Feasibility of Using New Technologies and Artificial Intelligence in Preventive Measures in Building Works

Abstract

1. Introduction

- Construction environments that are often increasingly complex and changing, making it difficult to anticipate potential risks.

- Traditional training that is not enough to prepare workers for dynamic and dangerous situations.

- Supervision limited to workers due to the breadth of construction sites and the diversity of tasks.

2. Literature Review

2.1. Digital Technologies in Construction Safety

2.2. Artificial Intelligence in Occupational Safety

2.3. Implementation Challenges and Barriers

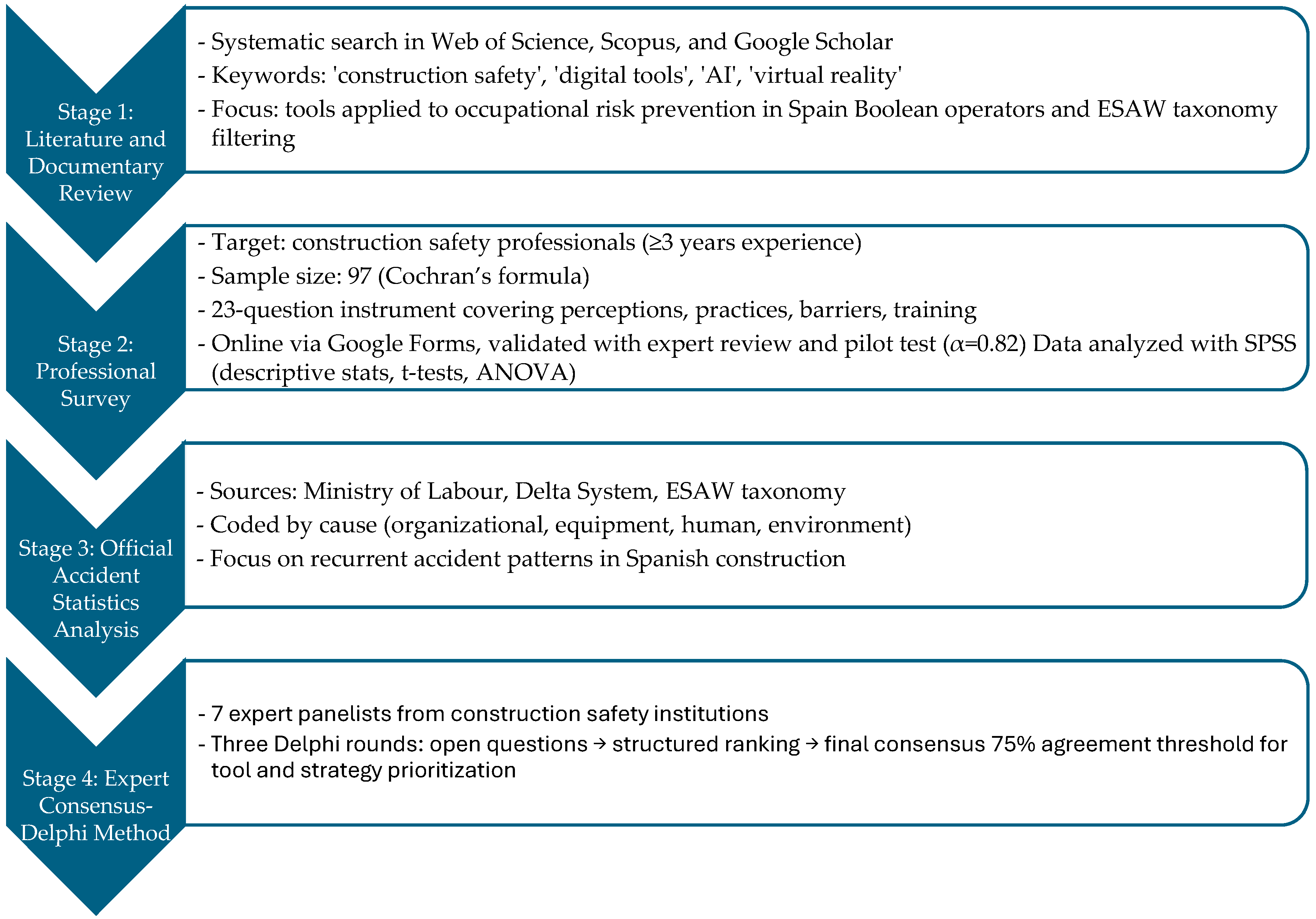

3. Methodology

3.1. Stage 1: Literature and Documentary Review

- Automated duplicate detection: Records were imported into Zotero (version 7) reference management software, which automatically identified 103 duplicate records using DOI matching and title similarity algorithms.

- Manual verification: All automatically flagged duplicates were manually reviewed to confirm true duplicates versus similar but distinct publications. This process involved comparing the following:

- -

- Author names and affiliations.

- -

- Publication titles and abstracts.

- -

- Publication years and journal names.

- -

- DOI numbers when available.

3.2. Stage 2: Professional Survey

- Ensure inclusion of participants with direct decision-making authority in safety protocols (e.g., site managers, safety officers).

- Prioritize depth of expertise over random representativeness in this exploratory phase.

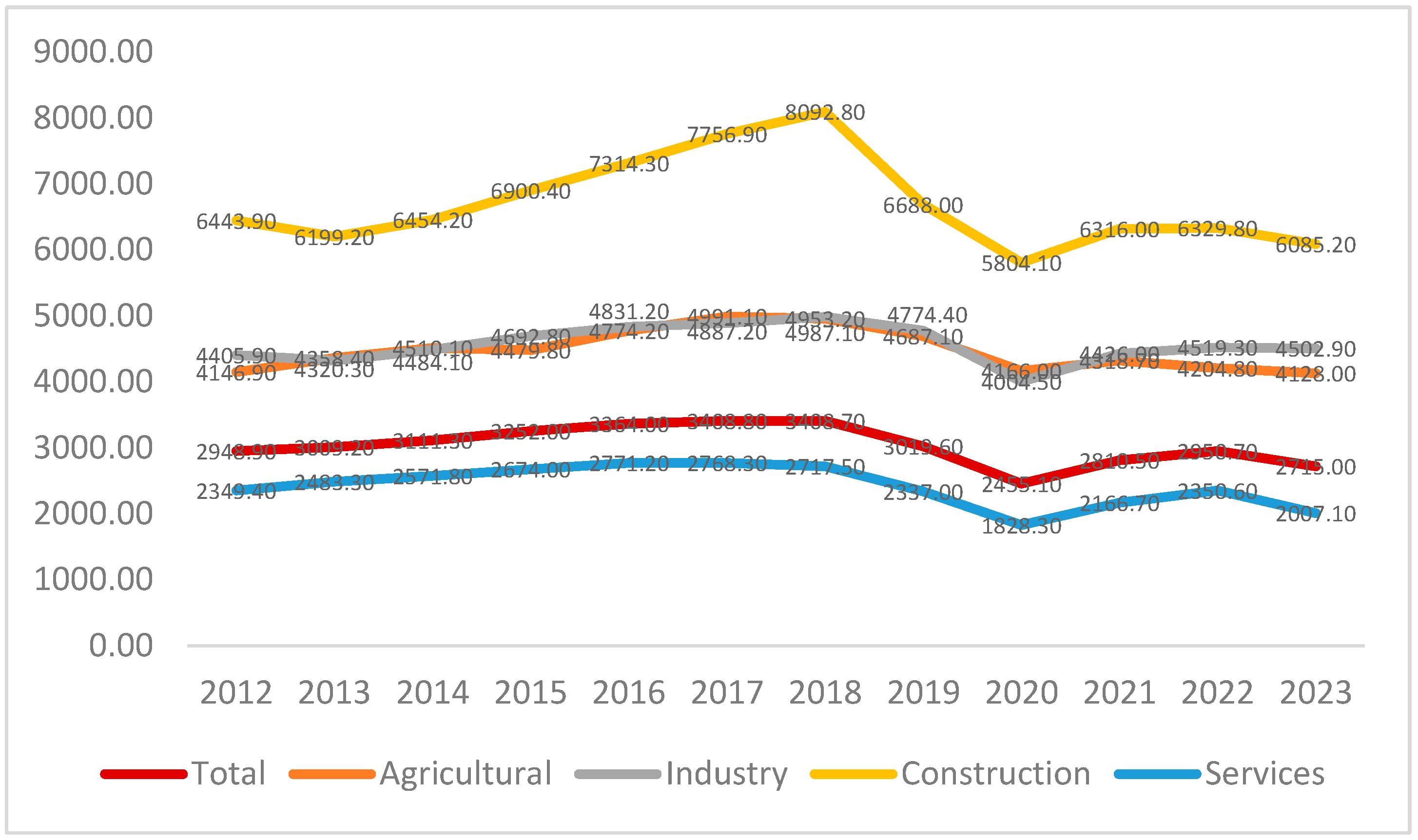

3.3. Stage 3: Official Accident Statistic Analysis

3.4. Stage 4: Expert Consensus via Delphi Method

- -

- Head of Health, Safety, Quality, and Environment Department, Madrid Territorial Council of Construction Labor Foundation.

- -

- Territorial Prevention Coordinator, ASEPEYO (mutual insurance company).

- -

- Director of Technical Office, General Council of Technical Architecture of Spain (CGATE).

- -

- Chief Executive Officer of MARTIN BRAINON (business consultant specializing in risk mitigation).

- -

- Head of Working Conditions Control Service, Regional Institute for Safety and Health at Work of the Community of Madrid.

- -

- Chief Executive Officer of GA GROUP (international leader in safety training technologies).

- -

- PLS Expert ET&A from HILTI (construction technology leader).

4. Results

4.1. Literature Review Findings

4.2. Professional Survey Results

4.2.1. Sample Characteristics

4.2.2. Technology Acceptance and Barriers

- -

- Lack of digital skills among workers (35%).

- -

- Insufficient budget (30%).

- -

- High tool costs (25%).

- -

- Lack of specific training (20%).

- -

- Falls from height (40%).

- -

- Improper machinery use or lack of control (30%).

- -

- Lack of danger awareness (25%).

- -

- BIM—50% of respondents highlighted its comprehensive planning and coordination capabilities.

- -

- VR/AR/MR—45% valued their ability to simulate real scenarios for training and awareness.

- -

- Drones—30% appreciated their real-time supervision and monitoring capabilities for difficult-to-access areas.

4.3. Official Accident Statistic Analysis

4.4. Expert Consensus Results

- -

- BIM methodology reduces on-site improvisation and improves risk communication.

- -

- Real-time monitoring through sensors and devices enables immediate hazard response.

- -

- Access control systems prevent unauthorized entry to hazardous areas.

- -

- Exoskeletons minimize overexertion and musculoskeletal injury risks.

- -

- AI optimizes document management and accident prediction.

- -

- VR/AR technologies provide effective training and accident investigation capabilities.

- -

- Digital skill gaps and resistance to change among workers and managers.

- -

- Digital divide between large companies and Small and Medium-sized Enterprises (SMEs).

- -

- Outdated regulations not designed for emerging technologies.

- -

- Unclear return on investment, particularly for SMEs.

- -

- Traditional safety culture not prioritizing technological solutions.

5. Discussion

5.1. Technology Acceptance and Feasibility

5.2. Implementation Barriers and Solutions

5.3. Regulatory and Policy Implications

5.4. Technology Prioritization

5.5. Study Limitations

5.6. Comparison with the International Literature

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Questionnaire Structure

Appendix A.1. Perceptions of Digital Tool Utility

- Technological innovation from other sectors can help improve occupational safety and health in construction—Likert scale.

- Simulating a construction site environment with mixed reality can help improve safety—Likert scale.

- Simulating an accident on site through mixed reality helps raise worker awareness and analyze causes—Likert scale.

- Using virtual reality can improve training and make it more inclusive for site workers—Likert scale.

- Monitoring site work can improve “in situ” safety—Likert scale.

- Predictive risk simulation can anticipate possible hazards in construction projects—Likert scale.

- Automating routine tasks with AI allows workers to focus on more complex and creative work, increasing productivity and job satisfaction—Likert scale.

- The use of smart devices in equipment and systems can help improve safety by providing real-time information—Likert scale.

Appendix A.2. Current Practices and Barriers to Adoption

- Is there a defined Digital Strategy in your company?—Open answer if “Yes” is selected, to specify “Which”.

- Do you know any digital tool specifically aimed at improving worker safety on site?—Open answer if “Yes” is selected, to specify “Which”.

- If you have used any of the above digital tools, has it led to a significant improvement in your work?—Open answer; free-text response.

- What do you think are the main factors influencing the decision to adopt digital tools for worker safety on site?—Selection from reference sample; closed.

- What do you think are the main barriers to not implementing digital tools for OSH on site?—Selection from reference sample; closed.

- Of all the risks faced by workers on a site, which would you prioritize for the application of digital tools to avoid or minimize them?—Selection from reference sample; closed.

- Which of the following tools do you think could improve safety on construction sites?—Open answer; free-text response.

- If you were offered a digital tool to improve site safety, would you use it?—Open answer if “Yes” is selected, to explain “Why”.

Appendix A.3. Training Needs

- What type of information would you like to obtain from a digital tool to improve safety management on your site?—Open answer; free-text response.

- What kind of support would you need to implement a digital tool on your site/company?—Open answer; free-text response.

Appendix A.4. Demographic Information

- Gender—Multiple choice selection.

- Age—Multiple choice selection.

- Profession—Multiple choice selection.

- Type of Activity—Multiple choice selection.

- Company Size—Multiple choice selection.

References

- McKinsey Global Institute. 2017. Reinventing Construction: A Route to Higher Productivity. McKinsey & Company. Available online: https://www.mckinsey.com/~/media/mckinsey/business%20functions/operations/our%20insights/reinventing%20construction%20through%20a%20productivity%20revolution/mgi-reinventing-construction-a-route-to-higher-productivity-full-report.pdf (accessed on 21 May 2025).

- HSE Review. EU’s Construction Sector Fatalities Continue to Rise. MENA HSE Review 2024. Available online: https://hsereview.com/regional-coverage/europe/eu-s-construction-sector-fatalities-continue-to-rise (accessed on 26 May 2025).

- Eurostat. Accidents at Work Statistics. Statistics Explained 2024. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Accidents_at_work_statistics (accessed on 26 May 2025).

- OCDE. Informe Sobre Productividad 2024. Available online: https://www.lamoncloa.gob.es/serviciosdeprensa/notasprensa/trabajo14/Documents/2024/050624-informe-productividad-ocde.pdf.pdf (accessed on 12 May 2025).

- Confederación Sindical de CCOO. Análisis de Las Estadísticas de Accidentes de Trabajo y Enfermedades Profesionales en España en 2023. Abril 2024. Available online: https://www.ccoo.es/33fd8e17affff93e3f0cc94a395b07b7000001.pdf (accessed on 20 May 2025).

- Olena, O. Digital transformation in the construction industry: Analysing the impact of technological changes on construction processes. Estoa. J. Fac. Archit. Urban. 2025, 14, 257–268. [Google Scholar] [CrossRef]

- UPV-EHU. Estrategia para la construcción inteligente y sostenible. In Proceedings of the 8th European Conference on Energy Efficiency and Sustainability in Architecture and Planning, Donostia-San Sebastián, Spain, 5–7 July 2017. [Google Scholar]

- European Commission. Digital Strategy. Available online: https://digital-strategy.ec.europa.eu/en/policies/regulatory-framework-ai (accessed on 26 May 2025).

- Taheri, A.; Azimi, N.; Oliveira, D.V.; Tinoco, J.; Lourenço, P.B. Integrating Experimental Analysis and Gradient Boosting for the Durability Assessment of Lime-Based Mortar in Acidic Environment. Buildings 2025, 15, 408. [Google Scholar] [CrossRef]

- Mohammadi, A.; Karimzadeh, S.; Yaghmaei-Sabegh, S.; Ranjbari, M.; Lourenço, P.B. Utilising Artificial Neural Networks for Assessing Seismic Demands of Buckling Restrained Braces Due to Pulse-like Motions. Buildings 2023, 13, 2542. [Google Scholar] [CrossRef]

- David, A.B.; Olalusi, O.B.; Awoyera, P.O.; Simwanda, L. Suitability of Mechanics-Based and Optimized Machine Learning-Based Models in the Shear Strength Prediction of Slender Beams Without Stirrups. Buildings 2024, 14, 3946. [Google Scholar] [CrossRef]

- Tanguler-Bayramtan, M.; Aktas, C.B.; Yaman, I.O. Environmental Assessment of Calcium Sulfoaluminate Cement: A Monte Carlo Simulation in an Industrial Symbiosis Framework. Buildings 2024, 14, 3673. [Google Scholar] [CrossRef]

- European Union. AI Act—Regulation (EU) 2024/1689 laying down harmonised rules on artificial intelligence. Off. J. Eur. Union 2024. Available online: http://data.europa.eu/eli/reg/2024/1689/oj (accessed on 5 May 2025).

- Clifford Chance. What Does the EU AI Act Mean for Employers? 2024. Available online: https://www.cliffordchance.com/content/dam/cliffordchance/briefings/2024/08/what-does-the-eu-ai-act-mean-for-employers.pdf (accessed on 26 May 2025).

- DigiPLACE. Digital Platform for Construction in Europe. Available online: https://www.digiplaceproject.eu/ (accessed on 12 May 2025).

- Spanish Construction Technology Platform (PTEC). Spanish Construction Technology Platform Reports 2024. Available online: https://plataformaptec.es/ (accessed on 12 May 2025).

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications. Autom. Constr. 2022, 141, 104418. [Google Scholar] [CrossRef]

- CEOE. Plan Digital 2025: La Digitalización de la Sociedad Española; Confederación Española de Organizaciones Empresariales: Madrid, Spain, 2024; Available online: https://www.ceoe.es/sites/ceoe-corporativo/files/content/file/2020/03/29/38/plan_digital_2025.pdf (accessed on 12 May 2025).

- Zhang, Y.; Liu, H.; Kang, S.C.; Al-Hussein, M. Virtual reality applications for the built environment: Research trends and opportunities. Autom. Constr. 2020, 118, 103311. [Google Scholar] [CrossRef]

- Yue, P.; Limao, Z. Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Autom. Constr. 2021, 122, 103517. [Google Scholar] [CrossRef]

- Li, H. Sustainable construction through digitalization: A review. Autom. Constr. 2019, 107, 102930. [Google Scholar] [CrossRef]

- Akindele, N.; Taiwo, R.; Sarvari, H.; Oluleye, B.I.; Awodele, I.A.; Olaniran, T.O. A state-of-the-art analysis of virtual reality applications in construction health and safety. Results Eng. 2024, 23, 102382. [Google Scholar] [CrossRef]

- Jeelani, I.; Han, K.; Albert, A. Development of immersive personalized training environment for construction workers. In Computing in Civil Engineering; ASCE Library: online, 2017; pp. 407–415. [Google Scholar]

- Afzal, M.; Shafiq, M.T.; Al Jassmi, H. Improving construction safety with virtual-design construction technologies—A review. J. Inf. Technol. Constr. 2021, 26, 319–340. [Google Scholar] [CrossRef]

- Delgado, J.M.; Oyedele, L.; Demian, P.; Beach, T. A research agenda for augmented and virtual reality in architecture, engineering, and construction. Adv. Eng. Inform. 2020, 45, 101122. [Google Scholar] [CrossRef]

- Moore, H.F.; Gheisari, M. A review of virtual and mixed reality applications in construction safety literature. Saf. Now 2019, 5, 51. [Google Scholar] [CrossRef]

- ACCA Software. Health and Safety BIM. Available online: https://www.accasoftware.com/es/health-safety-bim (accessed on 12 May 2025).

- Honrubia, M. Los Wearables que Están Transformando el Sector de la Construcción. Available online: https://www.ennomotive.com/es/los-wearables-que-estan-transformando-el-sector-de-la-construccion/ (accessed on 12 May 2025).

- Bodytrak. Sistemas Wearables de Control de la Fatiga. Available online: https://bodytrak.co/es/sistemas-wearables-de-control-de-la-fatiga/ (accessed on 12 May 2025).

- PTEC. Metabuilding Project. Available online: https://plataformaptec.es/proyectos-nacionales-y-europeos/metabuilding-project/ (accessed on 12 May 2025).

- Concha Arcas, J. Plataforma Transversal: Compatibilizar el avance de las tecnologías y la Administración Pública. In Comunicación presentada al III Congreso Ciudades Inteligentes; 2024; Available online: https://www.esmartcity.es/comunicaciones/comunicacion-plataforma-transversal-compatibilizar-avance-tecnologias-administracion-publica (accessed on 12 May 2025).

- Merino, M. La UBU Transforma la Seguridad Laboral: Virtual Risk Prevention Entra en Acción; El Correo de Burgos: Burgos, Spain, 2023. [Google Scholar]

- Cordis EU-Acciona. Efectos Negativos del Estrés Térmico Sobre la Salud y la Productividad. 2020. Available online: https://cordis.europa.eu/article/id/421654-too-much-sunlight-on-the-head-obstructs-thinking-study-shows/es (accessed on 12 May 2025).

- Manzoor, B.; Othman, I.; Durdyev, S.; Ismail, S.; Wahab, M.H. Influence of Artificial Intelligence in Civil Engineering toward Sustainable Development—A Systematic Literature Review. Appl. Syst. Innov. 2021, 4, 52. [Google Scholar] [CrossRef]

- Abioye, S.O.; Oyedele, L.O.; Akanbi, L.; Ajayi, A.; Delgado, J.M.; Bilal, M.; Akinade, O.O.; Ahmed, A. Artificial intelligence in the construction industry: A review of present status, opportunities and future challenges. J. Build. Eng. 2021, 44, 103299. [Google Scholar] [CrossRef]

- Espino Timón, C. Análisis Predictivo: Técnicas y Modelos Utilizados y Aplicaciones del Mismo-Herramientas Open Source que Permiten su Uso; Trabajo de Fin de Grado; Universitat Oberta de Catalunya: Barcelona, Spain, 2017. [Google Scholar]

- European Commission. Commission Regulation (EU) No 349/2011 on European Statistics on Accidents at Work (ESAW); Publications Office of the European Union: Luxembourg, 2011. [Google Scholar]

- Zhou, X.; Li, Y.; Wang, J. Leveraging feature extraction and risk-based clustering for predictive maintenance in industrial settings. Int. J. Environ. Res. Public Health 2024, 22, 199. [Google Scholar] [CrossRef]

- European Parliament. EU AI Act: First Regulation on Artificial Intelligence. Available online: https://www.europarl.europa.eu/topics/en/article/20230601STO93804/eu-ai-act-first-regulation-on-artificial-intelligence (accessed on 26 May 2025).

- PTEC. Informe Sobre el Impacto de la Inteligencia Artificial en el Sector de la Construcción 2024. Available online: https://movicarga.com/se-publica-el-informe-el-impacto-de-la-inteligencia-artificial-ia-en-el-sector-de-la-construccion/ (accessed on 26 May 2025).

- Deloitte, A. Estado de la Adopción Digital en la Industria de la Construcción en Asia Pacífico. 2024. Available online: https://www.deloitte.com/es/es/Industries/energy/construccion-avanzada.html (accessed on 26 May 2025).

- Software Improvement Group. A Comprehensive EU AI Act Summary. 2025. Available online: https://www.softwareimprovementgroup.com/eu-ai-act-summary/ (accessed on 26 May 2025).

- HK Law. The European Union’s AI Act: What You Need to Know. 2024. Available online: https://www.hklaw.com/en/insights/publications/2024/03/the-european-unions-ai-act-what-you-need-to-know (accessed on 26 May 2025).

- Carnegie Endowment. AI and Product Safety Standards Under the EU AI Act. 2024. Available online: https://carnegieendowment.org/2024/03/05/ai-and-product-safety-standards-under-eu-ai-act-pub-91870 (accessed on 26 May 2025).

- ETUC. Enough is Enough: Zero Accidents at Work Now. Available online: https://www.etuc.org/en/pressrelease/enough-enough-zero-accidents-work-now (accessed on 26 May 2025).

- Eurostat. Accidents at Work—Statistics by Economic Activity. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Accidents_at_work_-_statistics_by_economic_activity (accessed on 26 May 2025).

- Ludus. Realidad Virtual y Cultura de Seguridad en las Empresas. Available online: https://www.ludusglobal.com/blog/realidad-virtual-cultura-de-seguridad-en-las-empresas (accessed on 12 May 2025).

- Artemar. Beneficios de la Realidad Virtual en la Capacitación en Seguridad de la Construcción. Available online: https://www.artemar.net/beneficios-de-la-realidad-virtual-en-la-capacitacion-en-seguridad-de-la-construccion/ (accessed on 12 May 2025).

- Santamaría, S. La realidad del mundo virtual. Bus. Technol. 2017, 39. [Google Scholar]

- Sandu, E. Cómo la IA y Los Wearables Revolucionan la Seguridad y la Eficiencia. Available online: https://metaverso.pro/blog/como-la-ia-y-los-wearables-revolucionan-la-seguridad-y-la-eficiencia/ (accessed on 12 May 2025).

- University of Burgos. Virtual Risk Prevention Project. Available online: https://www.ubu.es/ (accessed on 12 May 2025).

- Zhao, D.; Lucas, J.; Thabet, W. Using Virtual Reality to Improve Construction Safety Performance: A Case Study. J. Constr. Eng. Manag. 2019, 145, 04018124. [Google Scholar] [CrossRef]

- Generalitat Valenciana. Prevención y Retos 4.0. Exoesqueletos en Prevención de Riesgos Laborales. Available online: https://www.femeval.es/dam/jcr:57e9814c-7825-4db7-b4d9-1b3ba12ce75d/GUIA-EXOESQUELETOS.pdf (accessed on 12 May 2025).

- Eurostat. Accidents at Work—Statistics on Causes and Circumstances. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Accidents_at_work_-_statistics_on_causes_and_circumstances (accessed on 26 May 2025).

- Ministerio de Trabajo y Economía Social. Guía de cumplimentación del parte de accidente de trabajo (PAT). Marzo 2023. [Google Scholar]

- Observatorio Industrial de la Construcción; Fundación Laboral de la Construcción. Informe 2017 Accidentalidad en el Sector de la Construcción; 2019; Available online: https://blog.fundacionlaboral.org/prevencion-2/la-ultima-infografia-del-observatorio-industrial-de-la-construccion-muestra-la-evolucion-de-los-accidentes-de-trabajo-en-el-sector/ (accessed on 26 May 2025).

- Jiménez Pulido, C. Estrategias para la Mejora de la Información y la Adaptación de Instrumentos Técnicos a las Oportunidades de Regeneración del Parque Edificado. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2022. [Google Scholar]

- Jiménez-Pulido, C.; Jiménez-Rivero, A.; García-Navarro, J. Caracterización de fachadas: Clasificación de las tipologías constructivas más habituales en España. Inf. Construcción 2022, 74, e471. [Google Scholar] [CrossRef]

- European Commission. AI Act Implementation Guidelines; European Commission: Brussels, Belgium, 2024. [Google Scholar]

- European Commission. European Green Deal and Digital Strategy; European Commission: Brussels, Belgium, 2024. [Google Scholar]

- European Agency for Safety and Health at Work. Construction Safety Statistics Across Europe; EU-OSHA: Bilbao, Belgium, 2024. [Google Scholar]

- Asian Development Bank. Digital Transformation in Construction: Regional Perspectives; ADB: Manila, Philippines, 2024. [Google Scholar]

- European Construction Industry Federation. Digital Readiness in EUROPEAN Construction; FIEC: Brussels, Belgium, 2024. [Google Scholar]

| Filters and Selection Criteria |

Search Strategy

Focus on digital technologies or AI applications in construction safety Empirical studies, reviews, or technical implementations Published in peer-reviewed journals, conference proceedings, or recognized institutional reports Available in English or Spanish Exclusion criteria Studies focused solely on other industries mining, manufacturing, agriculture Purely theoretical studies without practical applications Editorials, commentaries, or opinion pieces without empirical data Duplicates or substantially overlapping content |

| Characteristic | Category | Percentage | Total |

| Gender | Women | 30.00% | |

| Men | 70.00% | ||

| 100.00% | |||

| Professional Role | Teachers | 25.80% | |

| Self-employed professionals | 26.80% | ||

| Contractors | 17.50% | ||

| Engineering/consulting | 12.40% | ||

| Non-existent procedures | Architecture studios | 10.30% | |

| No identification of risks | Developers | 4.00% | |

| There are no processes that regulate directed activities | Subcontractors | 3.10% | |

| 100.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

del Río Merino, M.; Segarra Cañamares, M.; Zamora Calleja, M.; Ros Serrano, A.; Heredia Morante, R.A. Feasibility of Using New Technologies and Artificial Intelligence in Preventive Measures in Building Works. Buildings 2025, 15, 2132. https://doi.org/10.3390/buildings15122132

del Río Merino M, Segarra Cañamares M, Zamora Calleja M, Ros Serrano A, Heredia Morante RA. Feasibility of Using New Technologies and Artificial Intelligence in Preventive Measures in Building Works. Buildings. 2025; 15(12):2132. https://doi.org/10.3390/buildings15122132

Chicago/Turabian Styledel Río Merino, Mercedes, María Segarra Cañamares, Miriam Zamora Calleja, Antonio Ros Serrano, and Rafael Alberto Heredia Morante. 2025. "Feasibility of Using New Technologies and Artificial Intelligence in Preventive Measures in Building Works" Buildings 15, no. 12: 2132. https://doi.org/10.3390/buildings15122132

APA Styledel Río Merino, M., Segarra Cañamares, M., Zamora Calleja, M., Ros Serrano, A., & Heredia Morante, R. A. (2025). Feasibility of Using New Technologies and Artificial Intelligence in Preventive Measures in Building Works. Buildings, 15(12), 2132. https://doi.org/10.3390/buildings15122132