Effect of the Integration of Alfa Natural Fibers and Demolition Waste on the Mechanical and Thermal Properties of Warm Mix Asphalt

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

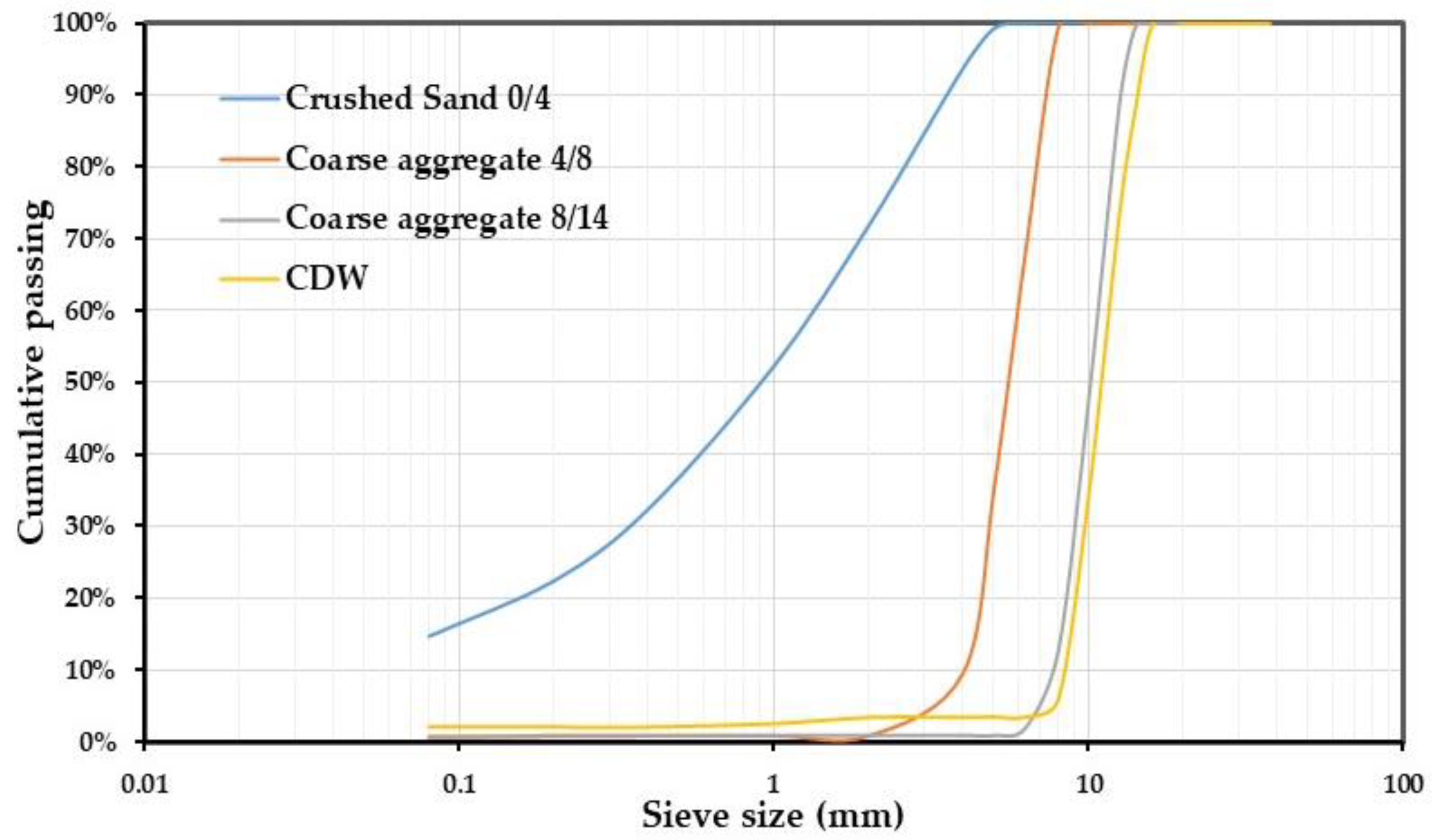

2.1.1. Aggregates

2.1.2. Construction and Demolition Waste

2.1.3. Bitumen

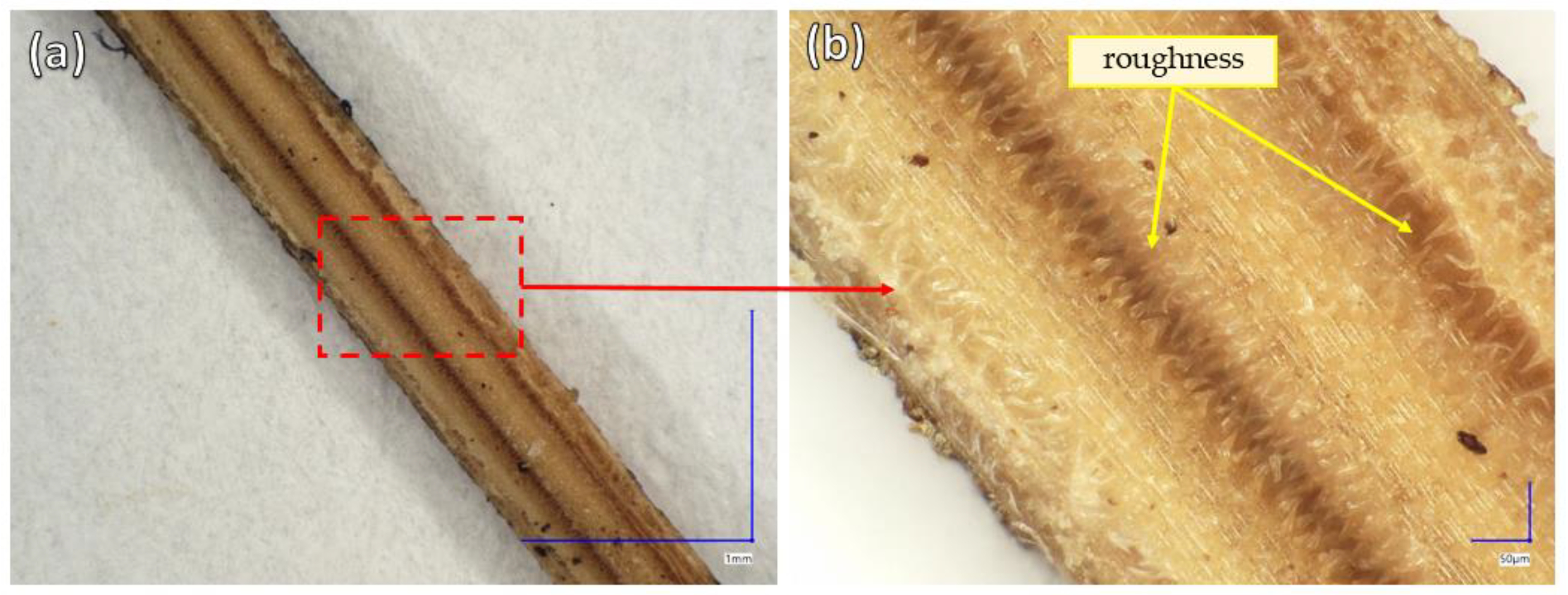

2.1.4. Alfa Fiber

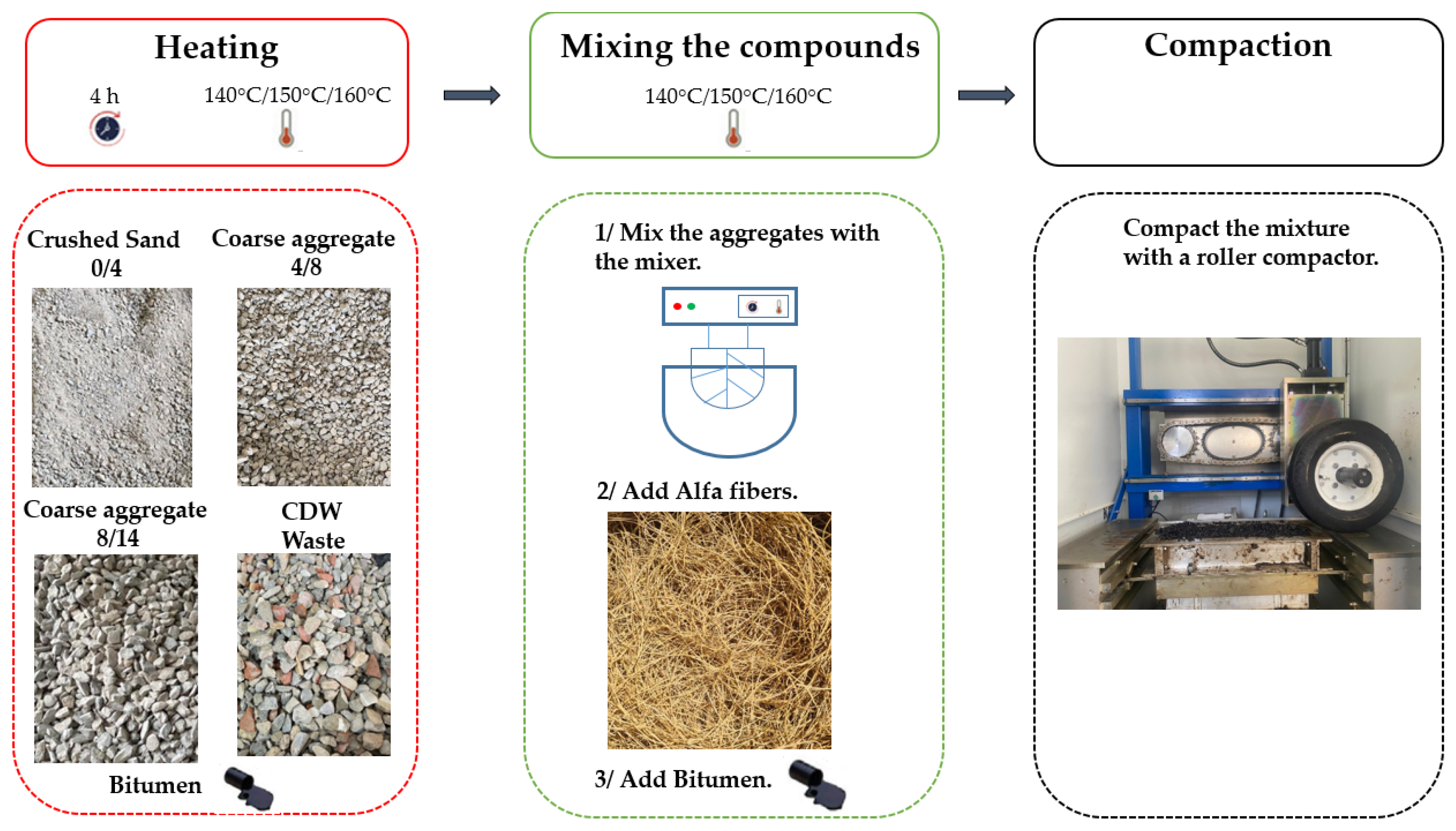

2.2. Sample Preparation

2.3. Experimental Methods

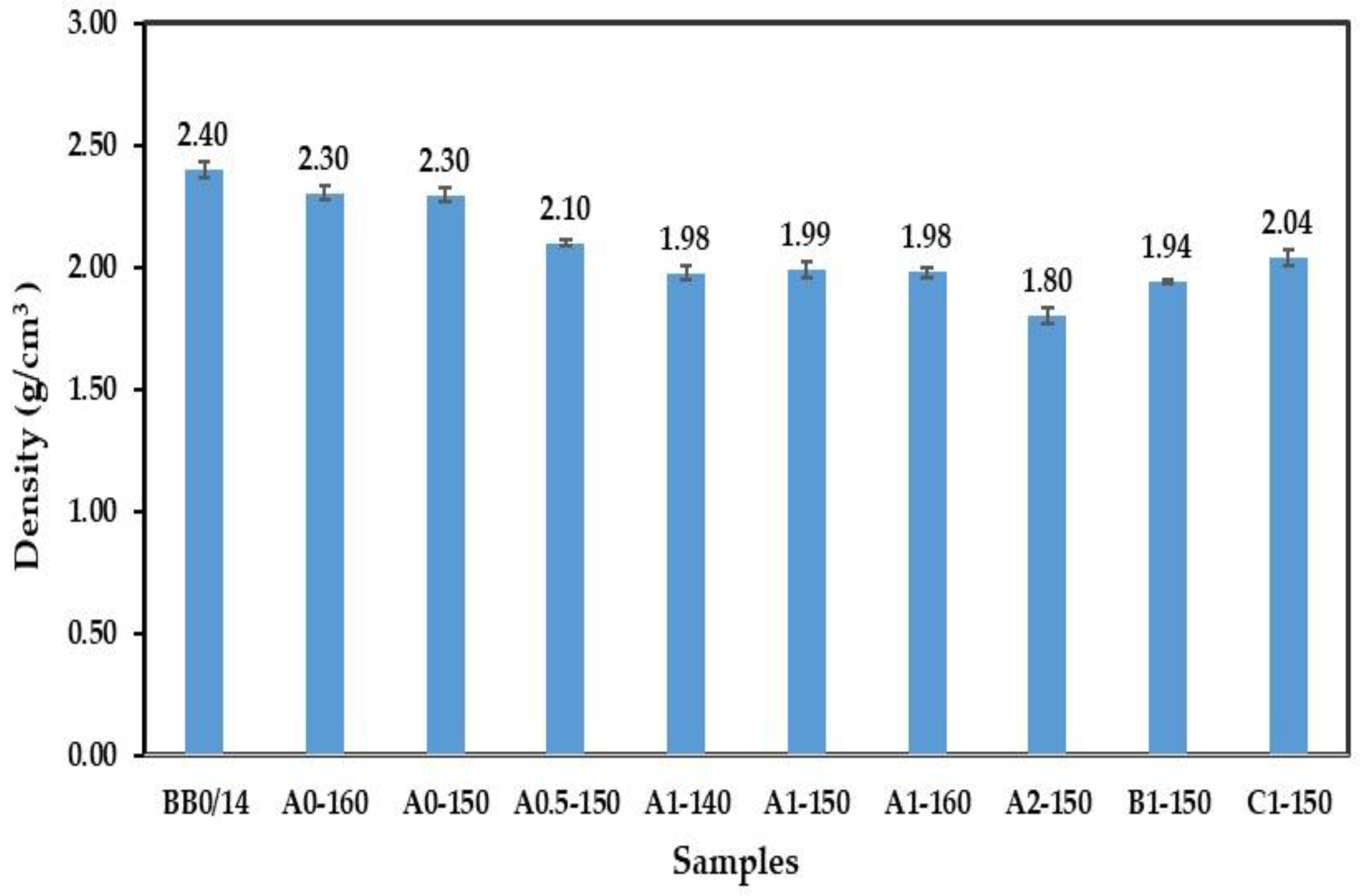

2.3.1. Density

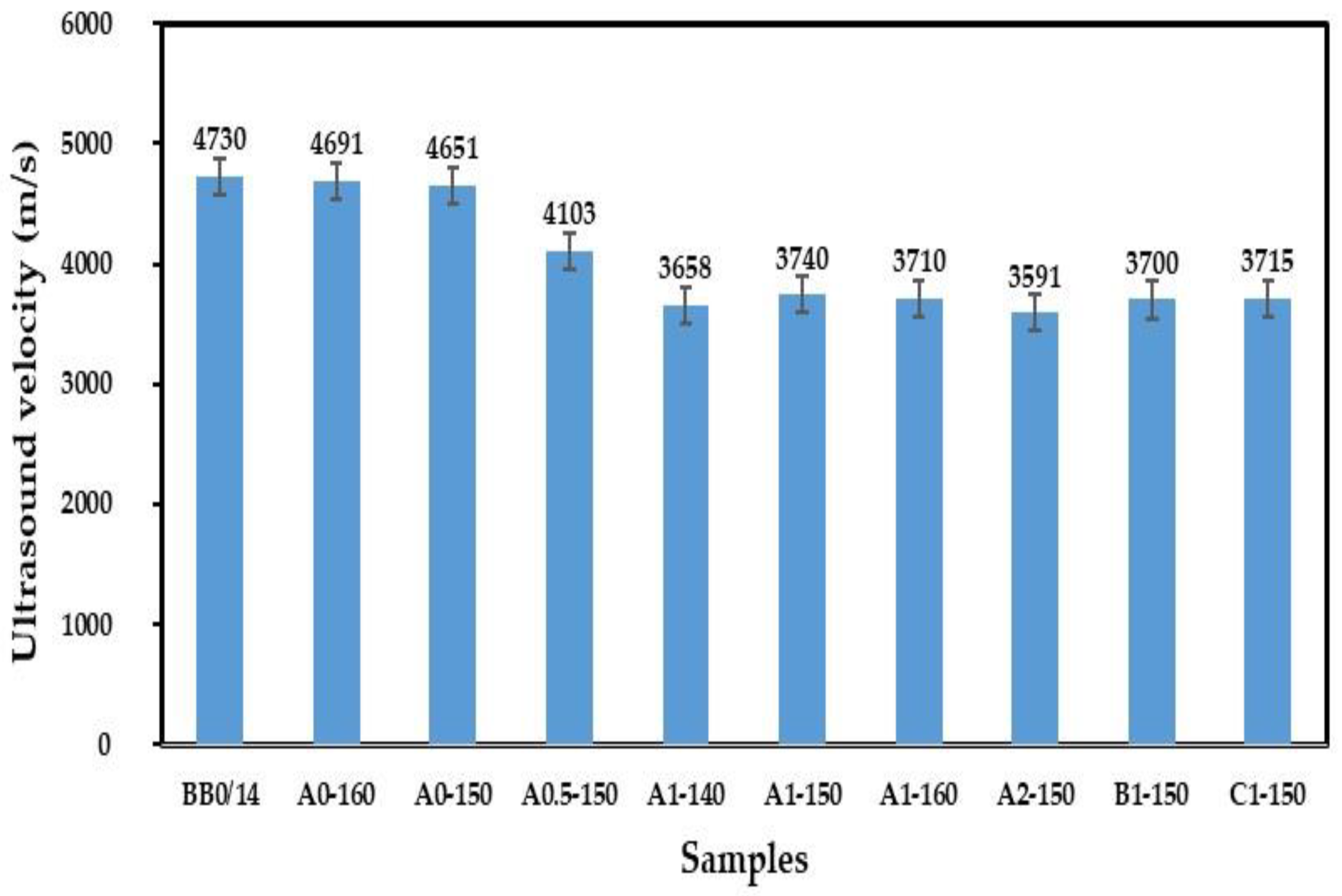

2.3.2. Determination of the Ultrasonic Pulse Velocity

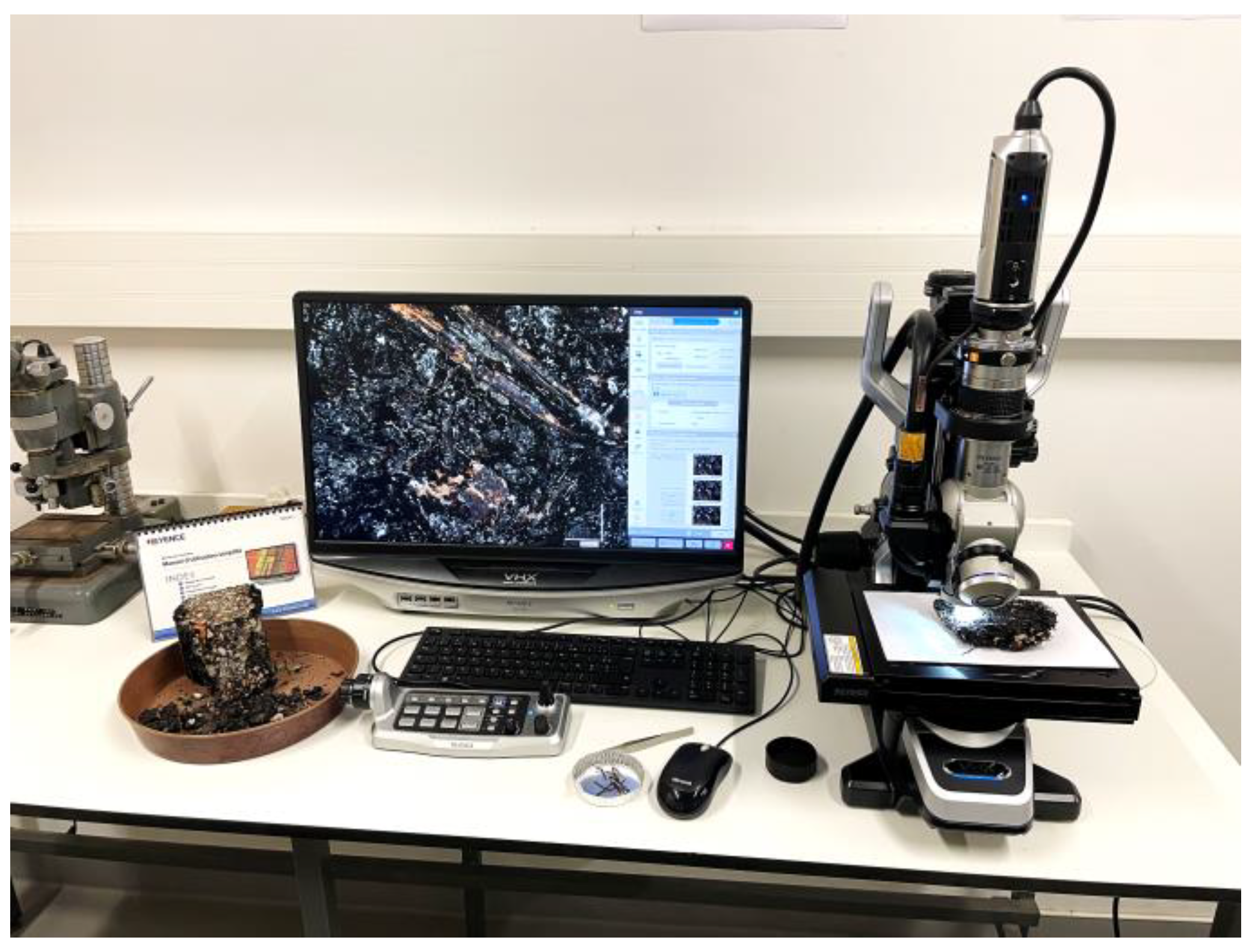

2.3.3. Microscopic Investigation of Asphalt Mixtures

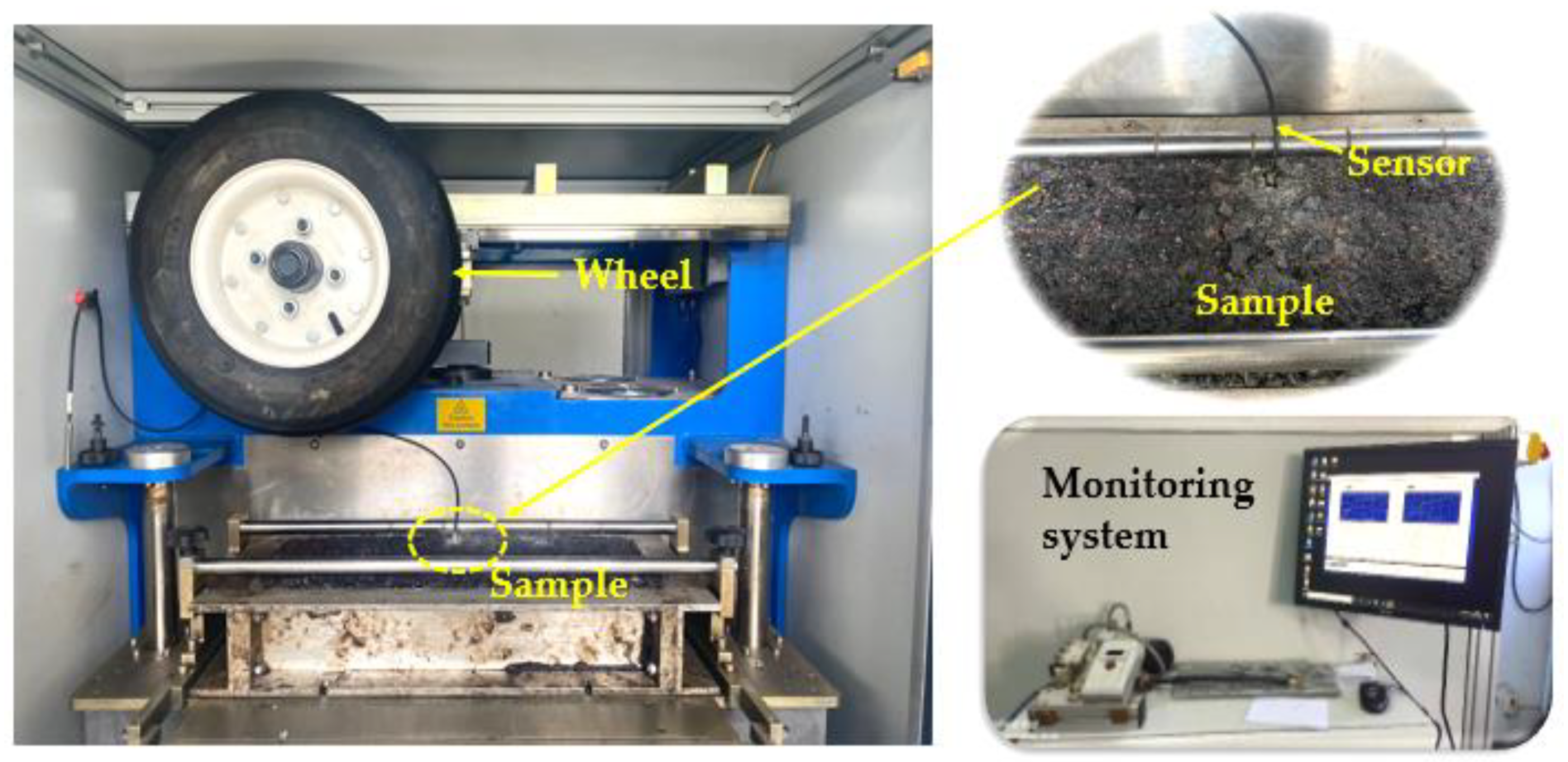

2.3.4. Rutting Resistance

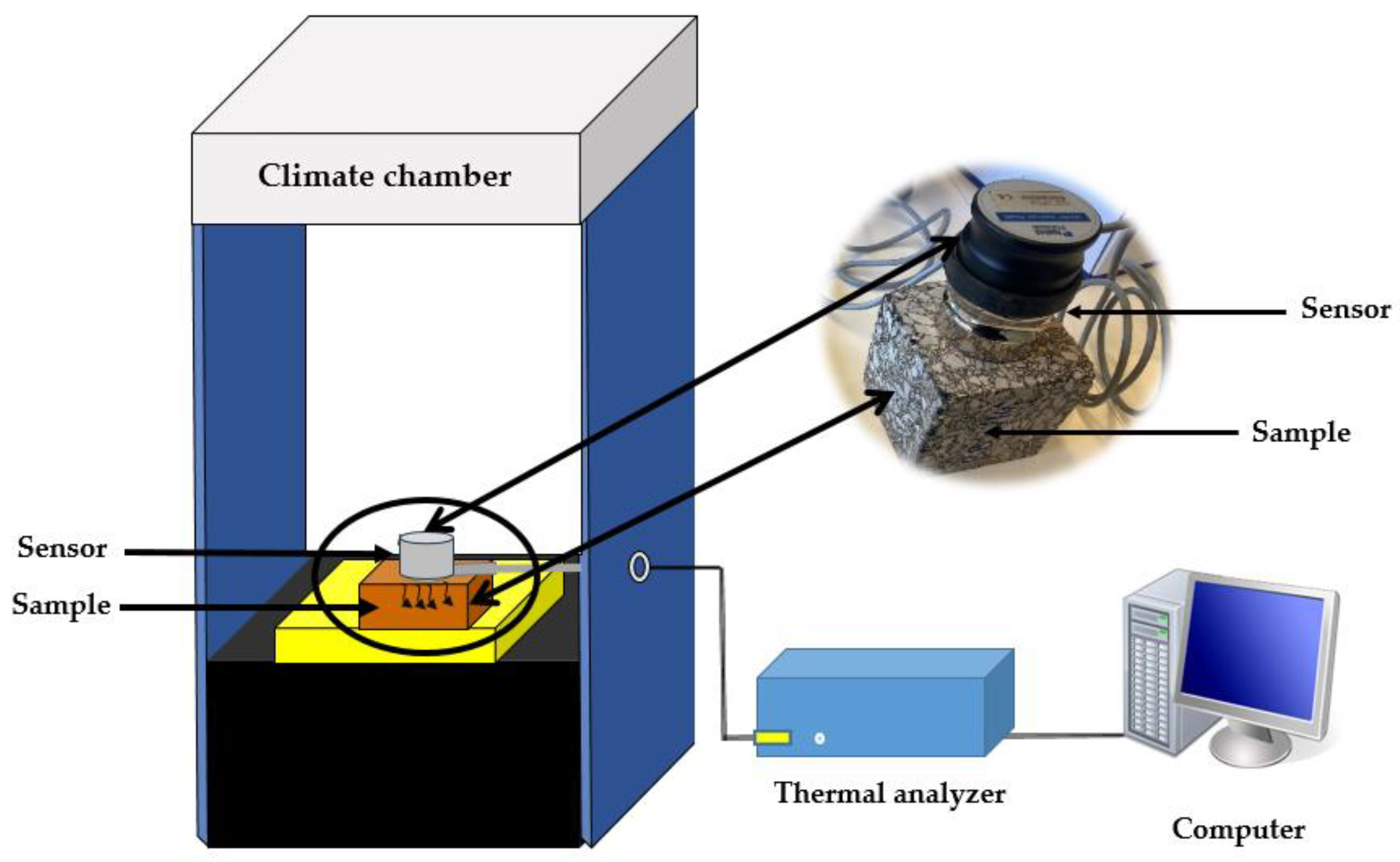

2.3.5. Thermophysical Characterization

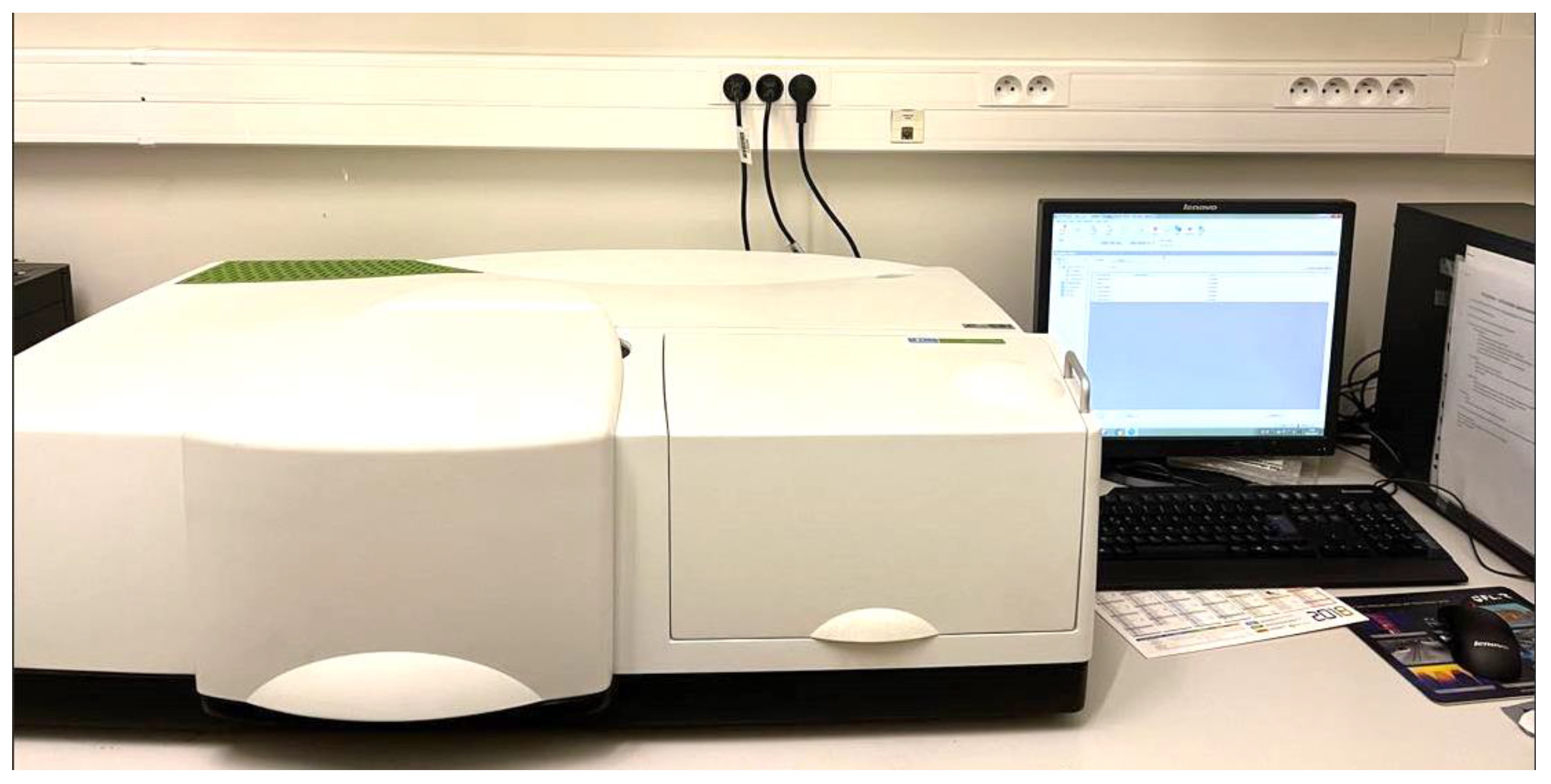

2.3.6. Spectral Reflectance Test

3. Results and Discussion

3.1. Density

3.2. Ultrasonic Pulse Velocity

3.3. Microscopic Investigation of Asphalt Mixtures

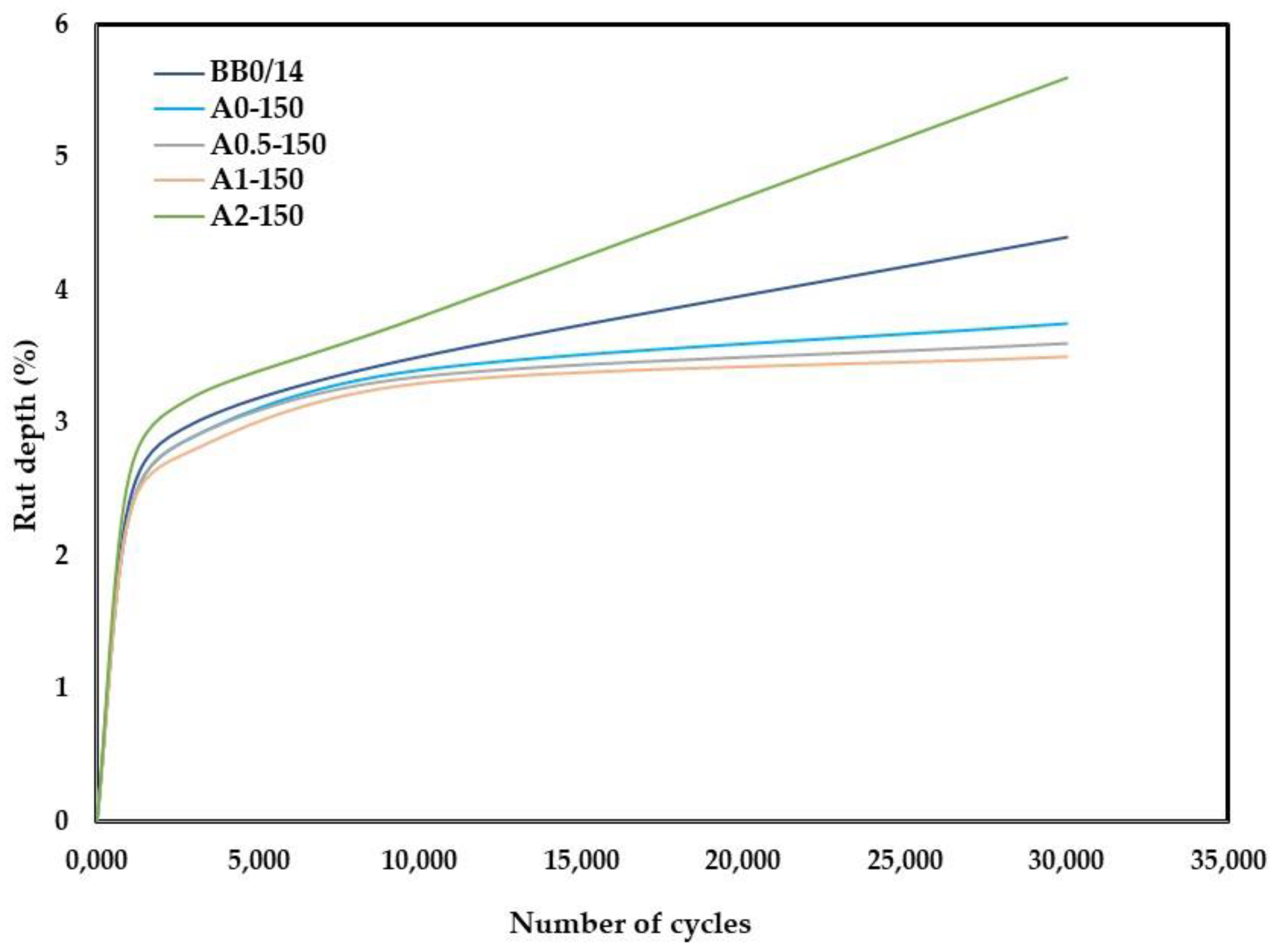

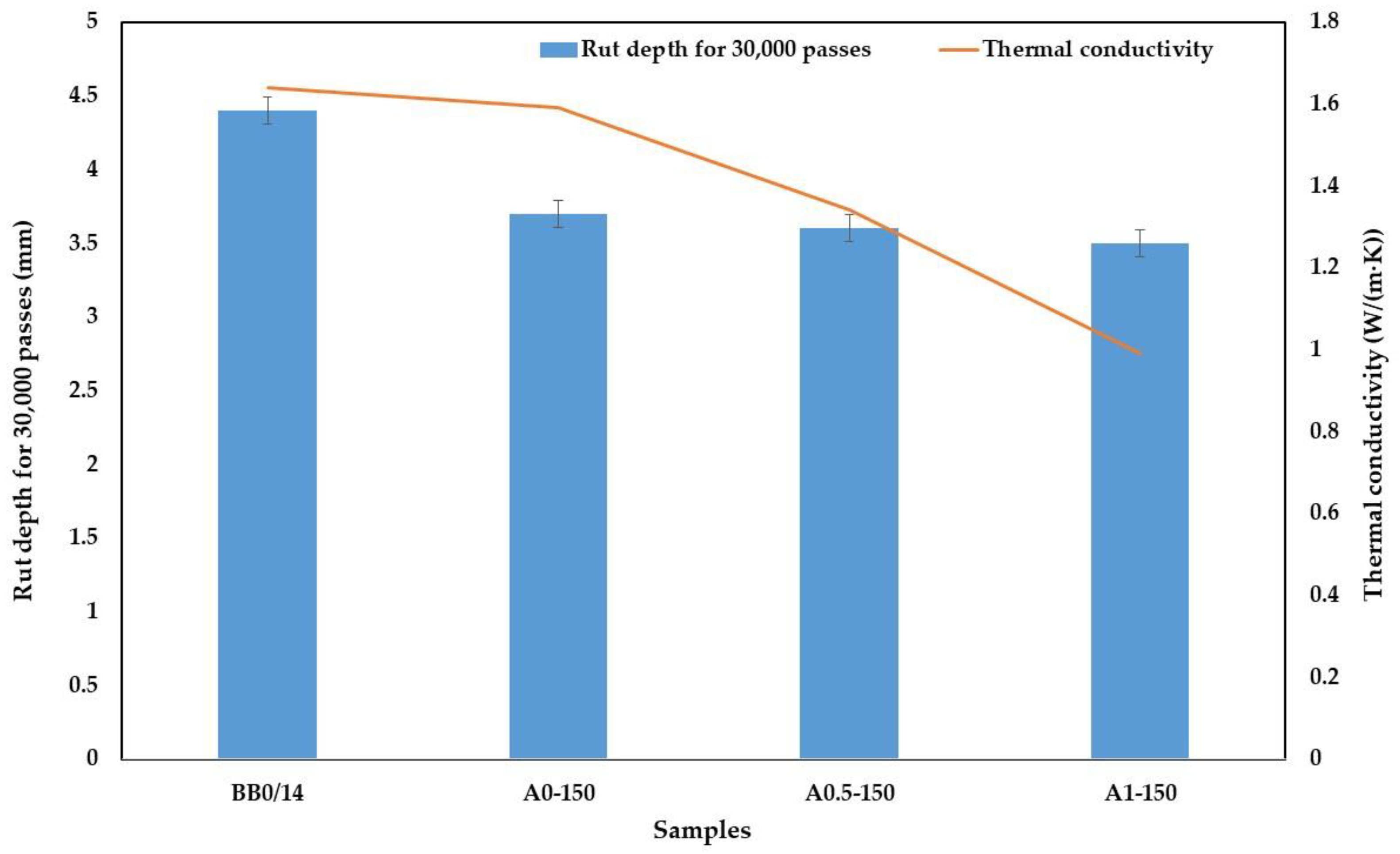

3.4. Rutting Resistance

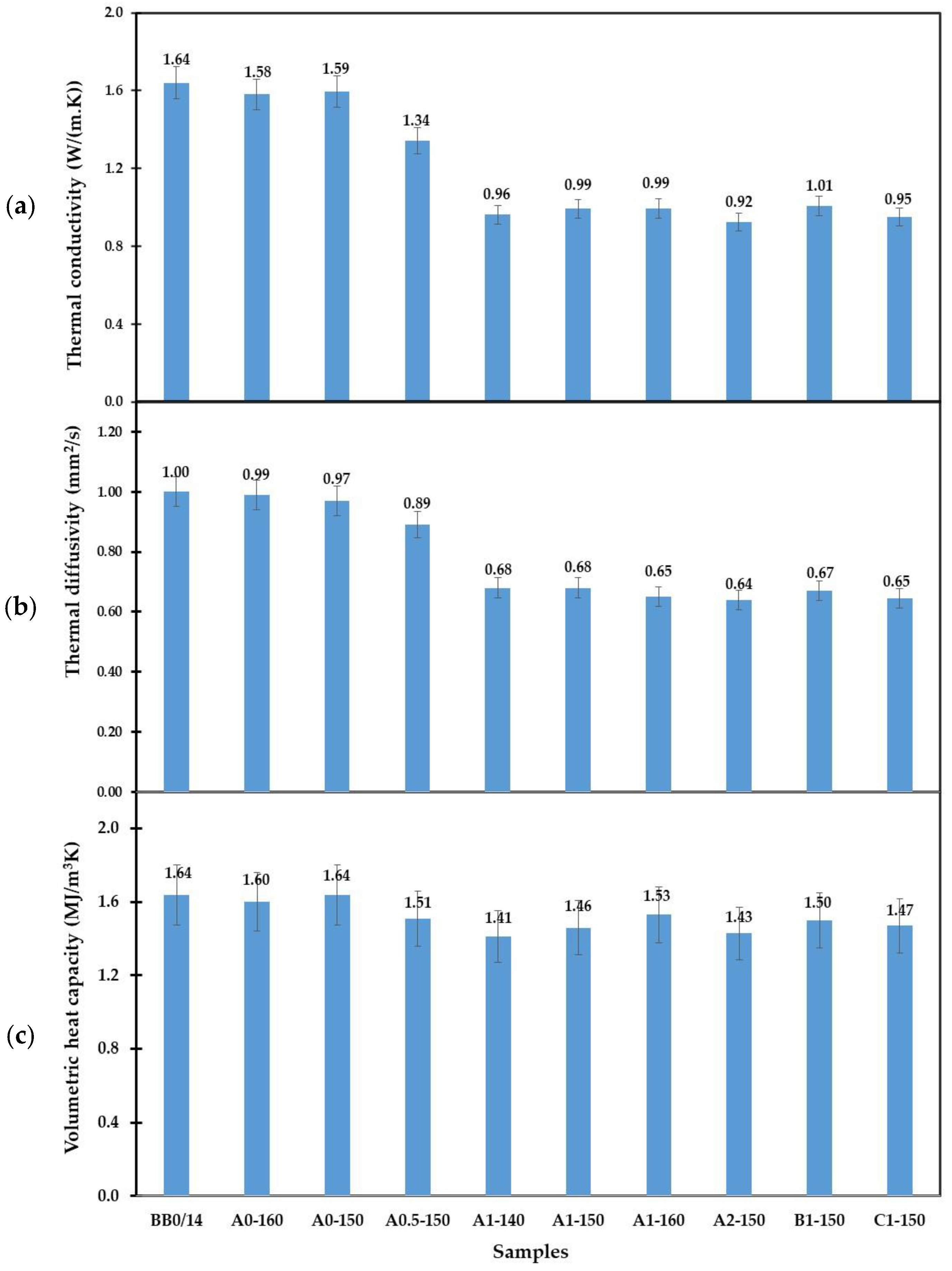

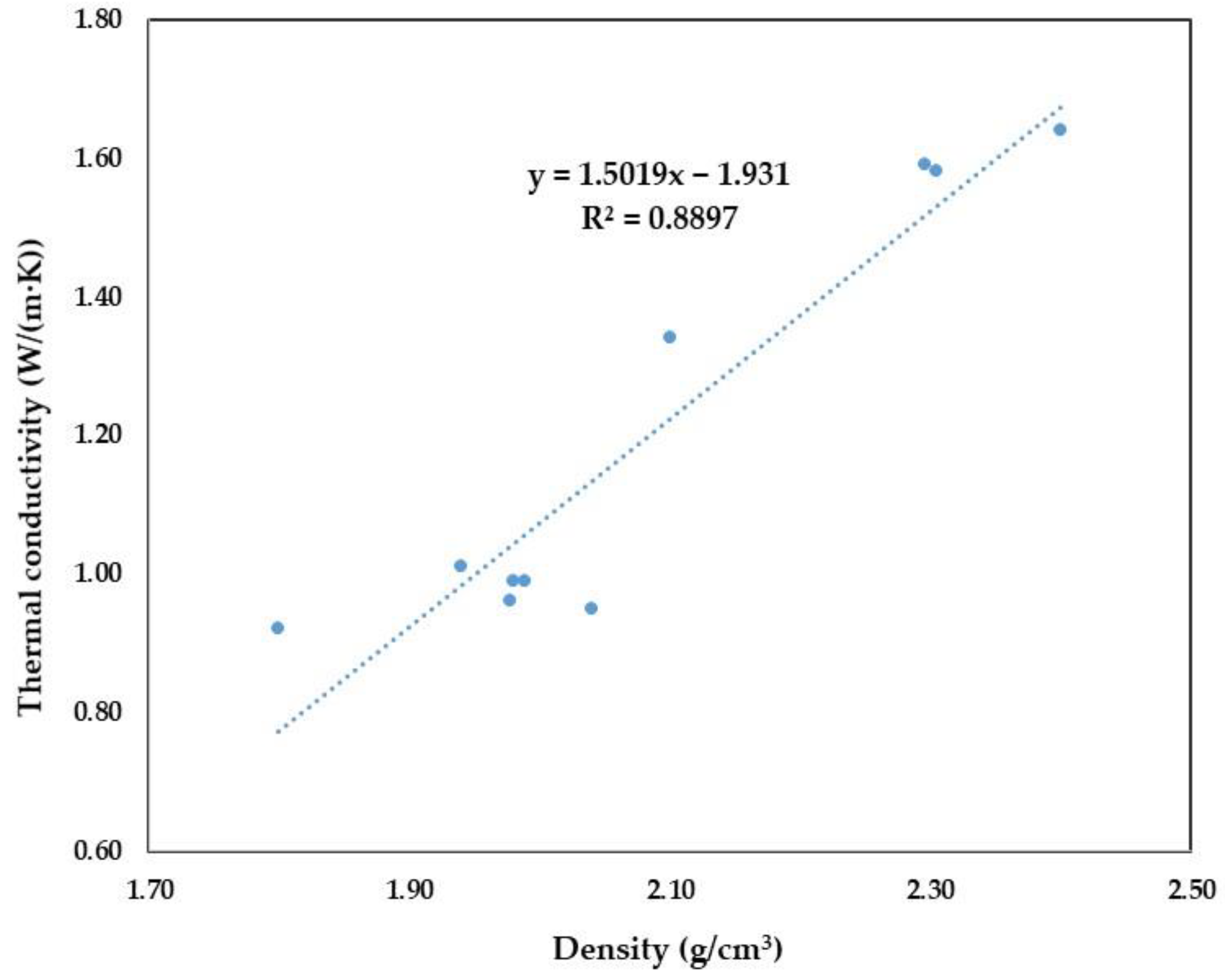

3.5. Thermophysical Properties

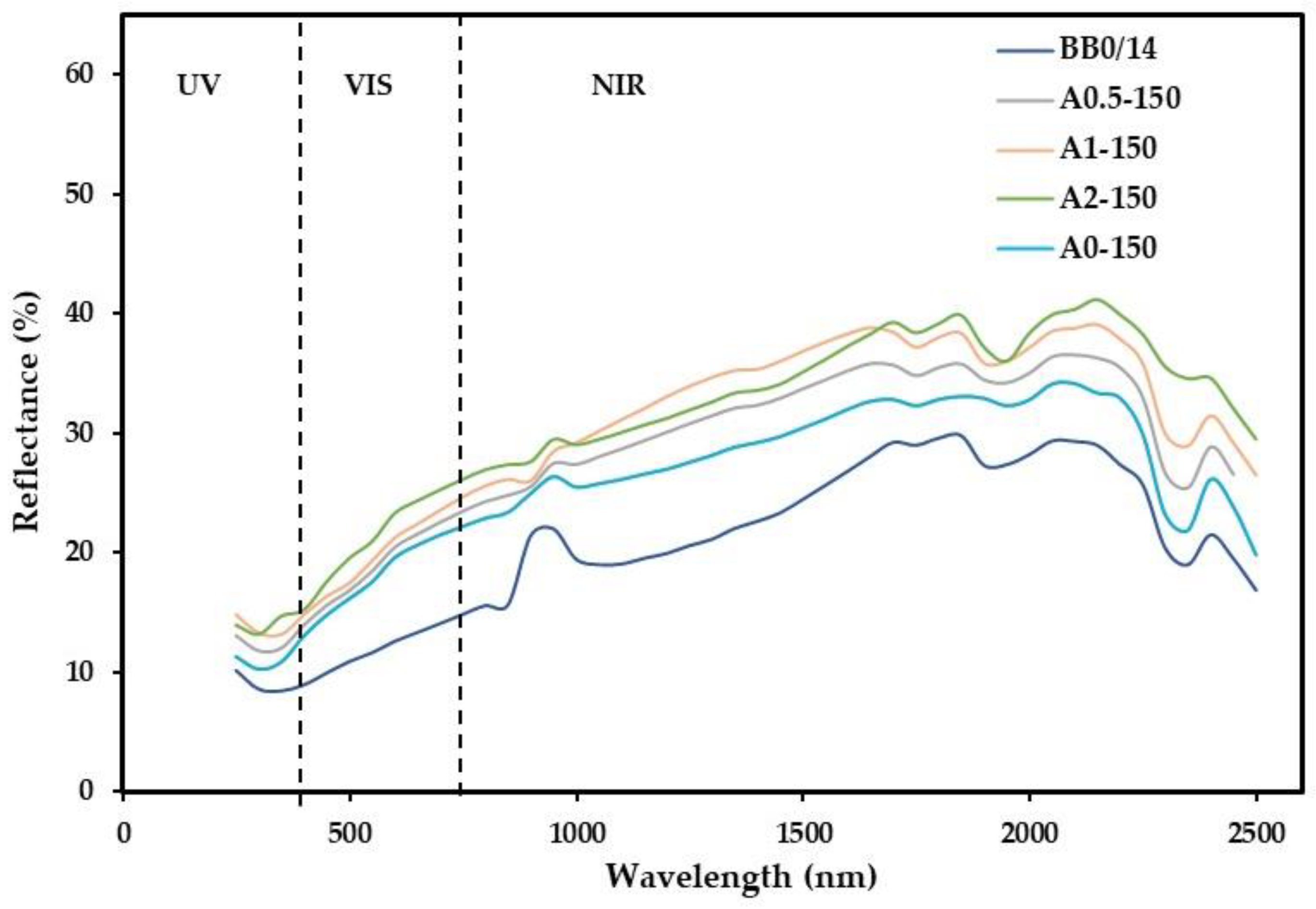

3.6. Spectral Reflectance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Darshan, N.; Kataware, A.V. Exploring different approaches to understand effect of WMA modification on mixing and compaction temperatures of asphalt binders: A laboratory study. Constr. Build. Mater. 2025, 458, 139562. [Google Scholar] [CrossRef]

- Androjić, I.; Alduk, Z.D.; Dimter, S.; Rukavina, T. Analysis of impact of aggregate moisture content on energy demand during the production of hot mix asphalt (HMA). J. Clean. Prod. 2020, 244, 118868. [Google Scholar] [CrossRef]

- Almeida-Costa, A.; Benta, A. Economic and environmental impact study of warm mix asphalt compared to hot mix asphalt. J. Clean. Prod. 2016, 112, 2308–2317. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M. Comparative evaluation of warm mix asphalt containing high percentages of reclaimed asphalt pavement. Constr. Build. Mater. 2013, 44, 92–100. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, R.; Zhou, H.; Huang, W.; Feng, D.; Li, X. Optimizing of asphalt mix design considering mixture performance, environmental impact, and life cycle cost. J. Clean. Prod. 2025, 512, 145618. [Google Scholar] [CrossRef]

- Hasheminezhad, A.; Ceylan, H.; Kim, S. Sustainability promotion through asphalt pavements: A review of existing tools and innovations. Sustain. Mater. Technol. 2024, 42, e01162. [Google Scholar] [CrossRef]

- Daryaee, D.; Habibpour, M.; Norouzi, Y. Chemical properties and mechanical performance of bitumen and asphalt Mixtures with Reclaimed Asphalt Pavement (RAP) under varying temperature conditions. Constr. Build. Mater. 2025, 489, 145343. [Google Scholar] [CrossRef]

- Boarie, A.; Abdelsalam, M.; Gamal, A.; Rabah, M. Laboratory and Environmental Assessment of Asphalt Mixture Modified with a Compound of Reclaimed Asphalt Pavement and Waste Polyethylene. Buildings 2024, 14, 1186. [Google Scholar] [CrossRef]

- Gkyrtis, K.; Pomoni, M. An Overview of the Recyclability of Alternative Materials for Building Surface Courses at Pavement Structures. Buildings 2024, 14, 1571. [Google Scholar] [CrossRef]

- Coelho, L.M.; dos Santos, W.W.; Guimarães, A.C.R.; Monteiro, S.N. Influence of the Baily Gradation Method on the Mechanical Behavior of Asphalt Mixture Containing Steel Slag as an Alternative Aggregate. Buildings 2024, 14, 3942. [Google Scholar] [CrossRef]

- Woszuk, A.; Bandura, L.; Franus, W. Fly ash as low cost and environmentally friendly filler and its effect on the properties of mix asphalt. J. Clean. Prod. 2019, 235, 493–502. [Google Scholar] [CrossRef]

- Silveira, V.L.; Guimarães, A.C.R.; Coelho, L.M.; dos Santos, W.W.; da Silveira, P.H.P.M.; Monteiro, S.N. Recycling Iron Ore Waste through Low-Cost Paving Techniques. Sustainability 2024, 16, 5570. [Google Scholar] [CrossRef]

- Abedin Khan, Z.; Balunaini, U.; Costa, S. Environmental feasibility and implications in using recycled construction and demolition waste aggregates in road construction based on leaching and life cycle assessment—A state-of-the-art review. Clean. Mater. 2024, 12, 100239. [Google Scholar] [CrossRef]

- Zhu, J.; Wu, S.; Zhong, J.; Wang, D. Investigation of asphalt mixture containing demolition waste obtained from earthquake-damaged buildings. Constr. Build. Mater. 2012, 29, 466–475. [Google Scholar] [CrossRef]

- Pesandín, A.; Pérez, I. Laboratory evaluation of hot-mix asphalt containing construction and demolition waste. Constr. Build. Mater. 2013, 43, 497–505. [Google Scholar] [CrossRef]

- Radević, A.; Đureković, A.; Zakić, D.; Mladenović, G. Effects of recycled concrete aggregate on stiffness and rutting resistance of asphalt concrete. Constr. Build. Mater. 2017, 136, 386–393. [Google Scholar] [CrossRef]

- Albayati, A.; Wang, Y.; Wang, Y.; Haynes, J. A sustainable pavement concrete using warm mix asphalt and hydrated lime treated recycled concrete aggregates. Sustain. Mater. Technol. 2018, 18, e0008. [Google Scholar] [CrossRef]

- El-Tahan, D.; Gabr, A.; Dessouky, S.; El-Badawy, S. Study of the Performance of Warm-Mix Asphalt Containing Recycled Concrete as Coarse Aggregate in Egypt and the Middle East. J. Mater. Civ. Eng. 2024, 36, 1–14. [Google Scholar] [CrossRef]

- Guo, Y.; Tataranni, P.; Sangiorgi, C. The use of fibres in asphalt mixtures: A state of the art review. Constr. Build. Mater. 2023, 390, 131754. [Google Scholar] [CrossRef]

- Ramalingam, S.; Murugasan, R.; Nagabhushana, M.N. Laboratory performance evaluation of environmentally sustainable sisal fibre reinforced bituminous mixes. Constr. Build. Mater. 2017, 148, 22–29. [Google Scholar] [CrossRef]

- Xie, T.; Ren, W.; Chen, Y.; Sheng, J.; Wang, L. Enhancing the performance of Asphalt Mastic with Natural Fiber Reinforcement Basalt and Bamboo Fibers. Appl. Sci. 2023, 13, 7946. [Google Scholar] [CrossRef]

- Hussein, F.K.; Isamel, M.Q.; Huseien, G.F. Rock Wool Fiber-Reinforced and Recycled Concrete Aggregate-Imbued Hot Asphalt Mixtures: Design and Susceptibility Evaluation. J. Compos. Sci. 2023, 7, 428. [Google Scholar] [CrossRef]

- Jia, H.; Chen, H.; Sheng, Y.; Meng, J.; Cui, S.; Richard Kim, Y.; Huang, S.; Qin, H. Effect of laboratory aging on the stiffness and fatigue cracking of asphalt mixture containing bamboo fiber. J. Clean. Prod. 2022, 333, 130120. [Google Scholar] [CrossRef]

- Liu, K.; Li, T.; Wu, C.; Jiang, K.; Shi, X. Bamboo fiber has engineering properties and performance suitable as reinforcement for asphalt mixture. Constr. Build. Mater. 2021, 290, 123240. [Google Scholar] [CrossRef]

- Helaili, S.; Chafra, M.; Chevalier, Y. Natural fiber alfa/epoxy randomly reinforced composite mechanical properties identification. Structures 2021, 34, 542–549. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbasi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Mondher, N.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Hanana, S.; Elloumi, A.; Placet, V.; Tounsi, H.; Belghith, H.; Bradai, C. An efficient enzymatic-based process for the extraction of high mechanical properties of alfa fibers. Ind. Crops Prod. 2015, 70, 190–200. [Google Scholar] [CrossRef]

- Garrouri, S.; Lakhal, W.; Benazzouk, A.; Sediki, E. Potential use of Alfa fibers in construction material: Physico-mechanical and thermal characterisation of reinforced specimen. Constr. Build. Mater. 2022, 342, 127787. [Google Scholar] [CrossRef]

- Ajouguim, S.; Page, J.; Djelal, C.; Waqif, M.; Saâdi, L. Impact of Alfa fibers morphology on hydration and mechanical properties of cement mortars. Constr. Build. Mater. 2021, 293, 123514. [Google Scholar] [CrossRef]

- EN 13043; Aggregates for bituminous mixtures and surface treatments for roads, airfields and other trafficked areas. European Committee for Standardization: Brussels, Belgium, 2003.

- EN 1097-6; Tests for mechanical and physical properties of aggregates- Part 6: Determination of particle density and water absorption. European Committee for Standardization: Brussels, Belgium, 2022.

- EN 933-8; Tests for geometrical properties of aggregates- Part 8: Assessment of fines—Sand equivalent test. European Committee for Standardization: Brussels, Belgium, 2015.

- EN 1097-2; Tests for mechanical and physical properties of aggregates—Part 2: Methods for the determination of resistance to fragmentation. European Committee for Standardization: Brussels, Belgium, 2020.

- EN 1097-1; Tests for mechanical and physical properties of aggregates—Part 1: Determination of the resistance to wear (micro-Deval). European Committee for Standardization: Brussels, Belgium, 2023.

- Fatemi, S.; Imaninasab, R. Performance evaluation of recycled asphalt mixtures by construction and demolition waste materials. Constr. Build. Mater. 2016, 120, 450–456. [Google Scholar] [CrossRef]

- EN 12591; Bitumen and bituminous binders—Specifications for paving grade bitumens. European Committee for Standardization: Brussels, Belgium, 2009.

- Prosperi, E.; Bocci, E.; Bocci, M. Effect of Bitumen Production Process and Mix Heating Temperature on the Rheological Properties of Hot Recycled Mix Asphalt. Sustainability 2022, 14, 9677. [Google Scholar] [CrossRef]

- EN 1426; Bitumen and bituminous binders—Determination of needle penetration. European Committee for Standardization: Brussels, Belgium, 2024.

- EN 1427; Bitumen and bituminous binders—Determination of the softening point—Ring and Ball method. European Committee for Standardization: Brussels, Belgium, 2015.

- EN 12607-1; Bitumen and bituminous binders—Determination of the resistance to hardening under the influence of heat and air—Part 1: RTFOT method. European Committee for Standardization: Brussels, Belgium, 2024.

- EN ISO 2592; Determination of flash and fire points—Cleveland open cup method. European Committee for Standardization: Brussels, Belgium, 2017.

- EN 13108-1; Bituminous mixtures—Material specifications-part 1: Asphalt concrete. European Committee for Standardization: Brussels, Belgium, 2016.

- EN 13108-20; Bituminous mixtures—Material specifications—Part 20: Type Testing. European Committee for Standardization: Brussels, Belgium, 2016.

- XP P98-151; Bituminous mixtures—Specifications and test methods for manufacturing, laying and compacting of bituminous mixes for roads and airfields. French Standardization Association: Paris, France, 1996.

- EN 12504-4; Testing concrete in structures—Part 4: Determination of ultrasonic pulse velocity. European Committee for Standardization: Brussels, Belgium, 2004.

- EN 12697-22; Bituminous mixtures—Test methods for hot mix asphalt—Part 22: Wheel tracking. European Committee for Standardization: Brussels, Belgium, 2020.

- Mirzanamadi, R.; Johansson, P.; Grammatikos, S.A. Thermal properties of asphalt concrete: A numerical and experimental study. Constr. Build. Mater. 2018, 158, 774–785. [Google Scholar] [CrossRef]

- ISO 22007-2; Plastics—Determination of thermal conductivity and thermal diffusivity—Part 2: Transient plane heat source (hot disc) method. International Organization for Standardization: Geneva, Switzerland, 2015.

- Ajouguim, S.; Page, J.; Djelal, C.; Saâdi, L. Effect of treated Alfa fibers on hydration kinetics, mechanical, and adhesion properties of fiber cement composit. J. Build. Eng. 2023, 71, 106558. [Google Scholar] [CrossRef]

- Ahmed, K.U.; Geremew, A.; Jemal, A. The comparative study on the performance of bamboo fiber and sugarcane bagasse fiber as modifiers in asphalt concrete production. Heliyon 2022, 8, e09842. [Google Scholar] [CrossRef] [PubMed]

- Kareem, A.I.; Sahib Banyhussan, Q.; Al-Taweel, H.M. Measurement of aggregates breakage of asphalt mixtures with construction and demolition waste. Mater. Today Proc. 2022, 61, 420–427. [Google Scholar] [CrossRef]

- Al-Mufti, R.; Fried, A. Improving the strength properties of recycled asphalt aggregate concrete. Constr. Build. Mater. 2017, 149, 45–52. [Google Scholar] [CrossRef]

- Borinaga-Traviño, R.; Orbe, A.; Canales, J.; Norambuena-Contreras, J. Thermal and mechanical properties of mortars reinforced with recycled brass fibres. Constr. Build. Mater. 2021, 284, 122832. [Google Scholar] [CrossRef]

- Tang, N.; Guo, S.; Yang, Y.; Sun, W. Ultrasonic waves generated by smart aggregates for concealed crack detection in asphalt mixture. Constr. Build. Mater. 2024, 438, 137183. [Google Scholar] [CrossRef]

- Cui, S.; Sheng, Y.; Wang, Z.; Jia, H.; Qiu, W.; Temitope, A.A.; Xu, Z. Effect of the fiber surface treatment on the mechanical performance of bamboo fiber modified asphalt binder. Constr. Build. Mater. 2022, 347, 128453. [Google Scholar] [CrossRef]

- Jia, H.; Sheng, Y.; Lv, H.; Kim, Y.R.; Zhao, X.; Meng, J.; Xiong, R. Effects of bamboo fiber on the mechanical properties of asphalt mixtures. Constr. Build. Mater. 2021, 289, 123196. [Google Scholar] [CrossRef]

- Shamsaei, M.; Carter, A.; Vaillancourt, M. Using construction and demolition waste materials to alleviate the negative effect of pavements on the urban heat island: A laboratory, field, and numerical study. Case Stud. Constr. Mater. 2024, 20, e03346. [Google Scholar] [CrossRef]

- Charai, M.; Mezrhab, A.; Moga, L.; Karkri, M. Hygrothermal, mechanical and durability assessment of vegetable concrete mixes made with Alfa fibers for structural and thermal insulating. Constr. Build. Mater. 2022, 335, 127518. [Google Scholar] [CrossRef]

- Qiu, H.; Wu, Y.; Chen, H.; Wang, R.; Yu, J.; Lin, Y. Influence of SiC on the thermal energy transfer and storage characteristics of microwave-absorbing concrete containing magnetite and/or carbonyl iron powder. Constr. Build. Mater. 2023, 366, 130191. [Google Scholar] [CrossRef]

- Ajouguim, S.; Talibi, S.; Djelal-Dantec, C.; Hajjou, H.; Waqif, M.; Stefanidou, M.; Saadi, L. Effect of Alfa fibers on the mechanical and thermal properties of compacted earth bricks. Mater. Today Proc. 2021, 37, 4049–4057. [Google Scholar] [CrossRef]

- Mohajerani, A.; Bakaric, J.; Jeffrey-Bailey, T. The urban heat island effect, its causes, and mitigation, with reference to the thermal properties of asphalt concrete. J. Environ. Manag. 2017, 197, 522–538. [Google Scholar] [CrossRef] [PubMed]

- Sabri, K.F.; Wang, Y.D.; Liu, J. Improving rheological and thermal performance of Gilsonite-Modified binder with phase change materials. Constr. Build. Mater. 2023, 399, 132557. [Google Scholar] [CrossRef]

- Hassn, A.; Aboufoul, M.; Wu, Y.; Dawson, A.; Garcia, A. Effect of air voids content on thermal properties of asphalt mixtures. Constr. Build. Mater. 2016, 115, 327–335. [Google Scholar] [CrossRef]

- Elhamdouni, Y.; Khabbazi, A.; Benayad, C.; Dadi, A.; Ahmid, O.I. Effect of fiber on thermophysical characteristics of a material based on clay. Energy Procedia 2015, 74, 718–727. [Google Scholar] [CrossRef]

- Akçaözoğlu, S.; Akçaözoğlu, K.; Atis, C.D. Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Compos. Part. B 2013, 45, 721–726. [Google Scholar] [CrossRef]

- Shanbara, H.K.; Ruddock, F.; Atherton, W. Predicting the rutting behaviour of natural fibre-reinforced cold mix asphalt using the finite element method. Constr. Build. Mater. 2018, 167, 907–917. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Jia, N.; Xie, N.; Kousis, I.; Santamouris, M. Laboratorial investigation on optical, thermal and pavement performance of biomimetic dark reflective coatings with composite structure for pavement cooling. Build. Environ. 2024, 266, 112057. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, H.; Yang, X.; Leng, Z.; Tang, Y. Cooling efficiency of thermochromic asphalt pavement material and its contribution to field performance enhancement of asphalt mixture. Constr. Build. Mater. 2024, 411, 134562. [Google Scholar] [CrossRef]

- Yang, L.; Luo, W.; Muhammad, Y.; Meng, F.; Li, J.; Zhao, Z.; Li, J. Surface modification of bagasse fibers based on polyphenol-induced self-supplied lignin for the creation of composite SBS-modified asphalt. Ind. Crops Prod. 2024, 208, 117835. [Google Scholar] [CrossRef]

| Study | Material Used | Key Findings |

|---|---|---|

| Zhu et al. [14] | CDW | Improved permanent deformation resistance |

| Pesandín et al. [15] | CDW (5-30%) | Up to 20% of CDW yielded fatigue life similar to conventional mix |

| Radević et al. [16] | RCA (30%) | Enhanced rutting resistance |

| El-Tahan et al. [18] | Treated CDW | Enhanced resistance to water damage and improved fatigue durability |

| Xie et al. [21] | Bamboo + Basalt Fibers | Enhanced rutting resistance |

| Hussein et al. [22] | RCA + Rock Wool fibers | Improved cracking resistance and mixture stability |

| Jia et al. [23] | Bamboo Fiber | Increased cracking resistance and mixture stiffness |

| Liu et al. [24] | Bamboo Fiber | Improved the overall performance of the asphalt, in terms of thermal stability and resistance to cracking |

| Composition | Property | Unit | Value | Specifications | Test Method |

|---|---|---|---|---|---|

| Fine aggregate 0–4 mm | Density | g/cm3 | 2.69 | - | EN 1097-6 [31] |

| Sand equivalent test | % | 68 | ≥50 | EN 933-8 [32] | |

| Coarse aggregate 4–8 mm | Density | g/cm3 | 2.6 | - | EN 1097-6 [31] |

| Water absorption | % | 0.66 | ≤2 | EN 1097-6 [31] | |

| Coarse aggregate 8–14 mm | Density | g/cm3 | 2.58 | - | EN 1097-6 [31] |

| Los Angelos Abrasion test | % | 21 | ≤25 | EN 1097-2 [33] | |

| Micro-Deval wearing test | % | 18 | ≤25 | EN 1097-1 [34] | |

| Water absorption | % | 0.58 | ≤2 | EN 1097-6 [31] |

| Property | Unit | Value | Test Method |

|---|---|---|---|

| Density | g/cm3 | 2.1 | EN 1097-6 [31] |

| Water absorption | % | 5.8 | EN 1097-6 [31] |

| Los Angeles Abrasion test | % | 33 | EN 1097-2 [33] |

| Micro-Deval wearing test | % | 31 | EN 1097-1 [34] |

| Property | Unit | Value | Specifications | Test Method |

|---|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 38 | 35 to 50 | EN 1426 [38] |

| Softening point | °C | 52 | 50 to 58 | EN 1427 [39] |

| Retained penetration | % | 67.31 | ≥53 | EN 12607-1 [40] |

| Softening point variation | °C | 2 | ≤11 | EN 12607-1 [40] |

| Flash point | °C | 240 | ≥240 °C | EN ISO 2592 [41] |

| Mixture Nomenclature | NA Content (%) | CDW (%) | Alfa Fibers Content (%) | Asphalt Binder (%) | Mixing T (°C) |

|---|---|---|---|---|---|

| BB0/14 | 100 | 0 | 0 | 5.2 | 160 |

| A0-160 | 80 | 20 | 0 | 5.2 | 160 |

| A0-150 | 80 | 20 | 0 | 5.2 | 150 |

| A0.5-150 | 80 | 20 | 0.5 | 5.2 | 150 |

| A1-160 | 80 | 20 | 1 | 5.2 | 160 |

| A1-150 | 80 | 20 | 1 | 5.2 | 150 |

| A1-140 | 80 | 20 | 1 | 5.2 | 140 |

| A2-150 | 80 | 20 | 2 | 5.2 | 150 |

| B1-150 | 75 | 25 | 1 | 5.2 | 150 |

| C1-150 | 85 | 15 | 1 | 5.2 | 150 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chehata, H.; Jendoubi, A.; Boudenne, A.; Neji, J. Effect of the Integration of Alfa Natural Fibers and Demolition Waste on the Mechanical and Thermal Properties of Warm Mix Asphalt. Buildings 2025, 15, 2845. https://doi.org/10.3390/buildings15162845

Chehata H, Jendoubi A, Boudenne A, Neji J. Effect of the Integration of Alfa Natural Fibers and Demolition Waste on the Mechanical and Thermal Properties of Warm Mix Asphalt. Buildings. 2025; 15(16):2845. https://doi.org/10.3390/buildings15162845

Chicago/Turabian StyleChehata, Haifa, Abir Jendoubi, Abderrahim Boudenne, and Jamel Neji. 2025. "Effect of the Integration of Alfa Natural Fibers and Demolition Waste on the Mechanical and Thermal Properties of Warm Mix Asphalt" Buildings 15, no. 16: 2845. https://doi.org/10.3390/buildings15162845

APA StyleChehata, H., Jendoubi, A., Boudenne, A., & Neji, J. (2025). Effect of the Integration of Alfa Natural Fibers and Demolition Waste on the Mechanical and Thermal Properties of Warm Mix Asphalt. Buildings, 15(16), 2845. https://doi.org/10.3390/buildings15162845