On-Site Safety Inspections Through Marker-Less Augmented Reality and Blockchain Notarization of BIM-Based Processes †

Abstract

1. Introduction

1.1. Background

1.2. State of the Art

1.2.1. Digital H&S Plan

1.2.2. The Benefits Provided by AR/MR for On-Site Applications

1.2.3. Blockchain

2. Materials and Methods

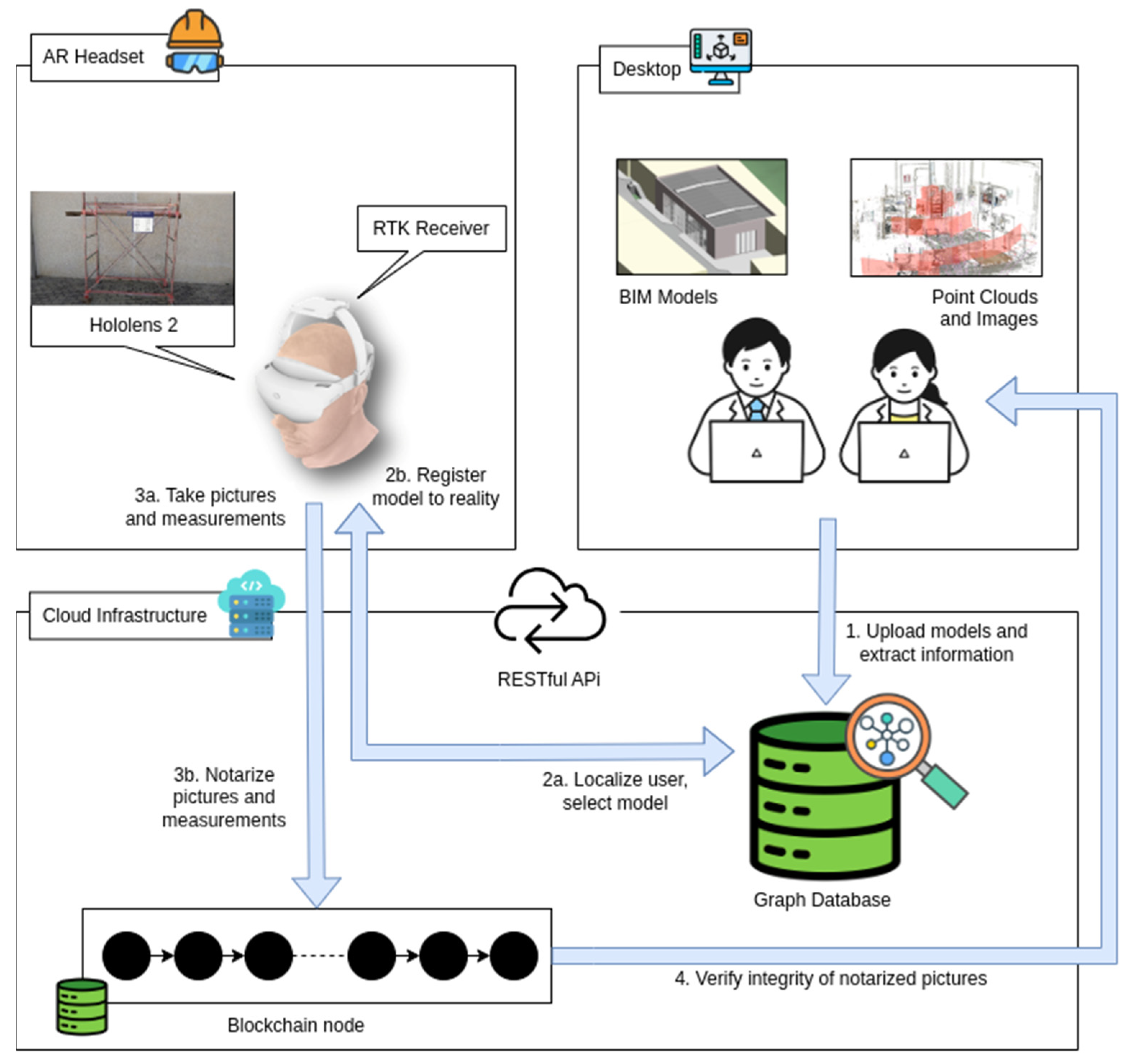

2.1. The System Architecture

- Data storage;

- GNSS-based AR registration engine;

- Image-based AR registration engine;

- Engine switcher;

- Notarization engine.

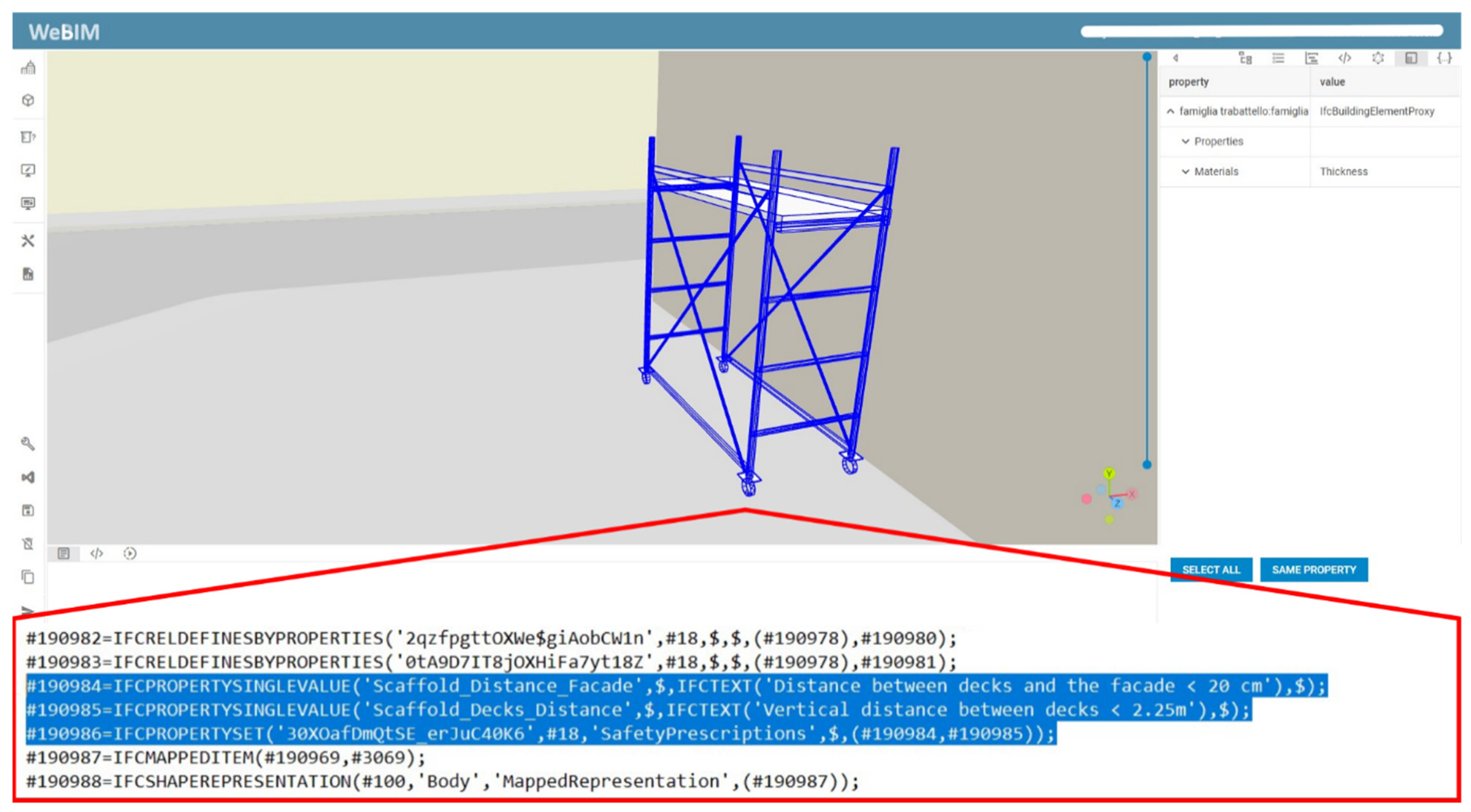

2.2. Digital Model of the H&S Plan

2.3. AR Registration Engines for Indoor and Outdoor Alignment of Virtual Models

2.4. Blockchain

- It maps two different arrays of bytes to very different hash digests in a pseudo-random manner.

- It is not possible to predict how a byte changed in the file content can reflect in the hash digest of the updated file.

- It is not possible to recover the file content starting from the hash digest.

- A hash function can be computed very efficiently (they have linear computational complexity, which is considered very good in practical applications).

- The probability of two different files mapping onto the same hash digest is negligible.

- When a file F is stored, the hash digest dF is computed.

- The file F is sent to a cloud storage provider and made available at hyperlink lF.

- The hash digest dF is sent to a smart contract by passing it as an input parameter when invoking a method in the smart contract itself; this returns a transaction signature tsF confirming that the information has been wrapped in a transaction and notarized by a block of the blockchain.

- The hyperlink lF, the transaction signature tsF, and the hash digest dF are stored in a database managed by the application, together with the name of file F.

- When accessing file F after a period of time, the application downloads file F using the hyperlink lF and, before showing it to the user, again computes the hash digest dF′ of file F.

- If the two hash digests dF′ and dF indeed match, the application shows the file F with a confirmation (e.g., a special mark) certifying that it has not been tampered with since the file was last updated; otherwise, the application can choose to either make the file available to the user showing that an exception arose in the integrity verification procedure or to prevent the user from downloading the file content. The latter, a more radical approach, may be justified in contexts where absolute adherence to security policy must be ensured when accessing critical information.

3. Results

3.1. Design of Experiments

- Indoor image collection and recognition verification by alignment;

- Verification of outdoor registration via GNSS;

- Verification of the correct display of prescriptions supporting outdoor and indoor inspections;

- Verification of notarization of the images collected via blockchain.

3.2. Test of the Accuracy of the Registration Engine

3.2.1. Indoor Image-Based Registration Test

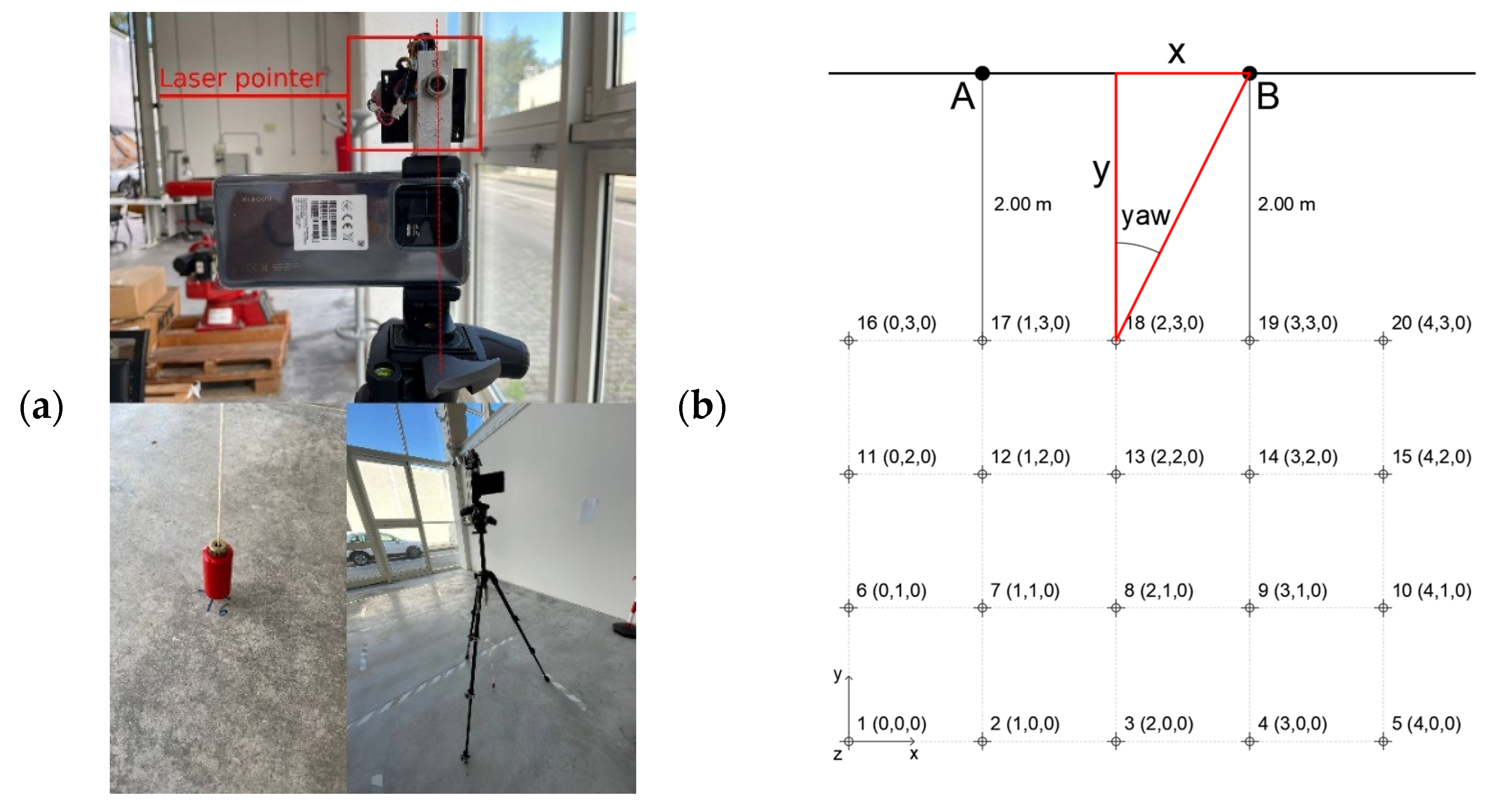

3.2.2. Outdoor GNSS/RTK-IMU Registration Test

3.3. Experimental Tests

3.4. Visualization of the BIM Model and Checking of Annotated Safety Prescriptions

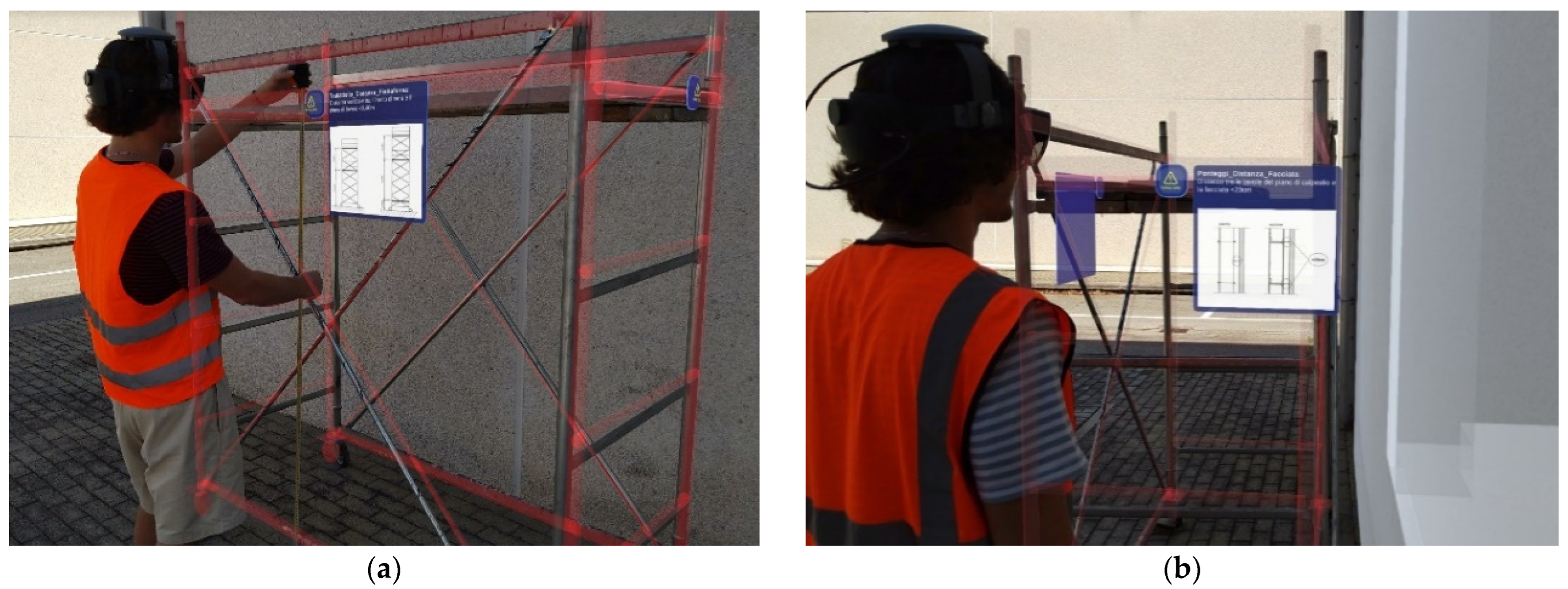

3.5. Alignment of the MR Hologram, Uploading of Pictures, Alignment of the Pictures in the Platform, and Measurement of Distances

3.6. Results and Tests on Smart Contracts

4. Discussion

- RQ1: Can safety prescriptions be efficiently represented in BIM models?

- RQ2: Can augmented reality be the right technology for representing information on-site?

- RQ3: Is the proposed procedure a feasible way to conduct inspections?

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rodrigues, F.; Antunes, F.; Matos, R. Safety plugins for risks prevention through design resourcing BIM. Constr. Innov. 2021, 21, 244–258. [Google Scholar] [CrossRef]

- Shanti, M.Z.; Cho, C.S.; Byon, Y.J.; Yeun, C.Y.; Kim, T.Y.; Kim, S.K.; Altunaiji, A. A Novel Implementation of an AI-Based Smart Construction Safety Inspection Protocol in the UAE. IEEE Access 2021, 9, 166603–166616. [Google Scholar] [CrossRef]

- Lingard, H.; Cooke, T.; Zelic, G.; Harley, J. A qualitative analysis of crane safety incident causation in the Australian construction industry. Saf. Sci. 2021, 133, 105028. [Google Scholar] [CrossRef]

- Wu, H.; Zhong, B.; Li, H.; Chi, H.L.; Wang, Y. On-site safety inspection of tower cranes: A blockchain-enabled conceptual framework. Saf. Sci. 2022, 153, 105815. [Google Scholar] [CrossRef]

- Ramos-Hurtado, J.; Muñoz-La Rivera, F.; Mora-Serrano, J.; Deraemaeker, A.; Valero, I. Proposal for the Deployment of an Augmented Reality Tool for Construction Safety Inspection. Buildings 2022, 12, 500. [Google Scholar] [CrossRef]

- Love, P.E.D.; Tenekedjiev, K. Understanding near-miss count data on construction sites using Greedy D-vine Copula Marginal Regression: A comment. Reliab. Eng. Syst. Saf. 2022, 217, 108021. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Lee, W.K. Analysing the underlying factors affecting safety performance in building construction. Prod. Plan. Control 2020, 31, 1061–1076. Available online: https://www.tandfonline.com/doi/abs/10.1080/09537287.2019.1695292 (accessed on 30 June 2025). [CrossRef]

- Luo, Q.; Sun, C.; Li, Y.; Qi, Z.; Zhang, G. Applications of digital twin technology in construction safety risk management: A literature review. Eng. Constr. Archit. Manag. 2024, 32, 3587–3607. [Google Scholar] [CrossRef]

- Liu, J.; Duan, L.; Lin, S.; Miao, J.; Zhao, J. Concept, Creation, Services and Future Directions of Digital Twins in the Construction Industry: A Systematic Literature Review. Arch. Comput. Methods Eng. 2025, 32, 319–342. [Google Scholar] [CrossRef]

- Yan, H.; Liu, C.; Yang, X.; Feng, K. Real-Time Digital Twin–Driven 3D Near-Miss Detection System at Construction Sites. J. Constr. Eng. Manag. 2025, 151, 04025021. [Google Scholar] [CrossRef]

- Jang, D.H.; Roh, G.T.; Jeon, C.H.; Shim, C.S. Simulation-Based Optimization of Crane Lifting Position and Capacity Using a Construction Digital Twin for Prefabricated Bridge Deck Assembly. Buildings 2025, 15, 475. [Google Scholar] [CrossRef]

- Dobrucali, E.; Sadikoglu, E.; Demirkesen, S.; Zhang, C.; Tezel, A.; Kiral, I.A. A bibliometric analysis of digital technologies use in construction health and safety. Eng. Constr. Archit. Manag. 2024, 31, 3249–3282. [Google Scholar] [CrossRef]

- Jelonek, M.; Fiala, E.; Herrmann, T.; Teizer, J.; Embers, S.; König, M.; Mathis, A. Evaluating Virtual Reality Simulations for Construction Safety Training A User Study Exploring Learning Effects, Usability and User Experience. i-com 2022, 21, 269–281. [Google Scholar] [CrossRef]

- Akram, R.; Thaheem, M.J.; Nasir, A.R.; Ali, T.H.; Khan, S. Exploring the role of building information modeling in construction safety through science mapping. Saf. Sci. 2019, 120, 456–470. [Google Scholar] [CrossRef]

- Zhang, S.; Sulankivi, K.; Kiviniemi, M.; Romo, I.; Eastman, C.M.; Teizer, J. BIM-based fall hazard identification and prevention in construction safety planning. Saf. Sci. 2015, 72, 31–45. [Google Scholar] [CrossRef]

- Isatto, E.L.; An, I.F.C. Representation for Process-Based Cost Modeling. In Proceedings of the 18th International Conference on Computing in Civil and Building Engineering, São Paulo, Brazil, 18–20 August 2020; Springer International Publishing: Cham, Switzerland, 2021; pp. 519–528. [Google Scholar]

- Ding, L.; Li, K.; Zhou, Y.; Love, P.E.D. An IFC-inspection process model for infrastructure projects: Enabling real-time quality monitoring and control. Autom. Constr. 2017, 84, 96–110. [Google Scholar] [CrossRef]

- Zhang, S.; Teizer, J.; Lee, J.K.; Eastman, C.M.; Venugopal, M. Building Information Modeling (BIM) and Safety: Automatic Safety Checking of Construction Models and Schedules. Autom. Constr. 2013, 29, 183–195. [Google Scholar] [CrossRef]

- Park, J.; Kim, K.; Cho, Y.K. Framework of Automated Construction-Safety Monitoring Using Cloud-Enabled BIM and BLE Mobile Tracking Sensors. J. Constr. Eng. Manag. 2017, 143, 05016019. [Google Scholar] [CrossRef]

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. Available online: https://bitcoin.org/bitcoin.pdf (accessed on 30 June 2025).

- Manolache, M.A.; Manolache, S.; Tapus, N. Decision Making using the Blockchain Proof of Authority Consensus. In Procedia Computer Science; Elsevier: Amsterdam, The Netherlands, 2021; pp. 580–588. [Google Scholar]

- García-Bañuelos, L.; Ponomarev, A.; Dumas, M.; Weber, I. Optimized Execution of Business Processes on Blockchain. arXiv 2016, arXiv:1612.03152. [Google Scholar] [CrossRef]

- Tran, A.B.; Lu, Q.; Weber, I. Lorikeet: A Model-Driven Engineering Tool for Blockchain-Based Business Process Execution and Asset Management. Available online: https://github.com/bpmn-io/bpmn-js (accessed on 30 June 2025).

- Weber, I.; Xu, X.; Riveret, R.; Governatori, G.; Ponomarev, A.; Mendling, J. Untrusted Business Process Monitoring and Execution Using Blockchain. In Proceedings of the Business Process Management: 14th International Conference, BPM 2016, Rio de Janeiro, Brazil, 18–22 September 2016; pp. 329–347. [Google Scholar]

- Ladleif, J.; Weske, M.; Weber, I. Modeling and Enforcing Blockchain-Based Choreographies. In Proceedings of the Business Process Management: 17th International Conference, BPM 2019, Vienna, Austria, 1–6 September 2019; pp. 69–85. [Google Scholar]

- Osterland, T.; Rose, T.; Putschli, C. On the Implementation of Business Process Logic in DLT Nodes. In Proceedings of the 2020 Asia Service Sciences and Software Engineering Conference, Nagoya, Japan, 13–15 May 2020; pp. 91–99. [Google Scholar]

- Accelerate Blockchain Technology Adoption with Bonita BPM and Chain Core! YouTube. Available online: https://www.youtube.com/watch?v=GPBiaKjLswc (accessed on 30 June 2025).

- Di Ciccio, C.; Cecconi, A.; Dumas, M.; García-Bañuelos, L.; López-Pintado, O.; Lu, Q.; Mendling, J.; Ponomarev, A.; Binh Tran, A.; Weber, I. Blockchain Support for Collaborative Business Processes. Inform. Spektrum 2019, 42, 182–190. [Google Scholar] [CrossRef]

- Spalazzi, L.; Spegni, F.; Corneli, A.; Naticchia, B. Blockchain based choreographies: The construction industry case study. Concurr. Comput. 2023, 35, e6740. [Google Scholar] [CrossRef]

- Ye, X.; Tao, X.; Cheng, J.C.P.; König, M. Blockchain-BPMN Integrated Framework for Construction Management. In Proceedings of the 23rd International Conference on Construction Applications of Virtual Reality; Firenze University Press: Firenze, Italy, 2023; pp. 309–317. [Google Scholar]

- Doan, T.V.; Psaras, Y.; Ott, J.; Bajpai, V. Towards Decentralised Cloud Storage with IPFS: Opportunities, Challenges, and Future Directions. 13 February 2022. Available online: http://arxiv.org/abs/2202.06315 (accessed on 30 June 2025).

- Adel, K.; Elhakeem, A.; Marzouk, M. Decentralized system for construction projects data management using blockchain and IPFS. J. Civil Eng. Manag. 2023, 29, 342–359. [Google Scholar] [CrossRef]

- Spegni, F.; Fratini, L.; Pirani, M.; Spalazzi, L. ChoEn: A Smart Contract Based Choreography Enforcer. In Proceedings of the 2023 IEEE International Conference on Pervasive Computing and Communications Workshops and Other Affiliated Events (PerCom Workshops), Atlanta, GA, USA, 13–17 March 2023; pp. 86–91. [Google Scholar]

- Corneli, A.; Spegni, F.; Bragadin, M.A.; Vaccarini, M. A Smart Contract-based BPMN Choreography Execution for Management of Construction Processes. In Proceedings of the 38th International Symposium on Automation and Robotics in Construction, Dubai, United Arab Emirates, 2–4 November 2021. [Google Scholar]

- Messi, L.; Spegni, F.; Vaccarini, M.; Corneli, A.; Binni, L. Seamless Indoor/Outdoor Marker-Less Augmented Reality Registration Supporting Facility Management Operations. In Proceedings of the 23rd International Conference on Construction Applications of Virtual Reality, Florence, Italy, 13–16 November 2023; pp. 109–120. [Google Scholar]

- Sarlin, P.E.; Cadena, C.; Siegwart, R.; Dymczyk, M. From Coarse to Fine: Robust Hierarchical Localization at Large Scale. 9 December 2018. Available online: http://arxiv.org/abs/1812.03506 (accessed on 30 June 2025).

- Sarlin, P.E.; Debraine, F.; Dymczyk, M.; Siegwart, R.; Cadena, C. Leveraging Deep Visual Descriptors for Hierarchical Efficient Localization. 4 September 2018. Available online: http://arxiv.org/abs/1809.01019 (accessed on 30 June 2025).

- Semeraro, G. Il Cantiere Sicuro. Available online: https://www.epc.it/contenuti/9788892881693_sito.pdf?srsltid=AfmBOooD0LbOa4TXWaSa_htXdKAQ7K32ARLzFqn2anq_EG3CznDe5yA_ (accessed on 30 June 2025).

- Wu, C.; Li, X.; Guo, Y.; Wang, J.; Ren, Z.; Wang, M.; Yang, Z. Natural language processing for smart construction: Current status and future directions. Autom. Constr. 2022, 134, 104059. [Google Scholar] [CrossRef]

- Ding, Y.; Ma, J.; Luo, X. Applications of natural language processing in construction. Autom. Constr. 2022, 136, 104169. [Google Scholar] [CrossRef]

- Locatelli, M.; Seghezzi, E.; Pellegrini, L.; Tagliabue, L.C.; Di Giuda, G.M. Exploring natural language processing in construction and integration with building information modeling: A scientometric analysis. Buildings 2021, 11, 583. [Google Scholar] [CrossRef]

- Shamshiri, A.; Ryu, K.R.; Park, J.Y. Text mining and natural language processing in construction. Autom. Constr. 2024, 158, 105200. [Google Scholar] [CrossRef]

- Zhang, J.; El-Gohary, N.M. Semantic NLP-Based Information Extraction from Construction Regulatory Documents for Automated Compliance Checking. J. Comput. Civil Eng. 2016, 30, 04015014. [Google Scholar] [CrossRef]

- Kneip, L.; Scaramuzza, D.; Siegwart, R. A novel parametrization of the perspective-three-point problem for a direct computation of absolute camera position and orientation. In Proceedings of the CVPR 2011, Colorado Springs, CO, USA, 20–25 June 2011; pp. 2969–2976. [Google Scholar]

- Messi, L.; Spegni, F.; Ridolfi, L. Process-based simulation models using BPMN for construction management at runtime. In Proceedings of the Conference CIB W, Luxembourg, 11–15 October 2021. [Google Scholar]

- Ghazali, M.; Budi Nugroho, D.; Latief, Y. Analyzing the Effect of the Construction Safety Audit Model Using the Business Process Model and Notation (BPMN) Method on Improving Communication and Collaboration Between Stakeholders. CSID J. Infrastruct. Dev. 2024, 7, 323–336. [Google Scholar] [CrossRef]

- Corneli, A.; Naticchia, B.; Spegni, F.; Spalazzi, L. Combining Blockchain and BPMN Choreographies for Construction Management. In Proceedings of the 2021 European Conference on Computing in Construction, Online, 26–28 July 2021; Volume 2. pp. 34–41. Available online: https://scispace.com/pdf/combining-blockchain-and-bpmn-coreographies-for-construction-262jr1q2k8.pdf (accessed on 30 May 2025).

- Cocco, L.; Tonelli, R.; Marchesi, M. A System Proposal for Information Management in Building Sector Based on BIM, SSI, IoT and Blockchain. Future Internet 2022, 14, 140. [Google Scholar] [CrossRef]

- Sarlin, P.E.; Dusmanu, M.; Schönberger, J.L.; Speciale, P.; Gruber, L.; Larsson, V.; Miksik, O.; Pollefeys, M. LaMAR: Benchmarking Localization and Mapping for Augmented Reality. 19 October 2022. Available online: http://arxiv.org/abs/2210.10770 (accessed on 30 May 2025).

- Zhao, T.; Kazemi, S.E.; Liu, W.; Zhang, M. The Last Mile: Safety Management Implementation in Construction Sites. Adv. Civil Eng. 2018, 2018, 4901707. [Google Scholar] [CrossRef]

- Augmented Reality, seamless indoor and outdoor localization and Blockchain for safety inspection support in construction sites. In Proceedings of the 24th International Conference on Construction Applications of Virtual Reality (CONVR 2024), Sydney, Australia, 4–6 November 2024.

- BuildingSmart. IFC Specifications Database. Available online: https://technical.buildingsmart.org/standards/ifc/ifc-schema-specifications/ (accessed on 27 April 2025).

| Scenario | Calibration | Parameters | Mapping | Type of Assessment |

|---|---|---|---|---|

| DC3_1 | Exif-based calibration | 300/150 KPTS + 640 PX | 10 images | Recall @ (10 cm, 1°) |

| Recall @ (5 cm, 0.5°) | ||||

| DC3_2 | 300/150 KPTS + 640 PX | 20 images | Recall @ (10 cm, 1°) | |

| Recall @ (5 cm, 0.5°) | ||||

| DC3_3 | 5000/5000 KPTS + 1600 PX | 10 images | Recall @ (10 cm, 1°) | |

| Recall @ (5 cm, 0.5°) | ||||

| DC3_4 | 5000/5000 KPTS + 1600 PX | 20 images | Recall @ (10 cm, 1°) | |

| Recall @ (5 cm, 0.5°) | ||||

| DC3_5 | High-resolution calibration | 300/150 KPTS + 640 PX | 10 images | Recall @ (10 cm, 1°) |

| Recall @ (5 cm, 0.5°) | ||||

| DC3_6 | 300/150 KPTS + 640 PX | 20 images | Recall @ (10 cm, 1°) | |

| Recall @ (5 cm, 0.5°) |

| Factor | Item | Relevant | Not Relevant | Benefits over Traditional Systems (If Any) |

|---|---|---|---|---|

| Human factor | Safety attitude of workers | X | N. A. | |

| Safety behavior of workers | X | N. A. | ||

| Safety training received by workers | X | N. A. | ||

| Experience and skills of workers | X | N. A. | ||

| Education level of workers | X | N. A. | ||

| Safety experience and skills of contractors and supervisors | X | The inspection process is agreed upon at the design phase and includes the experience of designers, too. The results of a survey are collected in the platform, and additional assessments are possible anytime. | ||

| Safety attitude of contractors and supervisors | X | The notarization of the results of safety surveys through smart contracts increases the level of awareness and commitment of contractors and supervisors. | ||

| Safety education and knowledge of contractors and supervisors | X | Safety measures are modeled through BIM and stored in IFC models. Thus, safety inspections do not rely on the knowledge of supervisors and contractors only. | ||

| Effective communication and cooperation | X | Information is first transmitted from the WeBIM platform to the site, and then inspection data is retrieved from the site and provided to all the members of the team having access to WeBIM. | ||

| Quantity of workers at construction sites | X | N. A. | ||

| Mobility of workers at construction sites | X | N. A. | ||

| Equipment factor | Personal protective equipment | X | N. A. | |

| Proper installation and dismantling of plants and equipment | X | Spatial registration allows supervisors to display and compare the actual installation with the expected installation of equipment. | ||

| Maintenance regime for all equipment and plants | X | Mandatory maintenance actions can be included within textual parameters included in the IFC models of the digital H&S plan. | ||

| Reasonable choice of work equipment | X | N. A. | ||

| Environmental factor | Complexity of geology and hydrology | X | N. A. | |

| Frequency of adverse weather | X | N. A. | ||

| Schedule and cost pressures | X | N. A. | ||

| Complexity of surrounding environment | X | Alignment algorithms guide supervisors even in complex environments. Unexpected scenarios can be reported in the pictures collected during a survey. | ||

| Management factor | Health and safety file | X | N. A. | |

| Safety meeting | X | N. A. | ||

| Safety management commitment | X | Inspections guided throughout the areas to be verified by means of real-time, on-site control and a predetermined protocol. | ||

| Safety regulation and plan enforcement | X | N. A. | ||

| Safety incentive and punishment | X | N. A. | ||

| Safety inspection and guidance | X | The information stored in IFC models includes input for safety inspections, and AR/MR tools display safety requirements even on-site. | ||

| Allocation of safety responsibility | X | The integrated notarization tools certify the completion of inspections. | ||

| Technical factor | Safety risk identification and analysis | X | The digital health and safety plan streamlines inspection procedures, which are embedded in textual parameters of the respective IFC models. | |

| First aid and emergency preparedness | X | N. A. | ||

| Complexity, type, and technique of construction | X | N. A. |

| Test Network | Stage | Time (s) | |||

|---|---|---|---|---|---|

| Avg. | Min. | Max. | Std. Dev. | ||

| Sepolia | Compilation | 31.96 | 12.13 | 128.95 | 28.82 |

| Execution | 26.35 | 13.19 | 95.24 | 22.64 | |

| Holesky | Compilation | 28.85 | 16.33 | 70.80 | 16.22 |

| Execution | 20.66 | 6.31 | 105.65 | 16.47 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Corneli, A.; Carbonari, A.; Spegni, F.; Pieroni, T.; Naticchia, B. On-Site Safety Inspections Through Marker-Less Augmented Reality and Blockchain Notarization of BIM-Based Processes. Buildings 2025, 15, 2318. https://doi.org/10.3390/buildings15132318

Corneli A, Carbonari A, Spegni F, Pieroni T, Naticchia B. On-Site Safety Inspections Through Marker-Less Augmented Reality and Blockchain Notarization of BIM-Based Processes. Buildings. 2025; 15(13):2318. https://doi.org/10.3390/buildings15132318

Chicago/Turabian StyleCorneli, Alessandra, Alessandro Carbonari, Francesco Spegni, Tommaso Pieroni, and Berardo Naticchia. 2025. "On-Site Safety Inspections Through Marker-Less Augmented Reality and Blockchain Notarization of BIM-Based Processes" Buildings 15, no. 13: 2318. https://doi.org/10.3390/buildings15132318

APA StyleCorneli, A., Carbonari, A., Spegni, F., Pieroni, T., & Naticchia, B. (2025). On-Site Safety Inspections Through Marker-Less Augmented Reality and Blockchain Notarization of BIM-Based Processes. Buildings, 15(13), 2318. https://doi.org/10.3390/buildings15132318