Mechanical Properties of EGC Incorporating Ternary Precursors

Abstract

1. Introduction

2. Materials and Methods

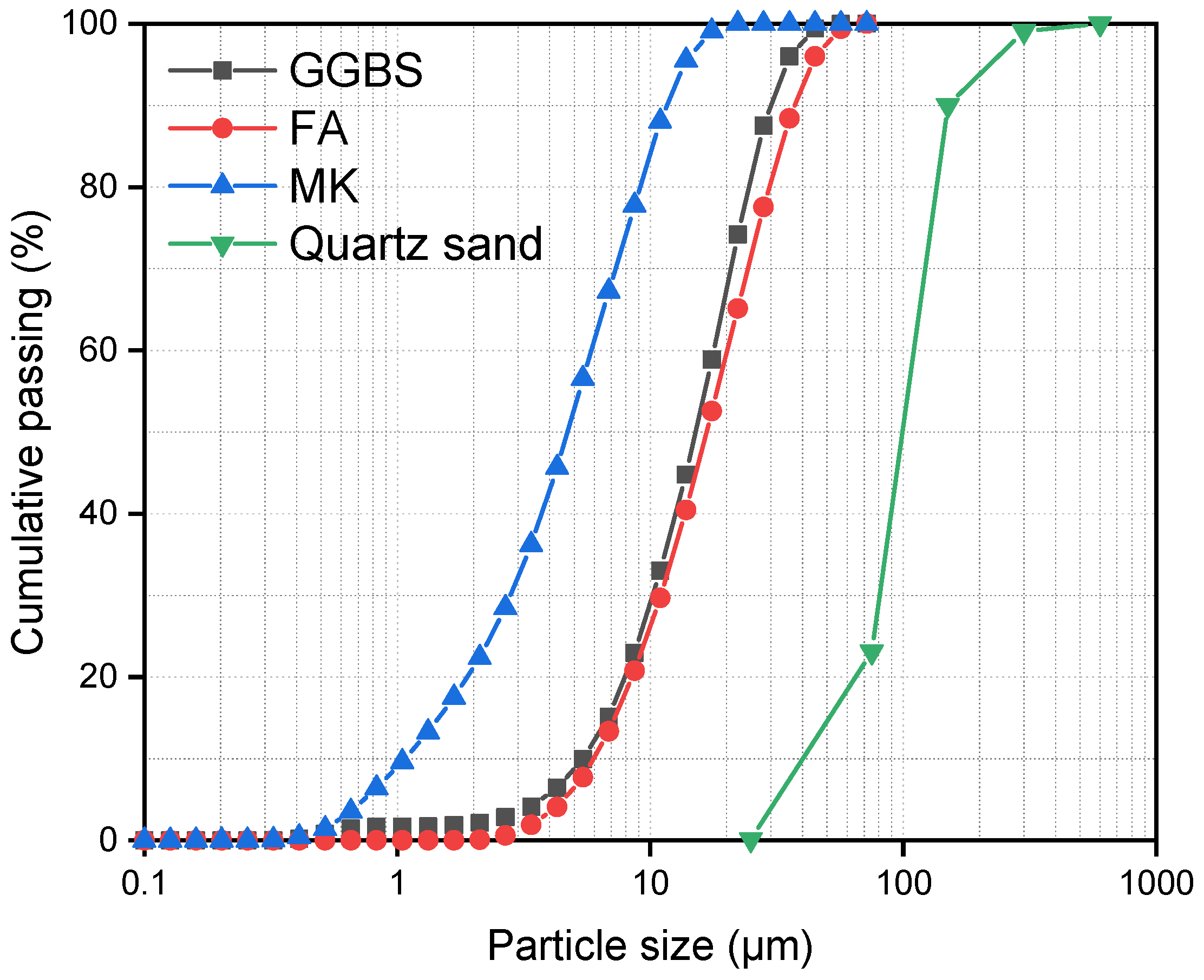

2.1. Raw Materials

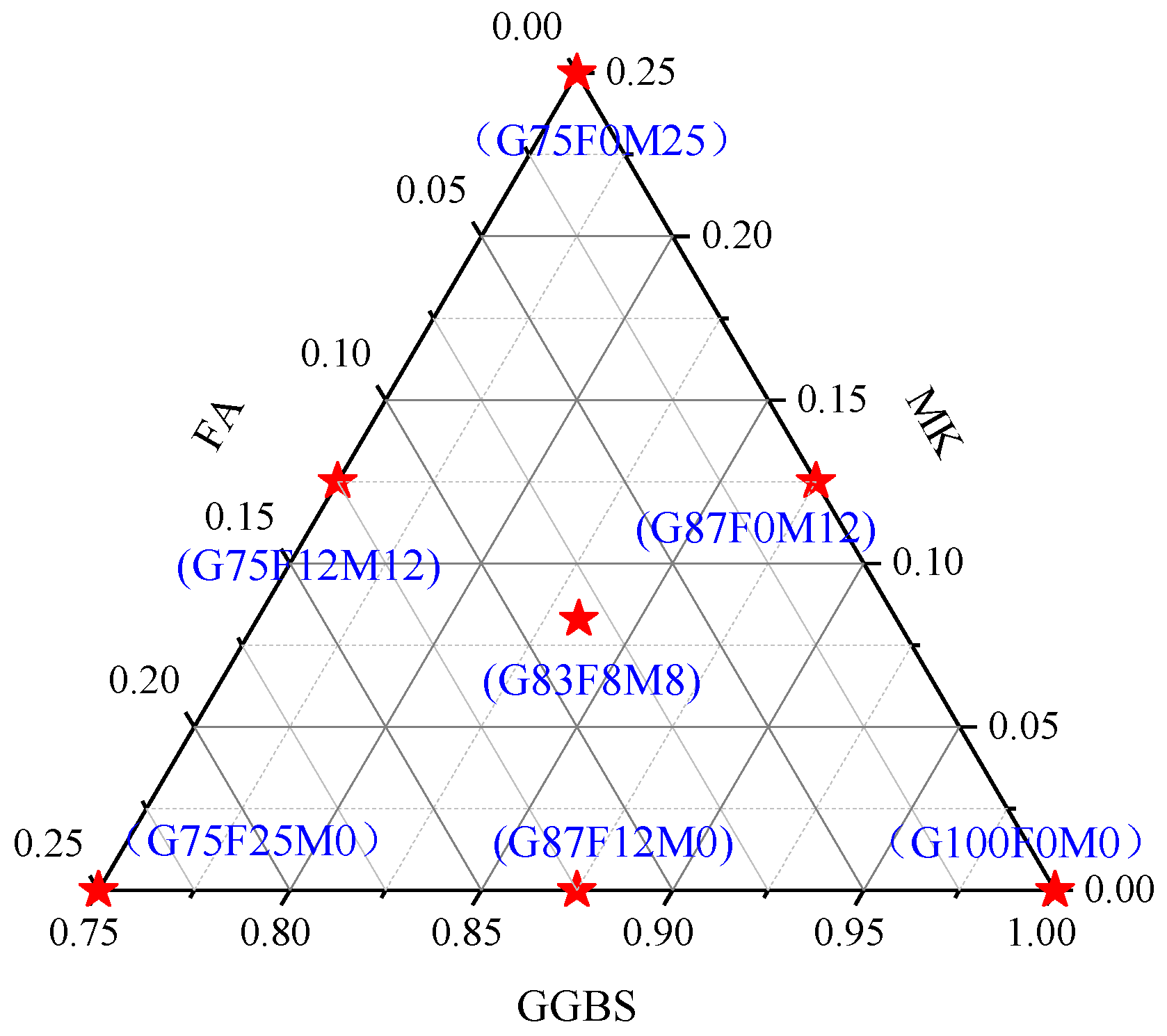

2.2. Mixture Design

2.3. Specimen Preparation

2.4. Methodology

2.4.1. Compressive and Flexural Strength

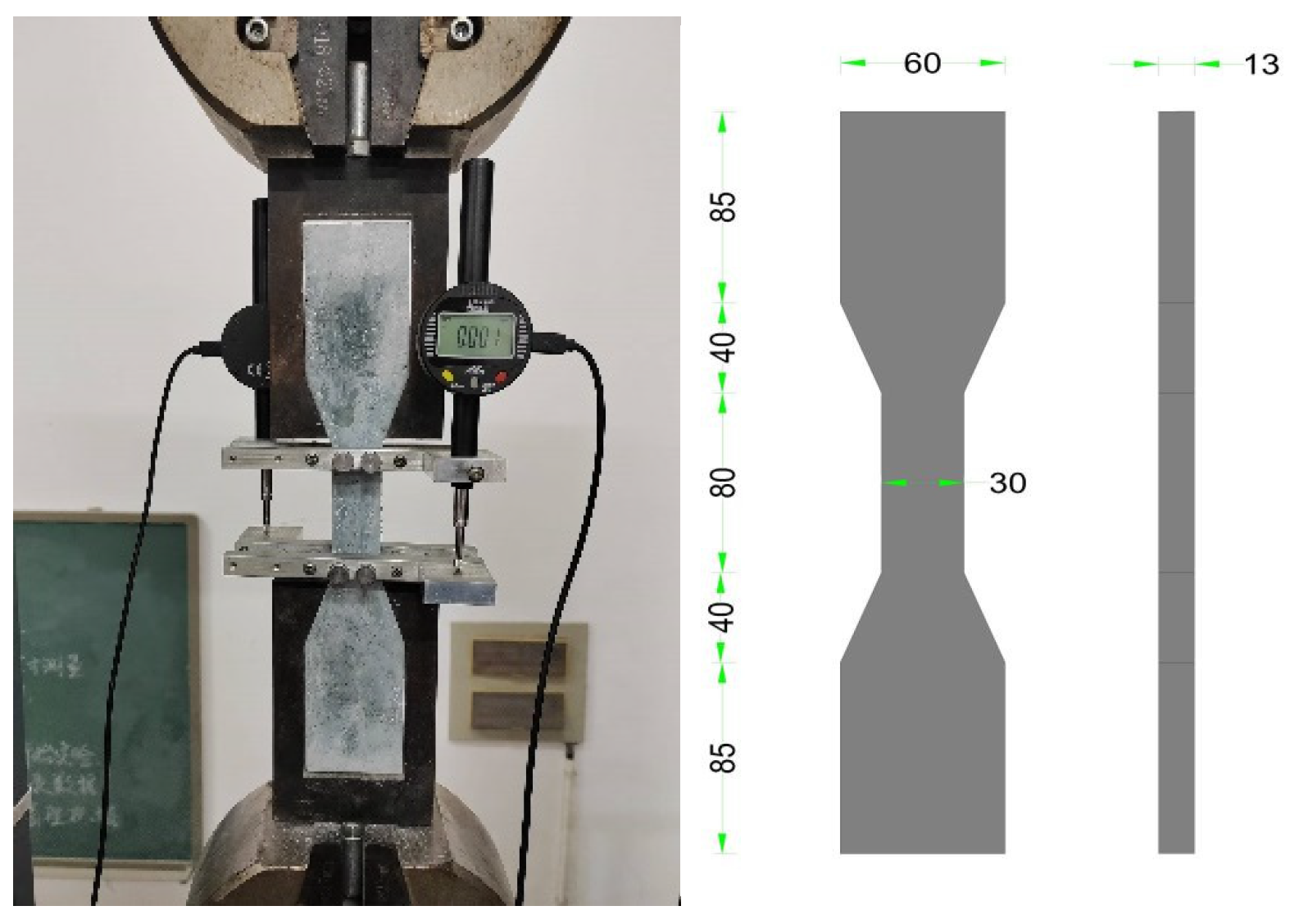

2.4.2. Uniaxial Tensile Strength

2.4.3. Fiber Dispersion Analysis

2.4.4. Mercury Intrusion Porosimetry (MIP)

3. Results and Discussion

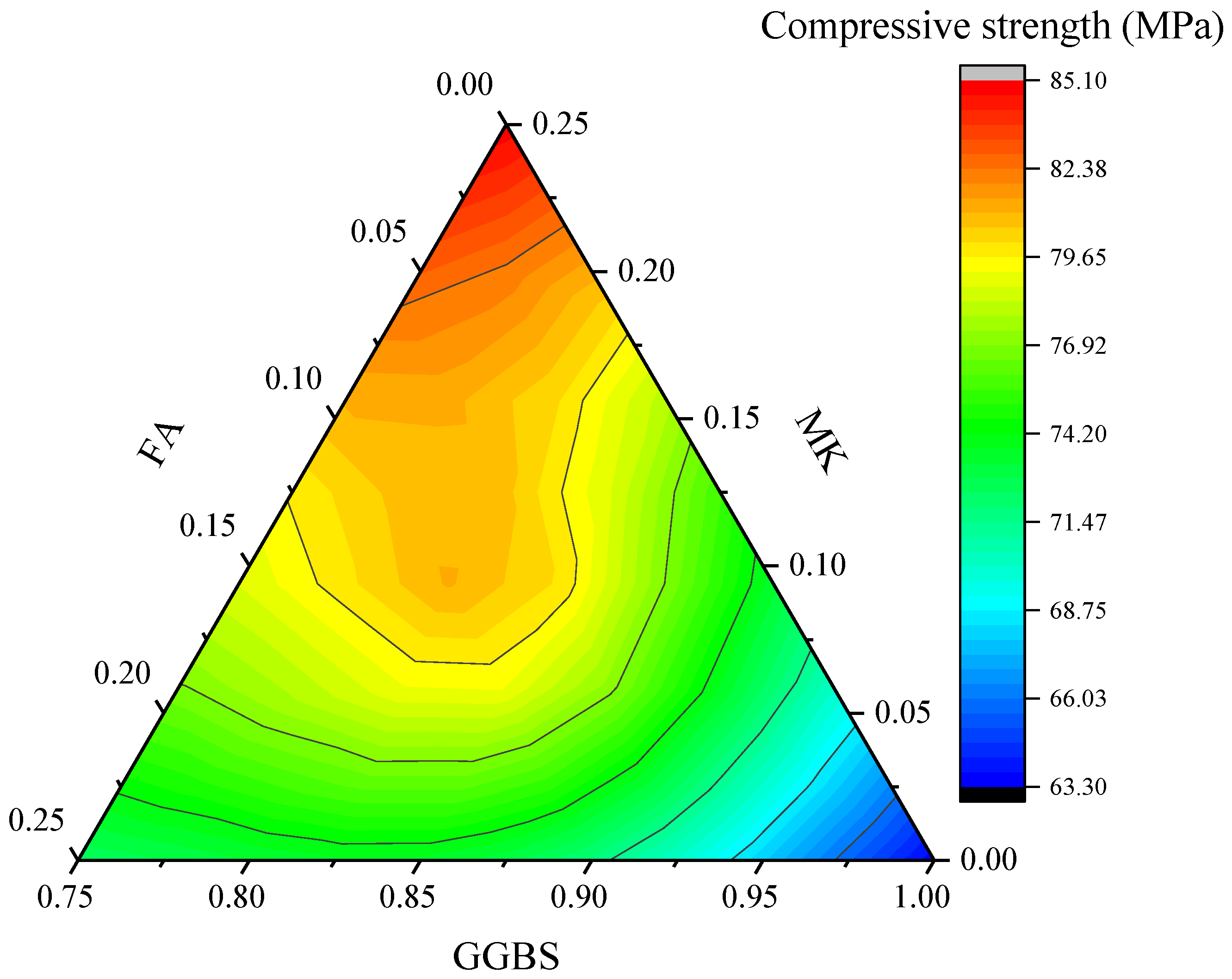

3.1. Compressive Strength

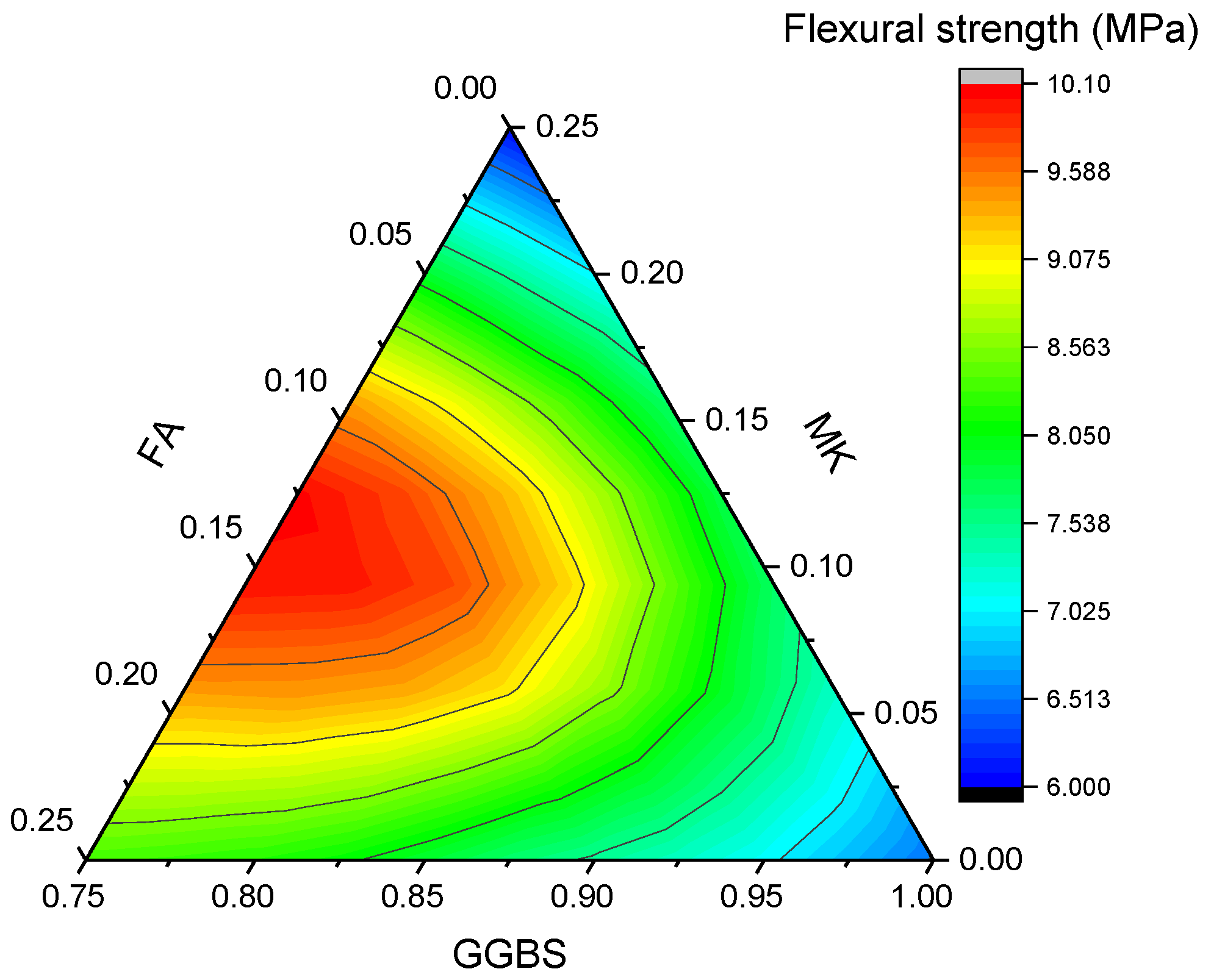

3.2. Flexural Strength

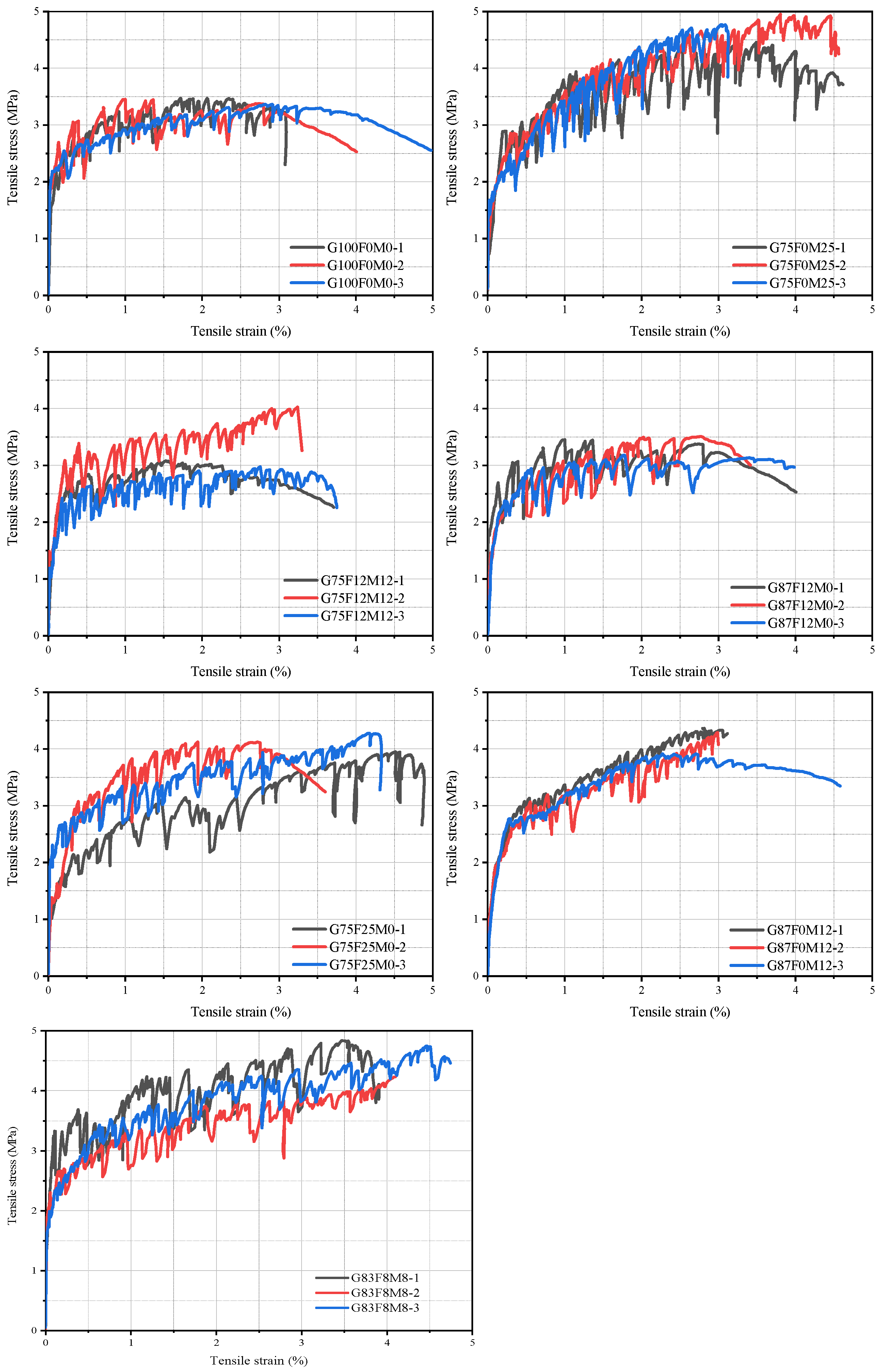

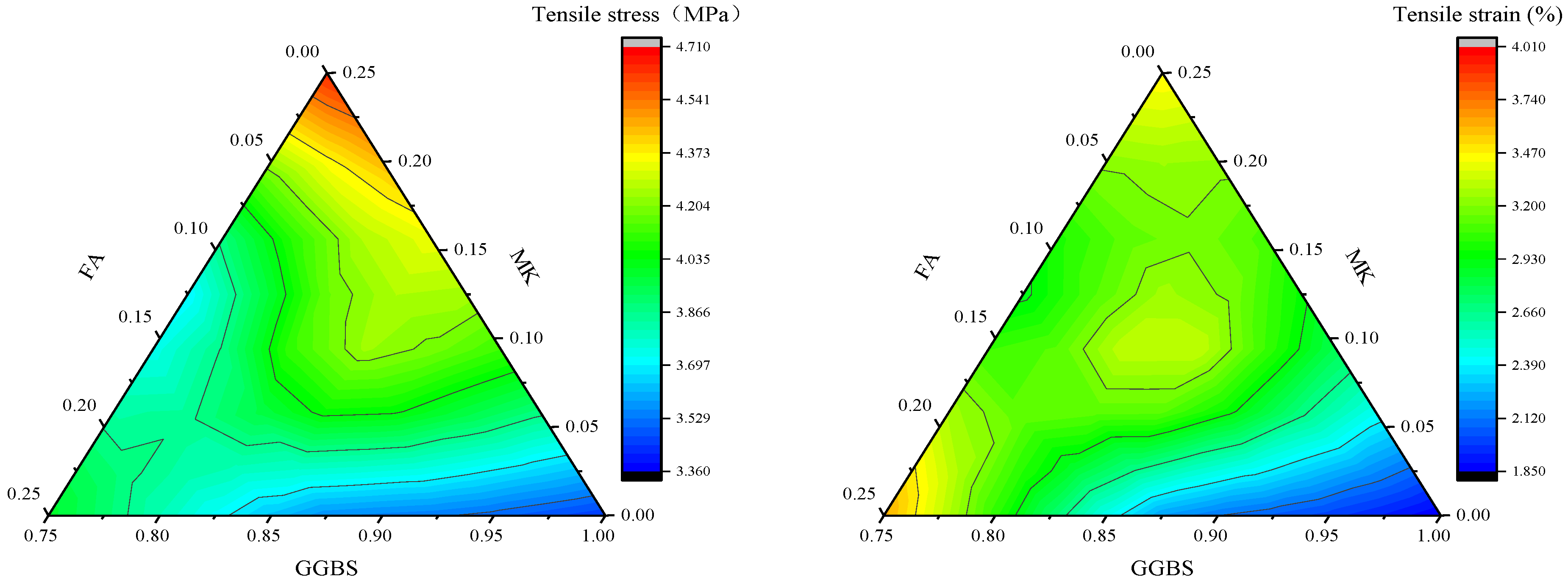

3.3. Tensile Stress–Strain Behavior

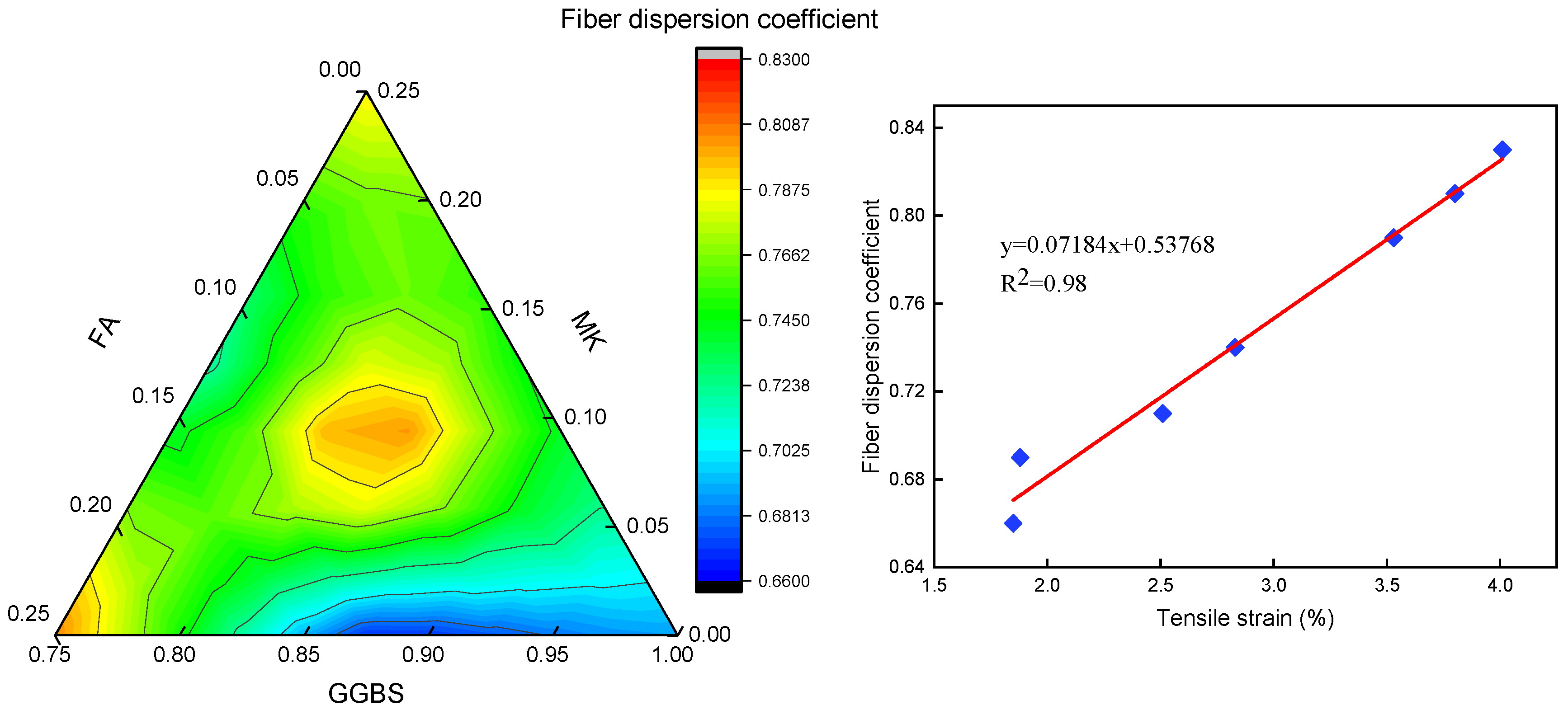

3.4. Fiber Dispersion

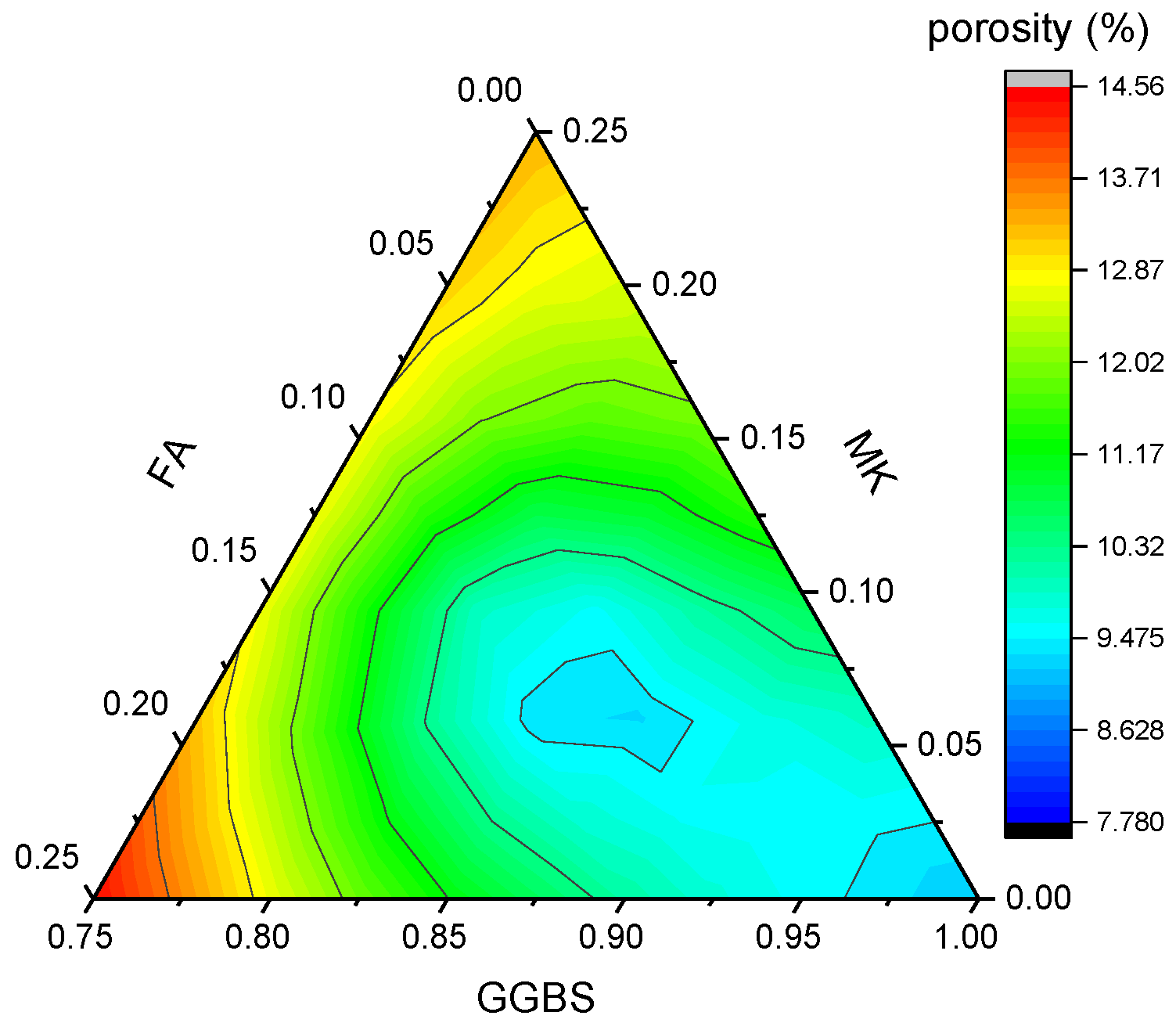

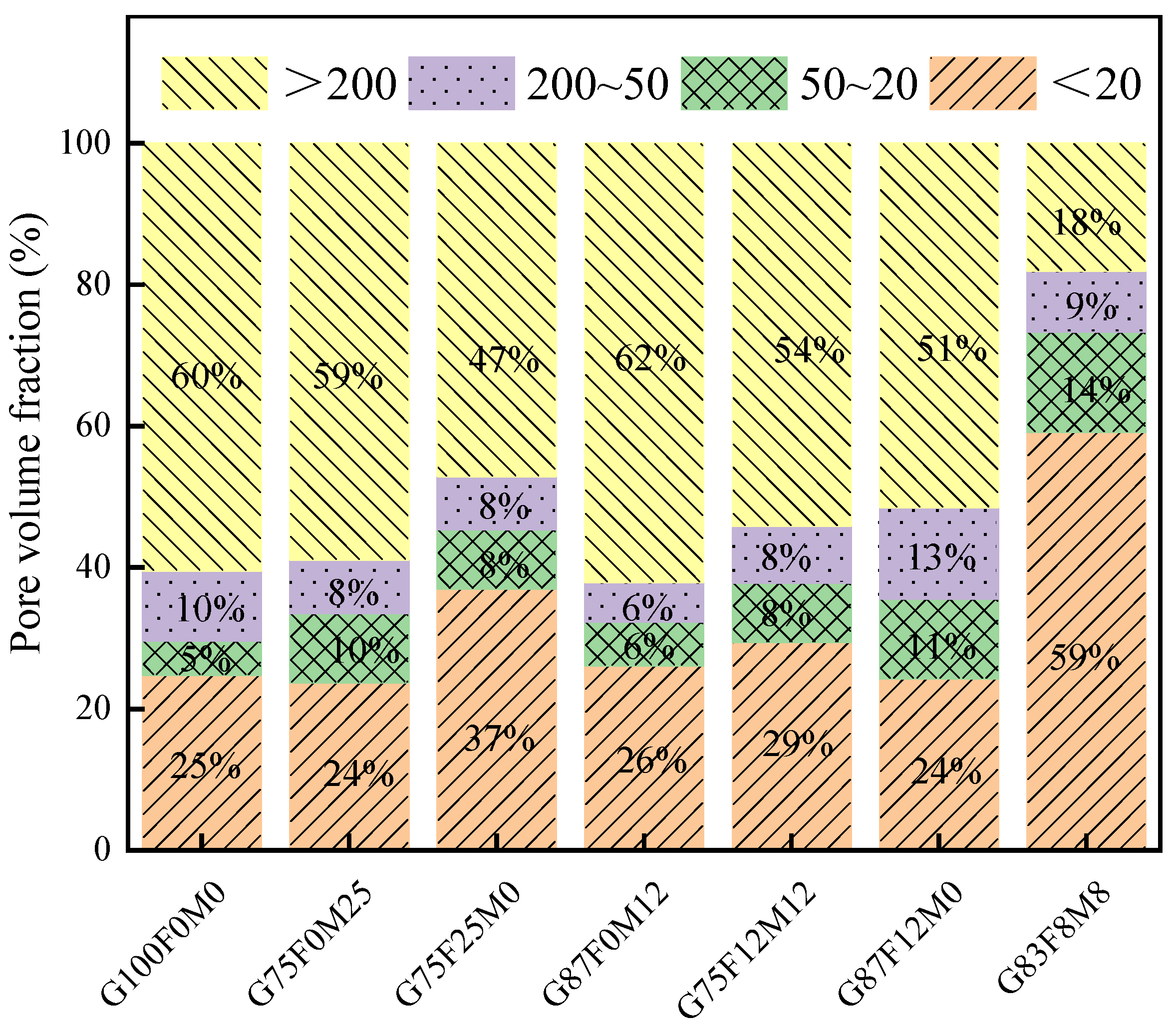

3.5. Pore Distribution

- Nanopores (<20 nm);

- Mesopores (20–50 nm);

- Macropores (50–200 nm);

- Large macropores (>200 nm) [31].

4. Conclusions

- (1)

- GGBS and FA content are inversely correlated with compressive strength, while MK content exhibits a positive correlation. The highest compressive strength (>85 MPa) is achieved when GGBS is 75% and MK is 25%.

- (2)

- Flexural strength generally decreases with increasing GGBS content. FA content initially enhances flexural strength but reduces it at higher concentrations. MK content positively influences flexural strength. The highest flexural strength (10 MPa) is observed at 75% GGBS, 12.5% FA, and 12.5% MK.

- (3)

- The most pronounced strain-hardening effect is observed in mixtures with 75% GGBS and 25% MK, as well as 83% GGBS, 8% FA, and 8% MK, where tensile strain exceeds 4% and tensile stress exceeds 4 MPa.

- (4)

- A strong positive correlation is observed between fiber dispersion and tensile strain capacity. More uniform fiber distribution leads to improved strain-hardening behavior.

- (5)

- FA and MK contribute to pore refinement, reducing the presence of coarse pores. The G83F8M8 mixture exhibits the lowest porosity and the most refined pore structure, resulting in superior mechanical performance. The compressive strength, flexural strength, tensile strength, and tensile strain of this mixture were 81.59MPa, 9.6 MPa, 4.61 MPa, and 4.01%, respectively. Therefore, the G83F8M8 mixture was identified as the optimal ternary composite.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, V.C.; Leung, C.K.Y. Steady-State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Li, V.C. From Micromechanics To Structural Engineering. Doboku Gakkai Ronbunshu 1993, 1993, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Ranade, R.; Li, V.C.; Heard, W.F.; Williams, B.A. Impact resistance of high strength-high ductility concrete. Cem. Concr. Res. 2017, 98, 24–35. [Google Scholar] [CrossRef]

- Curosu, I.; Liebscher, M.; Mechtcherine, V.; Bellmann, C.; Michel, S. Tensile behavior of high-strength strain-hardening cement-based composites (HS-SHCC) made with high-performance polyethylene, aramid and PBO fibers. Cem. Concr. Res. 2017, 98, 71–81. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, J.; Leung, C.K.Y. Use of high strength strain-hardening cementitious composites for flexural repair of concrete structures with significant steel corrosion. Constr. Build. Mater. 2018, 167, 325–337. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2017. Earth Syst. Sci. Data 2018, 10, 2213–2239. [Google Scholar] [CrossRef]

- Ohno, M.; Li, V.C. A feasibility study of strain hardening fiber reinforced fly ash-based geopolymer composites. Constr. Build. Mater. 2014, 57, 163–168. [Google Scholar] [CrossRef]

- Nguyễn, H.H.; Choi, J.-I.; Kim, H.-K.; Lee, B.Y. Mechanical properties and self-healing capacity of eco-friendly ultra-high ductile fiber-reinforced slag-based composites. Compos. Struct. 2019, 229, 111401. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Han, J.; Wang, X. Mechanical Behaviors of Metakaolin-Based Engineered Geopolymer Composite under Ambient Curing Condition. J. Mater. Civ. Eng. 2022, 34, 04022152. [Google Scholar] [CrossRef]

- Lao, J.-C.; Huang, B.-T.; Xu, L.-Y.; Khan, M.; Fang, Y.; Dai, J.-G. Seawater sea-sand Engineered Geopolymer Composites (EGC) with high strength and high ductility. Cem. Concr. Compos. 2023, 138, 104998. [Google Scholar] [CrossRef]

- Kan, L.-l.; Wang, W.-S.; Liu, W.-D.; Wu, M. Development and characterization of fly ash based PVA fiber reinforced Engineered Geopolymer Composites incorporating metakaolin. Cem. Concr. Compos. 2020, 108, 103521. [Google Scholar] [CrossRef]

- Nematollahi, B.; Sanjayan, J.; Qiu, J.; Yang, E.-H. Micromechanics-based investigation of a sustainable ambient temperature cured one-part strain hardening geopolymer composite. Constr. Build. Mater. 2017, 131, 552–563. [Google Scholar] [CrossRef]

- He, P.; Drissi, S.; Hu, X.; Liu, J.; Shi, C. Properties of CO2-cured cement incorporating fly ash and slag subjected to further water curing. Cem. Concr. Compos. 2024, 152, 105633. [Google Scholar] [CrossRef]

- He, P.; Zhang, B.; Lu, J.-X.; Poon, C.S. A ternary optimization of alkali-activated cement mortars incorporating glass powder, slag and calcium aluminate cement. Constr. Build. Mater. 2020, 240, 117983. [Google Scholar] [CrossRef]

- Wang, D.; Chen, Z. On predicting compressive strengths of mortars with ternary blends of cement, ggbfs and fly ash. Cem. Concr. Res. 1997, 27, 487–493. [Google Scholar] [CrossRef]

- Douglas, E.; Pouskouleli, G. Prediction of compressive strength of mortars made with portland cement-blast-furnace slag-fly ash blends. Cem. Concr. Res. 1991, 21, 523–534. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Method of Testing Cements—Determination of Strength (ISO Method). Standardization Administration of China (SAC): Beijing, China, 2021.

- Huang, X.; Ranade, R.; Ni, W.; Li, V.C. Development of green engineered cementitious composites using iron ore tailings as aggregates. Constr. Build. Mater. 2013, 44, 757–764. [Google Scholar] [CrossRef]

- Lee, B.Y.; Kim, J.-K.; Kim, J.-S.; Kim, Y.Y. Quantitative evaluation technique of Polyvinyl Alcohol (PVA) fiber dispersion in engineered cementitious composites. Cem. Concr. Compos. 2009, 31, 408–417. [Google Scholar] [CrossRef]

- Kamath, M.; Prashant, S.; Kumar, M. Micro-characterisation of alkali activated paste with fly ash-GGBS-metakaolin binder system with ambient setting characteristics. Constr. Build. Mater. 2021, 277, 122323. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Hamdan, S.; van Deventer, J.S.J. Modification of phase evolution in alkali-activated blast furnace slag by the incorporation of fly ash. Cem. Concr. Compos. 2014, 45, 125–135. [Google Scholar] [CrossRef]

- Nagajothi, S.; Elavenil, S. Effect of GGBS addition on reactivity and microstructure properties of ambient cured fly ash based geopolymer concrete. Silicon 2021, 13, 507–516. [Google Scholar] [CrossRef]

- Swanepoel, J.; Strydom, C. Utilisation of fly ash in a geopolymeric material. Appl. Geochem. 2002, 17, 1143–1148. [Google Scholar] [CrossRef]

- JC/T 2461-2018; Test Methods for Mechanical Properties of High Ductility Fiber-Reinforced Cementitious Composites. China Building Materials Press: Beijing, China, 2018.

- Ling, Y.; Wang, K.; Li, W.; Shi, G.; Lu, P. Effect of slag on the mechanical properties and bond strength of fly ash-based engineered geopolymer composites. Compos. Part B Eng. 2019, 164, 747–757. [Google Scholar] [CrossRef]

- Babanajad, S.K.; Farnam, Y.; Shekarchi, M. Failure criteria and triaxial behaviour of HPFRC containing high reactivity metakaolin and silica fume. Constr. Build. Mater. 2012, 29, 215–229. [Google Scholar] [CrossRef]

- Li, M.; Li, V.C. Rheology, fiber dispersion, and robust properties of engineered cementitious composites. Mater. Struct. 2013, 46, 405–420. [Google Scholar] [CrossRef]

- Lei, D. Design and Key Performance of Eco-Nano Ultra-High Strength and Ultra-High Ductility Cementitious Composites. Ph.D. Thesis, Southeast University, Nanjing, China, 2019. (In Chinese). [Google Scholar]

- Torigoe, S.-I.; Horikoshi, T.; Ogawa, A.; Saito, T.; Hamada, T. Study on Evaluation Method for PVA Fiber Distribution in Engineered Cementitious Composite. J. Adv. Concr. Technol. 2003, 1, 265–268. [Google Scholar] [CrossRef]

- Ma, J.; Wang, D.; Zhao, S.; Duan, P.; Yang, S. Influence of particle morphology of ground fly ash on the fluidity and strength of cement paste. Materials 2021, 14, 283. [Google Scholar] [CrossRef]

- Sang, G.; Liu, S.; Zhang, R.; Elsworth, D.; He, L. Nanopore characterization of mine roof shales by SANS, nitrogen adsorption, and mercury intrusion: Impact on water adsorption/retention behavior. Int. J. Coal Geol. 2018, 200, 173–185. [Google Scholar] [CrossRef]

| Material | SiO2 | Al2O3 | CaO | MgO | Fe2O3 | Na2O | SO3 |

|---|---|---|---|---|---|---|---|

| FA | 45.10 | 36.80 | 4.50 | 0.95 | 2.50 | 0.54 | 1.20 |

| GGBS | 34.20 | 17.60 | 34.00 | 6.21 | 1.01 | - | 1.62 |

| MK | 53.00 | 39.00 | 0.17 | 0.90 | 1.76 | 0.30 | - |

| Mixture | Precursors | Quartz Sand | Water | Sodium Silicate | PE Fiber (by Volume) | ||

|---|---|---|---|---|---|---|---|

| GGBS | FA | MK | |||||

| G100F0M0 | 1 | 0 | 0 | 0.36 | 0.35 | 0.285 | 2% |

| G75F0M25 | 0.75 | 0 | 0.25 | ||||

| G75F25M0 | 0.75 | 0.25 | 0 | ||||

| G87F0M12 | 0.875 | 0 | 0.125 | ||||

| G75F12M12 | 0.75 | 0.125 | 0.125 | ||||

| G87F12M0 | 0.875 | 0.125 | 0 | ||||

| G83F8M8 | 0.834 | 0.083 | 0.083 | ||||

| Mixture | G100 F0M0 | G75 F0M25 | G75 F25M0 | G87 F0M12 | G75 F12M12 | G87 F12M0 | G83 F8M8 |

|---|---|---|---|---|---|---|---|

| Compressive strength (MPa) | 63.35 | 85.04 | 72.34 | 75.31 | 79.42 | 72.99 | 81.59 |

| Flexural strength (MPa) | 6.5 | 6.0 | 8.3 | 7.8 | 10.1 | 7.6 | 9.6 |

| Initial stress (MPa) | 2.37 | 2.69 | 2.38 | 2.82 | 2.44 | 2.59 | 2.38 |

| Ultimate stress (MPa) | 3.43 | 4.71 | 4.12 | 4.19 | 3.36 | 3.38 | 4.61 |

| Ultimate strain (%) | 1.88 | 3.53 | 3.80 | 2.83 | 2.51 | 1.85 | 4.01 |

| Crack width (µm) | 86.9 | 75.5 | 51.9 | 84.4 | 64.8 | 65.7 | 70.5 |

| Fiber dispersion | 0.69 | 0.79 | 0.81 | 0.74 | 0.71 | 0.66 | 0.83 |

| Porosity (%) | 9.13 | 13.17 | 14.56 | 12.23 | 13.18 | 11.0 | 7.79 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, P.; Wang, L.; Yu, X.; Liu, Y.; Fan, L.; Chen, C. Mechanical Properties of EGC Incorporating Ternary Precursors. Buildings 2025, 15, 2919. https://doi.org/10.3390/buildings15162919

He P, Wang L, Yu X, Liu Y, Fan L, Chen C. Mechanical Properties of EGC Incorporating Ternary Precursors. Buildings. 2025; 15(16):2919. https://doi.org/10.3390/buildings15162919

Chicago/Turabian StyleHe, Pingping, Long Wang, Xin Yu, Yusong Liu, Lin Fan, and Chen Chen. 2025. "Mechanical Properties of EGC Incorporating Ternary Precursors" Buildings 15, no. 16: 2919. https://doi.org/10.3390/buildings15162919

APA StyleHe, P., Wang, L., Yu, X., Liu, Y., Fan, L., & Chen, C. (2025). Mechanical Properties of EGC Incorporating Ternary Precursors. Buildings, 15(16), 2919. https://doi.org/10.3390/buildings15162919