Deformation and Control Measures of Existing Metro Shield Tunnels Induced by Large-Section Pipe Jacking Over-Crossing: A Case Study

Abstract

1. Introduction

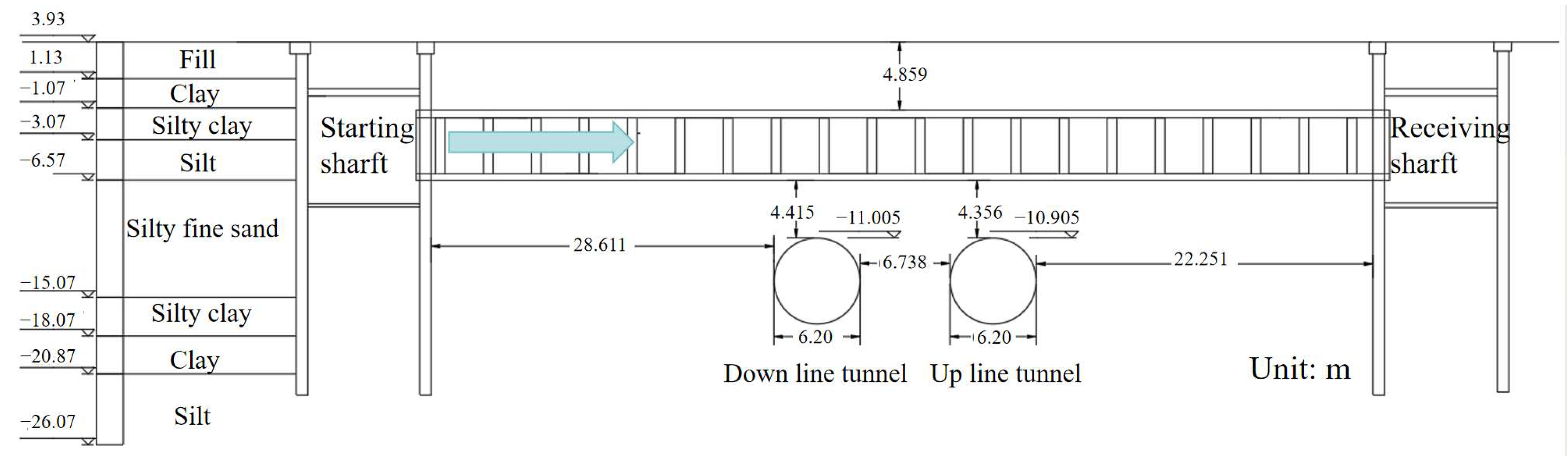

2. Project Background

2.1. Pipe-Jacking Project and Site Condition

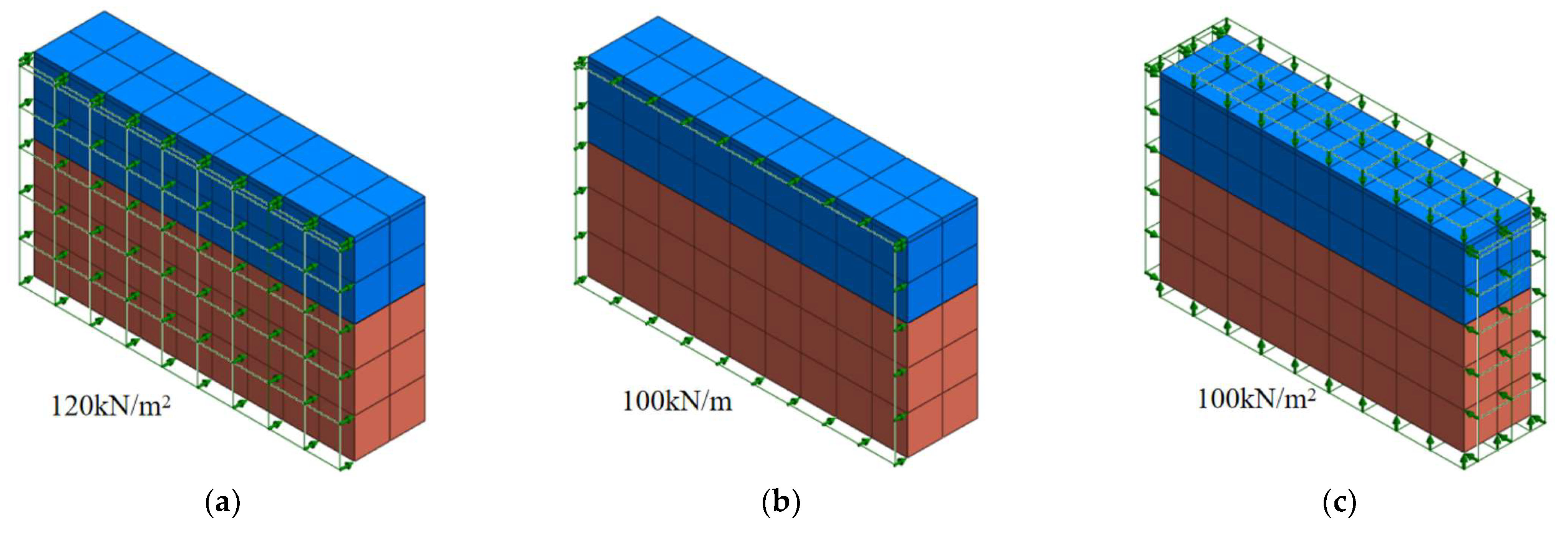

2.2. Anti-Floating Counterweights

2.3. Construction Schemes

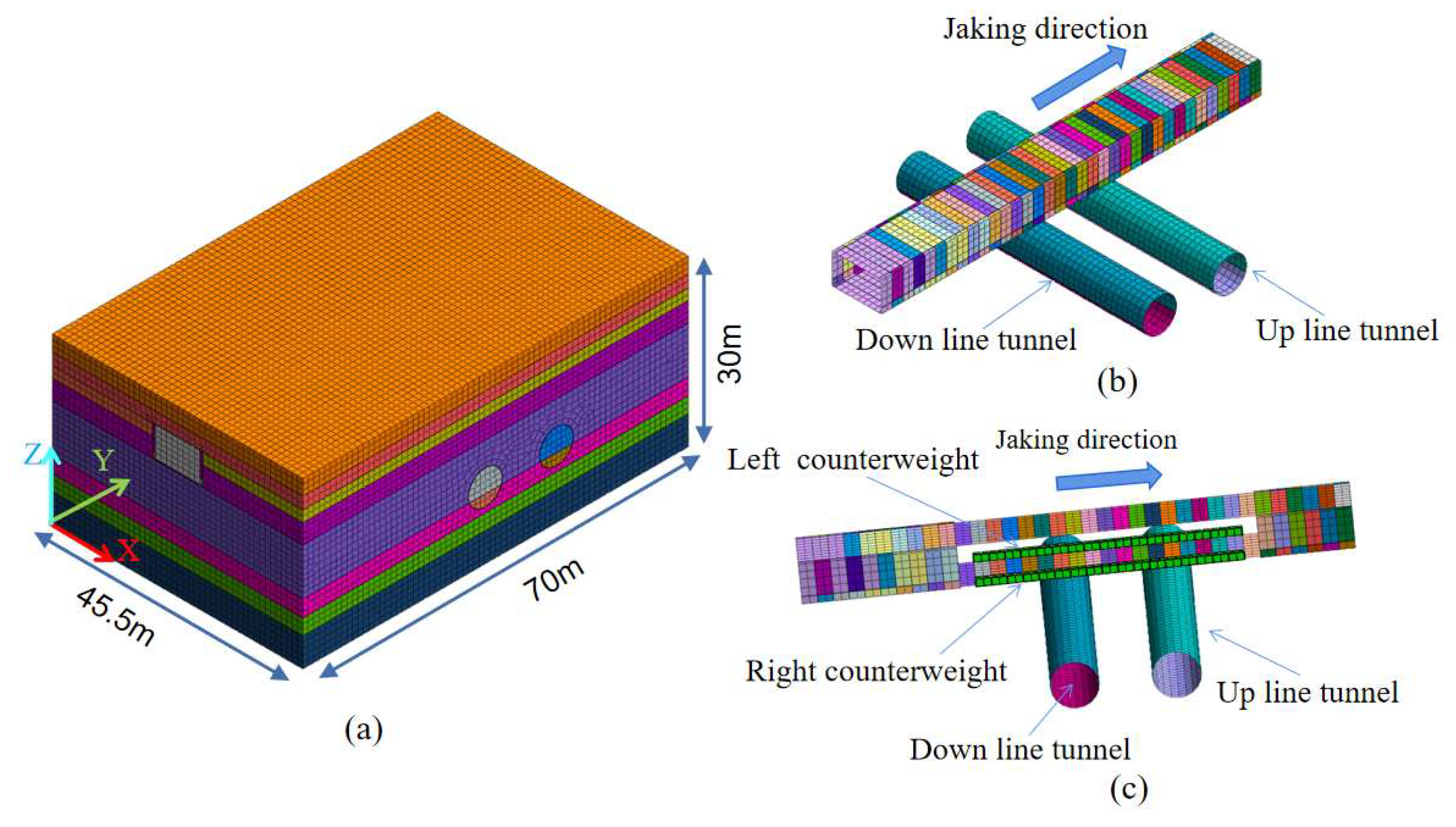

3. Numerical Simulation

3.1. Numerical Model for the Case

3.2. Simulation Parameters

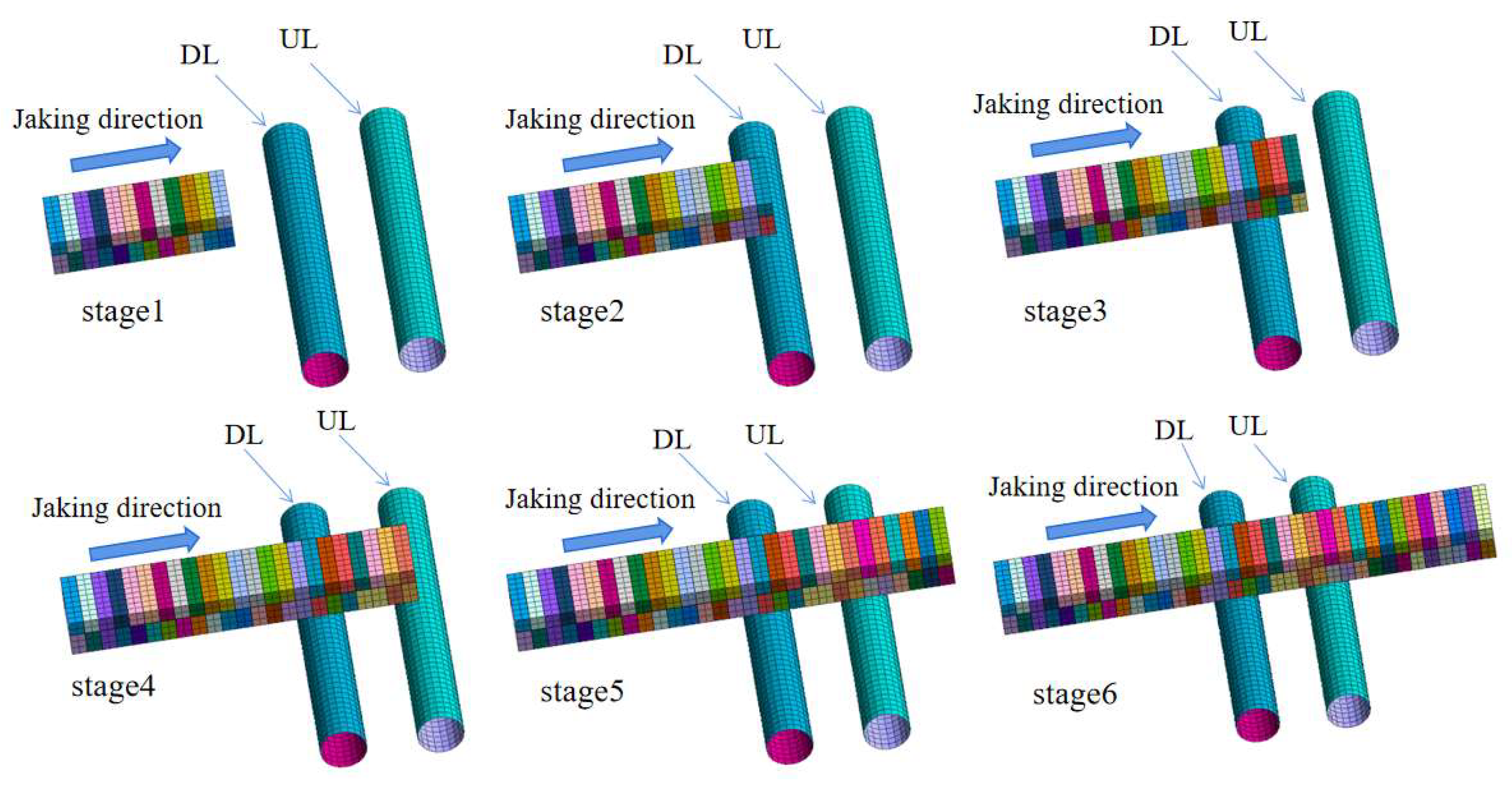

3.3. Simulation of the Jacking Process

3.4. Construction Analysis Stage

4. Numerical Simulation Results

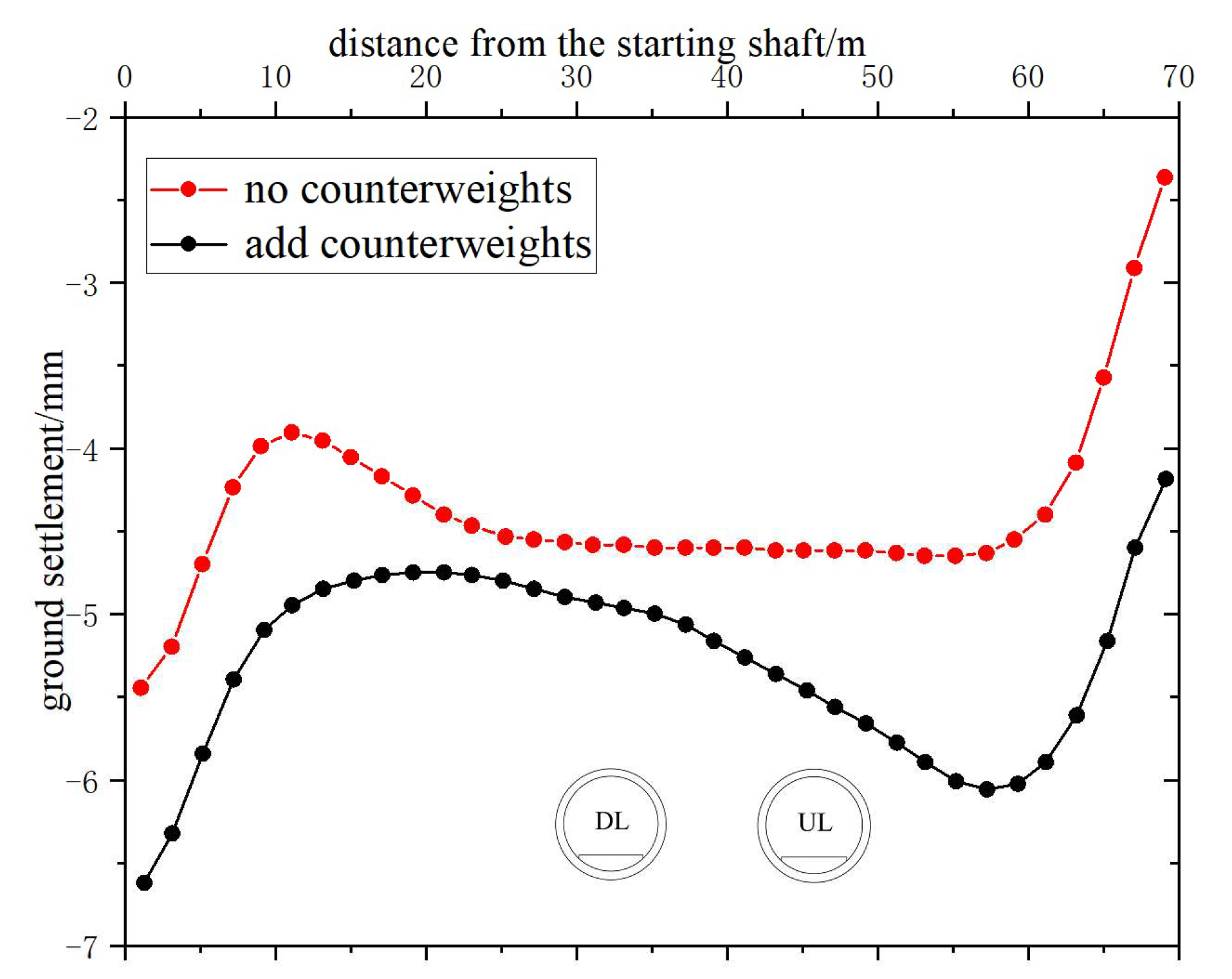

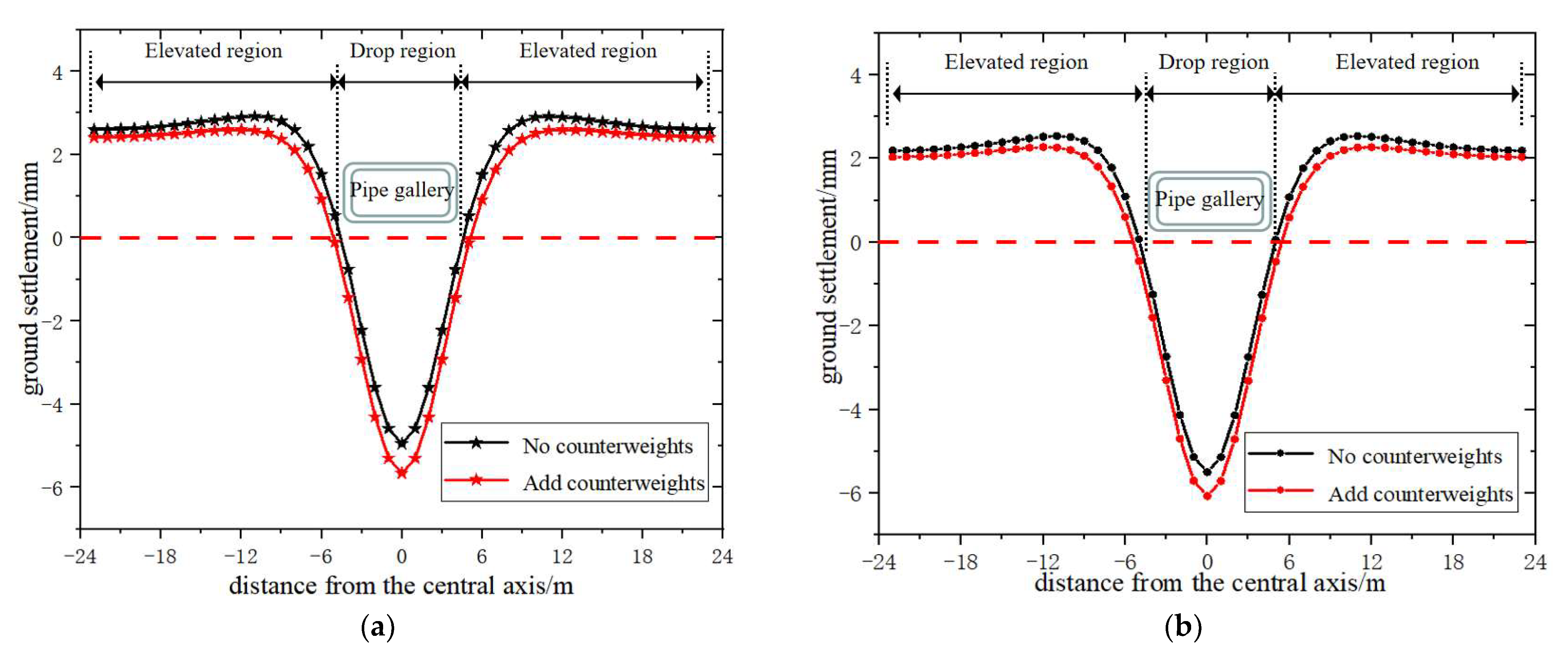

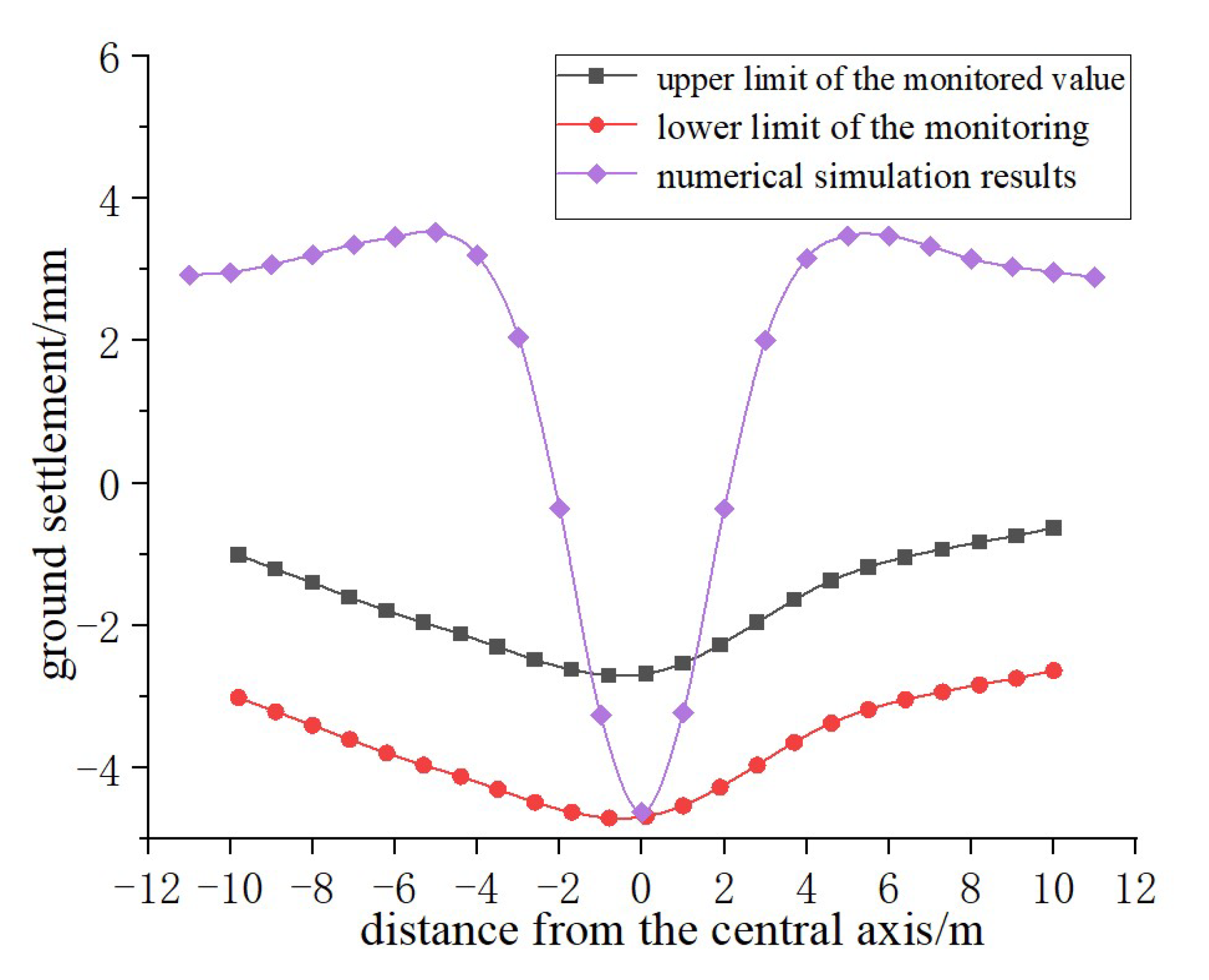

4.1. Ground Settlement

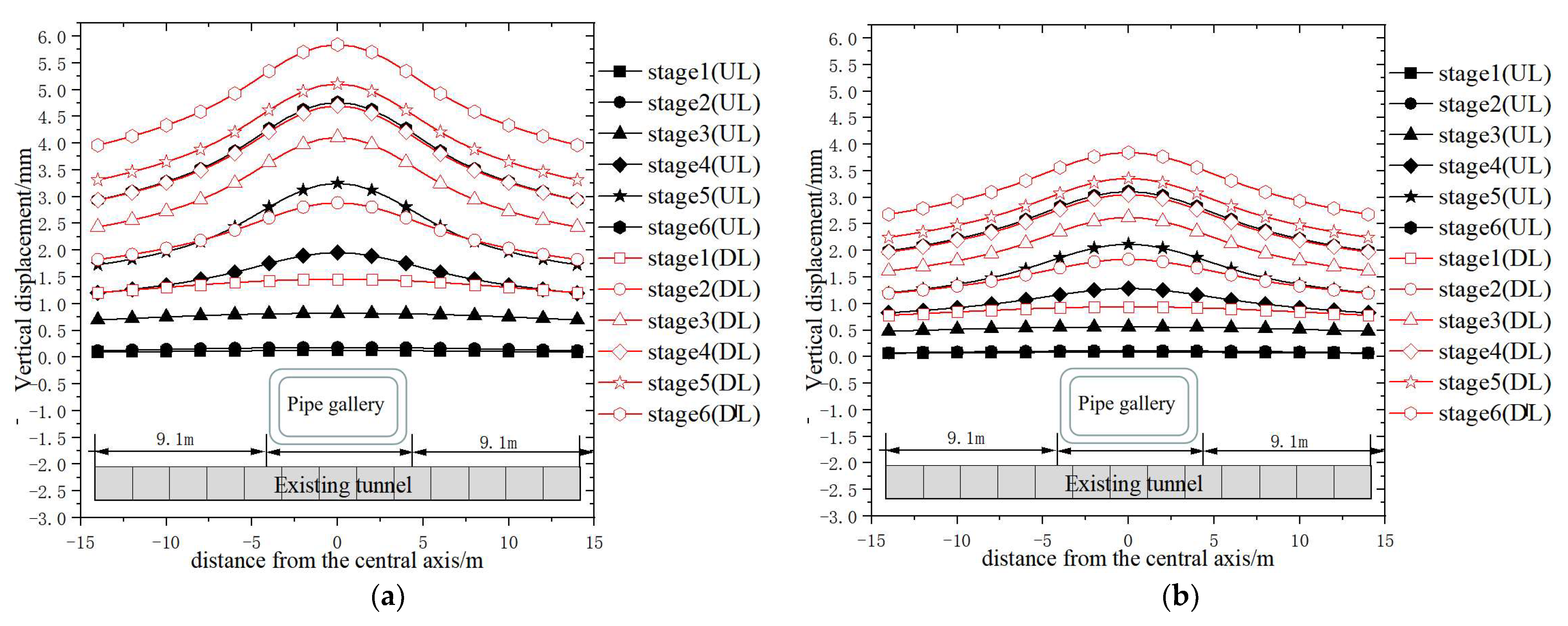

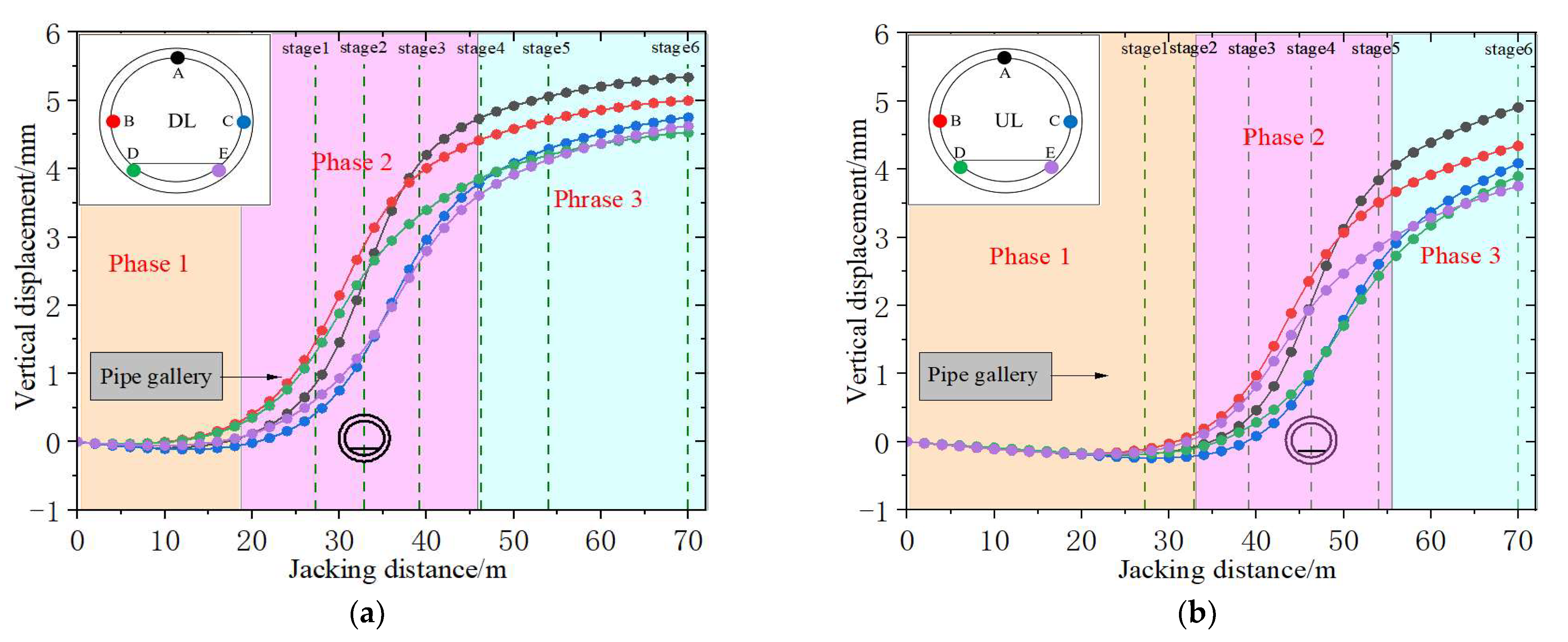

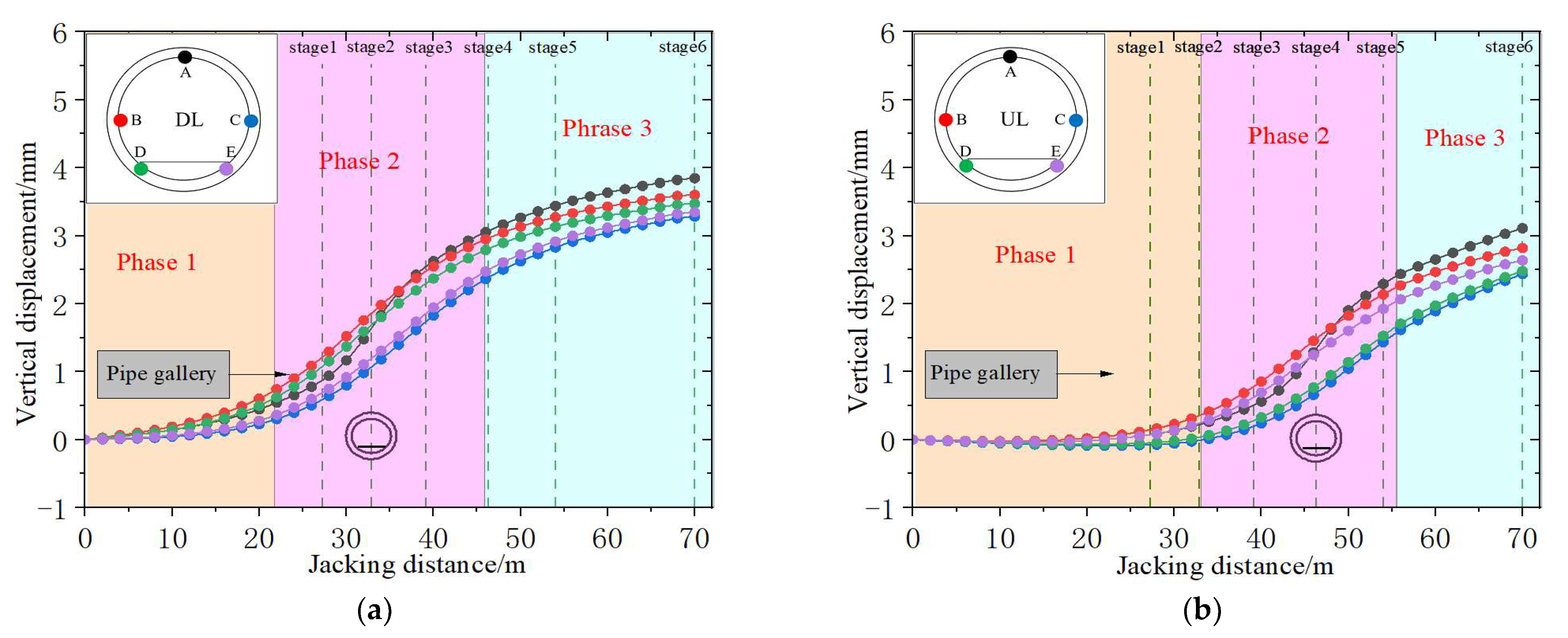

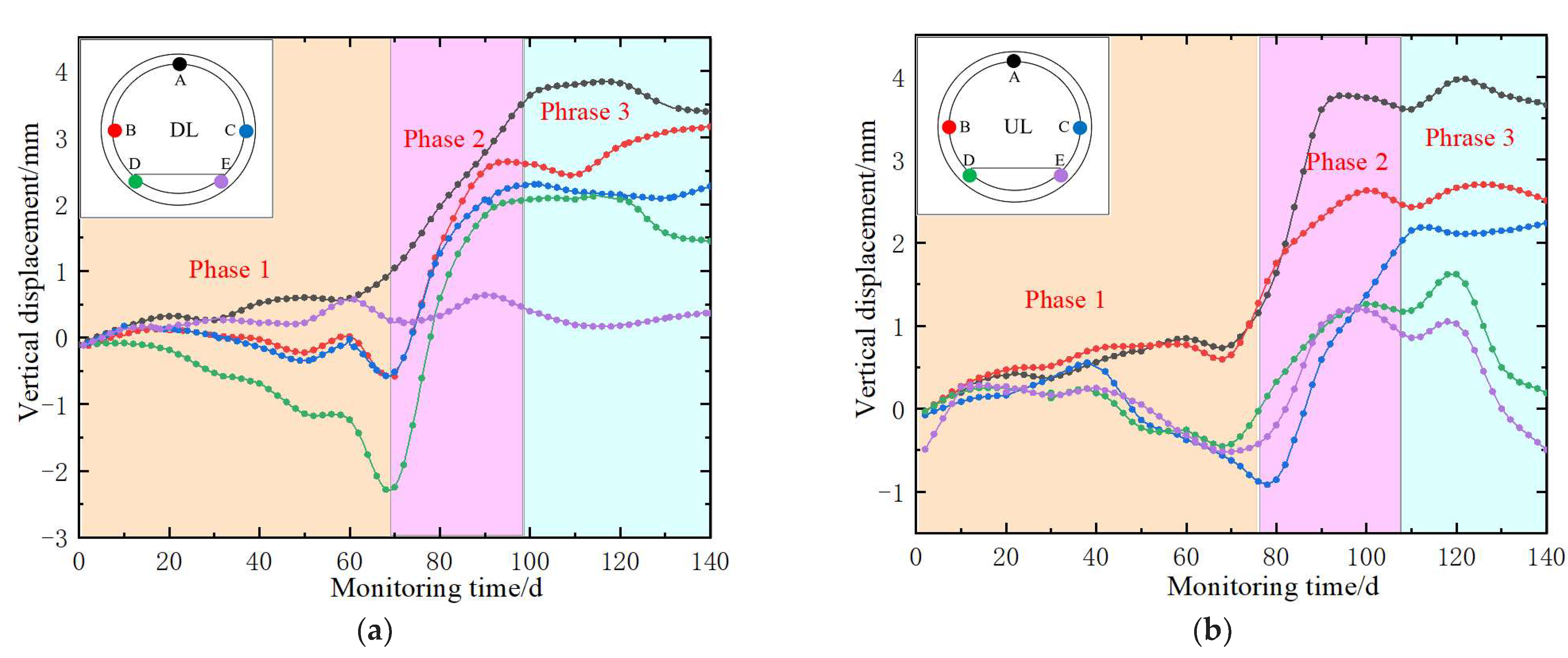

4.2. Tunnels Vertical Displacement

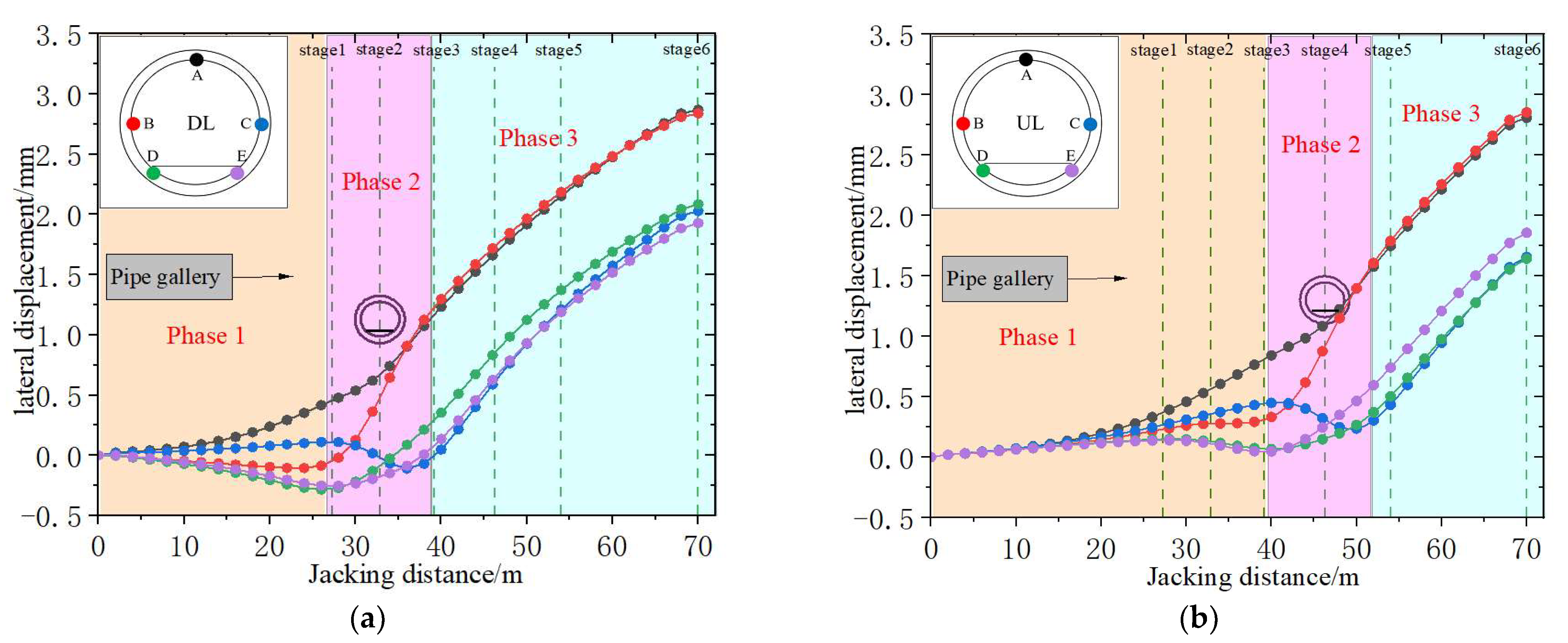

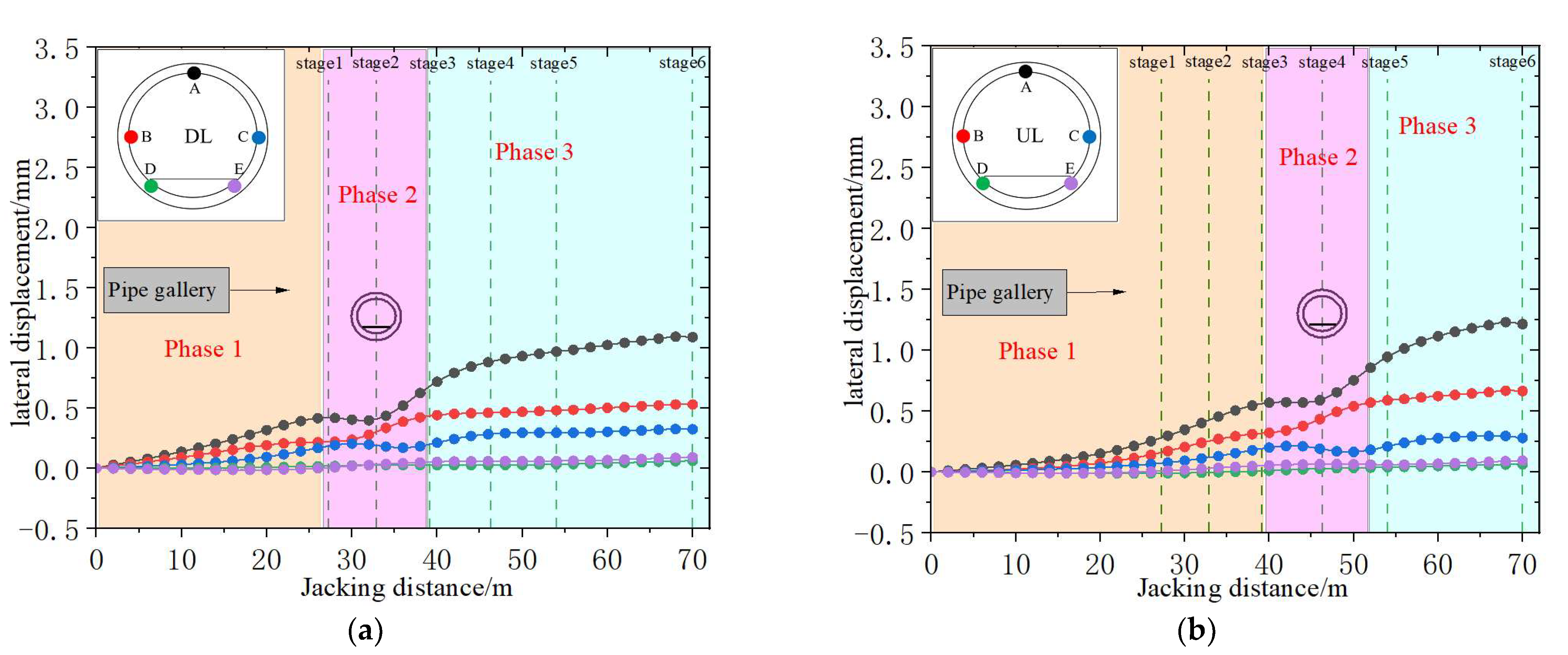

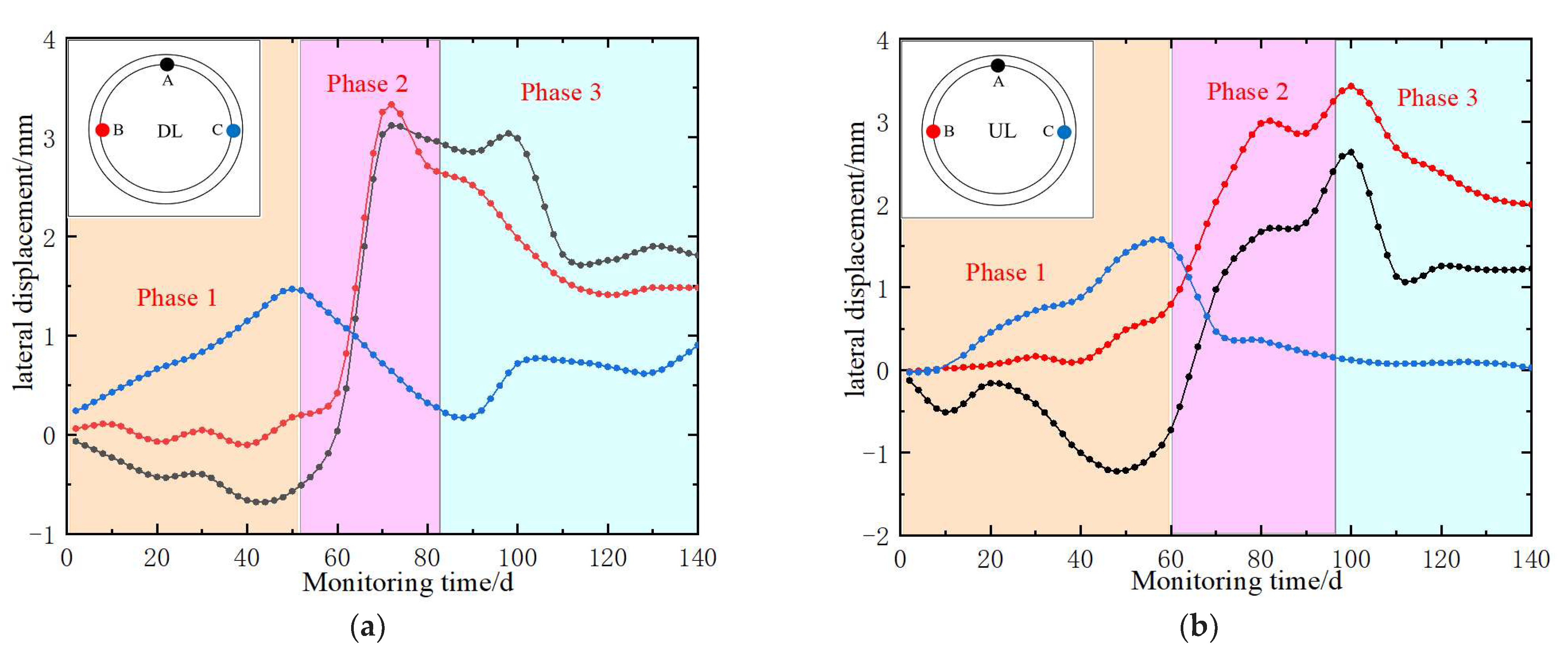

4.3. Tunnels Lateral Displacement

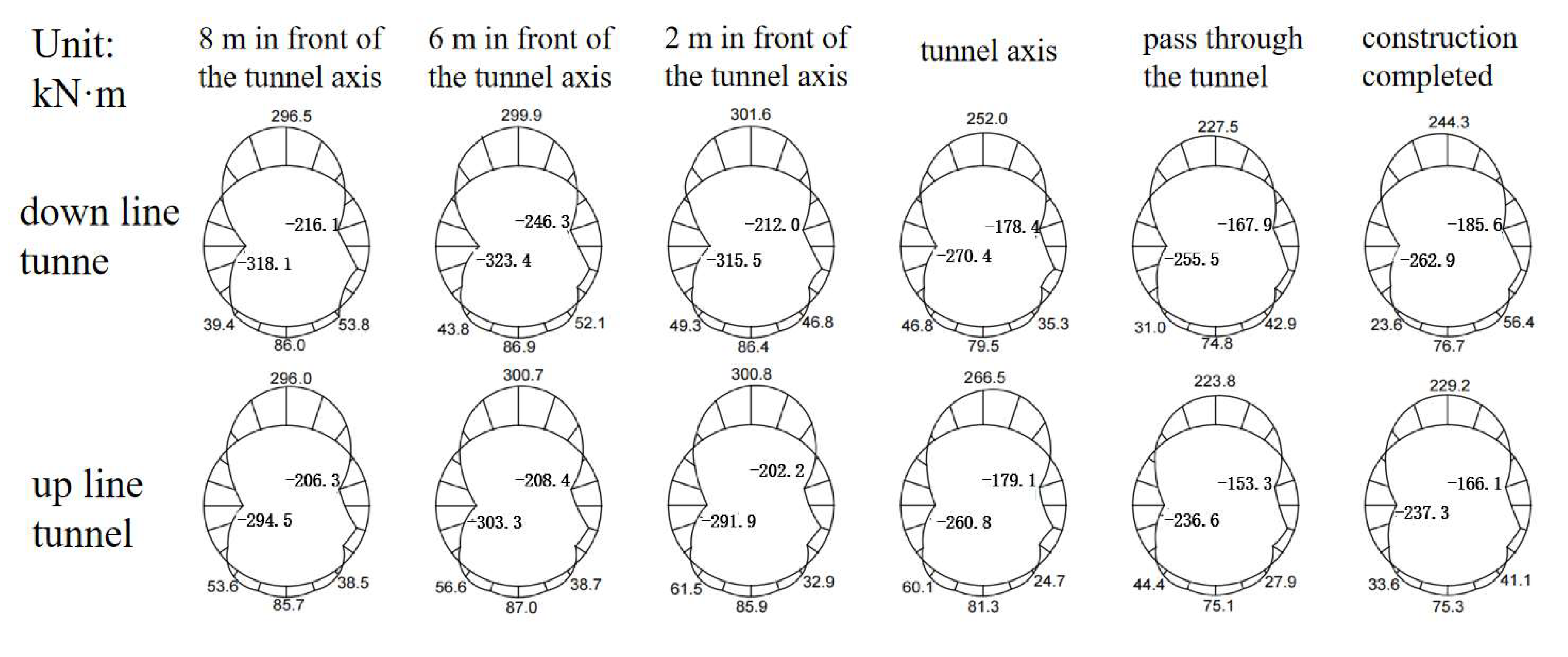

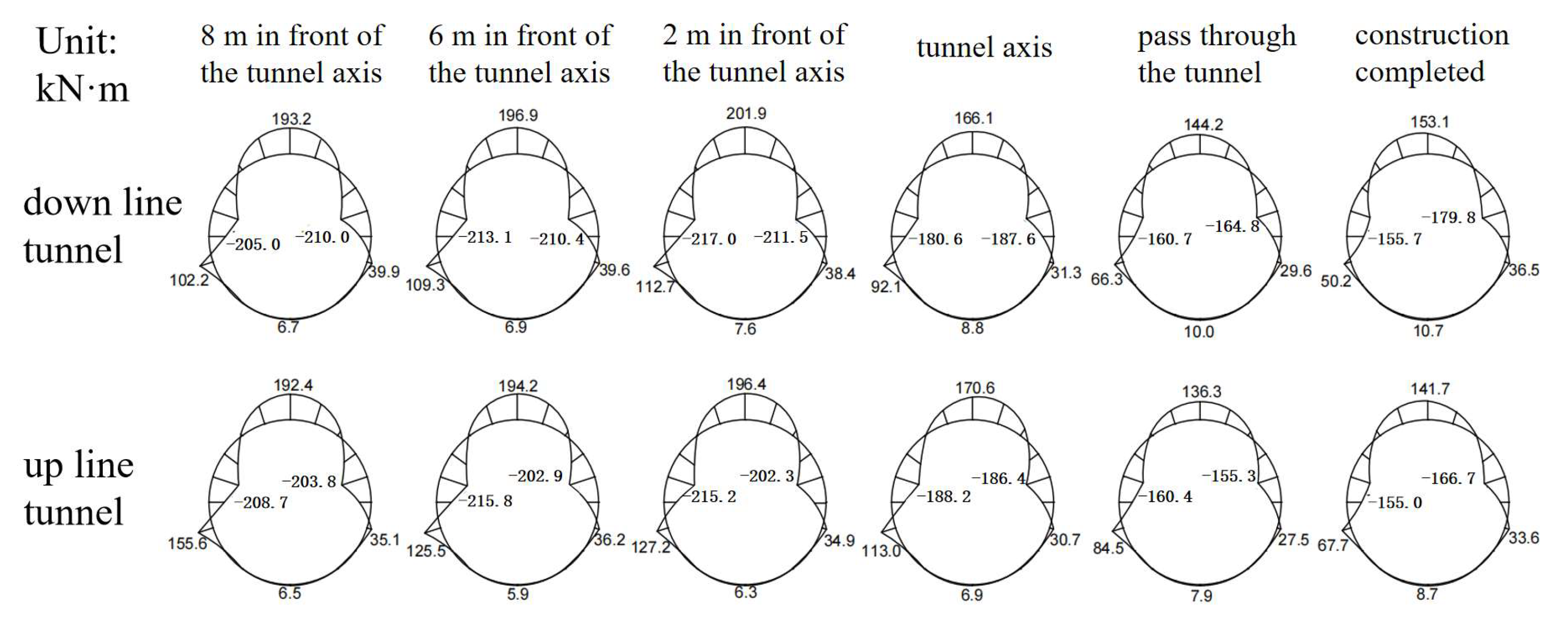

4.4. Tunnel Lining Moments

5. Field Monitoring Scheme and Results

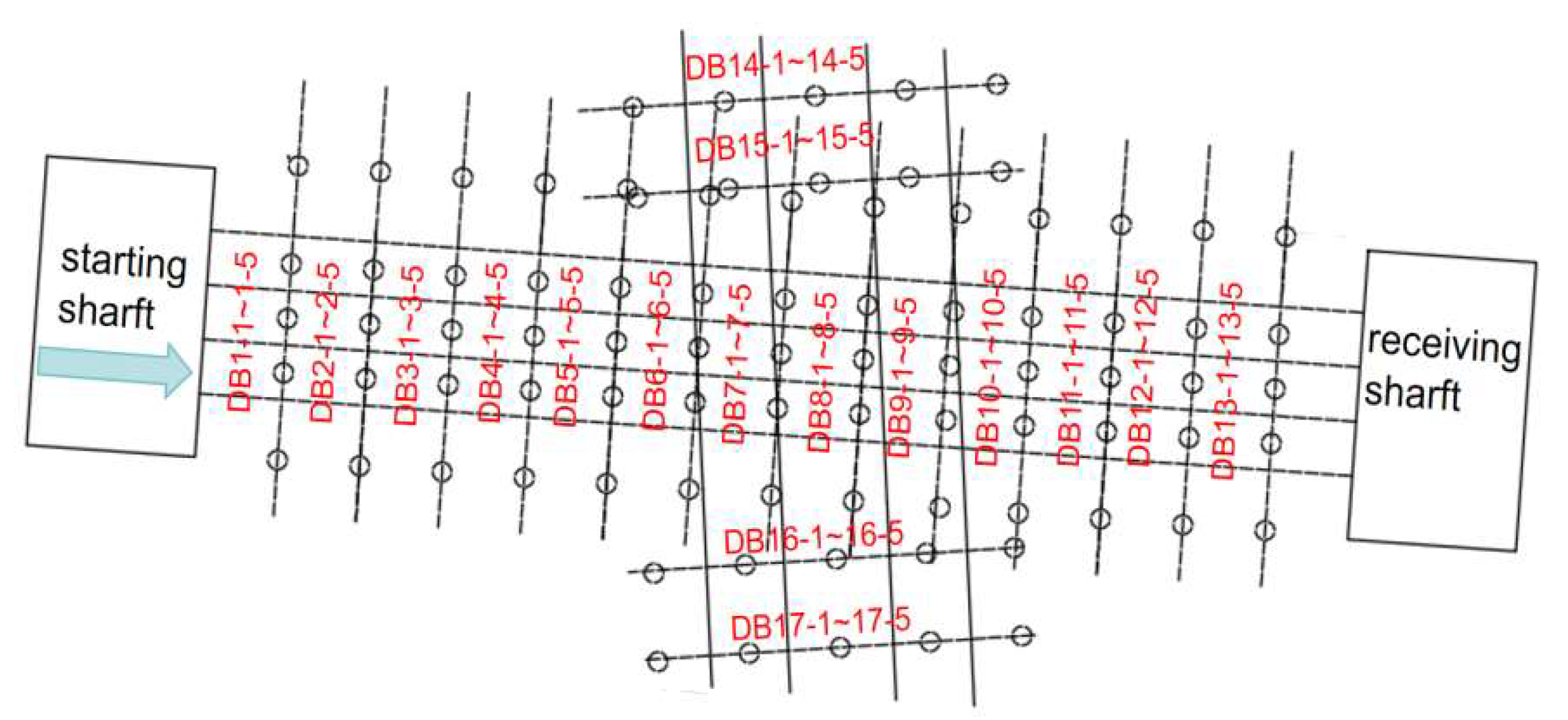

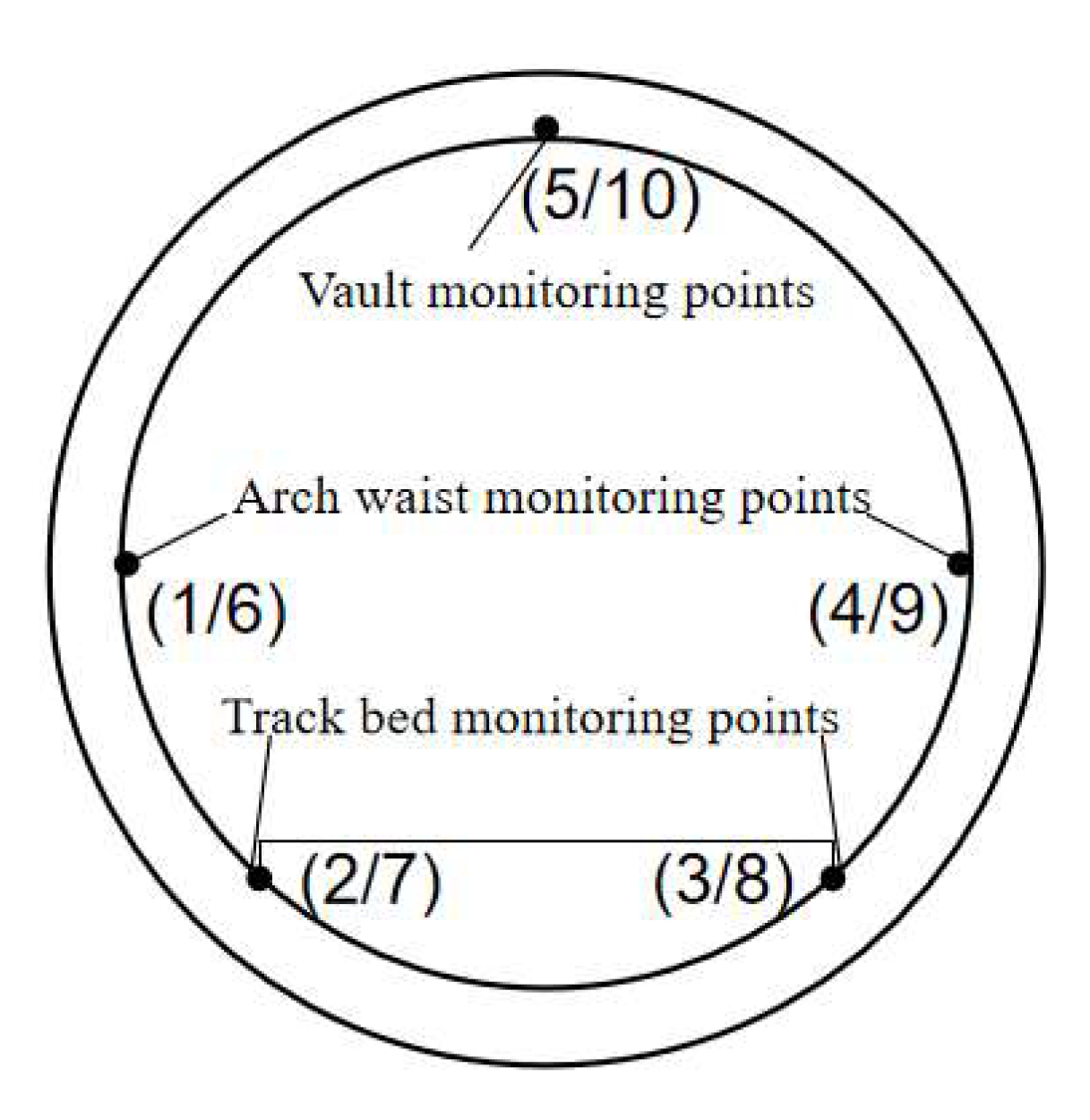

5.1. Field Monitoring Scheme

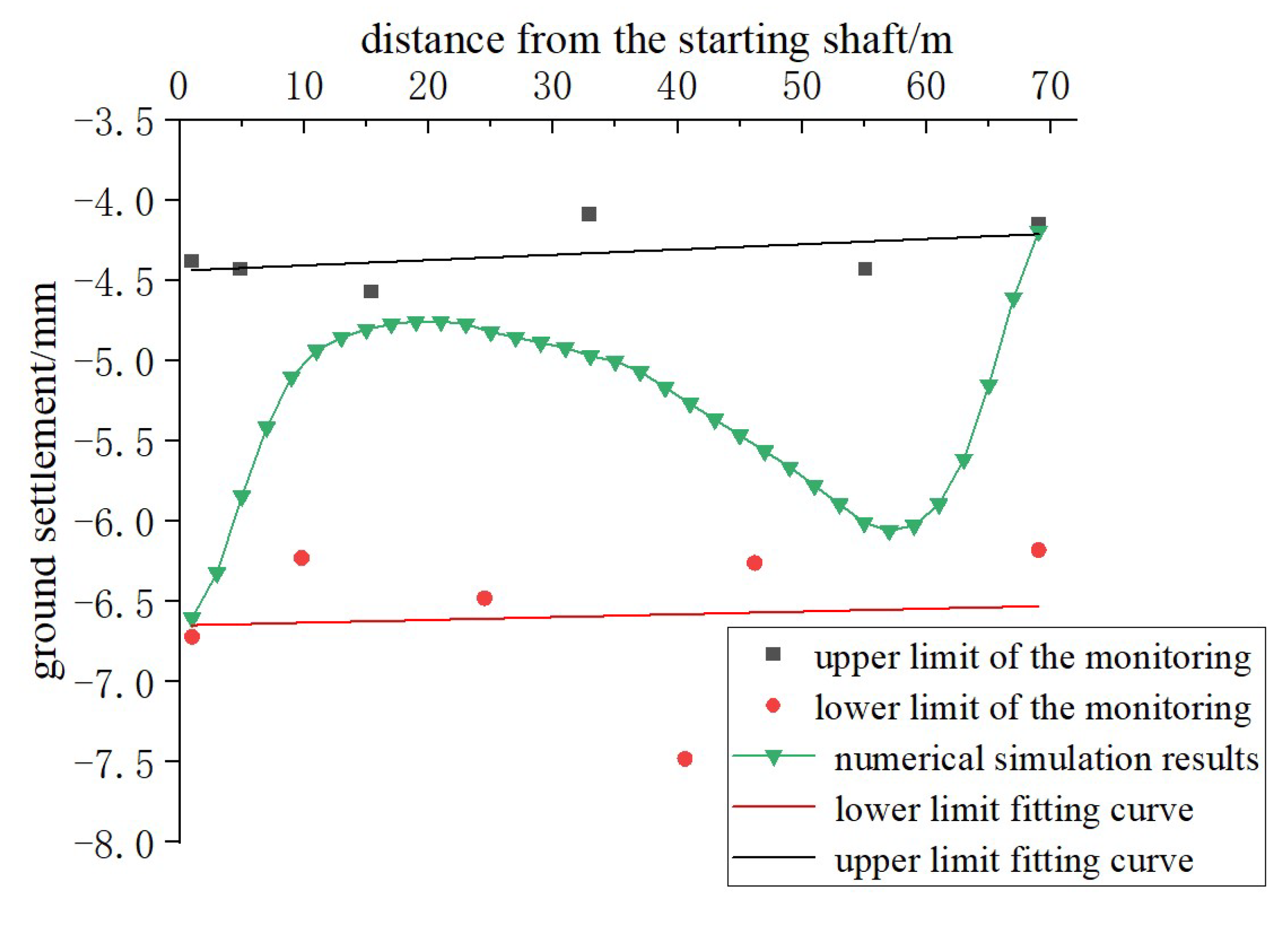

5.2. Field-Measured Ground Settlement

5.3. Field-Measured Tunnels Vertical Displacement

5.4. Field-Measured Tunnels Lateral Displacement

6. Discussion

6.1. Analysis of Discrepancies Between Numerical Simulation and Field Monitoring Results

6.2. Applicability of the Construction Method

7. Conclusions

- (1)

- During pipe-jacking excavation, the unloading effect from the upper section causes uplift of the existing subway tunnel, with the maximum uplift occurring at the central axis of the pipe-jacking tunnel. The vertical displacement of the tunnel evolves in three phases: initial settlement, rapid uplift transition, and stable uplift.

- (2)

- The lateral displacement of the existing tunnel during pipe jacking is influenced by both the unloading effect and the compression from the pipe jacking machine. The displacement process is divided into three phases: lateral extension, compression, and overall shift. In the first and third phases, the unloading effect predominates, while in the second phase, as the pipe jacking machine approaches the existing tunnel, the self-weight and grouting pressure from the machine become the dominant factors.

- (3)

- During pipe jacking, the maximum bending moment in the tunnel lining first increases, then decreases, and slightly rebounds. When the pipe jacking machine reaches a position 2 m in front of the tunnel, the compressive force from the machine causes lateral bias in the tunnel, leading to the maximum bending moment in the lining. Monitoring should be intensified at this stage to mitigate potential risks.

- (4)

- The addition of counterweights proves effective in mitigating the impact of pipe jacking on the subway tunnel. After introducing anti-floating counterweights inside the rectangular pipe jacking tunnel, the maximum uplift in the DL and UL tunnels decreased by 28.0% and 35.5%, respectively. The maximum horizontal displacement was reduced by 61.6% and 55.9%, and the maximum bending moment decreased by 32.9% and 28.8%, respectively. The use of counterweights significantly reduced the tunnel’s deformation, highlighting the importance of this measure in controlling construction-induced impacts.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Song, Z.P.; Wu, Y.C.; Zhang, Y.W.; Wang, K.S.; Tian, J.L.; Tian, X.X. Deformation Response of a Pipeline to Nearby Deep Foundation Pit Excavation: Numerical Simulations and Field Tests. Appl. Sci. 2023, 13, 6597. [Google Scholar] [CrossRef]

- Tang, J.F.; Xu, J.K.; Zhou, D.Z.; Huang, D.; Zeng, K.; Li, Y.H.; Chen, Z. Ground Surface Deformation Caused by Pipe Jacking Construction in a Soft Soil Area: An Experiment-Based Study. Buildings 2023, 13, 1628. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, X.; Luo, F.; Shi, T.; Xu, T.; Zhang, P. Field Test and Numerical Simulation Study on Pipe Sticking of Pipe Jacking in Composite Stratum. Buildings 2024, 14, 3992. [Google Scholar] [CrossRef]

- Wu, X.; Xu, J.; Wang, S.; Sha, P.; Han, Z.; Chen, X.; Shu, S.; Qiao, W.; Zeng, X. Ground Deformation of Shield Tunneling through Composite Strata in Coastal Areas. Buildings 2024, 14, 19. [Google Scholar] [CrossRef]

- Liu, X.; Fang, Q.; Zhang, D. Mechanical responses of existing tunnel due to new tunnelling below without clearance. Tunn. Undergr. Space Technol. 2018, 80, 44–52. [Google Scholar] [CrossRef]

- Weng, X.; Yu, H.; Niu, H.; Hu, J.; Han, W.; Huang, X. Interactive effects of crossing tunnel construction on existing tunnel: Three-dimensional centrifugal test and numerical analyses. Transp. Geotech. 2022, 35, 100789. [Google Scholar] [CrossRef]

- Fang, Q.; Liu, X.; Zeng, K.H.; Zhang, X.D.; Zhou, M.Z.; Du, J.M. Centrifuge modelling of tunnelling below existing twin tunnels with different types of support. Undergr. Space 2022, 7, 1125–1138. [Google Scholar] [CrossRef]

- Lin, X.T.; Chen, R.P.; Wu, H.N.; Cheng, H.Z. Deformation behaviors of existing tunnels caused by shield tunneling undercrossing with oblique angle. Tunn. Undergr. Space Technol. 2019, 89, 78–90. [Google Scholar] [CrossRef]

- Liu, H.; Li, P.; Liu, J. Numerical investigation of underlying tunnel heave during a new tunnel construction. Tunn. Undergr. Space Technol. 2011, 26, 276–283. [Google Scholar] [CrossRef]

- Chen, R.P.; Lin, X.T.; Kang, X.; Zhong, Z.Q.; Liu, Y.; Zhang, P.; Wu, H.N. Deformation and stress characteristics of existing twin tunnels induced by close-distance EPBS under-crossing. Tunn. Undergr. Space Technol. 2018, 82, 468–481. [Google Scholar] [CrossRef]

- Jin, D.; Yuan, D.; Li, X.; Zheng, H. An in-tunnel grouting protection method for excavating twin tunnels beneath an existing tunnel. Tunn. Undergr. Space Technol. 2018, 71, 27–35. [Google Scholar] [CrossRef]

- Liu, X.; Fang, Q.; Zhang, D.; Wang, Z. Behaviour of existing tunnel due to new tunnel construction below. Comput. Geotech. 2019, 110, 71–81. [Google Scholar] [CrossRef]

- Zhai, L.H.; Cai, G.S.; Liang, Y.H.; Guan, S.X.; Wang, S.Y.; Liaquat, L. Structural Behaviors of Large-Section Mine Tunnels Undercrossing Existing Metro Lines. Buildings 2023, 13, 1771. [Google Scholar] [CrossRef]

- He, H.J.; Wang, S.; Shen, W.; Zhang, W. The influence of pipe-jacking tunneling on deformation of existing tunnels in soft soils and the effectiveness of protection measures. Transp. Geotech. 2023, 42, 101061. [Google Scholar] [CrossRef]

- Liang, R.; Xia, T.; Hong, Y.; Yu, F. Effects of above-crossing tunnelling on the existing shield tunnels. Tunneling Undergr. Space Technol. 2016, 58, 159–176. [Google Scholar] [CrossRef]

- Zhang, D.W.; Liu, B.; Qin, Y.J. Construction of a large-section long pedestrian underpass using pipe jacking in muddy silty clay: A case study. Tunn. Undergr. Space Technol. 2016, 60, 151–164. [Google Scholar] [CrossRef]

- Xu, X.; Tong, L.; Li, Z.; Liu, X.; Hu, Q.; Yao, H.; Li, J. Influence of extreme shallow jacked box tunnelling on underlying metro tunnels: A case study. Undergr. Space 2023, 12, 234–250. [Google Scholar] [CrossRef]

- Li, Z.; Weng, X.; Cui, Y. Study on the influence of pipe jacking construction on existing subway tunnels. Environ. Earth Sci. 2024, 83, 651. [Google Scholar] [CrossRef]

- Qi, W.; Yang, Z.; Jiang, Y.; Shao, X.; Yang, X.; He, Q. Structural Deformation of Existing Horseshoe-Shaped Tunnels by Shield Overcrossing. KSCE J. Civ. Eng. 2021, 25, 735–749. [Google Scholar] [CrossRef]

- He, J.; Yang, Z.; Zhang, X. Effect of Undercrossing Shield Tunnels Excavation on Existing Rectangular Pipe-Jacking Tunnels. Appl. Sci. 2023, 13, 12235. [Google Scholar] [CrossRef]

- Yan, Y.C.; Zhang, M.X.; Cao, M.J. Study on the Effect of Large Cross-Section Quasi-Rectangular Pipe Jacking near Side Crossing Viaduct Piles in Soft Soil Areas. Appl. Sci. 2023, 13, 9799. [Google Scholar] [CrossRef]

- Li, X.G.; Yuan, D.J. Response of a double-decked metro tunnel to shield driving of twin closely under-crossing tunnels. Tunn. Undergr. Space Technol. Inc. Trenchless Technol. Res. 2012, 28, 18–30. [Google Scholar] [CrossRef]

- He, Y.J.; Cheng, J.; Shi, Z.L.; Zhang, B.; Chen, L.; Li, X.; Wang, X.L.; Zhang, P. Research on Axial Stress and Strain Characteristics of Reinforced-Concrete Curved Pipe Jacking in Power Tunnels. Buildings 2024, 14, 3030. [Google Scholar] [CrossRef]

- Fan, S.Y.; Song, Z.P.; Xu, T.; Wang, K.M.; Zhang, Y.W. Tunnel deformation and stress response under the bilateral foundation pit construction: A case study. Arch. Civ. Mech. Eng. 2021, 21, 19. [Google Scholar] [CrossRef]

- Gan, X.; Yu, J.; Gong, X.; Liu, N.; Zheng, D. Behaviours of existing shield tunnels due to tunnelling underneath considering asymmetric ground settlements. Undergr. Space 2022, 7, 882–897. [Google Scholar] [CrossRef]

- Miao, L. Deformations of Subway Tunnels Induced by the Overcrossing Jacked Box Tunnels. Symmetry 2021, 13, 1800. [Google Scholar] [CrossRef]

- Zhang, Z.; Huang, M. Geotechnical influence on existing subway tunnels induced by multiline tunneling in Shanghai soft soil. Comput. Geotech. 2014, 56, 121–132. [Google Scholar] [CrossRef]

- Lai, H.; Zheng, H.; Chen, R.; Kang, Z.; Liu, Y. Settlement behaviors of existing tunnel caused by obliquely under-crossing shield tunneling in close proximity with small intersection angle. Tunn. Undergr. Space Technol. 2020, 97, 103258. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Shen, X.L.; Tian, X.X.; Song, Z.P.; Zhou, P.Y. Study on the Influence and Deformation Control of Rich Water Foundation Excavation on Adjacent Buildings. Buildings 2025, 15, 52. [Google Scholar] [CrossRef]

| Material Type | Young’s Modulus (MPa) | Poisson’s Ratio | Unit Weight (kN/m3) | Cohesion (kPa) | Friction (°) |

|---|---|---|---|---|---|

| Fill | 16.4 | 0.25 | 19.1 | 24 | 9.4 |

| Clay | 26.4 | 0.3 | 19.4 | 47.9 | 15.3 |

| Silty clay | 23.1 | 0.3 | 18.5 | 13 | 14.3 |

| Silt | 64.3 | 0.3 | 20.5 | 17 | 26.4 |

| Silty fine sand | 90.2 | 0.27 | 20.8 | 0.1 | 32 |

| Silty clay | 23.1 | 0.3 | 18.5 | 18 | 19 |

| Clay | 26.4 | 0.3 | 19.4 | 47.9 | 15.3 |

| Silt | 64.3 | 0.3 | 18.5 | 13 | 14.3 |

| Counterweights | 26,000 | 0.15 | 25 | - | - |

| Tunnel segment | 34,500 | 0.15 | 25 | - | - |

| Pipe gallery | 34,500 | 0.15 | 25 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, X.; Shen, X.; Song, Z.; Ma, P.; Fan, S. Deformation and Control Measures of Existing Metro Shield Tunnels Induced by Large-Section Pipe Jacking Over-Crossing: A Case Study. Buildings 2025, 15, 2105. https://doi.org/10.3390/buildings15122105

Tian X, Shen X, Song Z, Ma P, Fan S. Deformation and Control Measures of Existing Metro Shield Tunnels Induced by Large-Section Pipe Jacking Over-Crossing: A Case Study. Buildings. 2025; 15(12):2105. https://doi.org/10.3390/buildings15122105

Chicago/Turabian StyleTian, Xiaoxu, Xiaole Shen, Zhanping Song, Peng Ma, and Shengyuan Fan. 2025. "Deformation and Control Measures of Existing Metro Shield Tunnels Induced by Large-Section Pipe Jacking Over-Crossing: A Case Study" Buildings 15, no. 12: 2105. https://doi.org/10.3390/buildings15122105

APA StyleTian, X., Shen, X., Song, Z., Ma, P., & Fan, S. (2025). Deformation and Control Measures of Existing Metro Shield Tunnels Induced by Large-Section Pipe Jacking Over-Crossing: A Case Study. Buildings, 15(12), 2105. https://doi.org/10.3390/buildings15122105