Research on Working and Mechanical Properties of Self-Compacting Steel-Fiber-Reinforced High-Strength Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement

2.1.2. Mineral Admixtures

| Class | Chemical Composition (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | MgO | Fe2O3 | TiO2 | SO3 | Na2O | MnO | Ignition Loss | |

| silica fume | / | 95.19 | / | 0.80 | 0.13 | / | / | 1.05 | 0.50 | 1.90 |

| slag | 40.0 | 33.36 | 12.69 | 6.75 | 2.80 | / | / | / | 0.56 | / |

2.1.3. Coarse Aggregate

2.1.4. Fine Aggregate

2.1.5. High Efficiency Water Reducing Agent

2.1.6. Steel Fiber

2.1.7. Mixing Water

2.2. Proportion of Mixture and Sample Preparation

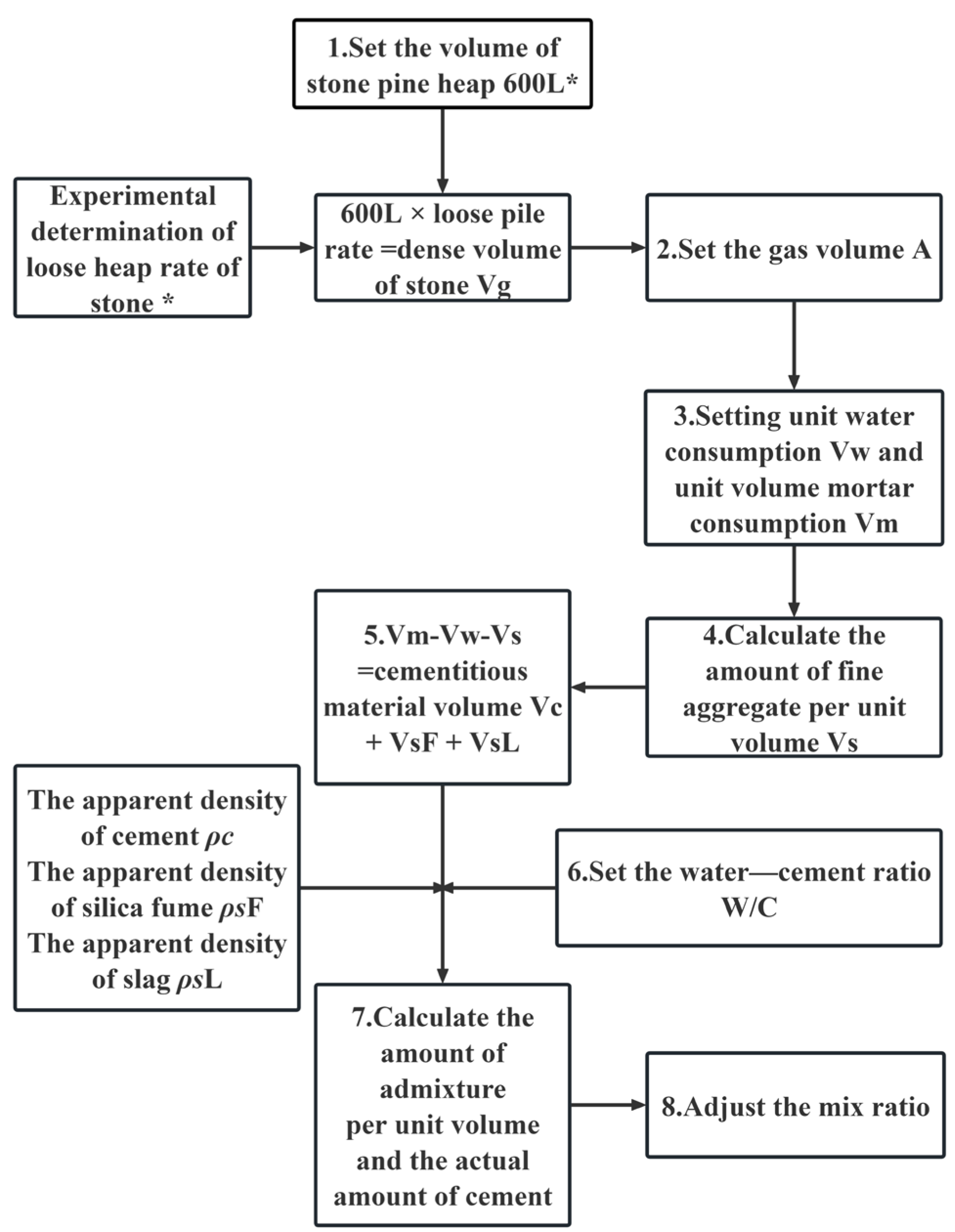

2.3. Self-Compacting Concrete Mix Design Adjustment

2.4. Test Method

2.4.1. Working Performance Test

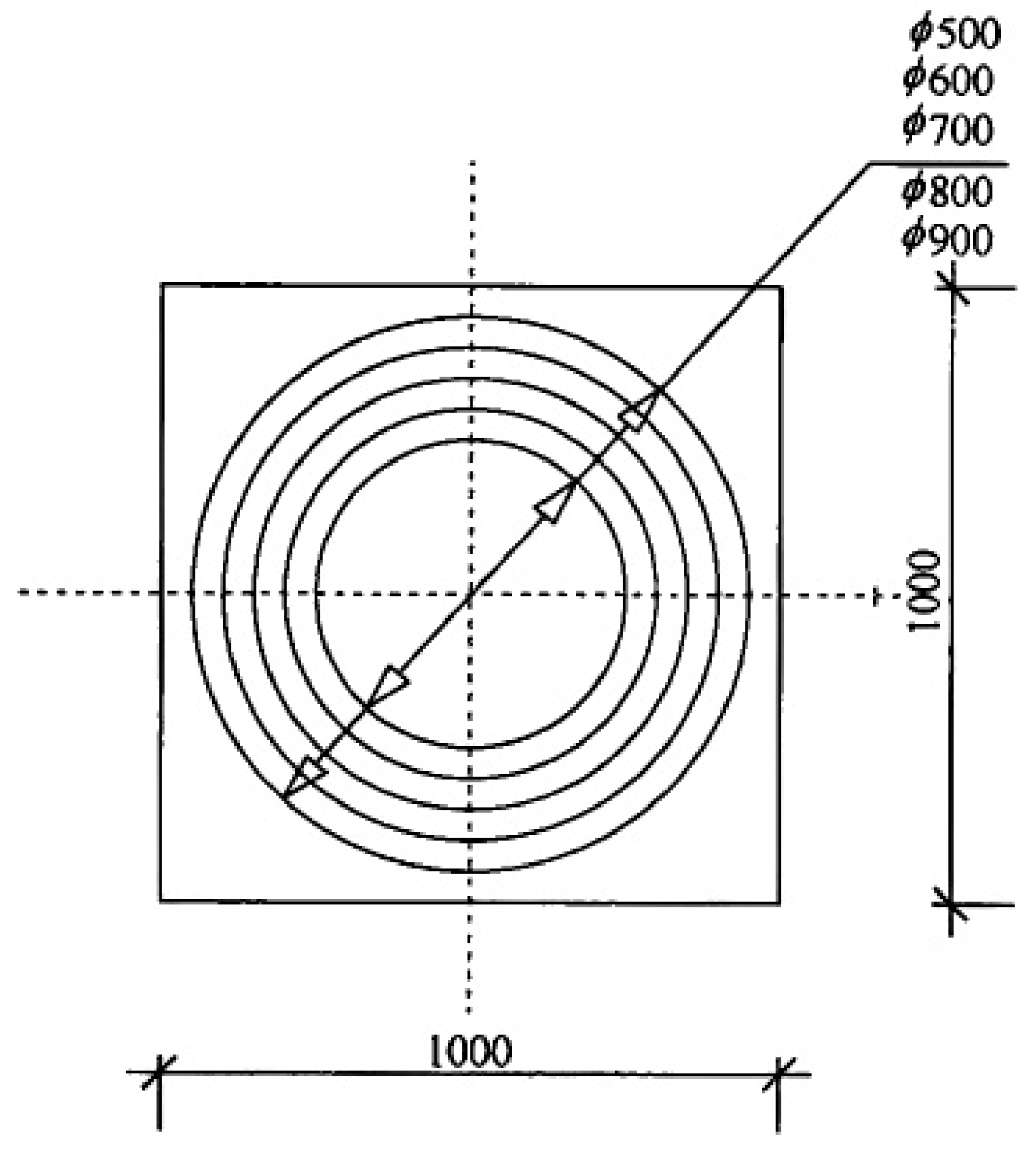

2.4.2. U-Shaped Instrument Test

2.4.3. L-Shaped Instrument

2.4.4. Test Method of Concrete Microstructure

2.4.5. Shrinkage and Mechanical Properties Test

3. Results

3.1. Effect of Steel Fiber

3.1.1. Effect of Steel Fiber on Working Performance

3.1.2. Effect of Steel Fiber on Shrinkage

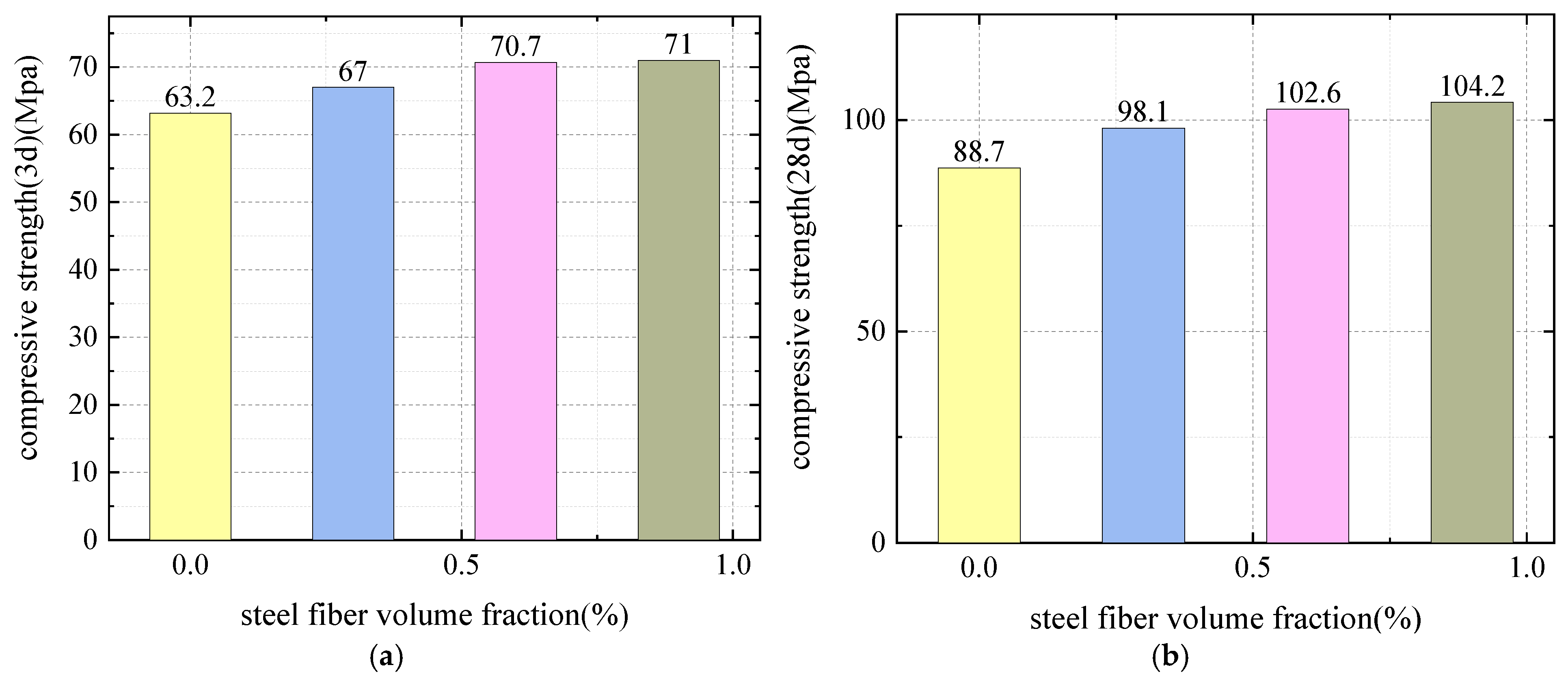

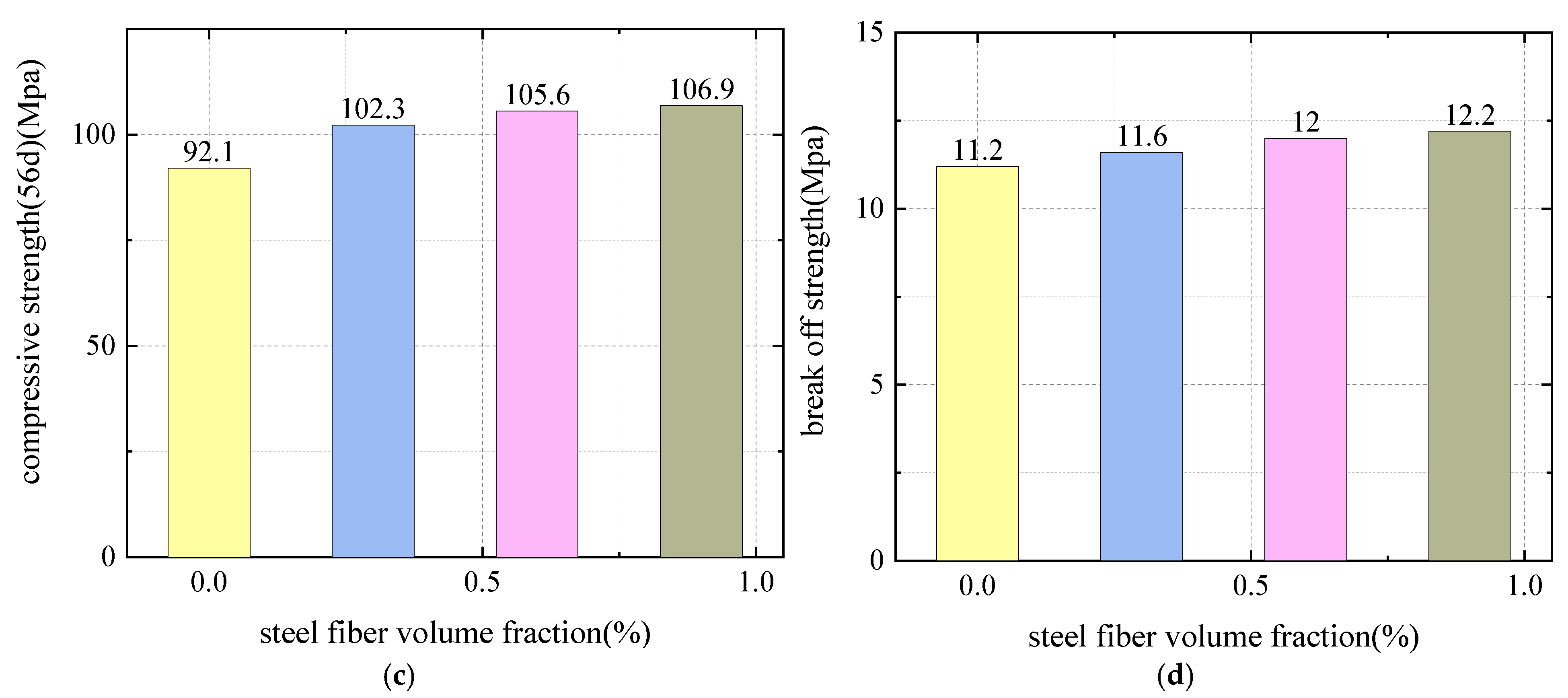

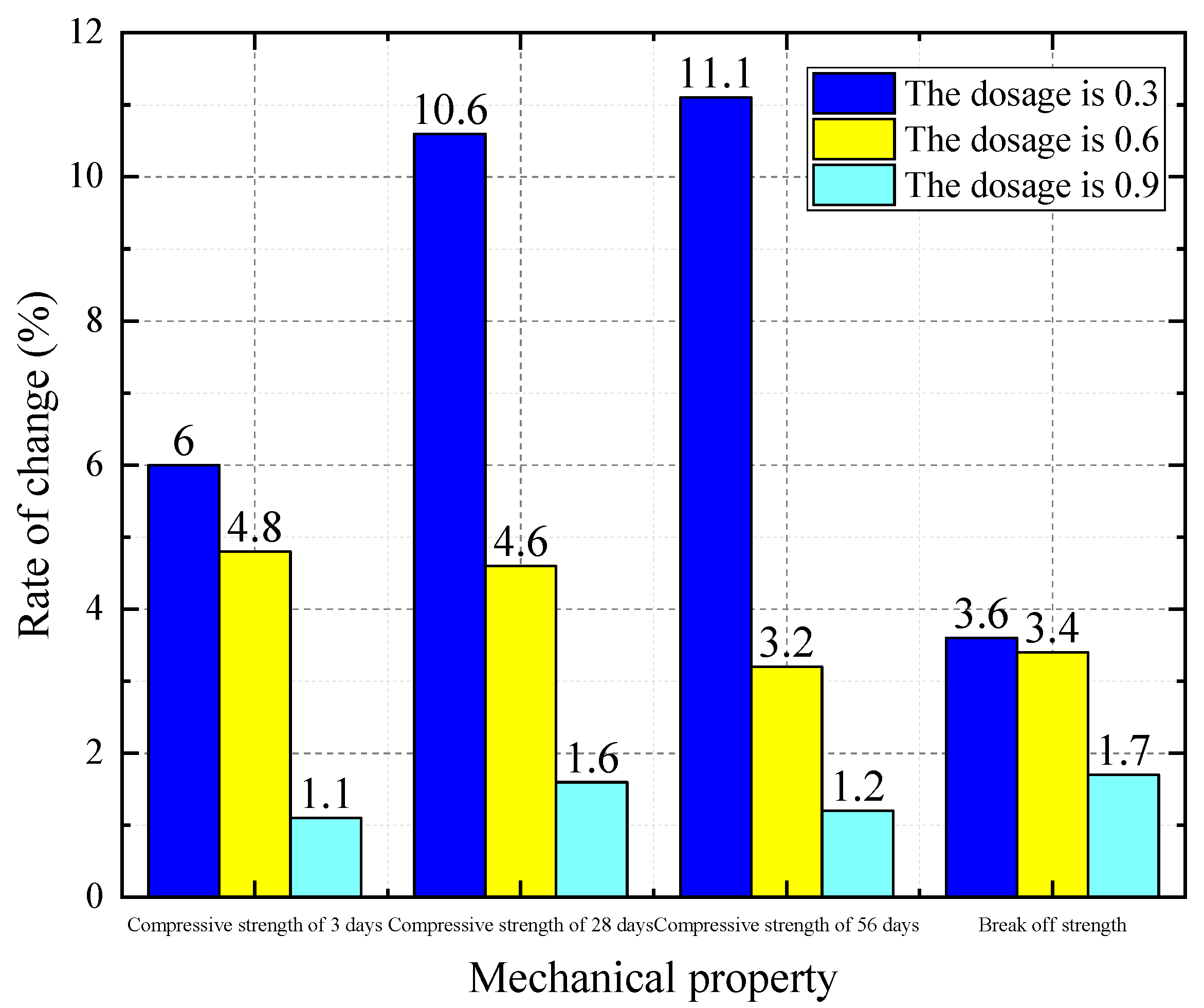

3.1.3. Effect of Steel Fiber on Mechanical Properties

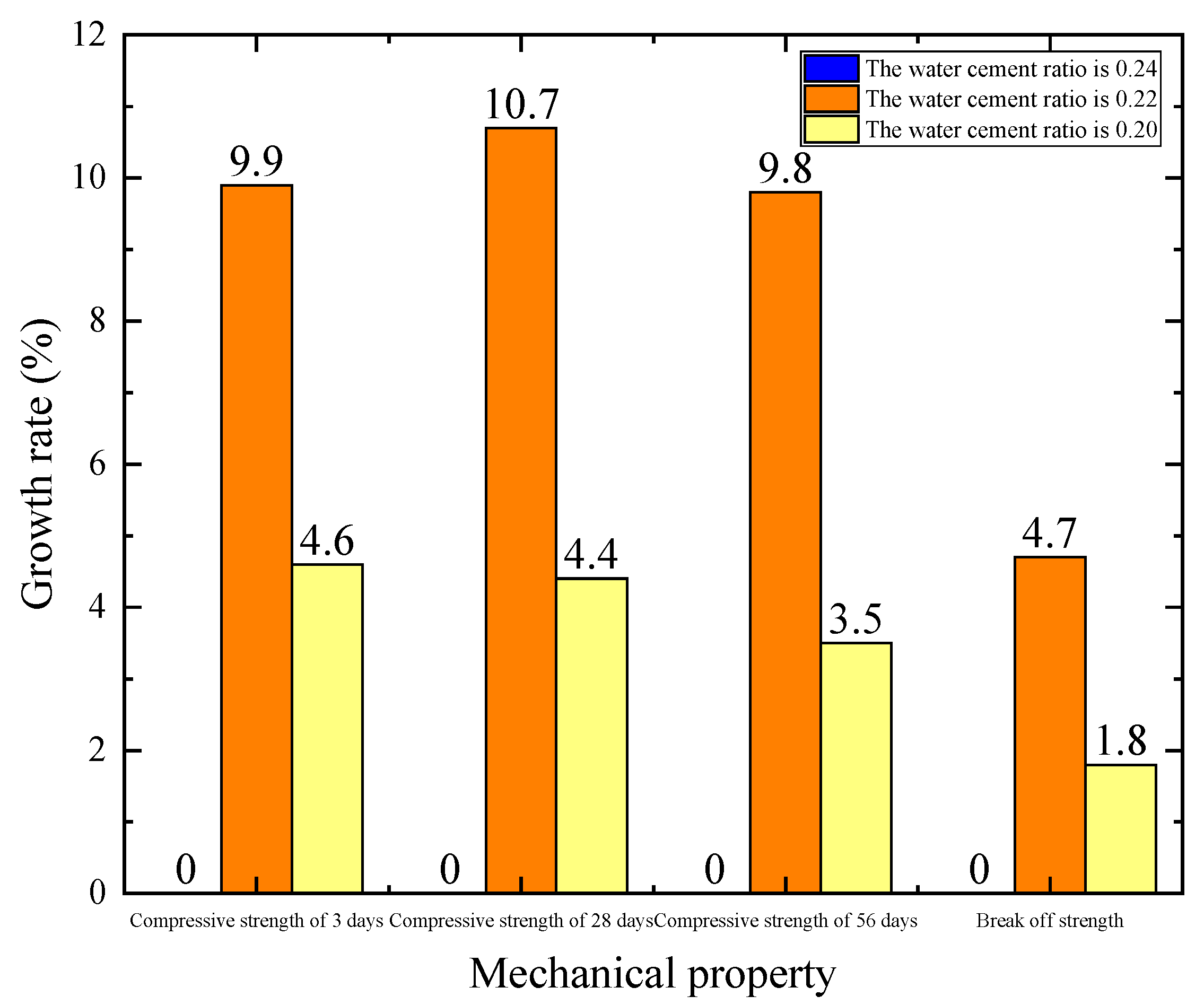

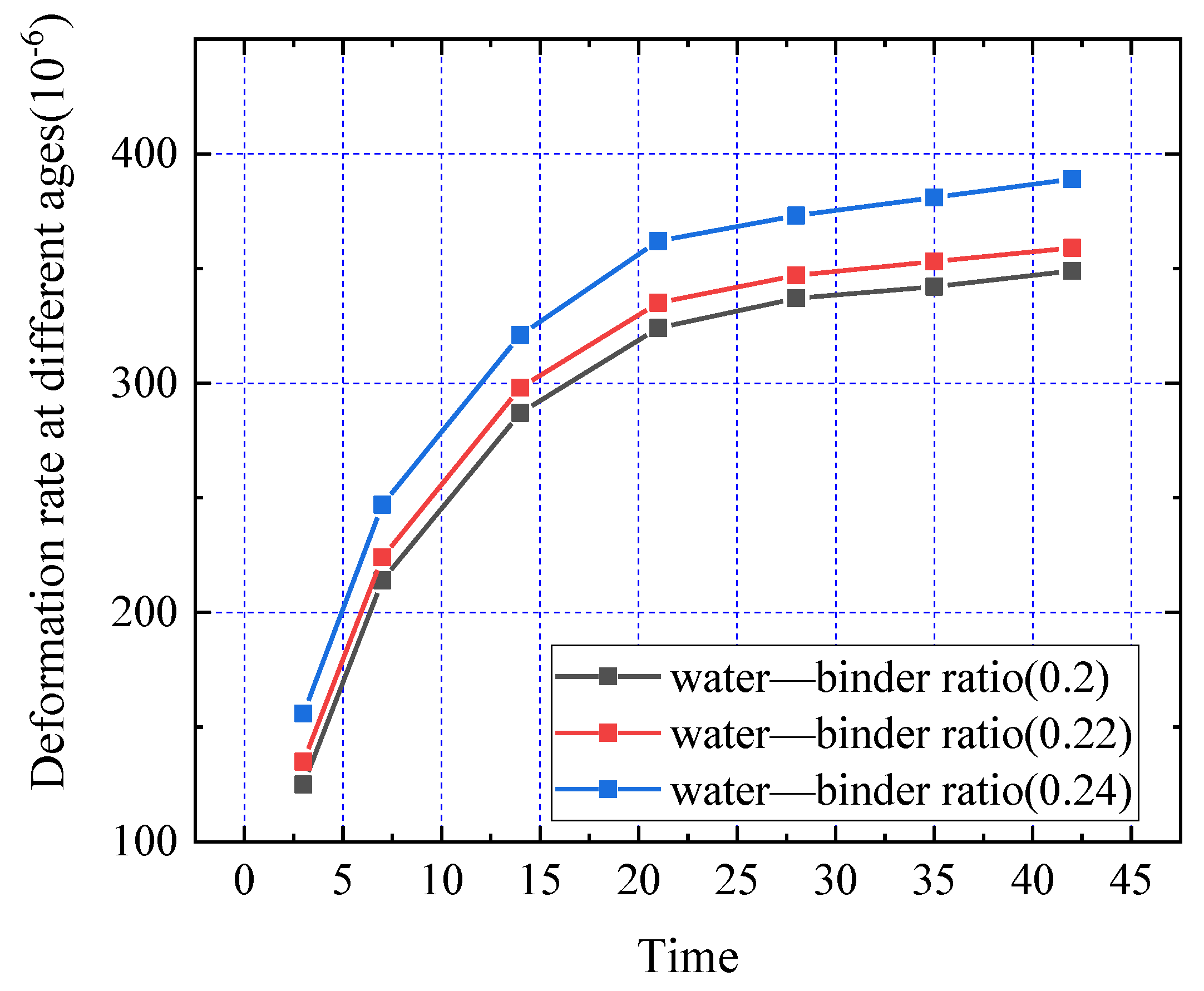

3.2. Effect of Water–Binder Ratio

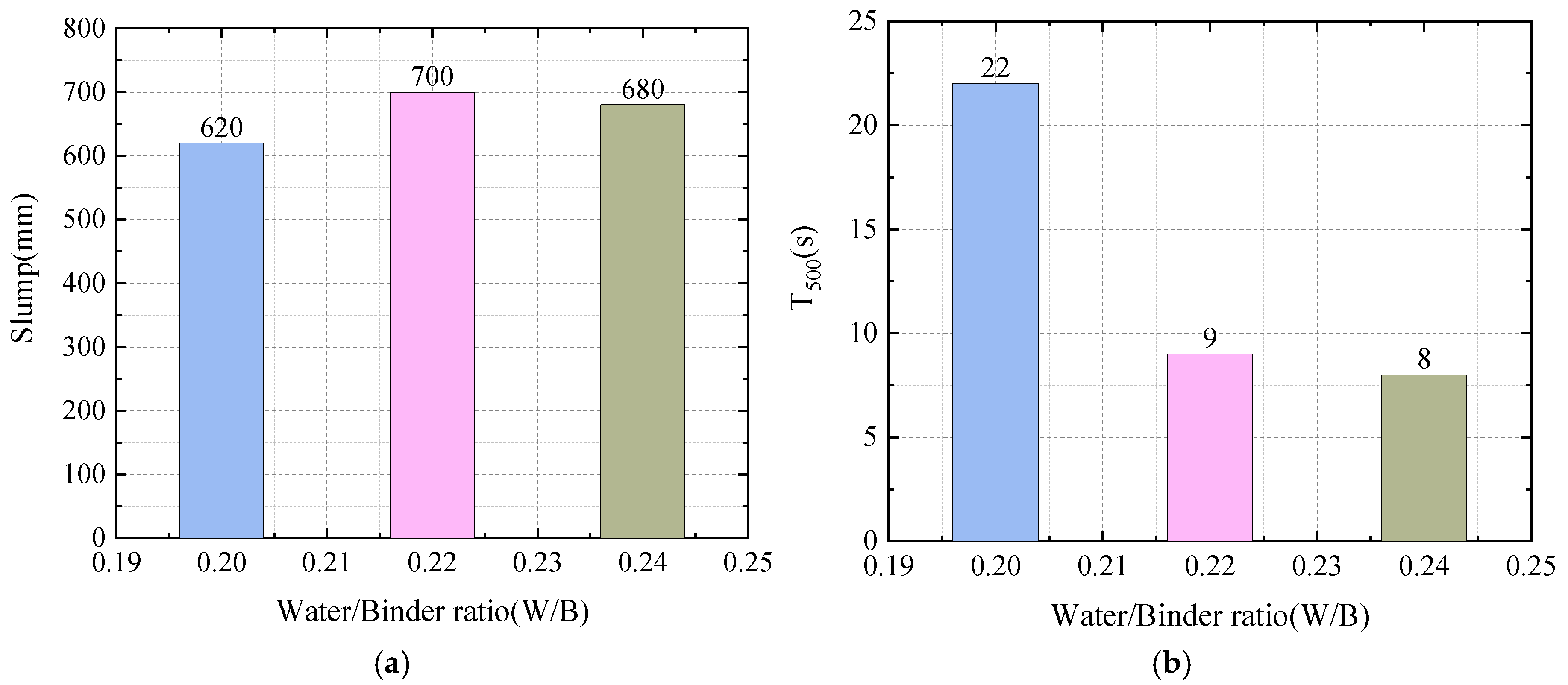

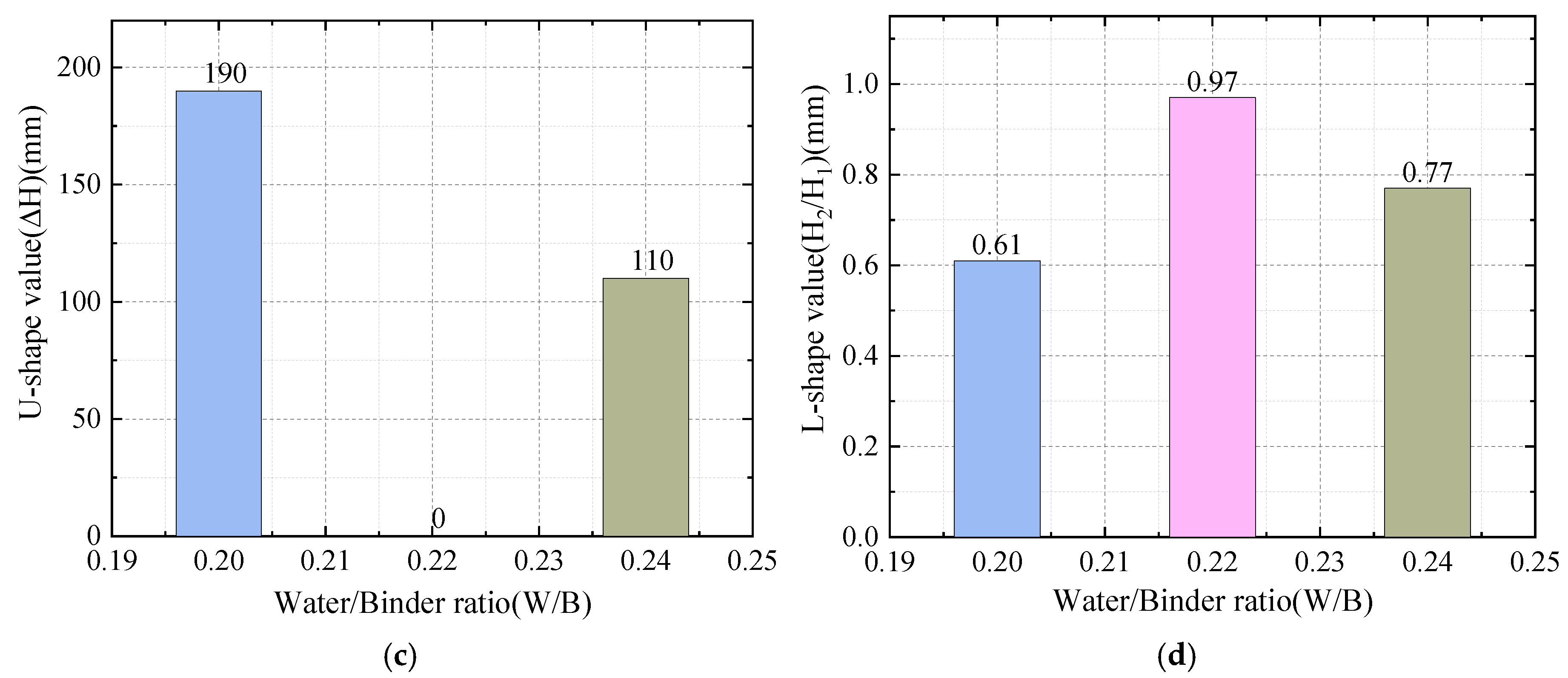

3.2.1. Effect on Working Performance

3.2.2. Effect of Water–Binder Ratio on Shrinkage Performance

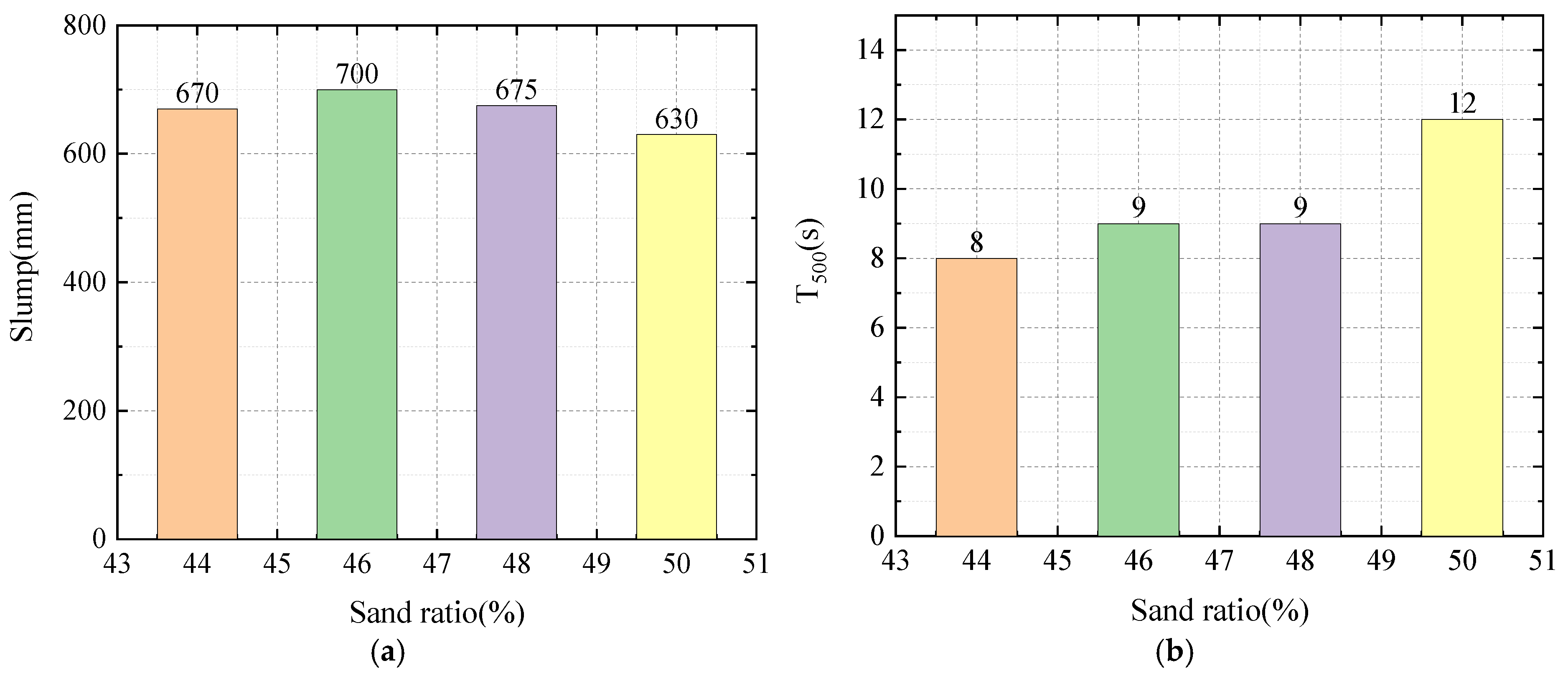

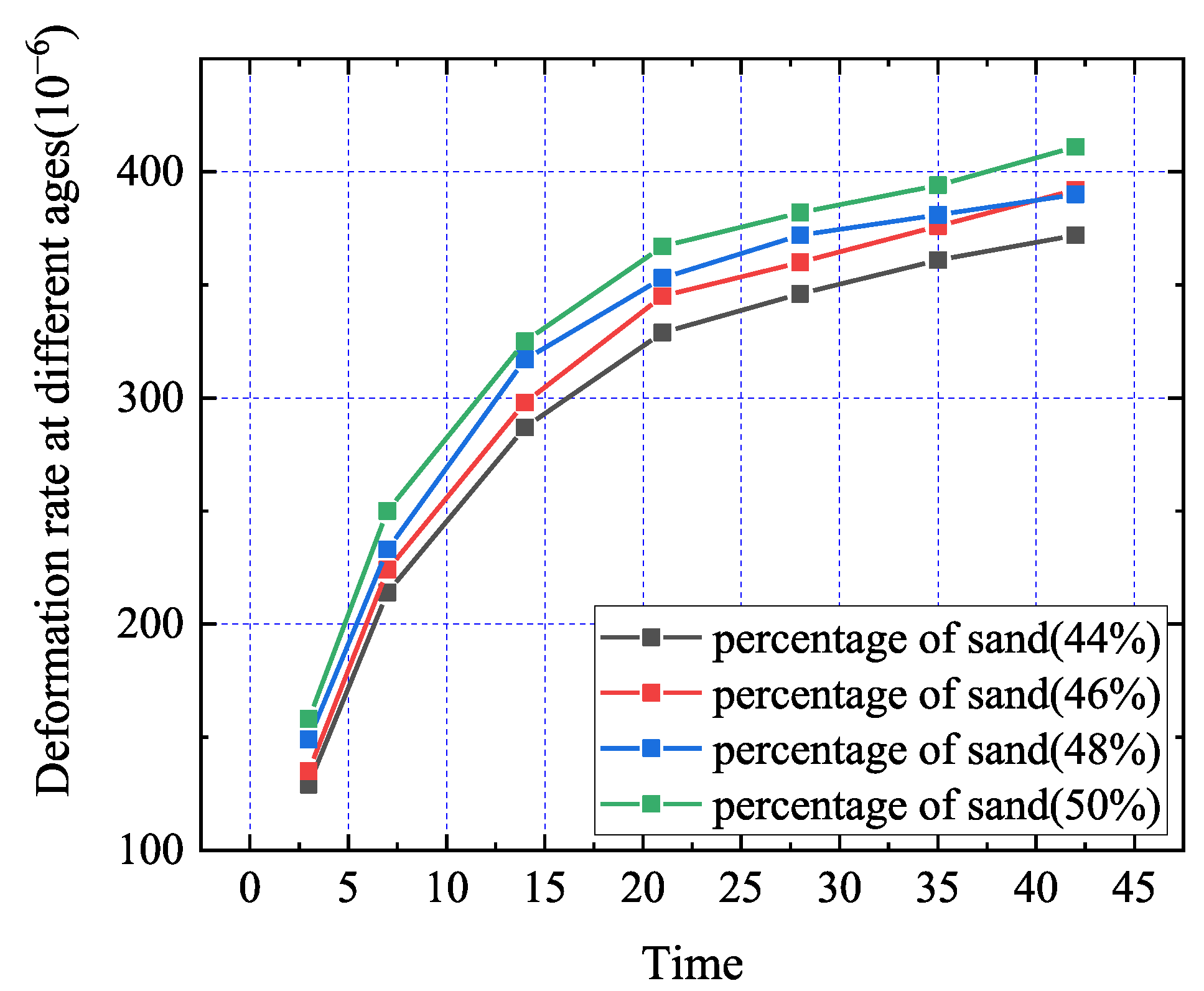

3.3. Effect of Sand Ratio

3.3.1. Effect of Sand Ratio on Working Performance

3.3.2. Effect of Sand Ratio on Mechanical Properties

3.3.3. Effect of Sand Ratio on Shrinkage Performance

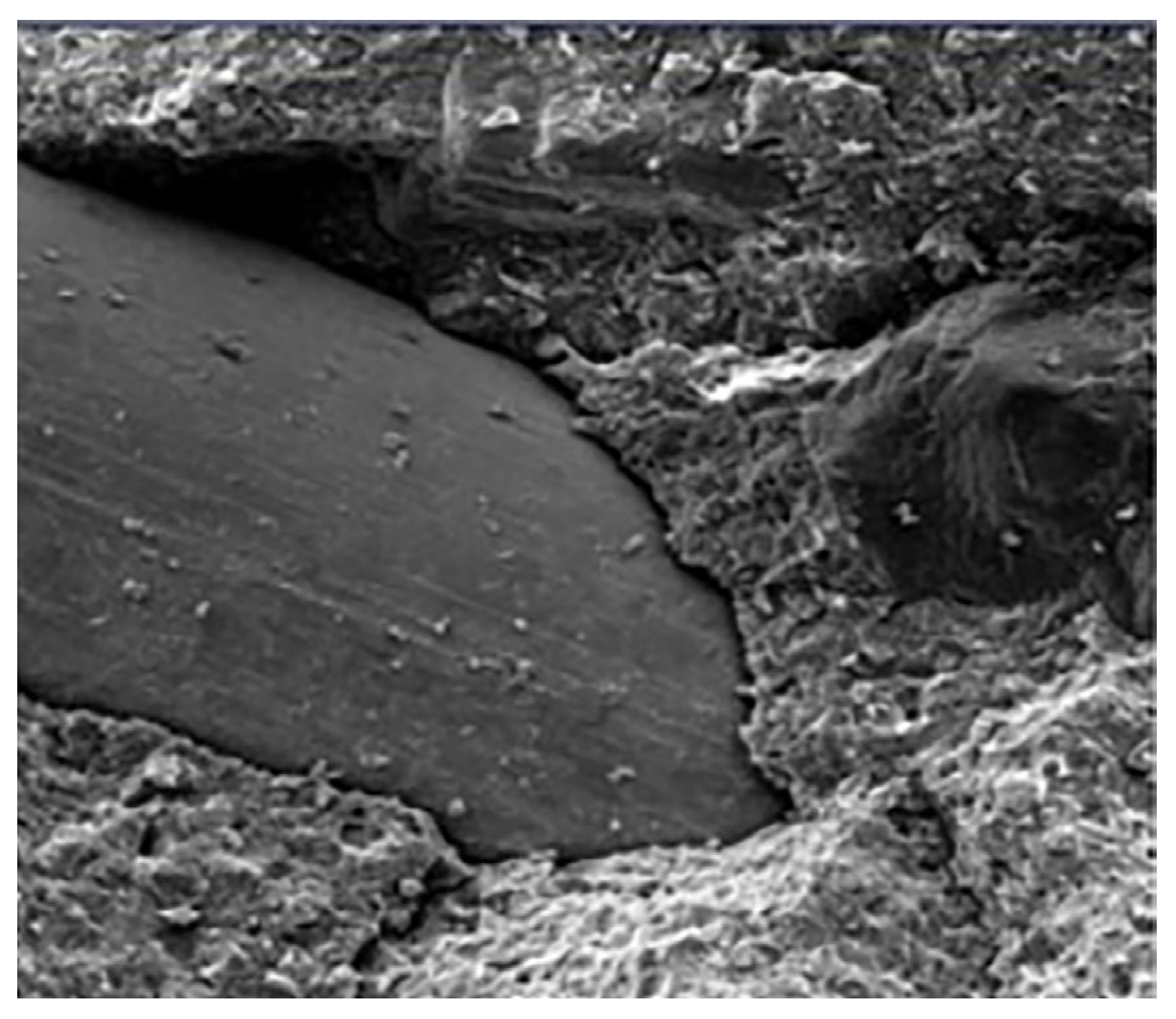

3.4. Interface Microstructure Between Steel Fiber and Concrete Matrix

4. Conclusions

- The C90 high-strength self-compacting concrete prepared in this experiment has the best mix ratio, which makes its working performance, mechanical properties, and shrinkage performance better. The best mix ratio is a water–binder ratio of 0.22, sand ratio of 46%, and steel fiber content of 0.3%.

- When the steel fiber content is 0.3%, the compressive strength of self-compacting high-strength concrete can be increased by more than 4%, the flexural strength can be increased by more than 5%, and the working performance, autogenous shrinkage, and drying shrinkage are better, which can meet the performance index of self-compaction. When the steel fiber is 0.6% and 0.9%, the compressive strength of concrete can be increased by more than 10%, and the flexural strength can be increased by more than 7%. However, with the increase in the volume fraction of micro-steel fiber, the working performance of steel fiber self-compacting high-strength concrete is getting worse and worse, which makes the self-compacting concrete more and more uncompacted, and this trend becomes more and more serious with the increase in steel fiber content.

- Under the experimental conditions, when the water–binder ratio is 0.20, the flow performance of self-compacting high-strength concrete is poor, and the concrete forming effect is not good. When the water–binder ratio is 0.24, the self-compacting high-strength concrete has good fluidity, but the cohesion is poor and segregation may easily occur. When the water–binder ratio is 0.22, the working performance of self-compacting concrete is the best.

- Under the experimental conditions, when the optimum sand ratio is 46%, the working performance of self-compacting concrete is the best; when the sand ratio is lower than the optimum sand ratio, the self-compacting high-strength concrete will produce segregation. When the sand ratio is higher than the optimum sand ratio, the flow performance of self-compacting high-strength concrete is very poor.

- The SEM images show that the steel fiber in the steel fiber self-compacting high-strength concrete prepared in this experiment is closely bonded to the interface of the self-compacting concrete.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sobuz, M.R.; Aditto, F.S.; Datta, S.D.; Kabbo, K.I.; Jabin, J.A.; Hasan, N.M.S.; Khan, M.H.; Rahman, S.M.A.; Raazi, M.; Zaman, A.A.U. High-Strength Self-Compacting Concrete Production Incorporating Supplementary Cementitious Materials: Experimental Evaluations and Machine Learning Modelling. Int. J. Concr. Struct. Mater. 2024, 18, 67. [Google Scholar] [CrossRef]

- Şenol, A.F.; Karakurt, C. High-strength self-compacting concrete produced with recycled clay brick powders: Rheological, mechanical and microstructural properties. J. Build. Eng. 2024, 88, 109175. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yaman, I.O. Hybrid fiber reinforced self-compacting concrete with a high-volume coarse fly ash. Constr. Build. Mater. 2007, 21, 150–156. [Google Scholar] [CrossRef]

- Carballosa, P.; García Calvo, J.L.; Revuelta, D. Influence of expansive calcium sulfoaluminate agent dosage on properties and microstructure of expansive self-compacting concretes. Cem. Concr. Compos. 2025, 107, 103464. [Google Scholar] [CrossRef]

- Gupta, P.K.; Rajhans, P.; Panda, S.K.; Nayak, S.; Das, S.K. Mix Design Method for Self-Compacting Recycled Aggregate Concrete and Its Microstructural Investigation by Considering Adhered Mortar in Aggregate. J. Mater. Civ. Eng. 2020, 32, 3. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslan, F.; Taherinezhad, J. Effect of silica fume on durability of self-compacting concrete made with waste recycled concrete aggregates. Constr. Build. Mater. 2019, 227, 116598. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Algın, Z.; Yazıcı, H. Effect of surface treatment methods on the properties of self-compacting concrete with recycled aggregates. Constr. Build. Mater. 2014, 64, 172–183. [Google Scholar] [CrossRef]

- Chakkamalayath, J.; Joseph, A.; Al-Baghli, H.; Hamadah, O.; Dashti, D.; Abdulmalek, N. Performance evaluation of self-compacting concrete containing volcanic ash and recycled coarse aggregates. Asian J. Civ. Eng. 2020, 21, 2. [Google Scholar] [CrossRef]

- Wen, C.; Shen, D.; Jiao, Y.; Liu, C.; Li, M. Early-Age Cracking Resistance of Reinforced High- Strength Concrete. ACI Struct. J. 2024, 121, 11. [Google Scholar] [CrossRef]

- Astarlioglu, S.; Krauthammer, T. Response of normal-strength and ultra-high-performance fiber-reinforced concrete columns to idealized blast loads. Eng. Struct. 2014, 61, 1–12. [Google Scholar] [CrossRef]

- Hammoud, A.; Yan, J.; Li, Y.; Aoude, H. Blast Behavior of Columns Built with High-Strength Concrete and Grade 690 MPa High-Strength Reinforcement. Can. J. Civ. Eng. 2021, 48, 1422–1439. [Google Scholar] [CrossRef]

- Rahal, K.N.; Khaleefi, A.L.; Al-Sanee, A. An experimental investigation of shear-transfer strength of normal and high strength self compacting concrete. Eng. Struct. 2016, 109, 16–25. [Google Scholar] [CrossRef]

- Xiong, M.X.; Xiong, D.X.; Liew, J.Y.R. Axial performance of short concrete filled steel tubes with high- and ultra-high-strength materials. Eng. Struct. 2017, 136, 494–510. [Google Scholar] [CrossRef]

- Bae, B.I.; Chung, J.H.; Choi, H.K.; Jung, H.S.; Choi, C.S. Experimental study on the cyclic behavior of steel fiber reinforced high strength concrete columns and evaluation of shear strength. Eng. Struct. 2018, 157, 250–267. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Yuan, T.; Yang, J.M.; Yoon, Y.S. Feasibility of replacing minimum shear reinforcement with steel fibers for sustainable high-strength concrete beams. Eng. Struct. 2017, 147, 207–222. [Google Scholar] [CrossRef]

- Rukhaiyar, S.; Sajwan, G.; Samadhiya, N.K. Strength behavior of plain cement concrete subjected to true-triaxial Compression. Can. J. Civ. Eng. 2018, 45, 179–196. [Google Scholar] [CrossRef]

- Powers, T.C.; Brownyard, T.L. Studies of the Physical Properties of Hardened Portland Cement Paste. Concr. Int. 2003, 9, 25. [Google Scholar]

- Yang, D. Study on mix proportion, brittleness and durability of high strength concrete. Concrete 1996, 2, 8. [Google Scholar]

- Deeb, R.; Ghanbari, A.; Karihaloo, B.L. Development of self-compacting high and ultra high performance concretes with and without steel fibres. Cem. Concr. Compos. 2012, 34, 185–190. [Google Scholar] [CrossRef]

- Frazão, C.; Camões, A.; Barros, J.; Gonçalves, D. Durability of steel fiber reinforced self-compacting concrete. Constr. Build. Mater. 2015, 80, 155–166. [Google Scholar] [CrossRef]

- Khaloo, A.; Raisi, E.M.; Hosseini, P.; Tahsiri, H. Mechanical performance of self-compacting concrete reinforced with steel fibers. Constr. Build. Mater. 2014, 51, 179–186. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, S. Study of the flexural and shear toughness of steel fiber reinforced self-compacting concrete. China Civ. Eng. J. 2010, 43, 55–63. [Google Scholar]

- Akcay, B.; Tasdemir, M.A. Mechanical behaviour and fibre dispersion of hybrid steel fibre reinforced self-compacting concrete. Constr. Build. Mater. 2012, 28, 287–293. [Google Scholar] [CrossRef]

- Siddique, R.; Kaur, G. Strength and permeation properties of self-compacting concrete containing fly ash and hooked steel fibres. Constr. Build. Mater. 2016, 103, 5–22. [Google Scholar] [CrossRef]

- Alabduljabbar, H.; Alyousef, R.; Alrshoudi, F.; Alaskar, A.; Fathi, A.; Mohamed, A.M. Mechanical Effect of Steel Fiber on the Cement Replacement Materials of Self-Compacting Concrete. Fibers 2019, 7, 36. [Google Scholar] [CrossRef]

- Liu, X.; Wang, X.; Wang, Y.; Liu, Q.; Tian, Y.; Zhou, J.; Meng, Y. Mix Design and Performance Study of High-Strength Self-Compacting Concrete with Manufactured Sand. Materials 2025, 18, 1. [Google Scholar] [CrossRef]

- Yehia, S.; Douba, A.; Abdullahi, O.; Farrag, S. Mechanical and durability evaluation of fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2016, 121, 120–133. [Google Scholar] [CrossRef]

- Kang, X.R.; Fang, G.X. Experimental Study of Composite High Strength Self-Compacting Concrete. Appl. Mech. Mater. 2017, 865, 289–294. [Google Scholar] [CrossRef]

- JGJ/T 283-2012.2012; Technical Specification for Application of Self-Compacting Concrete (with Provisions). Industry Standard—Construction Industry: Beijing, China, 2013.

- Wang, Y. Study on the Composition, Structure, Shrinkage and Compensation of Ultra-High Strength and High Performance Concrete. Master’s Thesis, Chongqing University, Chongqing, China, 2025. [Google Scholar]

- Ba, H.; Zhang, W. Effect of aggregate on rheological parameters of high performance concrete. Concrete 2003, 6, 3. [Google Scholar]

| Material | Chemical Composition (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Fe2O3 | Al2O3 | CaO | MgO | SO3 | Total Alkali | Ignition Loss | |

| cement | 21.3 | 2.53 | 5.79 | 60.15 | 2.35 | 2.54 | 0.72 | 3.66 |

| Fineness (m2/kg) | Normal Consistency (%) | Initial Setting Time (min) | Final Setting Time (min) | Specific Gravity of Cement | Stability (Pie Method) | Compressive Strength (Mpa) | Break-Off Strength (Mpa) | ||

|---|---|---|---|---|---|---|---|---|---|

| 3 d | 28 d | 3 d | 28 d | ||||||

| 350 | 28.4 | 179 | 239 | 3.1 | No cracks were found | 27.6 | 53.0 | 5.5 | 8.8 |

| Ballast Grain Sizes (mm) | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Percentage of Void (%) | Soil Content (%) | ||

|---|---|---|---|---|---|---|

| Loosening | Compact | Loosening | Compact | |||

| 5–10 | 2670 | 1380 | 1470 | 48.3 | 44.9 | 0.7 |

| 10–20 | 2670 | 1400 | 1520 | 47.6 | 43.1 | 0.5 |

| Apparent Density (kg/m3) | Bulk Density (kg/m3) | Percentage of Void (%) | Soil Content (%) | ||

|---|---|---|---|---|---|

| Loosening | Compact | Loosening | Compact | ||

| 2690 | 1570 | 1630 | 41.6 | 39.4 | 1.4 |

| Name of Plasticizer Admixture | Density (g/cm3) | PH Value | Viscosity (mPa·s) |

|---|---|---|---|

| Polycarboxylate superplasticizer | 1.1 | 6.7 | 95 |

| Fiber Name | Fiber Length (mm) | Fiber Diameter (mm) | Length-to-Diameter Ratio |

|---|---|---|---|

| Copper-plated micro-steel fiber | 10 | 0.15 | 66.7 |

| Unit Water Use (kg/m3) | Binding Material (kg/m3) | Cement (%) | Slag (%) | Silica Fume(%) | Coarse Aggregate (kg/m3) | Fine Aggregate (kg/m3) | Water Reducing Admixture (%) |

|---|---|---|---|---|---|---|---|

| 155 | 705 | 70 | 20 | 10 | 834 | 710 | 2 |

| Numbering | Water–Binder Ratio | Unit Water Use (kg/m3) | Cementitious Material Content (kg/m3) | Coarse Aggregate Content (kg/m3) | Amount of Fine Aggregate (kg/m3) | Water Reducing Admixture (%) | ||

|---|---|---|---|---|---|---|---|---|

| Cement | Slag | Silica Fume | ||||||

| A1 | 0.20 | 155 | 543 | 155 | 77.5 | 794 | 676 | 2 |

| A2 | 0.22 | 155 | 494 | 141 | 70.5 | 834 | 710 | 2 |

| A3 | 0.24 | 155 | 452 | 129 | 64.5 | 864 | 736 | 2 |

| Numbering | Percentage of Sand (%) | Unit Water Use (kg/m3) | Cementitious Material Content (kg/m3) | Coarse Aggregate Content (kg/m3) | Amount of Fine Aggregate (kg/m3) | Water Reducing Admixture (%) | ||

|---|---|---|---|---|---|---|---|---|

| Cement | Slag | Silica Fume | ||||||

| B1 | 44 | 155 | 494 | 141 | 70.5 | 862 | 678 | 2 |

| B2 | 46 | 155 | 494 | 141 | 70.5 | 834 | 710 | 2 |

| B3 | 48 | 155 | 494 | 141 | 70.5 | 801 | 739 | 2 |

| B4 | 50 | 155 | 494 | 141 | 70.5 | 770 | 770 | 2 |

| Numbering | Fiber Content (%) | Unit Water Use (kg/m3) | Cementitious Material Content (kg/m3) | Coarse Aggregate Content (kg/m3) | Amount of Fine Aggregate (kg/m3) | Water Reducing Admixture (%) | ||

|---|---|---|---|---|---|---|---|---|

| Cement | Slag | Silica Fume | ||||||

| C1 | 0 | 155 | 494 | 141 | 70.5 | 834 | 710 | 2 |

| C2 | 0.3 | 155 | 494 | 141 | 70.5 | 834 | 710 | 2 |

| C3 | 0.6 | 155 | 494 | 141 | 70.5 | 834 | 710 | 2 |

| C4 | 0.9 | 155 | 494 | 141 | 70.5 | 834 | 710 | 2 |

| Number | Fiber Content (%) | Slump (mm) | T500 (s) | U-Funnel Testing (ΔH) (mm) | L-Funnel Testing (H2/H1) |

|---|---|---|---|---|---|

| C1 | 0 | 700 | 9 | 0 | 0.97 |

| C2 | 0.3 | 653 | 11 | 5 | 0.97 |

| C3 | 0.6 | 630 | 16 | 90 | 0.81 |

| C4 | 0.9 | 570 | 30 | 160 | 0.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Shi, N.; Yu, Z.; Zhu, Y. Research on Working and Mechanical Properties of Self-Compacting Steel-Fiber-Reinforced High-Strength Concrete. Buildings 2025, 15, 2875. https://doi.org/10.3390/buildings15162875

Liu H, Shi N, Yu Z, Zhu Y. Research on Working and Mechanical Properties of Self-Compacting Steel-Fiber-Reinforced High-Strength Concrete. Buildings. 2025; 15(16):2875. https://doi.org/10.3390/buildings15162875

Chicago/Turabian StyleLiu, Huanqin, Nuoqi Shi, Zhifa Yu, and Yonglin Zhu. 2025. "Research on Working and Mechanical Properties of Self-Compacting Steel-Fiber-Reinforced High-Strength Concrete" Buildings 15, no. 16: 2875. https://doi.org/10.3390/buildings15162875

APA StyleLiu, H., Shi, N., Yu, Z., & Zhu, Y. (2025). Research on Working and Mechanical Properties of Self-Compacting Steel-Fiber-Reinforced High-Strength Concrete. Buildings, 15(16), 2875. https://doi.org/10.3390/buildings15162875