1. Introduction

Increasing energy efficiency requirements in the construction sector encouraged the adoption of advanced insulation materials with lower thermal conductivity as alternatives to conventional systems. In this context, vacuum insulated panels (VIPs) offer 10–20 times higher insulation performance compared to traditional polyurethane-based systems, thanks to the extremely low thermal conductivity achieved by maintaining their core materials under vacuum. Owing to these superior properties, VIPs are used across a broad range of applications, from energy-efficient cooling systems to sustainable building design.

The application of VIP technology in building insulation dates back to the 1980s, when the first evaluations of their service life were initiated. Since then, VIPs have been extensively studied as insulation materials in both new and renovated buildings, where they demonstrated excellent thermal performance [

1].

The core materials of VIPs typically consist of glass fiber or fumed silica, enclosed within laminated barrier films and hermetically sealed under vacuum. The thermal insulation properties of porous materials under vacuum, including glass fiber, have been experimentally investigated, revealing that gas pressure and pore size significantly influence heat transfer through the panel [

2,

3,

4].

Maintaining a low internal pressure is essential for sustaining the insulation performance of VIPs. Over time, gas permeation, moisture ingress, and adsorption effects within the core material lead to an increase in internal pressure, resulting in a notable rise in the effective thermal conductivity (λ) of the panel [

5,

6]. Traditionally, this degradation has been monitored via periodic testing of panels placed in controlled laboratory vacuum chambers. However, such procedures are both costly and limited in applicability for field conditions.

To address long-term performance prediction, several studies proposed models that correlate effective thermal conductivity (λ) with internal gas pressure under vacuum conditions. These models successfully captured the behavior of different core compositions and examined how changes in material formulation influence thermal performance [

7]. Despite their accuracy, widespread application is constrained by the infrastructure requirements and time-consuming nature of conventional testing methods.

As a result, there is a growing need for low-cost, in situ measurement systems capable of collecting real-time data in the field, especially considering the increasing diversity in VIP manufacturing techniques, core materials, opacifier compositions, and novel formulations.

In this broader context, time and cost optimization have become more important in the development of field-deployable systems [

8]. Decision-making frameworks have also been proposed to support effective planning of sensor-based technologies under uncertainty [

9].

In this regard, direct monitoring of pressure changes within the panel presents a practical alternative for indirectly estimating thermal conductivity degradation over time.

Recent studies focused on validating theoretical models using sensor-integrated panels capable of collecting in situ measurements [

10]. Additionally, aging models developed for predicting the service life of VIPs emphasize the importance of getter material behavior under environmental temperature and humidity conditions, particularly in terms of gas adsorption–desorption balance [

11].

In this study, a novel measurement method is introduced based on embedded micro-electro-mechanical system (MEMS) sensors for monitoring internal pressure, temperature, and humidity variations in real time. The system is supported by wireless communication and intermittent energy transfer. Using this framework, machine learning-based curve fitting models are employed to estimate the time-dependent thermal conductivity of the VIPs.

Although numerous laboratory-based techniques have been developed for direct measurement of λ [

1], only a limited number of studies proposed low-cost, continuous in situ monitoring systems that operate in the field and produce synchronized data under real-life conditions.

While prior sensor-based studies provided valuable insights, often focusing on instantaneous state monitoring or the validation of physics-based models [

10,

11], the present study advances this field by introducing a holistic, data-driven methodology with several key innovations. First, it integrates machine learning by using the sensor data stream to directly train a predictive model, rather than to validate a pre-existing theoretical model. Second, the system′s primary output is a direct service life prediction, forecasting the time until a critical performance threshold is reached, moving beyond simple condition monitoring. Finally, the implementation of wireless power transfer enables a sustainable, battery-less design, which is crucial for the practical, long-term, and autonomous field monitoring of VIPs without compromising the panel′s hermetic seal for maintenance. This combination of features distinguishes our approach and offers a scalable solution for in situ performance assessment.

Therefore, the primary aim of this study is to develop a new monitoring methodology supported by passive and non-degrading sensor infrastructure that can directly track the temporal effects of production parameters, core material composition, and component variations on VIP performance, while demonstrating the field applicability of this approach.

2. Theoretical Model

In vacuum insulated panels (VIPs), the effective thermal conductivity (λ) is directly dependent on the internal pressure level. The total thermal conductivity of a panel is composed of three main components: solid conduction (λsolid), gas-phase conduction (λgas), and radiative conduction (λrad) [

1,

12,

13]:

Among these, gas-phase conductivity is especially sensitive to the vacuum level and increases nonlinearly with pressure. The gas conduction component is commonly modeled as follows [

1,

6]:

where

λ0: Thermal conductivity of the gas at atmospheric pressure (W/m·K)

p: Internal pressure inside the panel (Pa)

pref: Reference pressure corresponding to the mean free path of gas molecules.

Heat transfer in gas-filled porous insulation materials depends not only on pressure, but also on pore geometry and size distribution. This relationship has been experimentally verified in studies involving different fumed silica and glass fiber core materials [

2,

3]. Over time, the permeability of VIP barrier films increases, which significantly contributes to the internal pressure rise [

7,

14].

Equation (2) reflects the Knudsen effect, showing that at low pressure, molecular collisions decrease, resulting in reduced gas-phase conductivity [

13,

15].

Additionally, the total effective conductivity λ can be expressed by Fourier’s law of heat conduction:

where q represents the heat flux density (W/m

2) and ∇T is the temperature gradient (K/m). Equation (3) indicates that an increase in λ leads directly to higher heat transfer. Therefore, combining Equations (2) and (3) provides a quantifiable framework for understanding the impact of internal pressure increase.

Experimental studies have shown that such λ–

p relationships can be characterized for various core materials with different fiber and opacifier compositions [

5,

16].

In applications where high-temperature effects become significant, the radiative conduction component (λrad) must also be considered. Based on the Stefan–Boltzmann law, this component is defined as [

4]:

where

σ: Stefan–Boltzmann constant (5.67 × 10−8 W/m2·K4)

T: Absolute temperature (K)

β: Extinction coefficient of the material.

This component is particularly relevant in systems where thermal radiation cannot be neglected, as confirmed in various high-temperature VIP studies [

17].

In conclusion, internal pressure (

p), temperature (T), and relative humidity (RH) are the key variables for predicting the time-varying effective thermal conductivity of VIPs. In this study, the effective thermal conductivity over time is estimated using the following multivariable function:

This approach enables real-time, in-field monitoring of VIP performance changes, making it possible to evaluate degradation processes that were previously limited to laboratory environments [

10,

18,

19].

3. Materials and Methods

3.1. Conventional Measurement Techniques and Their Limitations

The thermal conductivity (λ) of vacuum insulated panels (VIPs) plays a central role in determining the energy efficiency of building materials. Over the years, numerous measurement techniques have been developed in the literature to assess this parameter with high precision. Typically, the thermal performance evaluation of VIPs is conducted under controlled laboratory conditions using specialized equipment. Early implementations of VIPs in buildings emphasized the criticality of such testing methods [

1,

12]. However, most conventional techniques require physical intervention in the structure of the panel to obtain accurate measurements. Among these, the guarded hot plate (GHP) method—recognized by ISO 8302 [

20]—is one of the most widely accepted reference methods. In this technique, the panel specimen is sandwiched between two temperature-controlled plates, and the heat flux is measured to calculate λ. While GHP offers high precision, it suffers from several drawbacks, including prolonged test durations, high equipment costs, and the risk of compromising panel integrity during testing. Its restriction to laboratory settings further limits its applicability in field-based performance assessments [

1,

13,

19].

An alternative method, the heat flow meter (HFM), provides faster results and is commonly used for quality control on production lines. This approach estimates thermal conductivity using heat flux sensors. However, HFM cannot match the accuracy of GHP, particularly in monitoring long-term performance degradation. Furthermore, it is not capable of capturing internal pressure shifts or gas permeation effects linked to aging [

1,

4].

Another approach is the transient plane source (TPS) method, a transient thermal measurement technique that relies on short-duration heat pulses to determine the thermal properties of a sample. The sensor functions both as a heater and a temperature detector. However, its accuracy is highly dependent on the homogeneity and thickness of the sample. For systems such as VIPs that exhibit extremely low λ values and operate under a high vacuum, environmental interferences may distort the measurements and reduce reliability. Moreover, the unsuitability of TPS sensors for vacuum conditions further limits its practical application to VIP analysis [

19,

20].

Surface-based measurement methods, such as the heat flux sensor (HFS) technique rely on temperature differences across the VIP surface to estimate λ indirectly. However, due to the multilayer structure of VIPs, factors such as internal pressure variations, core material density, and moisture ingress are not detectable using this method. As a result, the measurements may not accurately reflect the true thermal performance of the panel, making HFS a limited-value tool for VIP applications [

1,

4].

Although each of the above techniques offer value under certain conditions, they also share common limitations. Primarily, these methods are unable to provide real-time data and are not suitable for in-field monitoring. The requirement for laboratory infrastructure makes it difficult to evaluate systems operating under actual usage conditions. Additionally, some techniques may disrupt the structural integrity of the panel during measurement, thereby altering its natural behavior. A critical gap is the inability of these methods to track aging-related changes, limiting their usefulness in assessing long-term performance. Furthermore, the complexity and high cost of equipment also constrain widespread adoption.

To address this, indirect measurement strategies based on heat flux and temperature fluctuation monitoring have been proposed in the literature for long-term performance evaluation of VIPs [

21,

22]. However, these approaches often rely on extended laboratory testing under fixed environmental conditions, which do not reflect real-world variability. This limits their ability to offer comprehensive and continuous evaluations.

Some studies also introduced mass-balance-based predictive models for estimating VIP lifetime. These models simulate the evolution of internal pressure over time by balancing gas permeation, desorption, and the effect of getter materials [

10,

11,

23]. While insightful, such models depend on pre-defined parameters and steady-state assumptions, and they do not leverage real-time measurement data. Therefore, they may fail to accurately represent panel behavior under dynamic environmental conditions.

In light of these constraints, it is evident that novel monitoring approaches are needed—methods that provide practical, cost-effective, continuous in situ monitoring, and are capable of generating real-time data. The next section introduces the real-time integrated sensor-based thermal conductivity monitoring method (RISTCMM), which addresses these shortcomings through a holistic approach.

3.2. Experimental Setup and Panel Configuration

This study employed an experimental setup based on two identical vacuum insulated panels (VIPs) to validate the proposed real-time monitoring methodology. Both panels, manufactured by İzocam with a fumed silica core, were specifically produced to undergo accelerated aging, allowing for the observation of degradation within a condensed timeframe. The panels were configured with distinct roles:

Test panel (Panel 1): This panel was embedded with the integrated sensor module described in Section “Integration of Sensors into the VIP Panel”. Its primary purpose was to continuously collect real-time, hourly data of internal pressure, temperature, and humidity under ambient conditions. The data from this panel were used as the direct input for the machine learning model.

Control panel (Panel 2): This panel, identical in structure and material to the test panel but without any embedded sensors, served as the calibration reference. It was subjected to parallel aging, and its thermal conductivity (λ) was measured periodically using a conventional laboratory method (heat flow meter). Concurrently, its internal pressure was determined at each measurement point. This process allowed for the establishment of an empirical pressure–thermal conductivity (p-λ) relationship specific to the panel type used in this study.

This dual-panel approach ensures that the p-λ relationship used for converting the sensor data from Panel 1 into thermal conductivity values is not merely based on general literature, but is calibrated against the actual performance of an identical control panel, thereby strengthening the foundation of the lifetime prediction model.

3.2.1. Design and Structure of the Real-Time Integrated Sensor-Based Measurement System

This section describes the physical characteristics of the VIP panels used in the experimental study, along with details of sensor integration, data acquisition intervals, power transfer mechanisms, and the test setup.

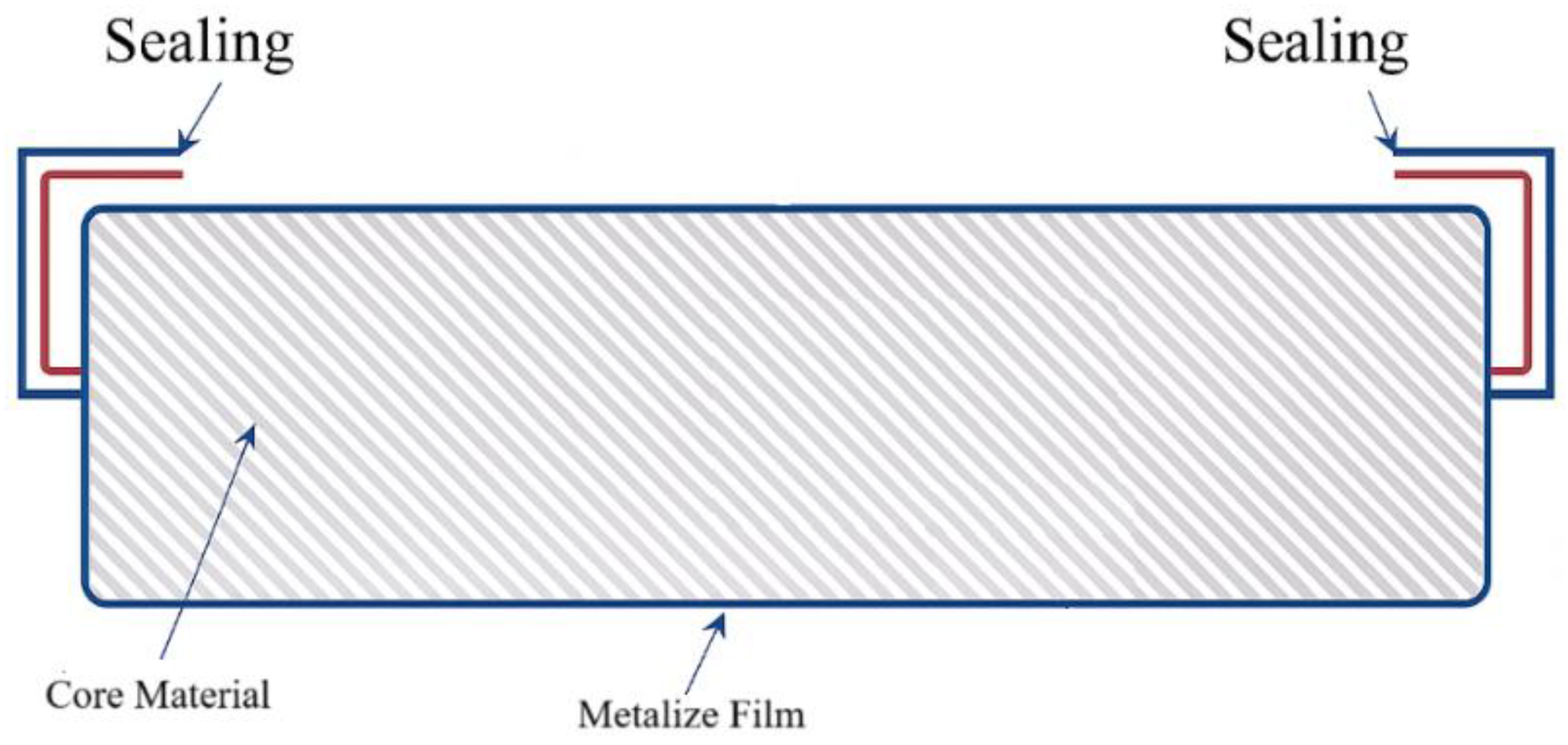

The integrated sensor system was embedded into the test panel (Panel 1), which was manufactured by İzocam and features a fumed silica core. The panel dimensions are 30 cm × 30 cm, and during production, its internal pressure was reduced below 0.1 Pa [

2]. The exterior surface of the panel is laminated with an aluminum-based reflective film, offering high thermal reflectance. Edge sealing is achieved through a multi-layer, heat-sealed barrier structure designed to minimize vacuum loss [

24,

25]. A schematic representation of this construction is provided in

Figure 1.

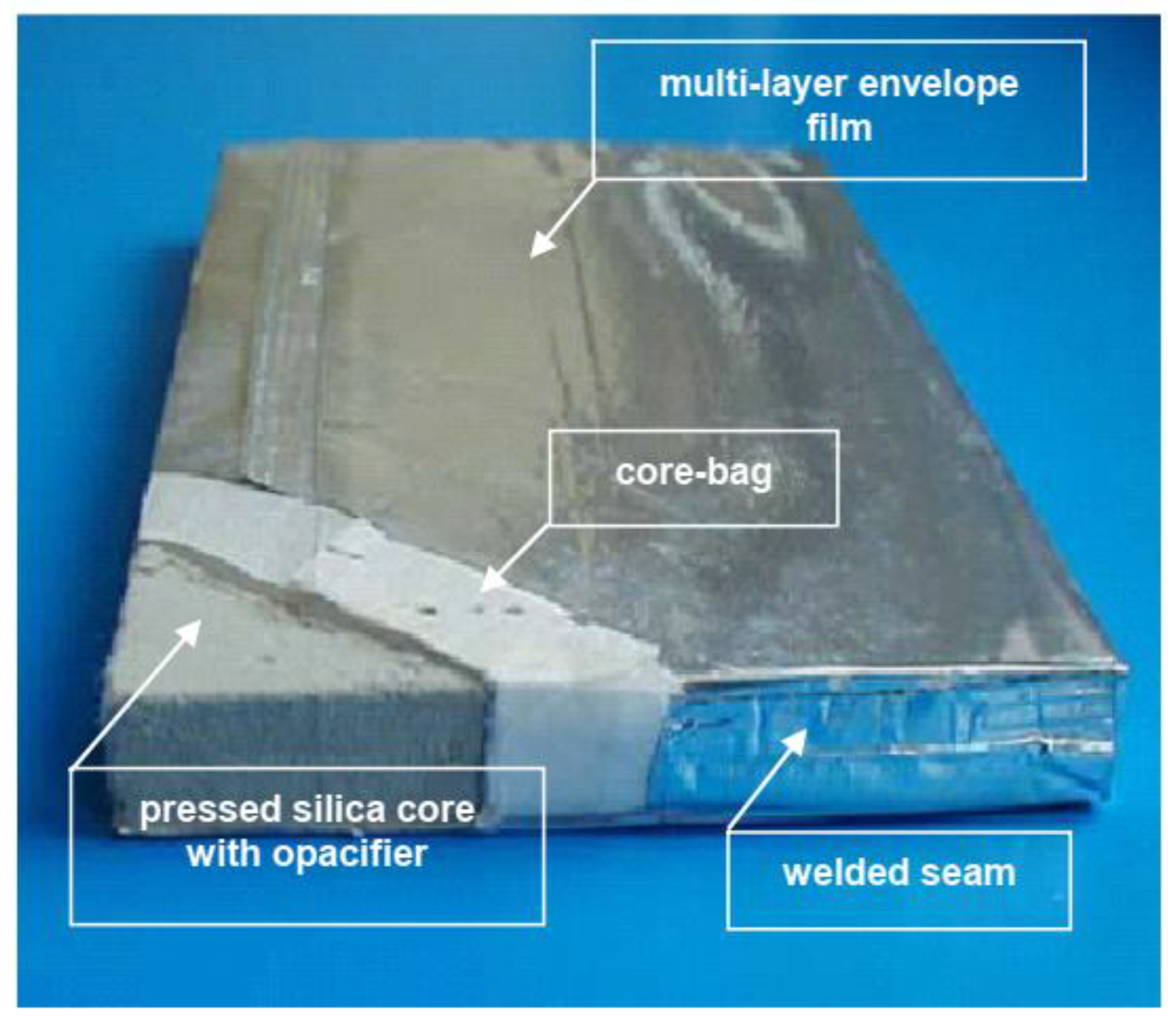

An actual image of the VIP panel used in the test is shown below, where the production date, batch code, and vacuum level are visibly marked (

Figure 2).

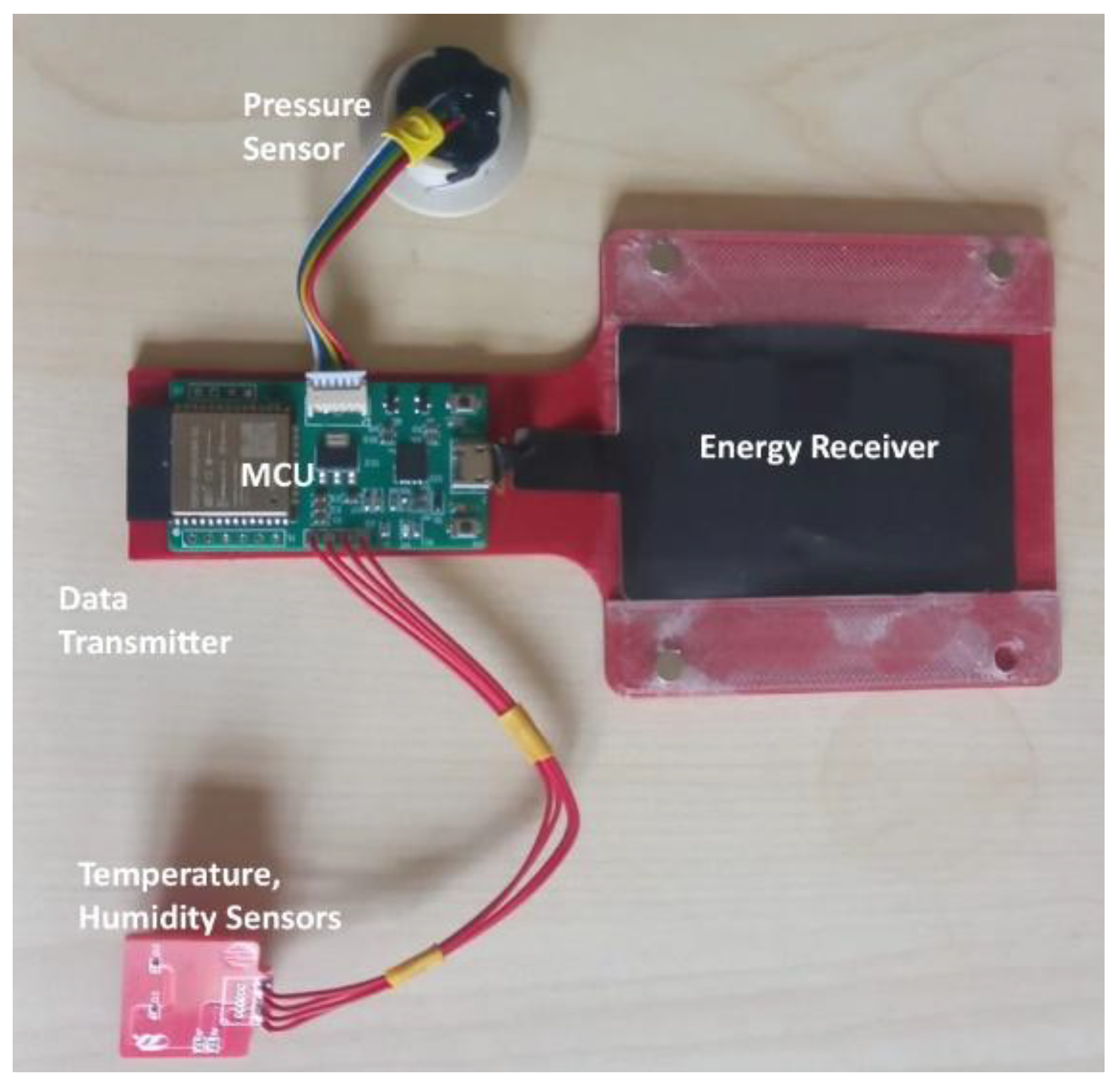

The sensor measurement system developed for this study is embedded inside the VIP and has been optimized to function reliably under low-pressure conditions. The system is composed of three main subsystems: a sensor module, a data processing and wireless communication module, and a power supply module.

The technical specifications of the selected sensors are tailored to reliably capture changes inside the panel. These sensors enhance the accuracy of the measurement circuit and contribute to long-term system stability. The PVC4000 pressure sensor operates in the range of 0.01 Pa to 100 kPa and offers a resolution of ±0.01 Pa. For temperature and humidity monitoring, the SHT45 sensor provides high precision, with ±0.1 °C temperature accuracy and ±0.5% RH humidity resolution.

3.2.2. Sensor, Data Processing, and Power Modules

The developed monitoring system consists of three primary subsystems: (1) the sensor module, (2) data processing and wireless communication unit, and (3) power transfer mechanism. Each subsystem has been optimized for seamless integration into VIPs and reliable long-term operation under low-pressure conditions.

The general block diagram of the integrated sensor measurement system is illustrated in

Figure 3.

Thanks to this embedded structure (

Figure 4), the internal pressure and environmental conditions of the vacuum panel can be monitored in real time, enabling the creation of a high-resolution dataset for long-term performance evaluation and degradation analysis.

3.3. Calibration and Measurement Method

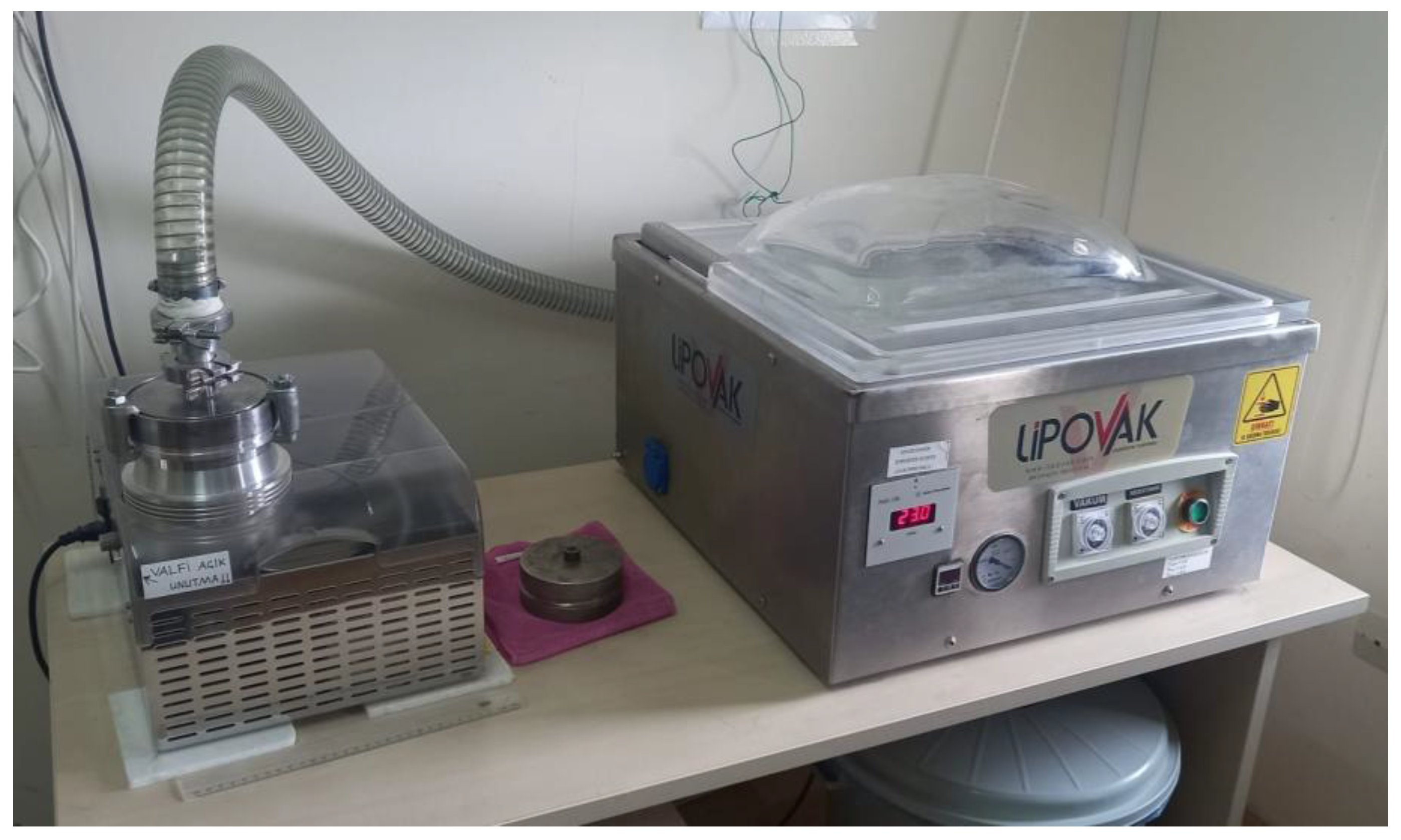

To ensure the accuracy and reliability of the embedded monitoring system developed for observing internal conditions within vacuum insulation panels (VIPs), all integrated sensors—namely pressure, temperature, and humidity—were individually calibrated prior to experimental deployment. This process was particularly critical for maintaining measurement precision in the low-pressure range.

The calibration of the PVC4000 pressure sensor was performed using a vacuum calibration system certified with traceable accuracy (

Figure 5).

The sensor circuit was powered by an external regulated source and placed directly inside the vacuum chamber. The calibration device was capable of generating pressures ranging from atmospheric level (~101,325 Pa) down to 0.001 Pa. During the calibration procedure, reference pressure values displayed on the device and the simultaneous digital outputs of the sensor were recorded. Based on this dataset, correction curves were developed to compensate for measurement deviations.

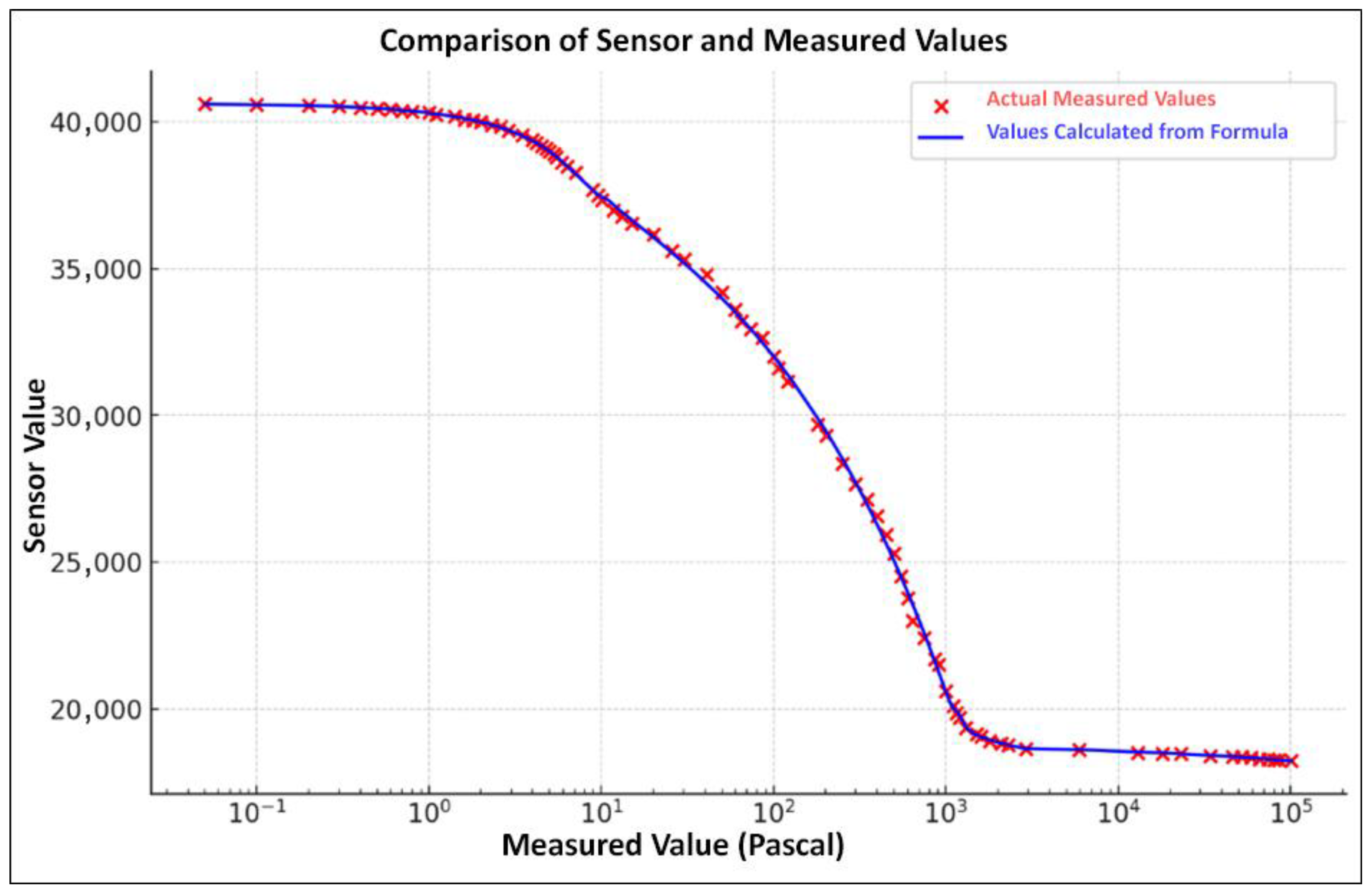

A graphical representation of the regression curves, including fitted equations and measured values, is shown in

Figure 6.

A detailed analysis of the calibration results indicated that the sensor provided high sensitivity and accuracy, particularly in the sub-100 Pa pressure region (

Figure 6). This level of precision makes it possible to monitor even minor internal pressure fluctuations occurring within VIPs over time.

The raw digital output data were grouped into specific pressure intervals, and a separate polynomial regression model was applied for each segment. The resulting conversion formulas are summarized in

Table 1 (the detailed polynomial equations for each segment are provided in

Appendix A).

These polynomials were determined separately for different digital output ranges, increasing the sensor’s accuracy rate to above 99%. As a result, the measurement system became capable of estimating the actual internal pressure of the VIP with high precision.

Similarly, the reliability of temperature and humidity measurements from the SHT45 sensor was verified based on the calibration data provided by the manufacturer, which enhanced the overall accuracy of the system.

This calibration process is critically important in terms of data reliability, which forms the foundation of the developed real-time integrated sensor-based measurement system, and represents a key step that supports the real-time monitoring capability of the system.

Integration of Sensors into the VIP Panel

The sensor measurement system, developed for integration into vacuum insulated panels, was embedded into the core of the test panel (Panel 1) in a manner that would not damage its physical integrity. This process was carefully designed to ensure reliable long-term monitoring of thermal performance in field applications.

In the initial step, a dedicated cavity was created inside the panel to accommodate the sensor system. This slot enabled both the integration and stabilization of the sensor circuit within the panel structure.

The sensor system was carefully placed into this cavity and covered with a permeable film to maintain direct contact with the internal environment. The sensor circuit was positioned directly within the core material of the panel, enabling measurement without compromising the panel’s physical integrity (

Figure 7).

In the final stage of integration, the sensor-containing structure was enclosed within a metallized lamination film with three sides pre-sealed. The final edge was sealed after the vacuuming process. This ensured airtightness and allowed the sensor system to be integrated without causing physical damage to the panel.

Following the placement of the system, the VIP was re-evacuated in accordance with its production procedure, and the integrated sensor system was confirmed to be fully operational (

Figure 8).

Additionally, the energy transfer unit was mounted on the exterior surface of the VIP, ensuring uninterrupted operation of the system (

Figure 9).

5. Lifetime Estimation of VIPs Based on Real-Time Measurement Data

The long-term performance prediction of vacuum insulated panels (VIPs) traditionally relied on prolonged laboratory tests conducted under controlled thermal conditions. However, such methods are often costly in terms of time and resources and are limited in their ability to reflect the dynamic environmental variations encountered in real-world applications [

1,

4].

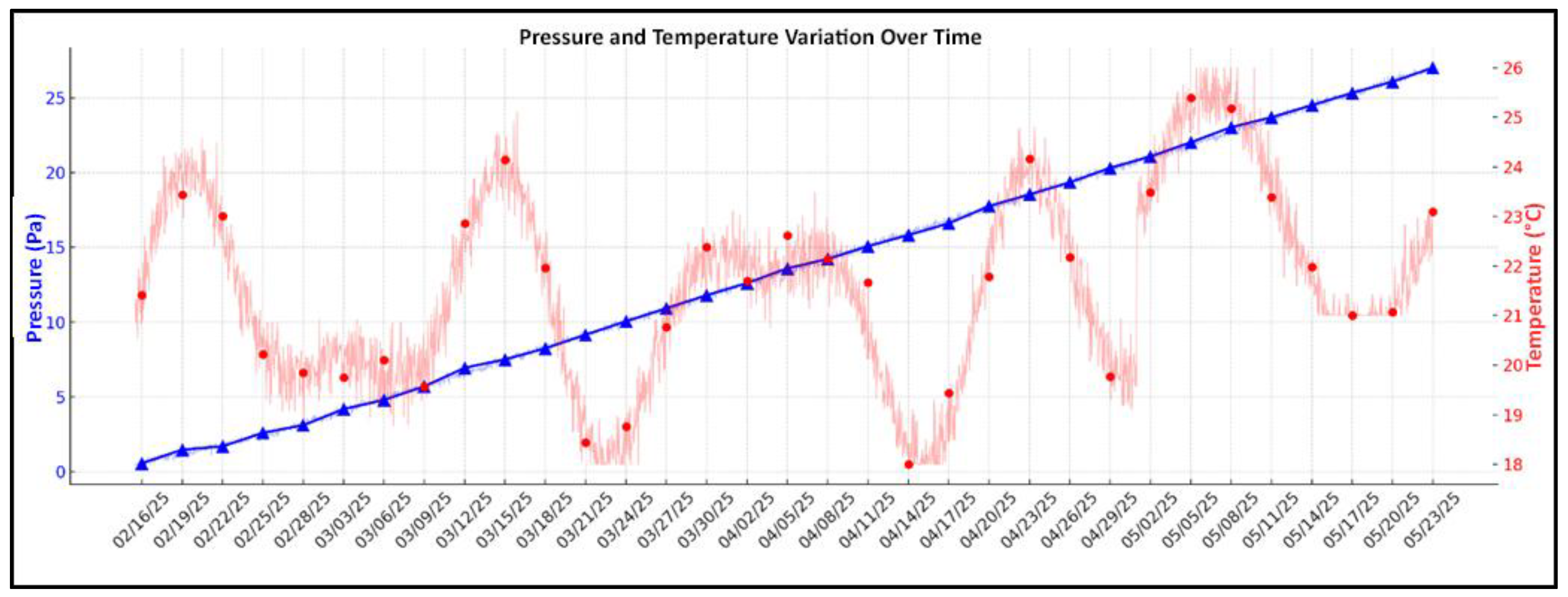

In this study, real-time pressure and temperature data collected via an embedded sensor module were used to track the time-dependent thermal conductivity curve of the VIP. A machine learning-based regression model was then employed to directly estimate the panel’s service life. This approach eliminates the need for conventional laboratory testing and enables in situ lifetime prediction based on continuous monitoring.

5.1. Lifetime Estimation Using Machine Learning

To predict panel lifespan, the temporal evolution of thermal conductivity (λ) was analyzed using a regression-based machine learning model. The goal was to estimate the time at which λ would exceed a critical threshold value of 8.0 mW/m·K, which indicates the loss of effective insulation performance.

The random forest regressor algorithm was chosen due to its robustness in modeling non-linear relationships and its effectiveness in handling time series-like data with minimal hyperparameter tuning [

19]. While alternative models, such as Gaussian process regression, offer powerful capabilities such as uncertainty quantification, RF was deemed sufficient to demonstrate the primary goal of the study: validating the feasibility of the overall sensor-based monitoring methodology.

It is important to note that while the embedded SHT45 sensor also monitored humidity, this variable was not included as a direct input to the final lifetime prediction model. This decision was based on the experimental design, which utilized an accelerated aging process over a short duration (67 days). In this condensed timeframe, the rapid increase in internal pressure was identified as the dominant factor driving thermal conductivity degradation, whereas the slower-acting effects of moisture ingress were considered negligible. Therefore, the model was focused on the primary variable of pressure to establish the proof-of-concept for this monitoring methodology.

For the implementation, the dataset, consisting of hourly thermal conductivity values, was split into a training set (80%) and a testing set (20%) to evaluate the model’s performance. The model was developed using the scikit-learn library in Python 3.13.6. Key hyperparameters for the random forest regressor were set to standard values, such as nestimators = 100, which proved effective for this application.

The model yielded the following performance metrics during training and testing:

These results demonstrate that the model can accurately predict real thermal conductivity values and is thus well-suited for reliable service life estimation based on time-dependent data. The model′s strong performance confirms the feasibility of utilizing real-time field data for rapid and effective VIP lifetime prediction.

5.2. Determining the Panel’s Service Life

The predicted λ values were analyzed over time, and the commonly accepted upper limit for effective thermal conductivity in VIPs (8.0 mW/m·K) was used as the failure threshold [

1,

10]. This threshold defines the point at which the panel is considered to have lost its insulating effectiveness.

As a result of the analysis, the estimated service life of the test panel—intentionally manufactured with a shortened life expectancy—was found to be approximately 67 days. This estimate was derived solely from real-time sensor data without the need for laboratory measurements. Notably, actual measurements showed that λ reached 7.4 mW/m·K by day 63, reinforcing the accuracy of the model’s predictions.

5.3. Evaluation of the Proposed Approach

The proposed machine learning-based lifetime prediction approach offers several key advantages over conventional methods such as the guarded hot plate (GHP) or heat flow meter (HFM). A comparative evaluation is provided below:

Accuracy: While GHP is the accepted reference method for a single-point λ measurement [

1,

20], it cannot capture the performance degradation trend over time. Our method’s accuracy relies on calibrated sensors and an experimentally validated

p-λ relationship, enabling it to model the continuous degradation trend with very high precision (R

2 = 0.9999), which is a capability that conventional methods lack.

Cost: Conventional methods such as GHP require high capital investment in equipment and have significant operational costs per test [

1,

13,

19]. In contrast, the proposed sensor module has a low initial cost, and its automated, in situ operation eliminates recurring test expenses, making it highly cost-effective for long-term or large-scale monitoring.

Time-to-result: GHP tests are known for prolonged test durations, which can take hours or even days for a single data point [

1,

13,

19]. Our system provides data in real-time on an hourly basis, allowing for immediate analysis and continuous updating of the service life prediction as more data become available.

This methodology allows for accurate lifetime prediction under actual operating conditions, without being constrained by predefined laboratory environments or test standards. As such, it offers a practical tool for energy performance evaluation in building physics applications. It should be noted, however, that a quantitative verification of the sensor integration′s impact on the overall degradation rate compared to a virgin panel was outside the scope of this initial study. This is recognized as a limitation and a direction for future validation.

Additionally, while the dataset proved sufficient for this proof-of-concept study, its limited size is acknowledged.

5.4. Practical Implementation Considerations

For real-world applications, the proposed system is envisioned to be integrated with a building management system (BMS) or a dedicated monitoring dashboard to provide actionable insights for building operators. Rather than a single end-of-life prediction, the system can implement a tiered alert strategy (e.g., green for normal operation, yellow for a warning as λ approaches the threshold, and red for critical failure). This approach facilitates predictive maintenance, allowing operators to plan for replacements proactively instead of responding to unexpected failures.

6. Conclusions

In this study, a novel sensor-integrated measurement system was developed to assess the long-term performance of vacuum insulated panels (VIPs). Hourly pressure and temperature data were collected, and based on these inputs, the thermal conductivity trend of the panel was modeled. This model was then used in conjunction with machine learning algorithms to predict the expected service life of the panel.

The developed system is not limited to VIP technology; it also holds potential for applications in thermal insulation materials, energy management systems, cold chain logistics, and sustainable building engineering. Moreover, by integrating sensor-based monitoring with machine learning, early detection of material degradation and the development of strategies to extend service life become feasible.

The analyses demonstrated that the system can not only assess current performance, but can also reliably forecast future degradation. The high predictive accuracy of the model enhances the practical applicability of the proposed method.

This new approach eliminates the need for laboratory-dependent testing and enables real-time monitoring and lifetime prediction of VIPs operating under actual field conditions. Accordingly, it is expected to contribute significantly to energy-efficient building design and durable insulation applications.

Future work will focus on several key areas to enhance the applicability and reliability of the proposed system. The system′s generalizability will be increased by testing it with different VIP materials, core types, and under diverse environmental conditions. The machine learning model itself will be improved by incorporating the long-term effects of humidity to enhance predictive accuracy, and its robustness will be further validated using more advanced techniques suitable for time series data, such as time series cross-validation, especially on larger datasets from long-term deployments. A critical next step involves conducting dedicated control experiments, aging sensor-embedded and virgin panels in parallel, to quantitatively assess any potential thermal bridging effects from the sensor integration. Furthermore, to ensure long-term reliability, research will focus on developing algorithms to detect and compensate for potential sensor drift and on implementing signal processing filters to improve robustness against false positives. These technical enhancements will ultimately support the development of practical strategies for recommending maintenance intervals and performance-enhancing interventions.

To create a more holistic understanding of panel degradation, future studies could also integrate external visual monitoring through computer vision techniques. This approach would complement the internal sensor data by detecting physical aging phenomena such as surface delamination, wrinkling, or mechanical damage. For this purpose, advanced deep learning models could be employed. For instance, a semantic segmentation model such as DeepLab could be used to precisely identify and quantify the area of specific defects on the panel’s surface [

26]. Concurrently, highly efficient image classification models such as EfficientNet could assess the overall visual health of the panel, providing a rapid classification of its condition [

27]. Fusing the data from these visual analyses with the internal sensor readings would establish a multi-modal diagnostic system, leading to more robust and accurate service life predictions.

In conclusion, the proposed integrated approach presents a scalable, data-driven system capable of monitoring the operational lifespan of VIPs in real-time. It offers a strong solution for enhancing energy efficiency, facilitating predictive maintenance, and promoting sustainable material utilization. Future studies are encouraged to explore the comparison of alternative machine learning models, validation across diverse panel types, and real-world deployment of the monitoring system.