Liquefaction Response and Reinforcement Effect of Saturated Soil Treated by Dynamic Compaction Based on Hydro-Mechanically Coupled Explicit Analysis

Abstract

1. Introduction

2. Hydro-Mechanically Coupled Explicit Model

2.1. Incorporation of Excess Pore Water

2.2. Constitutive Model

3. Model Verification

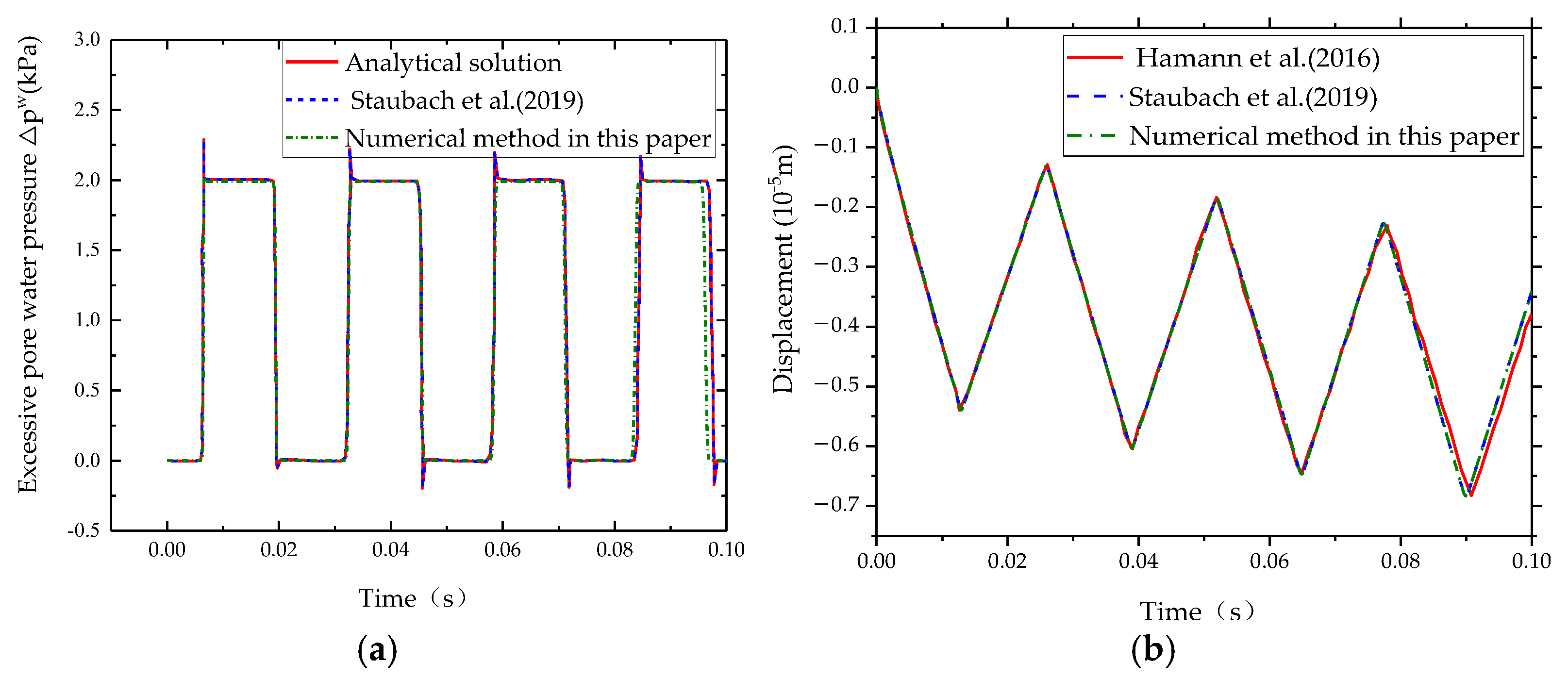

3.1. Comparison of Numerical and Semi-Analytical Results for 1D Wave Propagation

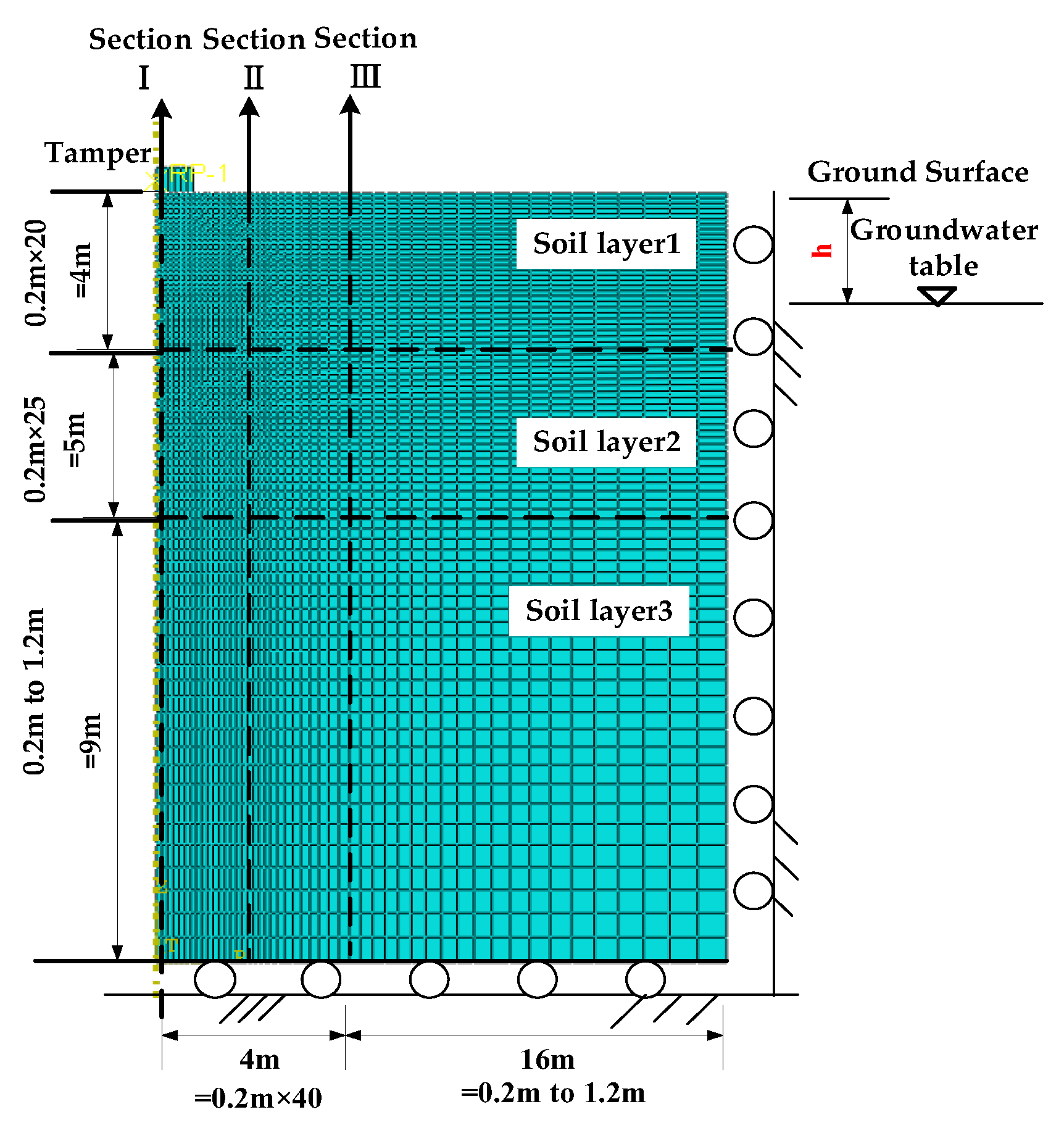

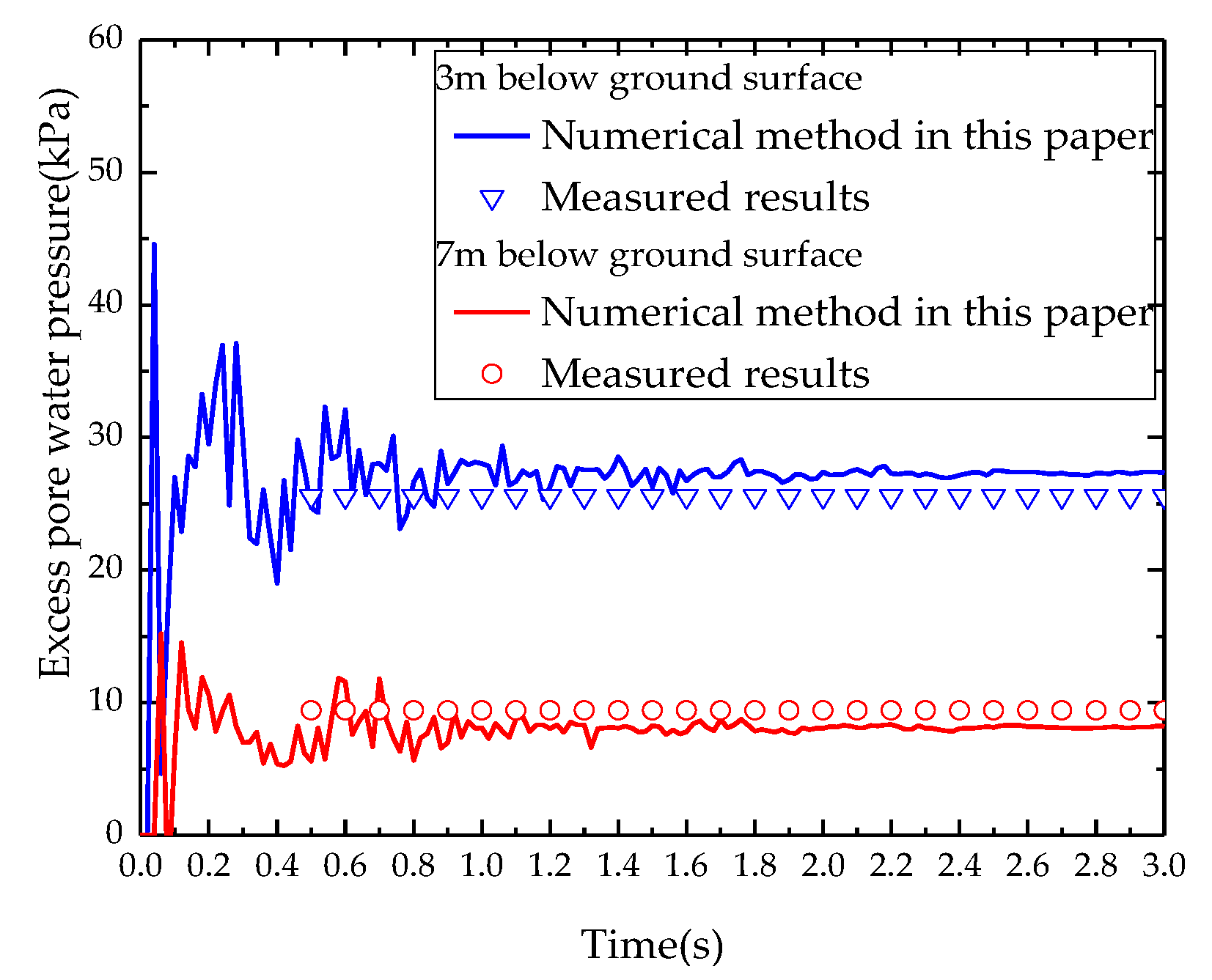

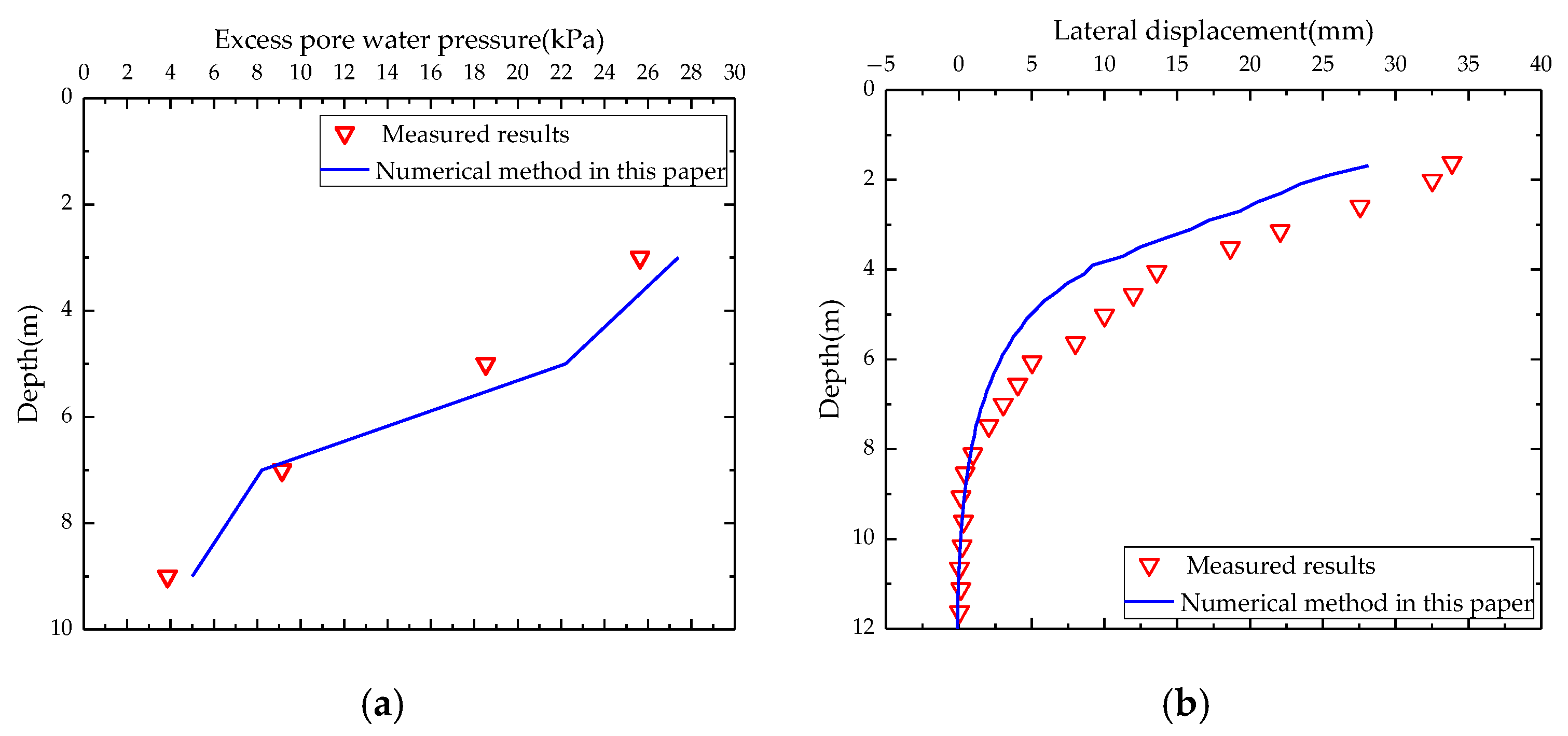

3.2. Verification of Coupled Model

4. Parameter Analysis

4.1. Reinforcement Mechanism and the Influence

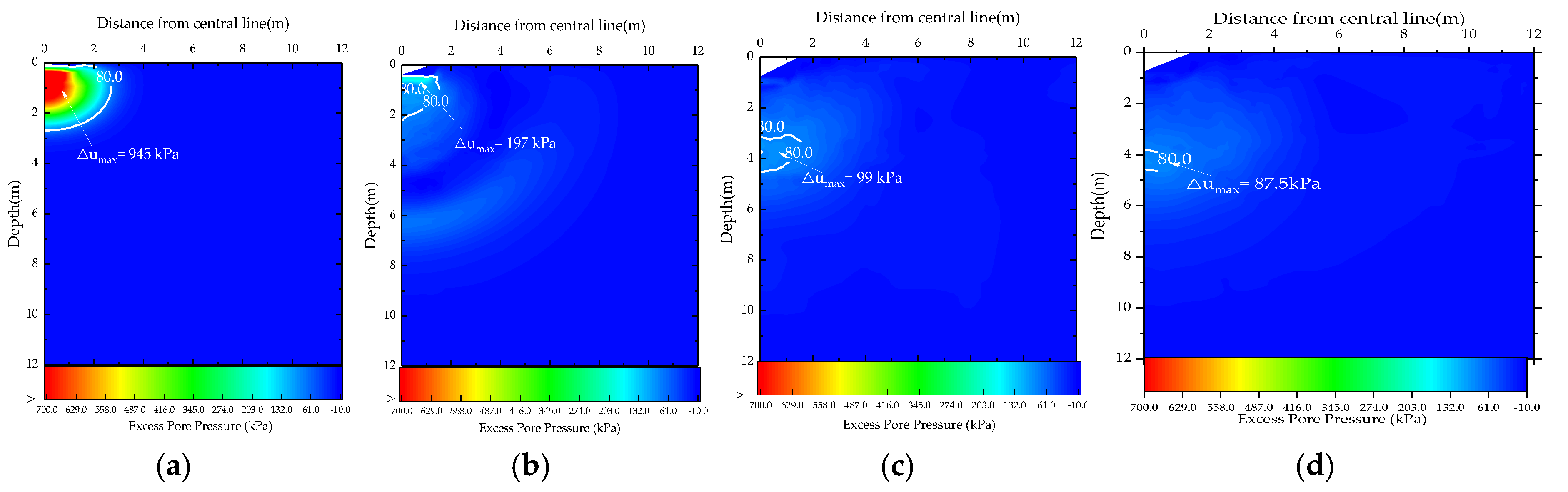

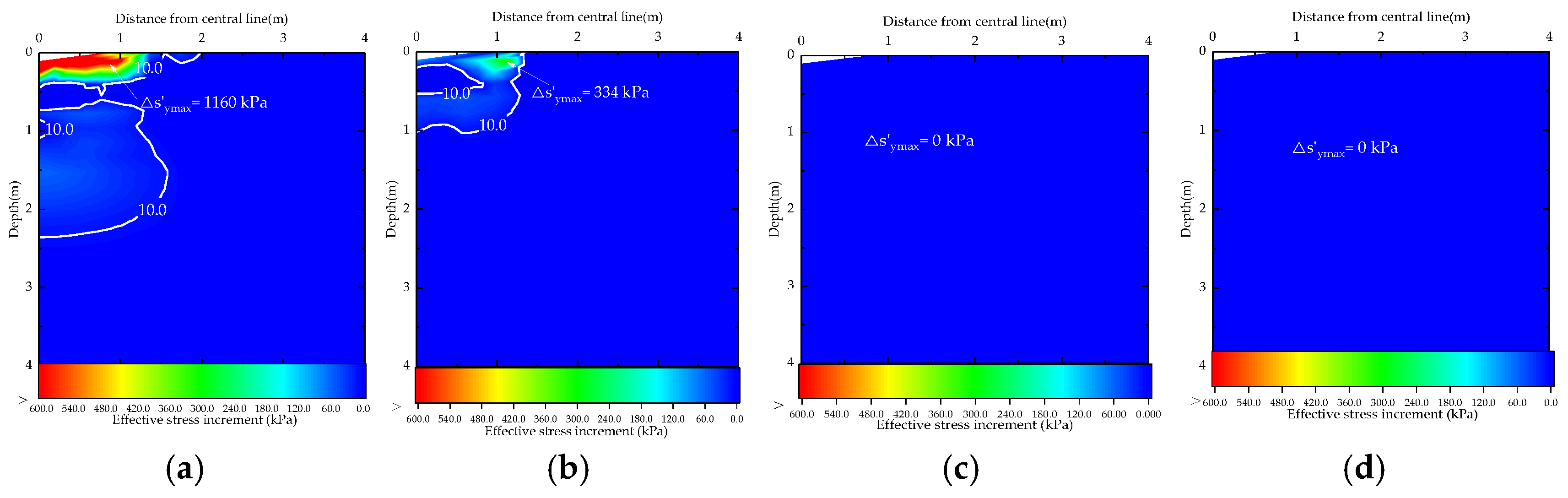

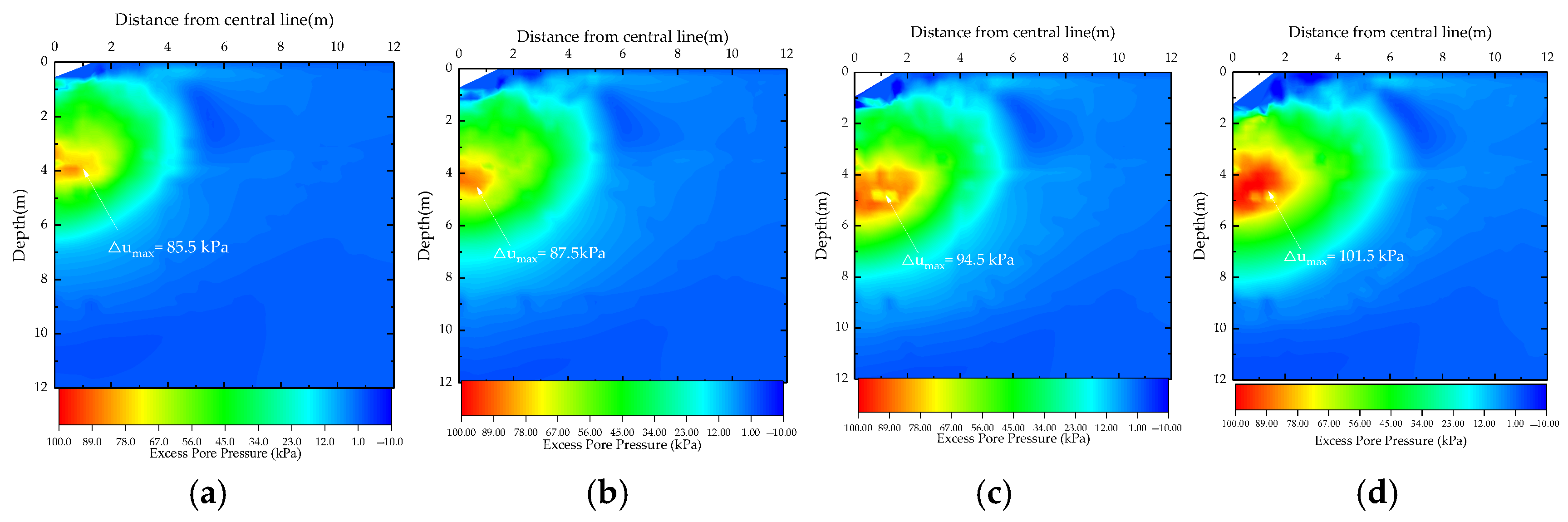

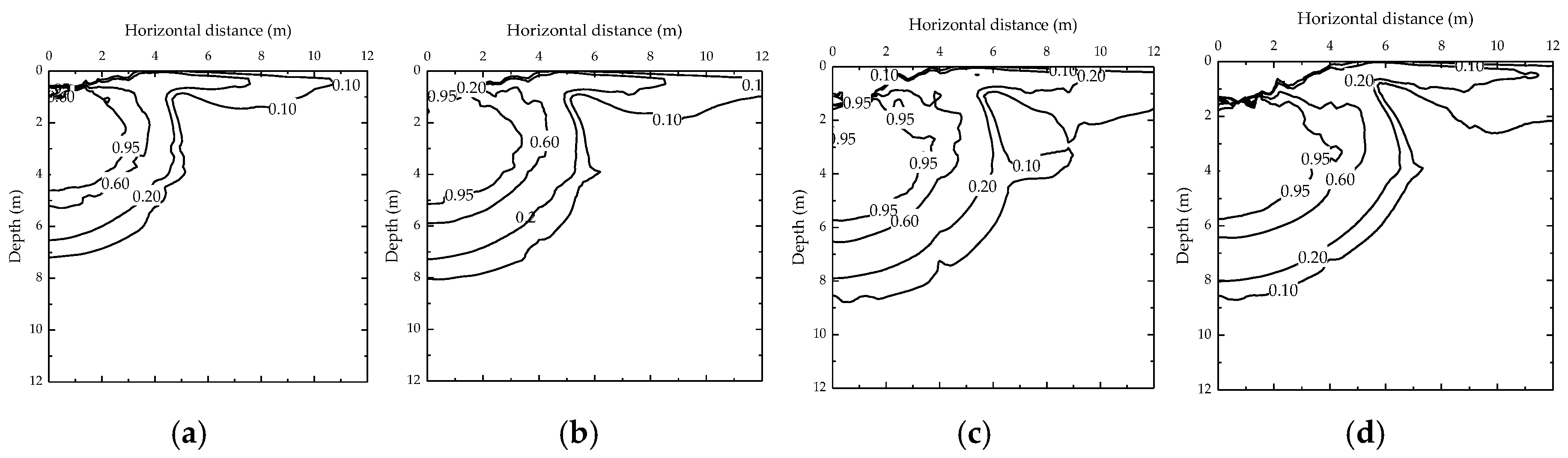

4.2. Effect of Drop Energy

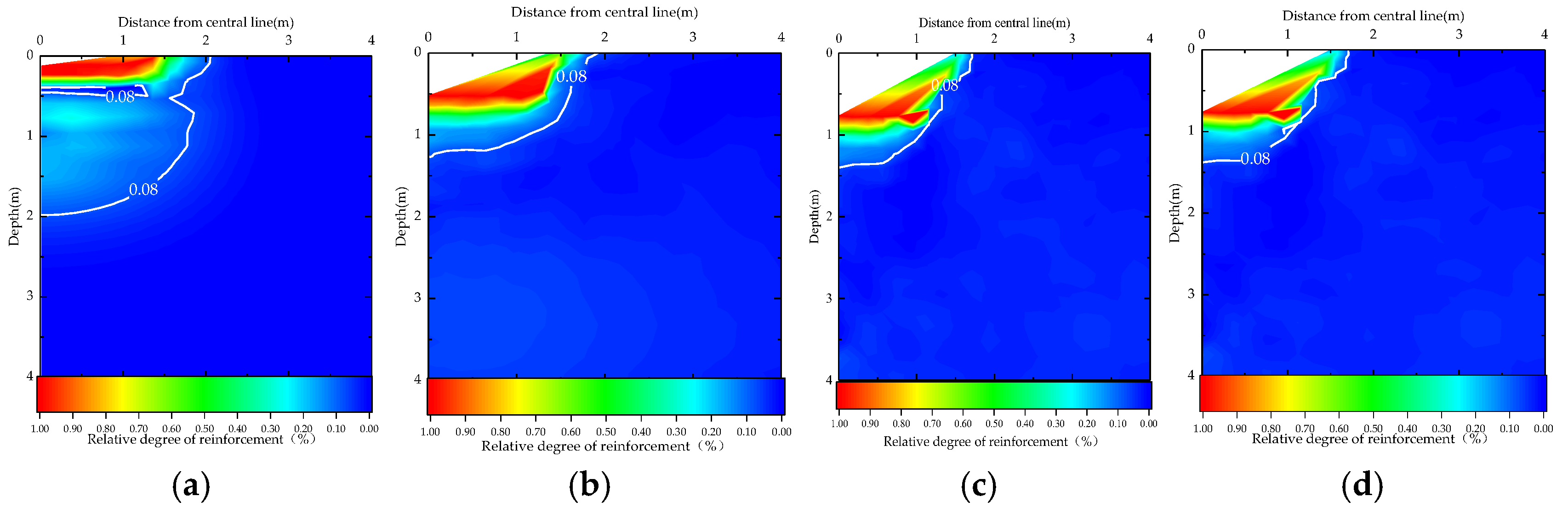

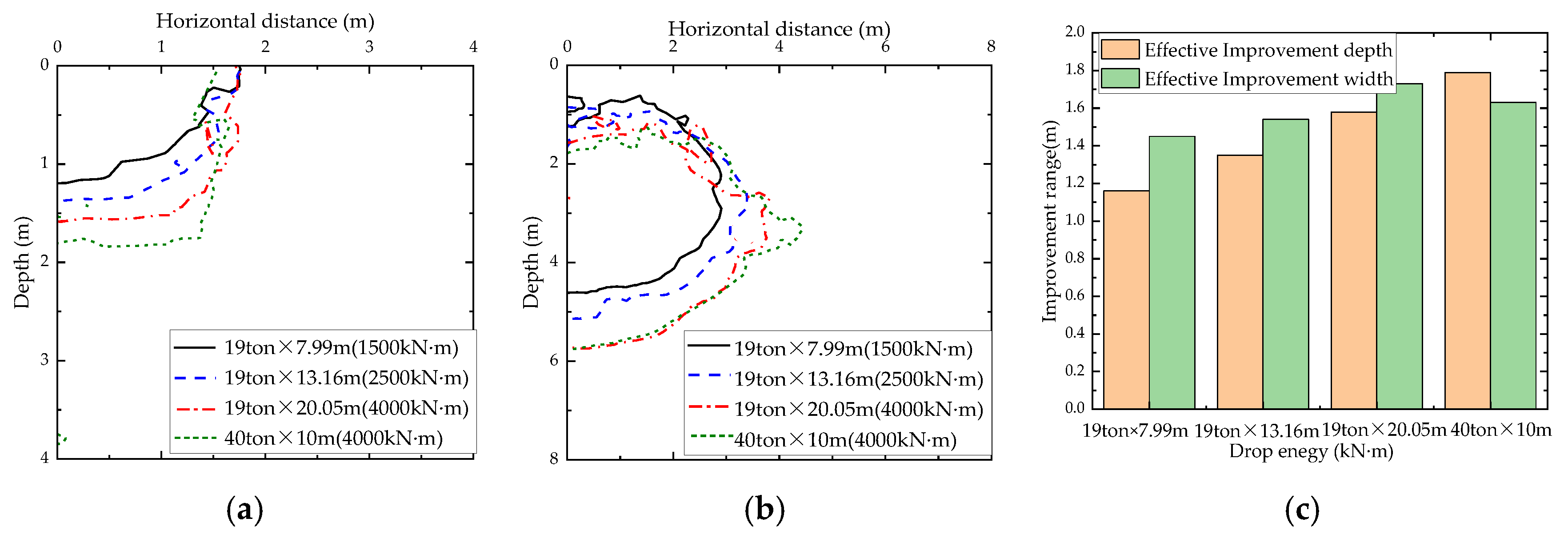

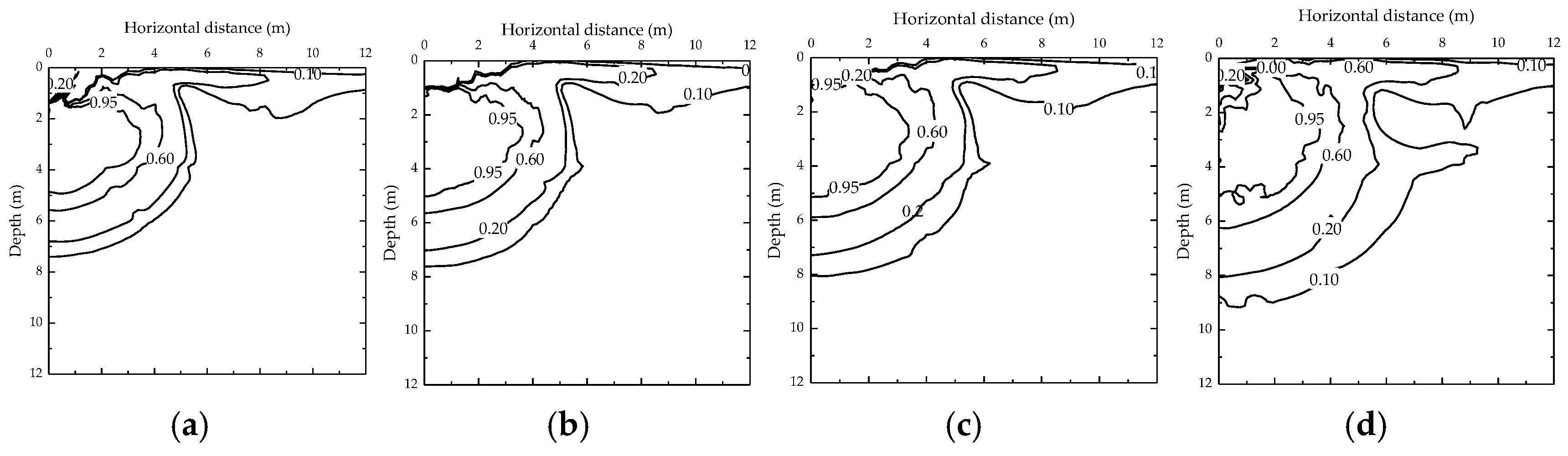

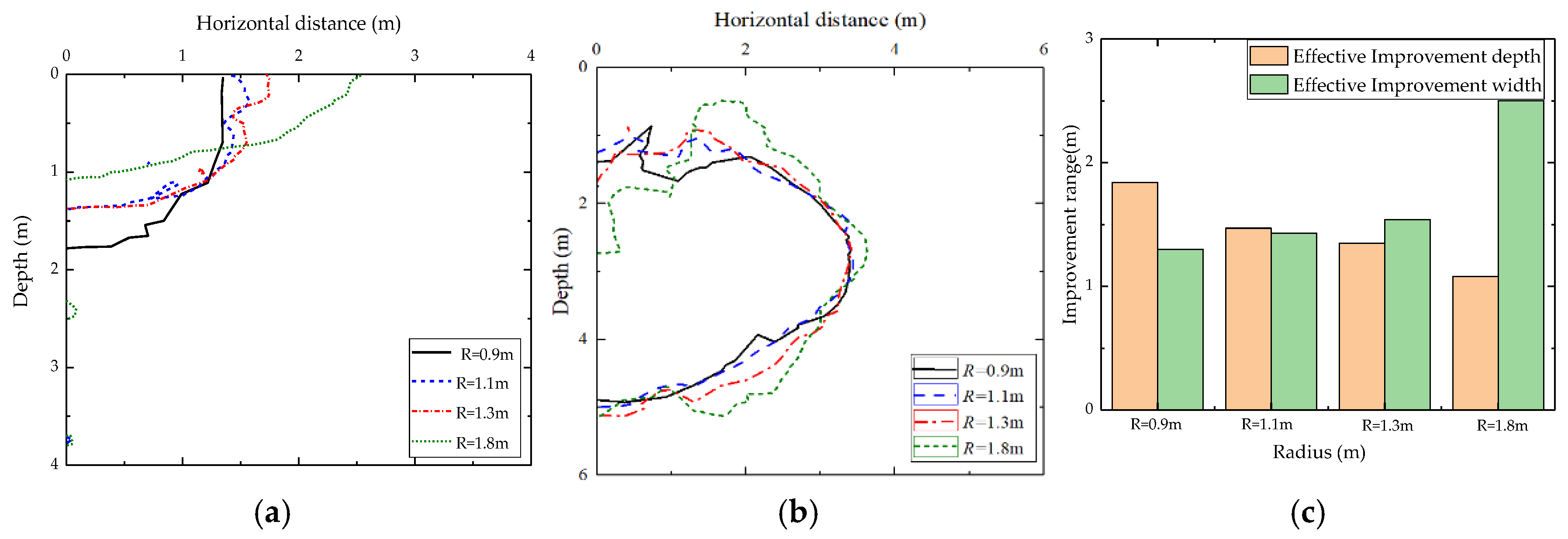

4.3. Effect of Tamper Radius

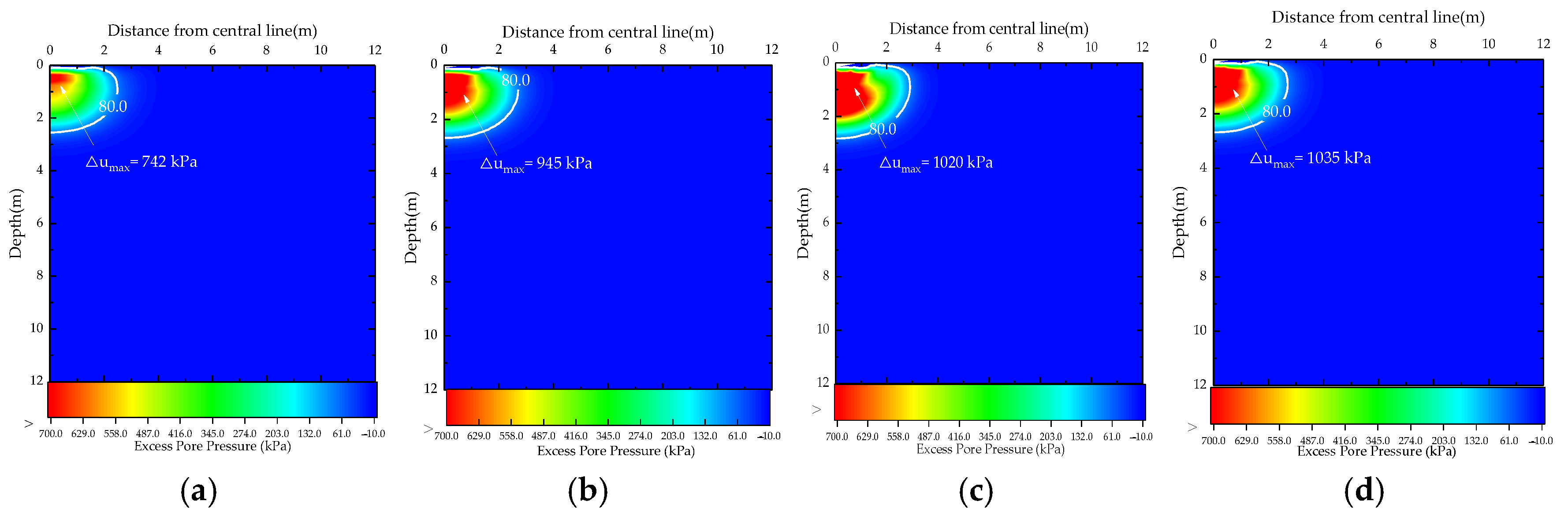

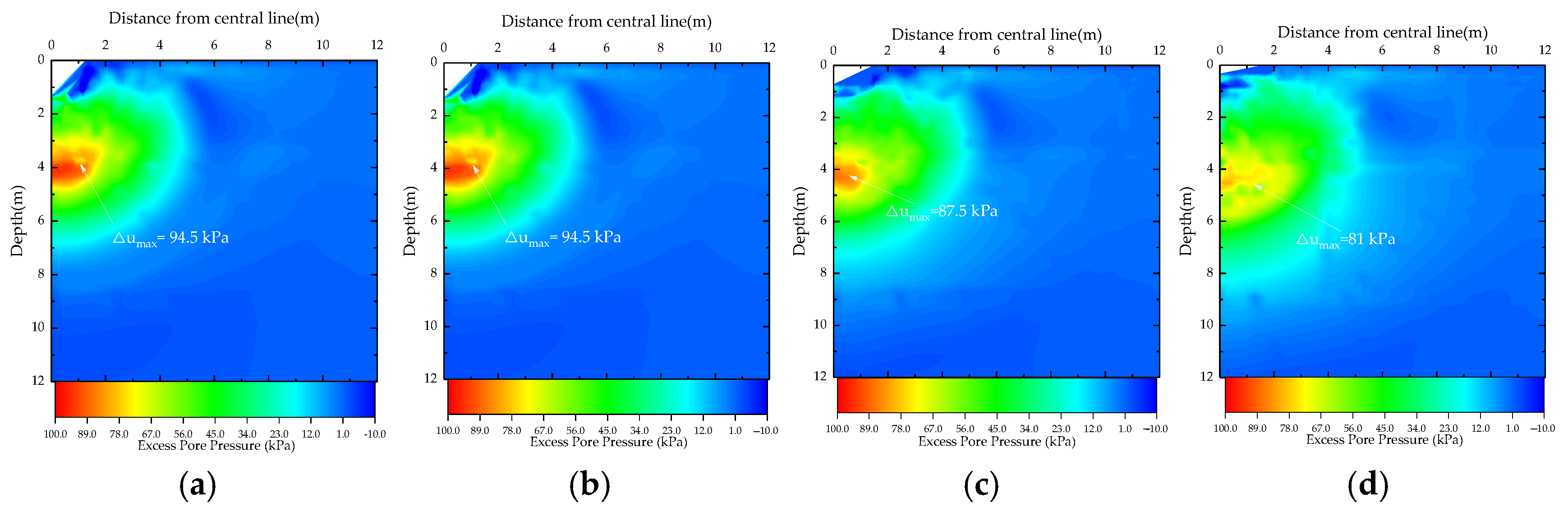

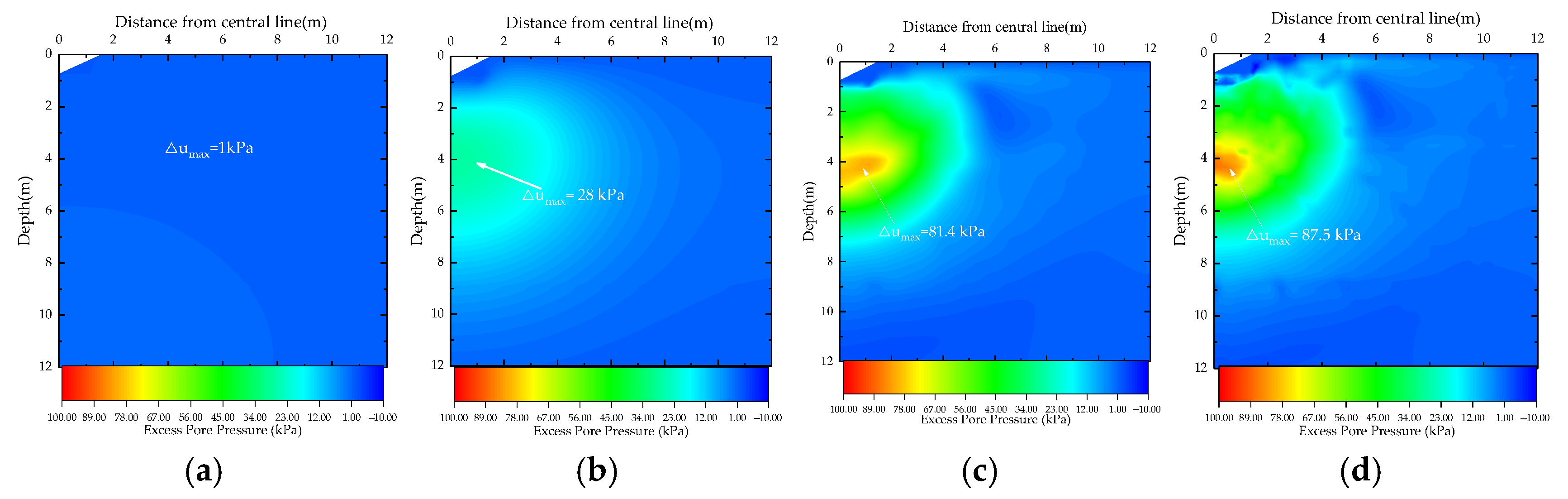

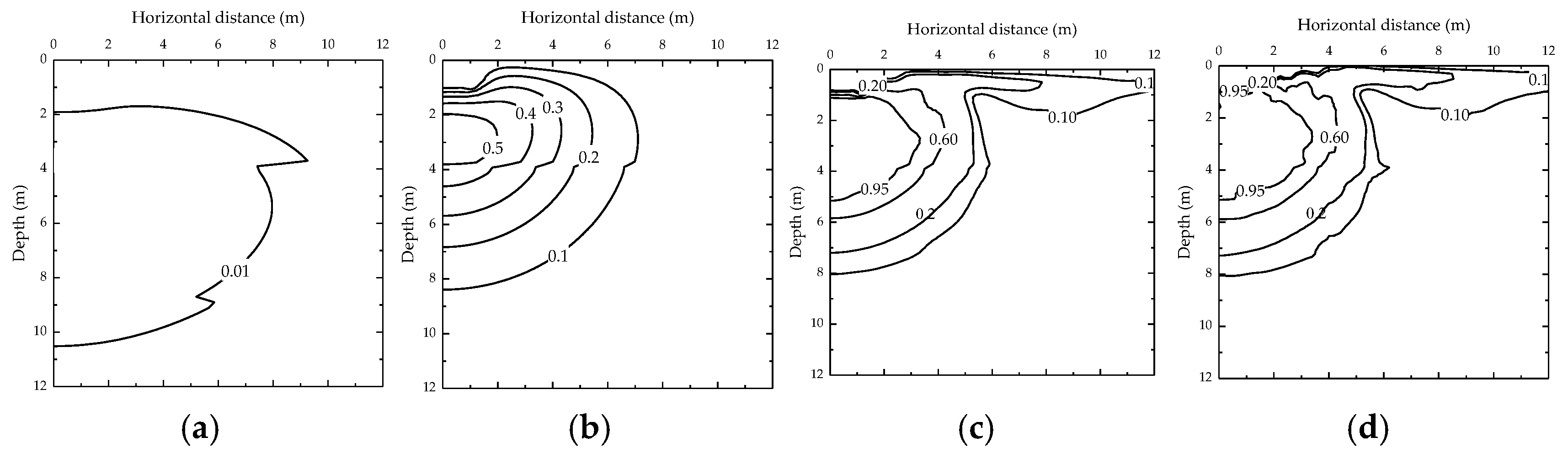

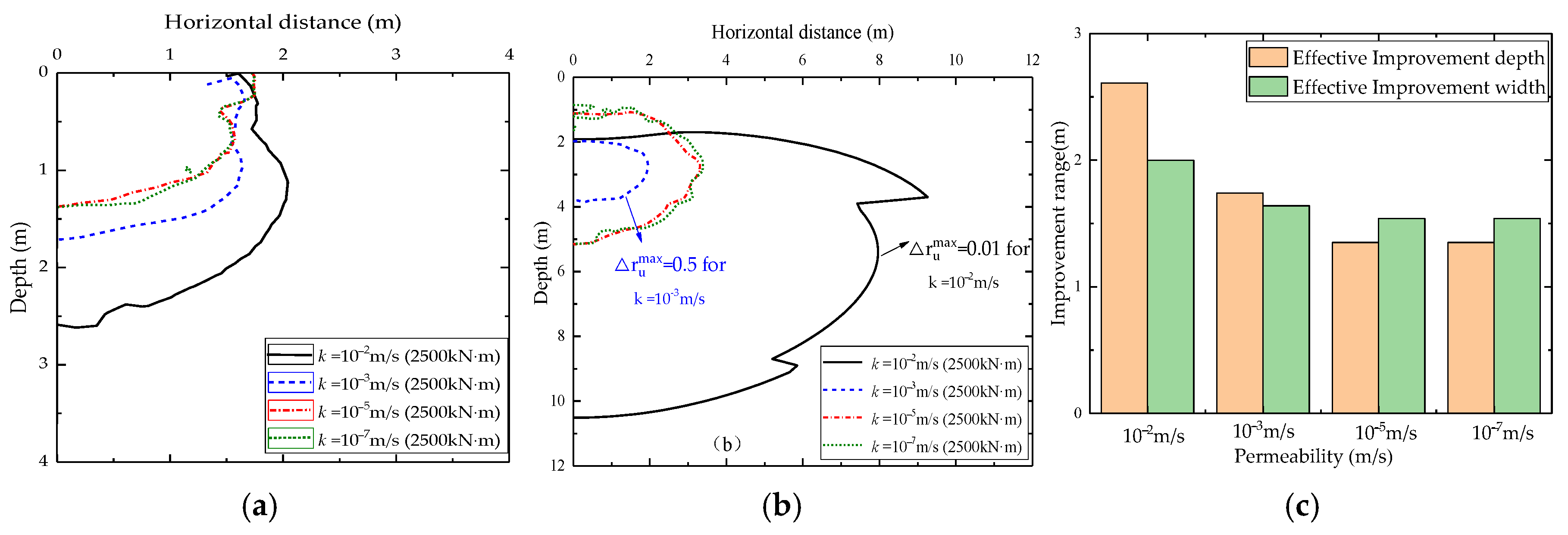

4.4. Effect of Permeability

5. Conclusions

- (1)

- The hydro-mechanically coupled explicit analysis method shows good agreement with field test data. It can also predict stresses, displacements, and pore pressures of saturated soil under DC with higher accuracy.

- (2)

- Drop energy is the primary factor governing both the extent of the liquefaction zone and the effective reinforcement depth. A 2.5-times increase in drop energy can increase the maximum liquefaction depth by 1.1 m (4.6 m to 5.7 m) and the effective reinforcement depth (Ir ≥ 0.08) by 0.6 m (1.2 m to 1.8 m). It is recommended that the reinforcement effect should be improved by reducing drop energy with a low drop and a heavy tamper in real-life projects.

- (3)

- A greater tamper radius can extend the dimension of the liquefaction zone but lower localized excess pore water pressures. A smaller tamper radius can effectively improve the local soil improvement but also generate higher localized excess pore water pressures.

- (4)

- Soil permeability critically controls the liquefaction potential and the excess pore water pressure dissipation. Low permeability soils demonstrated significant liquefaction depths and slower consolidation, whereas high permeability gravels (k = 10−2 m/s) showed minimal liquefaction and greater depths. To diminish the effect of the underground water, the gravel cushions should be used to drain pore water out before dynamic compaction.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Heh, K.S. Dynamic Compaction of Sand. Ph.D. Thesis, Polytechnic University of New York, New York, NY, USA, 1991. [Google Scholar]

- Dumas, J.C.; Beaton, N.F.; Morel, J.F. Dynamic compaction of saturated silt and silty sand-A case history. In In-Situ Deep Soil Improvement; ASCE: Reston, VA, USA, 1994; pp. 80–89. [Google Scholar]

- Nashed, R. Liquefaction Mitigation of Silty Soils Using Dynamic Compaction. Ph.D. Thesis, State University of New York, Buffalo, NY, USA, 2006. [Google Scholar]

- Menard, L.; Broise, Y. Theoretical and practical aspect of dynamic consolidation. Geotechnique 1975, 25, 3–18. [Google Scholar] [CrossRef]

- Van Impe, W.F.; Bouazza, A. Densification of domestic waste fills by dynamic compaction. Can. Geotech. J. 1997, 33, 879–887. [Google Scholar] [CrossRef]

- Feng, S.J.; Shi, Z.M.; Shen, Y.; Li, L.C. Elimination of loess collapsibility with application to construction and demolition waste during dynamic compaction. Environ. Earth Sci. 2015, 73, 5317–5332. [Google Scholar] [CrossRef]

- Feng, S.J.; Shui, W.H.; Gao, L.Y.; He, L.J.; Tan, K. Field studies of the effectiveness of dynamic compaction in coastal reclamation areas. Bull. Eng. Geol. Environ. 2010, 69, 129–136. [Google Scholar] [CrossRef]

- Feng, S.J.; Du, F.L.; Shi, Z.M.; Shui, W.H.; Tan, K. Field study on the reinforcement of collapsible loess using dynamic compaction. Eng. Geol. 2015, 185, 105–115. [Google Scholar] [CrossRef]

- Bo, M.W.; Na, Y.M.; Arulrajah, A.; Chang, M.F. Densification of granular soil by dynamic compaction. Proc. Inst. Civ. Eng.-Ground Improv. 2009, 162, 121–132. [Google Scholar] [CrossRef]

- Feng, S.J.; Tan, K.; Shui, W.H.; Zhang, Y. Densification of desert sands by high energy dynamic compaction. Eng. Geol. 2013, 157, 48–54. [Google Scholar] [CrossRef]

- Zhou, C.; Yang, C.; Qi, H.; Yao, K.; Yao, Z.; Wang, K.; Li, H. Evaluation on improvement zone of foundation after dynamic compaction. Appl. Sci. 2021, 11, 2156. [Google Scholar] [CrossRef]

- Mayne, P.W.; Jones, J.S., Jr. Impact stresses during dynamic compaction. J. Geotech. Eng. 1983, 109, 1342–1346. [Google Scholar] [CrossRef]

- Michalowski, R.L.; Nadukuru, S.S. Static fatigue, time effects, and delayed increase in penetration resistance after dynamic compaction of sands. J. Geotech. Geoenvironmental Eng. 2012, 138, 564–574. [Google Scholar] [CrossRef]

- Scott, R.A.; Pearce, R.W. Soil compaction by impact. Geotechnique 1975, 25, 19–30. [Google Scholar] [CrossRef]

- Wang, W.; Feng, Q.; Yang, C. Investigation on the dynamic liquefaction responses of saturated granular soils due to dynamic compaction in coastal area. Appl. Ocean Res. 2019, 89, 273–283. [Google Scholar] [CrossRef]

- Wei, J.H.; Men, Y.; Zhu, F.; Le, H.L.; Fan, H.T. The reinforcement effects of deep soft soil foundation with high degree of saturation under dynamic compaction. Eng. Environ. Sci. 2018, 10, 168781401878263. [Google Scholar] [CrossRef]

- Sun, J.; Ge, X.; Li, P. Vibration mechanism and energy transfer analysis of dynamic compaction method on ground with high groundwater level. Int. J. Geomech. 2023, 23, 04023200. [Google Scholar] [CrossRef]

- Perucho, A.; Olalla, C. Dynamic consolidation of a saturated plastic clayey fill. Proc. Inst. Civ. Eng.-Ground Improv. 2006, 10, 55–68. [Google Scholar] [CrossRef]

- Arslan, H.; Baykal, G.; Ertas, O. Influence of tamper weight shape on dynamic compaction. Proc. Inst. Civ. Eng.-Ground Improv. 2007, 11, 61–66. [Google Scholar] [CrossRef]

- Lukas, R. Geotechnical Engineering Circular No. 1-Dynamic Compaction (No. FHWA-SA-95-037); United States. Federal Highway Administration; Office of Technology Applications: Washington, DC, USA, 1995. [Google Scholar]

- Feng, S.J.; Shui, W.H.; Tan, K.; Gao, L.Y.; He, L.J. Field evaluation of dynamic compaction on granular deposits. J. Perform. Constr. Facil. 2011, 25, 241–249. [Google Scholar] [CrossRef]

- Liu, J.H.; Yuan, J.B.; Xiong, H.; Chen, W. Dynamic compaction treatment technology research of red clay soil embankment in southern mountains. J. Cent. South Univ. Technol. 2008, 15 (Suppl. S2), 50–57. [Google Scholar] [CrossRef]

- Zou, W.L.; Wang, Z.; Yao, Z.F. Effect of dynamic compaction on placement of high-road embankment. J. Perform. Constr. Facil. 2005, 19, 316–323. [Google Scholar] [CrossRef]

- Pan, J.L.; Selby, A.R. Simulation of dynamic compaction of loose granular soils. Adv. Eng. Softw. 2002, 33, 631–640. [Google Scholar] [CrossRef]

- Gu, Q.; Lee, F.H. Ground response to dynamic compaction of dry sand. Geotechnique 2002, 52, 481–493. [Google Scholar] [CrossRef]

- Oshima, A.; Takada, N.; Tanaka, Y. Relation between compacted area and ram momentum by heavy tamping density and strength increases due to single point tamping. Doboku Gakkai Ronbunshu 1996, 554, 185–196. [Google Scholar] [CrossRef] [PubMed]

- Jafarzadeh, F. Dynamic compaction method in physical model tests. Sci. Iran. 2006, 13, 187–192. [Google Scholar][Green Version]

- Kovalsky, E.; Kongar-Syuryun, C.; Morgoeva, A.; Klyuev, R.; Khayrutdinov, M. Backfill for advanced potash ore mining technologies. Technologies 2025, 13, 60. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.B. Industrial waste in backfill composite—the paradigm of environmental and process safety during field development. Bezop. Tr. V Promyshlennosti 2025, 3, 73–78. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.B. Influence of mine water on the strength of artificial mass based on industrial waste. Ugol 2024, 12, 75–78. [Google Scholar]

- Golik, V.I.; Kongar-Syuryun, C.B.; Michałek, A.; Pires, P.; Rybak, A. Ground transmitted vibrations in course of innovative vinyl sheet piles driving. J. Phys. Conf. Ser. 2021, 1921, 012083. [Google Scholar] [CrossRef]

- Raja, M.N.A.; Abdoun, T.; El-Sekelly, W. Smart prediction of liquefaction-induced lateral spreading. J. Rock Mech. Geotech. Eng. 2024, 16, 2310–2325. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, L.L.; Chen, J.J.; Wang, J.H. Parameter estimation for coupled hydromechanical simulation of dynamic compaction based on pareto multi objective optimization. Shock Vib. 2015, 2015, 127878. [Google Scholar]

- Ye, F.; Goh, S.H.; Lee, F.H. Dual-phase coupled u–U analysis of wave propagation in saturated porous media using a commercial code. Comput. Geotech. 2014, 55, 316–329. [Google Scholar] [CrossRef]

- Zhou, C.; Jiang, H.; Yao, Z.; Li, H.; Yang, C.; Chen, L.; Geng, X. Evaluation of dynamic compaction to improve saturated foundation based on the fluid-solid coupled method with soil cap model. Comput. Geotech. 2020, 125, 103686. [Google Scholar] [CrossRef]

- Hamann, T. Zur Modellierung Wassergesättigter Böden Unter Dynamischer Belastung und Großen Bodenverformungen am Beispiel der Pfahleinbringung; Technische Universität Hamburg-Harburg, Institut für Geotechnik und Baubetrieb: Hamburg, Germany, 2016. [Google Scholar]

- Staubach, P.; Machaček, J.; Moscoso, M.C.; Wichtmann, T. Impact of the installation on the long-term cyclic behaviour of piles in sand: A numerical study. Soil Dyn. Earthq. Eng. 2020, 138, 106223. [Google Scholar] [CrossRef]

- Staubach, P.; Machaček, J.; Skowronek, J.; Wichtmann, T. Vibratory pile driving in water-saturated sand: Back-analysis of model tests using a hydro-mechanically coupled CEL method. Soils Found. 2021, 61, 144–159. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Shiomi, T. Dynamic behaviour of saturated porous media; the generalized Biot formulation and its numerical solution. Int. J. Numer. Anal. Methods Geomech. 1984, 8, 71–96. [Google Scholar] [CrossRef]

- Lee, F.H.; Gu, Q. Method for estimating dynamic compaction effect on sand. J. Geotech. Geoenvironmental Eng. 2004, 130, 139–152. [Google Scholar] [CrossRef]

- Zhou, C.; Yao, K.; Rong, Y.; Lee, F.H.; Zhang, D.; Jiang, H.; Chen, L. Numerical investigation on zone of improvement for dynamic compaction of sandy ground with high groundwater table. Acta Geotech. 2023, 18, 695–709. [Google Scholar] [CrossRef]

- Simo, J.C.; Ju, J.W.; Pister, K.S.; Taylor, R.L. Assessment of cap model: Consistent return algorithms and rate-dependent extension. J. Eng. Mech. 1988, 114, 191–218. [Google Scholar] [CrossRef]

- Staubach, P.; Machaček, J. Influence of relative acceleration in saturated sand: Analytical approach and simulation of vibratory pile driving tests. Comput. Geotech. 2019, 112, 173–184. [Google Scholar] [CrossRef]

- Miao, L.; Chen, G.; Hong, Z. Application of dynamic compaction in highway: A case study. Geotech. Geol. Eng. 2006, 24, 91–99. [Google Scholar] [CrossRef]

- Seed, H.B.; Idriss, I.M. Simplified procedure for evaluating soil liquefaction potential. J. Soil Mech. Found. Div. 1971, 97, 1249–1273. [Google Scholar] [CrossRef]

- Jia, M.; Zhao, Y.; Zhou, X. Field studies of dynamic compaction on marine deposits. Mar. Georesources Geotechnol. 2016, 34, 313–320. [Google Scholar] [CrossRef]

- Zhang, R.; Sun, Y.; Song, E. Simulation of dynamic compaction and analysis of its efficiency with the material point method. Comput. Geotech. 2019, 116, 103218. [Google Scholar] [CrossRef]

| Soil Layer | ρ (kg/m3) | E (MPa) | v | α (kPa) | θ | R’ | W | D (kPa−1) |

|---|---|---|---|---|---|---|---|---|

| soil1 | 1940 | 6.00 | 0.30 | 17.8 | 0.25 | 4.33 | 0.5 | 0.0003 |

| soil2 | 1940 | 8.0 | 0.30 | 21.2 | 0.21 | 4.33 | 0.5 | 0.0003 |

| soil3 | 1940 | 7.00 | 0.30 | 30.5 | 0.19 | 4.33 | 0.5 | 0.0003 |

| Drop Energy (kN·m) | Measured at Field (m) | Present Model (m) | Error (%) |

|---|---|---|---|

| 2500 | 0.94 | 0.948 | 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Zhao, G.; Yang, X.; Xu, R.; Weng, Z.; Liu, J.; Zhou, C.; Li, C. Liquefaction Response and Reinforcement Effect of Saturated Soil Treated by Dynamic Compaction Based on Hydro-Mechanically Coupled Explicit Analysis. Buildings 2025, 15, 2527. https://doi.org/10.3390/buildings15142527

Ma S, Zhao G, Yang X, Xu R, Weng Z, Liu J, Zhou C, Li C. Liquefaction Response and Reinforcement Effect of Saturated Soil Treated by Dynamic Compaction Based on Hydro-Mechanically Coupled Explicit Analysis. Buildings. 2025; 15(14):2527. https://doi.org/10.3390/buildings15142527

Chicago/Turabian StyleMa, Sihan, Guo Zhao, Xiaoyuan Yang, Run Xu, Zhiqiang Weng, Jiawei Liu, Chong Zhou, and Chao Li. 2025. "Liquefaction Response and Reinforcement Effect of Saturated Soil Treated by Dynamic Compaction Based on Hydro-Mechanically Coupled Explicit Analysis" Buildings 15, no. 14: 2527. https://doi.org/10.3390/buildings15142527

APA StyleMa, S., Zhao, G., Yang, X., Xu, R., Weng, Z., Liu, J., Zhou, C., & Li, C. (2025). Liquefaction Response and Reinforcement Effect of Saturated Soil Treated by Dynamic Compaction Based on Hydro-Mechanically Coupled Explicit Analysis. Buildings, 15(14), 2527. https://doi.org/10.3390/buildings15142527