Enhancing Metakaolin-Based Geopolymer Mortar with Eggshell Powder and Fibers for Improved Sustainability

Abstract

1. Introduction

2. Test Materials and Methods

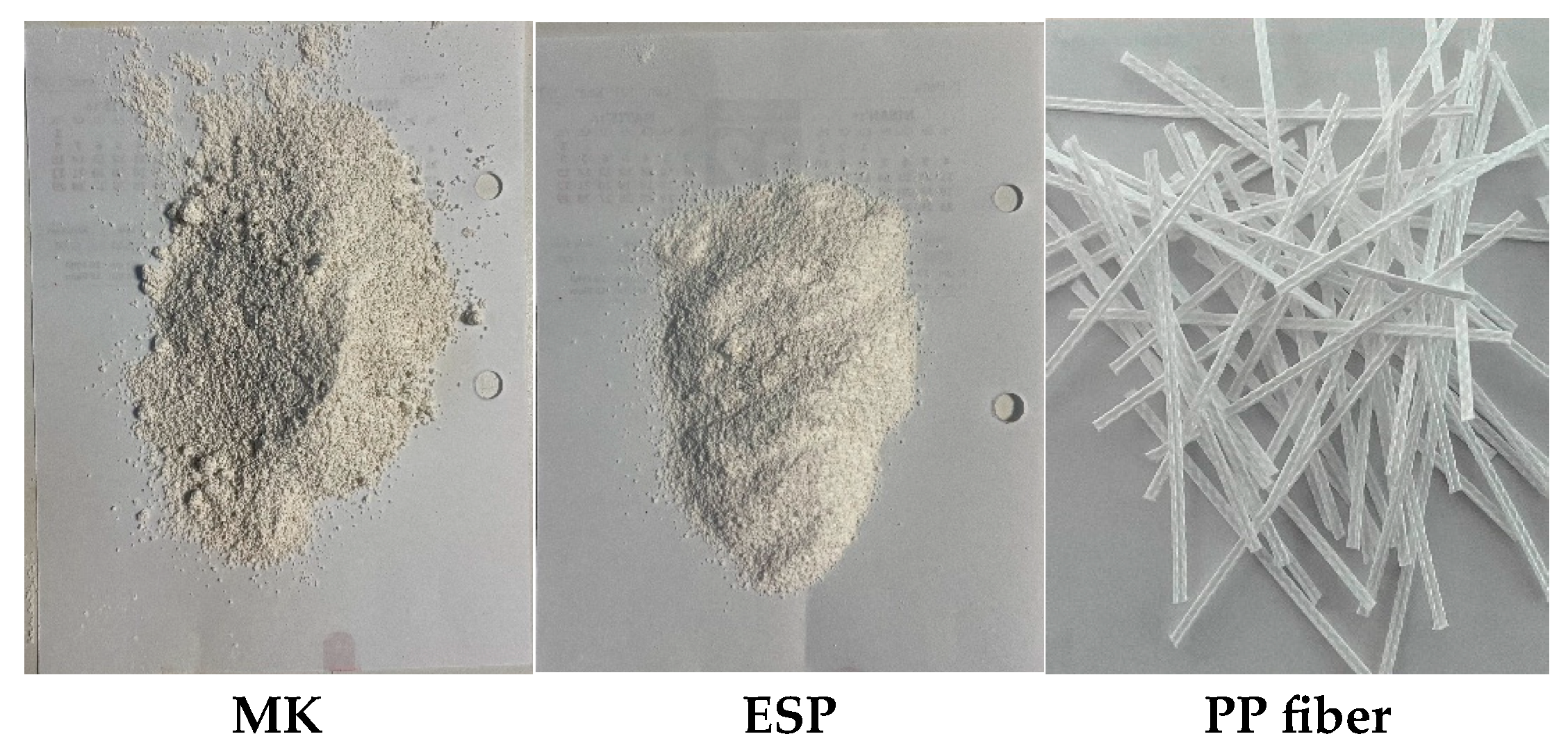

2.1. Test Materials

2.2. Mix Design and Preparation

2.3. Testing

3. Results and Discussion

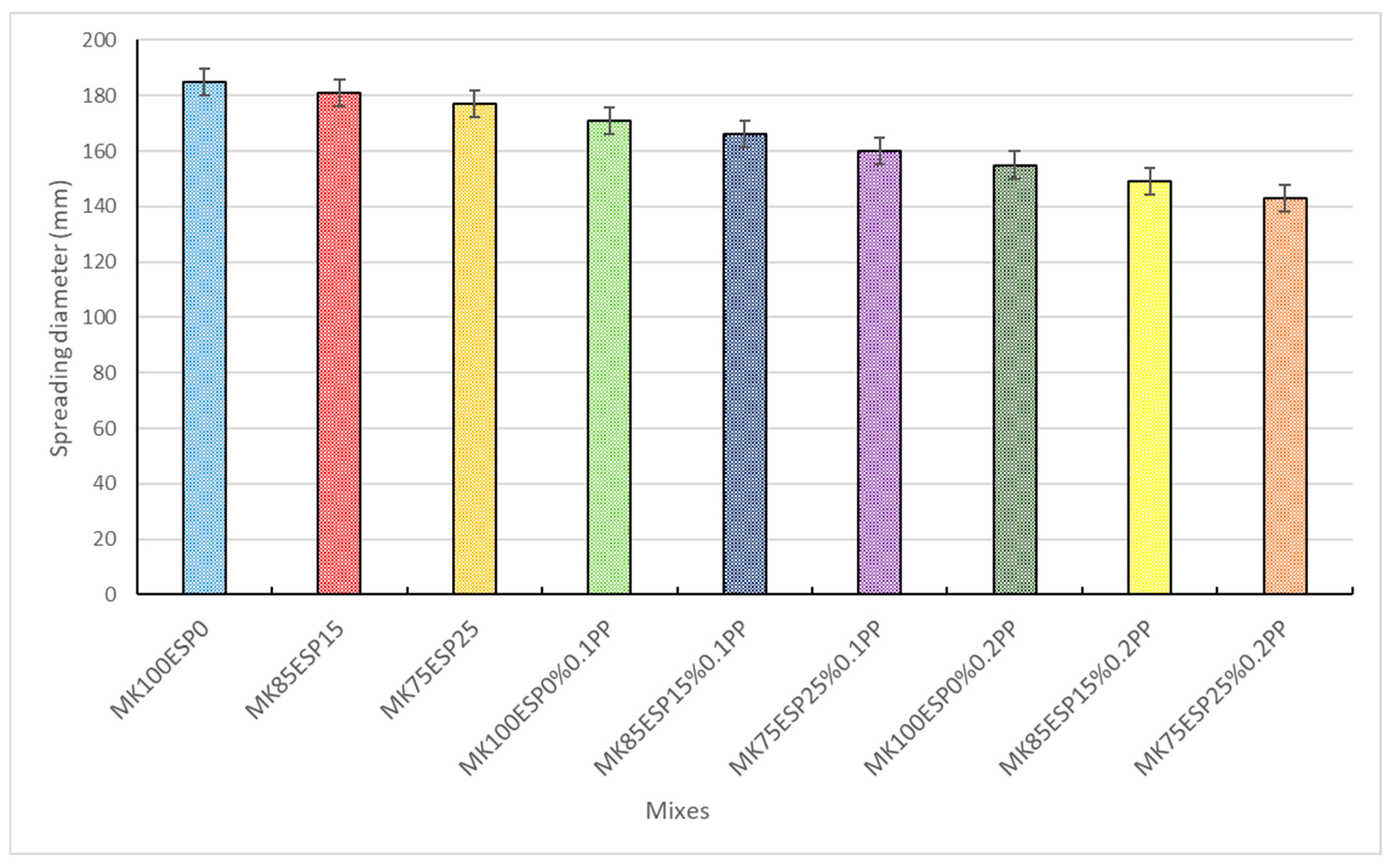

3.1. Flowability (Spreading Diameters)

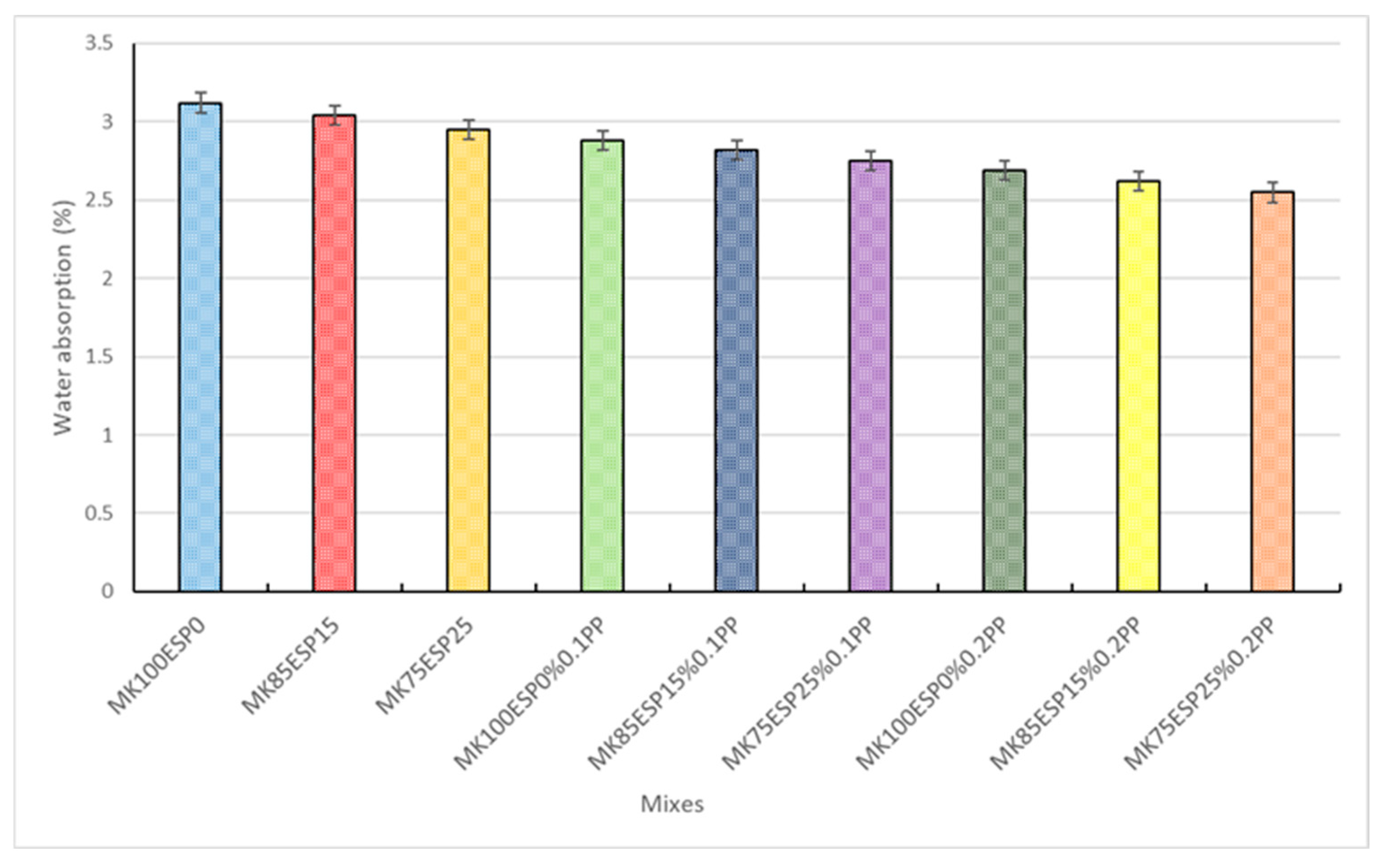

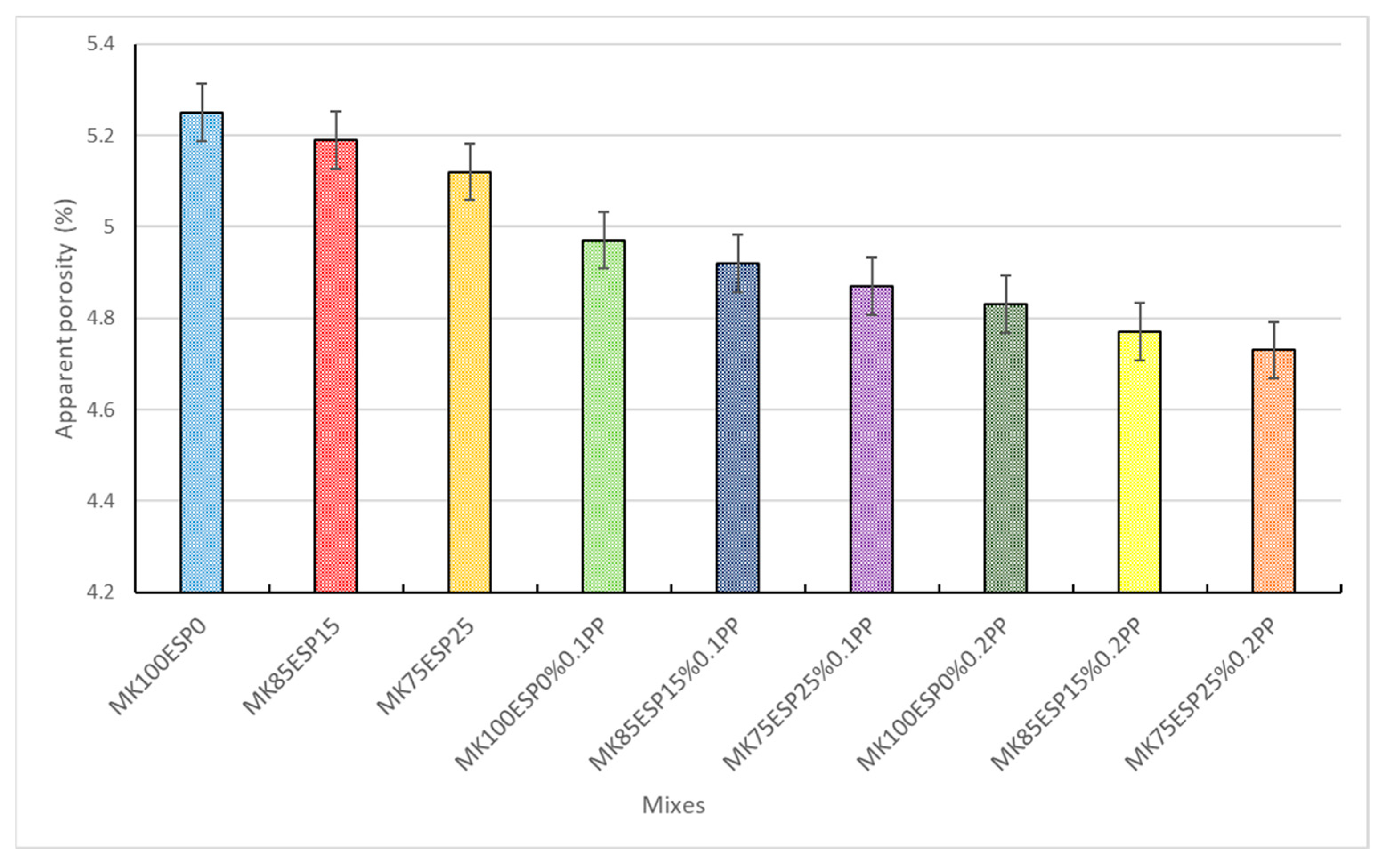

3.2. Water Absorption and Apparent Porosity

3.3. Flexural Strength

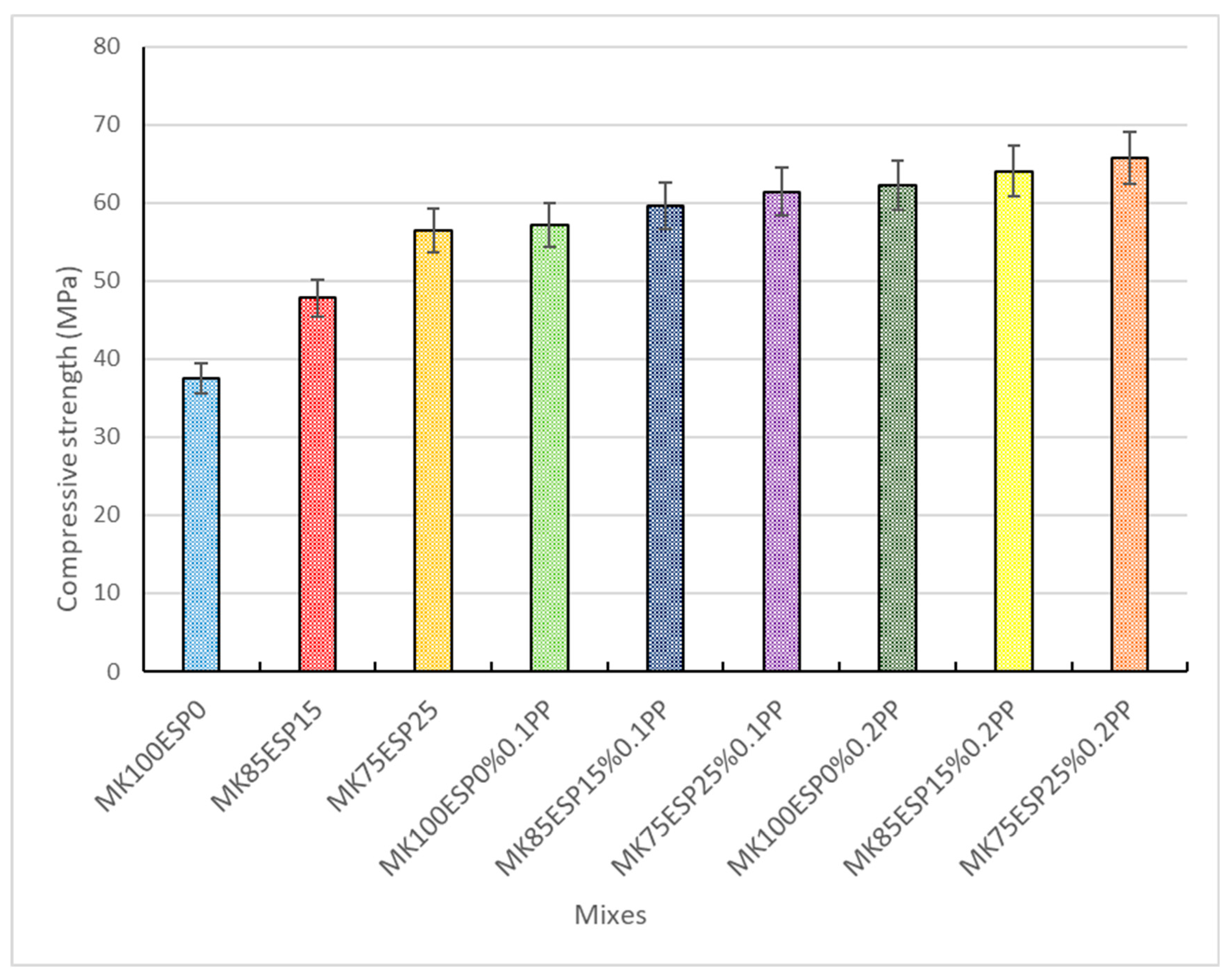

3.4. Compressive Strength

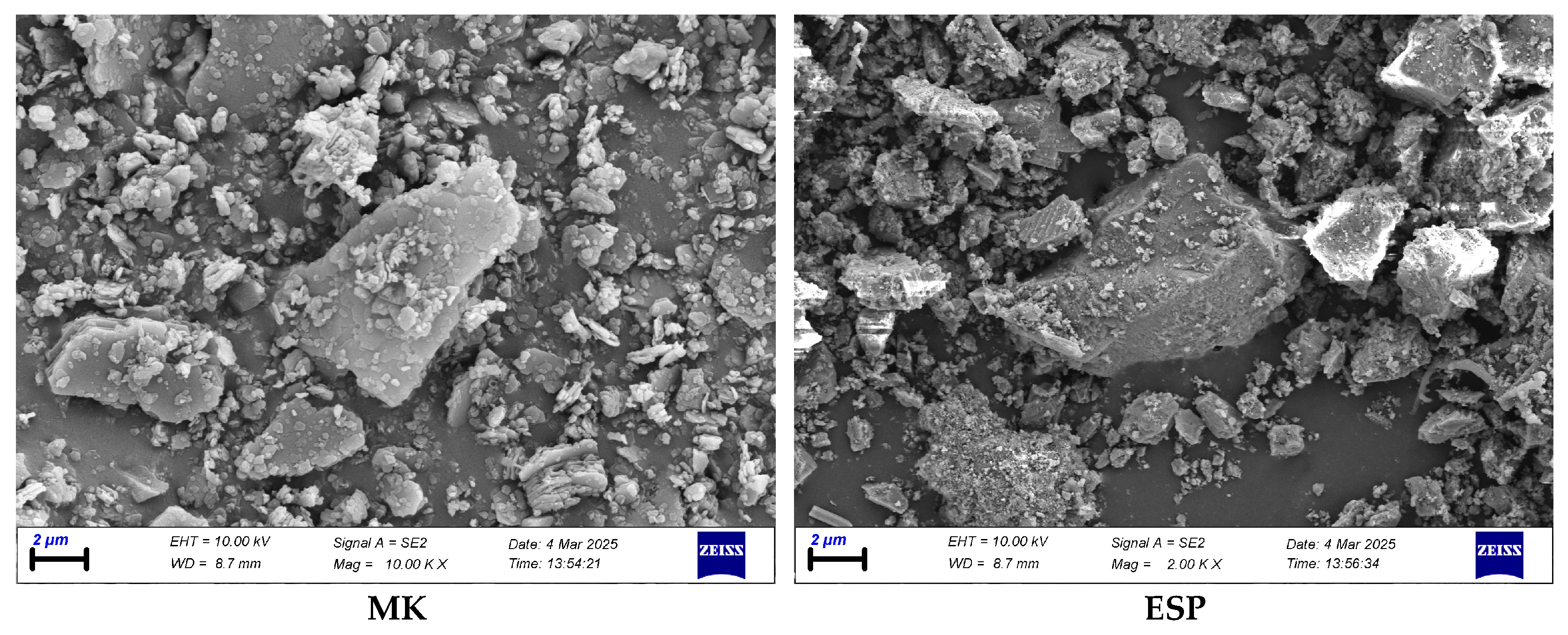

3.5. Microstructure Analysis

4. Conclusions

- Workability decreased when using ESP instead of MK in GP mortars.

- By increasing the amount of ESP, the water absorption and apparent porosity values of GP mortars decreased.

- The use of ESP positively affected the mechanical behavior of GP mortars. In the mixture using 25% ESP, the flexural and compressive strengths increased by 37.1% and 50.7%, respectively, compared to the control.

- The use of PP fiber decreased the workability of GP mortars, similarly to ESP. In addition, as the PP fiber dosage increased, the mortars’ apparent porosity and water absorption values decreased.

- Increasing amounts of PP fiber usage increased both the flexural and compressive strengths of the mortars. It was observed that the flexural strengths were more sharply affected by the use of fibers, while the highest flexural strength was obtained with 6.9 MPa from the mixture in which 0.2% PP fiber was used by volume.

- Microstructure analysis demonstrated a dense microstructure and strong bonding between components, highlighting the positive influence of ESP on the overall performance of GP mortars.

- The use of eggshell powder in metakaolin-based geopolymer mortars stands out as a promising alternative due to the high calcium content of eggshells, as it is sustainable and cost-effective. In addition to waste utilization, the reaction mechanisms within the geopolymer matrix change when eggshells are used instead of metakaolin. With the increased calcium ions, the formation of calcium–sodium–aluminosilicate–hydrate (C,N)-A-S-H) gels is facilitated in addition to traditional sodium–aluminosilicate–hydrate (N-A-S-H) gels, depending on the activator content and curing conditions. A more dense microstructure and improved strength can be achieved with these hybrid gels formed within the geopolymer mortar.

- These results enhance the comprehension of ESP’s potential as an environmentally friendly alternative to GP mortars, offer perspectives on material enhancement, and show better mechanical and durability characteristics. Future studies can investigate the usability of ESP in GP mortar production by using various fibers, different fiber dosages, and alternative binders.

Funding

Data Availability Statement

Conflicts of Interest

References

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2014, 47, 1055–1065. [Google Scholar] [CrossRef]

- Akbulut, Z.F.; Guler, S.; Khan, M. The effects of waste iron powder and steel fiber on the physical and mechanical properties of geopolymer mortars exposed to high temperatures. Structures 2023, 58, 105398. [Google Scholar] [CrossRef]

- Neupane, K.; Chalmers, D.; Kidd, P. High-Strength Geopolymer Concrete- Properties, Advantages and Challenges. Adv. Mater. 2018, 7, 15. [Google Scholar] [CrossRef]

- Nurruddin, E.A. Methods of curing geopolymer concrete: A review. Int. J. Adv. Appl. Sci. 2018, 5, 31–36. [Google Scholar] [CrossRef]

- Gultekin, A.; Ramyar, K. Effect of curing type on microstructure and compressive strength of geopolymer mortars. Ceram. Int. 2022, 48, 16156–16172. [Google Scholar] [CrossRef]

- Tokdemir, M.; Ramyar, K.; Gultekin, A. High-Temperature Resistance of Industrial Waste-Based Lightweight Geopolymer Mortars Produced Using Microwave Technology. Arab. J. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- Verma, M.; Dev, N.; Rahman, I.; Nigam, M.; Ahmed, M.; Mallick, J. Geopolymer Concrete: A Material for Sustainable Development in Indian Construction Industries. Crystals 2022, 12, 514. [Google Scholar] [CrossRef]

- Jindal, B.B.; Alomayri, T.; Hasan, A.; Kaze, C.R. Geopolymer concrete with metakaolin for sustainability: A comprehensive review on raw material’s properties, synthesis, performance, and potential application. Environ. Sci. Pollut. Res. 2022, 30, 25299–25324. [Google Scholar] [CrossRef] [PubMed]

- Alanazi, H.; Yang, M.; Zhang, D.; Gao, Z. Bond strength of PCC pavement repairs using metakaolin-based geopolymer mortar. Cem. Concr. Compos. 2016, 65, 75–82. [Google Scholar] [CrossRef]

- Marín-López, C.; Araiza, J.L.R.; Manzano-Ramírez, A.; Avalos, J.C.R.; Perez-Bueno, J.J.; Muñiz-Villareal, M.S.; Ventura-Ramos, E.; Vorobiev, Y. Synthesis and characterization of a concrete based on metakaolin geopolymer. Inorg. Mater. 2009, 45, 1429–1432. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Melo, K.A.; Carneiro, A.M. Effect of Metakaolin’s finesses and content in self-consolidating concrete. Constr. Build. Mater. 2010, 24, 1529–1535. [Google Scholar] [CrossRef]

- Weng, T.-L.; Lin, W.-T.; Cheng, A.; Aggelis, D.; Chen, S.; Jha, M.; Lui, E. Effect of Metakaolin on Strength and Efflorescence Quantity of Cement-Based Composites. Sci. World J. 2013, 2013, 606524. [Google Scholar] [CrossRef] [PubMed]

- Pouhet, R.; Cyr, M. Formulation and performance of flash metakaolin geopolymer concretes. Constr. Build. Mater. 2016, 120, 150–160. [Google Scholar] [CrossRef]

- Faridi, H.; Arabhosseini, A. Application of eggshell wastes as valuable and utilizable products: A review. Res. Agric. Eng. 2018, 64, 104–114. [Google Scholar] [CrossRef]

- Chong, B.; Othman, R.; Ramadhansyah, P.; Doh, S.; Li, X. Properties of concrete with eggshell powder: A review. Phys. Chem. Earth Parts A/B/C 2020, 120, 102951. [Google Scholar] [CrossRef]

- Parthasarathi, N.; Prakash, M.; Satyanarayanan, K.S. Experimental study on partial replacement of cement with egg shell powder and silica fume. Rasayan J. Chem. 2017, 10, 442–449. [Google Scholar] [CrossRef]

- Parkash, A.; Singh, E.R. Behaviour of concrete containing egg shell powder as cement replacing material. Int. J. Latest Res. Eng. Comput. (IJLREC) 2017, 5, 1–5. [Google Scholar]

- Jhatial, A.A.; Sohu, S.; Memon, M.J.; Bhatti, N.U.K.; Memon, D. Eggshell powder as partial cement replacement and its effect on the workability and compressive strength of concrete. Int. J. Adv. Appl. Sci. 2019, 6, 71–75. [Google Scholar] [CrossRef]

- Ing, D.S.; Chin, S.C. Eggshell Powder: Potential Filler in Concrete. 2014. Available online: https://www.researchgate.net/publication/283007876 (accessed on 12 March 2025).

- Al-Safy, R.A. Experimental investigation on properties of cement mortar incorporating eggshell powder. J. Eng. Sustain. Dev. 2015, 19, 198–209. [Google Scholar]

- Gajjar, R.A. Utilization of egg shell powder & GGBS in concrete. Int. J. Adv. Res. Innov. Ideas Educ. 2018, 4, 76–86. [Google Scholar]

- Latifi, M.R.; Biricik, Ö.; Aghabaglou, A.M. Effect of the addition of polypropylene fiber on concrete properties. J. Adhes. Sci. Technol. 2022, 36, 345–369. [Google Scholar] [CrossRef]

- Wongprachum, W.; Sappakittipakorn, M.; Sukontasukkul, P.; Chindaprasirt, P.; Banthia, N. Resistance to sulfate attack and underwater abrasion of fiber reinforced cement mortar. Constr. Build. Mater. 2018, 189, 686–694. [Google Scholar] [CrossRef]

- Ding, M.; Zhang, F.; Ling, X.; Lin, B. Effects of freeze-thaw cycles on mechanical properties of polypropylene Fiber and cement stabilized clay. Cold Reg. Sci. Technol. 2018, 154, 155–165. [Google Scholar] [CrossRef]

- Behfarnia, K.; Farshadfar, O. The effects of pozzolanic binders and polypropylene fibers on durability of SCC to magnesium sulfate attack. Constr. Build. Mater. 2013, 38, 64–71. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Özen, S.; Altun, M.G. Durability Performance And Dimensional Stability Of Polypropylene Fiber Reinforced Concrete. J. Green Build. 2018, 13, 20–41. [Google Scholar] [CrossRef]

- Yuan, X.; Xu, W.; AlAteah, A.H.; Mostafa, S.A. Evaluation of the performance of high-strength geopolymer concrete prepared with recycled coarse aggregate containing eggshell powder and rice husk ash cured at different curing regimes. Constr. Build. Mater. 2024, 434, 136722. [Google Scholar] [CrossRef]

- Abdellatief, M.; Ahmed, Y.M.; Taman, M.; Elfadaly, E.; Tang, Y.; Abadel, A.A. Physico-mechanical, thermal insulation properties, and microstructure of geopolymer foam concrete containing sawdust ash and egg shell. J. Build. Eng. 2024, 90, 109374. [Google Scholar] [CrossRef]

- Feng, D.; Chen, D.; Yu, Y.; Liang, S. Experimental study on preparation of fly ash-based geopolymer blended with recycled calcium source. Sustain. Mater. Technol. 2024, 41, e01078. [Google Scholar] [CrossRef]

- Poorveekan, K.; Ath, K.; Anburuvel, A.; Sathiparan, N. Investigation of the engineering properties of cementless stabilized earth blocks with alkali-activated eggshell and rice husk ash as a binder. Constr. Build. Mater. 2021, 277, 122371. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Sammak, M. An assessment of the effect of Na2SiO3/NaOH ratio, NaOH solution concentration, and aging on the fracture properties of ultra-high-performance geopolymer concrete: The application of the work of fracture and size effect methods. Structures 2022, 39, 434–443. [Google Scholar] [CrossRef]

- Parthasarathy, P.; Srinivasula, R.M.; Dinakar, P.; Rao, B.K.; Satpathy, B.N.; Mohanty, A. Effect of the Na2SiO3/NaOH Ratio and NaOH Molarity on the Synthesis of Fly Ash-Based Geopolymer Mortar. In Proceedings of the Geo-Chicago 2016, Chicago, IL, USA, 14–18 August 2016; pp. 336–344. [Google Scholar] [CrossRef]

- ASTM C1437-15; Test Method for Flow of Hydraulic Cement Mortar. ASTM: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM C642-21; Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM: West Conshohocken, PA, USA, 2021. [CrossRef]

- Huang, J.; Kumar, G.S.; Ren, J.; Sun, Y.; Li, Y.; Wang, C. Towards the potential usage of eggshell powder as bio-modifier for asphalt binder and mixture: Workability and mechanical properties. Int. J. Pavement Eng. 2022, 23, 3553–3565. [Google Scholar] [CrossRef]

- Cao, M.; Li, L. New models for predicting workability and toughness of hybrid fiber reinforced cement-based composites. Constr. Build. Mater. 2018, 176, 618–628. [Google Scholar] [CrossRef]

- Mehdipour, I.; Libre, N.A.; Shekarchi, M.; Khanjani, M. Effect of workability characteristics on the hardened performance of FRSCCMs. Constr. Build. Mater. 2013, 40, 611–621. [Google Scholar] [CrossRef]

- Cao, Q.; Cheng, Y.; Cao, M.; Gao, Q. Workability, strength and shrinkage of fiber reinforced expansive self-consolidating concrete. Constr. Build. Mater. 2017, 131, 178–185. [Google Scholar] [CrossRef]

- Hu, C.-F.; Li, L.; Li, Z. Effect of fiber factor on the workability and mechanical properties of polyethylene fiber-reinforced high toughness geopolymers. Ceram. Int. 2022, 48, 10458–10471. [Google Scholar] [CrossRef]

- Claisse, P.A.; Cabrera, J.G.; Hunt, D.N. Measurement of porosity as a predictor of the durability performance of concrete with and without condensed silica fume. Adv. Cem. Res. 2001, 13, 165–174. [Google Scholar] [CrossRef]

- Lafhaj, Z.; Goueygou, M.; Djerbi, A.; Kaczmarek, M. Correlation between porosity, permeability and ultrasonic parameters of mortar with variable water/cement ratio and water content. Cem. Concr. Res. 2006, 36, 625–633. [Google Scholar] [CrossRef]

- Li, L.G.; Feng, J.-J.; Zhu, J.; Chu, S.-H.; Kwan, A.K.H. Pervious concrete: Effects of porosity on permeability and strength. Mag. Concr. Res. 2021, 73, 69–79. [Google Scholar] [CrossRef]

- Hoseini, M.; Bindiganavile, V.; Banthia, N. The effect of mechanical stress on permeability of concrete: A review. Cem. Concr. Compos. 2009, 31, 213–220. [Google Scholar] [CrossRef]

- Glasser, F.P.; Marchand, J.; Samson, E. Durability of concrete—Degradation phenomena involving detrimental chemical reactions. Cem. Concr. Res. 2008, 38, 226–246. [Google Scholar] [CrossRef]

- Maglad, A.M.; Mydin, A.O.; Majeed, S.S.; Tayeh, B.A.; Tobbala, D.E. Exploring the influence of calcinated eggshell powder on lightweight foamed concrete: A comprehensive study on freshness, mechanical strength, thermal characteristics and transport properties. J. Build. Eng. 2024, 87, 108966. [Google Scholar] [CrossRef]

- Hamada, H.M.; Tayeh, B.A.; Al-Attar, A.; Yahaya, F.M.; Muthusamy, K.; Humada, A.M. The present state of the use of eggshell powder in concrete: A review. J. Build. Eng. 2020, 32, 101583. [Google Scholar] [CrossRef]

- Niyasom, S.; Tangboriboon, N. Development of biomaterial fillers using eggshells, water hyacinth fibers, and banana fibers for green concrete construction. Constr. Build. Mater. 2021, 283, 122627. [Google Scholar] [CrossRef]

- Teara, A.; I Doh, S.; Chin, S.C.; Ding, Y.J.; Wong, J.; Jiang, X.X. Investigation on the durability of use fly ash and eggshells powder to replace the cement in concrete productions. IOP Conf. Ser. Earth Environ. Sci. 2019, 244, 012025. [Google Scholar] [CrossRef]

- Zaid, O.; Hashmi, S.R.Z.; El Ouni, M.H.; Martínez-García, R.; de Prado-Gil, J.; Yousef, S.E.A. Experimental and analytical study of ultra-high-performance fiber-reinforced concrete modified with egg shell powder and nano-silica. J. Mater. Res. Technol. 2023, 24, 7162–7188. [Google Scholar] [CrossRef]

- Temuujin, J.; van Riessen, A.; Williams, R. Influence of calcium compounds on the mechanical properties of fly ash geopolymer pastes. J. Hazard. Mater. 2009, 167, 82–88. [Google Scholar] [CrossRef] [PubMed]

- Ayawanna, J.; Poowancum, A. Enhancing flexural strength of metakaolin-based geopolymer reinforced with different types of fibers. Sustain. Chem. Pharm. 2024, 37, 101439. [Google Scholar] [CrossRef]

- Mashri, M.; Johari, M.A.M.; Ahmad, Z.A.; Mijarsh, M. Enhancing the properties of UPOFA-based geopolymer mortar via the incorporation of eggshell ash and silica fume. J. Build. Eng. 2022, 65, 105677. [Google Scholar] [CrossRef]

- Amin, M.N.; Ahmad, W.; Khan, K.; Al-Hashem, M.N.; Deifalla, A.F.; Ahmad, A. Testing and modeling methods to experiment the flexural performance of cement mortar modified with eggshell powder. Case Stud. Constr. Mater. 2023, 18, e01759. [Google Scholar] [CrossRef]

- Ahamed, A.J.N.; Yamani, S.S.; Dissanayaka, L.S.; Sathiparan, N. Predicting the strength of alkali-activated masonry blocks using machine learning models: Geopolymer mortar with quarry waste, rice husk ash, and eggshell ash. J. Build. Pathol. Rehabilitation 2025, 10, 60. [Google Scholar] [CrossRef]

- Shin, L.J.; Dassan, E.G.B.; Abidin, M.S.Z.; Anjang, A. Tensile and Compressive Properties of Glass Fiber-Reinforced Polymer Hybrid Composite with Eggshell Powder. Arab. J. Sci. Eng. 2020, 45, 5783–5791. [Google Scholar] [CrossRef]

- Moradikhou, A.B.; Esparham, A.; Avanaki, M.J. Physical & mechanical properties of fiber reinforced metakaolin-based geopolymer concrete. Constr. Build. Mater. 2020, 251, 118965. [Google Scholar] [CrossRef]

- Ziada, M.; Erdem, S.; González-Lezcano, R.A.; Tammam, Y.; Unkar, I. Influence of various fibers on the physico-mechanical properties of a sustainable geopolymer mortar-based on metakaolin and slag. Eng. Sci. Technol. Int. J. 2023, 46, 101501. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, K.; Wang, J.; Guo, J.; Ling, Y. Macroscopic and microscopic analyses on mechanical performance of metakaolin/fly ash based geopolymer mortar. J. Clean. Prod. 2021, 294, 126193. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Hakamy, A.; Amin, M.; Zeyad, A.M.; Agwa, I.S. Effect of air agent on mechanical properties and microstructure of lightweight geopolymer concrete under high temperature. Case Stud. Constr. Mater. 2022, 16, e00951. [Google Scholar] [CrossRef]

- Mani, S.; Pradhan, B. Investigation on effect of fly ash content on strength and microstructure of geopolymer concrete in chloride-rich environment. Mater. Today Proc. 2020, 32, 865–870. [Google Scholar] [CrossRef]

- Chen, W.; Garofalo, A.C.; Geng, H.; Liu, Y.; Wang, D.; Li, Q. Effect of high temperature heating on the microstructure and performance of cesium-based geopolymer reinforced by cordierite. Cem. Concr. Compos. 2022, 129, 104474. [Google Scholar] [CrossRef]

| Chemical Properties | MK | ESP |

|---|---|---|

| SiO2 | 63.51 | 0.08 |

| Al2O3 | 30.37 | 0.03 |

| Fe2O3 | 0.57 | 0.04 |

| CaO | 0.27 | 53.4 |

| MgO | 0.16 | 0.21 |

| Na2O | 0.34 | 0.17 |

| K2O | 1.07 | 0.02 |

| SO3 | - | 0.59 |

| P2O5 | - | 0.75 |

| Loss in ignition | 1.98 | 43.5 |

| Physical properties | ||

| Specific gravity (g/cm3) | 2.54 | 2.15 |

| Specific surface area (cm2/g) | 1176 | 2960 |

| PP Fiber | Characteristic Features |

|---|---|

| Density (g/cm3) | 0.91 |

| Length (mm) | 27 |

| Diameter (mm) | 0.95 |

| Tensile stress (MPa) | 530 |

| Modulus of elasticity (GPa) | 7.2 |

| Melting point (°C) | 160 |

| Aspect ratio (l/d) | 28 |

| Mixes | Mix ID | MK (g) | ESP (g) | Sand (g) | Na2SiO3 (g) | NaOH (g) | Water (g) | Fiber (%) |

|---|---|---|---|---|---|---|---|---|

| MK100ESP0 | Control | 450 | 0 | 1350 | 265.2 | 106 | 100 | - |

| MK85ESP15 | A1 | 382.5 | 67.5 | 1350 | 265.2 | 106 | 100 | - |

| MK75ESP25 | A2 | 337.5 | 112.5 | 1350 | 265.2 | 106 | 100 | - |

| MK100ESP0%0.1PP | A3 | 450 | 0 | 1350 | 265.2 | 106 | 100 | 0.1 |

| MK85ESP15%0.1PP | A4 | 382.5 | 67.5 | 1350 | 265.2 | 106 | 100 | 0.1 |

| MK75ESP25%0.1PP | A5 | 337.5 | 112.5 | 1350 | 265.2 | 106 | 100 | 0.1 |

| MK100ESP0%0.2PP | A6 | 450 | 0 | 1350 | 265.2 | 106 | 100 | 0.2 |

| MK85ESP15%0.2PP | A7 | 382.5 | 67.5 | 1350 | 265.2 | 106 | 100 | 0.2 |

| MK75ESP25%0.2PP | A8 | 337.5 | 112.5 | 1350 | 265.2 | 106 | 100 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yavuz, D. Enhancing Metakaolin-Based Geopolymer Mortar with Eggshell Powder and Fibers for Improved Sustainability. Buildings 2025, 15, 2526. https://doi.org/10.3390/buildings15142526

Yavuz D. Enhancing Metakaolin-Based Geopolymer Mortar with Eggshell Powder and Fibers for Improved Sustainability. Buildings. 2025; 15(14):2526. https://doi.org/10.3390/buildings15142526

Chicago/Turabian StyleYavuz, Demet. 2025. "Enhancing Metakaolin-Based Geopolymer Mortar with Eggshell Powder and Fibers for Improved Sustainability" Buildings 15, no. 14: 2526. https://doi.org/10.3390/buildings15142526

APA StyleYavuz, D. (2025). Enhancing Metakaolin-Based Geopolymer Mortar with Eggshell Powder and Fibers for Improved Sustainability. Buildings, 15(14), 2526. https://doi.org/10.3390/buildings15142526