A Comprehensive Review of Sustainable Thermal and Acoustic Insulation Materials from Various Waste Sources

Abstract

1. Introduction

- This review paper explores sustainable thermal and acoustic insulation materials derived from both natural and recycled waste sources, offering solutions to reduce energy consumption and environmental impact. These materials provide significant advantages, including low density, high thermal resistance, strong sound insulation, and cost-effectiveness.

- The paper provides a thorough analysis of the theoretical foundations, production techniques, and key measurement methods used for assessing the thermal conductivity and sound absorption of waste-based insulation materials. It also investigates factors influencing the durability and long-term performance of these sustainable materials in insulation applications.

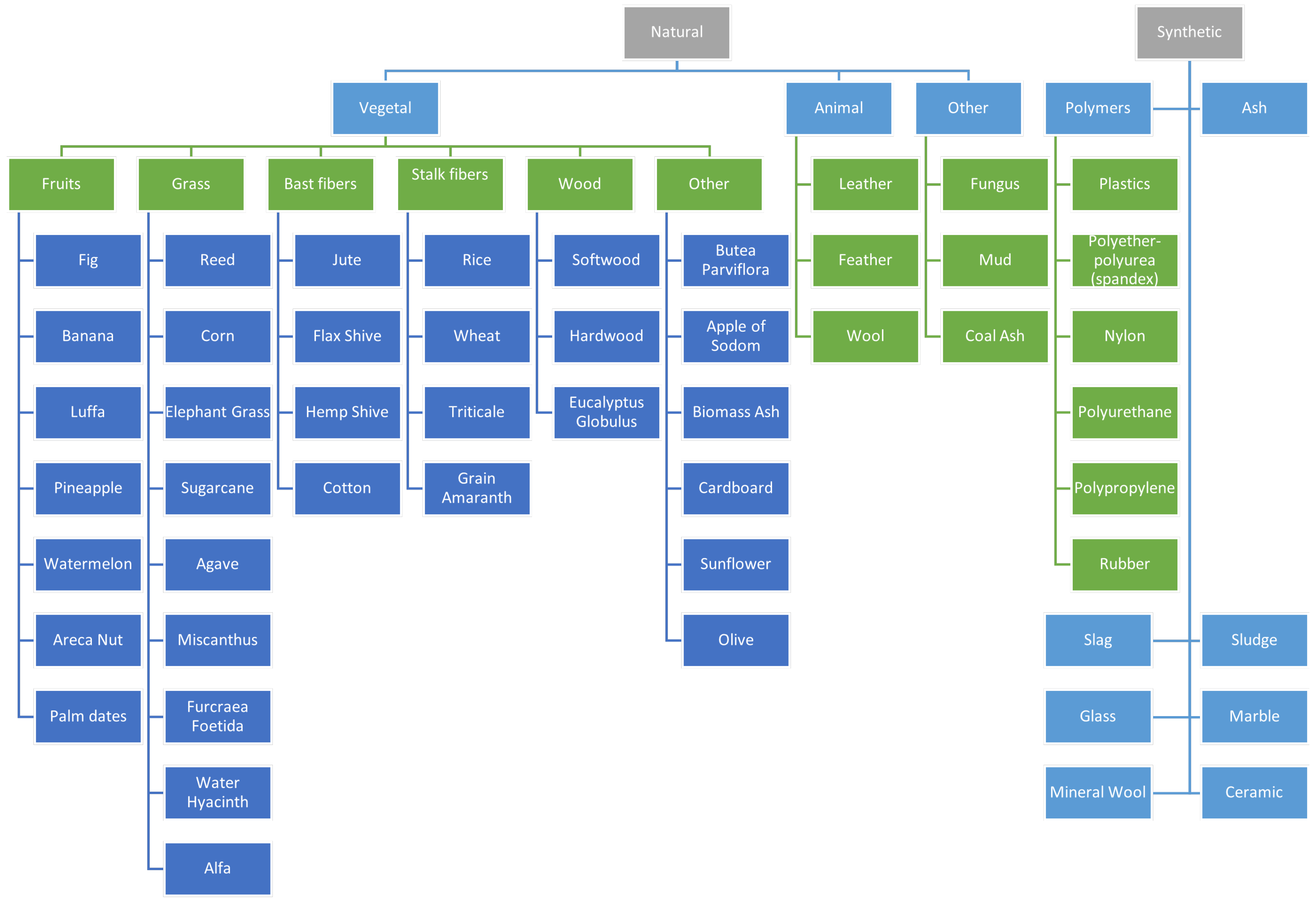

2. Insulation Materials

2.1. Natural Materials

2.2. Recycled (Synthetic) Materials

2.3. Role of Sustainable Insulation Materials in Advancing the Sustainable Development Goals (SDGs)

- SDG 3: Good Health and Well-Being—by promoting non-toxic, breathable materials that enhance indoor air quality and thermal comfort;

- SDG 7: Affordable and Clean Energy—through improved thermal efficiency that reduces energy demand for heating and cooling;

- SDG 9: Industry, Innovation, and Infrastructure—by advancing eco-innovative material technologies and sustainable manufacturing practices;

- SDG 11: Sustainable Cities and Communities—by enabling the design of low-carbon, energy-resilient buildings;

- SDG 12: Responsible Consumption and Production—through the use of recycled and renewable resources, reducing waste and raw material dependency;

- SDG 13: Climate Action—by lowering greenhouse gas emissions associated with both operational energy use and material production.

3. Characterization of Insulation Materials: Thermal and Acoustic Insulation Properties

3.1. Theory of Thermal Insulation

3.2. Thermal Insulation Measurement Techniques

3.2.1. Steady-State Techniques

3.2.2. Transient Techniques

3.2.3. Differential Scanning Calorimetry (DSC)

3.3. Theory of Acoustic Insulation

3.4. Acoustic Insulation Measurement Techniques

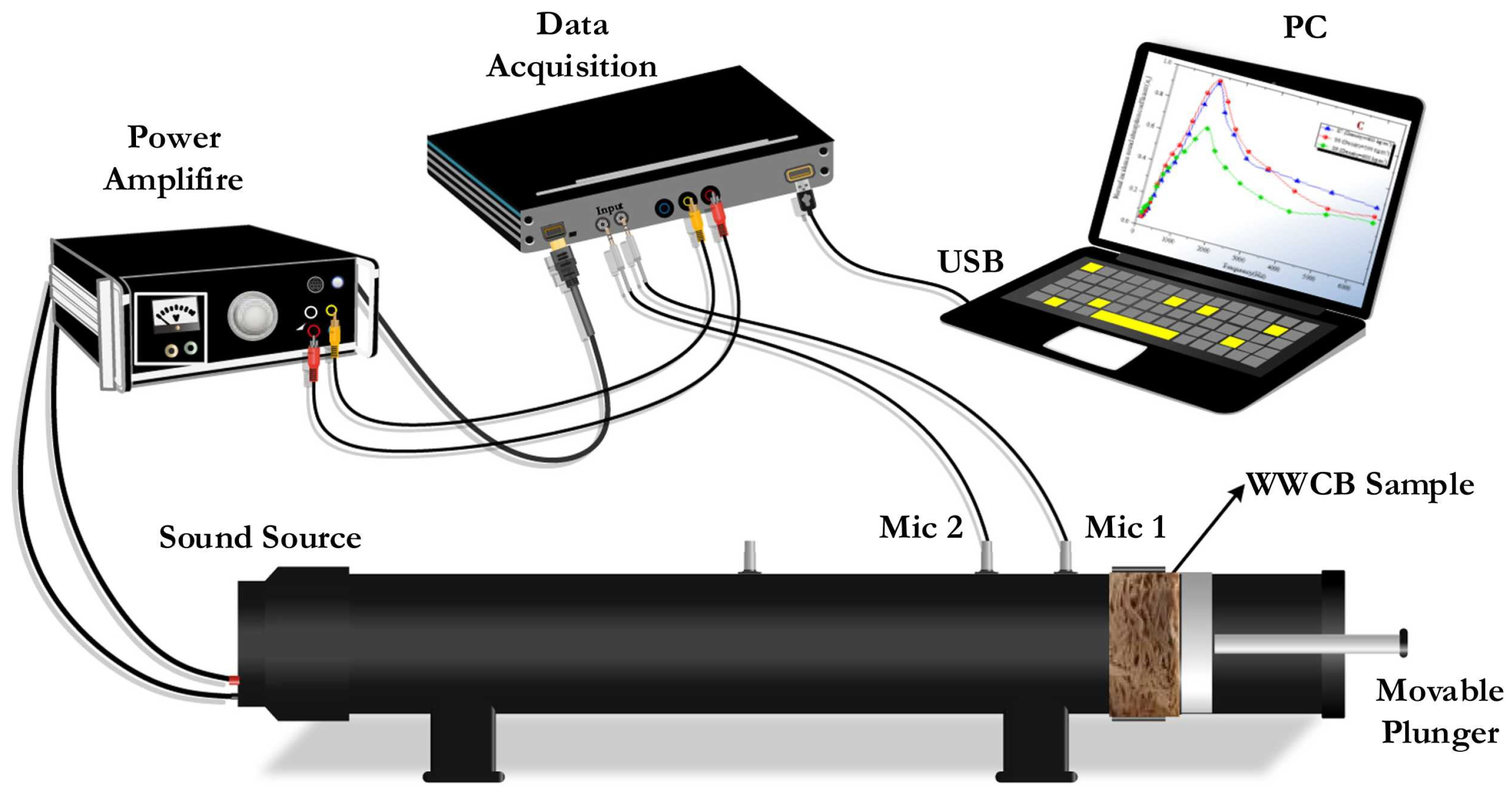

3.4.1. Impedance Tube Method

3.4.2. Reverberation Room Method

3.4.3. Reflection (or In Situ) Method

3.4.4. Sound Intensity Method

4. Fabrication Techniques of Natural Fiber Composites

5. State of the Art of Sustainable Building Insulation Materials

5.1. Thermal Insulation Materials

5.1.1. Natural Fibers

Plant Fibers

- Fruits

- Grass

- Wood

- Bast fibers

- Stalk fibers

Animal Fibers

Other Natural Fibers

5.1.2. Synthetic Waste Materials

5.2. Acoustic Insulation Materials

5.2.1. Natural Fibers

Plant Fibers

- Fruit fiber

- Grass fiber

- Bast fiber

- Stalk fiber

- Wood fiber

Animal Fibers

Other Natural Fibers

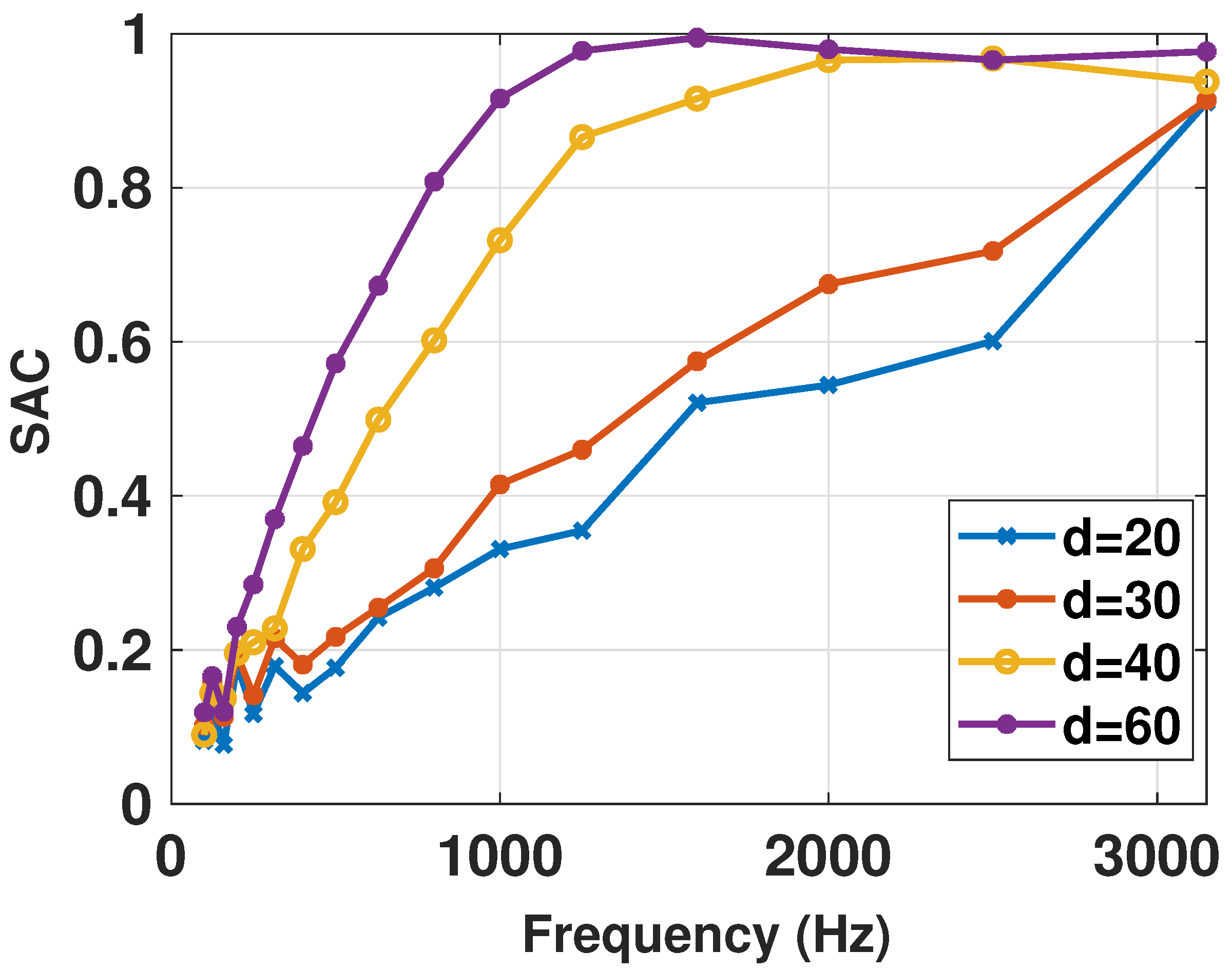

5.2.2. Recycled (Synthetic) Fibers

6. Challenges in the Use of Natural Fiber Composites

6.1. Durability

6.2. Flame Resistance

7. Discussion: Comparative Analysis of Thermal and Acoustic Insulation Materials

8. Conclusions and Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ASTM | American Society for Testing and Materials |

| ISO | International Organization for Standardization |

| AGR | Aerogel |

| EPS | Expanded polystyrene |

| XPS | Extruded polystyrene |

| IEA | International Energy Agency |

| MENA | Middle East and North Africa |

| MWF | Mineral wool fiber |

| NM | Natural material |

| NRC | Noise reduction coefficient |

| PCM | Phase change materials |

| PS | Polystyrene |

| PF | Phenolic foam |

| RSF | Rice straw fiber |

| RPET | Recycled polyester |

| SDGs | Sustainable Development Goals |

| SAC | Sound absorption coefficient |

| XPS | Extruded polystyrene |

| GHP | Guarded hot plate |

| HFM | Heat flow meter |

| TPS | Transient plane source |

| LFA | Laser flash analysis |

| TLS | Transient line source |

| DSC | Differential scanning calorimetry |

| NRC | Noise reduction coefficient |

| RTM | Resin transfer model |

| VOCs | Volatile organic compounds |

| DSFs | Date palm surface fibers |

| Density (kg/m3) | |

| Thermal conductivity (mW/m·K) | |

| Q | Heat transfer rate (W/m3) |

| Sound absorption coefficient | |

| Reaction to fire | |

| Equivalent embodied carbon (kg CO2-eq/kg) |

References

- IEA. World Energy Outlook 2022; International Energy Agency (IEA): Paris, France, 2022. [Google Scholar]

- Ali, A.; Issa, A.; Elshaer, A. A Comprehensive Review and Recent Trends in Thermal Insulation Materials for Energy Conservation in Buildings. Sustainability 2024, 16, 8782. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Khosla, R.; Bernhardt, R.; Chan, Y.C.; Vérez, D.; Hu, S.; Cabeza, L.F. Advances toward a net-zero global building sector. Annu. Rev. Environ. Resour. 2020, 45, 227–269. [Google Scholar] [CrossRef]

- Mfon, I.; Bassey, L. Sustainable Materials and Construction Practices in Industrial Buildings. Int. J. Dev. Stud. Environ. Monit. 2023, 1, 1–7. [Google Scholar] [CrossRef]

- Chen, L.; Hu, Y.; Wang, R.; Li, X.; Chen, Z.; Hua, J.; Osman, A.I.; Farghali, M.; Huang, L.; Li, J.; et al. Green building practices to integrate renewable energy in the construction sector: A review. Environ. Chem. Lett. 2023, 22, 751–784. [Google Scholar] [CrossRef]

- Chen, L.; Yang, M.; Chen, Z.; Xie, Z.; Huang, L.; Osman, A.I.; Farghali, M.; Sandanayake, M.; Liu, E.; Ahn, Y.H.; et al. Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Mater. Today Sustain. 2024, 27, 100930. [Google Scholar] [CrossRef]

- Hahad, O.; Kuntic, M.; Al-Kindi, S.; Kuntic, I.; Gilan, D.; Petrowski, K.; Daiber, A.; Münzel, T. Noise and mental health: Evidence, mechanisms, and consequences. J. Expo. Sci. Environ. Epidemiol. 2024, 35, 16–23. [Google Scholar] [CrossRef]

- Li, A.; Martino, E.; Mansour, A.; Bentley, R. Environmental Noise Exposure and Mental Health: Evidence From a Population-Based Longitudinal Study. Am. J. Prev. Med. 2022, 63, e39–e48. [Google Scholar] [CrossRef] [PubMed]

- Eze, A.H.; Lakatos, Á. Applications of thermal insulation materials by aircraft. J. Physics: Conf. Ser. 2023, 2628, 012018. [Google Scholar] [CrossRef]

- Yap, Z.S.; Khalid, N.H.A.; Haron, Z.; Mohamed, A.; Tahir, M.M.; Hasyim, S.; Saggaff, A. Waste Mineral Wool and Its Opportunities—A Review. Materials 2021, 14, 5777. [Google Scholar] [CrossRef]

- Raja, P.; Murugan, V.; Ravichandran, S.; Behera, L.; Mensah, R.A.; Mani, S.; Kasi, A.; Balasubramanian, K.B.N.; Sas, G.; Vahabi, H.; et al. A Review of Sustainable Bio-Based Insulation Materials for Energy-Efficient Buildings. Macromol. Mater. Eng. 2023, 308, 2300086. [Google Scholar] [CrossRef]

- Francesco, A.; Francesco, D.; Samuele, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Alazzawi, S.; Mahmood, W.A.; Shihab, S.K. Comparative study of natural fiber-Reinforced composites for sustainable thermal insulation in construction. Int. J. Thermofluids 2024, 24, 100839. [Google Scholar] [CrossRef]

- Palumbo, M.; Navarro, A.; Avellaneda, J.; Lacasta, A.M. Characterization of thermal insulation materials developed with crop wastes and natural binders. In Proceedings of the WSB 14 Barcelona Sustainable Building Conference, Barcelona, Brazil, 28–30 October 2014; pp. 1–10. [Google Scholar]

- Singh, H.; Singh, Y. Applications of Recycled and Waste Materials in Infrastructure Projects. Lect. Notes Civ. Eng. 2019, 21 LNCE, 569–585. [Google Scholar] [CrossRef]

- Massoudinejad, M.; Amanidaz, N.; Santos, R.M.; Bakhshoodeh, R. Use of municipal, agricultural, industrial, construction and demolition waste in thermal and sound building insulation materials: A review article 09 Engineering 0912 Materials Engineering. J. Environ. Health Sci. Eng. 2019, 17, 1227–1242. [Google Scholar] [CrossRef]

- Oyejobi, D.O.; Firoozi, A.A.; Fernández, D.B.; Avudaiappan, S. Integrating circular economy principles into concrete technology: Enhancing sustainability through industrial waste utilization. Results Eng. 2024, 24, 102846. [Google Scholar] [CrossRef]

- Lakatos, Á. Stability investigations of the thermal insulating performance of aerogel blanket. Energy Build. 2019, 185, 103–111. [Google Scholar] [CrossRef]

- Dev, B.; Rahman, M.A.; Repon, M.R.; Rahman, M.M.; Haji, A.; Nawab, Y. Recent progress in thermal and acoustic properties of natural fiber reinforced polymer composites: Preparation, characterization, and data analysis. Polym. Compos. 2023, 44, 7235–7297. [Google Scholar] [CrossRef]

- Holcombe, B. Wool performance apparel for sport. In Advances in Wool Technology; Elsevier: Amsterdam, The Netherlands, 2009; pp. 265–283. [Google Scholar]

- Babashov, V.; Bespalov, A.; Istomin, A.; Varrik, N. Heat and sound insulation material prepared using plant raw material. Refract. Ind. Ceram. 2017, 58, 208–213. [Google Scholar] [CrossRef]

- Midolo, G.; Del Zoppo, M.; Porto, S.; Valenti, F. Recycling of wasted wool fibers from sheep shearing for green building components: A review. Case Stud. Constr. Mater. 2024, 21, e03623. [Google Scholar] [CrossRef]

- Jamshaid, H.; Mishra, R. A green material from rock: Basalt fiber–a review. J. Text. Inst. 2016, 107, 923–937. [Google Scholar] [CrossRef]

- Verma, S.; Bajpai, H.; Suresh, S.; Mili, M.; Gupta, R.K.; Shetty, R.; Kamble, S.; Khan, M.A.; Hashmi, S.A.; Srivastava, A.K. Synthesis of advanced asbestos-free material using rice husk ash and marble waste for thermal insulation applications. Biomass Convers. Biorefinery 2023, 13, 8985–8998. [Google Scholar] [CrossRef]

- Aguilera Benito, P.; Morales-Segura, M.; Caballol, D.; Porras-Amores, C. Thermal and acoustic properties of new plasterboard composites with additions of cigarette butt waste. Constr. Build. Mater. 2023, 402, 133050. [Google Scholar] [CrossRef]

- Benkreira, H.; Khan, A.; Horoshenkov, K.V. Sustainable acoustic and thermal insulation materials from elastomeric waste residues. Chem. Eng. Sci. 2011, 66, 4157–4171. [Google Scholar] [CrossRef]

- Malet-Damour, B.; Habas, J.P.; Bigot, D. Is Loose-Fill Plastic Waste an Opportunity for Thermal Insulation in Cold and Humid Tropical Climates? Sustainability 2023, 15, 9483. [Google Scholar] [CrossRef]

- Cozzarini, L.; Marsich, L.; Ferluga, A. Innovative Thermal and Acoustic Insulation Foams from Recycled Fiberglass Waste. Adv. Mater. Technol. 2023, 8, 2201953. [Google Scholar] [CrossRef]

- Gounni, A.; Mabrouk, M.T.; El Wazna, M.; Kheiri, A.; El Alami, M.; El Bouari, A.; Cherkaoui, O. Thermal and economic evaluation of new insulation materials for building envelope based on textile waste. Appl. Therm. Eng. 2019, 149, 475–483. [Google Scholar] [CrossRef]

- de Moraes, E.G.; Sangiacomo, L.; Stochero, N.P.; Arcaro, S.; Barbosa, L.R.; Lenzi, A.; Siligardi, C.; Novaes de Oliveira, A.P. Innovative thermal and acoustic insulation foam by using recycled ceramic shell and expandable styrofoam (EPS) wastes. Waste Manag. 2019, 89, 336–344. [Google Scholar] [CrossRef]

- Zhao, J.; Li, S. Life cycle cost assessment and multi-criteria decision analysis of environment-friendly building insulation materials—A review. Energy Build. 2022, 254, 111582. [Google Scholar] [CrossRef]

- Tritt, T.M. Thermal Conductivity: Theory, Properties, and Applications; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

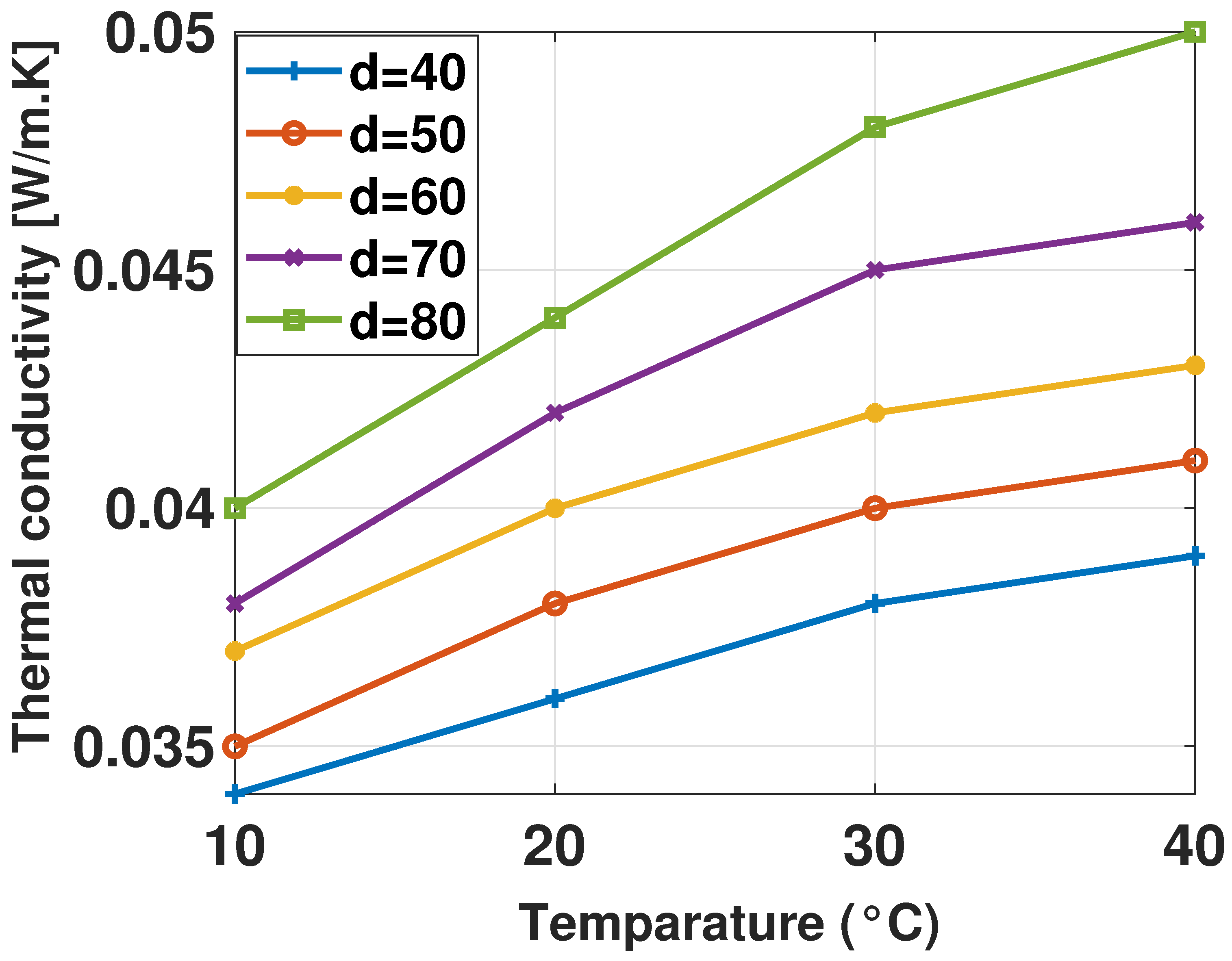

- Hung Anh, L.D.; Pásztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Diamant, R.M.E. Thermal and Acoustic Insulation; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Palacios, A.; Cong, L.; Navarro, M.; Ding, Y.; Barreneche, C. Thermal conductivity measurement techniques for characterizing thermal energy storage materials—A review. Renew. Sustain. Energy Rev. 2019, 108, 32–52. [Google Scholar] [CrossRef]

- Medved, S.; Tudor, E.M.; Barbu, M.C.; Young, T.M. Thermal conductivity of different bio-based insulation materials: Toplotna prevodnost različnih bio-izolacijskih materialov. Les/Wood 2021, 70, 73–82. [Google Scholar] [CrossRef]

- Neuberger, P.; Kic, P. Thermal conductivity of natural materials used for thermal insulation. Eng. Rural. Dev. 2017, 16, 420–424. [Google Scholar] [CrossRef]

- Kijo Kleczkowska, A.; Szumera, M.; Gnatowski, A.; Sadkowski, D. Comparative thermal analysis of coal fuels, biomass, fly ash and polyamide. Energy 2022, 258, 124840. [Google Scholar] [CrossRef]

- Lawanwadeekul, S.; Chindaprasirt, P. Sustainable construction materials from leveraging water hyacinth and wastepaper for superior sound absorption and thermal insulation. J. Build. Eng. 2025, 103, 112147. [Google Scholar] [CrossRef]

- Bhingare, N.H.; Prakash, S.; Jatti, V.S. A review on natural and waste material composite as acoustic material. Polym. Test. 2019, 80, 106142. [Google Scholar] [CrossRef]

- ISO 354: 2003; Acoustics ƒ Measurement of Sound Absorption in a Reverberation Room. ISO: Geneva, Switzerland, 2003.

- ASTM C423; Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method. ASTM International: West Conshohocken, PN, USA, 1990.

- Hopkins, C. Sound Insulation; Routledge: London, UK, 2012. [Google Scholar]

- Salunkhe, S.; Patil, C.; Thakar, C.M. Exploring the potential of natural materials as eco-friendly sound absorbers. Mater. Today Proc. 2023, 3, 98. [Google Scholar] [CrossRef]

- ISO 10534-2; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-Function Method. International Organization for Standardization: Geneva, Switzerland, 1998.

- Sanada, A.; Fujimoto, N.; Nakagawa, H. High-frequency measurement method of normal-incidence sound absorption coefficient with a square cross-section impedance tube using eight microphones. NOISE-CON Proc. 2023, 268, 2551–2558. [Google Scholar] [CrossRef]

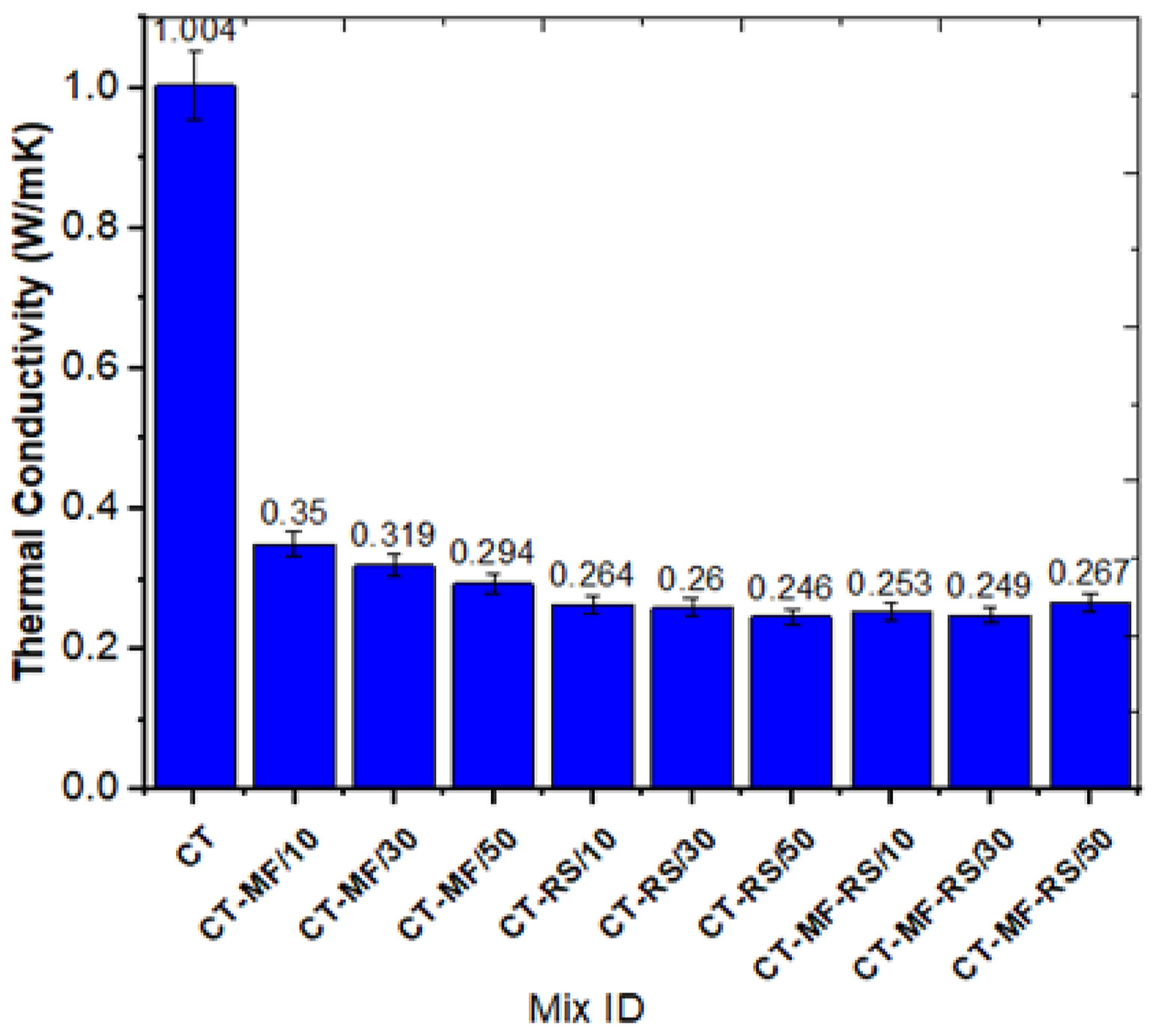

- Hemmati, N.; Mirzaei, R.; Soltani, P.; Berardi, U.; SheikhMozafari, M.J.; Edalat, H.; Rezaieyan, E.; Taban, E. Acoustic and thermal performance of wood strands-rock wool-cement composite boards as eco-friendly construction materials. Constr. Build. Mater. 2024, 445, 137935. [Google Scholar] [CrossRef]

- Prinn, A.G. A finite element study of absorption coefficient measurement at low frequencies. NOISE-CON Proc. 2023, 268, 4996–5007. [Google Scholar] [CrossRef]

- Mellert, V.; Nocke, C. Applications of In-Situ Measurement Techniques of Absorption. Ph.D. Thesis, Oldenburg University, Institute for Physics, Germany, 1975. [Google Scholar]

- ISO 13472-1; Acoustics—Measurement of Sound Absorption Properties of Road Surfaces In Situ. ISO: Geneva, Switzerland, 2022.

- Wijnant, Y.H.; Kuipers, E.R.; de Boer, A. An alternative coefficient for sound absorption. In Proceedings of the International Conference on Noise and Vibration Engineering 2012, ISMA 2012, including USD 2012: International Conference on Uncertainty in Structure Dynamics, Leuven, Belgium, 17–19 September 2012; Volume 1, pp. 85–94. [Google Scholar]

- Dittenber, D.B.; Gangarao, H.V. Critical review of recent publications on use of natural composites in infrastructure. Compos. Part Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Herrmann, A.S.; Nickel, J.; Riedel, U. Construction materials based upon biologically renewable resources—from components to finished parts. Polym. Degrad. Stab. 1998, 59, 251–261. [Google Scholar] [CrossRef]

- Jiang, T.; Hu, C.; Zeng, G. Effect of compression parameters on stress relaxation behavior of bamboo fiber reinforced polypropylene composites. Polym. Compos. 2022, 43, 2584–2592. [Google Scholar] [CrossRef]

- Campilho, R.D. Natural Fiber Composites; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Matsuoka, T.; Takabatake, J.-I.; Inoue, Y.; Takahashi, H. Prediction of fiber orientation in injection molded parts of short-fiber-reinforced thermoplastics. Polym. Eng. Sci. 1990, 30, 957–966. [Google Scholar] [CrossRef]

- Leong, Y.W.; Thitithanasarn, S.; Yamada, K.; Hamada, H. Compression and injection molding techniques for natural fiber composites. Nat. Fibre Compos. Mater. Processes Appl. 2014, 216–232. [Google Scholar] [CrossRef]

- Perna, A.S.; Viscusi, A.; Astarita, A.; Boccarusso, L.; Carrino, L.; Durante, M.; Sansone, R. Manufacturing of a Metal Matrix Composite Coating on a Polymer Matrix Composite Through Cold Gas Dynamic Spray Technique. J. Mater. Eng. Perform. 2019, 28, 3211–3219. [Google Scholar] [CrossRef]

- Sun, Z.; Xiao, J.; Tao, L.; Wei, Y.; Wang, S.; Zhang, H.; Zhu, S.; Yu, M. Preparation of High-Performance Carbon Fiber-Reinforced Epoxy Composites by Compression Resin Transfer Molding. Materials 2018, 12, 13. [Google Scholar] [CrossRef]

- Benallel, A.; Tilioua, A.; Ettakni, M.; Ouakarrouch, M.; Garoum, M.; Ahmed Alaoui Hamdi, M. Design and thermophysical characterization of new thermal insulation panels based on cardboard waste and vegetable fibers. Sustain. Energy Technol. Assess. 2021, 48, 101639. [Google Scholar] [CrossRef]

- Mohamed, G.R.; Mahmoud, R.K.; Shaban, M.; Fahim, I.S.; Abd El-Salam, H.M.; Mahmoud, H.M. Towards a circular economy: Valorization of banana peels by developing bio-composites thermal insulators. Sci. Rep. 2023, 13, 12756. [Google Scholar] [CrossRef]

- Halashi, K.; Taban, E.; Soltani, P.; Amininasab, S.; Samaei, E.; Moghadam, D.N.; Khavanin, A. Acoustic and thermal performance of luffa fiber panels for sustainable building applications. Build. Environ. 2024, 247, 111051. [Google Scholar] [CrossRef]

- Thilagavathi, G.; Muthukumar, N.; Neela Krishnanan, S.; Senthilram, T. Development and Characterization of Pineapple Fibre Nonwovens for Thermal and Sound Insulation Applications. J. Nat. Fibers 2020, 17, 1391–1400. [Google Scholar] [CrossRef]

- Srinivasan, H.; Arumugam, H.; A, A.D.; Krishnasamy, B.; MI, A.A.; Murugesan, A.; Muthukaruppan, A. Desert cotton and areca nut husk fibre reinforced hybridized bio-benzoxazine/epoxy bio-composites: Thermal, electrical and acoustic insulation applications. Constr. Build. Mater. 2023, 363, 129870. [Google Scholar] [CrossRef]

- Alabdulkarem, A.; Ali, M.; Iannace, G.; Sadek, S.; Almuzaiqer, R. Thermal analysis, microstructure and acoustic characteristics of some hybrid natural insulating materials. Constr. Build. Mater. 2018, 187, 185–196. [Google Scholar] [CrossRef]

- SheikhMozafari, M.J.; Taban, E.; Soltani, P.; Faridan, M.; Khavanin, A. Sound absorption and thermal insulation performance of sustainable fruit stone panels. Appl. Acoust. 2024, 217, 109836. [Google Scholar] [CrossRef]

- Ali, M.; Al-Suhaibani, Z.; Almuzaiqer, R.; Al-Salem, K.; Nuhait, A.; Algubllan, F.; Al-Howaish, M.; Aloraini, A.; Alqahtani, I. Sunflower and Watermelon Seeds and Their Hybrids with Pineapple Leaf Fibers as New Novel Thermal Insulation and Sound-Absorbing Materials. Polymers 2023, 15, 4422. [Google Scholar] [CrossRef]

- Segura, J.; Montava, I.; Juliá, E.; Gadea, J. Acoustic and thermal properties of panels made of fruit stones waste with coconut fibre. Constr. Build. Mater. 2024, 426, 136054. [Google Scholar] [CrossRef]

- Sair, S.; Mandili, B.; Taqi, M.; El Bouari, A. Development of a new eco-friendly composite material based on gypsum reinforced with a mixture of cork fibre and cardboard waste for building thermal insulation. Compos. Commun. 2019, 16, 20–24. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Barkhad, M.S.; Mourad, A.H.I.; Iqbal, M.Z. Date palm wood waste-based composites for green thermal insulation boards. J. Build. Eng. 2021, 43, 103224. [Google Scholar] [CrossRef]

- Raza, M.; Al Abdallah, H.; Kozal, M.; Al Khaldi, A.; Ammar, T.; Abu-Jdayil, B. Development and characterization of Polystyrene–Date palm surface fibers composites for sustainable heat insulation in construction. J. Build. Eng. 2023, 75, 106982. [Google Scholar] [CrossRef]

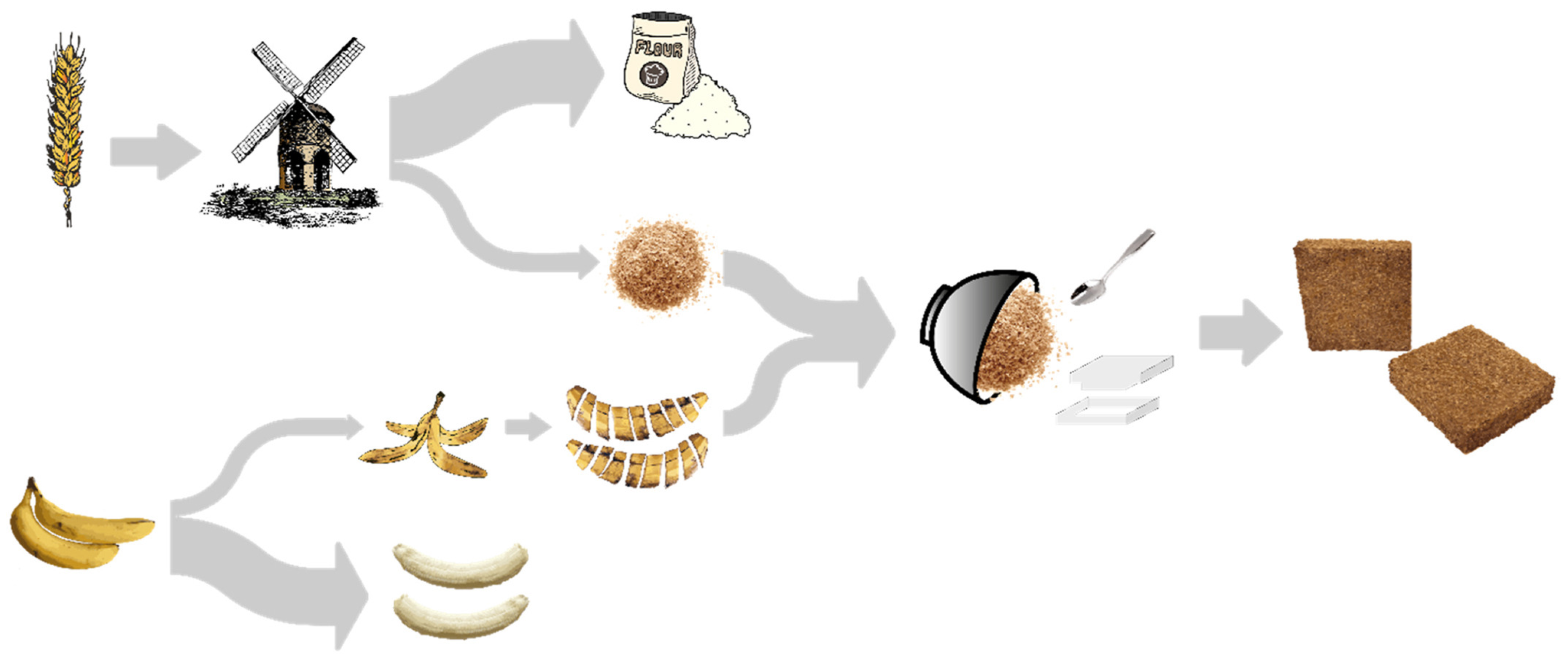

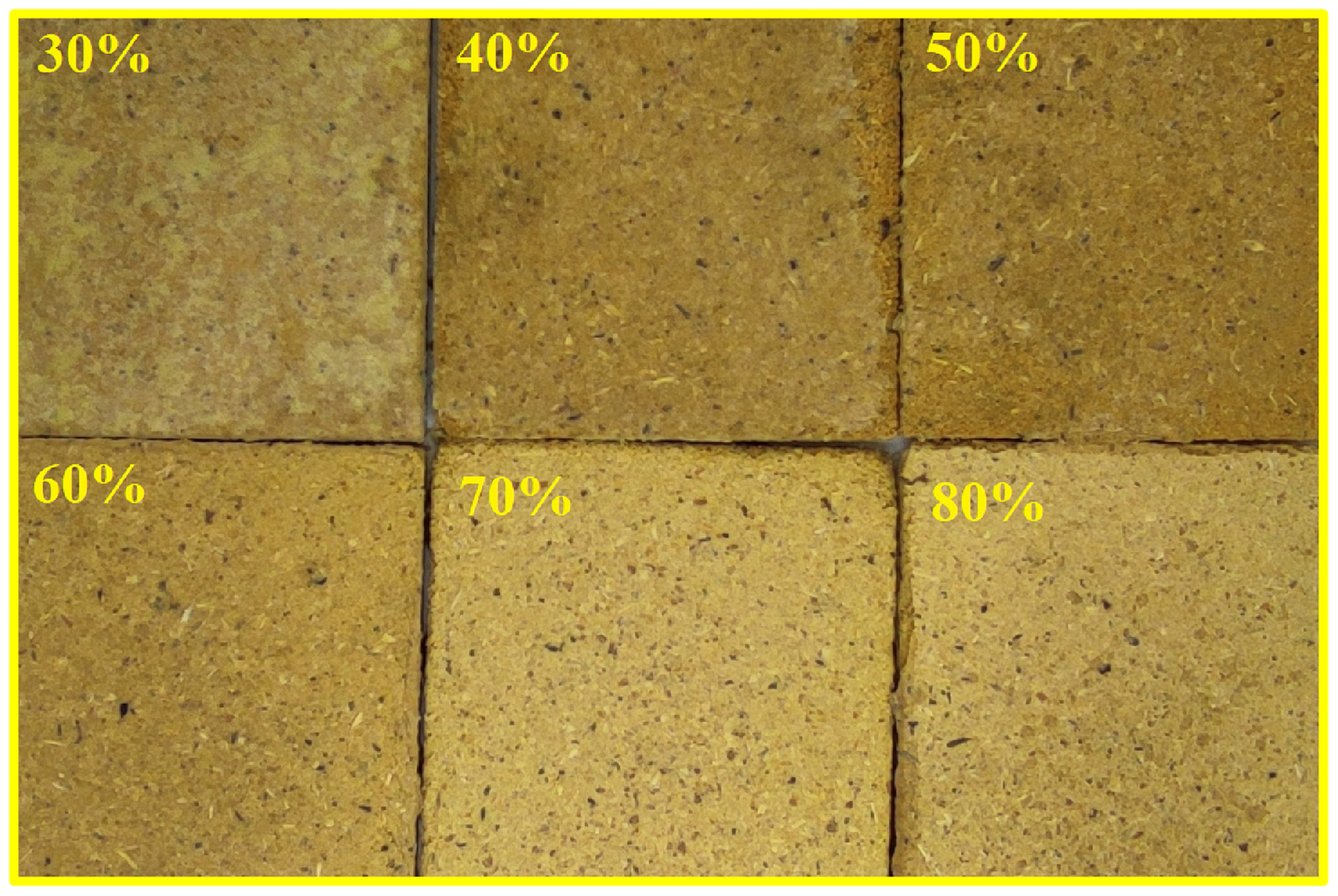

- Trobiani Di Canto, J.A.; Malfait, W.J.; Wernery, J. Turning waste into insulation—A new sustainable thermal insulation board based on wheat bran and banana peels. Build. Environ. 2023, 244, 110740. [Google Scholar] [CrossRef]

- Binici, H.; Aksogan, O.; Demirhan, C. Mechanical, thermal and acoustical characterizations of an insulation composite made of bio-based materials. Sustain. Cities Soc. 2016, 20, 17–26. [Google Scholar] [CrossRef]

- Mehrzad, S.; Taban, E.; Soltani, P.; Samaei, S.E.; Khavanin, A. Sugarcane bagasse waste fibers as novel thermal insulation and sound-absorbing materials for application in sustainable buildings. Build. Environ. 2022, 211, 108753. [Google Scholar] [CrossRef]

- Chen, Y.X.; Wu, F.; Yu, Q.; Brouwers, H.J.H. Bio-based ultra-lightweight concrete applying miscanthus fibers: Acoustic absorption and thermal insulation. Cem. Concr. Compos. 2020, 114, 103829. [Google Scholar] [CrossRef]

- Madival, A.S.; Shetty, R.; Doreswamy, D.; Maddasani, S. Characterization and optimization of thermal properties of rice straw and Furcraea foetida fiber reinforced polymer composite for thermal insulation application. J. Build. Eng. 2023, 78, 107723. [Google Scholar] [CrossRef]

- Olivares-Marín, M.; Román, S.; Gómez Escobar, V.; Moreno González, C.; Chaves-Zapata, A.; Ledesma, B. Thermal performance and sound absorption capability of water hyacinth stems-based materials. J. Clean. Prod. 2023, 425, 138903. [Google Scholar] [CrossRef]

- Ouakarrouch, M.; Bousshine, S.; Bybi, A.; Laaroussi, N.; Garoum, M. Acoustic and thermal performances assessment of sustainable insulation panels made from cardboard waste and natural fibers. Appl. Acoust. 2022, 199, 109007. [Google Scholar] [CrossRef]

- Silva, A.; Gaspar, F.; Bakatovich, A. Composite Materials of Rice Husk and Reed Fibers for Thermal Insulation Plates Using Sodium Silicate as a Binder. Sustainability 2023, 15, 11273. [Google Scholar] [CrossRef]

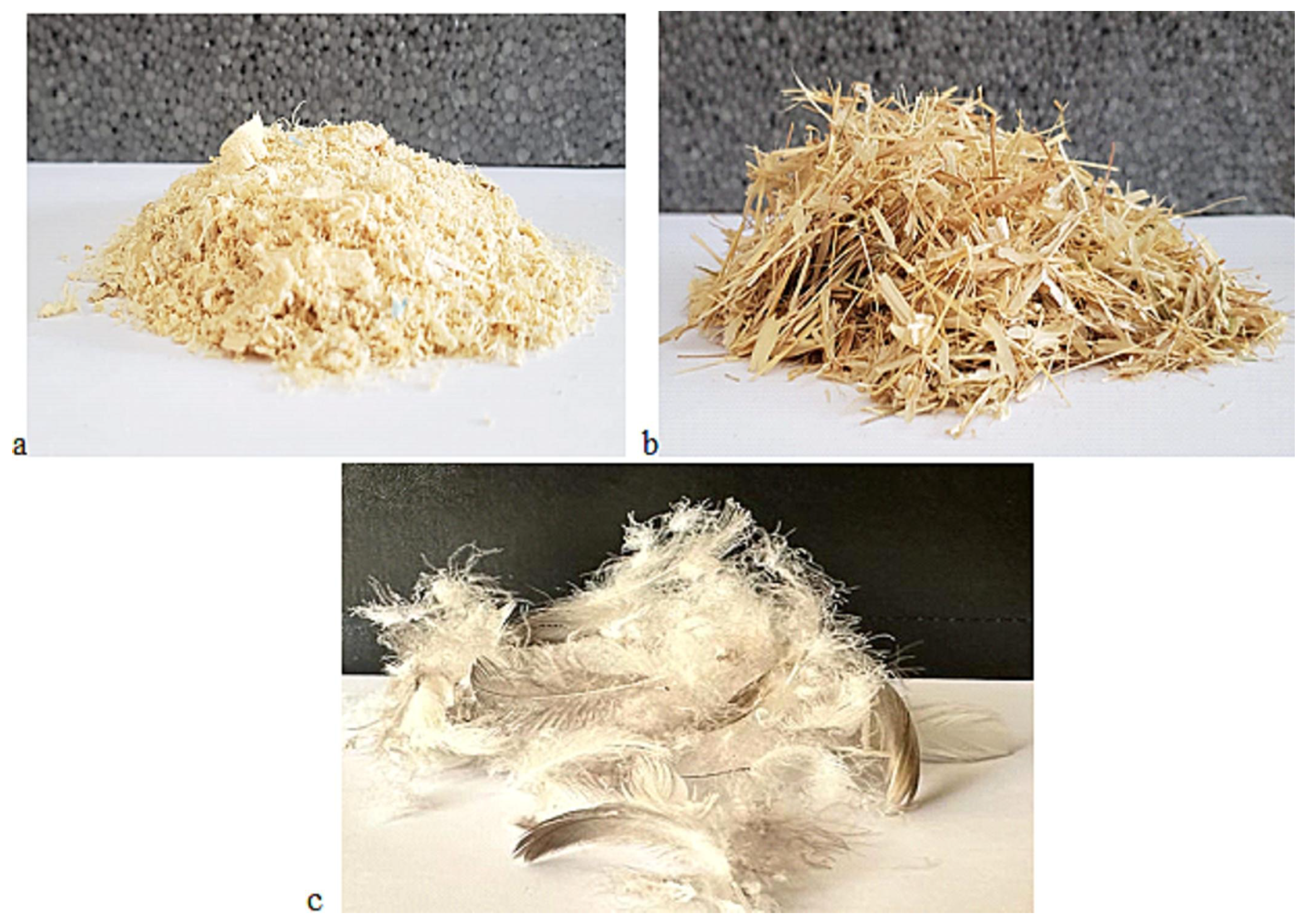

- Bousshine, S.; Ouakarrouch, M.; Bybi, A.; Laaroussi, N.; Garoum, M.; Tilioua, A. Acoustical and thermal characterization of sustainable materials derived from vegetable, agricultural, and animal fibers. Appl. Acoust. 2022, 187, 108520. [Google Scholar] [CrossRef]

- Bovo, M.; Giani, N.; Barbaresi, A.; Mazzocchetti, L.; Barbaresi, L.; Giorgini, L.; Torreggiani, D.; Tassinari, P. Contribution to thermal and acoustic characterization of corn cob for bio-based building insulation applications. Energy Build. 2022, 262, 111994. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Olszewski, A.; Kosmela, P.; Piszczyk, Ł. A novel approach in wood waste utilization for manufacturing of catalyst-free polyurethane-wood composites (PU-WC). Sustain. Mater. Technol. 2023, 36, e00619. [Google Scholar] [CrossRef]

- Aly, N.M.; Seddeq, H.S.; Elnagar, K.; Hamouda, T. Acoustic and thermal performance of sustainable fiber reinforced thermoplastic composite panels for insulation in buildings. J. Build. Eng. 2021, 40, 102747. [Google Scholar] [CrossRef]

- Vitola, L.; Gendelis, S.; Sinka, M.; Pundiene, I.; Bajare, D. Assessment of Plant Origin By-Products as Lightweight Aggregates for Bio-Composite Bounded by Starch Binder. Energies 2022, 15, 5330. [Google Scholar] [CrossRef]

- Martínez, B.; Mendizabal, V.; Roncero, M.B.; Bernat-Maso, E.; Gil, L. Towards sustainable building solutions: Development of hemp shiv-based green insulation material. Constr. Build. Mater. 2024, 414, 134987. [Google Scholar] [CrossRef]

- Majumder, A.; Achenza, M.; Mastino, C.C.; Baccoli, R.; Frattolillo, A. Thermo-acoustic building insulation materials fabricated with recycled fibers—Jute, Wool and Loofah. Energy Build. 2023, 293, 113211. [Google Scholar] [CrossRef]

- Samanta, K.K.; Mustafa, I.; Debnath, S.; Das, E.; Basu, G.; Ghosh, S.K. Study of Thermal Insulation Performance of Layered Jute Nonwoven: A Sustainable Material. J. Nat. Fibers 2022, 19, 4249–4262. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Verma, A.; Sethi, S.K.; Rangappa, S.M.; Siengchin, S. Stalk fibers (rice, wheat, barley, etc.) composites and applications. In Plant Fibers, Their Composites, and Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 347–362. [Google Scholar]

- Tran, D.T.; Nguyen, S.T.; Do, N.D.; Thai, N.N.T.; Thai, Q.B.; Huynh, H.K.P.; Nguyen, V.T.T.; Phan, A.N. Green aerogels from rice straw for thermal, acoustic insulation and oil spill cleaning applications. Mater. Chem. Phys. 2020, 253, 123363. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Akinrinade, A.D.; de Sousa Galdino, A.G.; Althoey, F.; Kirgiz, M.S.; Tayeh, B.A. Thermal insulation and mechanical characteristics of cement mortar reinforced with mineral wool and rice straw fibers. J. Build. Eng. 2022, 53, 104568. [Google Scholar] [CrossRef]

- Merli, F.; Fiorini, C.V.; Barbanera, M.; Pietroni, G.; Spaccini, F.; Buratti, C. Thermal, Acoustic, and Hygrothermal Properties of Recycled Bovine Leather Cutting Waste-Based Panels with Different Compositions. Sustainability 2023, 15, 1779. [Google Scholar] [CrossRef]

- Abdulmunem, A.R.; Samin, P.M.; Sopian, K.; Hoseinzadeh, S.; Al-Jaber, H.A.; Garcia, D.A. Waste chicken feathers integrated with phase change materials as new inner insulation envelope for buildings. J. Energy Storage 2022, 56, 106130. [Google Scholar] [CrossRef]

- Patnaik, A.; Mvubu, M.; Muniyasamy, S.; Botha, A.; Anandjiwala, R.D. Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy Build. 2015, 92, 161–169. [Google Scholar] [CrossRef]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance evaluation and research of alternative thermal insulations based on sheep wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- Erkmen, J.; Yakut, R.; Hamamci, B.; Özer, R.A. Production of Insulation Material Using Styrene Acrylic Resin from Animal and Agricultural Waste Part 1. Thermal Insulation and Water Absorption. Energy Build. 2023, 303, 113817. [Google Scholar] [CrossRef]

- Sudalai, P.N.R.; Manoharan, M. Experimental study on affordable thermal insulation of exhaust manifolds using modified sheep wool waste. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Armentano, M.; Belloni, B.E.; Buratti, C.; Calabrò, G.; Marconi, M.; Merli2, F.; Armentano, I. Recycled leather cutting waste-based boards: Thermal, acoustic, hygrothermal and ignitability properties. J. Mater. Cycles Waste Manag. 2020, 22, 1339–1351. [Google Scholar] [CrossRef]

- Răut, I.; Călin, M.; Vuluga, Z.; Oancea, F.; Paceagiu, J.; Radu, N.; Doni, M.; Alexandrescu, E.; Purcar, V.; Gurban, A.M.; et al. Fungal based biopolymer composites for construction materials. Materials 2021, 14, 2906. [Google Scholar] [CrossRef]

- Sarkar, T.; Naskar, M.K.; Chakraborty, A.; Roy, P.K.; Chakraborty, S. Preparation of high-strength waste-derived eco-friendly ceramic foam as face brick and its estimation of building energy consumption for thermal insulation. J. Build. Eng. 2024, 88, 109043. [Google Scholar] [CrossRef]

- Duong, H.M.; Ling, N.R.; Thai, Q.B.; Le, D.K.; Nguyen, P.T.; Goh, X.Y.; Phan-Thien, N. A novel aerogel from thermal power plant waste for thermal and acoustic insulation applications. Waste Manag. 2021, 124, 1–7. [Google Scholar] [CrossRef]

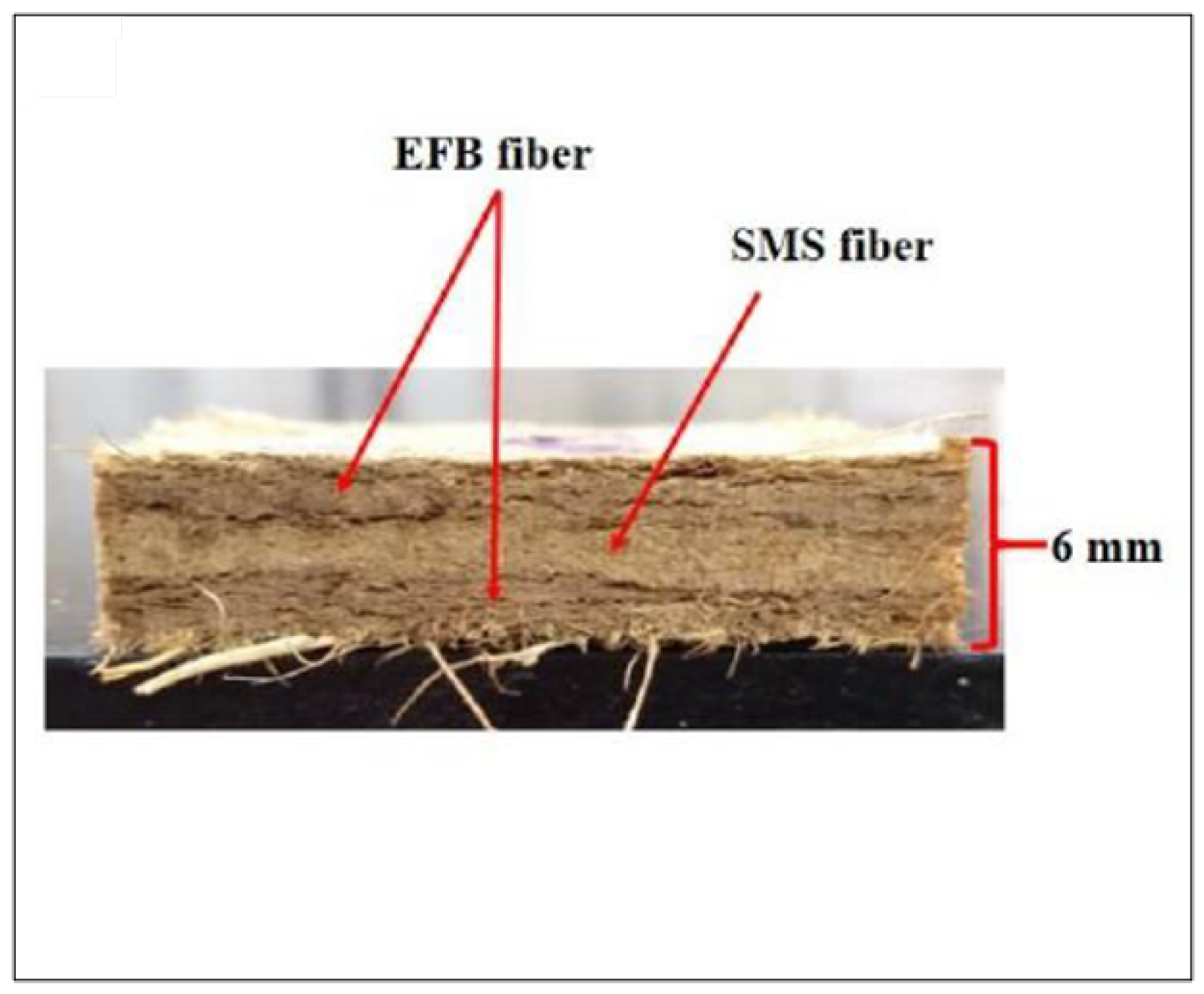

- Shakir, M.A.; Ahmad, M.I.; Yusup, Y.; Wabaidur, S.M.; Siddiqui, M.R.; Alam, M.; Rafatullah, M. Sandwich Composite Panel from Spent Mushroom Substrate Fiber and Empty Fruit Bunch Fiber for Potential Green Thermal Insulation. Buildings 2023, 13, 224. [Google Scholar] [CrossRef]

- Chau, Q.N.; Le, Q.T.; Huynh, H.K.; Nguyen, S.T. Fabrication of cellulose-based aerogel from banana stem for thermal insulation and water treatment. IOP Conf. Ser. Earth Environ. Sci. 2023, 1226, 12023. [Google Scholar] [CrossRef]

- ISO 8301; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. International Organization for Standardization: Geneva, Switzerland, 1991.

- DIN EN 1946-3; Ventilation for Buildings—Mechanical Ventilation Systems in Buildings—Part 3: Performance Testing of Components Used in Air Handling Units and Other Ventilation System Components. Deutsches Institut für Normung: Berlin, Germany, 2007.

- ASTM C1045-07; Standard Practice for Heat Transfer Applications of Thermocouples. ASTM International: West Conshohocken, PA, USA, 2007.

- AlQdah, K.S. Thermal Performance of Medina Date Palm Components as Thermal Insulation in Local Buildings. Arab. J. Sci. Eng. 2022, 47, 9075–9084. [Google Scholar] [CrossRef]

- DIN 52612; Thermal Insulating Materials; Determination of Thermal Conductivity; Guarded Hot Plate Method. Deutsches Institut für Normung: Berlin, Germany, 1984.

- Raza, M.; Al Abdallah, H.; Abdullah, A.; Abu-Jdayil, B. Date Palm Surface Fibers for Green Thermal Insulation. Buildings 2022, 12, 866. [Google Scholar] [CrossRef]

- Benallel, A.; Tilioua, A.; Garoum, M. Development of thermal insulation panels bio-composite containing cardboard and date palm fibers. J. Clean. Prod. 2024, 434, 139995. [Google Scholar] [CrossRef]

- ASTM C177-85; Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus. ASTM International: West Conshohocken, PA, USA, 1985.

- Fattahi, M.; Taban, E.; Soltani, P.; Berardi, U.; Khavanin, A.; Zaroushani, V. Waste corn husk fibers for sound absorption and thermal insulation applications: A step towards sustainable buildings. J. Build. Eng. 2023, 77, 107468. [Google Scholar] [CrossRef]

- Lesiecki, M.; Kawalerczyk, J.; Derkowski, A.; Wieruszewski, M.; Dziurka, D.; Mirski, R. Properties of Lightweight Insulating Boards Produced from Triticale Straw Particles. Materials 2023, 16, 5272. [Google Scholar] [CrossRef]

- ASTM E1461-13; Standard Test Method for Thermal Diffusivity by the Flash Method. ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- Yang, Z.; Wang, K.; Wang, X.; Huan, S.; Yang, H.; Wang, C. Low-cost, superhydrophobic, flame-retardant sunflower straw-based xerogel as thermal insulation materials for energy-efficient buildings. Sustain. Mater. Technol. 2023, 38, e00748. [Google Scholar] [CrossRef]

- Ilangovan, M.; Navada, A.P.; Guna, V.; Touchaleaume, F.; Saulnier, B.; Grohens, Y.; Reddy, N. Hybrid biocomposites with high thermal and noise insulation from discarded wool, poultry feathers, and their blends. Constr. Build. Mater. 2022, 345, 128324. [Google Scholar] [CrossRef]

- JIS A 1412-2; Testing Method for Thermal Insulation Materials—Part 2: Determination of Thermal Conductivity. Japanese Standards Association: Tokyo, Japan, 1999.

- ASTM C518; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM International: West Conshohocken, PA, USA, 2021.

- Khaleel, M.; Soykan, U.; Çetin, S. Influences of turkey feather fiber loading on significant characteristics of rigid polyurethane foam: Thermal degradation, heat insulation, acoustic performance, air permeability and cellular structure. Constr. Build. Mater. 2021, 308, 125014. [Google Scholar] [CrossRef]

- Ghermezgoli, Z.M.; Moezzi, M.; Yekrang, J.; Rafat, S.A.; Soltani, P.; Barez, F. Sound absorption and thermal insulation characteristics of fabrics made of pure and crossbred sheep waste wool. J. Build. Eng. 2021, 35, 102060. [Google Scholar] [CrossRef]

- ASTM C177-19; Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Leiva, C.; Arenas, C.; Vilches, L.F.; Alonso-Fariñas, B.; Rodriguez-Galán, M. Development of fly ash boards with thermal, acoustic and fire insulation properties. Waste Manag. 2015, 46, 298–303. [Google Scholar] [CrossRef]

- EN 993-15:2005; Methods of Test for Dense Shaped Refractory Products—Part 15: Determination of Thermal Conductivity by the Hot-Wire (Parallel) Method. e-Library: online, 2005.

- Zhu, M.; Ji, R.; Li, Z.; Wang, H.; Liu, L.L.; Zhang, Z. Preparation of glass ceramic foams for thermal insulation applications from coal fly ash and waste glass. Constr. Build. Mater. 2016, 112, 398–405. [Google Scholar] [CrossRef]

- Yasira, N.; Mansur, F.Z.; Shafinas, N.I.; Omardin, M.A.; Bakhari, N. Thermal Behaviour Assessment of Brick Utilizing Plastic Waste for Enhanced Insulation Properties. Platform J. Eng. 2024, 8, 23–28. [Google Scholar] [CrossRef]

- ISO 8302:1991; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Guarded Hot Plate Apparatus. ISO: Geneva, Switzerland, 1991.

- BS 1902-5.8:1992; Methods of Testing Refractory Materials. Refractory and Thermal Properties—Determination of Thermal Conductivity (Split Column Method) (Method 1902-508). BSI: Sydney, Australia, 1992.

- Caniato, M.; Cozzarini, L.; Schmid, C.; Gasparella, A. Acoustic and thermal characterization of a novel sustainable material incorporating recycled microplastic waste. Sustain. Mater. Technol. 2021, 28, e00274. [Google Scholar] [CrossRef]

- Dehdashti, Z.; Soltani, P.; Taban, E. Utilizing discarded face masks to fabricate sustainable high-performance panels for enhanced building thermal and acoustic comfort. J. Clean. Prod. 2024, 446, 141304. [Google Scholar] [CrossRef]

- Dissanayake, D.; Weerasinghe, D.; Wijesinghe, K.; Kalpage, K. Developing a compression moulded thermal insulation panel using postindustrial textile waste. Waste Manag. 2018, 79, 356–361. [Google Scholar] [CrossRef]

- Majdoubi, H.; Haddaji, Y.; Bourzik, O.; Nadi, M.; Ziraoui, J.; Alomayri, T.S.; Oumam, M.; Manoun, B.; Alami, J.; Tamraoui, Y.; et al. Enhancing thermal insulation with phosphate washing sludge waste as an inorganic foaming agent in porous acid-based geopolymers: Formulation and processing optimization. Constr. Build. Mater. 2023, 407, 133486. [Google Scholar] [CrossRef]

- ASTM D7984-16; Standard Test Method for Thermal Conductivity and Thermal Diffusivity by the Transient Plane Source (TPS) Technique. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- Tao, Y.; Ren, M.; Zhang, H.; Peijs, T. Recent progress in acoustic materials and noise control strategies—A review. Appl. Mater. Today 2021, 24, 101141. [Google Scholar] [CrossRef]

- Asdrubali, F.; Schiavoni, S.; Horoshenkov, K.V. A review of sustainable materials for acoustic applications. Build. Acoust. 2012, 19, 283–312. [Google Scholar] [CrossRef]

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.P.; Selvakumar, K.K.; Jyothi, M.S.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar] [CrossRef]

- Or, K.H.; Putra, A.; Selamat, M.Z. Oil palm empty fruit bunch fibres as sustainable acoustic absorber. Appl. Acoust. 2017, 119, 9–16. [Google Scholar] [CrossRef]

- Zhu, S.; Xie, J.; Sun, Q.; Zhang, Z.; Wan, J.; Zhou, Z.; Lu, J.; Chen, J.; Xu, J.; Chen, K.; et al. Recent advances on bast fiber composites: Engineering innovations, applications and perspectives. Compos. Part B Eng. 2024, 284, 111738. [Google Scholar] [CrossRef]

- Lim, Z.Y.; Putra, A.; Nor, M.J.; Yaakob, M.Y. Sound absorption performance of natural kenaf fibres. Appl. Acoust. 2018, 130, 107–114. [Google Scholar] [CrossRef]

- Wang, S.; Li, H.; Zou, S.; Liu, L.; Bai, C.; Zhang, G.; Fang, L. Experimental study on durability and acoustic absorption performance of biomass geopolymer-based insulation materials. Constr. Build. Mater. 2022, 361, 129575. [Google Scholar] [CrossRef]

- Villalón Fornés, I.; Vaičiukynienė, D.; Nizevičienė, D.; Tamošaitis, G.; Pupeikis, D. The improvement of the thermal and acoustic insulation properties of phosphogypsum specimens by adding waste wood fibre. Constr. Build. Mater. 2022, 331, 127341. [Google Scholar] [CrossRef]

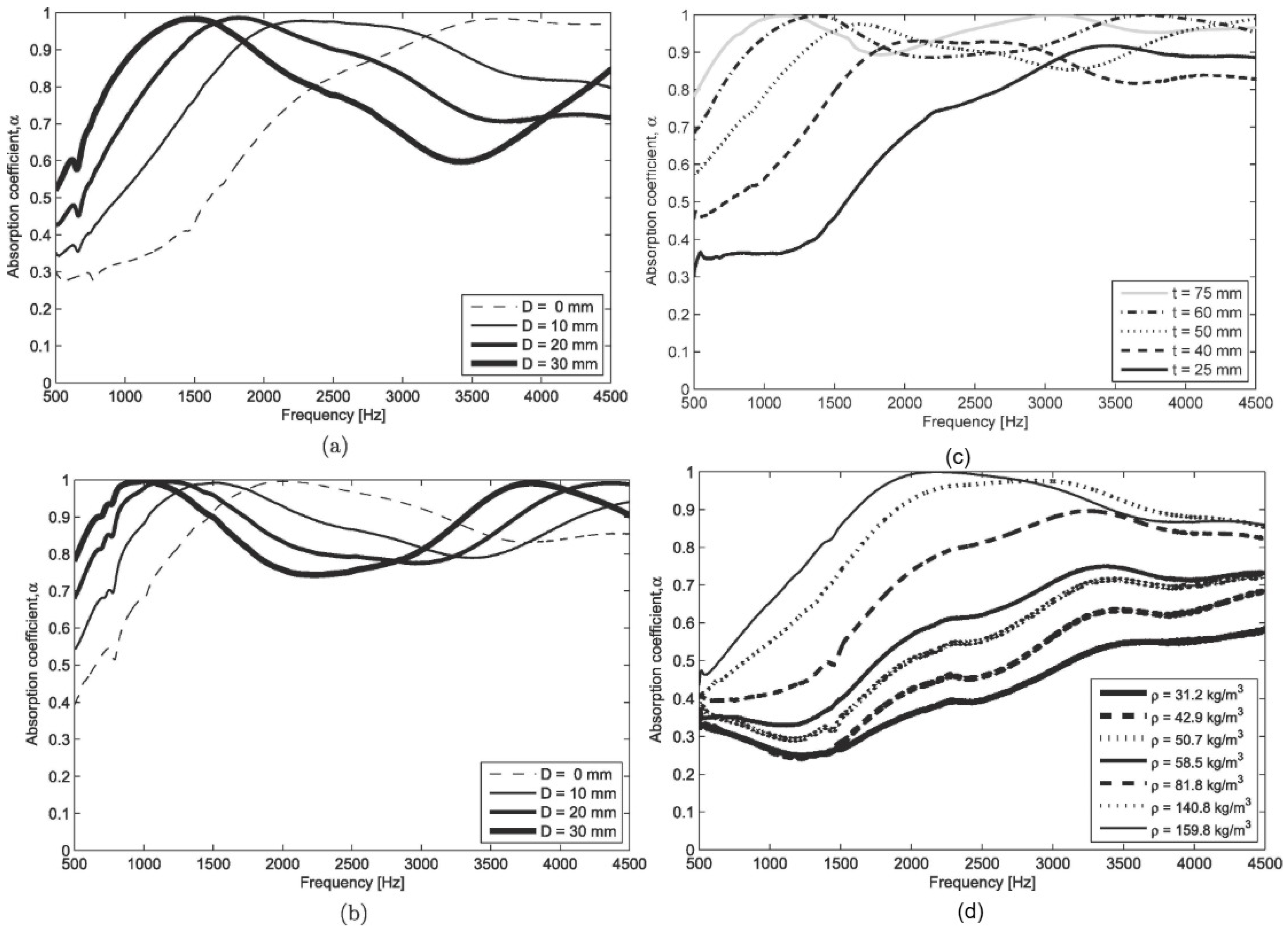

- Borlea, S.I.; Tiuc, A.E.; Nemeş, O.; Vermeşan, H.; Vasile, O. Innovative use of sheep wool for obtaining materials with improved sound-absorbing properties. Materials 2020, 13, 694. [Google Scholar] [CrossRef]

- Kusno, A.; Mulyadi, R.; Haisah, S. Study on Chicken Feather as Acoustical Absorptive Material. J. Phys. Conf. Ser. 2019, 1150, 012052. [Google Scholar] [CrossRef]

- Oliveira, M.A.; António, J. Animal-based waste for building acoustic applications: A review. J. Build. Eng. 2024, 84, 108430. [Google Scholar] [CrossRef]

- Ballagh, K. Acoustical properties of wool. Appl. Acoust. 1996, 48, 101–120. [Google Scholar] [CrossRef]

- Muthukumar, N.; Thilagavathi, G. Development of sustainable thermal and sound insulation materials from textile fiber wastes. In Biocomposites-Bio-Based Fibers and Polymers from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2024; pp. 247–256. [Google Scholar]

- Del Rey, R.; Uris, A.; Alba, J.; Candelas, P. Characterization of sheep wool as a sustainable material for acoustic applications. Materials 2017, 10, 1277. [Google Scholar] [CrossRef]

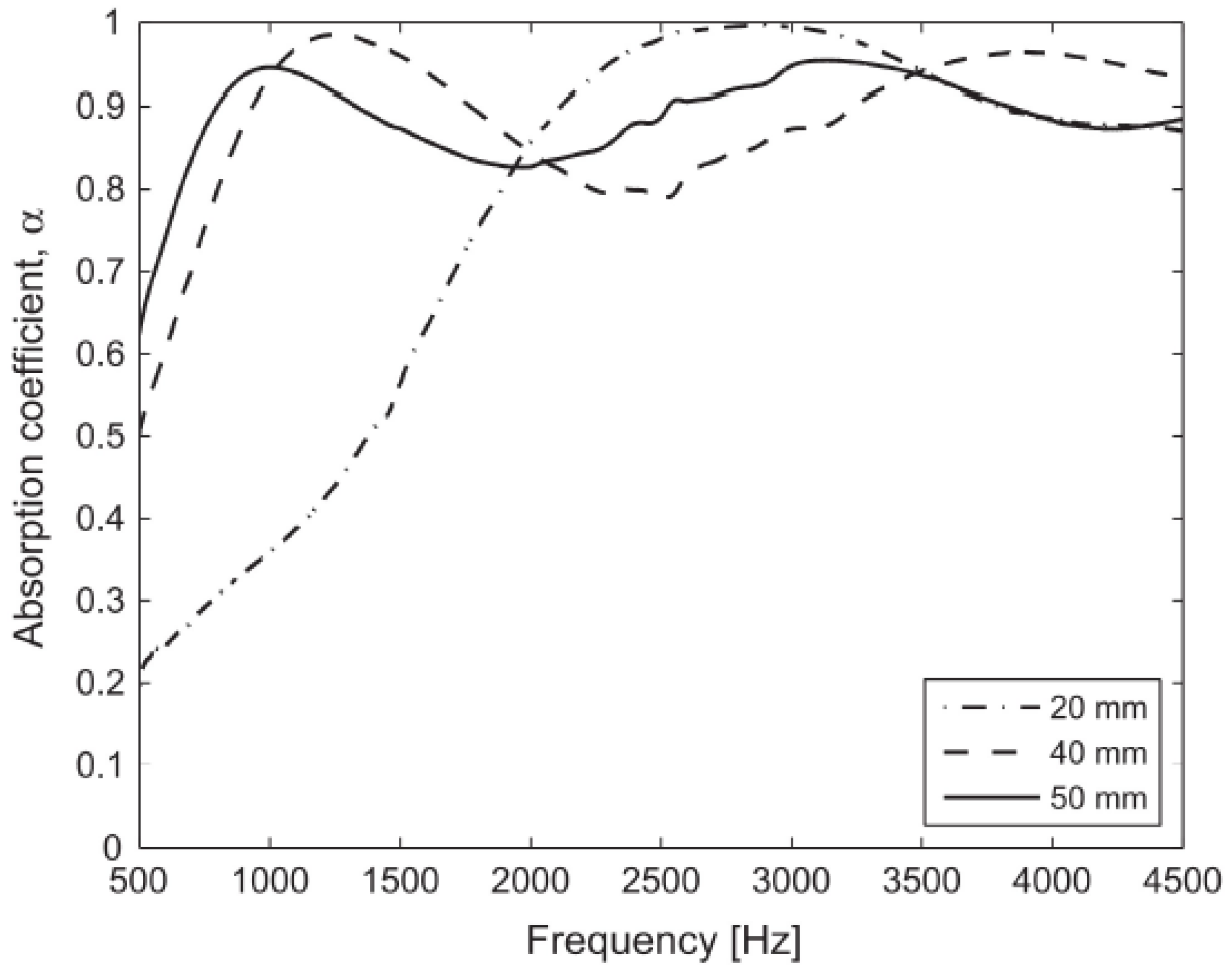

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Rabbat, C.; Awad, S.; Villot, A.; Andres, Y. Towards the Production of High Added-Value Products from the Pyrolysis and Steam Pyro-Gasification of Five Biomass-Based Building Insulation Materials at End-of-Life. Waste Biomass Valorization 2023, 14, 2061–2083. [Google Scholar] [CrossRef]

- Kyaw Oo D’Amore, G.; Caniato, M.; Travan, A.; Turco, G.; Marsich, L.; Ferluga, A.; Schmid, C. Innovative thermal and acoustic insulation foam from recycled waste glass powder. J. Clean. Prod. 2017, 165, 1306–1315. [Google Scholar] [CrossRef]

- Taban, E.; Khavanin, A.; Ohadi, A.; Putra, A.; Jafari, A.J.; Faridan, M.; Soleimanian, A. Study on the acoustic characteristics of natural date palm fibres: Experimental and theoretical approaches. Build. Environ. 2019, 161, 106274. [Google Scholar] [CrossRef]

- Gumanová, V.; Sobotová, L.; Dzuro, T.; Badida, M.; Moravec, M. Experimental Survey of the Sound Absorption Performance of Natural Fibres in Comparison with Conventional Insulating Materials. Sustainability 2022, 14, 4258. [Google Scholar] [CrossRef]

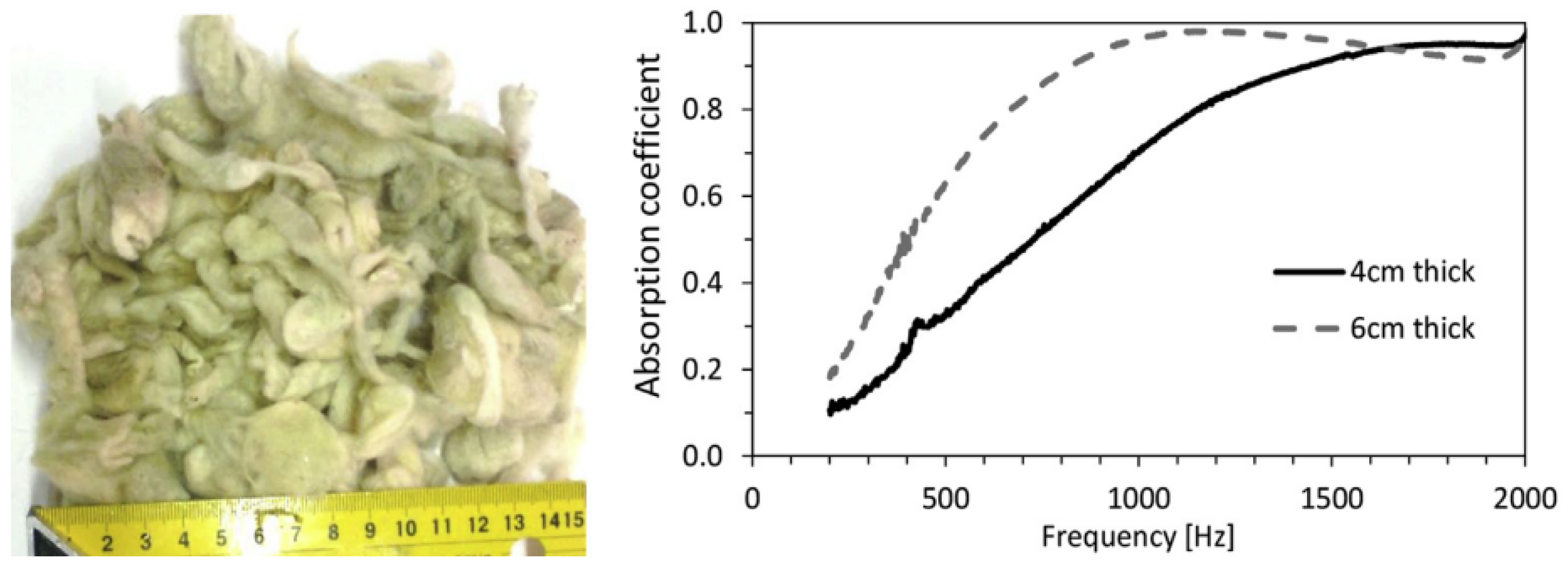

- Oldham, D.J.; Egan, C.A.; Cookson, R.D. Sustainable Acoustic Absorbers from the Biomass.pdf. 2011. Available online: https://www.researchgate.net/publication/251448266_Sustainable_acoustic_absorbers_from_the_biomass (accessed on 12 April 2025).

- Mamtaz, H.; Fouladi, M.H.; Al-Atabi, M.; Namasivayam, S.N. Acoustic absorption of natural fiber composites. J. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Hajj, N.E.; Mboumba-Mamboundou, B.; Dheilly, R.M.; Aboura, Z.; Benzeggagh, M.; Queneudec, M. Development of thermal insulating and sound absorbing agro-sourced materials from auto linked flax-tows. Ind. Crops Prod. 2011, 34, 921–928. [Google Scholar] [CrossRef]

- Raj, M.; Fatima, S.; Tandon, N. An experimental and theoretical study on environment-friendly sound absorber sourced from nettle fibers. J. Build. Eng. 2020, 31, 101395. [Google Scholar] [CrossRef]

- Martellotta, F.; Cannavale, A.; De Matteis, V.; Ayr, U. Sustainable sound absorbers obtained from olive pruning wastes and chitosan binder. Appl. Acoust. 2018, 141, 71–78. [Google Scholar] [CrossRef]

- Liang, M.; Wu, H.; Liu, J.; Shen, Y.; Wu, G. Improved sound absorption performance of synthetic fiber materials for industrial noise reduction: A review. J. Porous Mater. 2022, 29, 869–892. [Google Scholar] [CrossRef]

- Sejdinović, B. Modern thermal insulation and sound insulation materials. In Proceedings of the International Symposium on Innovative and Interdisciplinary Applications of Advanced Technologies; Springer: Berlin/Heidelberg, Germany, 2022; pp. 218–233. [Google Scholar]

- Kanta Mahapatra, T.; Satapathy, S.; Kumar Panda, S. Thermal and acoustic properties evaluation of waste tire and textile reinforced epoxy composites. Mater. Today Proc. 2022, 62, 5982–5986. [Google Scholar] [CrossRef]

- Stoleriu, S.; Vlasceanu, I.; Dima, C.; Badanoiu, A.; Voicu, G. Alkali activated materials based on glass waste and slag for thermal and acoustic insulation. Mater. Construcción 2019, 69, e194. [Google Scholar] [CrossRef]

- Stolz, J.; Boluk, Y.; Bindiganavile, V. Wood ash as a supplementary cementing material in foams for thermal and acoustic insulation. Constr. Build. Mater. 2019, 215, 104–113. [Google Scholar] [CrossRef]

- Koh, H.W.; Le, D.K.; Ng, G.N.; Zhang, X.; Phan-Thien, N.; Kureemun, U.; Duong, H.M. Advanced recycled polyethylene terephthalate aerogels from plastic waste for acoustic and thermal insulation applications. Gels 2018, 4, 43. [Google Scholar] [CrossRef]

- Escobar, V.G.; González, C.M.; Gozalo, G.R. Analysis of the influence of thickness and density on acoustic absorption of materials made from used cigarette butts. Materials 2021, 14, 4524. [Google Scholar] [CrossRef] [PubMed]

- Methacanon, P.; Weerawatsophon, U.; Sumransin, N.; Prahsarn, C.; Bergado, D.T. Properties and potential application of the selected natural fibers as limited life geotextiles. Carbohydr. Polym. 2010, 82, 1090–1096. [Google Scholar] [CrossRef]

- Carvalho, R.; Fangueiro, R.; Neves, J. Durability of natural fibers for geotechnical engineering. Key Eng. Mater. 2015, 634, 447–454. [Google Scholar] [CrossRef]

- Bello, C.B.d.C.; Cecchi, A. Experiments on natural fibers: Durability and mechanical properties. Adv. Mater. Process. Technol. 2017, 3, 632–639. [Google Scholar] [CrossRef]

- Trindade, A.; Silva, F.; Alcamand, H.; Borges, P. On the durability behavior of natural fiber reinforced geopolymers. In Proceedings of the 41st International Conference on Advanced Ceramics and Composites: Ceramic Engineering and Science Proceedings; Wiley: Hoboken, NJ, USA, 2018; Volume 38, pp. 215–228. [Google Scholar]

- Yeh, S.K.; Hu, C.R.; Rizkiana, M.B.; Kuo, C.H. Effect of fiber size, cyclic moisture absorption and fungal decay on the durability of natural fiber composites. Constr. Build. Mater. 2021, 286, 122819. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Antico, F.; Carrasco, M.; Rojas, P.; García-Herrera, C. Effectiveness of new natural fibers on damage-mechanical performance of mortar. Constr. Build. Mater. 2017, 152, 672–682. [Google Scholar] [CrossRef]

- Demircan, R.K.; Tayeh, B.A.; Celik, D.N.; Kaplan, G.; Tobbala, D.E. The effect of animal and synthetic fibers on the physico-mechanical durability and microstructure properties of natural hydraulic lime-based mortars. Mater. Today Commun. 2023, 35, 106041. [Google Scholar] [CrossRef]

- Wang, Z.; Geng, L.; Zhao, J.; Qiao, W.; Liu, C. Comprehensive Utilization of Fossil Energy: Fabrication of Fire-Retardant Building Materials from Waste Plastic. J. Compos. Sci. 2024, 8, 266. [Google Scholar] [CrossRef]

- Mohd Sabee, M.M.S.; Itam, Z.; Beddu, S.; Zahari, N.M.; Mohd Kamal, N.L.; Mohamad, D.; Zulkepli, N.A.; Shafiq, M.D.; Abdul Hamid, Z.A. Flame Retardant Coatings: Additives, Binders, and Fillers. Polymers 2022, 14, 2911. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Liang, J.; Lin, X.; Lin, H.; Yu, J.; Wang, S. The Flame-Retardant Mechanisms and Preparation of Polymer Composites and Their Potential Application in Construction Engineering. Polymers 2021, 14, 82. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.; Sanjayan, J.G.; Memon, R.A. Comparative analysis of building insulation material properties and performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Schiavoni, S.; D’Alessandro, F.; Bianchi, F.; Asdrubali, F. Insulation materials for the building sector: A review and comparative analysis. Renew. Sustain. Energy Rev. 2016, 62, 988–1011. [Google Scholar] [CrossRef]

- Hill, C.; Norton, A.; Dibdiakova, J. A comparison of the environmental impacts of different categories of insulation materials. Energy Build. 2018, 162, 12–20. [Google Scholar] [CrossRef]

- Yuan, J. Impact of insulation type and thickness on the dynamic thermal characteristics of an external wall structure. Sustainability 2018, 10, 2835. [Google Scholar] [CrossRef]

- Bademlioğlu, A.; Kaynaklı, Ö.; Yamankaradeniz, N. The effect of water vapor diffusion resistance factor of insulation materials for outer walls on condensation. Isı Bilimi ve Tekniği Dergisi 2018, 38, 15–23. [Google Scholar]

- Li, T.T.; Chuang, Y.C.; Huang, C.H.; Lou, C.W.; Lin, J.H. Applying vermiculite and perlite fillers to sound-absorbing/thermal-insulating resilient PU foam composites. Fibers Polym. 2015, 16, 691–698. [Google Scholar] [CrossRef]

- Ibrahim, M.; Melik, R. Optimized sound absorption of a rigid polyurethane foam. Arch. Acoust. 2003, 28. [Google Scholar]

- König, J.; Nemanič, V.; Žumer, M.; Petersen, R.R.; Østergaard, M.B.; Yue, Y.; Suvorov, D. Evaluation of the contributions to the effective thermal conductivity of an open-porous-type foamed glass. Constr. Build. Mater. 2019, 214, 337–343. [Google Scholar] [CrossRef]

- Owoeye, S.S.; Matthew, G.O.; Ovienmhanda, F.O.; Tunmilayo, S.O. Preparation and characterization of foam glass from waste container glasses and water glass for application in thermal insulations. Ceram. Int. 2020, 46, 11770–11775. [Google Scholar] [CrossRef]

- Peletskii, V.; Shur, B. Experimental study of the thermal conductivity of heat insulation materials based on expanded vermiculite. Refract. Ind. Ceram. 2007, 48, 356–358. [Google Scholar] [CrossRef]

- Carbajo, J.; Esquerdo-Lloret, T.V.; Ramis-Soriano, J.; Nadal-Gisbert, A.V.; Denia, F.D. Acoustic properties of porous concrete made from arlite and vermiculite lightweight aggregates. Mater. Construcción 2015, 65, 8. [Google Scholar] [CrossRef]

- Tingley, D.D.; Hathway, A.; Davison, B.; Allwood, D. The environmental impact of phenolic foam insulation boards. Proc. Inst. Civ.-Eng.-Constr. Mater. 2017, 170, 91–103. [Google Scholar] [CrossRef]

- Tutikian, B.; Nunes, M.; Leal, L.; Marquetto, L. Impact sound insulation of lightweight concrete floor with EVA waste. Build. Acoust. 2012, 19, 75–88. [Google Scholar] [CrossRef]

- Yao, R.; Yao, Z.; Zhou, J.; Liu, P.; Lei, Y. Mechanical, thermal and acoustic properties of open-pore phenolic multi-structured cryogel. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 229, p. 012034. [Google Scholar]

- Sierra-Pérez, J.; García-Pérez, S.; Blanc, S.; Boschmonart-Rives, J.; Gabarrell, X. The use of forest-based materials for the efficient energy of cities: Environmental and economic implications of cork as insulation material. Sustain. Cities Soc. 2018, 37, 628–636. [Google Scholar] [CrossRef]

- Silvestre, J.D.; Pargana, N.; De Brito, J.; Pinheiro, M.D.; Durão, V. Insulation cork boards—Environmental life cycle assessment of an organic construction material. Materials 2016, 9, 394. [Google Scholar] [CrossRef]

- Hurtado, P.L.; Rouilly, A.; Vandenbossche, V.; Raynaud, C. A review on the properties of cellulose fibre insulation. Build. Environ. 2016, 96, 170–177. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Grillet, A.C.; Diep, T.M.H.; Thuc, C.N.H.; Woloszyn, M. Hygrothermal properties of bio-insulation building materials based on bamboo fibers and bio-glues. Constr. Build. Mater. 2017, 155, 852–866. [Google Scholar] [CrossRef]

- Khair, F.A.; Putra, A.; Mohd Nor, M.J.; Atiqah, N.; Selamat, M.Z. Preliminary study on bamboo as sound absorber. Appl. Mech. Mater. 2014, 554, 76–80. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Krishnaraj, V.; Senthil kumar, M.; Zitoune, R. Sound and vibration damping properties of flax fiber reinforced composites. Procedia Eng. 2014, 97, 573–581. [Google Scholar] [CrossRef]

- Sánchez, G.; Lopez, R.; Osorio, A.; Arroyo, E. Fique as thermal insulation morphologic and thermal characterization of fique fibers. Cogent Eng. 2019, 6, 1579427. [Google Scholar] [CrossRef]

- Vaitkus, S.; Karpavičiūtė, R.; Vėjelis, S.; Lekūnaitė, L. Development and research of thermal insulation materials from natural fibres. Key Eng. Mater. 2014, 604, 285–288. [Google Scholar] [CrossRef]

- Brzyski, P.; Barnat-Hunek, D.; Suchorab, Z.; Łagód, G. Composite materials based on hemp and flax for low-energy buildings. Materials 2017, 10, 510. [Google Scholar] [CrossRef]

- Lekavicius, V.; Shipkovs, P.; Ivanovs, S.; Rucins, A. Thermo-insulation properties of hemp-based products. Latv. J. Phys. Tech. Sci. 2015, 52, 38. [Google Scholar] [CrossRef]

- Gardner, L.; Munro, T.; Villarreal, E.; Harris, K.; Fronk, T.; Ban, H. Thermal characterization of alkali treated kenaf fibers and kenaf-epoxy composites. Fibers Polym. 2018, 19, 393–402. [Google Scholar] [CrossRef]

- Ardente, F.; Beccali, M.; Cellura, M.; Mistretta, M. Building energy performance: A LCA case study of kenaf-fibres insulation board. Energy Build. 2008, 40, 1–10. [Google Scholar] [CrossRef]

- Lee, C.; Salit, M.S.; Hassan, M. A review of the flammability factors of kenaf and allied fibre reinforced polymer composites. Adv. Mater. Sci. Eng. 2014, 2014, 514036. [Google Scholar] [CrossRef]

- Guillou, J.; Lavadiya, D.N.; Munro, T.; Fronk, T.; Ban, H. From lignocellulose to biocomposite: Multi-level modelling and experimental investigation of the thermal properties of kenaf fiber reinforced composites based on constituent materials. Appl. Therm. Eng. 2018, 128, 1372–1381. [Google Scholar] [CrossRef]

- da Silva, C.C.B.; Terashima, F.J.H.; Barbieri, N.; de Lima, K.F. Sound absorption coefficient assessment of sisal, coconut husk and sugar cane fibers for low frequencies based on three different methods. Appl. Acoust. 2019, 156, 92–100. [Google Scholar] [CrossRef]

- Asdrubali, F.; Bianchi, F.; Cotana, F.; D’Alessandro, F.; Pertosa, M.; Pisello, A.; Schiavoni, S. Experimental thermo-acoustic characterization of innovative common reed bio-based panels for building envelope. Build. Environ. 2016, 102, 217–229. [Google Scholar] [CrossRef]

- Miljan, M.; Miljan, J. Thermal transmittance and the embodied energy of timber frame lightweight walls insulated with straw and reed. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2015; Volume 96, p. 012076. [Google Scholar]

- Mati-Baouche, N.; de Baynast, H.; Michaud, P.; Dupont, T.; Leclaire, P. Sound absorption properties of a sunflower composite made from crushed stem particles and from chitosan bio-binder. Appl. Acoust. 2016, 111, 179–187. [Google Scholar] [CrossRef]

- Lenormand, H.; Glé, P.; Leblanc, N. Investigation of the acoustical and thermal properties of sunflower particleboards. Acta Acust. United Acust. 2017, 103, 149–157. [Google Scholar] [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: Elaboration and performances evaluation. Ind. Crops Prod. 2019, 135, 238–245. [Google Scholar] [CrossRef]

- Rojas, C.; Osorio, J.D.; Naranjo, Y.K.; González, C.; Rodríguez, D.F. Thermal insulation materials based on agricultural residual wheat straw and corn husk biomass, for application in sustainable buildings. Sustain. Mater. Technol. 2019, 20, e00102. [Google Scholar] [CrossRef]

- Ahn, E.; Yeom, D.; Lee, K.I. Experimental research on the indoor environment performance of complex natural insulation material: Carbonized rice hull and rice hull. J. Asian Archit. Build. Eng. 2017, 16, 239–246. [Google Scholar] [CrossRef][Green Version]

- Robin, O.; Berry, A.; Doutres, O.; Atalla, N. Measurement of the absorption coefficient of sound absorbing materials under a synthesized diffuse acoustic field. J. Acoust. Soc. Am. 2014, 136, EL13–EL19. [Google Scholar] [CrossRef]

- Panyakaew, S.; Fotios, S. New thermal insulation boards made from coconut husk and bagasse. Energy Build. 2011, 43, 1732–1739. [Google Scholar] [CrossRef]

- Luamkanchanaphan, T.; Chotikaprakhan, S.; Jarusombati, S. A Study of Physical, Mechanical and Thermal Properties for Thermal Insulation from Narrow-leaved Cattail Fibers. APCBEE Procedia 2012, 1, 46–52. [Google Scholar] [CrossRef]

- Agoudjil, B.; Benchabane, A.; Boudenne, A.; Ibos, L.; Fois, M. Renewable materials to reduce building heat loss: Characterization of date palm wood. Energy Build. 2011, 43, 491–497. [Google Scholar] [CrossRef]

- Gezer, E.D.; Kuştaş, S. Acoustic and thermal properties of mycelium-based insulation materials produced from desilicated wheat straw—Part B. BioResources 2024, 19, 1348. [Google Scholar] [CrossRef]

| NM Type | Fiber | Matrix | Fiber Weight Ratio (%) | Bulk Density (kg/m3) | Thermal Conductivity (W/mK) | Test Method | Ref. |

|---|---|---|---|---|---|---|---|

| Fruit | Fig Stem | Cardboard | 40 | 343.8 | 0.100 | Hot plate | [79] |

| Fig Stem | Binderless | 100 | 157 | 0.072 | Guarded hot plate | [81] | |

| Banana Stem | Polyvinyl alcohol, Carboxymethyl cellulose, glutaraldehyde | 60 | 0.043 | 0.036 | Tci Thermal Conductivity Analyzer | [104] | |

| Luffa | Clay | 59 | 397.6 | 0.101–0.116 | Heat flow meter (ISO 8301, DIN EN 1946-3) | [88,105,106] | |

| Date Palm Wood | Polylactic acid | 30 | 1200 (approx.) | 0.069 | Thermal conductivity meter (ASTM C1045-07) | [71,107] | |

| Date Palm Leaflet | Cement, sand, gypsum | 30 | 42.6 | 0.048 | Cold and hot plate (DIN 52612) | [108,109] | |

| Date Palm Surface Fibers | PVA | 203 | 0.038 | ASTM C 1045-07 | [107,110] | ||

| Date Palm Surface Fibers | Polystyrene | 60 | 937 | 0.053 | ASTM C 1045-19 | [72] | |

| Date Palm Components | Cardboard | 40 | 226.6–312.8 | 0.074–0.081 | Hot plane | [111] | |

| Grass | Corn Cobs | Binderless | 100 | 195 | 0.14 | Movable hot box | [82] |

| Corn Husk | PVA | 200 | 0.0386 | Guarded hot plate ASTM C177-85 | [112,113] | ||

| Miscanthus | Cement | 30 (vol.) | 554 | 0.09 | [76] | ||

| Furcraea foetida | Lapox L12 Epoxy, hardener K6 | 20 | 720 | 0.132 | Guarded hot plate ASTM C177-19 | [77] | |

| Cement | 0.374–0.513 | ||||||

| Gypsum | 0.269–0.389 | ||||||

| Wood | Wood waste | 117 | 0.048–0.055 | Hot plate | [83] | ||

| Bast Fibers | Hemp Shives | Potato starch | 208 | 0.062 | [86] | ||

| Flax Shives | Potato starch | 215 | 0.053 | ||||

| Stalk Fibers | Triticale Straw | pMDI glue | 90 | 200 | 0.033 | [114] | |

| Other plant fibers | Olive Leaves | Cardboard | 40 | 315.1 | 0.086 | Hot plate ASTM E1461-13 | [79,115] |

| Sunflower Straw | 155 | 0.0469 | Thermal constant analyzer | [116] | |||

| Rice Husk Ash | 0.477–0.571 | Transient heat conduction | [24] | ||||

| Animal | Chicken Feather | Polypropylene | 70 | 0.059 | JIS 1412-2 | [117,118] | |

| Turkey Feather | Polyurethane foam | 3 | 39 (approx.) | 0.0291 | ASTM C518 | [119,120] | |

| Sheep Wool | 100 | 235 | 0.0322 | Guarded hot plate ASTM C177 | [121,122] | ||

| Others | Spent Mushroom Substrate | 100 | 800 | 0.231 | [103] | ||

| Coal Fly Ash | PVA | 1.25–5 | 100–190 | 0.042–0.050 | Thermal conductivity analyzer | [102] | |

| Coal Fly Ash | Gypsum | 60 | 850 | 0.325 (approx.) | Hot wire method (EN 99315, 1998) | [123,124] | |

| Coal Fly Ash | Borax, calcium carbonate | 40 | 460 | 0.36 | Thermal analyzer | [125] |

| Fiber | Matrix | Fiber Weight Ratio (%) | Bulk Density (kg/m3) | Thermal Conductivity (W/mK) | Test Method | Ref. |

|---|---|---|---|---|---|---|

| Cellulose acetate plastic (cigarette butt waste) | gypsum | 1.5 | 994–1006 | 0.017–0.024 | A heat insulation house | [25] |

| Car shredded tire residue | Polyurethane | 50 | 40 | 0.034 | ISO 8302:1991 and BS 1902-5.8 standards | [26,127,128] |

| Carpet tiles shred | polyurethane | 90 | 366 | 0.06 | ||

| Loose-fill plastic waste | 100 | 56 | 0.022–0.032 | [27] | ||

| Microplastics | Alginate, Glycerol, CaCO3, D-gluconic acid -lactone (GDL) | 69.6–148.8 | 0.043–0.048 | Heat flow meter according to ASTM C518 | [119,129] | |

| Polypropylene face masks | Serishoom glue | 60–100 | 0.029 | Guarded hot plate ASTM C177-85 | [112,130] | |

| Nylon/Spandex and polyurethane | 60 | 1060 | 0.0953 | Guarded hot ASTM C177 | [122,131] | |

| Blast furnace slag (BSF), waste photovoltaic glass (WPG), rice husk ash (RHA), and plant ash (PA) | 0.0497–0.0581 | [31] | ||||

| Phosphate washing sludge and metakaolin | 50 | 1627 | 0.076 | ASTM C177 | [122,132] | |

| Fiberglass scraps | Alginate, CaCO3, D-gluconic acid -lactone (GDL) | 12.5 | 240–320 | 0.041–0.069 | ASTM C518 | [28,119] |

| Marble waste powder and rice husk ash | 0.477–0.571 | Transient heat conduction | [24] | |||

| Acrylic spinning waste | 100 | 25 | 0.04541 | [29] | ||

| Acrylic knitting waste | 100 | 30 | 0.04581 | |||

| Washed wool waste | 100 | 62 | 0.03745 | |||

| Carpet waste wool | 100 | 45 | 0.04076 | |||

| Ceramic shell waste | Styrofoam | 30 | 0.061 | ASTM D7984-16 | [30,133] |

| Natural Material Type | Material | Thickness (mm) | Density (Kg/m3) | Maximum SAC | Frequency (Hz) | Ref. |

|---|---|---|---|---|---|---|

| Fruit | Date palm empty fruit bunches (DPEFB) | 40 | 200 | 0.7–0.8 | Above 1500 | [151] |

| Luffa | 40 | 225 | 0.95 | 1200 | [63] | |

| Bast Fiber | Hemp | 20 | 0.99 | 2000 | [152] | |

| Cotton fibers | 50 | 40.5 | 0.96 | 3150 | ||

| Jute fibers | 50 | 65.6 | 0.76 | 3150 | ||

| Sisal fibers | 50 | 38.6 | 0.42 | 3150 | [153] | |

| Flax fibers | 50 | 78.4 | 0.96 | 3150 | ||

| Bamboo fibers | 50 | 120 | 0.95 | 1600 | [154] | |

| Flax-tows | 50 | 180 | 0.8 | 3150 | [155] | |

| Nettle fibers | 56 | 0.98 | 3150 | [156] | ||

| Animal | Chicken feathers | 25, 50, and 75 | 48 | 0.99 | 1600, 950, 650 | [143] |

| Other | Fiberglass | 15 | 170& 320 | Noise-reducing factor between 0.25–0.45 | 3000 | [28] |

| Olive tree pruning wastes | 50 | 0.9 | [157] | |||

| Salk Fiber | Rice straw | 18 | 0.05–0.06 g/cm3 | 0.99 | 3000 | [91] |

| Material | Thickness (mm) | Density (Kg/m3) | Maximum SAC | Frequency (Hz) | Methodology of Sample Preparation | Ref. |

|---|---|---|---|---|---|---|

| Waste tire and textile-reinforced epoxy composite | - | - | 0.61 | 3000–5000 |

| [160] |

| Cardboard waste and natural fibers | 80 | 278.6–343.8 | 0.6 | 200–1400 |

| [79] |

| Glass powder and slag mixtures | 0.98 | 1200–1500 |

| [161] | ||

| Wood ash was used as supplementary cementing material | - | 1000–1400 | High sound absorption at very low frequency and very high frequency (max absorption 0.7 at 125 Hz) | 250–2000 |

| [162] |

| Plastic waste | 30 | NRC = 0.45 | 2000–2500 |

| [163] | |

| Cigarette butts | 9.5, 19, 28, 38, 57, 67, 75, and 85 | 110–160 | 0.99 for 19 mm | 50–1450 |

| [164] |

| Natural Fibers | Testing Type | Testing Result | Ref. |

|---|---|---|---|

| Sisal, coir, banana fibers | UV rays heat moisture |

| [166] |

| Water hyacinth, reed, sisal, roselle | Moisture absorption |

| [165] |

| Tensile strengths and elongations |

| ||

| Accelerated weathering |

| ||

| Ramie, Jute, hemp, sisal wires | Alkaline sensitivity for plant fibers into cementitious composites |

| [167] |

| Silica Fume (SF), metakaolin (MK), blast furnace slag (BFS) | Compression |

| [168] |

| Tensile |

| ||

| Flexural loading |

| ||

| Wood flour | Moisture absorption |

| [169] |

| Pig hair | Compressive and flexural strength |

| [170] |

| Horsehair (HH), polypropylene (PF), carbon (CF), basalt (BF), glass fibers (GFs) | Dry bulk density and water absorption |

| [171] |

| Compressive strength |

| ||

| Flexural strength |

|

| Insulation Type | Density (kg/m3) | Thermal Conductivity (W/m·K) | SAC | Reaction to Fire | EC (kg CO2-eq/kg) | Ref. |

|---|---|---|---|---|---|---|

| Glass wool | 10–100 | 0.03–0.05 | 0.45–0.8 | A1 | 1.24 | [135,177,178,179] |

| Rock wool | 40–200 | 0.033–0.04 | 0.29–0.9 | A1–A2 | 1.05 | [12,135,177,178] |

| EPS | 18–50 | 0.029–0.041 | 0.22–0.365 | E | 6.3–7.3 | [12,135,177,178,180] |

| XPS | 32–40 | 0.032–0.037 | 0.2–0.65 | E | 7.55 | [12,177,178] |

| Polyurethane | 30–160 | 0.022–0.035 | 0.67 or 0.8 | D–F | 5.9 | [12,177,181,182] |

| Foamed glass | 100–200 | 0.038-0.055 | – | A1 | – | [183,184] |

| Vermiculite | 64–130 | 0.04-0.064 | 0.8 | A1 | – | [185,186] |

| Phenolic Foam | 40–160 | 0.018–0.024 | 0.3–0.5 | B–C | 4.15–7.21 | [187,188,189] |

| Cork | 100–120 | 0.037–0.043 | 0.39–0.85 | E | 0.82 | [190,191] |

| Cellulose | 30–80 | 0.037–0.042 | 0.53–0.9 | B–C–E | 0.31–1.83 | [135,192] |

| Bamboo fibers | 431–538 | 0.077–0.088 | 0.2–0.56 | – | – | [193,194] |

| Flax | 20–100 | 0.033–0.09 | 0.54–0.84 | C | 20 | [195,196,197] |

| Hemp | 25–100 | 0.039–0.123 | 0.52–0.6 | E | 0.14 | [148,198,199] |

| Kenaf | 30–180 | 0.026–0.044 | 0.3–0.95 | E | 0.59–2.09 | [139,148,200,201,202,203] |

| sisal | 200 | 0.042–0.044 | 0.16–0.5 | - | - | [204] |

| Reeds | 130–190 | 0.045–0.056 | 0.08–0.54 | E | – | [205,206] |

| Sunflower | 36–152 | 0.038–0.05 | 0.7 | – | 0.56 | [177,207,208] |

| Rice husk | 130–170 | 0.048–0.08 | 0.15–0.66 | A | 0.6 | [209,210,211] |

| Coconut husk | 250–350 | 0.045–0.069 | 0.16–0.52 | - | – | [204] |

| Bagasse | 250–350 | 0.049–0.055 | 0.46–0.71 | – | – | [212,213] |

| Date palm | 187–389 | 0.072–0.085 | 0.59–0.83 | – | – | [214,215] |

| Jute fibre | – | 0.033–0.046 | 0.54–0.72 | – | - | [177] |

| Sheep wool | 20–40 | 0.034–0.050 | 0.082–0.977 | E | 0.12 | [96] |

| mycelium | 87–112 | 0.047–0.05 | 0.87–0.9 | D–E | - | [216] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouda, M.; Abu Sanad, A.A.; Abdelaal, A.; Krishna, A.; Kandah, M.; Kurdi, J. A Comprehensive Review of Sustainable Thermal and Acoustic Insulation Materials from Various Waste Sources. Buildings 2025, 15, 2876. https://doi.org/10.3390/buildings15162876

Ouda M, Abu Sanad AA, Abdelaal A, Krishna A, Kandah M, Kurdi J. A Comprehensive Review of Sustainable Thermal and Acoustic Insulation Materials from Various Waste Sources. Buildings. 2025; 15(16):2876. https://doi.org/10.3390/buildings15162876

Chicago/Turabian StyleOuda, Mohamed, Ala A. Abu Sanad, Ali Abdelaal, Aparna Krishna, Munther Kandah, and Jamal Kurdi. 2025. "A Comprehensive Review of Sustainable Thermal and Acoustic Insulation Materials from Various Waste Sources" Buildings 15, no. 16: 2876. https://doi.org/10.3390/buildings15162876

APA StyleOuda, M., Abu Sanad, A. A., Abdelaal, A., Krishna, A., Kandah, M., & Kurdi, J. (2025). A Comprehensive Review of Sustainable Thermal and Acoustic Insulation Materials from Various Waste Sources. Buildings, 15(16), 2876. https://doi.org/10.3390/buildings15162876