Structural Behavior Analyses and Simple Calculation of Asynchronous-Pouring Construction in PC Composite Girder Bridges with Corrugated Webs for Sustainability

Abstract

1. Introduction

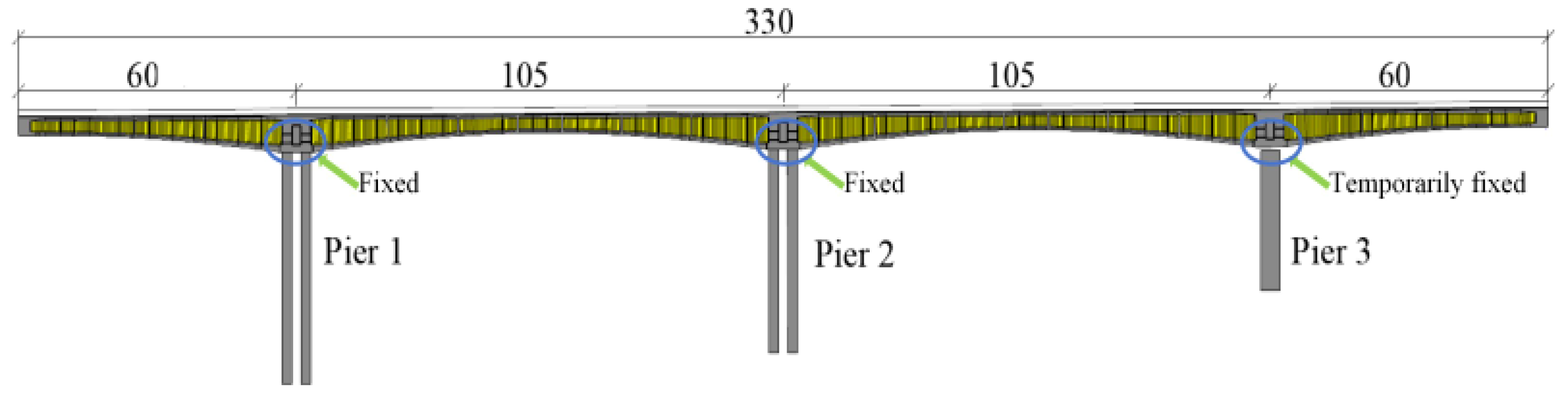

2. Practical Bridge Project

2.1. Bridge Overview

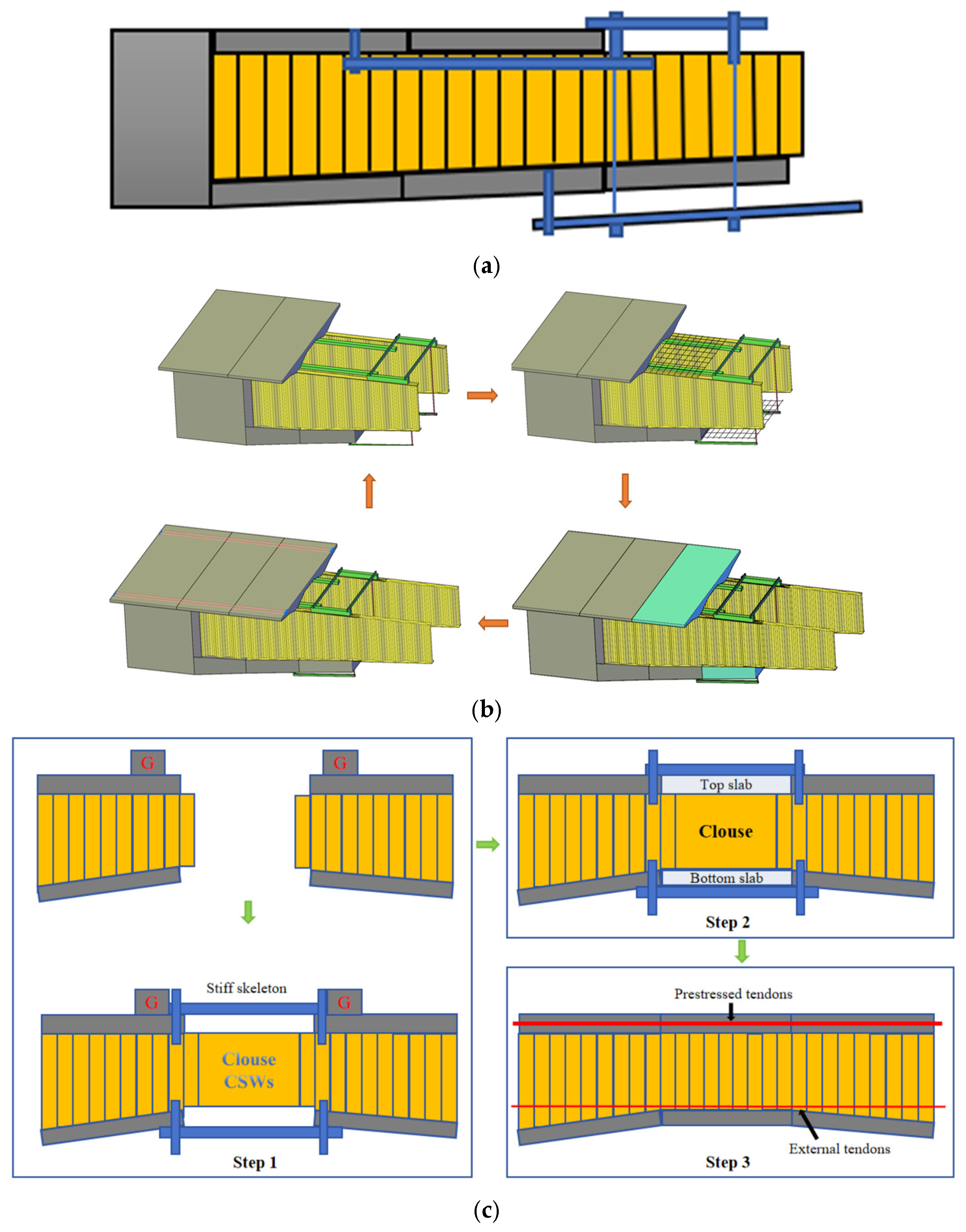

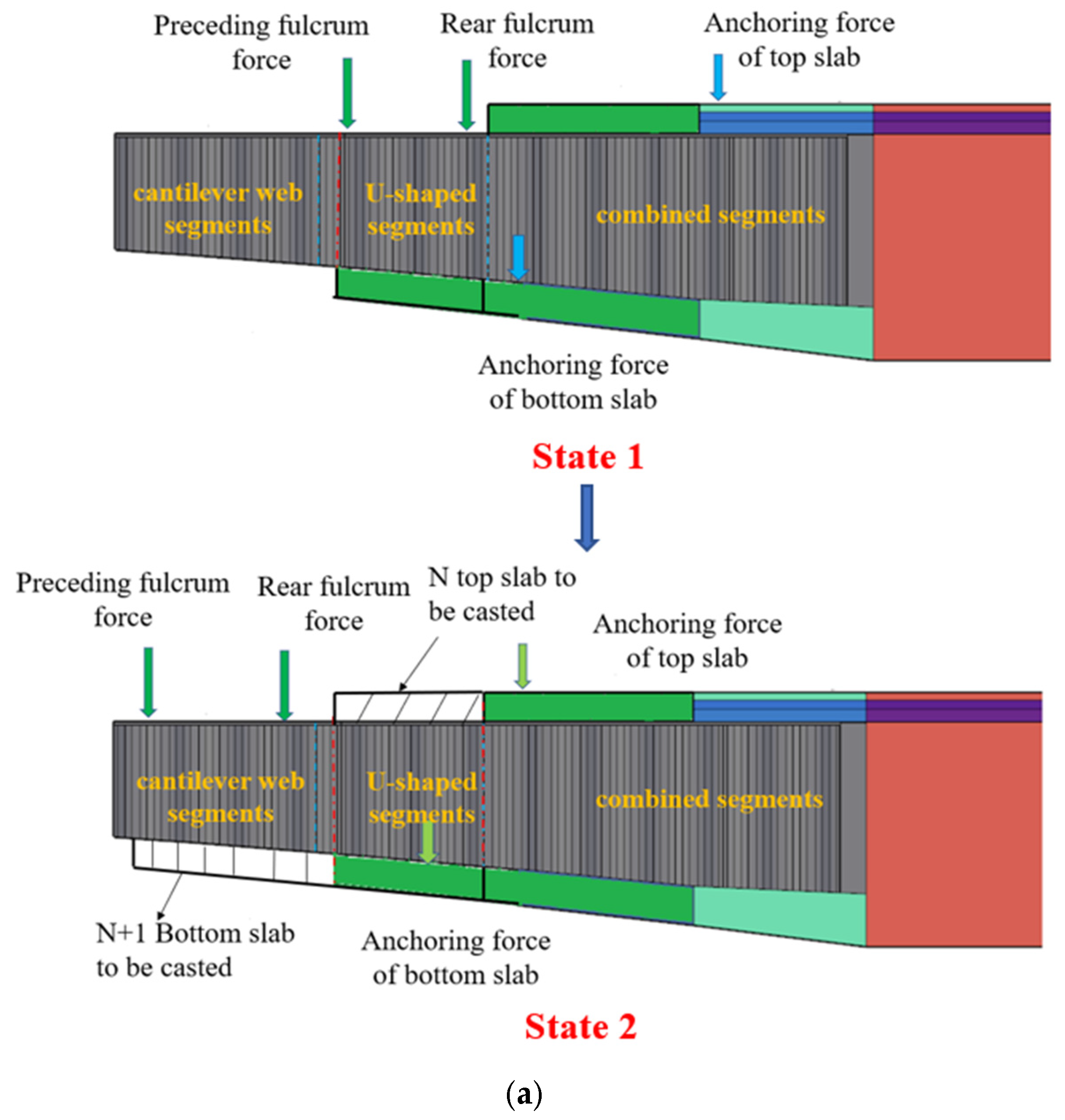

2.2. APC Technology

- Positioning: The hanging basket moves to Segment N; formwork is installed for the bottom slab (N) and top slab (N − 1).

- Reinforcement: Rebar is bound and welded concurrently for the bottom slab (N) and top slab (N − 1).

- Concreting: The bottom slab (N) and top slab (N − 1) are poured simultaneously, while CSWs for Segment N + 1 are installed during curing.

- Post-Tensioning and Cycle Advance: After the concrete strength meets requirements, Segment N’s tendons are tensioned. The basket then advances to Segment N+1, repeating the cycle.

- Step1: Apply counterweights on both sides of the closure segment, install pushing devices at the top and bottom slabs of the closure section to exert horizontal forces, and connect the stiff skeleton to ensure construction safety while simultaneously completing the connection of the corrugated steel webs in the closure segment.

- Step2: Pouring the concrete of the bottom and top slabs, releasing the counterweights simultaneously, and then removing the jacking devices when the concrete reaches sufficient strength.

- Step3: Remove the stiff skeleton and sequentially tension the prestressed tendons and external prestressed tendons in the closure segment.

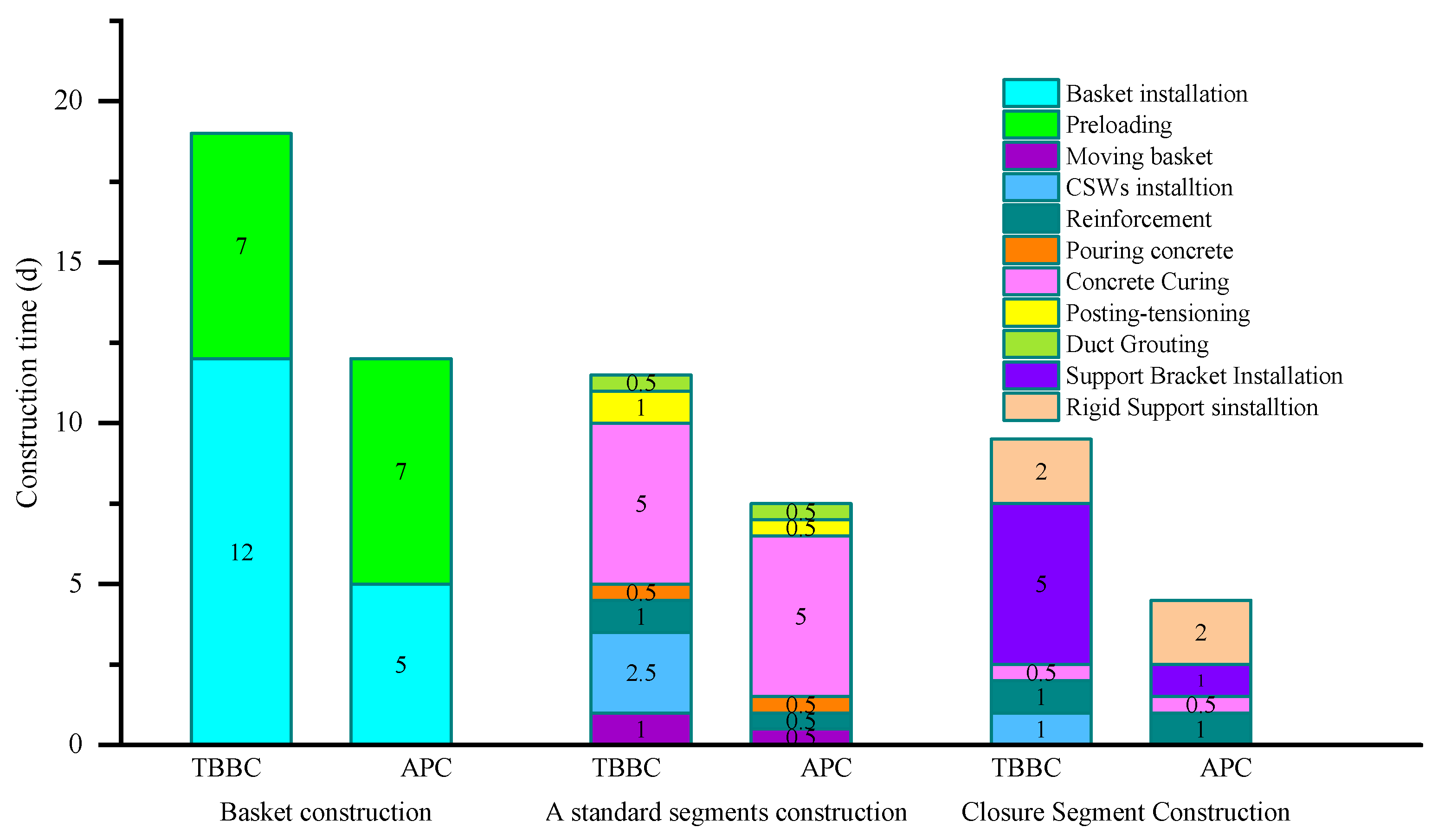

3. Environmental and Economic Sustainability Comparison Between APC and TTBC

3.1. Environmental Impact

3.2. Economic Cost

4. Mechanical Performance Comparison of APC and TBCC in Cantilever Construction Stage

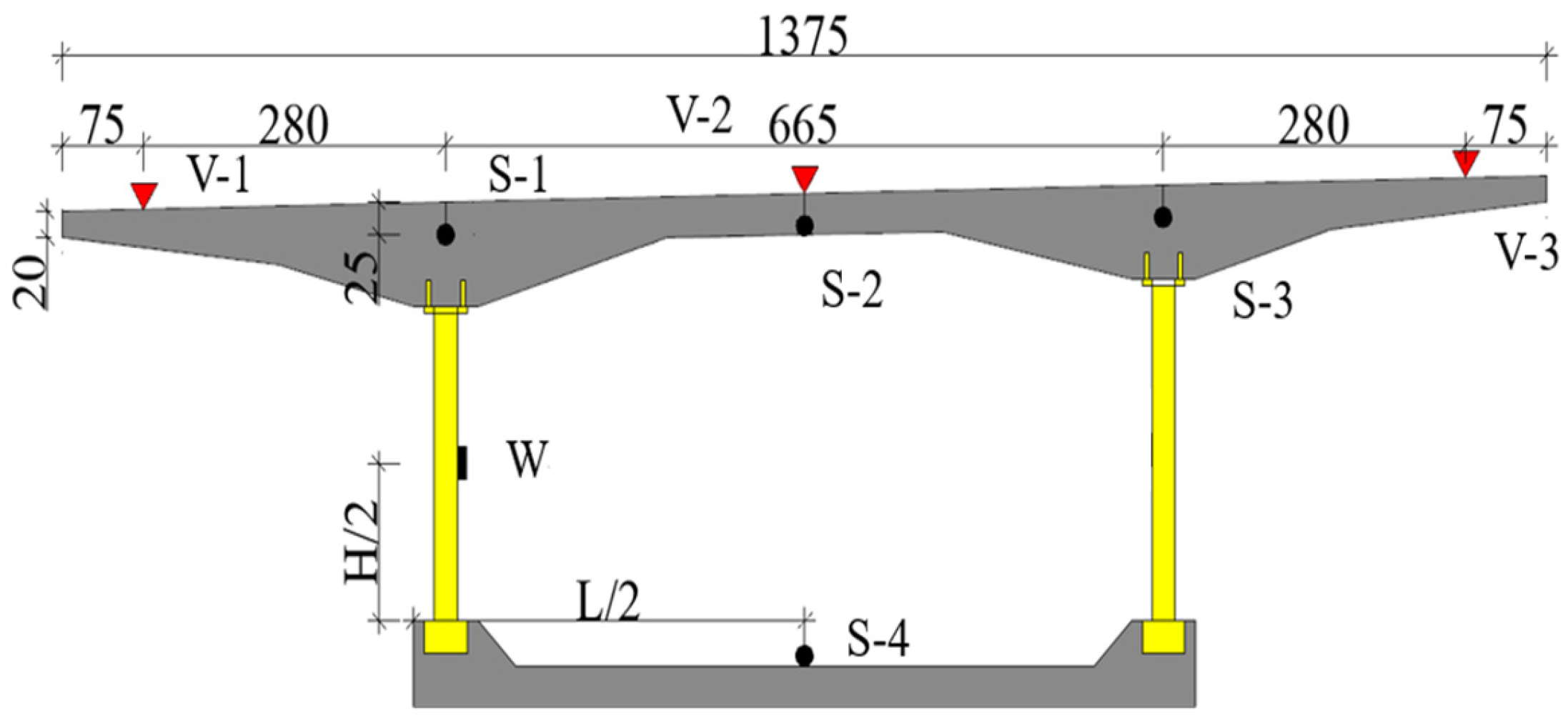

4.1. On-Site Measurement Arrangement

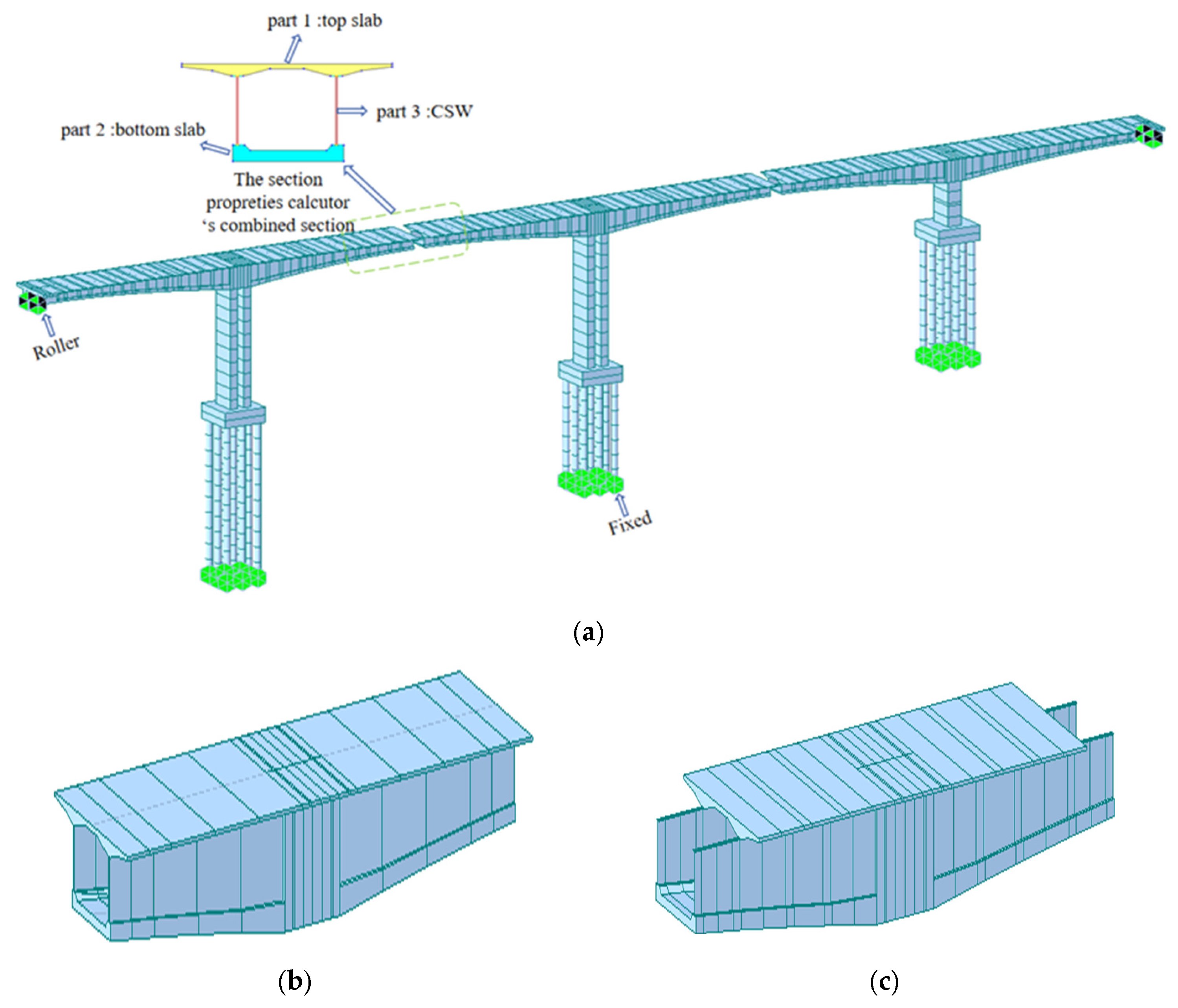

4.2. Finite Element Model

- Non-structural elements (e.g., formwork, diaphragms) were simplified as concentrated or linear loads.

- Identical geometric parameters, prestressing tendons, material properties, and boundary conditions were maintained for both models.

- Hanging basket loads (45 t for APC vs. 100 t for TBCC).

- Construction stage definitions.

- Stage 1: construction of Segment 0#.

- Stage 2: cast-in-place construction of Segment 1#.

- Stages 3–18: cantilever construction of standard Segments 2#–9#.

- Wet concrete pouring phase;

- Prestressing tendon tensioning phase.

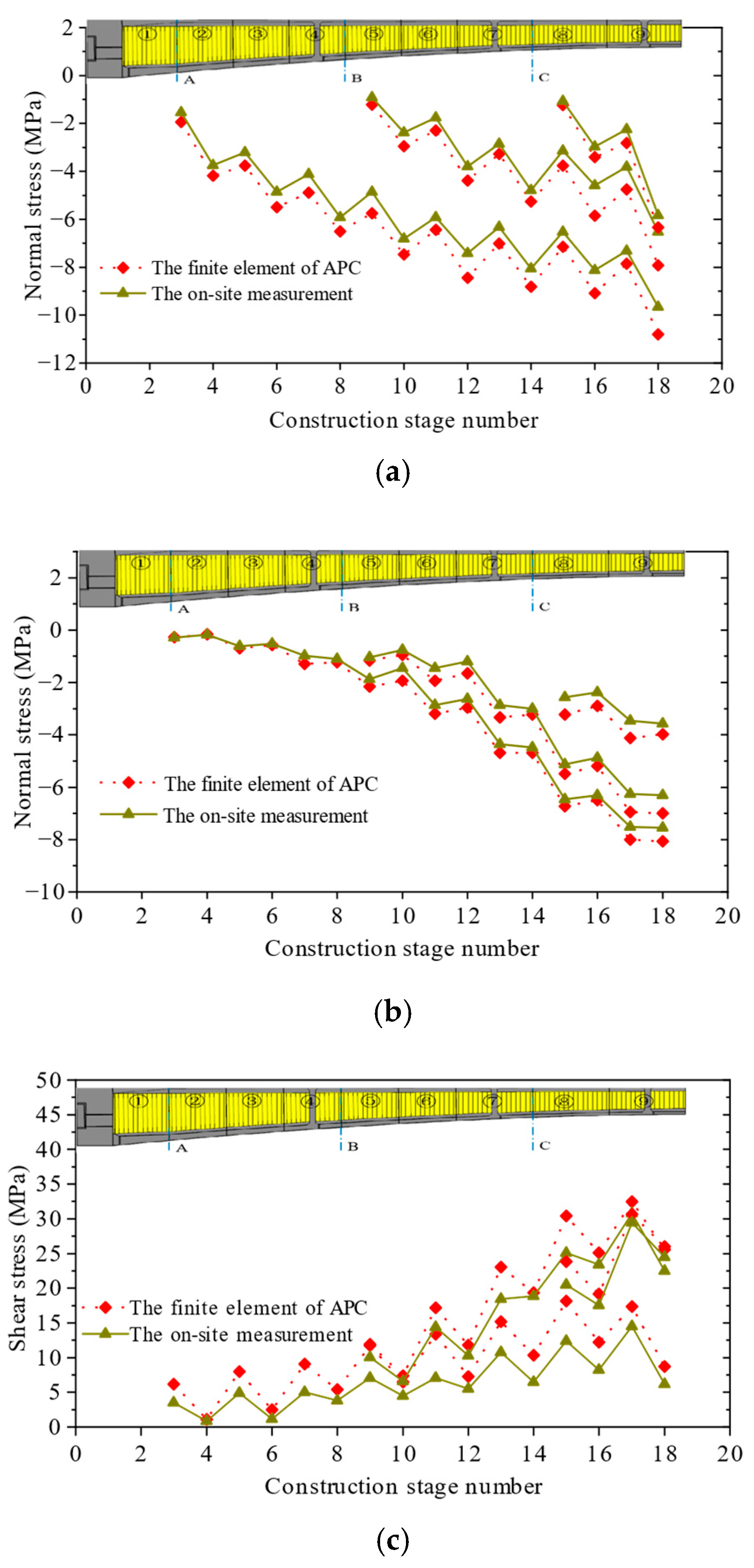

4.3. Validation of APC Finite Element Model

4.3.1. Structural Stress

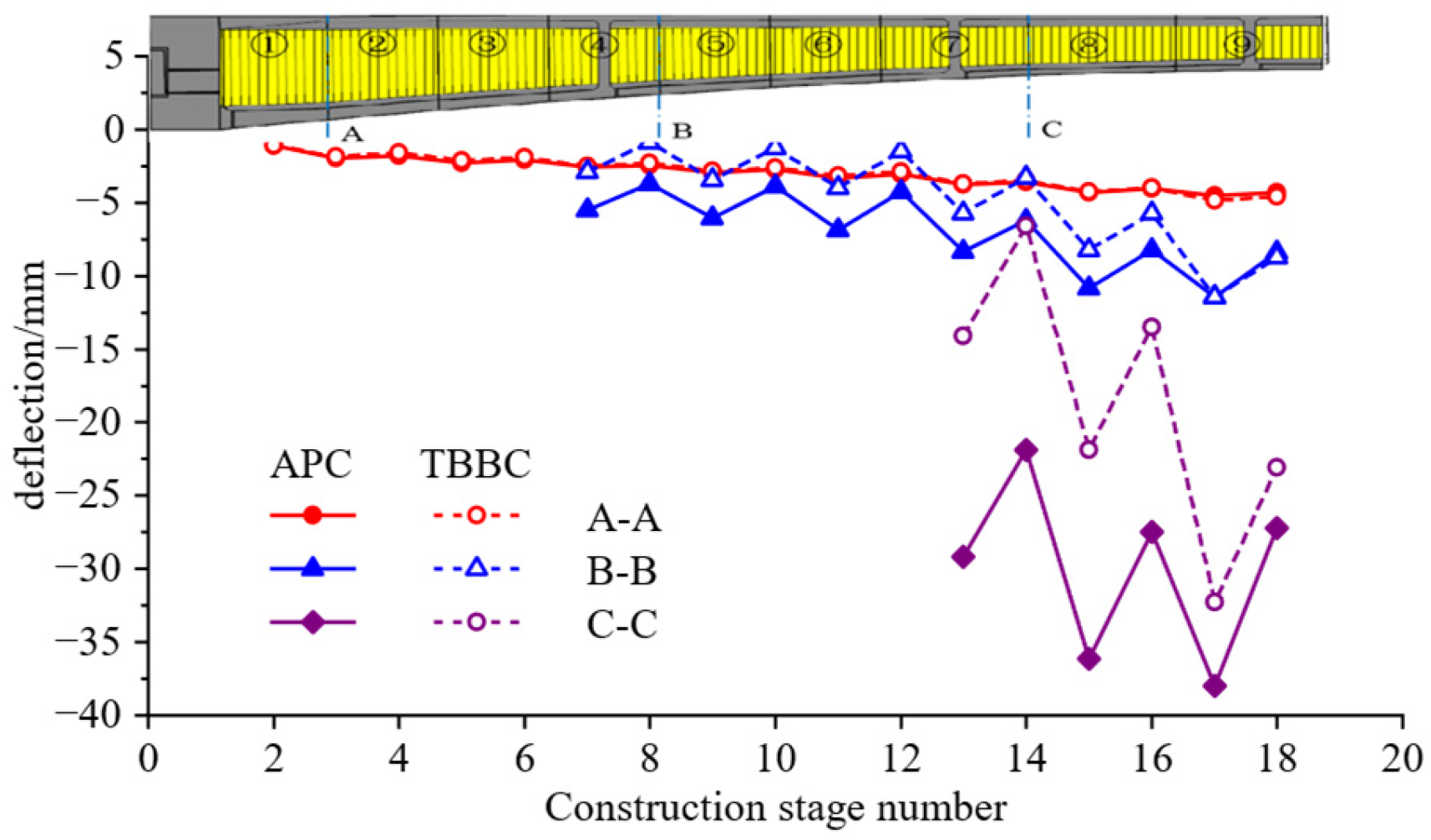

4.3.2. Main Girder Deflection

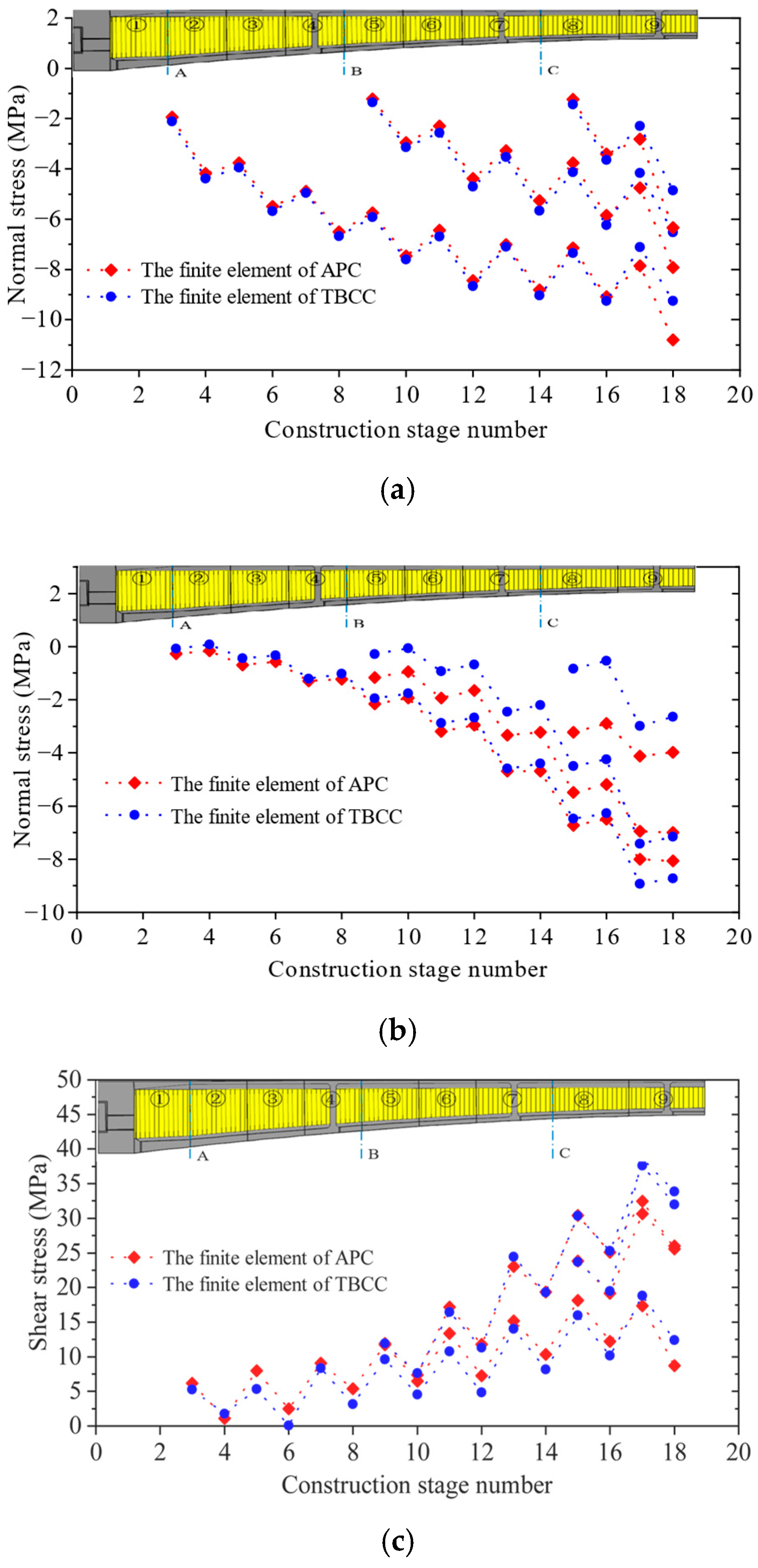

4.4. Comparative Analysis of Stress and Deflection

4.4.1. Normal Stress in Top Slabs

4.4.2. Normal Stress in Bottom Slabs

4.4.3. Shear Stress of CSWs

4.4.4. Deflection of the Main Girder

5. Simple Calculation for APC in Cantilever Construction Stage

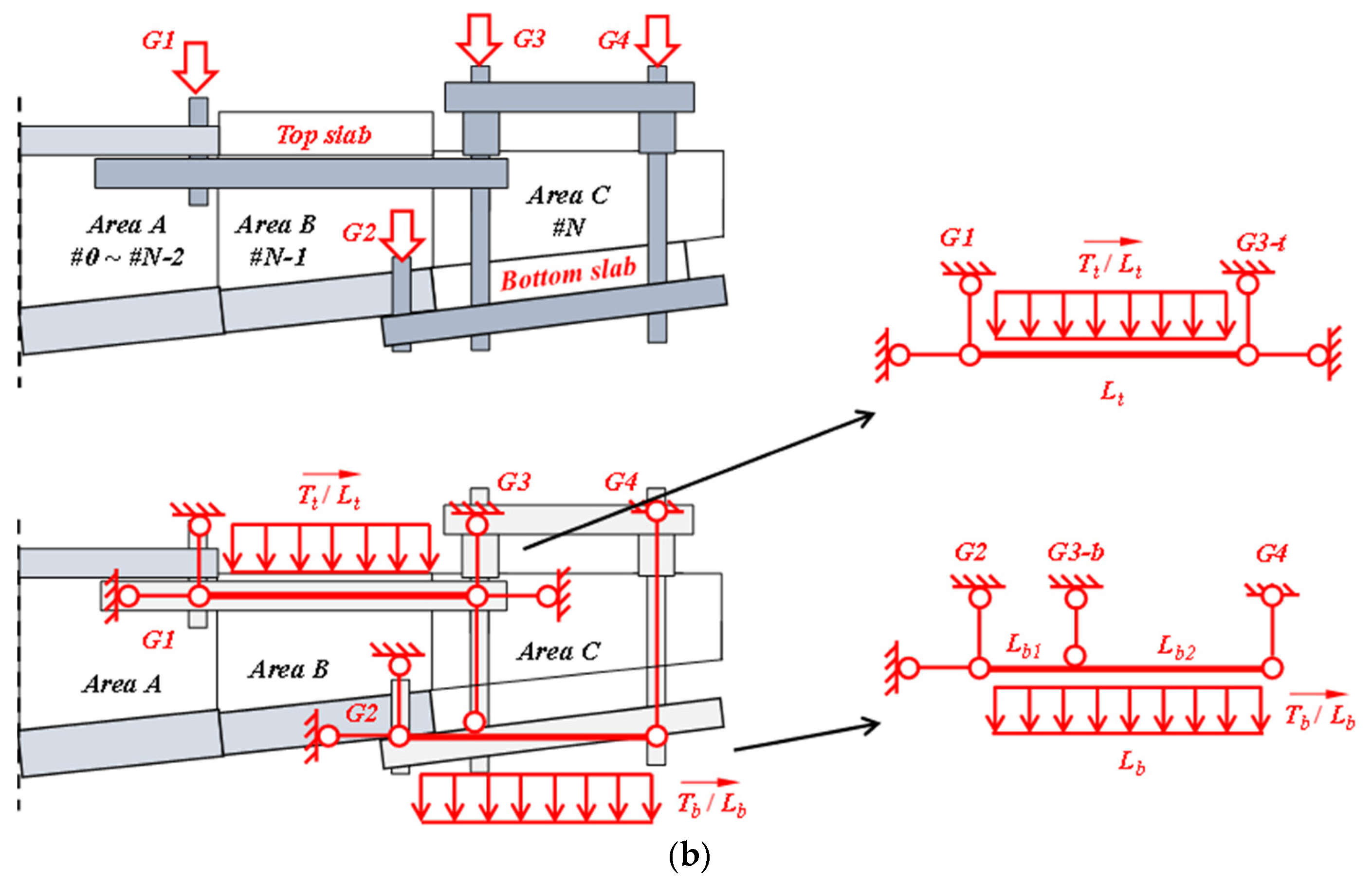

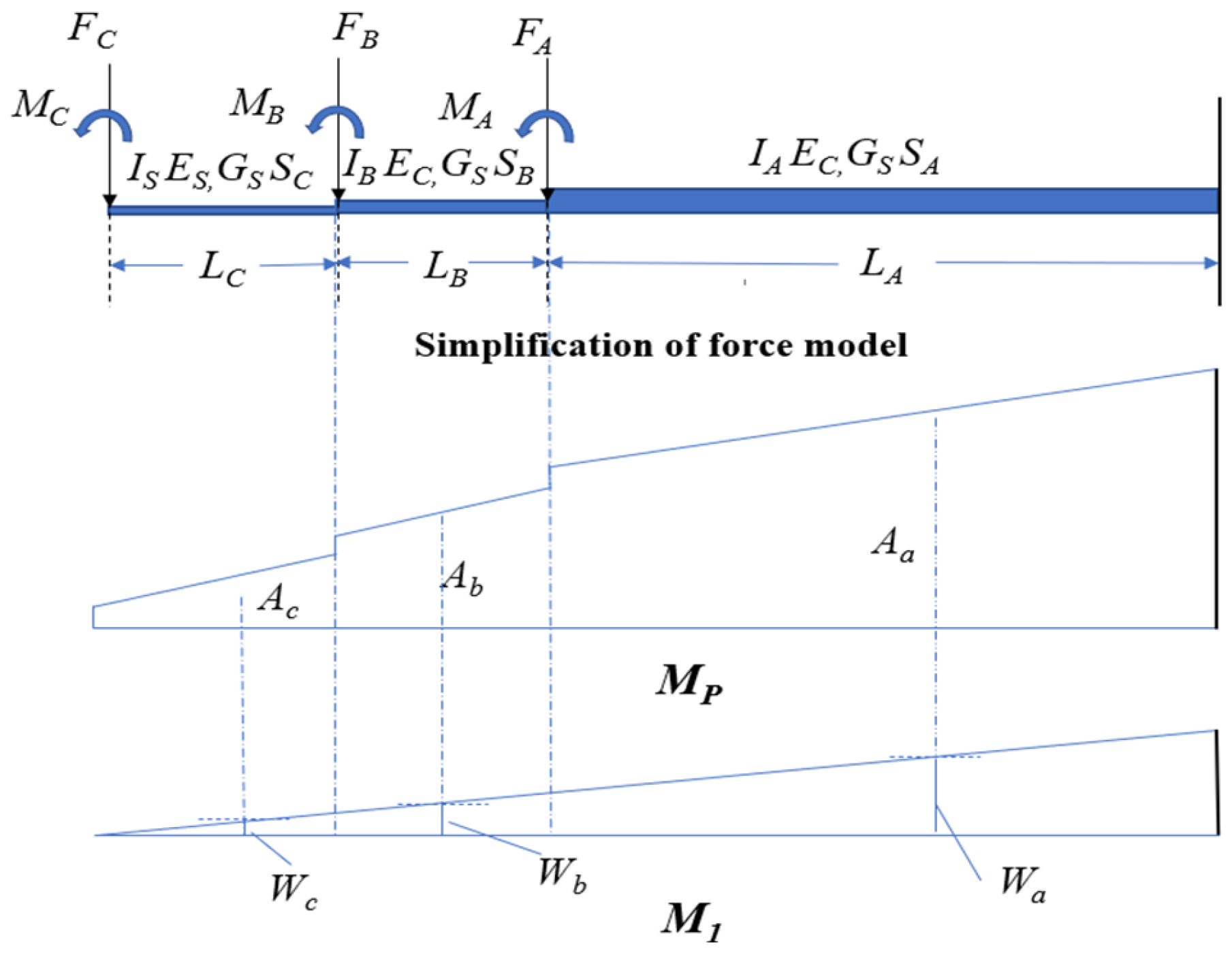

5.1. Asynchronous Cantilever Structure Partition

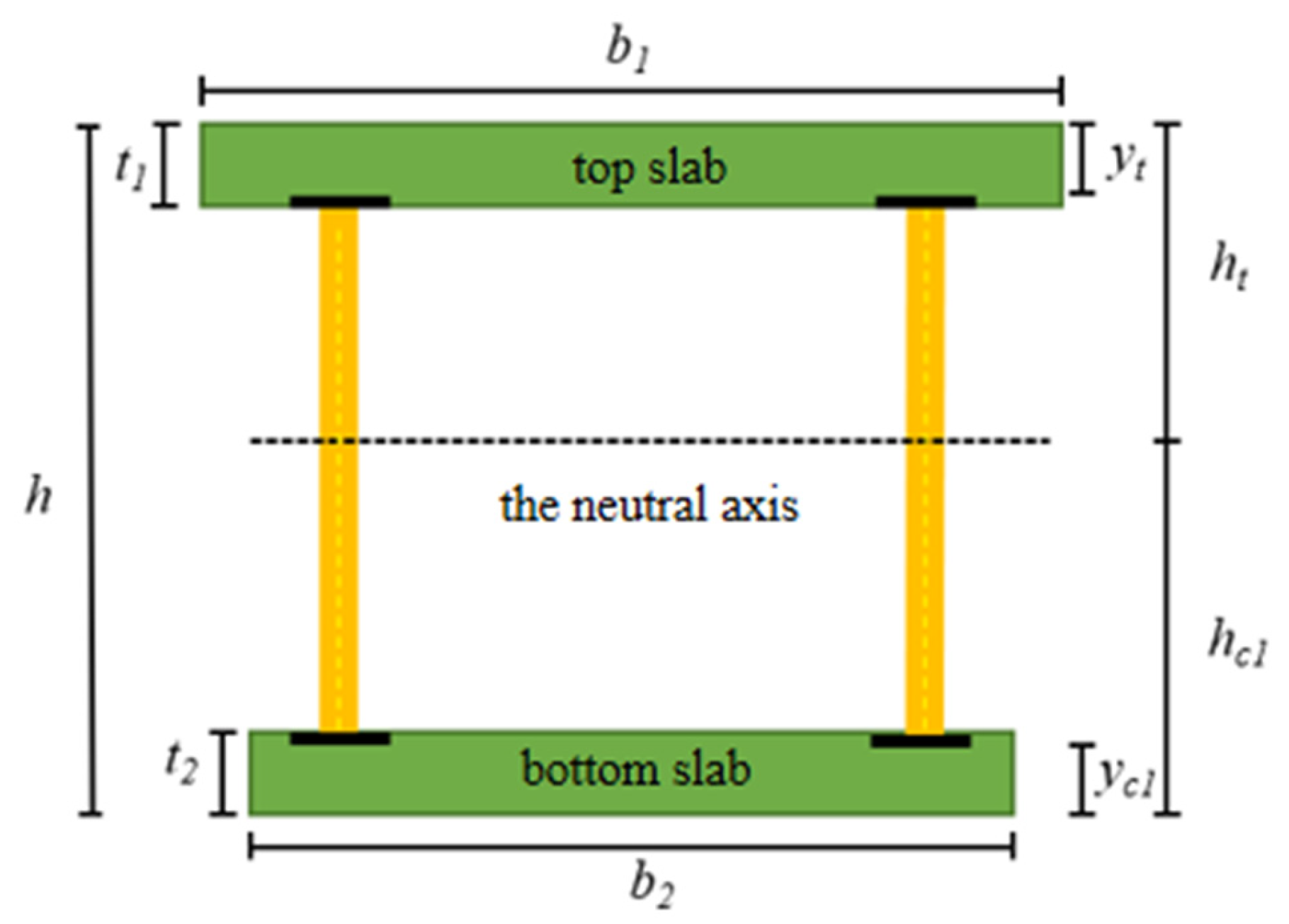

5.2. Calculation Assumption

- (1)

- Cross-section simplification:

- The variable composite cross-section segment is idealized as an equivalent uniform cross-section one.

- Simpson’s integration formula is employed, dividing the composite region into an even number of segments to compute the equivalent moment of inertia.

- Both U-shaped and cantilever web segments, owing to their limited lengths, are treated as uniform cross-section beams for moment of inertia calculations.

- (2)

- Bending behavior considerations:

- Corrugated steel webs (CSWs) are assumed to contribute negligibly to bending resistance.

- Composite segment region: only concrete top and bottom slabs are considered for bending strength.

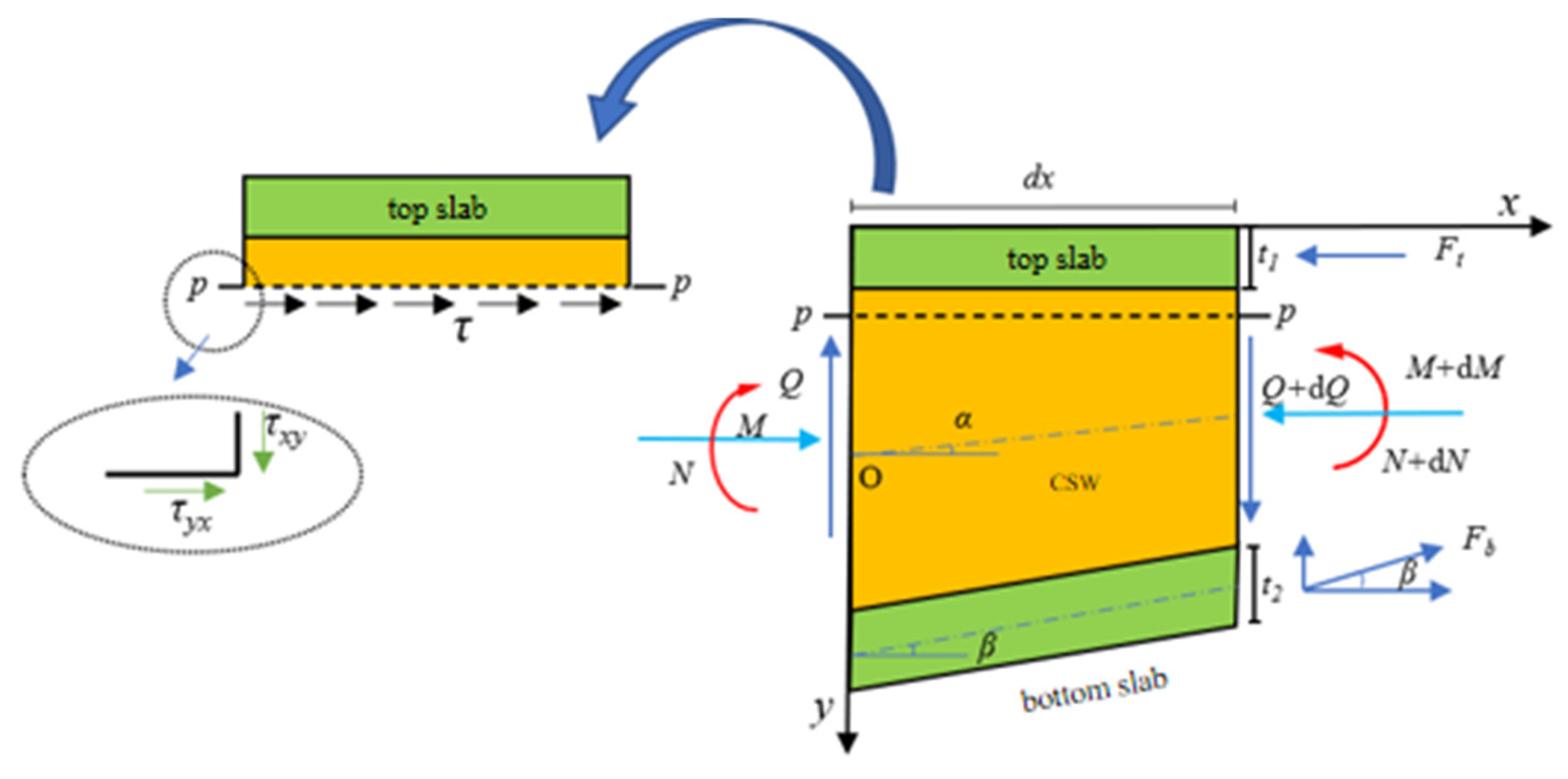

- (3)

- Shear stress distribution:

- Uniform shear stress distribution across the cross-section is assumed.

- (4)

- Load application:

- All applied loads are converted into equivalent concentrated forces and bending moments.

- (5)

- Material behavior:

- The structure remains entirely within the elastic deformation range.

- A perfect bond condition exists between concrete slabs and CSWs (no interfacial slip).

- (6)

- Decomposition of deformations:

- No interaction between bending and shear deformations is considered.

- Total deflection represents the linear superposition of both bending and shear deformation components.

5.3. Structural Stress Calculation

5.3.1. Normal Stress in Concrete Slabs

5.3.2. Shear Stress in CSWs

5.4. Deflection Calculation

5.4.1. Equivalent Inertia Moment of Asynchronous Cantilever Structure

5.4.2. Deflection Calculation Formula of CSW

5.5. Validation of Calculation Formula

5.5.1. The Stress of Slabs and CSWs

5.5.2. The Vertical Deflection of CSWs

6. Conclusions

- (1)

- The APC method demonstrated significant advantages over TBBC, achieving a 200-ton reduction in steel consumption, shortening the total construction period by 78.5 days (39.5% reduction), and realizing total cost savings of 3.045 million RMB (including both material and labor costs), making it a green and sustainable construction method.

- (2)

- The analysis of APC reveals that the main girder’s stress distribution and deflection characteristics, resulting from the combined action of self-weight and prestressing effects, demonstrate systematic variations while maintaining compliance with all applicable design specifications.

- (3)

- The structural response under APC involves coupled flexural–shear behavior. For analytical purposes, the structure is divided into three distinct flexural behavior regions based on composite action, a combined segment, U-shaped segment, and cantilever web segment, when calculating the bending deformation. Shear deformation may be conservatively assumed to be resisted solely by the corrugated webs.

- (4)

- The proposed simplified stress formulation demonstrates satisfactory agreement with Midas Civil finite element results for both web shear stresses and flange normal stresses across construction stages during the cyclic segmental erection process.

- (5)

- Based on the partitioned asynchronous construction model, the composite variable cross-sectional segments are equivalently transformed into uniform-section beams following Simpson’s integration formula. The derived simplified formula for cantilever tip deflection demonstrates high computational accuracy, with deviations between analytical predictions and finite element (FE) simulations. The maximum observed deviation was limited to acceptable engineering tolerances.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Calculation Parameters in Section 5.5.2

| Area A | Area B | Area C | |||||||

|---|---|---|---|---|---|---|---|---|---|

| LA (mm) | IA (mm4) | ASA (mm2) | LB (mm) | IB (mm4) | ASB (mm2) | LC (mm) | IS (mm4) | ASC (mm2) | |

| Working condition 1 | 28,800 | 8.769 × 1013 | 153,010 | 6400 | 1.041 × 1012 | 99,572 | 8800 | 5.209 × 1010 | 82,520 |

| Working condition 2 | 28,800 | 8.834 × 1013 | 153,010 | 6400 | 1.041 × 1012 | 99,572 | 8800 | 5.209 × 1010 | 82,520 |

| Working condition 3 | 28,800 | 8.897 × 1013 | 153,010 | 6400 | 1.041 × 1012 | 99,572 | 8800 | 5.209 × 1010 | 82,520 |

| Working condition 4 | 35,200 | 7.666 × 1013 | 142,700 | 6400 | 8.816 × 1011 | 82,520 | 7200 | 4.556 × 1010 | 79,320 |

| Area A | Area B | Area C | ||||

|---|---|---|---|---|---|---|

| Working condition 1 | FA (N) | 2.4 × 105 | FB (N) | 6.6 × 105 | ||

| MA (N·mm) | 6.72 × 108 | |||||

| Working condition 2 | FA(N) | 1 × 105 | FB (N) | 1.4 × 105 | FC (N) | 6.6 × 105 |

| MA (N·mm) | 8 × 107 | MF2 (N·mm) | 1.12 × 108 | |||

| Working condition 3 | FA (N) | 6.5 × 105 | FB (N) | 2.44 × 105 | FC(N) | 1.63 × 106 |

| MA(N·mm) | 5.2 × 108 | MB (N·mm) | 1.952 × 108 | |||

| Working condition 4 | MA (N·mm) | 2.04 × 1010 | ||||

References

- Elgaaly, M.; Seshadri, A.; Hamilton, R.W. Bending strength of steel beams with corrugated webs. J. Struct. Eng. 1997, 123, 772–782. [Google Scholar]

- Machimdamrong, C.; Watanabe, E.; Utsunomiya, T. Analysis of corrugated steel web girders by an efficient beam bending theory. Struct. Eng./Earthq. Eng. 2004, 21, 131s–142s. [Google Scholar]

- Deng, W.Q.; Zhou, M.; Hassanein, M.F.; Zhang, J.; Liu, D.; An, L. Growth of prestressed concrete bridges with corrugated steel webs in China. Proc. Inst. Civ. Eng. 2017, 171, 77–84. [Google Scholar]

- Chan, C.L.; Khalid, Y.A.; Sahari, B.B.; Hamouda, A.M.S. Finite element analysis of corrugated web beams under bending. J. Constr. Steel. Res. 2015, 58, 1391–1406. [Google Scholar]

- He, J.; Wang, S.H.; Liu, Y.; Dai, L.; TAN, C. The development of composite bridges with corrugated steel webs in China. Proc. Inst. Civ. Eng. Struct. Build. 2021, 174, 28–44. [Google Scholar]

- He, J.; LI, X.; LI, C.X. A novel asynchronous-pouring-construction technologies for prestressed concrete box girder bridges with corrugated steel webs. Structures 2020, 27, 1940–1950. [Google Scholar]

- Feng, S.D.; He, J.; Lin, W.W.; Li, C.Y.; Shao, Y.B.; Hassanein, M.F. Simplified deflection calculation method for PC box girder bridges with corrugated steel webs using asynchronous-pouring-construction technology. J. Constr. Steel Res. 2024, 214, 108482. [Google Scholar]

- Zhou, M.; Liu, Y.Y.; Wang, K.J.; Hassanein, M.F. New Asynchronous-Pouring Rapid-Construction Technologies for Long-Span Prestressed Concrete Box Girder Bridges with Corrugated Steel Webs. J. Constr. Eng. Manage 2020, 146, 05019021. [Google Scholar]

- Wang, D.; Wang, L.; Tang, C. Mechanical Characteristic Analysis of Corrugated Steel Webs Using Asynchronous Construction Technologies. J. Civ. Eng. 2021, 25, 185–196. [Google Scholar]

- Zhu, F.Q.; Jin, G.L.; Deng, W.Q.; Liu, D.; Zhang, J.D. Study on Asynchronous Construction Technologies for Long Span Composite Girder Bridge with Corrugated steel Webs. Mod. Transp. Technol. 2022, 19, 5–59+92. [Google Scholar]

- Tang, Y.S.; Lou, T.S.; Zhang, Y.; Wang, S.H.; Liu, Y.Q. Design of Main Bridge of Feilong Bridge in Hengzhou. World Bridges 2024, 52, 17–22. [Google Scholar]

- Luo, T.Y.; Zhang, Y.; Zhang, K.Q.; Liu, Y.Q.; Wang, S.H. Feilong Bridge, China: A super-long-span composite bridge with corrugated steel webs. Proc. Inst. Civ. Eng.-Civ. Eng. 2025, 178, 118–125. [Google Scholar]

- Cafolla, J.; Johnson, R.P. Local flange buckling in plate girders with corrugated webs. Proc. Inst. Civ. Eng. Struct. Build. 1997, 122, 148–156. [Google Scholar]

- Ledziewski, K.J.M. Influence of Corrugated Web Geometry on Mechanical Properties of I-Beam: Laboratory Tests. Materials 2021, 15, 277. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.L.; Wang, S.H.; Wang, J.J.; Yuan, H.Y. Research on flexural performance of composite girders with different shear connection degrees. Structures 2025, 77, 109144. [Google Scholar]

- Wu, F.; Fan, Z.; He, L.; Liu, S.; Zuo, J.; Yang, F. Comparative study of the negative bending behaviour of corrugated web steel–concrete composite beams using NC, ECC and UHPC. Eng. Struct. 2023, 283, 115925. [Google Scholar]

- Metwally, A.E.; Loov, R.E. Corrugated steel webs for prestressed concrete girders. Mater. Struct. 2003, 36, 127–134. [Google Scholar]

- Nie, J.G.; Zhu, L.; Tan, L. Shear strength of trapezoidal corrugated steel webs. China Civ. Eng. J. 2013, 46, 97–109. [Google Scholar]

- He, J.; Wang, S.H.; Liu, Y.Q.; Wang, D.; Xin, H. Shear behavior of steel I-girder with stiffened corrugated web, Part II: Numerical study. Thin-Walled Struct. 2020, 147, 106025. [Google Scholar]

- Wang, K.J.; Zhou, M.; Hassanein, M.; Zhong, J.; Ding, H.S.; An, L. Study on Elastic Global Shear Buckling of Curved Girders with Corrugated Steel Webs: Theoretical Analysis and FE Modelling. Appl. Sci. 2018, 8, 2457. [Google Scholar]

- Yuan, H.X.; He, K.X.; Gao, L.Q.; Wang, A.D.; Du, X.X. Shear behaviour and design of bolted steel girders with trapezoidal corrugated webs. J. Constr. Steel Res. 2024, 216, 108573. [Google Scholar]

- Li, Z.; Pasternak, H.; Robra, J.; Wang, J. Shear buckling resistance of sinusoidal corrugated web girders with stiffened openings: Analysis, Experiment, Simulation and Design guidance. Thin-Walled Struct. 2025, 215, 113368. [Google Scholar]

- Zhou, M.; Chai, J.L. Modified Calculation on Shear Stress in the Hogging Moment Regions of Tapered Girder Bridges with Corrugated Steel Webs. J. Struct. Eng. 2025, 151, 04025087. [Google Scholar]

- Zhu, Y.B.; Wan, S.; Shen, K.J.; Zhou, P.; Wang, X. Theoretical study on the nonlinear performance of single-box multi-cell composite box-girder with corrugated steel webs under pure torsion. Constr. Steel Res. 2021, 178, 106487. [Google Scholar]

- Huang, H.M.; Zhang, Y.H.; Ji, W.; Luo, K. Theoretical Study and Parametric Analysis on Restrained Torsion of Composite Box Girder Bridge with Corrugated Steel Webs. J. Bridge Eng. 2022, 27, 04022118. [Google Scholar]

- Zhang, H.; Chen, Y.; Pan, J.; Dong, J.; Zhao, Q. Torsional behavior of super-span composite box girder with corrugated steel webs. Structures 2024, 68, 107045. [Google Scholar]

- Zhang, H.P.; Liu, H.J.; Deng, Y.; Cao, Y.; He, Y.B.; Liu, Y.; Deng, Y. Fatigue behavior of high-strength steel wires considering coupled effect of multiple corrosion-pitting. Corros. Sci. 2025, 244, 112633. [Google Scholar]

- Chen, F.H.; Liu, X.; Zhang, H.P.; Luo, Y.; Lu, N.W.; Liu, Y.; Xiao, X.H. Assessment of fatigue crack propagation and lifetime of double-sided U-rib welds considering welding residual stress relaxation. Ocean Eng. 2025, 332, 121400. [Google Scholar]

- Zhang, H.P.; Deng, Y.; Cao, Y.; Chen, F.H.; Luo, Y.; Xiao, X.H.; Deng, Y.H.; Liu, Y. Field testing, analytical, and numerical assessments on the fatigue reliability on bridge suspender by considering the coupling effect of multiple pits. Struct. Infrastruct. Eng. 2025, 1–16. [Google Scholar] [CrossRef]

- Dai, H.; Zheng, G.H.; Du, S. Model test of asynchronous construction for corrugated steel web PC box girder. China Harb. Eng. 2021, 41, 50–54. [Google Scholar]

- Peng, D.L.; Yang, J.; Zheng, X. Study on local deformation of corrugated steel web in asynchronous suspension construction. J. Transp. Sci. Eng. 2021, 37, 89–94. [Google Scholar]

- Ren, H.C.; Chen, L.P.; Luo, Q.D.; Zhang, M.L. Analysis of Main Girder Cantilever Construction of Gexi Bridge on Wentai Expressway. Bridge Constr. 2021, 51, 138–143. [Google Scholar]

- Deng, W.Q.; Liu, D.; Xiong, Y.Q.; Zhang, J.D. Experimental study on asynchronous construction for composite bridges with corrugated steel webs. J. Constr. Steel Res. 2019, 157, 93–102. [Google Scholar]

- Deng, W.Q.; Xia, H.S.; Zha, S.; Pei, H.T.; Liu, D.; Zhang, J.D.; Gu, J.C. Experimental study on asynchronous construction for composite bridges with CSWs: Comparative study. Case Stud. Constr. Mater. 2024, 20, e02776. [Google Scholar]

- Zuo, S.H. Key Techniques of Design and Using Asynchronous Form Travelers to Construct West Qingxi Road Bridge. World Bridges 2022, 50, 44–50. [Google Scholar]

- Project Team on the Strategy and Pathway for Peaked Carbon Emissions and Carbon Neutrality. Analysis of a Peaked Carbon Emission Pathway in China Toward Carbon Neutrality. Engineering 2021, 7, 1673–1677. [Google Scholar]

- Leimbach, M.; Kriegler, E.; Roming, N.; Schwanitz, J. Future growth patterns of world regions–A GDP scenario approach. Glob. Environ. Change 2017, 42, 215–225. [Google Scholar]

- Yepes, V.; Martí, J.V.; García-Segura, T. Cost and CO2 emission optimization of precast–prestressed concrete U-beam road bridges by a hybrid glowworm swarm algorithm. Autom. Constr. 2015, 9, 123–134. [Google Scholar]

- China Iron & Steel Association. Available online: https://t.hk.uy/bS4j (accessed on 23 May 2025).

- Ministry of Communication of China (MOC). Specification for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts, (JTG 3362–2018); China Communications Press: Beijing, China, 2018; pp. 8–9. [Google Scholar]

- Zhou, M.; Liu, Z.; Zhang, J.; An, L.; He, Z. Equivalent computational models and deflection calculation methods of box girders with corrugated steel webs. Eng. Struct. 2016, 127, 615–634. [Google Scholar]

| Item | ① APC | ② TTBC | Price | ②-① |

|---|---|---|---|---|

| Steel for basket installation cost | 400 t | 200 t | 3450 RMB/t | 690,000 RMB |

| Labor cost | 198.5 d | 120 d | 30,000 RMB/d | 2,355,000 RMB |

| Mechanical Performance | Concrete Flange Slab | CSW | Steel Stranded |

|---|---|---|---|

| Elastic modulus/GPa | 35.5 | 206 | 195 |

| Tension strength/MPa | - | 310 | 1860 |

| Shear strength/MPa | - | 170 | - |

| Poisson ratio | 0.2 | 0.3 | 0.3 |

| Unit weight/(kN·m−3) | 26 | 78.5 | 78.5 |

| Work Conditions | Pouring Wet Weight of Concrete (mm) | Tensioning Prestressed Tendons (mm) | ||

|---|---|---|---|---|

| FAPC | TEST | FAPC | TEST | |

| 2# | 0.9 | 0.5 | 1.3 | 1.0 |

| 3# | 1.1 | 1.0 | 1.1 | 1.6 |

| 4# | 2.1 | 2.4 | 2.0 | 2.3 |

| 5# | 3.4 | 3.6 | 3.1 | 3.6 |

| 6# | 6.1 | 6.9 | 5.3 | 6.1 |

| 7# | 13.2 | 14.2 | 8.0 | 8.2 |

| 8# | 20.7 | 22.5 | 11.2 | 9.6 |

| 9# | 19.5 | 19.7 | 25.2 | 12.3 |

| Segment Number | Move the Hanging Basket Forward/MPa | Pouring Concrete/MPa | Tensioning Prestress/MPa | |||

|---|---|---|---|---|---|---|

| FE | Eq | FE | Eq | FE | Eq | |

| 2# | 0.08 | 0.09 | 1.51 | 1.41 | −2.03 | −1.74 |

| 3# | 0.10 | 0.09 | 1.44 | 1.32 | −2.08 | −1.73 |

| 4# | 0.12 | 0.10 | 1.32 | 1.18 | −2.14 | −1.71 |

| 5# | 0.12 | 0.11 | 1.15 | 1.00 | −2.18 | −1.70 |

| 6# | 0.14 | 0.12 | 0.91 | 0.75 | −2.21 | −1.68 |

| 7# | 0.16 | 0.13 | 0.47 | 0.44 | −2.22 | −1.66 |

| Segment Number | Move the Basket Forward/MPa | Pouring Concrete/MPa | Tension/MPa | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (a) FE | (b) Eq | |(a) − (b)| | (a) FE | (b) Eq | |(a) − (b)| | (a) FE | (b) Eq | |(a) − (b)| | |

| 2# | −0.11 | −0.11 | 0 | −1.99 | −1.79 | 0.20 | −0.26 | −0.19 | 0.07 |

| 3# | −0.14 | −0.13 | 0.01 | −2.02 | −1.85 | 0.17 | −0.28 | −0.23 | 0.05 |

| 4# | −0.17 | −0.16 | 0.01 | −2.00 | −1.84 | 0.16 | −0.30 | −0.28 | 0.02 |

| 5# | −0.20 | −0.19 | 0.01 | −1.85 | −1.71 | 0.14 | −0.32 | −0.34 | 0.02 |

| 6# | −0.24 | −0.23 | 0.01 | −1.55 | −1.39 | 0.16 | −0.34 | −0.40 | 0.06 |

| 7# | −0.29 | −0.28 | 0.01 | −0.84 | −0.90 | 0.06 | −0.34 | −0.48 | 0.14 |

| Segment Number | Move the Hanging Basket Forward/MPa | Pouring Concrete/MPa | Tensioning Prestress/MPa | |||

|---|---|---|---|---|---|---|

| FE | Eq | FE | Eq | FE | Eq | |

| 2# | −0.11 | −0.11 | −1.99 | −1.79 | −0.26 | −0.19 |

| 3# | −0.14 | −0.13 | −2.02 | −1.85 | −0.28 | −0.23 |

| 4# | −0.17 | −0.16 | −2.00 | −1.84 | −0.30 | −0.28 |

| 5# | −0.20 | −0.19 | −1.85 | −1.71 | −0.32 | −0.34 |

| 6# | −0.24 | −0.23 | −1.55 | −1.39 | −0.34 | −0.40 |

| 7# | −0.29 | −0.28 | −0.84 | −0.90 | −0.34 | −0.48 |

| Working Conditions | (a) Bend (mm) | (b) Shear (mm) | (c) Total (mm) | (d) Measured (mm) | Error |

|---|---|---|---|---|---|

| Move the basket forward | 11.8 | 0.7 | 12.5 | 13 | 3.80% |

| Pouring top and bottom slabs | 21.9 | 5.2 | 27.1 | 28 | 3.20% |

| Tension | 6.3 | / | 6.3 | 5 | 26.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, B.; He, J.; Feng, S.; Guo, B.; Liu, B.; Lu, W. Structural Behavior Analyses and Simple Calculation of Asynchronous-Pouring Construction in PC Composite Girder Bridges with Corrugated Webs for Sustainability. Buildings 2025, 15, 2434. https://doi.org/10.3390/buildings15142434

Gan B, He J, Feng S, Guo B, Liu B, Lu W. Structural Behavior Analyses and Simple Calculation of Asynchronous-Pouring Construction in PC Composite Girder Bridges with Corrugated Webs for Sustainability. Buildings. 2025; 15(14):2434. https://doi.org/10.3390/buildings15142434

Chicago/Turabian StyleGan, Bo, Jun He, Sidong Feng, Baojun Guo, Bo Liu, and Weisheng Lu. 2025. "Structural Behavior Analyses and Simple Calculation of Asynchronous-Pouring Construction in PC Composite Girder Bridges with Corrugated Webs for Sustainability" Buildings 15, no. 14: 2434. https://doi.org/10.3390/buildings15142434

APA StyleGan, B., He, J., Feng, S., Guo, B., Liu, B., & Lu, W. (2025). Structural Behavior Analyses and Simple Calculation of Asynchronous-Pouring Construction in PC Composite Girder Bridges with Corrugated Webs for Sustainability. Buildings, 15(14), 2434. https://doi.org/10.3390/buildings15142434