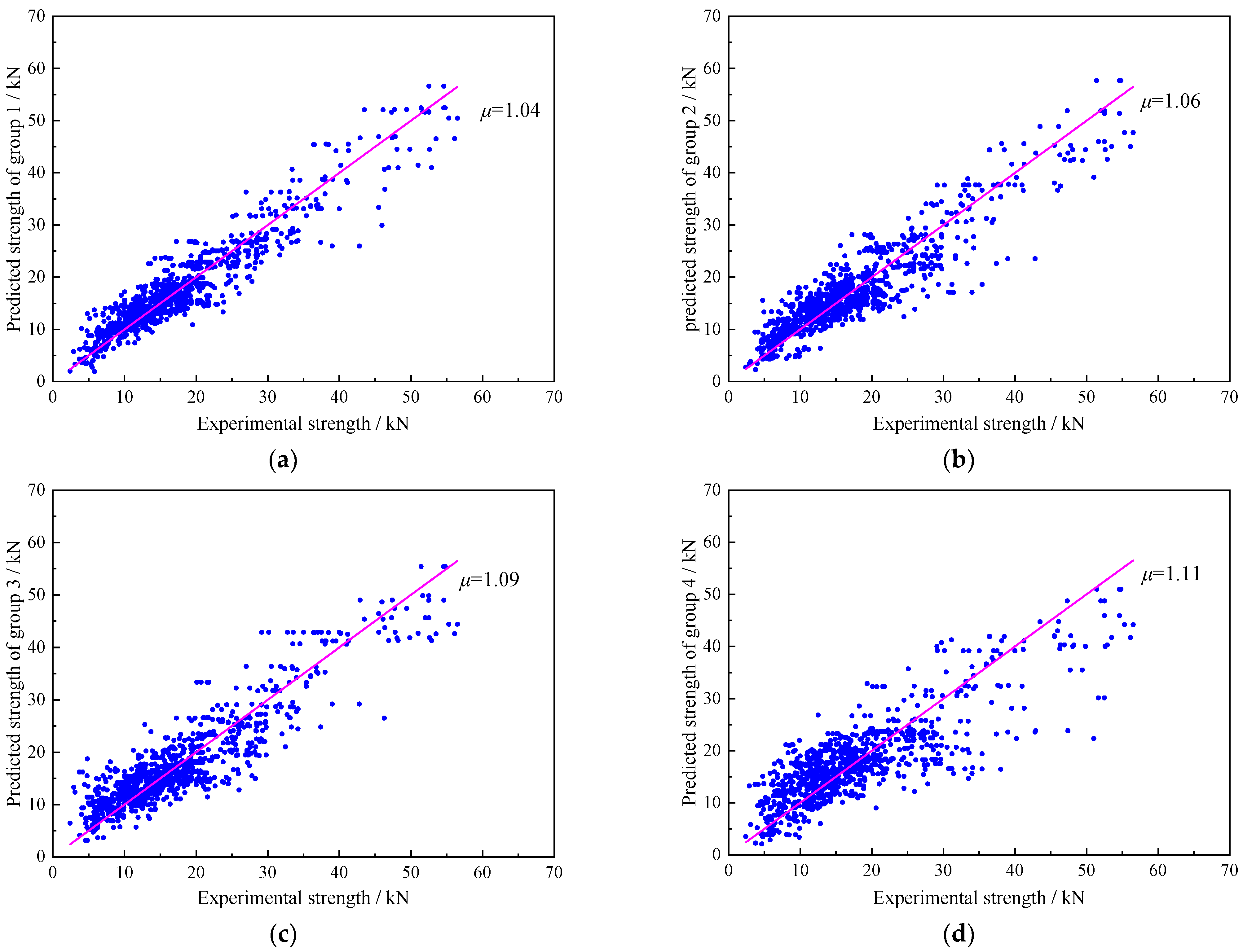

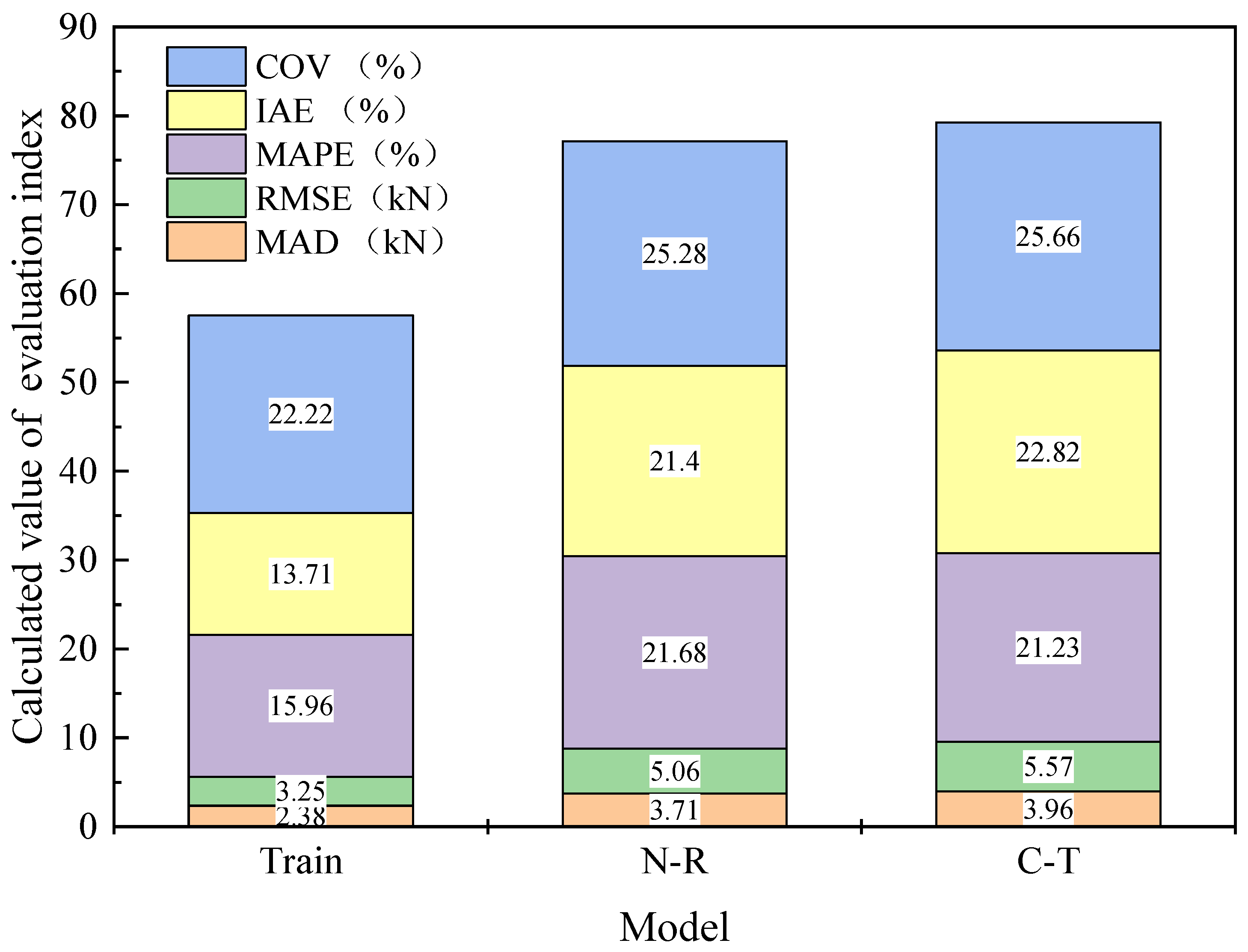

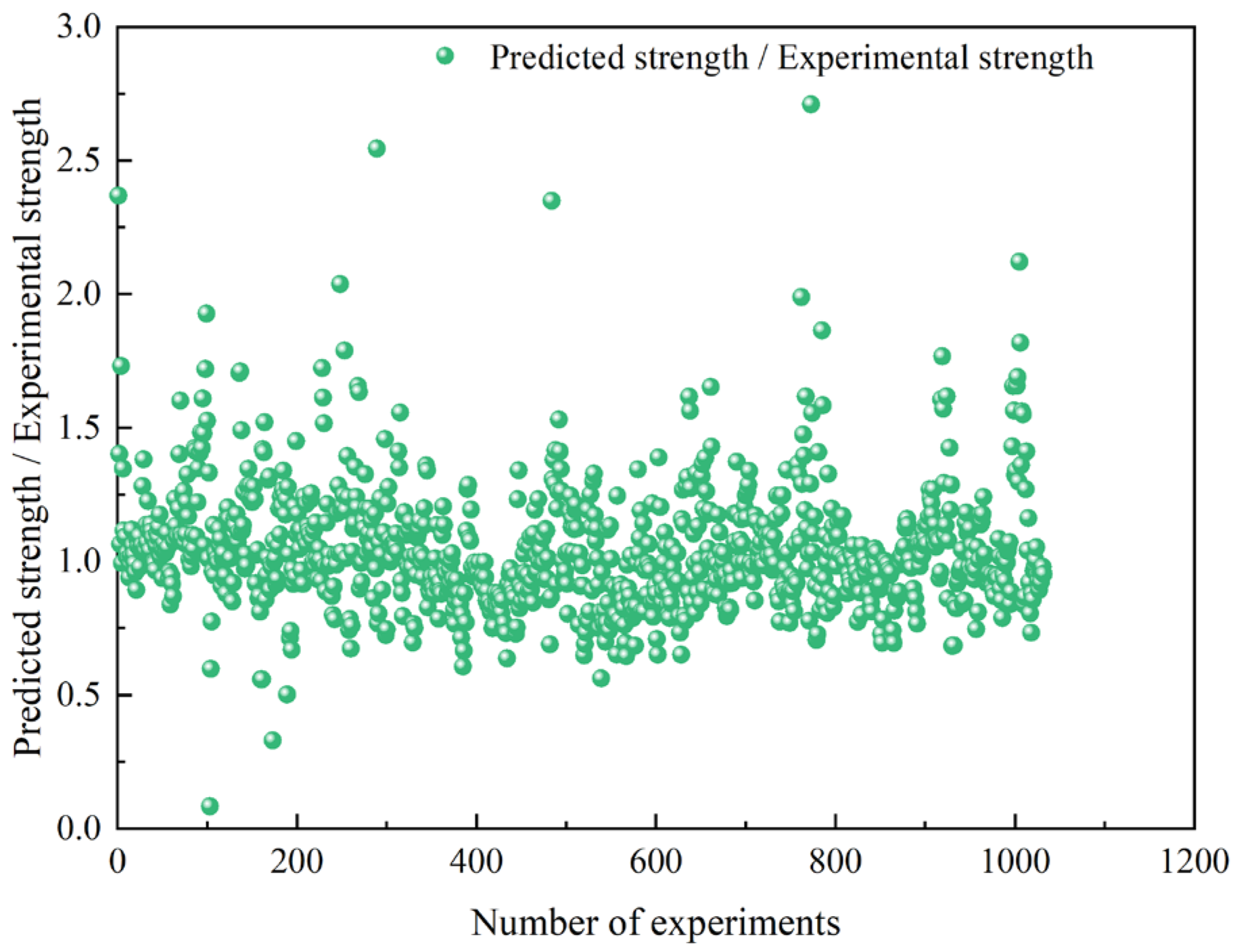

Figure 5, which consists of three layers: an input layer, a hidden layer, and an output layer. The input layer receives six key parameters that influence the FRP–concrete bond strength. The hidden layer serves as an intermediary to map inputs to outputs, and the output layer generates the predicted bond strength values. The activation function used between the hidden and output layers is a linear (purelin) function, appropriate for regression tasks involving continuous bond strength prediction. The dataset comprising 1032 single-shear test samples was randomly divided into 700 training samples and 332 testing samples (approximately 68% and 32%, respectively). Random sampling was employed due to the continuous nature of the output variable.

The connections between layers were governed by transfer functions, connection weights, and thresholds. The hyperbolic tangent sigmoid function (tansig), as defined in Equation (6), was adopted as the transfer function between the input and hidden layers. The connections between layers were governed by transfer functions, connection weights, and thresholds.

The mathematical formulations used to compute the outputs of the hidden and output layers are given in Equations (7) and (8), respectively.

Sj denotes the value of the hidden neuron;

xi and

yt represent the actual and predicted outputs, respectively;

Wij and

Vij are the connection weights from the input to the hidden layer and from the hidden to the output layer, respectively;

θj and

γt are the biases associated with the hidden and output layers; and

f and

g represent the activation functions used in each layer. The number of neurons (

n2) in the hidden layer was determined using an empirical formula, i.e.,

n2 = 2

n1 + 1, where

n1 denotes the number of output neurons, respectively. The selected configuration is widely adopted in previous studies as a practical approach to balancing model complexity and generalization capability [

45,

46]. To enhance training efficiency and reduce computational error, the input data were normalized using the mapminmax function.

The initial weights and thresholds of the neural network were found to significantly affect training performance. To determine optimal initial parameters, a genetic algorithm was utilized for global optimization. Based on the defined network topology, the number of parameters requiring optimization was calculated. Specifically, the number of weights between the input and hidden layers was n1 × n2 = 78, and the number of corresponding biases was n2 = 13. From the hidden layer to the output layer, the number of weights was n2*1 = 13, with one additional bias. Therefore, the total number of parameters to be optimized by the genetic algorithm, including all weights and biases, was 105.

The genetic algorithm enhanced both the convergence rate and prediction accuracy of the neural network by optimizing its initial weights and thresholds. Key components of the genetic algorithm included population initialization, fitness evaluation, selection, crossover, and mutation. Each weight or threshold was encoded using a 10-bit binary string, resulting in a chromosome length of 1050 bits. The objective function was defined as the norm of the error between predicted and actual outputs. A rank-based fitness assignment method was adopted, with the fitness calculated as

FitnV =

ranking(

obj), where

obj is the objective function value. Selection was carried out using a stochastic tournament method, and crossover was implemented using a single-point approach. The specific parameters used in the genetic algorithm are summarized in

Table 3.

5. Sensitivity Analysis of Influencing Factors

Sensitivity analysis aims to identify key influential variables among multiple uncertain factors that significantly affect the evaluation metric. In this study, the bond strength was selected as the evaluation indicator, and the six influencing parameters are considered uncertain factors. Sensitivity coefficients are calculated to assess the impact of each factor on the bond strength predicted by different models. The model whose sensitivity response aligns best with experimental data was identified as the optimal one. The sensitivity coefficient

SAF [

47,

48,

49] was calculated as follows:

where

A represents the evaluation index;

F denotes the uncertain factors; and Δ

A and Δ

F represent the variations in the evaluation index and the uncertain factor, respectively.

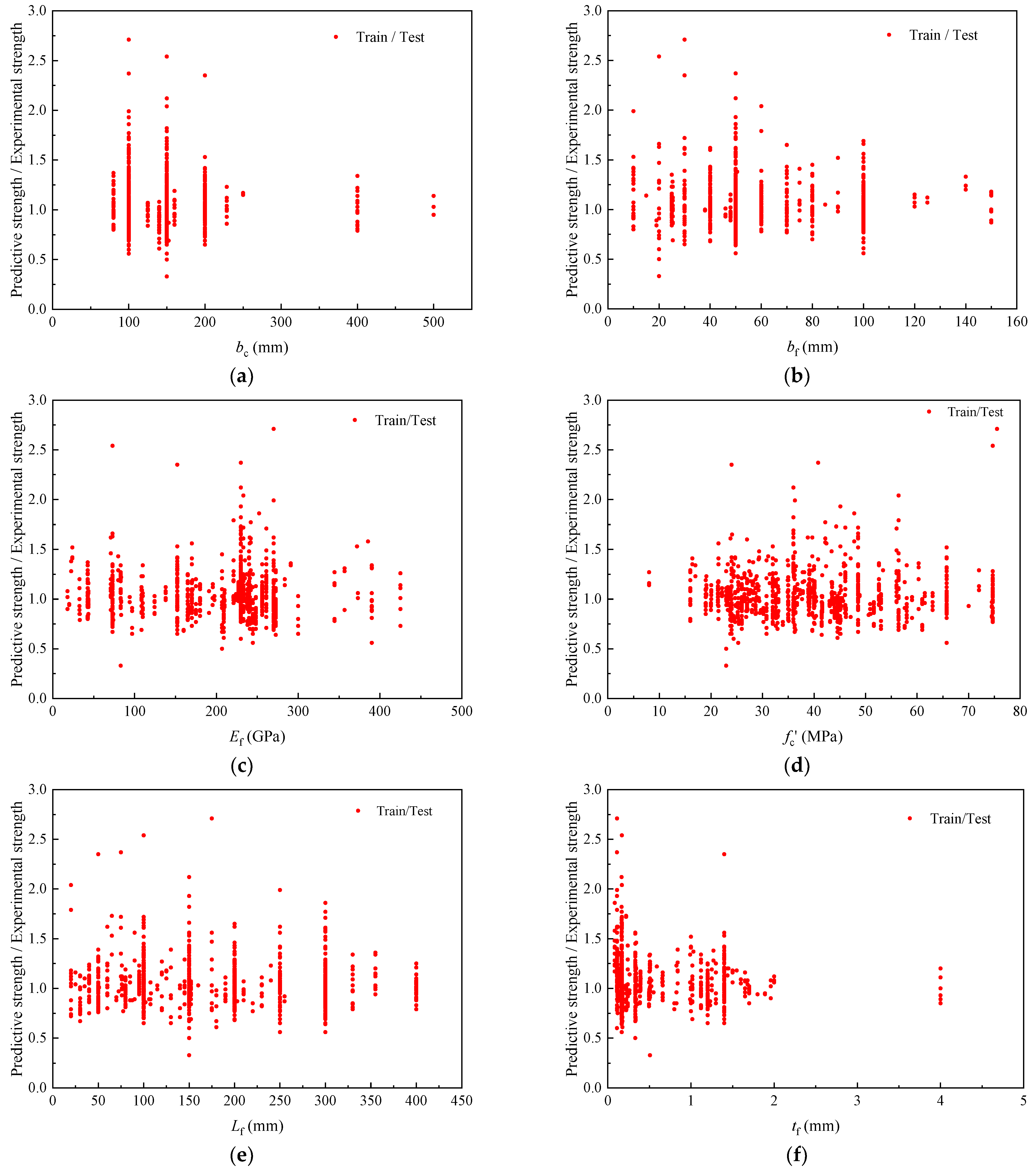

When SAF < 0, it indicated that the evaluation index was inversely proportional to the uncertain factor. Conversely, when SAF > 0, a direct proportional relationship was implied. Moreover, a larger absolute value of SAF suggested a greater sensitivity of the evaluation index to the corresponding uncertain factor. Sensitivity analysis can be categorized into single-factor and multi-factor analyses. In this study, a single-factor sensitivity analysis was adopted. Specifically, six uncertain factors (bc. fc′, bf, Ef, tf, and Lf) were considered individually to evaluate their influence on the bond strength.

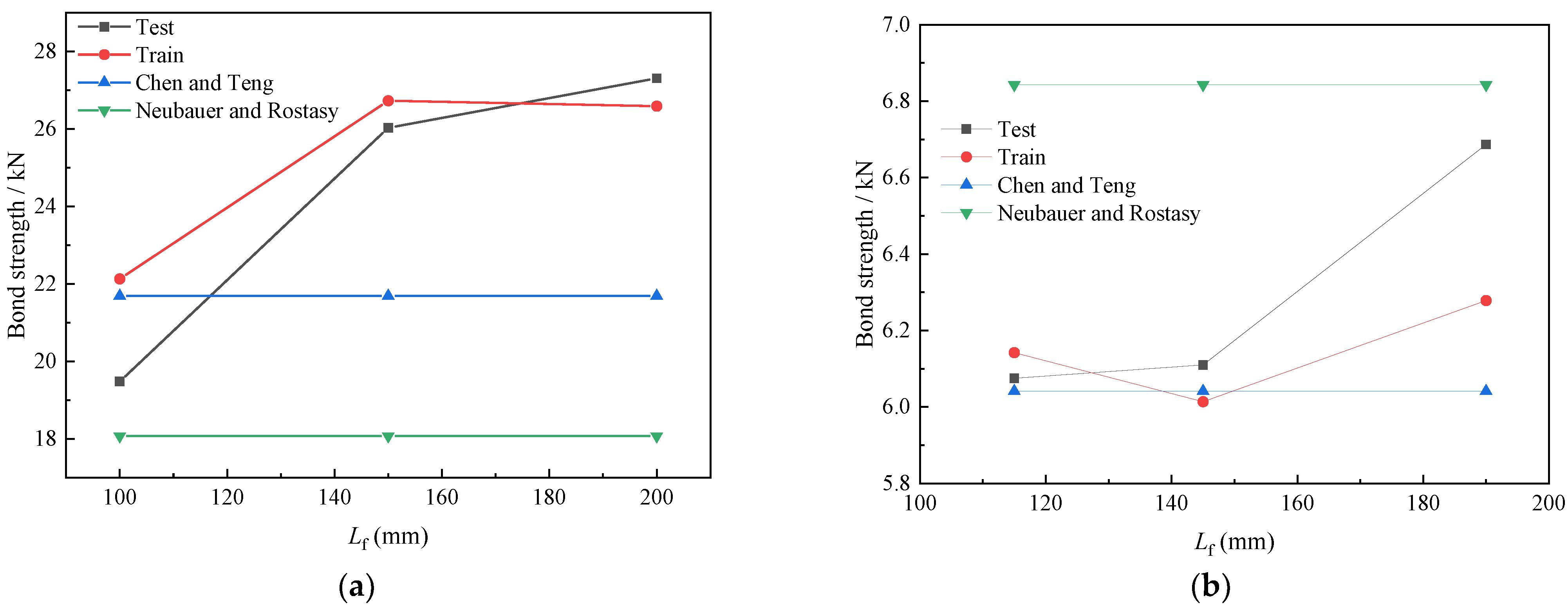

From the 1032 sets of single-shear experimental data, 14 representative samples were selected for analysis. Each influencing parameter’s sensitivity coefficient was computed by averaging the results from two different datasets. As shown in

Table 6, the experimental data for cases where the FRP bond length exceeded the effective bond length was predicted by the models.

Figure 10b and

Figure 11a illustrate the first and second sets of data from

Table 6, respectively. Sensitivity analysis was conducted using experimental bond strengths, GA-BP neural network predictions, C-T model values, and (N-R) model values. For samples with multiple experimental values, the average was used for comparison.

When the FRP bond length exceeded the model’s effective length, the averaged sensitivity coefficients obtained from

Figure 10b and

Figure 11a were 0.278 for experimental values, 0.118 for GA-BP neural network predictions, and 0 for both the C-T and N-R models, indicating insensitivity to bond length in these two traditional models beyond the effective threshold. Similar calculations were conducted for all influencing factors, with the results summarized in

Table 7.

The sensitivity coefficients of the genetic neural network predictions for bond strength were found to align more closely with the experimental data compared to other models. The predicted values obtained using the genetic algorithm demonstrated superior performance in the sensitivity analysis.

The relatively low sensitivity coefficient of FRP thickness (tf) suggests that, within the tested range, variations in thickness have a limited impact on bond strength prediction. This may be attributed to the fact that once the adhesive shear capacity is sufficiently mobilized, further increases in thickness no longer enhance load transfer efficiency. Thus, tf may be considered a secondary factor, allowing potential simplification in future parametric models. From an experimental design perspective, identifying such low-sensitivity parameters enables researchers to focus resources on more impactful variables, such as fc′ or bf, when designing bond tests or strengthening systems. Moreover, the high sensitivity of parameters such as fc′, bf, and Lf can be interpreted in terms of physical mechanisms. fc′ governs the substrate cracking resistance and the initiation of interfacial failure. bf influences the stress distribution along the interface and may affect the bond shear area. Lf, particularly when below the effective bond length, plays a key role in mobilizing adhesive strength prior to debonding. These connections between data-driven sensitivity analysis and the underlying bond-slip behavior enhance the physical interpretability of the model.