Advancements in Timber–Steel Hybridisation: A Review on Techniques, Applications, and Structural Performances

Abstract

1. Introduction

2. Adhesive Technologies

2.1. General

2.2. Major Types of Adhesives Used in Timber–Steel Hybridisation

2.2.1. Epoxy Resin

2.2.2. Polyurethane (PUR)

2.3. Surface Treatment for Optimal Adhesion

2.3.1. Steel Surface Treatment

- Mechanical abrasion through brushing is another effective method for roughening the surface of steel prior to bonding [70,71]. This process entails, for instance, using carbide steel brushes attached to power machines to mechanically abrade the steel surface, enhancing its roughness and facilitating better adhesion [18].

- Shot blasting, or grit blasting, represents a more aggressive approach to surface treatment, involving the propulsion of small abrasive particles at high velocity onto the steel surface [4]. This method effectively removes rust and contaminants, leaving behind a highly roughened texture conducive to improve adhesion. Shot blasting is particularly advantageous for steel surfaces that require thorough cleaning and preparation prior to bonding. Fernando [72], citing sources [73,74], has highlighted the superiority of shot blasting among other mechanical abrasion methods.

2.3.2. Timber Surface Treatment

2.4. Structural Performance of Adhesive Bonds in Timber–Steel Hybrid Connections

2.5. Concluding Remarks

- Adhesive selection: Both epoxy and PUR adhesives show strong adhesion between steel and timber. PUR adhesives have been noted for their ductility and usually superior performance in overall strength when gluing timber to steel. However, due to its versatility, epoxy has some manufacturing advantages and still provides good bonds between the two materials. Notably, both adhesive bonds typically fail within the timber rather than at the glue line, showcasing their effectiveness at creating strong composite action between different materials.

- Surface preparation: The optimal surface treatment method depends on the material and application. Shot blasting has been shown to be particularly effective for steel, as it thoroughly cleans and roughens surfaces, significantly enhancing adhesion. While laser and plasma treatments also offer substantial improvements, shot blasting was found in the literature to be a more aggressive abrasion method with better results. For timber, mechanical abrasion with or without chemical treatments, such as priming, would enhance adhesion by improving the surface texture and chemistry. The choice of treatment should be tailored to the specific needs and bonding requirements of the materials involved.

- Adhesive application: For polyurethane (PUR), a thinner glue line of approximately 0.5 mm was found to be more effective, whereas for epoxy, a slightly thicker line of around 1 mm was reported to enhance performance.

- Disassembly and end-of-life reuse: While adhesive bonding offers several advantages, it can hinder disassembly during construction, maintenance, or future modifications, as bonded joints are much more difficult to separate than mechanical fasteners. This also presents challenges at the end-of-life stage of a building, where recycling or repurposing hybrid structural products bonded with adhesive may be limited compared to mechanically fastened components, which are generally easier to remove and reuse.

3. Mechanical Fasteners

3.1. General

3.2. Major Types of Mechanical Fasteners Used in Timber–Steel Hybridisation

3.3. Structural Performances of Mechanical Fasteners in Timber–Steel Hybrid Components

3.4. Concluding Remarks

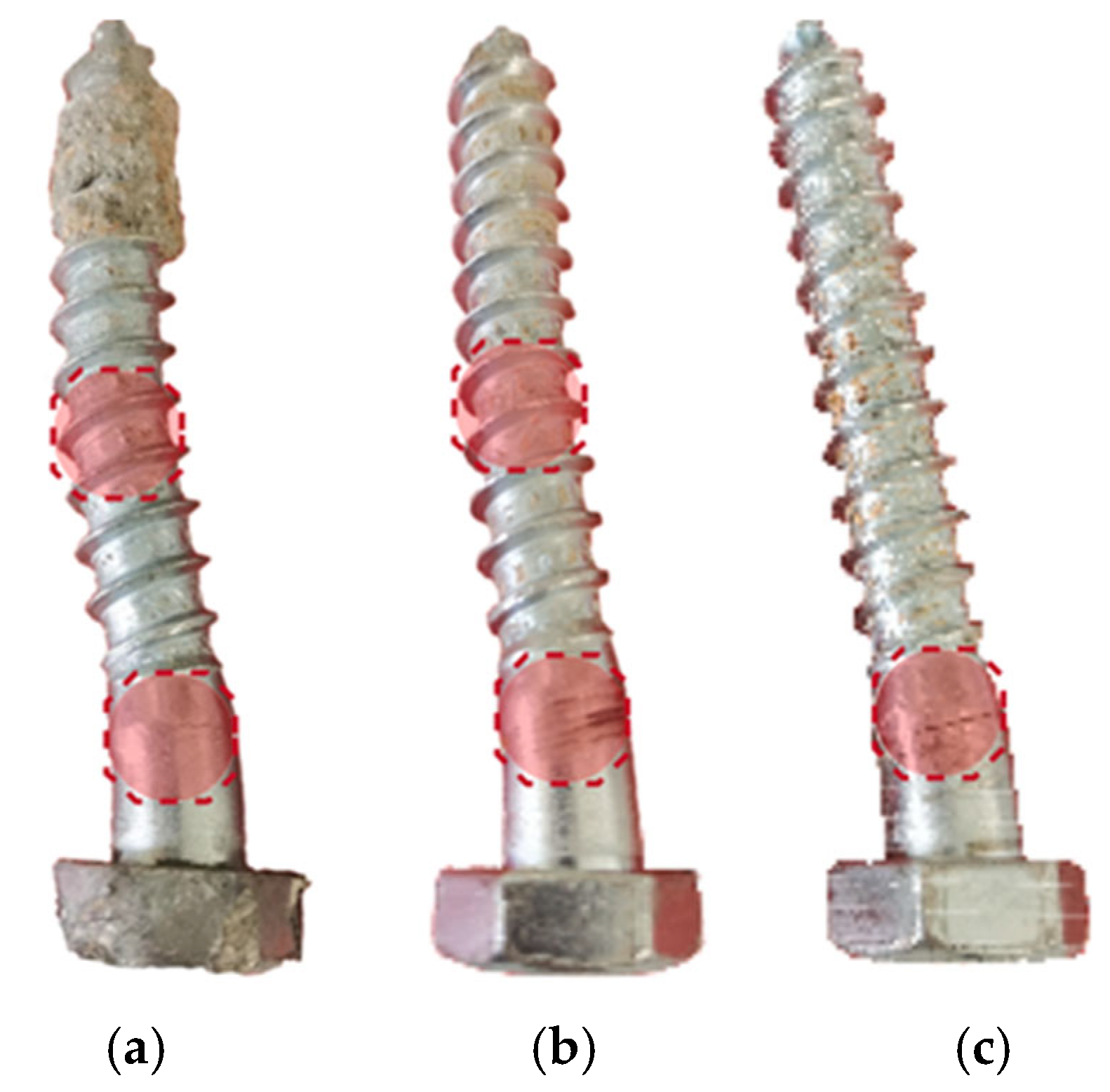

- Improved performance with inclined screws: Research indicates that screws inclined at angles from 30° to 60° offer enhancements in the shear capacity and stiffness compared to screws inserted at 90°. The use of tapered washers with inclined screws further boosts these benefits.

- Advantages of longer screws: Utilising longer screws increases the embedded depth in the timber, which enhances the withdrawal capacity of the screws and potentially the timber–steel hybrid connections, depending on the failure mode. Additionally, selecting screws with sufficiently long, smooth shanks is important. This design feature ensures that the transition from the smooth shank to the threaded shank occurs away from the shear plane.

- Enhanced performance through anchorage techniques: Integrating anchorage methods, such as using mortar or adhesive to secure screw tips, has been shown to enhance the overall performance of timber–steel hybrid connections. These techniques contribute to improved connection stiffness, peak load capacity, and ductility.

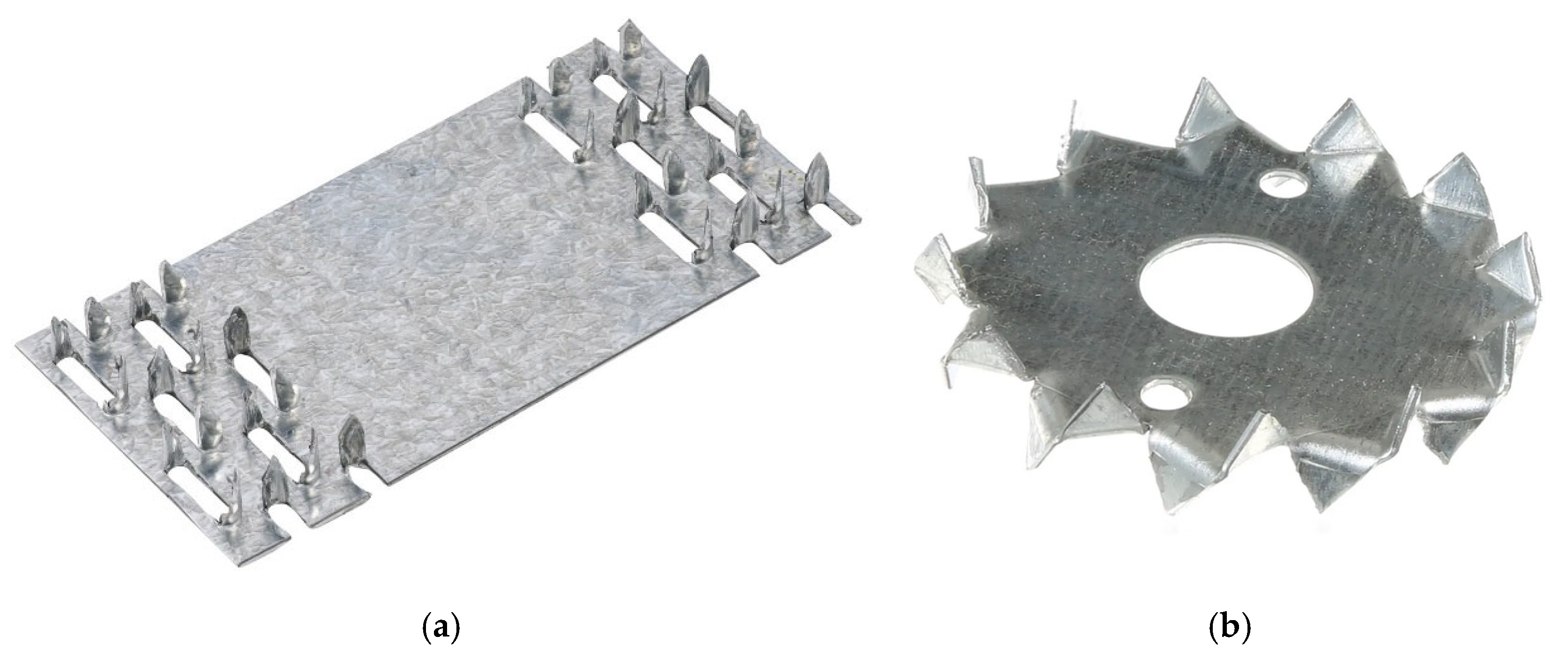

- Utilisation of metal plates: Metal plates, including nail plates and toothed plates, can potentially enhance the connection performance in timber–steel hybrid structures. Nail plates, with their embedded nails or spikes, are effective at increasing both the load-carrying capacity and stiffness, though they may reduce ductility. Conversely, toothed plates, featuring teeth designed to interlock with timber, have shown potential for improving the load-carrying capacity, though their impact on stiffness is less certain based on the current research.

4. Timber–Steel Hybrid Configurations for Composite Beams

4.1. General

4.2. Comments on the Fire Performance and Thermal Insulation

4.3. Structural Performances and Other Advantages of Various Timber–Steel Hybrid Configurations

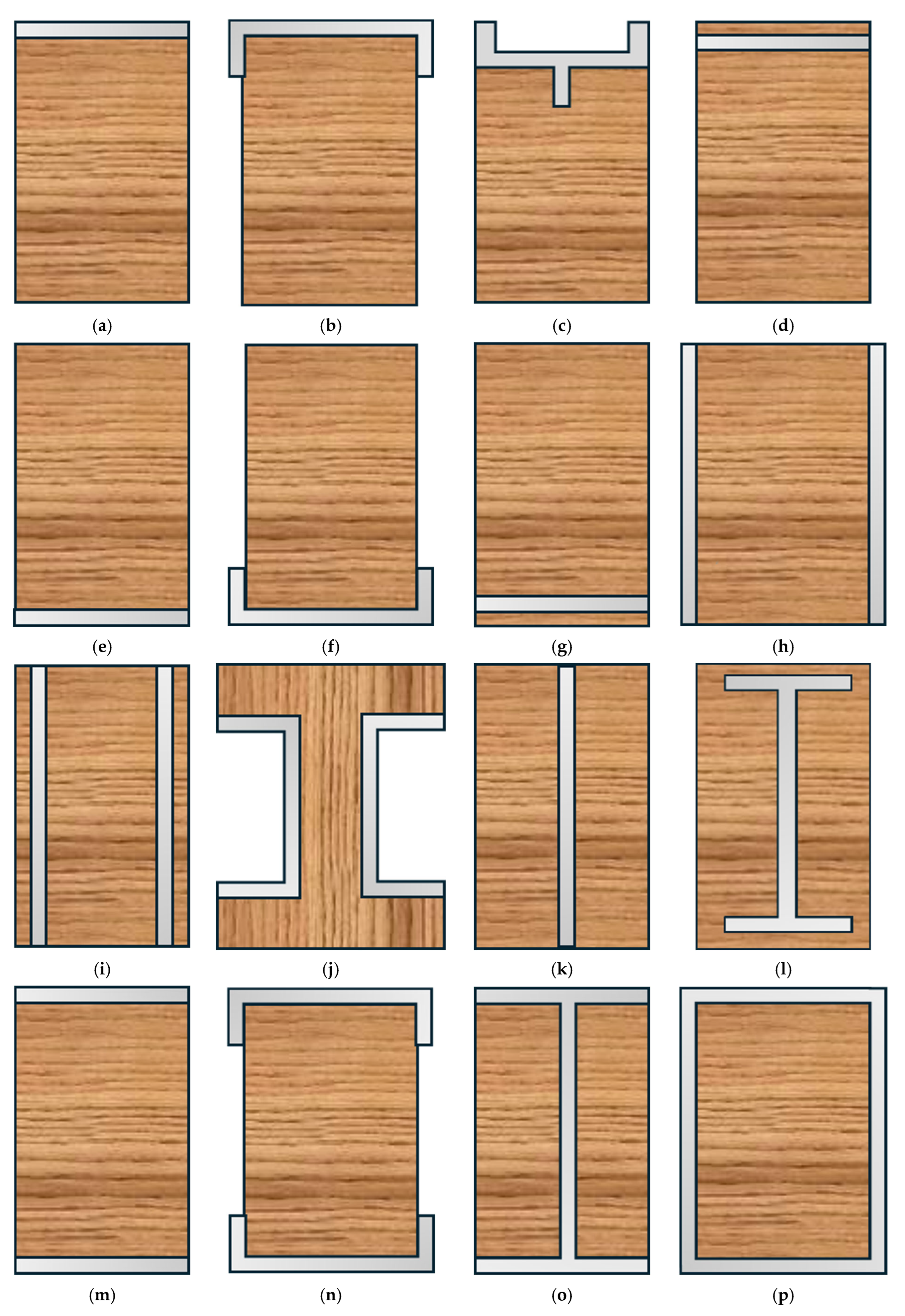

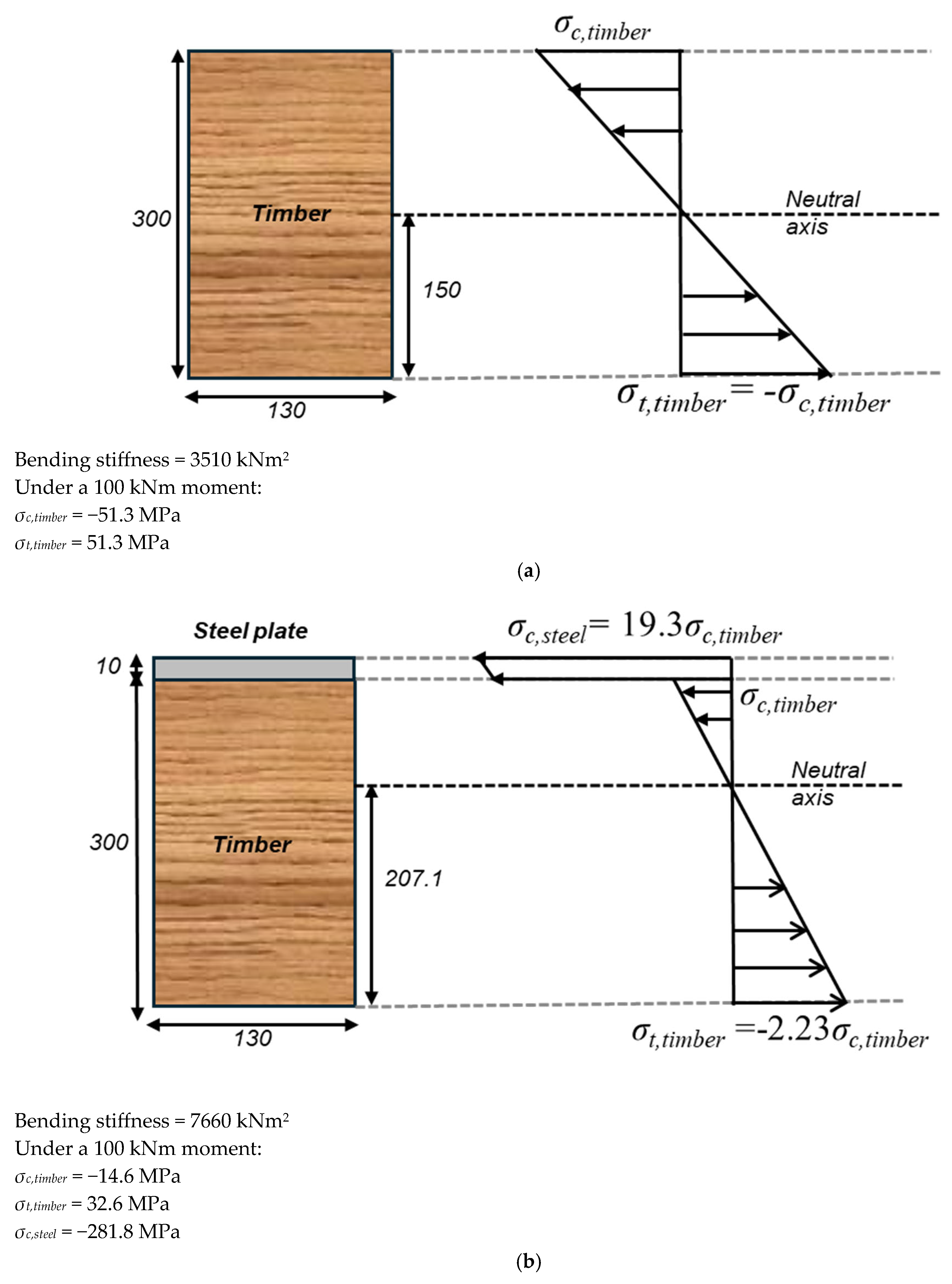

4.3.1. Top Reinforcement (Compressive Zone)

4.3.2. Bottom Reinforcement (Tension Zone)

4.3.3. Side Reinforcement

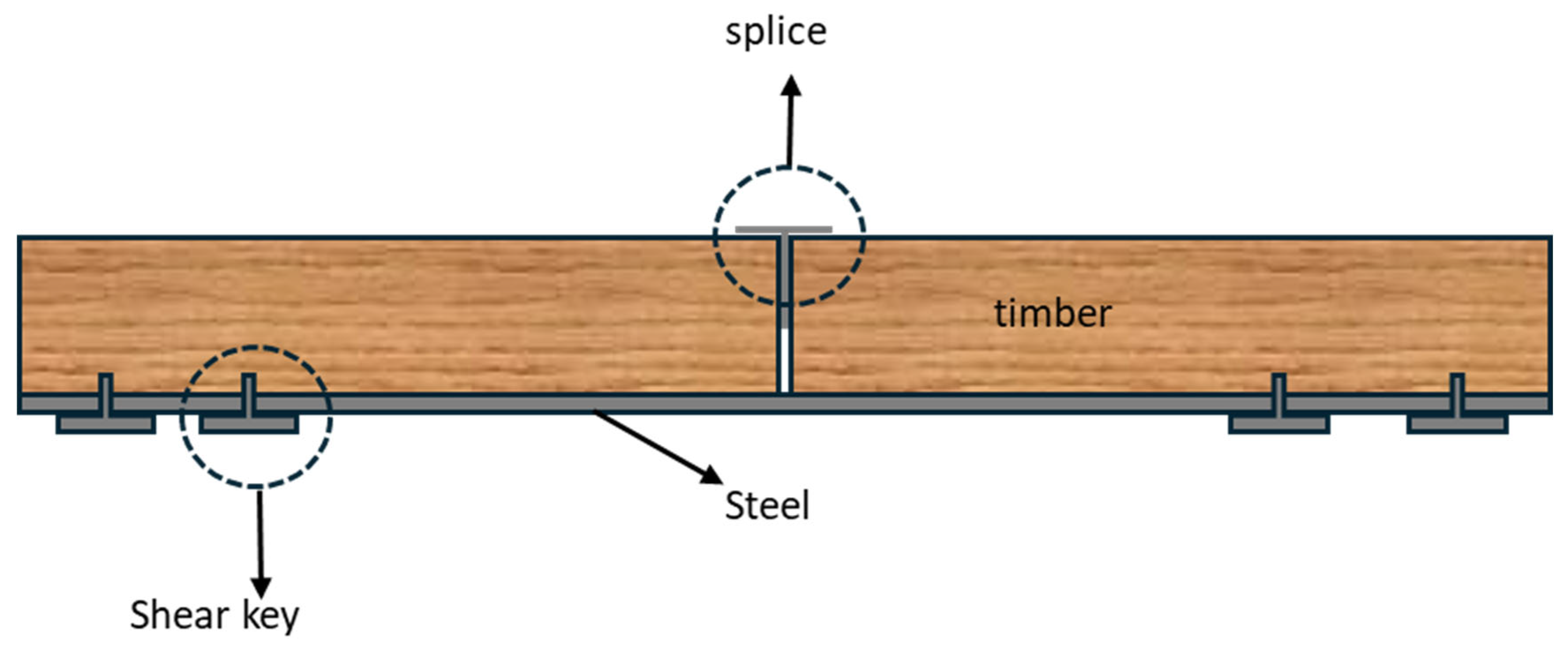

4.3.4. Embedded Reinforcement

4.3.5. Combined Reinforcement

| References/ Study Title | Authors | Hybridisation Configuration | Testing and Analysis Methodology | Materials Used | Surface Treatment | Results |

|---|---|---|---|---|---|---|

| [34] Solid timber beams strengthened with steel plates—Experimental studies | Jasieńko J, Nowak TP | Timber beams reinforced with steel plates in various configurations, including on the top, bottom, sides, and embedded within | Bending tests | Sawn timber (softwood), steel plates, epoxy adhesive | Steel plates were sandblasted and degreased. | Embedding two steel plates into the beam on the sides provided the best performance, with up to 100% increase in strength and up to 51% increase in stiffness compared to unreinforced beam. For surface reinforcement, top reinforcement was found to limit delamination. |

| [146] Experimental investigation on the flexural and shear behaviour of LVL I-beam strengthened with steel channels | Wang X, Zhang J, Wu P, Li Y | I-shaped LVL beam strengthened with cold-formed, thin-walled steel channels | Bending tests, shear tests | LVL, cold-formed steel channel, and structural adhesive (unspecified) | Stains and galvanised layer on the bonding surface of the steel were removed and polished with alcohol. | For shear and bending tests, the peak loads for specimens with the largest steel sections, were 1.45 times and 2.9 times higher, respectively, than those with thinner steel sections. |

| [8] Long—Term testing of timber-steel bar hybrid beams | Kiyoto S, Shioya S | GLT timber reinforced with deformed steel rebar and epoxy resin adhesive at both the top and bottom | Long-term bending creep test | Japanese cedar, deformed steel bar (rebar), epoxy resin adhesive | Unspecified | The hybrid beam had an increase in bending creep stiffness and strength by 3–4 times compared to the timber beam alone. |

| [30] Bending reinforcement of wooden beams with steel cross-sections | González-Bravo C, Arriaga-Martitegui F, Díez-Barra R. | U-shaped steel cross sections connected to timber from upper side | Bending tests | GLT, sawn timber, old solid timber beams, and U-shaped steel plates | Unspecified | Reinforced beams showed increased bending stiffness (by 45–98%) and strength capacity (by 27–58%). |

| [131] On the delamination phenomenon in the repair of timber beams with steel plates | Metelli G, Preti M, Giuriani E | Reinforcement of ancient wooden floors with steel plates into a groove | Experimental analysis using Moiré interferometry for stress observation and long-term deflection monitoring over 14 years | Steel plates, epoxy resin, high-strength steel nails | Timber grooves were cleaned and brushed while the steel plates were sandblasted. | Steel reinforcement effectively repaired the beam with deflection increases similar to those of undamaged beams. Delamination occurred at 1.64 times the service load, and deflection rose by 7 mm over 14 years (0.5 mm/year). |

| [5] Timber-steel hybrid beams for multi-storey buildings: Final report | Winter W, Tavoussi K, Parada FR, Bradley A | I-beam, grade S355, cold-formed or hot-rolled steel, embedded in GLT beams | Bending test | GLT bolted with I-shaped steel | Unspecified | Hybrid beams showed minimal buckling in the steel web and flange. Hot-rolled profiles, while 3% stiffer than cold-formed ones, presented some assembly challenges. |

| [6] Experimental and analytical study of hybrid steel-timber beams in bending | Jurkiewiez B, Durif S, Bouchair A, Grazide C | Steel I-beam connected to ungraded timber beams with knots and defects, fastened using bolts or screws on the sides of the web | Bending test and numerical modelling | Steel beams, ungraded wood beams, bolts, screws | Unspecified | Wood elements provided lateral support to the steel profile, reducing the local instability and lateral torsional buckling, resulting in an over 80% increase in strength for the studied configurations. |

| [114] Experimental and finite element analysis of flexural performance of steel-timber composite beams connected by hybrid-anchored screws | Zhao Y, Yuan Y, Wang CL, Meng S | Steel timber composite beams connected by hybrid-anchored screws with different filling materials | Experimental testing, finite element simulation | Hybrid-anchored screws, epoxy resin, mortar | Unspecified | Hybrid-anchored screws effectively improve flexural performance of steel timber composite beams. Mortar increased slip stiffness by 48.4% and capacity by 15.1%. Epoxy improved stiffness by 18.8% and capacity by 10.1%. |

| [103] Experimental investigation on in-plane stiffness and strength of innovative steel-timber hybrid floor diaphragms | Loss C, Frangi A | Steel placed in hybrid floor diaphragms with CLT panels | Monotonic and cyclic shear tests | Steel, timber, bolts, screws | Unspecified | Shear stiffness increased by up to 56%. Residual displacement was reduced from 9.4 mm to 2.0 mm. |

4.4. Concluding Remarks

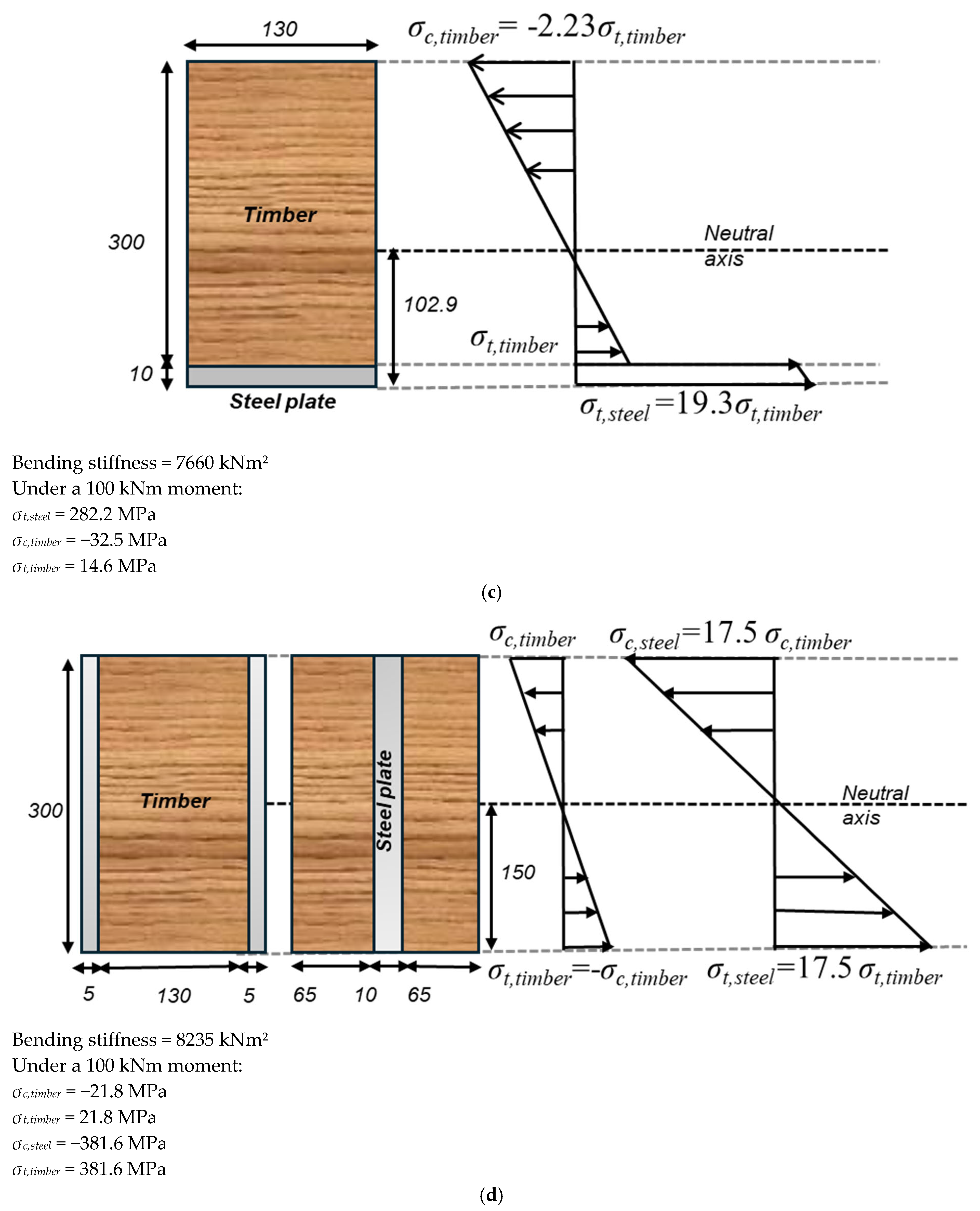

- Top reinforcement (compressive zone): This configuration increases the load bearing under concentrated load, bending capacity, and bending stiffness. It is also a better option for fire resistance. This configuration is particularly suitable for heritage buildings where aesthetics must be preserved. While it primarily reinforces the ductile compression zone of the beam material, it fails to utilise the strength and ductility of the steel to strengthen the brittle tension zone of the timber. Additionally, this reinforcement shifts the neutral axis toward the compression side, increasing the tensile stress in the timber at the bottom of the beam relative to the compressive stress, and the ductility of the composite beam may be limited. The existing work indicates performance improvements with the configuration, especially with U-shaped steel cross sections.

- Bottom reinforcement (tension zone): This configuration enhances the structural performance by directly addressing the brittle nature of the timber material in tension. By shifting the neutral axis toward the tension side, it reduces the tensile stress in the timber relative to the compressive stress and delays brittle failure. This also has the potential to improve the ductility if the beam is designed for the steel to yield. The use of bottom reinforcement has been shown to increase bending stiffness and strength. However, considerations regarding the exposure of steel to heat generated by fire remain essential. While intumescent coatings offer effective protection, designers must remain vigilant about the implications of this reinforcement approach on the overall structural integrity and aesthetics, especially in heritage applications.

- Side reinforcement: The incorporation of vertical steel plates for rectangular beams enhances the structural performance by improving the lateral stability and shear capacity. This configuration balances the stress profile across the beam. However, side reinforcement is not the most efficient way of using steel for increasing the bending stiffness and capacity, as the placement of steel near the neutral axis does not fully optimise the material location.

- Embedded reinforcement: This approach enhances the fire protection and overall performance by integrating steel components within the timber beam. The insulating properties of timber shield the embedded steel from heat, helping to maintain the structural integrity during fire exposure. While this method preserves the aesthetic appeal of structures—particularly of heritage buildings—it also adds complexity to the manufacturing process.

- Combined reinforcement: This approach incorporates two or more reinforcement methods (top, bottom, side, or embedded) to enhance the structural performance of timber beams. By optimising the stresses across the beam, these configurations combine the advantages of the other methods. Therefore, reinforcing all sides may represent the most structurally effective option, offering maximum strength, stiffness, and ductility. However, this approach is often less favourable when considering costs, sustainability, and fire due to the extensive use of steel, aesthetic considerations, and exposed steel, respectively.

5. Overall Conclusions

6. Future Studies

Funding

Acknowledgments

Conflicts of Interest

References

- Hindman, D.P.; Bouldin, J.C. Mechanical Properties of Southern Pine Cross-Laminated Timber. J. Mater. Civ. Eng. 2015, 27, 04014251. [Google Scholar] [CrossRef]

- Roos, A.; Woxblom, L.; Mccluskey, D. The influence of architects and structural engineers on timber in construction—Perceptions and roles. Silva Fenn. 2010, 44, 871–884. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ferracuti, B.; Lombardi, L.; Guattari, C.; Evangelisti, L.; Grazieschi, G. A review of structural, thermo-physical, acoustical, and environmental properties of wooden materials for building applications. Build. Environ. 2017, 114, 307–332. [Google Scholar] [CrossRef]

- Parvez, A. The Reinforcement of Timber for Structural Applications and Repair; University of Bath: Bath, UK, 2004. [Google Scholar]

- Winter, W.; Tavoussi, K.; Parada, F.R.; Bradley, A. Timber-Steel Hybrid Beams for Multi-Storey Buildings: Final Report; University of A Coruña: A Coruña, Spain, 2016. [Google Scholar]

- Jurkiewiez, B.; Durif, S.; Bouchair, A.; Grazide, C. Experimental and analytical study of hybrid steel-timber beams in bending. Structures 2022, 39, 1231–1248. [Google Scholar] [CrossRef]

- Alam, P.; Ansell, M.; Smedley, D. Effects of reinforcement geometry on strength and stiffness in adhesively bonded steel-timber flexural beams. Buildings 2012, 2, 231–244. [Google Scholar] [CrossRef]

- Kiyoto, S.; Shioya, S. Long-Term testing of timber-steel bar hybrid beams. In Proceedings of the WCTE 2018—World Conference on Timber Engineering, Seoul, Republic of Korea, 20–23 August 2018. [Google Scholar]

- Ataei, A.; Valipour, H.R.; Bradford, M.A.; Chiniforush, A.A. Experimental study of steel-timber composite beam-to-column joints with extended end plates. Constr. Build. Mater. 2019, 226, 636–650. [Google Scholar] [CrossRef]

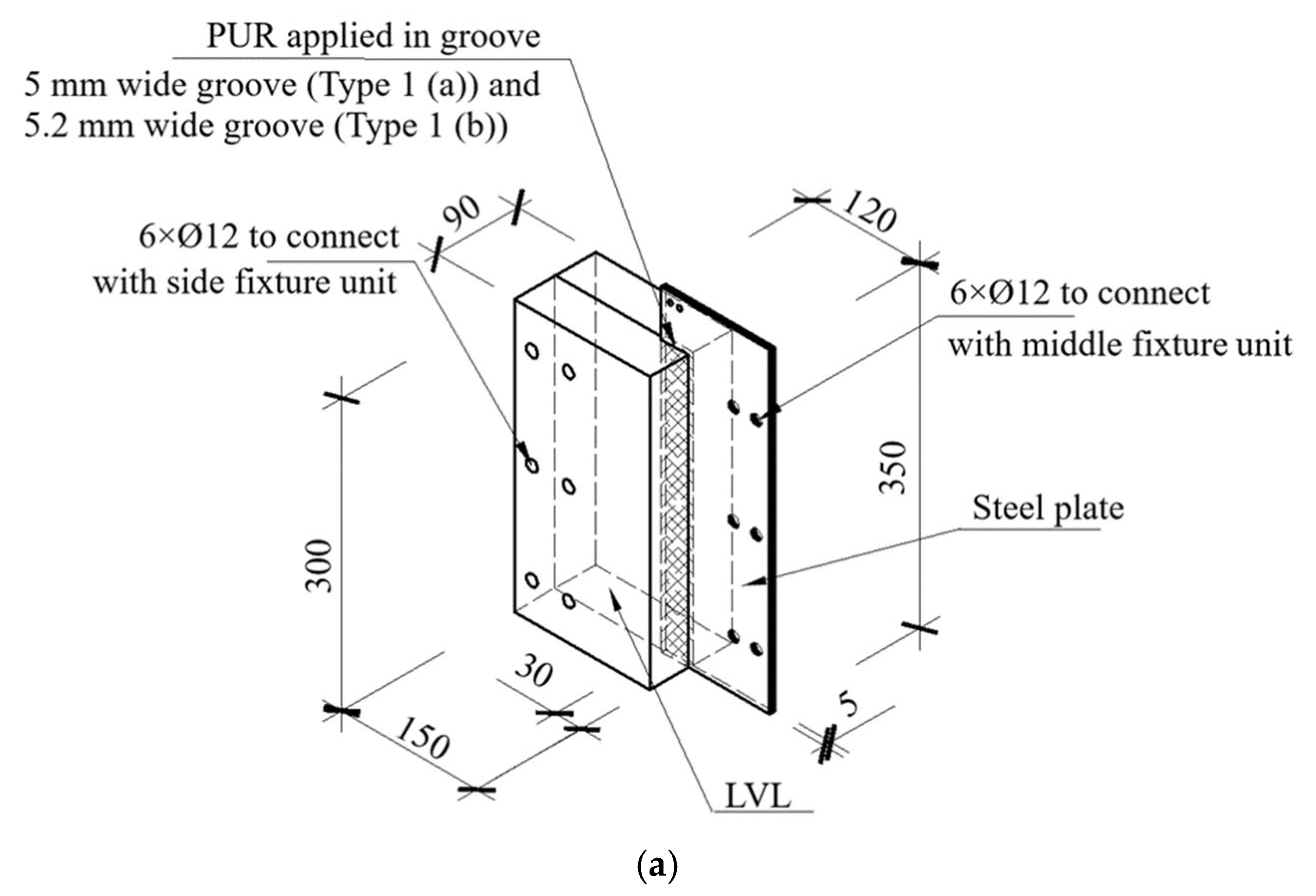

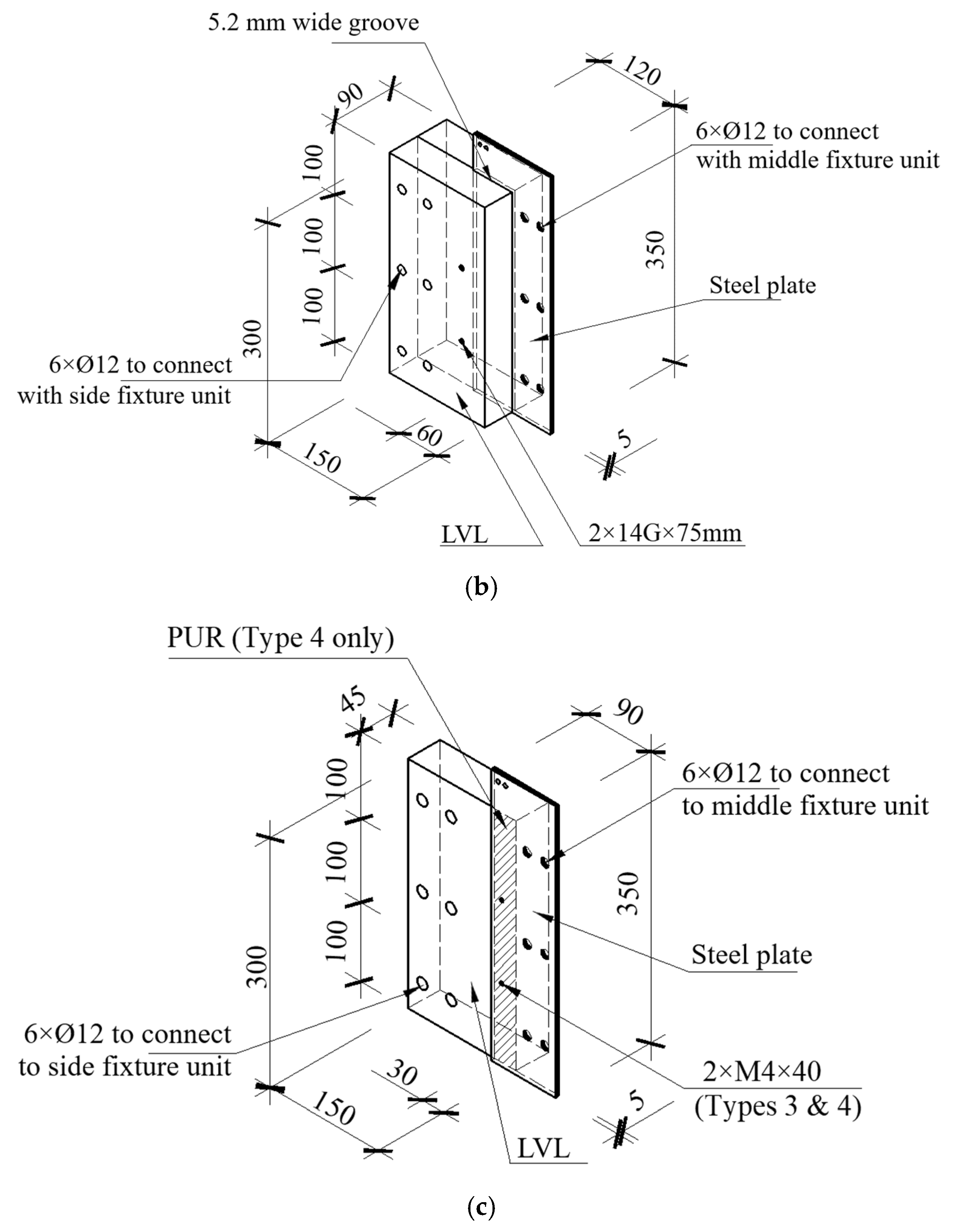

- Loss, C.; Piazza, M.; Zandonini, R. Connections for steel–timber hybrid prefabricated buildings. Part I: Experimental tests. Constr. Build. Mater. 2016, 122, 781–795. [Google Scholar] [CrossRef]

- Swami, P.; Bondre, R.A. Timber-Steel Hybrid Construction for Modern Multi-Story Building. Int. Res. J. Eng. Technol. 2020, 7, 450–457. [Google Scholar]

- Anwaar, O.; Bello-Garcia, M.; de Paula Filho, J.H.M. Efficient design of an office building as Steel/Timber hybrid—A case study. Ce/Papers 2023, 6, 1037–1042. [Google Scholar] [CrossRef]

- Li, Z.; Chen, F.; He, M.; Long, W.; Ou, J.; Li, M. Experimental Investigation on Self-Centering Steel-Timber Hybrid Beam-Column Connections. J. Struct. Eng. 2023, 149, 04022256. [Google Scholar] [CrossRef]

- Karagiannis, V.; Málaga-Chuquitaype, C.; Elghazouli, A.Y. Behaviour of hybrid timber beam-to-tubular steel column moment connections. Eng. Struct. 2017, 131, 243–263. [Google Scholar] [CrossRef]

- Azim, M.R. Numerical and Experimental Investigations of Connection for Timber-Steel Hybrid System. Ph.D. Thesis, Bangladesh University of Engineering & Technology, Dhaka, Bangladesh, 2014. [Google Scholar] [CrossRef]

- Schneider, J. Conventional and Novel Timber Steel Hybrid Connections: Testing, Performance and Assessment. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2017. [Google Scholar]

- Schober, K.U.; Tannert, T. Hybrid connections for timber structures. Eur. J. Wood Wood Prod. 2016, 74, 369–377. [Google Scholar] [CrossRef]

- Kemmsies, M. The Influence of Adhesives and Bonding; Swedish National Testing and Research Institute: Boras, Sweden, 1994. [Google Scholar]

- Shioya, S.; Koga, T.; Kumon, Y.; Otsuki, K.; Uchimura, K. An innovative hybrid timber structure in Japan: Performance of column and beams. In Proceedings of the WCTE 2016—World Conference on Timber Engineering, Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Hassanieh, A.; Valipour, H.R.; Bradford, M.A. Experimental and analytical behaviour of steel-timber composite connections. Constr. Build. Mater. 2016, 118, 63–75. [Google Scholar] [CrossRef]

- Hassanieh, A.; Valipour, H.R.; Bradford, M.A. Experimental and numerical study of steel-timber composite (STC) beams. J. Constr. Steel Res. 2016, 122, 367–378. [Google Scholar] [CrossRef]

- Tan, B.; Ji, Y.; Hu, Y.; Yuan, B.; Hu, X.; Huang, Z. Pretreatment using diluted epoxy adhesive resin solution for improving bond strength between steel and wood surfaces. Int. J. Adhes. Adhes. 2020, 98, 3–10. [Google Scholar] [CrossRef]

- Taskin, N.U.; Ordu, F. Effect of etching duration on roughness and wettability of different carbon steel substrates. Mater. Chem. Phys. 2021, 257, 123746. [Google Scholar] [CrossRef]

- Burnett, M.; Kahlmeyer, M.; Ratsch, N.; Böhm, S. Long-Term Resistant Bonding Between Wood and Aluminium Alloy for Hybrid Lightweight Composites. In 6th International Conference on Adhesive Bonding 2021: Selected Contributions of AB 2021; Springer International Publishing: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Almeida, E. Surface treatments and coatings for metals. A general overview. 1. Surface treatments, surface preparation, and the nature of coatings. Ind. Eng. Chem. Res. 2001, 40, 3–14. [Google Scholar] [CrossRef]

- Liu, C.; Wang, B.; Lu, P.; Xiang, Q.; Jin, Q. Improving the wettability of oxide layers to enhance the bonding strength of shot-blasting steel substrates by using simple resin pre-coating method. Int. J. Adhes. Adhes. 2024, 131, 103661. [Google Scholar] [CrossRef]

- Wang, T.; Wang, Y.; Crocetti, R.; Franco, L.; Schweigler, M.; Wålinder, M. An innovative timber-steel hybrid beam consisting of glulam mechanically reinforced by means of steel rod: Analytical and preliminary numerical investigations. J. Build. Eng. 2021, 43, 102549. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M. Strengthening of timber beams with high strength steel cords. Compos. Part B Eng. 2011, 42, 1480–1491. [Google Scholar] [CrossRef]

- Ghanbari Ghazijahani, T.; Jiao, H.; Holloway, D. Composite Timber Beams Strengthened by Steel and CFRP. J. Compos. Constr. 2017, 21, 04016059. [Google Scholar] [CrossRef]

- González-Bravo, C.; Arriaga-Martitegui, F.; Díez-Barra, R. Bending reinforcement of wooden beams with steel cross-sections. In Proceedings of the 10th World Conference on Timber Engineering, Miyazaki, Japan, 2–5 June 2008; Volume 4, pp. 1939–1946. [Google Scholar]

- Radford, D.W.; Van Goethem, D.; Gutkowski, R.M.; Peterson, M.L. Composite repair of timber structures. Constr. Build. Mater. 2002, 16, 417–425. [Google Scholar] [CrossRef]

- Kusumoto, S.; Shioya, S.; Kawabe, R.; Inomoto, K. An innovative hybrid timber structure in Japan: Beam-to-beam moment resisting connection. In Proceedings of the WCTE 2016—World Conference on Timber Engineering, Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Gómez, E.P.; González, M.N.; Hosokawa, K.; Cobo, A. Experimental study of the flexural behavior of timber beams reinforced with different kinds of FRP and metallic fibers. Compos. Struct. 2019, 213, 308–316. [Google Scholar] [CrossRef]

- Jasieńko, J.; Nowak, T.P. Solid timber beams strengthened with steel plates—Experimental studies. Constr. Build. Mater. 2014, 63, 81–88. [Google Scholar] [CrossRef]

- Malaska, M.; Alanen, M.; Salminen, M.; Jokinen, T.; Ranua, R. Fire Performance of Steel-Timber Hybrid Beam Section. Fire Technol. 2024, 60, 2581–2600. [Google Scholar] [CrossRef]

- Akotuah, A.O.; Ali, S.G.; Erochko, J.; Zhang, X.; Hadjisophocleous, G.V. Study of the fire performance of hybrid steel-timber connections with full-scale tests and finite element modelling. In Proceedings of the 2015 International Conference, Dubrovnik, Croatia, 15–16 October 2015. [Google Scholar] [CrossRef]

- Rantuch, P.; Martinka, J.; Wachter, I. Initiation Parameters of Wood Based Materials. In Proceedings of the 9th International Conference on Wood & Fire Safety, Štrbské Pleso, Slovakia, 3–6 May 2020; pp. 28–34. [Google Scholar] [CrossRef]

- Malaska, M.; Salminen, M.; Jokinen, T.; Ranua, R. Charring of steel-timber hybrid beam section. In Proceedings of the SiF 2022—The 12th International Conference on Structures in Fire, Hong Kong, China, 30 November–2 December 2022; pp. 1076–1086. [Google Scholar]

- Pastori, S.; Sergio Mazzucchelli, E.; Wallhagen, M. Hybrid timber-based structures: A state of the art review. Constr. Build. Mater. 2022, 359, 129505. [Google Scholar] [CrossRef]

- Blackman, B.R.K.; Kinloch, A.J.; Rodriguez Sanchez, F.S.; Teo, W.S.; Williams, J.G. The fracture behaviour of structural adhesives under high rates of testing. Eng. Fract. Mech. 2009, 76, 2868–2889. [Google Scholar] [CrossRef]

- Vallée, T.; Tannert, T.; Fecht, S.; Vallée, T.; Tannert, T. Adhesively bonded connections in the context of timber engineering—A Review. J. Adhes. 2017, 93, 257–287. [Google Scholar] [CrossRef]

- Scora, P.E.; Scora, R.W. Some Observations on the Nature of Papyrus Bonding. J. Ethnobiol. 1991, 11, 193–202. [Google Scholar]

- Selbo, M.L. Adhesive Bonding of Wood; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Washington, DC, USA, 1975. [Google Scholar]

- Tout, R. A review of adhesives for furniture. Int. J. Adhes. Adhes. 2000, 20, 269–272. [Google Scholar] [CrossRef]

- Thornton, J. A Brief History and Review of the Early Practice and Materials of Gap-Filling In the West. J. Am. Inst. Conserv. 2013, 1360, 3–22. [Google Scholar] [CrossRef]

- Schatzberg, E. Ideology and Technical Choice: The Decline of the Wooden Airplane in the United States, 1920–1945; The Johns Hopkins University Press: Baltimore, MD, USA, 1994; Volume 35, pp. 34–69. [Google Scholar]

- Rug, W. 100 Jahre Hetzer-Patent. Bautechnik 2006, 83, 533–540. [Google Scholar] [CrossRef]

- The Rockefeller Foundation. The President’s Review; The Rockefeller Foundation: New York, NY, USA, 1953. [Google Scholar]

- Stoeckel, F.; Konnerth, J.; Gindl-Altmutter, W. Mechanical properties of adhesives for bonding wood—A review. Int. J. Adhes. Adhes. 2013, 45, 32–41. [Google Scholar] [CrossRef]

- Anderson, J. Engineered Wood Products: Glue-Laminated Timber and Laminated Veneer Lumber Beams—A Comparative Life Cycle Assessment; CORRIM (Consortium for Research on Renewable Industrial Materials): Washington, DC, USA, 2008. [Google Scholar]

- Haase, P.; Boretzki, J.; Aurand, S.; Sandhaas, C.; Ummenhofer, T.; Albiez, M. Influence of the joining technique on the structural behaviour of hybrid timber-steel cross-sections. J. Adhes. 2025, 101, 529–556. [Google Scholar] [CrossRef]

- Hong, S.; Gu, Z.; Chen, L.; Zhu, P.; Lian, H. Synthesis of phenol formaldehyde (PF) resin for fast manufacturing laminated veneer lumber (LVL). Holzforschung 2018, 72, 745–752. [Google Scholar] [CrossRef]

- Lengowski, E.C.; Júnior, E.A.B.; Dallo, R.; Nisgoski, S.; de Mattos, J.L.M.; Prata, J.G. Nanocellulose-Reinforced Phenol-Formaldehyde Resin for Plywood Panel Production. Maderas Cienc. Tecnol. 2020, 23, 1–10. [Google Scholar] [CrossRef]

- Shirmohammadli, Y.; Pizzi, A.; Raftery, G.M.; Hashemi, A. One-component polyurethane adhesives in timber engineering applications: A review. Int. J. Adhes. Adhes. 2023, 123, 103358. [Google Scholar] [CrossRef]

- Sterley, M.; Serrano, E.; Källander, B. Building and construction: Timber engineering and wood-based products. In Adhesive Bonding: Science, Technology and Applications; Woodhead Publishing: Sawston, UK, 2021; pp. 571–603. [Google Scholar] [CrossRef]

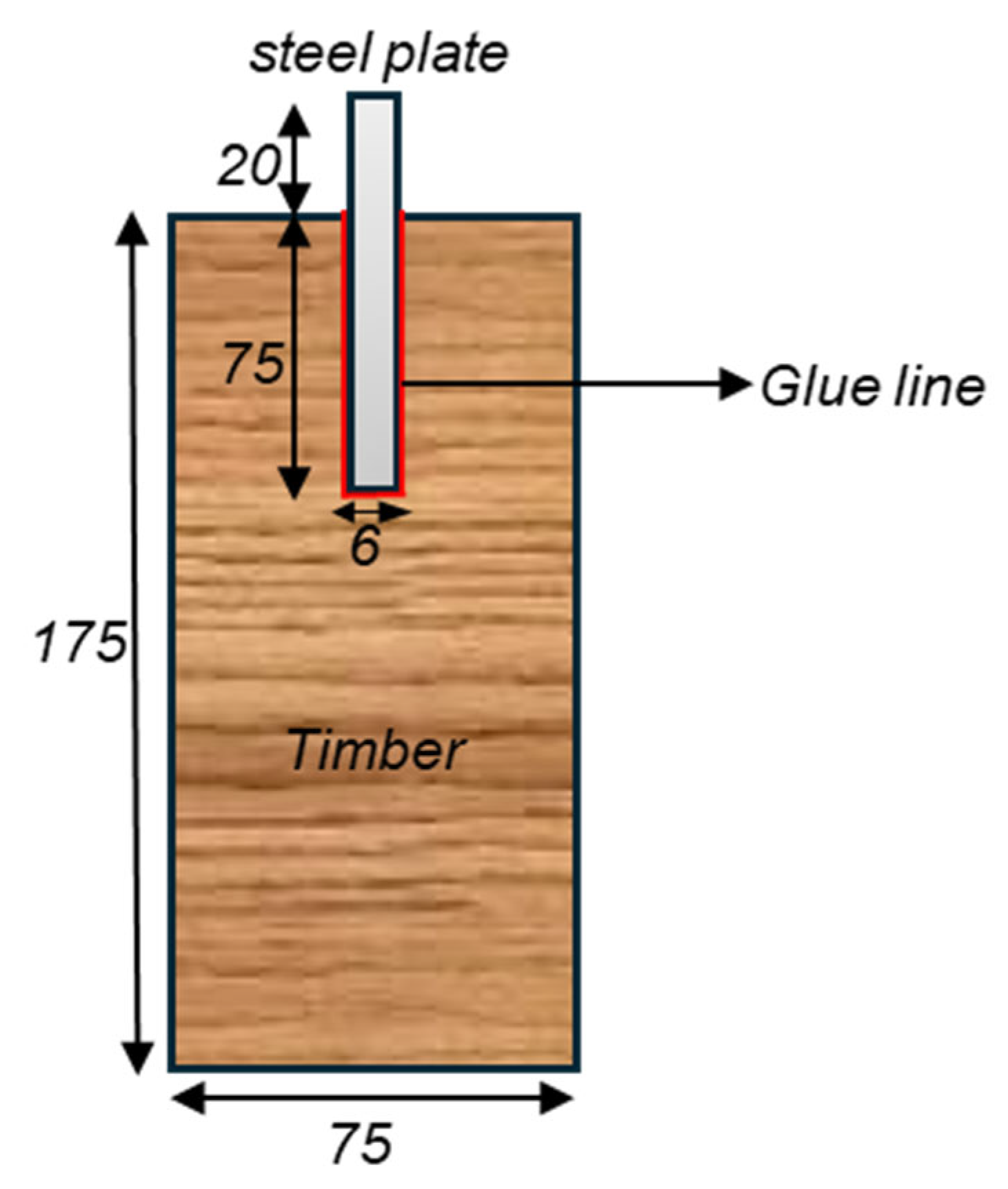

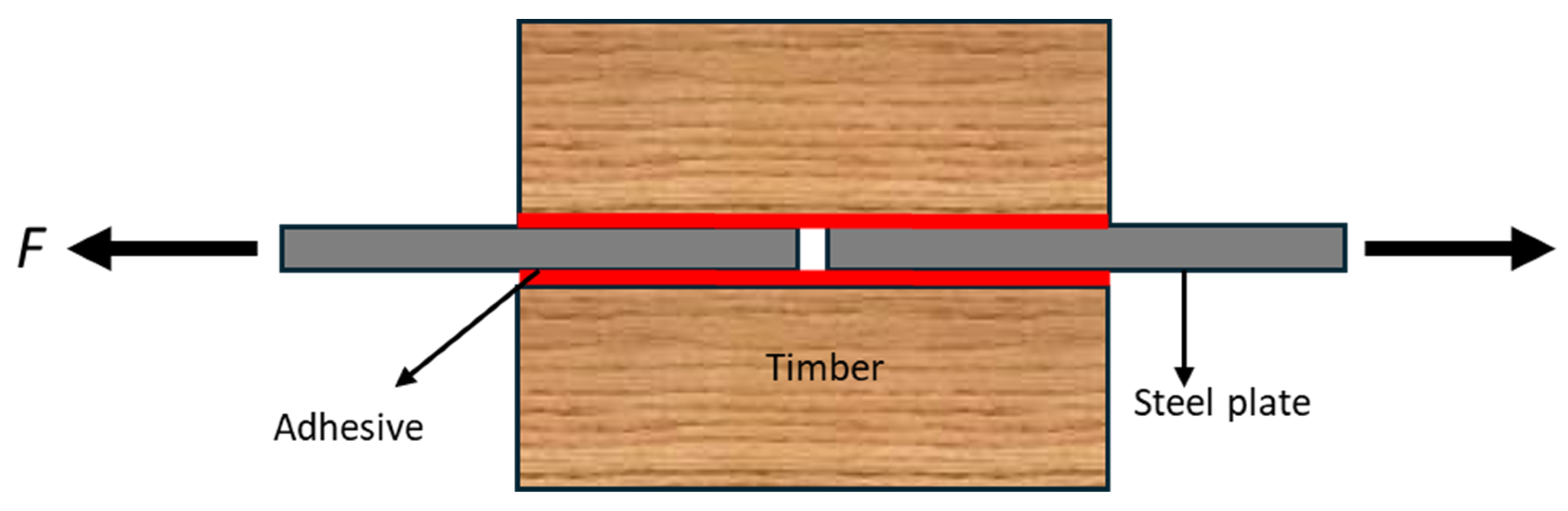

- Kawecki, B. Experimental Study on Wood-Adhesive-Steel-Bolts Hybrid Connections with Slotted-in Steel Plates. Adv. Sci. Technol. Res. J. 2024, 18, 76–88. [Google Scholar] [CrossRef]

- Nabati, A.; Ghanbari-Ghazijahani, T.; Valipour, H.R. Innovative flitch sandwich beams with steel core under four-point bending. Eng. Struct. 2021, 233, 111724. [Google Scholar] [CrossRef]

- Tlustochowicz, G.; Serrano, E.; Steiger, R. State-of-the-art review on timber connections with glued-in steel rods. Mater. Struct./Mater. Constr. 2011, 44, 997–1020. [Google Scholar] [CrossRef]

- Borges, C.S.P.; Akhavan-Safar, A.; Tsokanas, P.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. From Fundamental Concepts to Recent Developments in the Adhesive Bonding Technology: A General View; Springer International Publishing: Berlin/Heidelberg, Germany, 2023; Volume 2. [Google Scholar] [CrossRef]

- Martin Kemmsies, R.S. Glued timber-steelplate joints. In Proceedings of the 1st International RILEM Symposium on Timber Engineering, Stockholm, Sweden, 13–14 September 1999; pp. 389–398. [Google Scholar]

- Kasper, Y.; Albiez, M.; Ummenhofer, T.; Mayer, C.; Meier, T.; Choffat, F.; Ciupack, Y.; Pasternak, H. Application of toughened epoxy-adhesives for strengthening of fatigue-damaged steel structures. Constr. Build. Mater. 2021, 275, 121579. [Google Scholar] [CrossRef]

- Bray, D.J.; Dittanet, P.; Guild, F.J.; Kinloch, A.J.; Masania, K.; Pearson, R.A.; Taylor, A.C. The modelling of the toughening of epoxy polymers via silica nanoparticles: The effects of volume fraction and particle size. Polymer 2013, 54, 7022–7032. [Google Scholar] [CrossRef]

- Huang, Y.; Kinloch, A.J. Modelling of the toughening mechanisms in rubber-modified epoxy polymers—Part I Finite element analysis studies. J. Mater. Sci. 1992, 27, 2753–2762. [Google Scholar] [CrossRef]

- Bajpai, A.; Wetzel, B.; Friedrich, K. High strength epoxy system modified with soft block copolymer and stiff core-shell rubber nanoparticles: Morphology, mechanical properties, and fracture mechanisms. Express Polym. Lett. 2020, 14, 384–399. [Google Scholar] [CrossRef]

- Choffat, F.; Corsaro, A.; Di Fratta, C.; Kelch, S. Advances in Polyurethane Structural Adhesives, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Burchardt, B. Advances in Polyurethane Structural Adhesives; Woodhead Publishing Limited: Sawston, UK, 2010. [Google Scholar] [CrossRef]

- Konnerth, J.; Gindl, W.; Mu, U. Elastic Properties of Adhesive Polymers. I. Polymer Films By Means of Electronic Speckle Pattern Interferometry. J. Appl. Polym. Sci. 2007, 103, 3936–3939. [Google Scholar] [CrossRef]

- Palm, J. Glued Steel-Timber Joits—Test and Finite Element Analysis; Swedish Institute for Wood Technology Research: Boras, Sweden, 1991. [Google Scholar]

- Sun, Z.; Shi, S.; Hu, X.; Guo, X.; Chen, J.; Chen, H. Short-aramid- fiber toughening of epoxy adhesive joint between carbon fi ber composites and metal substrates with different surface morphology. Compos. Part B 2015, 77, 38–45. [Google Scholar] [CrossRef]

- Hu, Y.; Yuan, B.; Cheng, F.; Hu, X. NaOH etching and resin pre-coating treatments for stronger adhesive bonding between CFRP and aluminium alloy. Compos. Part B Eng. 2019, 178, 107478. [Google Scholar] [CrossRef]

- Kwon, D.J.; Kim, J.H.; Kim, Y.J.; Kim, J.J.; Park, S.M.; Kwon, I.J.; Shin, P.S.; DeVries, L.K.; Park, J.M. Comparison of interfacial adhesion of hybrid materials of aluminum/carbon fiber reinforced epoxy composites with different surface roughness. Compos. Part B Eng. 2019, 170, 11–18. [Google Scholar] [CrossRef]

- Fernando, D.; Teng, J.G.; Yu, T.; Zhao, X.L. Preparation and Characterization of Steel Surfaces for Adhesive Bonding. J. Compos. Constr. 2013, 17, 04013012. [Google Scholar] [CrossRef]

- Parker, B.M. Adhesive bonding of fibre-reinforced composites. Int. J. Adhes. Adhes. 1994, 14, 137–143. [Google Scholar] [CrossRef]

- Hollaway, L.C.; Cadei, J. Progress in the technique of upgrading metallic structures with advanced polymer composites. Prog. Struct. Eng. Mater. 2002, 4, 131–148. [Google Scholar] [CrossRef]

- Leggate, W.; McGavin, R.L.; Outhwaite, A.; Gilbert, B.P.; Gunalan, S. Barriers to the Effective Adhesion of High-Density Hardwood Timbers for Glue-Laminated Beams in Australia. Forests 2022, 13, 1038. [Google Scholar] [CrossRef]

- Leggate, W.; Outhwaite, A.; McGavin, R.L.; Gilbert, B.P.; Gunalan, S. The Effects of the Addition of Surfactants and the Machining Method on the Adhesive Bond Quality of Spotted Gum Glue-laminated Beams. BioResources 2022, 17, 3413–3434. [Google Scholar] [CrossRef]

- Khan, M.Z.R.; Srivastava, S.K.; Gupta, M.K. Enhancement of the properties of hybrid woods polymer composites by chemical pre-treatments. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 828–841. [Google Scholar] [CrossRef]

- Cruz, H.; Custódio, J. Adhesives for On-Site Rehabilitation of Timber Structures. J. Adhes. Sci. Technol. 2010, 24, 1473–1499. [Google Scholar] [CrossRef]

- Feligioni, L.; Lavisci, P.; Duchanois, G.; De Ciechi, M.; Spinelli, P. Influence of glue rheology and joint thickness on the strength of bonded-in rods. Holz Als Roh-Und Werkst. 2003, 61, 281–287. [Google Scholar] [CrossRef]

- Bainbridge, R.; Mettem, C.; Harvey, K.; Ansell, M. Bonded-in rod connections for timber structures—Development of design methods and test observations. Int. J. Adhes. Adhes. 2002, 22, 47–59. [Google Scholar] [CrossRef]

- Gilbert, B.P.; Guan, H.; Ngo, T.; Remennikov, A. Shear performance of glued and screwed timber-steel composite connections for composite timber-steel beams. Constr. Build. Mater. 2024, 450, 138762. [Google Scholar] [CrossRef]

- Hassanieh, A.; Valipour, H.R.; Bradford, M.A. Load-slip behaviour of steel-cross laminated timber (CLT) composite connections. J. Constr. Steel Res. 2016, 122, 110–121. [Google Scholar] [CrossRef]

- Jeandin, T.; Mascle, C. A New Model to Select Fasteners in Design for Disassembly. Procedia CIRP 2016, 40, 425–430. [Google Scholar] [CrossRef][Green Version]

- Ottenhaus, L.M.; Yan, Z.; Brandner, R.; Leardini, P.; Fink, G.; Jockwer, R. Design for adaptability, disassembly and reuse—A review of reversible timber connection systems. Constr. Build. Mater. 2023, 400, 132823. [Google Scholar] [CrossRef]

- Kenny, Ε.P.B. The distribution of load and stress in the threads of fasteners—A review. J. Mech. Behav. Mater. 1989, 2, 87–106. [Google Scholar] [CrossRef]

- Aicher, S.; Hezel, J.; Stapf, G. Mechanical and glued joints in glulam of ultra high efficency. In Proceedings of the World Conference on Timber Engineering 2012, WCTE 2012, Auckland, New Zealand, 15–19 July 2012; Volume 2, pp. 536–544. [Google Scholar]

- Hashim, A.M. The Performance of Structural Screws in Canadian Glulam; McGill University: Montreal, QC, Canada, 2012. [Google Scholar]

- Chybiński, M.; Polus, Ł. Withdrawal strength of hexagon head wood screws in laminated veneer lumber. Eur. J. Wood Wood Prod. 2022, 80, 541–553. [Google Scholar] [CrossRef]

- Uysal, B. Effects of the steam test on bonding strength of laminated veneer lumbers manufactured by using different adhesives. J. Appl. Polym. Sci. 2006, 99, 2973–2977. [Google Scholar] [CrossRef]

- Steinberg, E.; Selle, R.; Faust, T. Connectors for Timber–Lightweight Concrete Composite Structures. J. Struct. Eng. 2003, 129, 1538–1545. [Google Scholar] [CrossRef]

- He, G.; Xie, L.; Wang, X.; Yi, J.; Peng, L.; Chen, A.; Johan Gustafsson, P.; Crocetti, R. Timber-concrete structures. BioResources 2016, 11, 9205–9218. [Google Scholar]

- Shahnewaz, M.; Jackson, R.; Tannert, T. CLT concrete composite floors with steel kerf plate connectors. Constr. Build. Mater. 2022, 319, 126092. [Google Scholar] [CrossRef]

- Zhang, A.; Chen, Z.; Liu, J. Flexural performance of innovative thin-walled steel–timber composite floor slabs. Eng. Struct. 2024, 318, 118676. [Google Scholar] [CrossRef]

- Chen, Z.; Niu, X.; Liu, J.; Khan, K. Experimental study of thin-walled steel-timber single-shear connection with a self-tapping screw. Structures 2021, 34, 4389–4405. [Google Scholar] [CrossRef]

- Neagu, C.; Dubina, D.; Dinu, F.; Petran, I. Structural investigations on the progressive collapse of a steel-timber intermediate roofing. Proc. Rom. Acad. Ser. A-Math. Phys. Tech. Sci. Inf. Sci. 2021, 22, 255–264. [Google Scholar]

- Masaeli, M.; Karampour, H.; Gilbert, B.P. Numerical Evaluation of Failure Mechanisms and Retrofitting of Connections in Mass Timber Buildings. KSCE J. Civ. Eng. 2023, 27, 3019–3035. [Google Scholar] [CrossRef]

- Cheng, X.; Gilbert, B.P.; Guan, H.; Dias-da-Costa, D.; Karampour, H. Influence of the earthquake and progressive collapse strain rate on the structural response of timber dowel type connections through finite element modelling. J. Build. Eng. 2022, 57, 104953. [Google Scholar] [CrossRef]

- Mccomb, C.; Tehrani, F.M. Enhancement of shear transfer in composite deck with mechanical fasteners. Eng. Struct. 2015, 88, 251–261. [Google Scholar] [CrossRef]

- Hassanieh, A.; Valipour, H.R.; Bradford, M.A. Experimental and numerical investigation of short-term behaviour of CLT-steel composite beams. Eng. Struct. 2017, 144, 43–57. [Google Scholar] [CrossRef]

- Tapia, C.; Aicher, S. A new concept for column-to-column connections for multi-storey timber buildings—Numerical and experimental investigations. Eng. Struct. 2023, 295, 116770. [Google Scholar] [CrossRef]

- Hussein, A.B.; Papp, F. State-of-the-Art: Integrating Fastener Technology and Design Guidelines for Enhanced Performance of Cold-Formed Steel Sections. Buildings 2023, 13, 2338. [Google Scholar] [CrossRef]

- He, M.; Zhang, Q.; Sun, X.; Alhaddad, W. An experimental and numerical study on the shear performance of friction-type high-strength bolted connections used for CLT-steel hybrid shear walls. Eng. Struct. 2024, 306, 117868. [Google Scholar] [CrossRef]

- Loss, C.; Frangi, A. Experimental investigation on in-plane stiffness and strength of innovative steel-timber hybrid floor diaphragms. Eng. Struct. 2017, 138, 229–244. [Google Scholar] [CrossRef]

- Wang, C.L.; Lyu, J.; Zhao, J.; Yang, H. Experimental investigation of the shear characteristics of steel-to-timber composite joints with inclined self-tapping screws. Eng. Struct. 2020, 215, 110683. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Li, Z.; Yang, R.; Li, Z. Measurement of bolt axial stress using a combination of trailing wave and shear wave ultrasound. NDT E Int. 2024, 143, 103056. [Google Scholar] [CrossRef]

- ISO 4014:2022; Fasteners—Hexagon Head Bolts—Product Grades A and B. ISO: Geneva, Switzerland, 2022.

- Graves, F.E. Nuts and Bolts. Sci. Am. 1984, 6, 136–145. [Google Scholar] [CrossRef]

- Smith, D. Best Screwdriver Sets for 2023. 2023. Available online: https://protguide.com/hand-tool/best-screwdriver-sets/ (accessed on 15 April 2025).

- Lavrinenko, V.Y.; Lavrinenko, Y.A.; Govorov, V.A. Materials for Manufacturing Automotive Industry High-Strength Fasteners. Metallurgist 2020, 63, 960–966. [Google Scholar] [CrossRef]

- Godden, N. Develop an Algorithm Able to Select a Bolted Fastener Capable to Perform at Known Environmental Conditions. Bachelor’s Thesis, Buckinghamshire New University, Wycombe, UK, 2015. [Google Scholar]

- Chybiński, M.; Polus, Ł. Mechanical Behaviour of Aluminium-Timber Composite Connections with Screws and Toothed Plates. Materials 2022, 15, 68. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Asce, A.M.; He, M.; Asce, M.; Ma, Z.; Wang, K.; Ma, R. In-Plane Behavior of Timber-Steel Hybrid Floor Diaphragms: Experimental Testing and Numerical Simulation. J. Struct. Eng. 2016, 142, 04016119. [Google Scholar] [CrossRef]

- BS EN 1995-1-1:2004 4 +A2:2014; Eurocode 5—Design of Timber Structures—Part 1-1: General—Common Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2014. [CrossRef]

- Zhao, Y.; Yuan, Y.; Wang, C.L.; Meng, S. Experimental and finite element analysis of flexural performance of steel-timber composite beams connected by hybrid-anchored screws. Eng. Struct. 2023, 292, 116503. [Google Scholar] [CrossRef]

- Wang, C.L.; Zhao, Y.; Yuan, Y.; Meng, S. Enhance the performance of steel-wood composite screw connections with fast-curing adhesive. J. Build. Eng. 2024, 89, 109336. [Google Scholar] [CrossRef]

- Zhao, Y.; Yuan, Y.; Wang, C.L.; Zheng, J.; Zhou, Y. Experimental study on shear performance of steel-timber screw connectors with grout pockets. Eng. Struct. 2022, 266, 114535. [Google Scholar] [CrossRef]

- De Santis, Y.; Aloisio, A.; Gavrić, I.; Šušteršič, I.; Fragiacomo, M. Timber-to-steel inclined screws connections with interlayers: Experimental investigation, analytical and finite element modelling. Eng. Struct. 2023, 292, 116504. [Google Scholar] [CrossRef]

- Romero, A.; Odenbreit, C. Experimental investigation on novel shear connections for demountable steel-timber composite (STC) beams and flooring systems. Eng. Struct. 2024, 304, 117620. [Google Scholar] [CrossRef]

- Li, Z.; Feng, W.; Ou, J.; Liang, F.; He, M. Experimental investigations into the mechanical performance of glulam dowel-type connections with either bolts or screws as fasteners. J. Wood Sci. 2021, 67, 71. [Google Scholar] [CrossRef]

- He, M.; Luo, Q.; Li, Z.; Dong, H.; Li, M. Seismic performance evaluation of timber-steel hybrid structure through large-scale shaking table tests. Eng. Struct. 2018, 175, 483–500. [Google Scholar] [CrossRef]

- Li, Z.; Dong, H.; Wang, X.; He, M. Experimental and numerical investigations into seismic performance of timber-steel hybrid structure with supplemental dampers. Eng. Struct. 2017, 151, 33–43. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.; He, M.; Ou, J.; Li, M.; Luo, Q.; Dong, H. Structural Damage Evaluation of Multistory Timber–Steel Hybrid Structures through Shake Table Tests. J. Perform. Constr. Facil. 2021, 35, 04020139. [Google Scholar] [CrossRef]

- Tao, H.; Yang, H.; Ju, G.; Shi, B. Elastic stiffness of timber joints with dowel-type fasteners and slotted-in steel plate based on the theory of beam on elastic foundation. Constr. Build. Mater. 2021, 294, 123569. [Google Scholar] [CrossRef]

- Titirla, M.; Michel, L.; Ferrier, E. Mechanical behaviour of glued-in rods (carbon and glass fibre-reinforced polymers) for timber structures—An analytical and experimental study. Compos. Struct. 2019, 208, 70–77. [Google Scholar] [CrossRef]

- Raftery, G.M.; Kelly, F. Basalt FRP rods for reinforcement and repair of timber. Compos. Part B Eng. 2015, 70, 9–19. [Google Scholar] [CrossRef]

- Li, T.; Zhu, M.; Yang, Z.; Song, J.; Dai, J.; Yao, Y.; Luo, W.; Pastel, G.; Yang, B.; Hu, L. Wood Composite as an Energy Efficient Building Material: Guided Sunlight Transmittance and Effective Thermal Insulation. Adv. Energy Mater. 2016, 6, 1601122. [Google Scholar] [CrossRef]

- Lagüela, S.; Bison, P.; Peron, F.; Romagnoni, P. Thermal conductivity measurements on wood materials with transient plane source technique. Thermochim. Acta 2015, 600, 45–51. [Google Scholar] [CrossRef]

- Dumler, P.; Blankenhagen, J.; Werther, N.; Mensinger, M.; Winter, S. Fire Safety Design of Structures in Steel-Timber Hybrid Construction. In Wood & Fire Safety 2024; Osvaldová, L.M., Ed.; Springer Nature Switzerland AG: Cham, Switzerland, 2024; pp. 326–333. [Google Scholar] [CrossRef]

- Béreyziat, A.; Dhima, D.; Durif, S.; Audebert, M.; Bouchaïr, A.; Si Larbi, A. Fire Tests on Steel–Timber Composite Beams. Fire Technol. 2024, 60, 2601–2620. [Google Scholar] [CrossRef]

- Di Ha Le, T.; Tsai, M.T. Experimental assessment of the fire resistance mechanisms of timber-steel composites. Materials 2019, 12, 4003. [Google Scholar] [CrossRef]

- Metelli, G.; Preti, M.; Giuriani, E. On the delamination phenomenon in the repair of timber beams with steel plates. Constr. Build. Mater. 2016, 102, 1018–1028. [Google Scholar] [CrossRef]

- Palma, P.; Frangi, A.; Hugi, E.; Cachim, P.; Cruz, H. Fire resistance tests on steel-to-timber dowelled connections reinforced with self drilling screws. In Proceedings of the 2nd CILASCI—Ibero-Latin-American Congress on Fire Safety Engineering, Coimbra, Portugal, 29 May–1 June 2013. [Google Scholar]

- Hubbard, C.; Salem, O. Fire resistance of a fully concealed, moment-resisting new timber connection utilizing mechanically-fastened steel rods. Fire Saf. J. 2022, 129, 103546. [Google Scholar] [CrossRef]

- Yasir, M.; Ahmad, F.; Yusoff, P.S.M.M.; Ullah, S.; Jimenez, M. Latest trends for structural steel protection by using intumescent fire protective coatings: A review. Surf. Eng. 2020, 36, 334–363. [Google Scholar] [CrossRef]

- Jankowski, L.J.; Jasieńko, J.; Nowak, T.P. Experimental assessment of CFRP reinforced wooden beams by 4-point bending tests and photoelastic coating technique. Mater. Struct. 2010, 43, 141–150. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M.; Grazini, A. A method for flexural reinforcement of old wood beams with CFRP materials. Compos. Part B Eng. 2005, 36, 143–153. [Google Scholar] [CrossRef]

- Wilkinson, T. Structural Mechanics, 2nd ed.; Spon Press: London, UK, 2005. [Google Scholar]

- AS 1720.1; Timber Structures—Design Methods. Standards Australia: Sydney, Australia, 2010.

- Chen, T.; Chen, Z.; Liu, J.; Zhang, A. Bending Properties of Cold-Formed Thin-Walled Steel/Fast-Growing Timber Composite I-Beams. Forests 2024, 15, 857. [Google Scholar] [CrossRef]

- Hosseini, R.; Valipour, H.R. Timber–Encased-Steel Beams: Laboratory Experimentation and Analytical Modeling. J. Struct. Eng. 2024, 150, 04024074. [Google Scholar] [CrossRef]

- Pernigotto, G.; Prada, A.; Patuzzi, F.; Baratieri, M.; Gasparella, A. Characterization of the dynamic thermal properties of the opaque elements through experimental and numerical tests. Energy Procedia 2015, 78, 3234–3239. [Google Scholar] [CrossRef]

- Khorasani, Y. Feasibility Study of Hybrid Wood Steel Structures. Ph.D. Thesis, University of British Colombia, Vancouver, BC, Canada, 2011. [Google Scholar]

- Nowak, T.; Jasieńko, J.; Kotwica, E.; Krzosek, S. Strength enhancement of timber beams using steel plates—Review and experimental tests. Drewno 2016, 59, 75–90. [Google Scholar] [CrossRef]

- Song, X.; Zhao, L.; Liu, Y.; Gong, M. Experimental and nonlinear analytical of the flexural performance of timber-filled steel tubular composite beams. Eng. Struct. 2024, 301, 117312. [Google Scholar] [CrossRef]

- Karampour, H.; Bourges, M.; Gilbert, B.P.; Bismire, A.; Bailleres, H.; Guan, H. Compressive behaviour of novel timber-filled steel tubular (TFST) columns. Constr. Build. Mater. 2020, 238, 117734. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, J.; Wu, P.; Li, Y. Experimental investigation on the flexural and shear behaviour of LVL I-beam strengthened with steel channels. Constr. Build. Mater. 2022, 341, 127719. [Google Scholar] [CrossRef]

- Karki, D. Numerical and Experimental Investigations on Static Behaviour of Composite Cold-Formed Steel and Timber Flooring System; University of Technology Sydney: Ultimo, Australia, 2023. [Google Scholar]

| Reinforcement Location | Advantages | Disadvantages |

|---|---|---|

| Top Reinforcement |

|

|

| Bottom Reinforcement |

|

|

| Side Reinforcement |

|

|

| Embedded Reinforcement |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdulmalik, A.; Gilbert, B.P.; Guan, H.; Ngo, T.; Remennikov, A. Advancements in Timber–Steel Hybridisation: A Review on Techniques, Applications, and Structural Performances. Buildings 2025, 15, 2252. https://doi.org/10.3390/buildings15132252

Abdulmalik A, Gilbert BP, Guan H, Ngo T, Remennikov A. Advancements in Timber–Steel Hybridisation: A Review on Techniques, Applications, and Structural Performances. Buildings. 2025; 15(13):2252. https://doi.org/10.3390/buildings15132252

Chicago/Turabian StyleAbdulmalik, Abdulaziz, Benoit P. Gilbert, Hong Guan, Tuan Ngo, and Alex Remennikov. 2025. "Advancements in Timber–Steel Hybridisation: A Review on Techniques, Applications, and Structural Performances" Buildings 15, no. 13: 2252. https://doi.org/10.3390/buildings15132252

APA StyleAbdulmalik, A., Gilbert, B. P., Guan, H., Ngo, T., & Remennikov, A. (2025). Advancements in Timber–Steel Hybridisation: A Review on Techniques, Applications, and Structural Performances. Buildings, 15(13), 2252. https://doi.org/10.3390/buildings15132252